Water-absorbable polyacrylic acid (salt) resin and process for production thereof

A polyacrylate and manufacturing method technology, applied in absorbent pads, medical science, bandages, etc., can solve the problems of poor color of water-absorbent resin, reduced physical properties of water-absorbent resin, poor whiteness, etc., and achieve the effect of improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

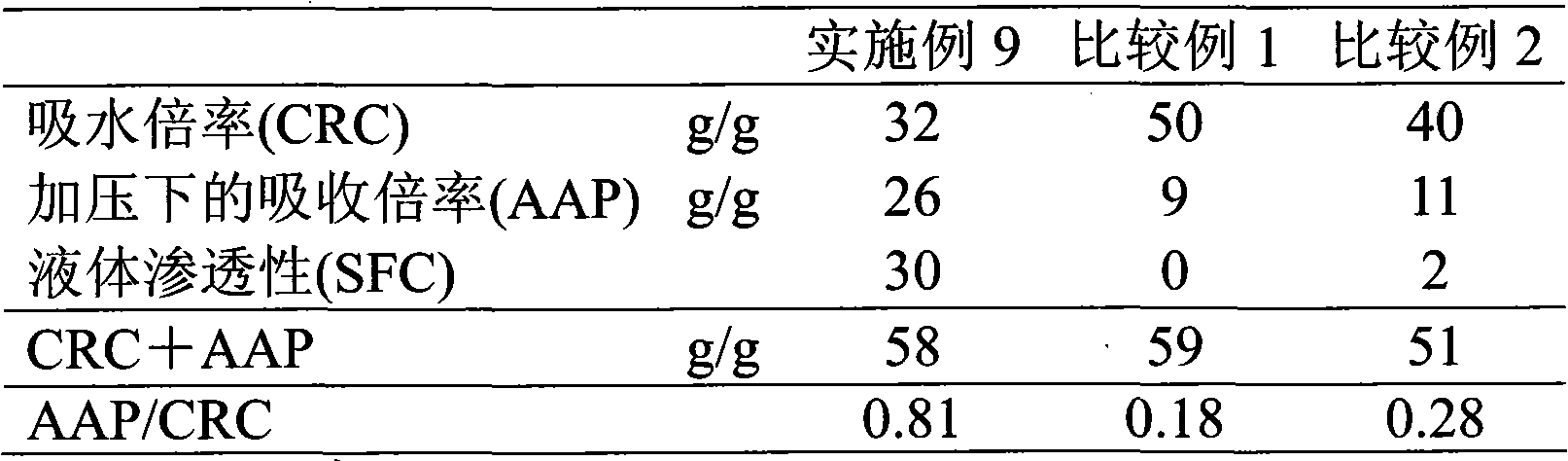

[0184] (Evaluation of physical properties)

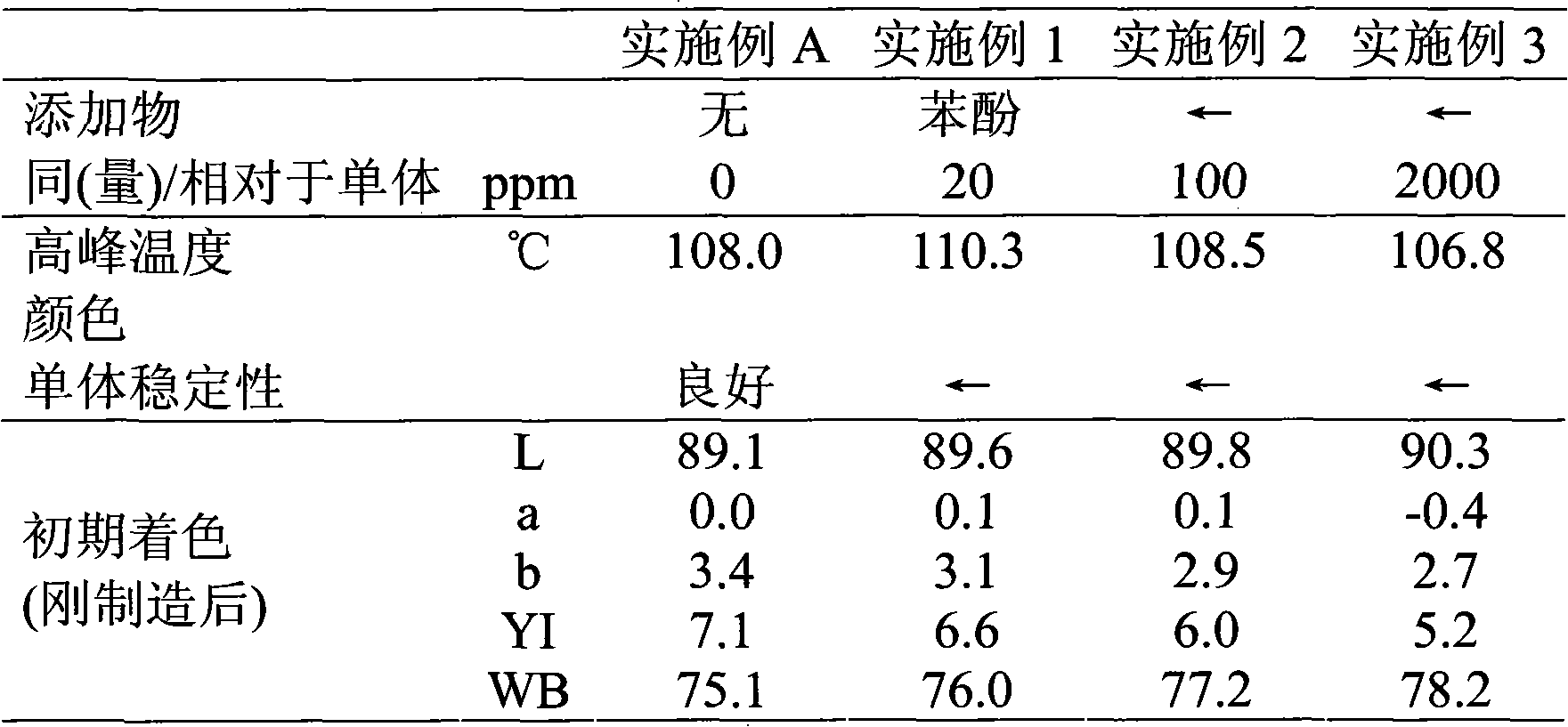

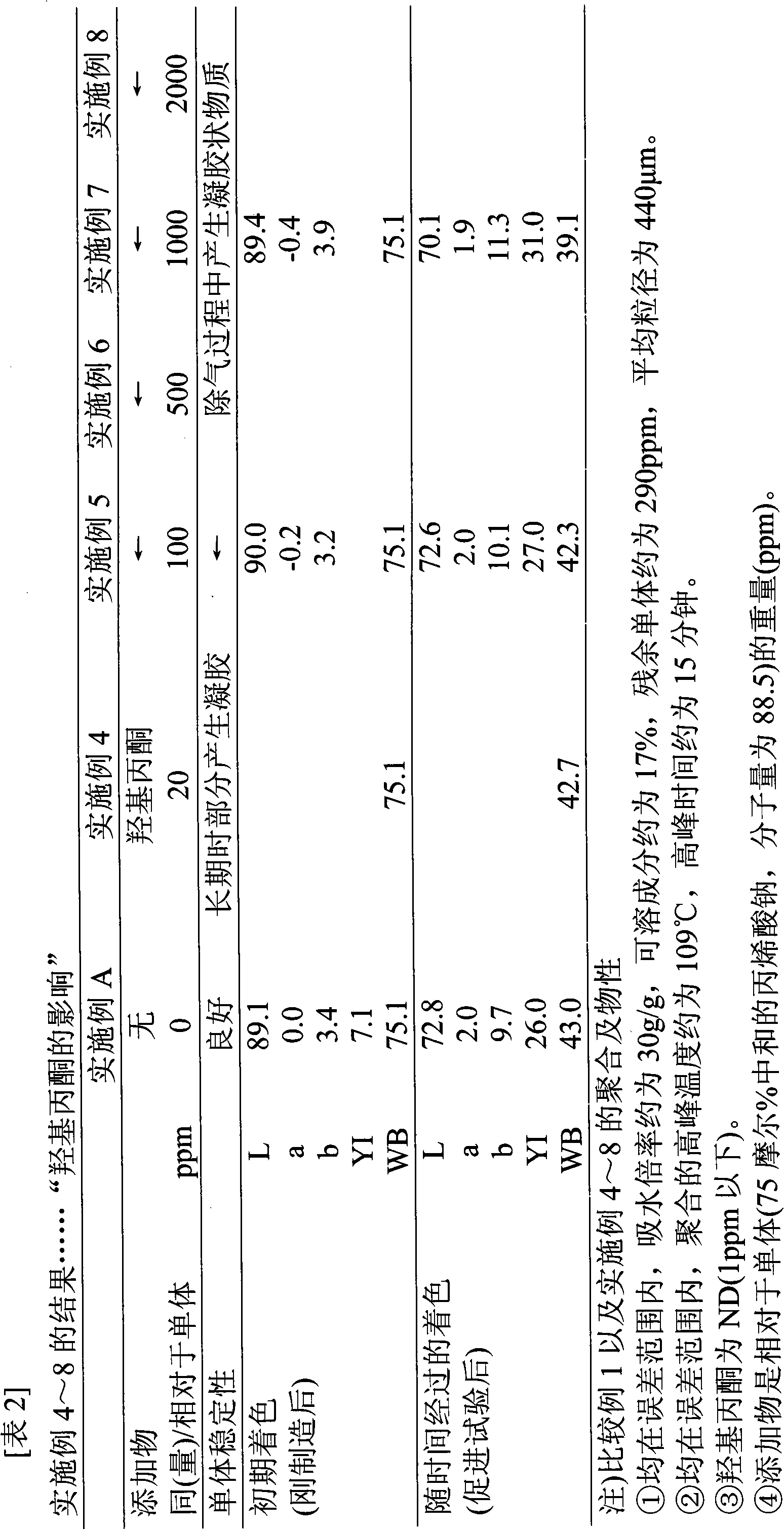

[0185] (a) Initial coloring

[0186] The measurement was performed using a spectroscopic color difference meter SZ-Σ80 COLOR MEASURING SYSTEM manufactured by Nippon Denshoku Industries Co., Ltd. The setting conditions for the measurement are selective reflectance measurement, use the attached container for powder and paste with an inner diameter of 30mm and a height of 12mm, use the standard round white board No.2 for powder and paste as the standard, and use a 30Φ lighting tube. About 5 g of water-absorbent resin is filled into the prepared powder and paste containers.

[0187] (b) Coloring over time

[0188] After leaving the water absorbent resin under high temperature and high humidity, the color was measured by the method of (1) above.

[0189] (c) Other physical properties

[0190] According to the ERT of EDANA or the specification of US Patent Application Publication No. 2006 / 204755, the unloaded water absorption capacity...

manufacture example 1

[0192] Acrylic acid containing no phenol and hydroxyacetone and containing 60 mass ppm of p-methoxyphenol polymerization inhibitor was prepared by distillation and crystallization. The amount of dimer was adjusted to be 100 mass ppm or less, furfural and protopulsatin were adjusted to be 1 mass ppm or less respectively, and the total amount of acetic acid and propionic acid was adjusted to 500 mass ppm (among which acetic acid was 400 ppm).

[0193] Moreover, 75 mol% of neutralization was performed by adding the said acrylic acid to the NaOH aqueous solution obtained from the sodium hydroxide containing 0.2 mass ppm of iron under cooling (liquid temperature 35 degreeC). Since acrylic acid and iron in water were below the detection limit, the amount of Fe in the monomer was calculated to be about 0.07 mass ppm.

Embodiment A

[0195] By dissolving 0.05 mol % of polyethylene glycol diacrylate (relative to monomer ) to obtain the monomer (1). 350 g of the monomer (1) was added to a cylindrical container with a volume of 1 L, and nitrogen gas was bubbled at 2 L / min to deaerate for 20 minutes. Next, an aqueous solution of 0.12 g / mol (with respect to the monomer) of sodium persulfate and 0.005 g / mol (with respect to the monomer) of L-ascorbic acid was added while stirring with a stirring bar, and polymerization was started. Stirring was stopped after the start of polymerization, and static aqueous solution polymerization was performed. The temperature of the monomer (1) showed a peak polymerization temperature of 108° C. after about 15 minutes (polymerization peak time), and then it was allowed to carry out polymerization for 30 minutes. Thereafter, it was taken out from the polymerization vessel to obtain a hydrogel-like crosslinked polymer (1).

[0196] The obtained water-containing gel-like crossli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com