Patents

Literature

34results about How to "Good surface color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of soil conditioner

InactiveCN102180744AHigh organic contentReduce compactionFertilizer mixturesActive agentOrganic content

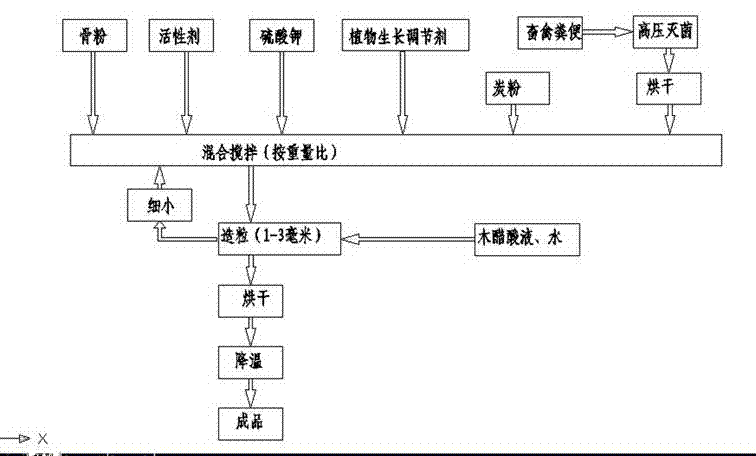

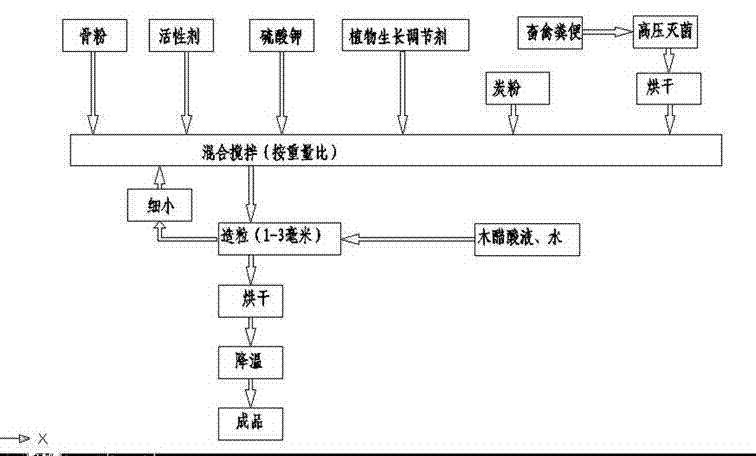

The invention relates to a preparation method of a soil conditioner, belonging to the technical field of fertilizer preparation. The soil conditioner is mainly prepared from the following raw materials in parts by weight: 50-70 parts of plant straw carbon, 20-35 parts of fowl / livestock dung, 10-15 parts of bone meal, 1-8 parts of potassium sulfate, 2-8 parts of wood vinegar liquid, 3-9 parts of plant growth regulator and 0.5-1 part of active agent. The preparation method comprises the following steps: preparing carbon powder, pretreating the fowl / livestock dung, preparing a mixture, assaying and detecting, granulating and packaging. The soil conditioner is prepared by mixing the crop straw / bamboo / wood / grass carbon, which is used as the main component, with certain amounts of trace elements, plant growth regulator and bamboo / wood / grass vinegar liquid; since the soil conditioner not only is rich in the three main nutrient elements (nitrogen, phosphorus and potassium) which are essential for crops, but also contains secondary and trace elements, such as calcium, magnesium, sulfur, iron, boron, molybdenum, copper, cobalt and the like, the nutrient proportion of the soil conditioner is reasonable; and when being used as a conditioner, the soil conditioner can increase the organic content of soil and provide more comprehensive nutrients for crops, so that the crops have the advantages of good growth vigor, plump grains and much higher yield.

Owner:唐山汇力科技有限公司

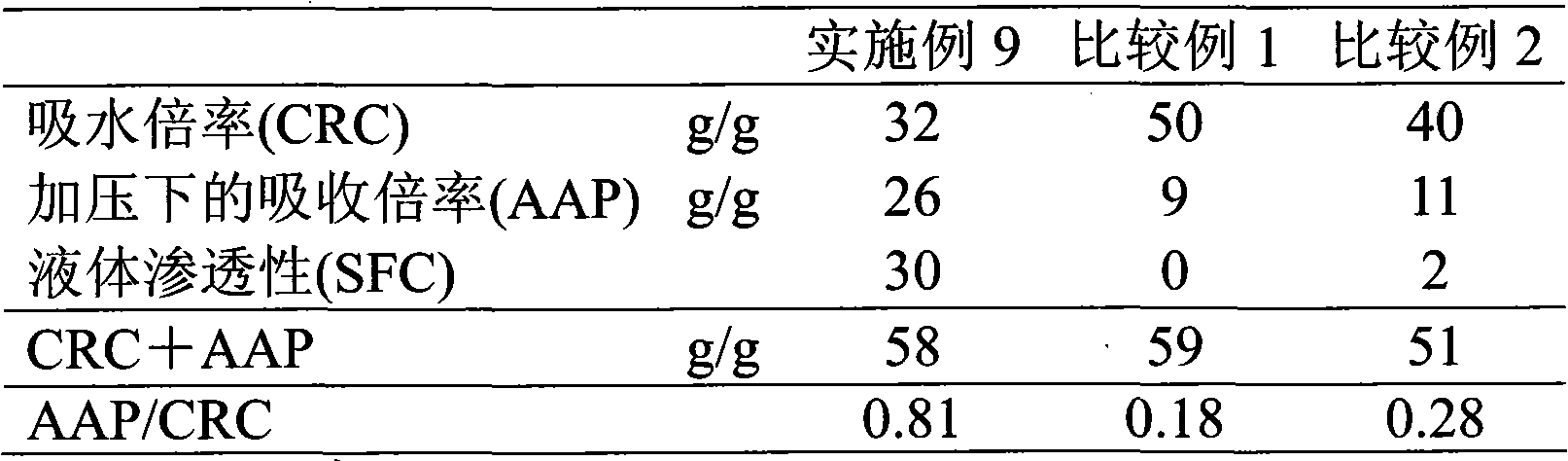

Particle-shaped water absorbing agent and method for producing the same

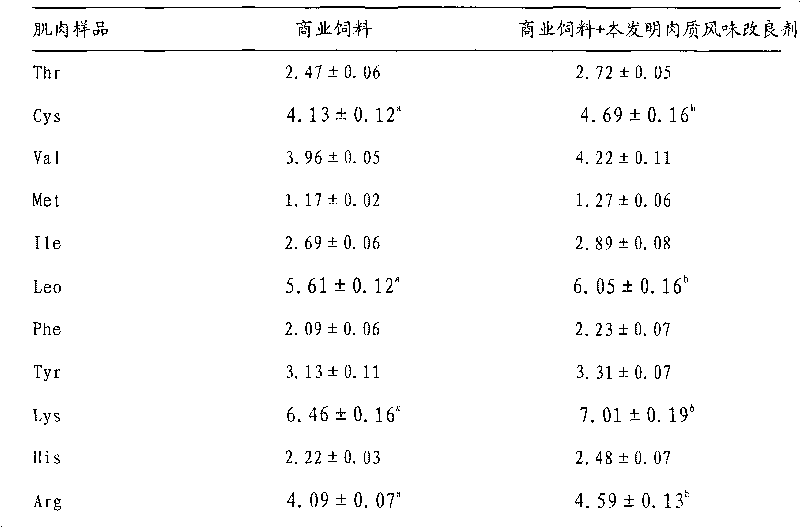

ActiveUS20100009846A1Good surface colorImprove water absorptionOther chemical processesSynthetic resin layered productsSaline waterCross-link

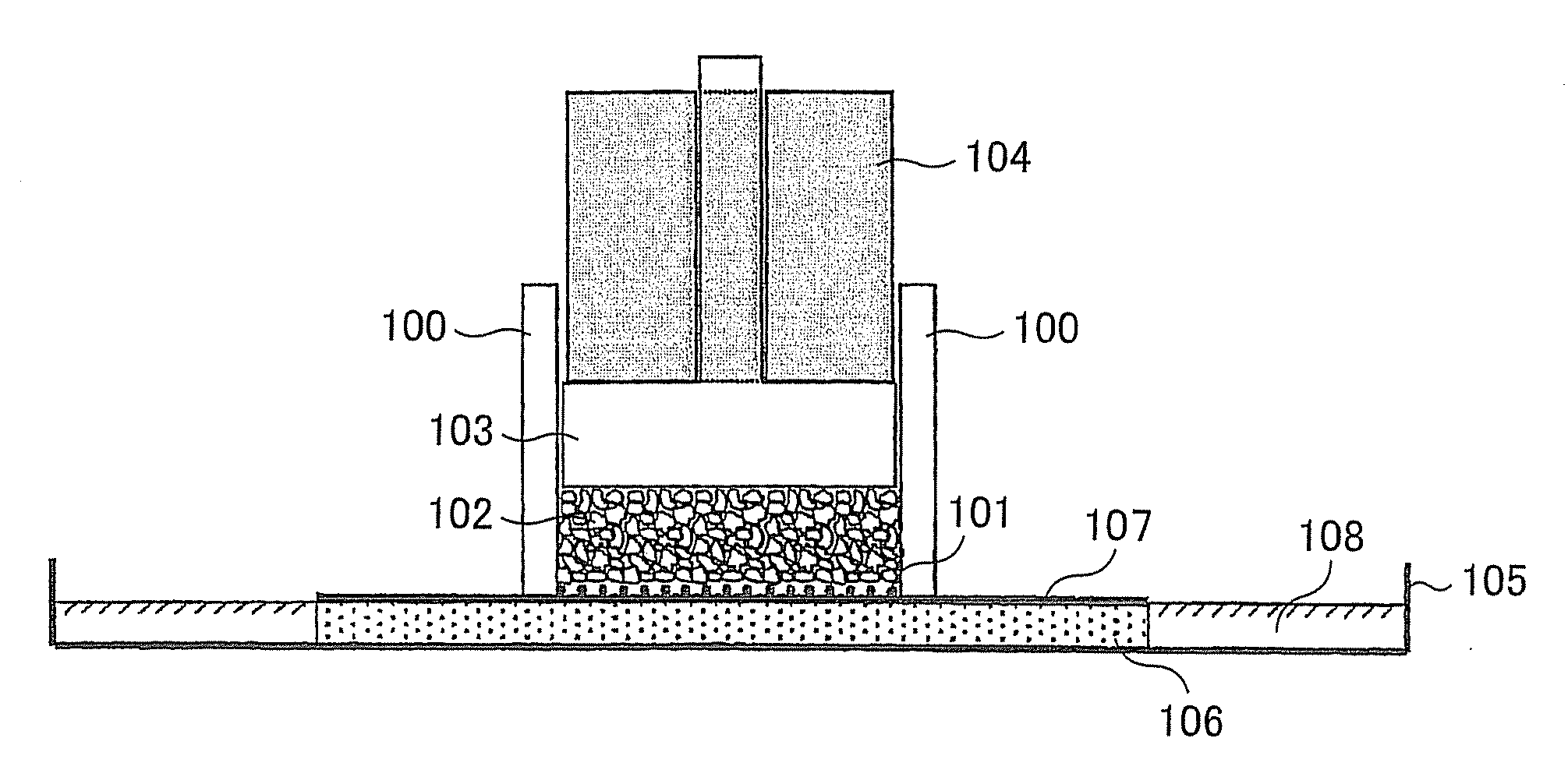

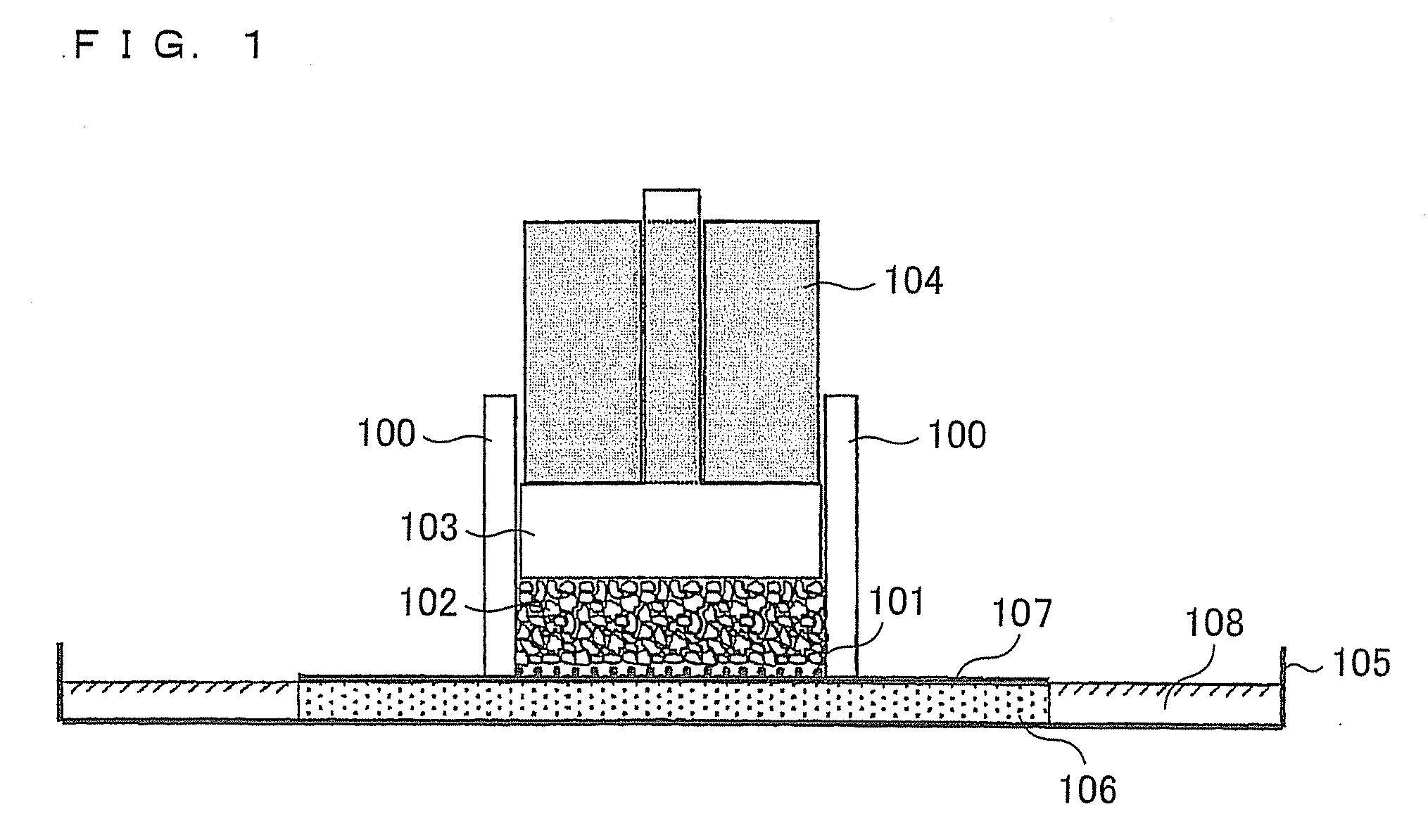

An object of the present invention is to provide a particle-shaped water absorbing agent having a remarkably improved surface color and excellent water-absorbing properties (better water absorption capacity, and lower water soluble content and residual monomer content) at the same time. In order to attain the object, a particle-shaped water absorbing agent according to the present invention is a particle-shaped water absorbing agent whose main component is a polyacrylic acid and / or a salt thereof, the particle-shaped water absorbing agent having a surface color of Hunter b value in a range of −5 to 10, and having a cross-linking absorption property index (CPI) in a range of 1 to 100, the CPI defined by the following two equations:GEX=(GVs+17) / Ln (water soluble content) Equation 1;CPI=(GEX / residual monomer content)×100 Equation 3where GVs is gel volume in saline, Ln (water soluble content) is a logarithm natural of water soluble content.

Owner:NIPPON SHOKUBAI CO LTD

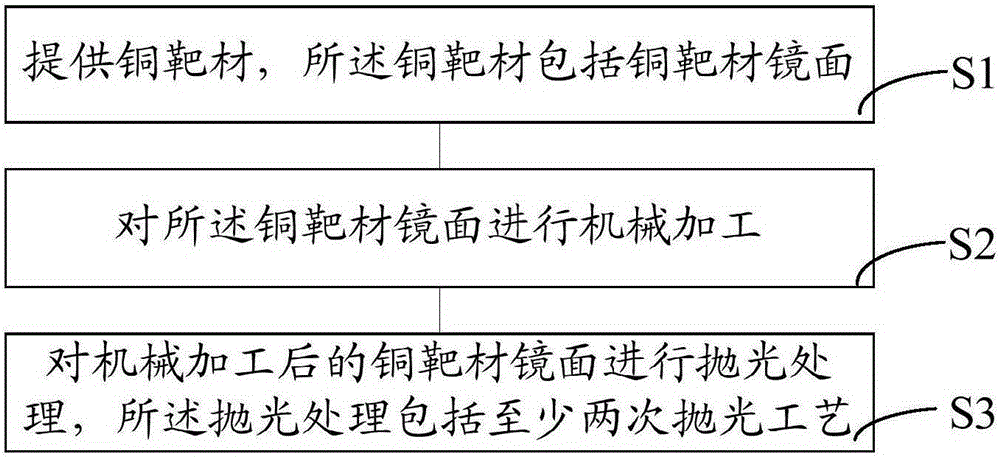

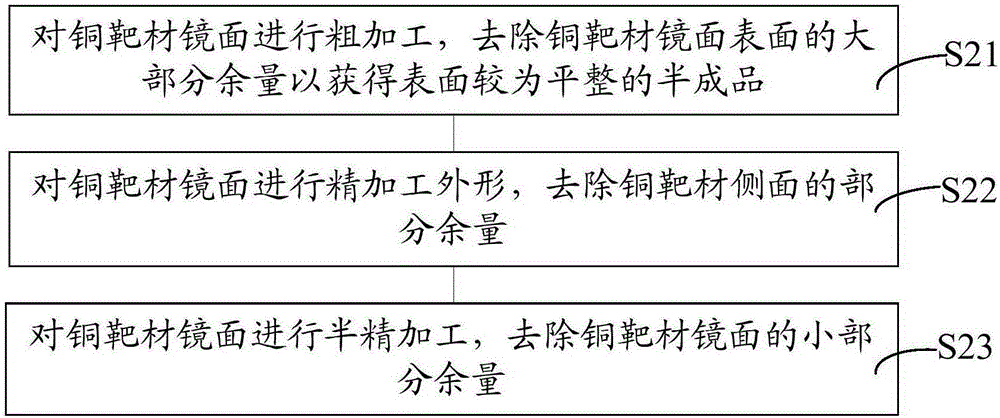

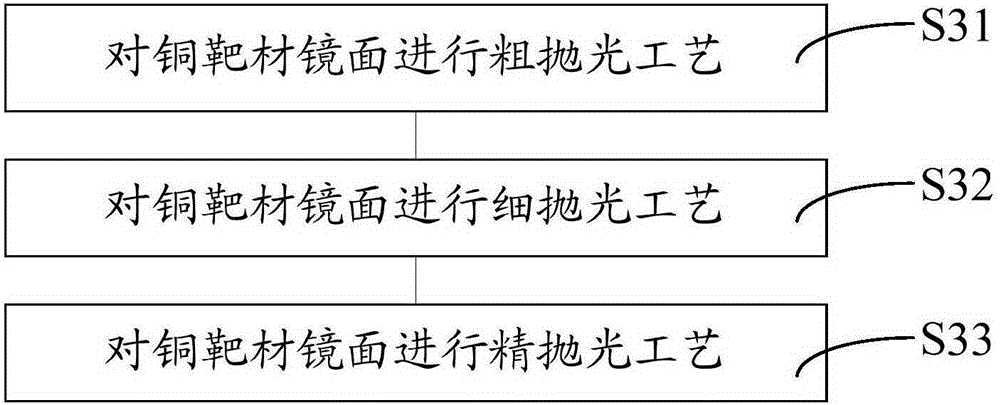

Copper target material surface processing method

The invention provides a copper target material surface processing method. The method includes the steps that a copper target material is provided and comprises a copper target material mirror surface; the copper target material mirror surface is machined; polishing processing is carried out on the machined copper target material mirror surface and includes two times of polishing processes. At least two times of polishing processes are adopted after machining, surface processing is carried out on the copper target material mirror surface, and scratches formed on the surface of the copper target material mirror surface by machining and an oxidation layer formed on the copper target material mirror surface by machining remaining liquid are removed by the polishing processes, so that surface glossiness and roughness of the copper target material mirror surface are higher, and the repair rate and rejection rate of the copper target material are reduced.

Owner:合肥江丰电子材料有限公司

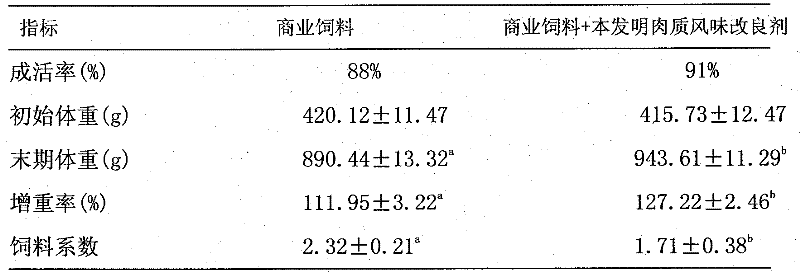

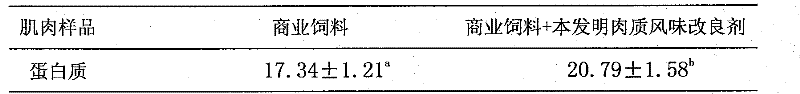

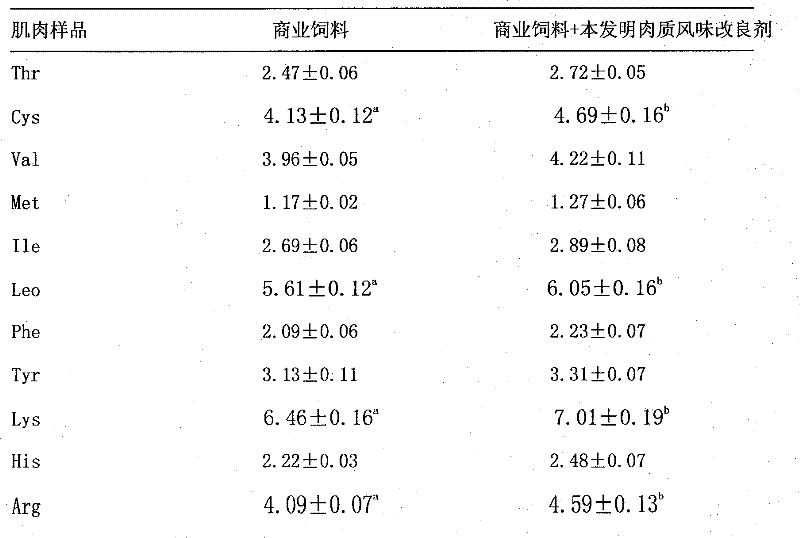

Meat quality flavor modifying agent for grass carp or carp and preparation method thereof

ActiveCN101744145AIncrease attractivenessImprove immunityAnimal feeding stuffBiotechnologyAquaculture industry

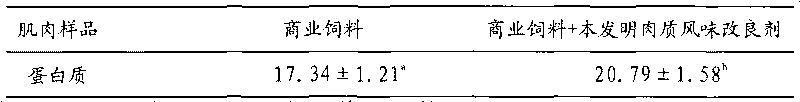

The invention relates to a feed additive of aquaculture industry, in particular to a meat quality flavor modifying agent for grass carp or carp and a preparation method thereof. Each kilogram of modifying agent comprises the following components: 30 to 50g of seaweed extract, 10 to 20g of combination of inosinic acid and guanylic acid, 20 to 30g of carnitine, 15 to 30g of glycin, 10 to 20g of alanine and the balance of zeolite powder. The preparation method comprises the following steps: firstly, crushing solid materials in the seaweed extract, the combination of inosinic acid and guanylic acid, the carnitine, the glycin, the alanine and the zeolite powder materials and sieving the crushed solid materials through a sieve with 80 to 100 meshes for later use; and secondly, mixing and stirring the crushed solid materials in the proportion to ensure that the coefficient of variation CV of the uniformity is less than 5 percent to obtain the product. The modifying agent can effectively improve protein content, content of total amino acids, content of essential amino acids and content of delicious amino acid in muscles of the grass carp and the carp.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Water-absorbable polyacrylic acid (salt) resin and process for production thereof

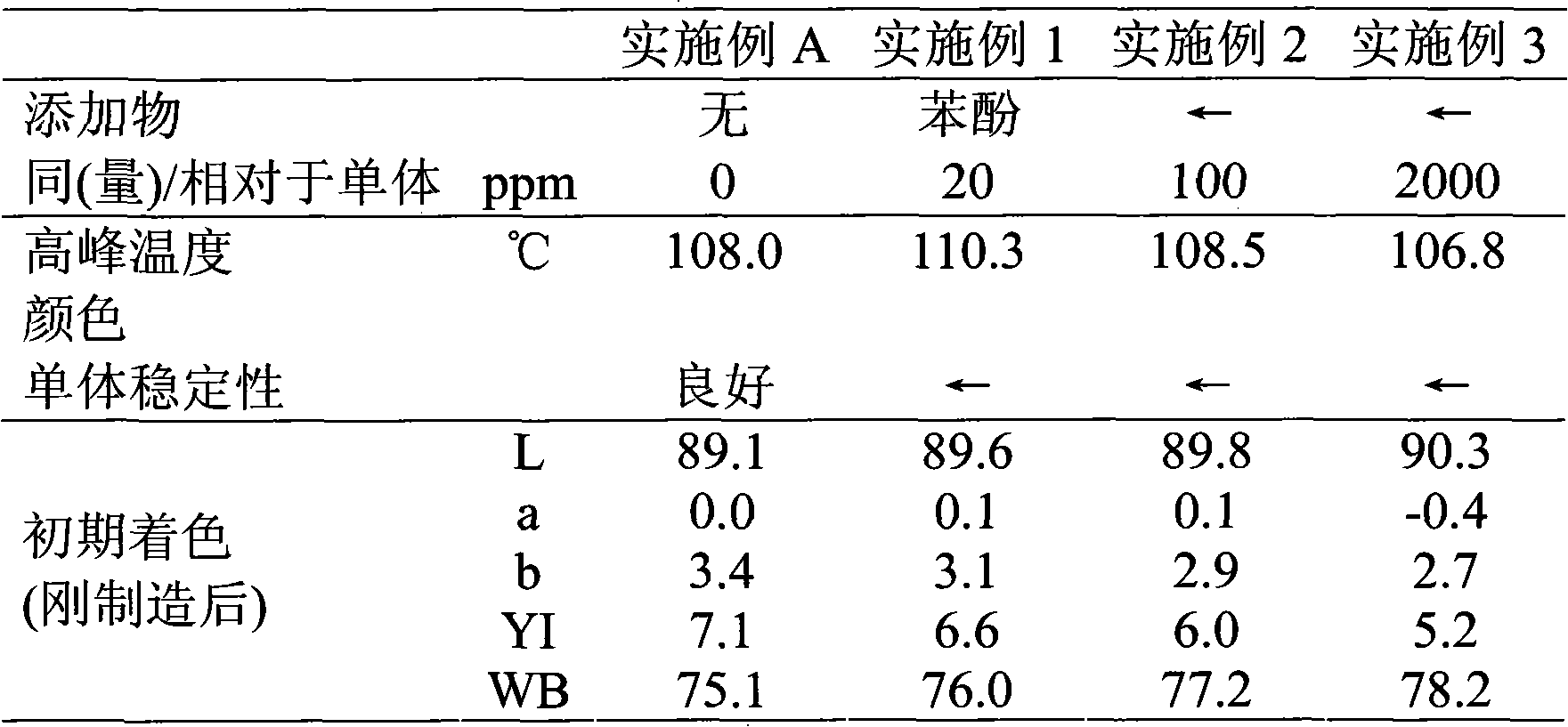

ActiveCN102015777AHigh whitenessNo loss of productivityAbsorbent padsBandagesPolymer scienceALLYL SUCROSE

The object aims to provide a water-absorbable resin which is prevented from the occurrence of gelatinization of a monomer before polymerization, hardly causes discoloration over time, has a remarkably improved surface color, and also has excellent absorption properties. For achieving the object, provided is a process for producing a water-absorbable polyacrylic acid resin, which comprises: a step of preparing a monomer by using acrylic acid having a hydroxyacetone content of 300 ppm by mass or less; a polymerization step of polymerizing the monomer to produce a hydrogel; and a drying step of drying the hydrogel. Also provided is a process for producing a water-absorbable polyacrylic acid resin, which comprises: a step of preparing a monomer by using acrylic acid; a step of polymerizing the monomer in the presence of phenol to produce a hydrogel; and a drying step of drying the hydrogel.

Owner:NIPPON SHOKUBAI CO LTD

Sintering process capable of reducing surface discoloration of metal injection molding product

PendingCN112808999AWell-proportioned materialEfficient removalTransportation and packagingMetal-working apparatusInjection molding processPartial pressure

The invention relates to the technical field of stainless steel sintering, in particular to a sintering process capable of reducing surface discoloration of a metal injection molding product. The sintering process comprises the following steps: S1, fully blending and mixing raw materials; S2, extruding, pelletizing and cooling a blocky mixture prepared by mixing in the S1, so as to prepare 316L feeding particles; S3, preparing the feeding particles prepared in the S2 into a sample blank through an injection molding process; S4, performing nitric acid catalytic degreasing treatment on the sample blank prepared in S3; S5, subjecting the degreased sample blank in the step S4 to heating and heat preservation treatment; and S6, carrying out vacuum sintering treatment on the sample blank subjected to heat preservation in S5, then carrying out partial pressure cleaning treatment, then carrying out partial pressure sintering treatment, finally cooling to room temperature, and finally completing product sintering. According to the process, the fluidity of powder can be enhanced, so that the powder can be mixed more uniformly; and in the sintering negative pressure degreasing stage, a binder can be effectively removed by adopting the heating rate of 1 DEG C / min.

Owner:SHENZHEN SHINDY TECH

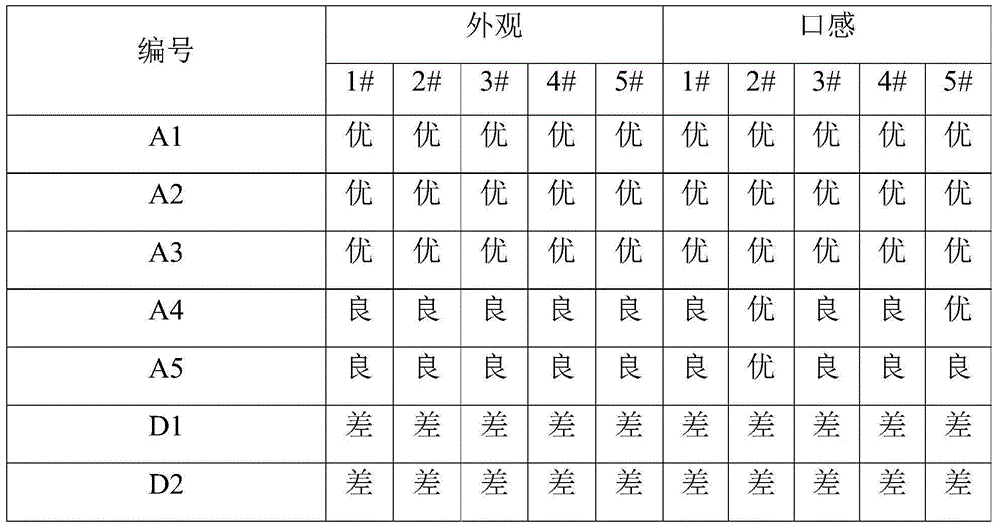

Cookies and making method thereof

The invention discloses cookies and a making method thereof. The making method includes the steps that 1, butter, sugar, salt, egg liquid, low-gluten flour and milk powder are mixed and stirred, and a mixture M1 is obtained; 2, the mixture M1 is pressed and formed and then frozen; 3, the frozen mixture M1 is taken out and sliced, and sheets M2 are obtained; 4, the sheets M2 are baked, wherein the sheets M2 are baked for 15-20 min under the conditions that the upper fire temperature ranges from 150 DEG C to 180 DEG C and the lower fire temperature ranges from 130 DEG C to 170 DEG C. Through the design, the made cookies are good in surface coloring effect, loose, fragrant and crispy in taste and proper in color, and the problems that in the prior art, cookies are easily burnt, and the surface coloring effect is poor due to the fact that preparation conditions are usually not well grasped in the preparation process due to the formula of the cookies and the like are solved.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS

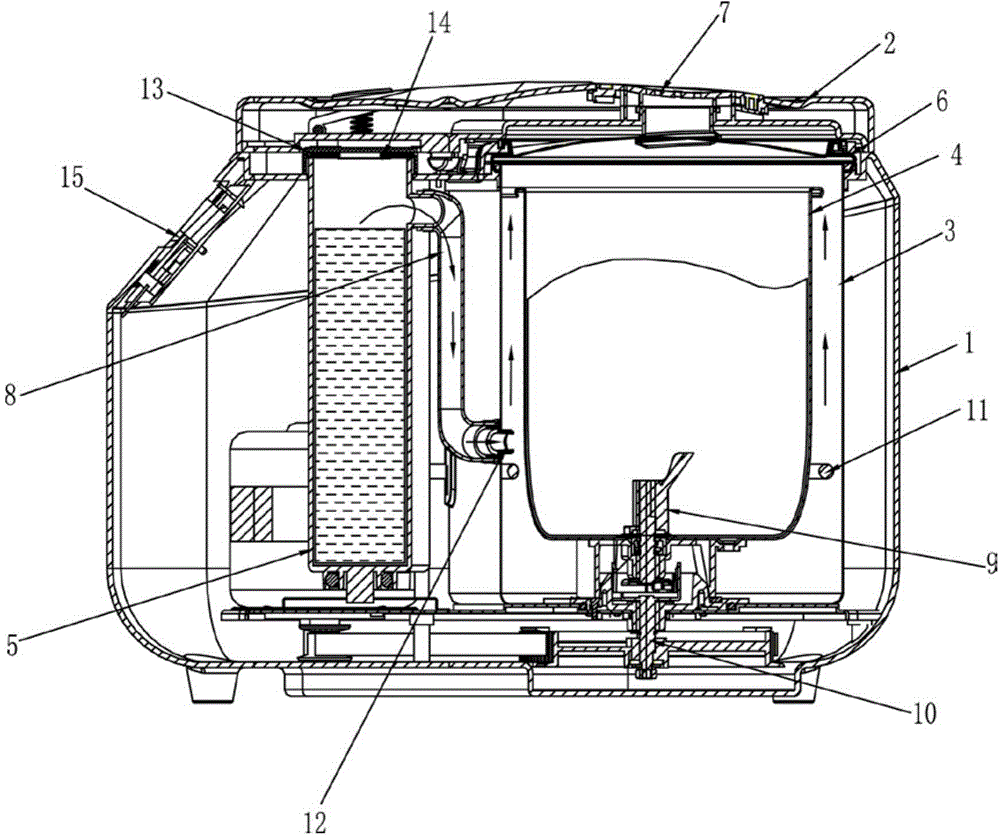

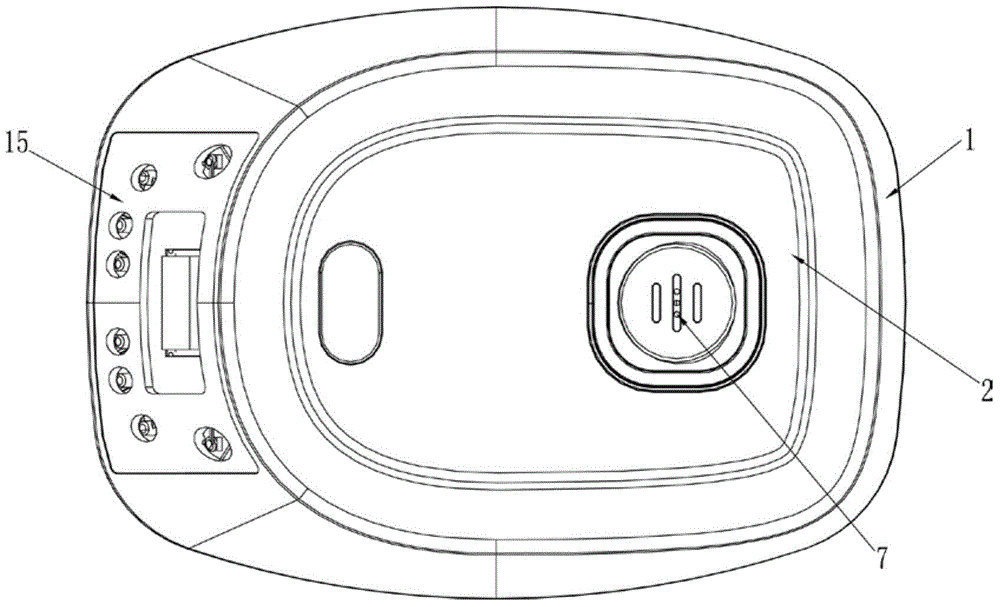

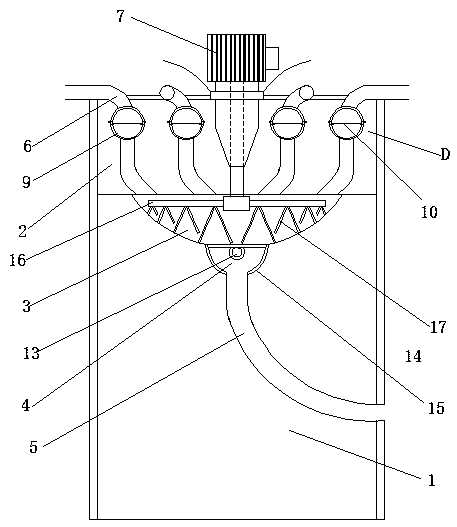

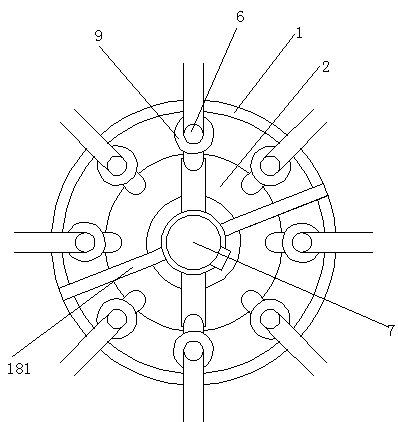

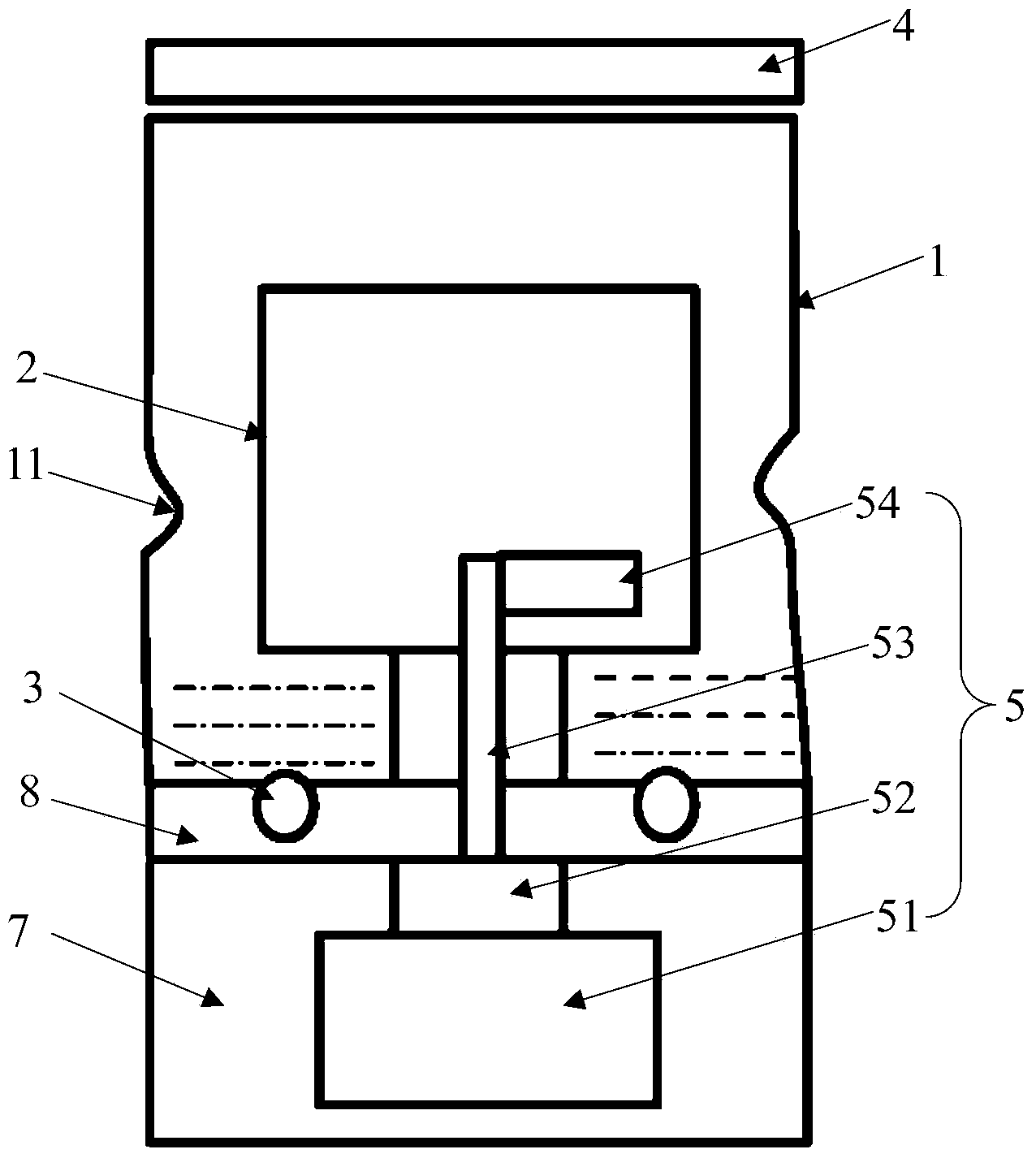

Steam-powered steamed bread machine and steamed bread making method

InactiveCN104083076AUniform temperatureEliminate the effects ofSteam cooking vesselsLiquid waterSteam power

The invention relates to the technical field of food processing, and discloses a steam-powered steamed bread machine which comprises a machine body and an upper cover covering the machine body, an outer cylinder, a steamed bread cylinder and a steam generator are arranged inside the machine body, the steamed bread cylinder is arranged inside the outer cylinder, the upper cover is sealed with the top of the outer cylinder, a gap is formed between the inner side wall of the outer cylinder and the outer side wall of the steamed bread cylinder, and the steam generator is arranged on the periphery of the outer cylinder and is connected with the lower portion of the outer cylinder through a steam connecting pipe. The invention further discloses a steamed bread making method based on the steam-powered steamed bread machine. According to the steam-powered steamed bread machine and the steamed bread making method, the steam generator for generating steam and the steamed bread cylinder for containing steamed breads are arranged in different containers, so that the liquid water and the gaseous steam can be separated effectively, the steam enters the steamed bread cylinder through the lower portion of the gap between the outer cylinder and the steamed bread cylinder, the inner area and the outer area of the steamed bread cylinder are filled with the steam, the steam temperature difference in the steamed bread steaming space can be eliminated effectively, and the surface color and luster of the steamed bread are improved; meanwhile, too much condensate water generated in the steamed bread steaming space can be avoided.

Owner:周武轩

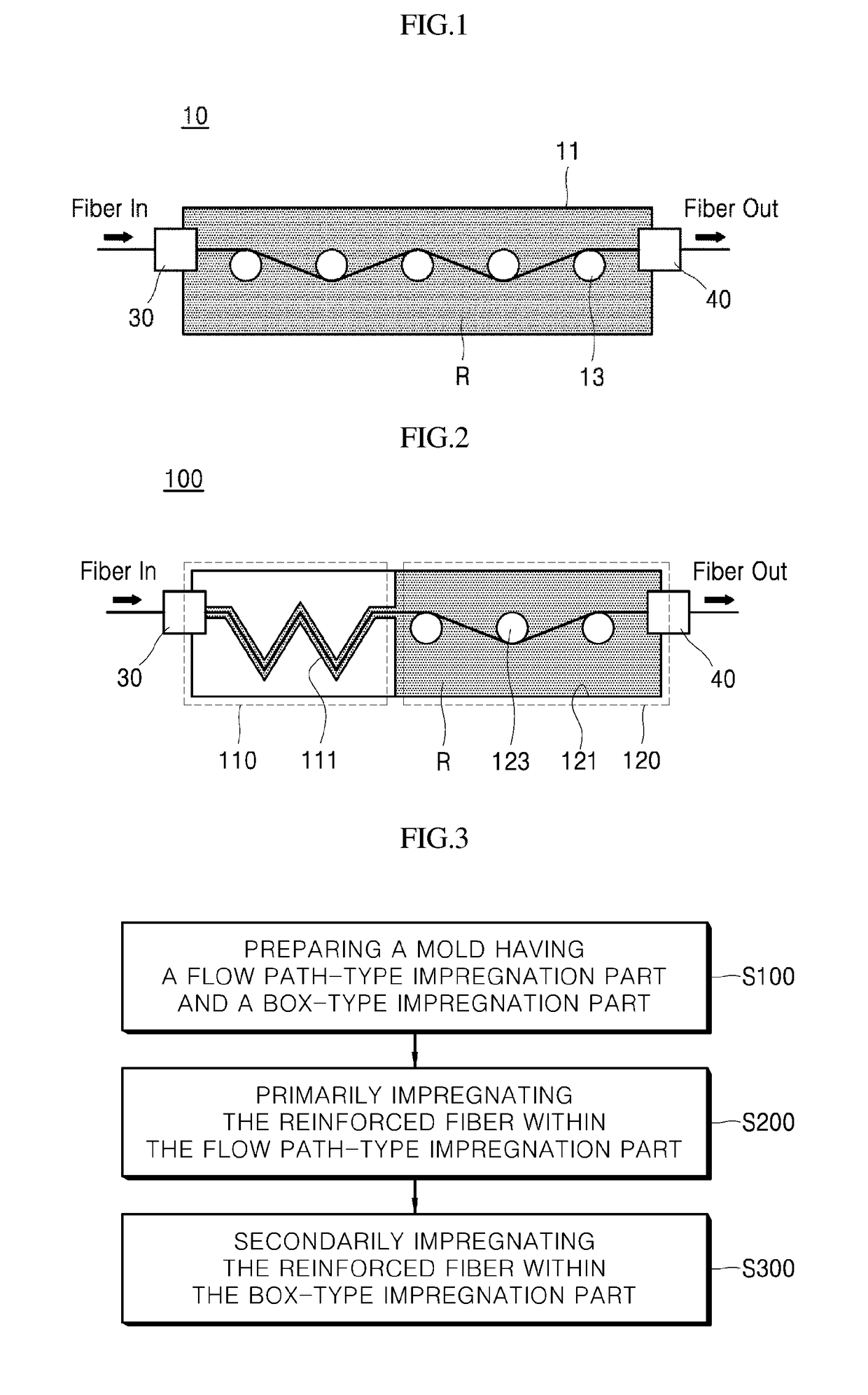

Prepreg preparation device and prepreg preparation method using same

A prepreg preparation device and a prepreg preparation method using the same are disclosed. According to an embodiment of the present invention, the prepreg preparation device comprises: a flow path-type impregnation part for impregnating, with a resin, a reinforced fiber transferred along a flow path; and a box-type impregnation part for impregnating, with the resin, the reinforced fiber transferred through a box-type space by passing through the flow path-type impregnation part.

Owner:LG HAUSYS LTD

Cranberry instant powder and preparation method thereof

The invention discloses cranberry instant powder and a preparation method thereof. The instant powder is prepared by a single component or a compound of one or more of cranberry whole fruit extract powder, a roselle extract, opuntia ficus-indica powder, roxburgh rose powder, roselle powder, elderberry concentrated juice powder, white grape juice powder and red beet juice powder, and one or more ofan appropriate amount of sorbitol, mannitol, maltitol, lactitol, isomalt, erythritol and xylitol which serve as auxiliary materials. The instant powder is prepared by the steps of sieving, weighing,mixing, soft material making, granulating, drying, pelleting, complete mixing, filling, quality inspection, packaging and warehousing, equipment with high promotion function of mixing and drying the materials is used in the preparation process, the quality of the cranberry instant powder is improved, and the preparation time is shortened.

Owner:BRAVEIY BIOTECHNOLOGY (ANHUI) CO LTD

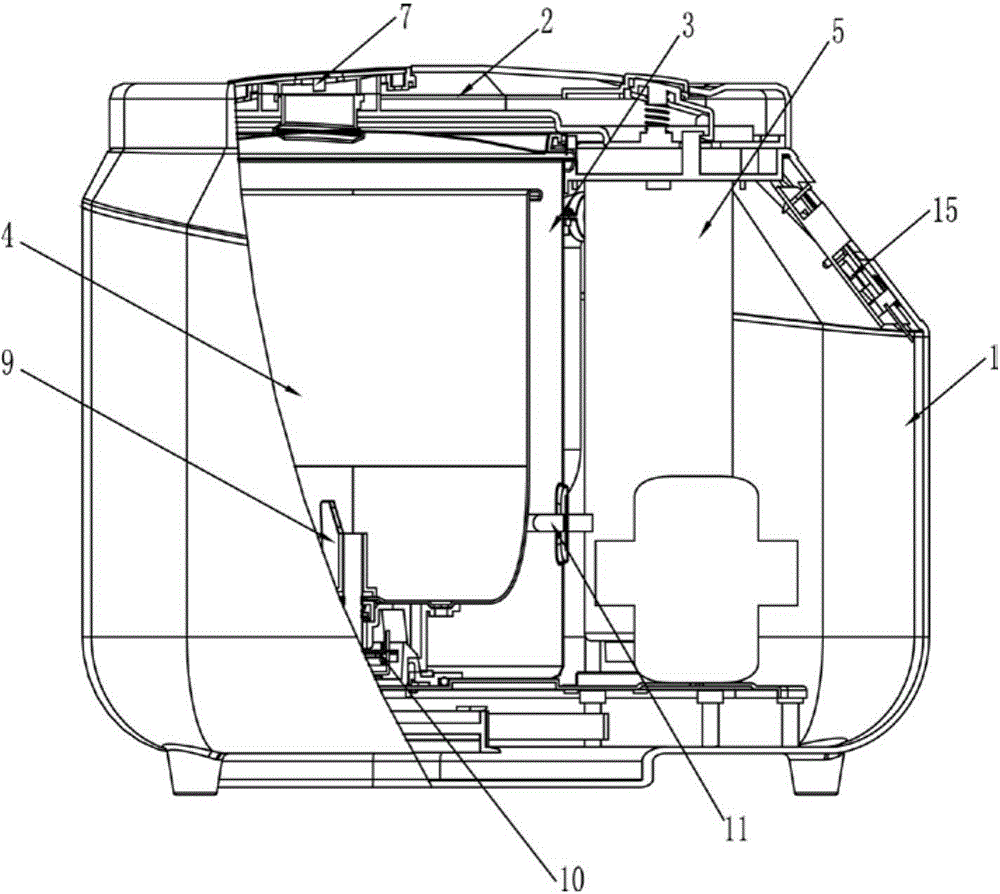

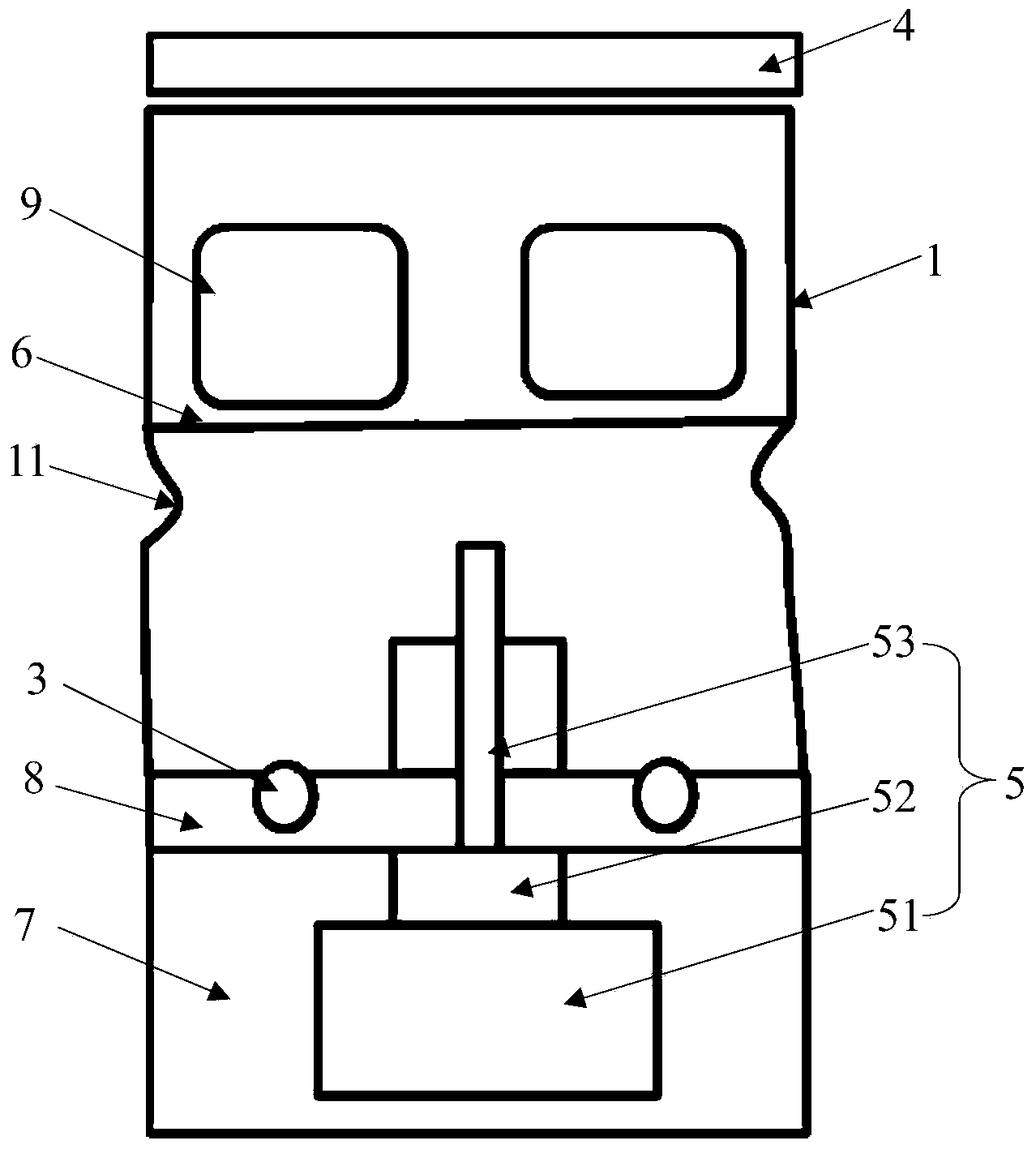

Steamed bun making method and steamed bun making machine

InactiveCN104171883AGood surface colorGreat tasteMixing/kneading with vertically-mounted toolsFood preparationEngineeringFermentation

The invention relates to the technical field of food processing, and discloses a steamed bun making method. The steamed bun making method comprises the following steps: adding raw materials which are required for making steamed buns into a steamed bun barrel, adding water into an outer barrel, switching on a heating device for preheating the steamed bun barrel, mixing the materials at different stirring speeds to form dough, and fermenting the dough; making steamed bun blanks of required specifications from the fermented dough, taking out the steamed bun barrel from a steamed bun making machine, putting a steaming sheet into the outer barrel, and placing the prepared steamed bun blanks on the steaming sheet; and covering the outer barrel with an upper cover, and heating water in the outer barrel by the heating device to generate steam until the steamed buns are cooked. The invention also provides the steamed bun making machine for the steamed bun making method. In the material mixing and fermenting processes, the step of preheating is added, and furthermore, the materials are mixed at different stirring speeds, so that the steamed bun making machine has a full-automatic function, manual dough kneading is really simulated, uniform kneading and complete fermentation of the dough are guaranteed, and the surface color and the taste of the steamed buns are improved.

Owner:QINGDAO AUCMA DOMESTIC ELECTRICAL APPLIANCE

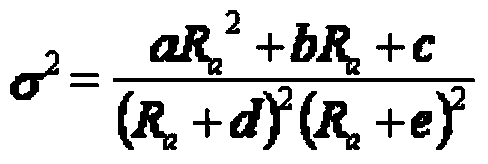

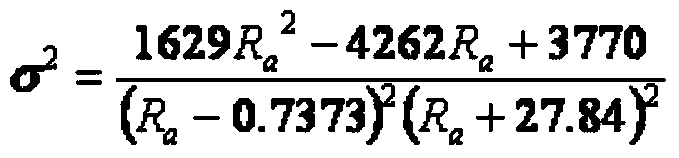

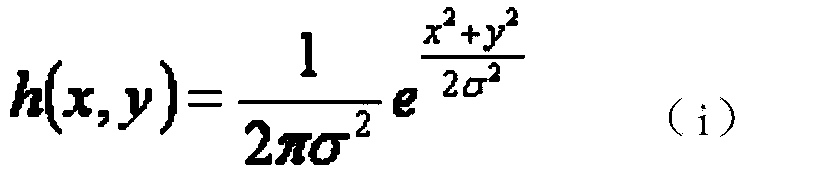

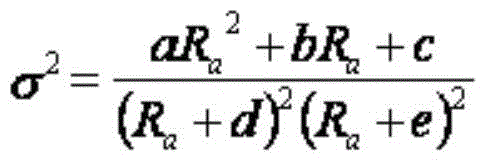

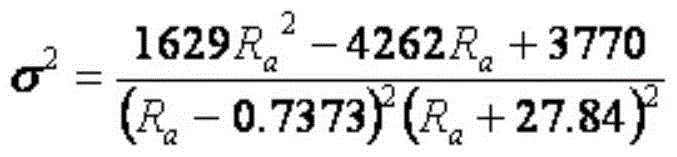

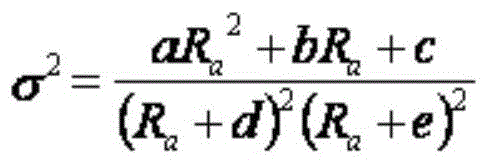

Method for quantitative description of surface color and luster degree of galvanized plate

ActiveCN103544403AImprove work efficiencyGood surface colorSpecial data processing applicationsColor intensitySurface roughness

The invention provides a method for quantitative description of the surface color and luster degree of galvanized plates. The method comprises the steps of (1) establishing a functional relation formula of the surface roughness Ra and a diffusion parameter sigma; (2) selecting at least 5 galvanized plates different in color intensity, respectively measuring the surface roughness Ra and the diffusion parameter sigma of each plate to obtain a formula determined by undetermined coefficients; (3) selecting the galvanized plates with normal surfaces, measuring the surface roughness Ra0, calculating the diffusion parameter sigma0 through the formula and using the diffusion parameter sigma0 as a reference; (4) measuring the surface roughness Ran of the galvanized plates having chromatic aberration and calculating the diffusion parameter sigman through the formula; (5) comparing the sigman with the sigma0, wherein the plates are brighter if a sigman-sigma0 numerical value is a positive number, the color and luster degree is higher if the value is larger, the plates are dimmer if the sigman-sigma0 numerical value is a negative number, and the color and luster degree is lower if the value is larger. The method utilizes online quantification of the surface color and luster degree of the galvanized plates to determine the chromatic aberration level of the surfaces of galvanized steel plates and is simple in operation, practical and high in working efficiency.

Owner:武汉钢铁有限公司

Non-sulfur anti-browning sweet potato slices and processing method thereof

InactiveCN106135837AGood surface colorIncrease nutritional contentInorganic compound food ingredientsFood dryingSulfurAdditive ingredient

The invention relates to non-sulfur anti-browning sweet potato slices and a processing method thereof. The method comprises the steps of peeling, slice cutting, rinsing, non-sulfur anti-browning, steam pre-cooking, solar-assisted heat pump combined drying, cooling, seasoning and packing. According to the making method, by means of a non-sulfur anti-browning agent, the surface color of dried sweet potatoes can be good, and the effect of inhibiting enzymatic and non-enzymatic browning can be achieved; meanwhile, a solar-assisted heat pump combined drying technology is utilized for producing the dried sweet potatoes, the flavor, color and relevant quality of dried products can be maintained to the maximum extent, the made dried sweet potatoes are bright in color and attractive in appearance, the nutritional ingredient are well maintained, and enhancement of the market competitiveness of dried sweet potato products is promoted.

Owner:福建健尔聪食品有限公司

A kind of treatment method before electroplating nickel of copper product

The invention relates to a treatment method for a copper product before electronickelling. The method comprises the following steps: firstly, polishing the copper product to be electroplated for the first time, and then washing; polishing for the second time, and then washing for three times; pickling, wherein a pickling solution for pickling is sulfuric acid of which the volume fraction is 30%; finally, activating to finish treatment, wherein the activating solution for activation is sulfuric acid of which the volume fraction is 3-5%. By adopting the treatment method, only oxide and greasy dirt on the surface of the copper product can be processed, and the copper layer is not corroded, so that the integrity of the product is greatly protected; meanwhile, the electroplated appearance is good in consistence, consistent in surface color and luster, and good in uniformity after electronickelling is carried out, and the brightness is improved.

Owner:YANGZHOU HY TECH DEV

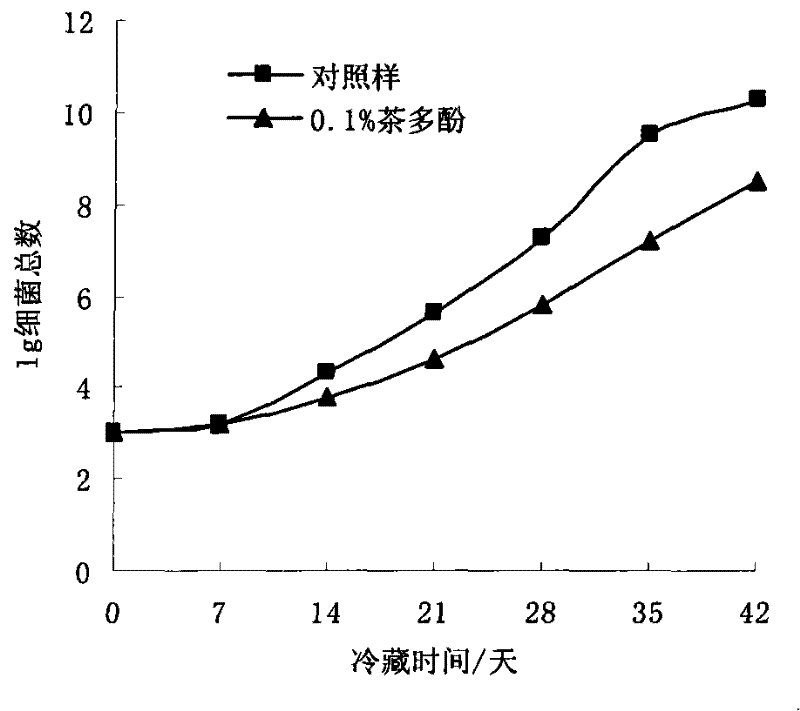

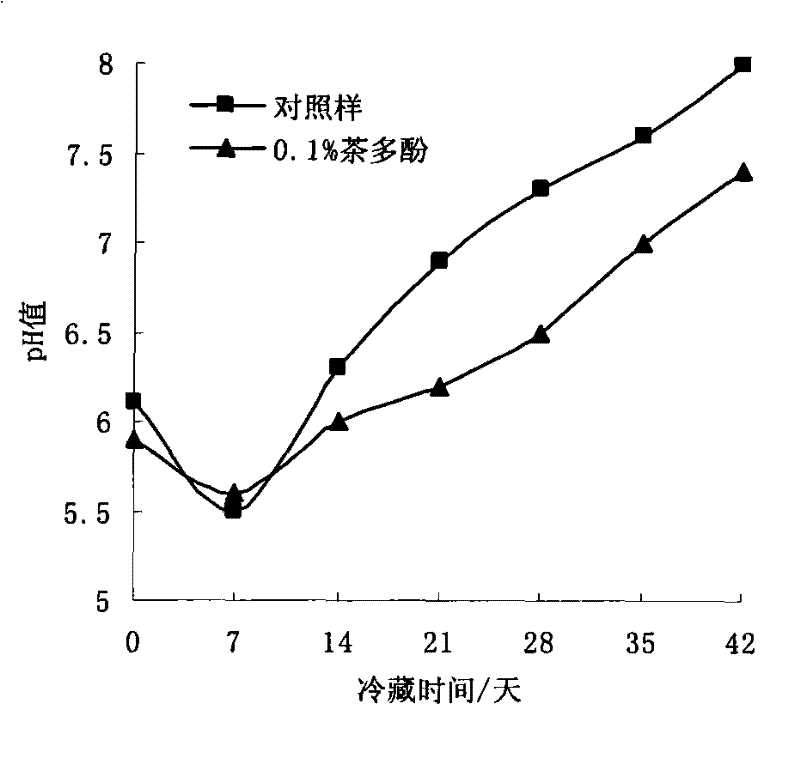

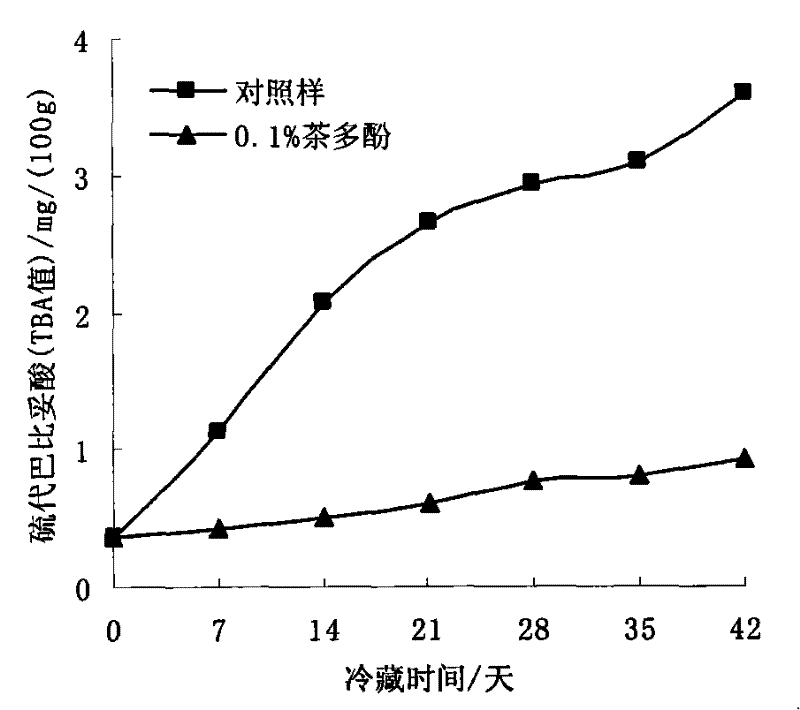

Fresh water fish cold-storage preservation method

InactiveCN101507447BReduce frost damageInhibition of reproductionMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsPolyphenolSeawater

The invention discloses a method for cold preservation and refreshment of freshwater fish, which comprises the following steps that: killed, cleaned and washed freshwater fish is soaked into a tea polyphenol acetic acid aqueous solution for 1.5 to 6 hours, drained and subjected to cold preservation and refreshment at the temperature of between 1 DEG C below zero and 8 DEG C below zero, wherein the tea polyphenol acetic acid aqueous solution contains the following materials in weight by percentage: 0.05 to 1.0 percent of tea polyphenol and 0.05 to 5.0 percent of acetic acid. The method not only has small freezing injury on the body of the freshwater fish, but also can further inhibit the propagation of body bacteria, retard the oxidation of fats, and increase the preserving effect on the basis of micro-freezing, and the storage period of the freshwater fish can reach 37 to 57 days. The method not only can be used for keeping freshwater fish products fresh, but also can be used in micro-freezing cold preservation technology for seawater fish and other meat products.

Owner:四川烹饪高等专科学校

Rose gold aluminum product mold designing extrusion surface treatment integrated forming process

InactiveCN110125365AGood surface colorGood imitationLiquid surface applicatorsSurface reaction electrolytic coatingRoughcastSurface finishing

The invention discloses a rose gold aluminum product mold designing extrusion surface treatment integrated forming process. The rose gold aluminum product mold designing extrusion surface treatment integrated forming process comprises the following production steps of first, carrying out designing, machining and production of a mold according to the shape of an aluminum product needing to be produced; second, a mold is placed into an extrusion forming device, aluminum product raw materials are fed into a smelting furnace to be melted into molten materials, the molten materials are fed into theextrusion forming device to be formed in the mold through the extrusion forming device, and a formed aluminum product workpiece blank is obtained; third, polishing treatment is carried out on the surface of the aluminum product workpiece blank, polishing is carried out on burrs and a gate on the surface of the blank, and then gloss finish treatment is carried out on the surface of the blank; andfourth, the aluminum product workpiece blank is soaked in a sulfuric acid solution, oil removal treatment is carried out with the sulfuric acid solution, and the aluminum product workpiece blank is spooned out after being soaked for some time, and then is cleaned up.

Owner:佛山市成铝金属制品有限公司

A kind of olive salting liquid and method for preventing olive precipitates from being produced

ActiveCN106820006BShorten subsequent salting timesReduce contentClimate change adaptationFood preservationBiotechnologySodium sulfites

The invention provides olive salting liquid and a method for preventing production of olive precipitate. The olive salting liquid is prepared from the following raw materials in parts by weight: 100 parts of water, 12 to 16 parts of sodium chloride, 0.6 to 1.2 parts of sodium metabisulfite, and 0.2 to 0.6 part of citric acid. The method for preventing the production of the olive precipitate comprises the following steps of 1, beating and flattening the olives after the epicutile wax layer is removed; 2, boiling the beat and flattened olives in water for 5 to 10min at the temperature of 80 to 100 DEG C; 3, soaking the boiled olives into the olive salting liquid. The method for preventing the production of the olive precipitate has the advantages that by performing beating and flattening, boiling, and controlling of component of olive salting liquid, the production of the olive precipitate is effectively prevented; the method is simple, the condition is controllable, the operability is strong, the salting time and the preserved olive processing cycle are greatly shortened, and the production cost is reduced.

Owner:FUJIAN AGRI & FORESTRY UNIV

Sulfur-free color-protected potato strips and processing method thereof

The invention relates to sulfur-free color-protected potato strips and a processing method thereof. The processing method comprises the following steps; removing peel; cutting potatoes into strips; rinsing the potato strips; performing sulfur-free color protection; performing steam pre-cooking; performing joint drying through a solar-assisted heat pump; cooling the dried potato strips; flavoring the cooled potato strips; and packaging the flavored potato strips. According to the processing method, a sulfur-free color protecting agent is adopted, so that the surfaces of dried potatoes have good color, and the effects of inhibiting enzymatic promotion and non-enzymatic browning can be achieved; besides, a joint drying technology of the solar-assisted heat pump is adopted to produce dried potatoes, so that the flavor, the color and relevant quality of the dried potatoes can be furthest maintained, the produced dried potato products are bright in color, beautiful in appearance, and good in reservation of nutritional ingredients; therefore, the enhancement of the market competitiveness of the dried potato products is facilitated.

Owner:WEITEJIA FOOD JIANGSU

Preparation method of caramel lotus seed snack

PendingCN114431326APrevent surface oxidative browningGreat tasteConfectionerySweetmeatsHealthy dietCaramel Flavor

The invention discloses a preparation method of a caramel lotus seed snack, and belongs to the technical field of deep processing of agricultural and sideline foods.The method comprises the steps that dry lotus seeds serve as raw materials, the dry lotus seeds are soaked in a sugar solution, fried to be golden yellow and wrapped with a caramel solution, and the caramel lotus seed snack which is burnt, crispy and fragrant in taste is produced. According to the method, the shape of the lotus seeds is completely reserved, the surfaces of the lotus seeds are crisp, good in taste and good in flavor, the surface color of the lotus seeds is improved through caramel color, the lotus seeds are attractive in sensory color and luster, appetite is promoted, the grease content is low, the requirement for low fat of healthy diet is met, the method is suitable for various consumer groups, development of the deep processing industry of the lotus seeds is promoted to a certain extent, and the method is worthy of popularization and application. The storage and the transportation are convenient.

Owner:NANCHANG UNIV

Three-mushroom fine dried noodles capable of nourishing stomach and preparation method thereof

InactiveCN106107496AEnsure safetyNo side effectsFood ingredient functionsNutritive valuesLaminaria japonica

The invention relates to three-mushroom fine dried noodles capable of nourishing stomach and a preparation method thereof. The three-mushroom fine dried noodles are prepared from the following raw materials in parts by weight: 68-72 parts of wheat flour, 8-12 parts of soybean meal, 8-12 parts of corn flour, 2-4 parts of almond meal and 4-8 parts of peanut meal; a fresh three-mushroom slurry is prepared from the following raw materials in parts by weight: 20-25 parts of white mushroom, 20-25 parts of fresh shiitake mushroom, 20-25 parts of phoenix mushroom, 1-3 parts of celery, 1-2 parts of black fungus, 1-2 parts of laminaria japonica and 1-2 parts of spinach. The fine dried noodles are prepared by preparing the fresh three-mushroom slurry, preparing flour, preparing fresh noodles and drying the noodles. The three-mushroom fine dried noodles capable of nourishing stomach have the advantages of rich nutritive value, pure taste and convenience in eating.

Owner:YUZHOU SIYUAN IND

A kind of olive salting liquid and method for preventing olive precipitates from being produced

ActiveCN106819323BShorten subsequent salting timesAvoid generatingFruit and vegetables preservationFood ingredient as colourBiotechnologySodium sulfites

The invention provides olive salting liquid and a method for preventing production of olive precipitate. The olive salting liquid is prepared from the following raw materials in parts by weight: 100 parts of water, 15 to 20 parts of sodium chloride, 0.6 to 1.5 parts of sodium metabisulfite, and 0.2 to 0.6 part of citric acid. The method for preventing the production of the olive precipitate comprises the following steps of 1, puncturing the olive after the epicuticle wax layer is removed; 2, soaking the punctured olive into the olive salting liquid. The method for preventing the production of the olive precipitate has the advantages that by puncturing to change the permeation speed of the salting liquid and control the component of the olive salting liquid, the production of the olive precipitate is effectively prevented; the method is simple, the condition is controllable, the operability is strong, the salting time and the preserved olive processing cycle are greatly shortened, and the production cost is reduced.

Owner:FUJIAN AGRI & FORESTRY UNIV

Process for manufacturing sulfur-free dried sweet potatoes

InactiveCN110638009AGood surface colorIncrease nutritional contentSugar food ingredientsOligosaccharide food ingredientsProcess engineeringBiology

The invention provides a process for manufacturing sulfur-free dried sweet potatoes. The process comprises the following steps: 1, peeling, slicing and soaking; 2, blanching; 3, candying; 4, candy soaking; 5, baking; 6, mixing and air-drying; and 7, re-baking. The dried sweet potatoes are taken out to obtain a finished product after the step of re-baking. The process enables the surface of the dried sweet potatoes to have a good color, can achieve a sulfur-free effect, and can furthest maintain the flavor, color and related quality of dried products; and the dried sweet potato product has bright color and attractive appearance, and the nutritional ingredient can be well maintained.

Owner:连城县宏丰食品厂

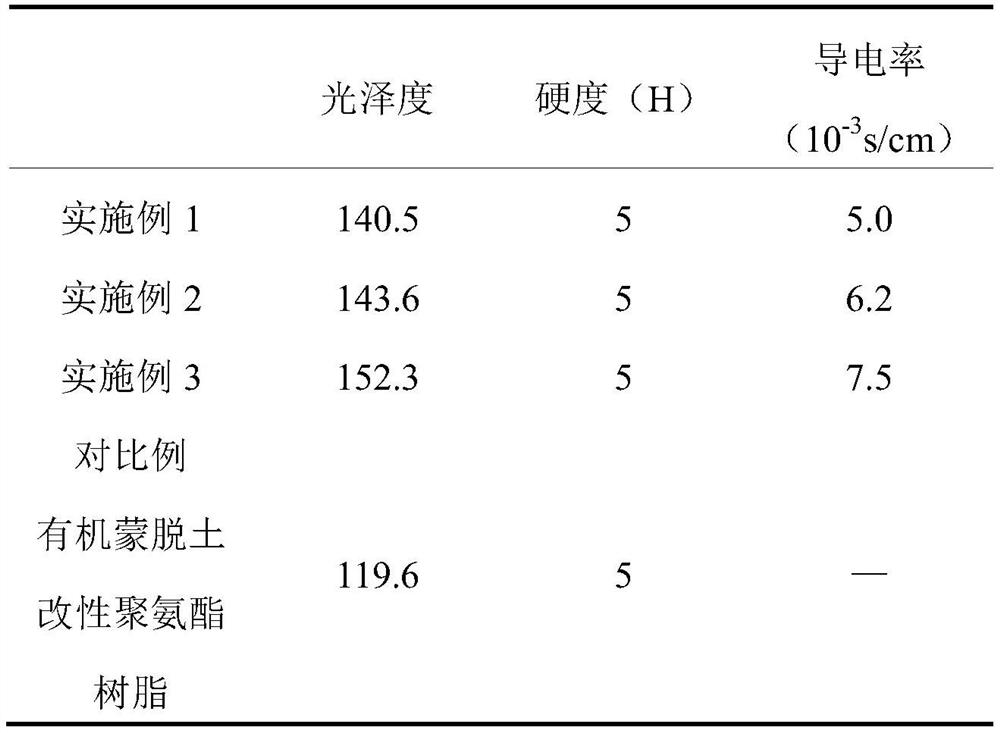

Nano titanium dioxide modified electrophoretic resin and its electrophoretic paint with high fullness and antibacterial and antiviral properties

ActiveCN112457464BGood surface colorStrong ability to resist ultraviolet radiationAntifouling/underwater paintsPaints with biocidesPhenyl EthersGlycol synthesis

The invention discloses a nano-titanium dioxide modified electrophoretic resin and an electrophoretic paint with high plumpness, antibacterial and antiviral properties, and belongs to the technical field of surface coating. The nano-titanium dioxide-modified polyurethane resin comprises the following chemical components in mass percent: hydroxyl functional group-containing polyurethane resin: 10-25%, nano-titanium dioxide: 45-65%, propylene glycol: 3-15%, and the balance is deionized water. The nano-titanium dioxide-modified polyurethane resin is used as one of the reaction raw materials to prepare an electrophoretic resin. The electrophoretic resin has a good surface color and has a certain antibacterial and antiviral ability. Continue to mix the electrophoretic resin with blocked isocyanate, propylene glycol phenyl ether and ethylene glycol butyl ether, and then forcefully shear in water to form an electrophoretic film to obtain an electrophoretic paint. The electrophoretic paint is not only bright and full in surface color, but also has a relatively Good electrical conductivity and antibacterial ability.

Owner:武汉科利尔电泳涂料有限公司

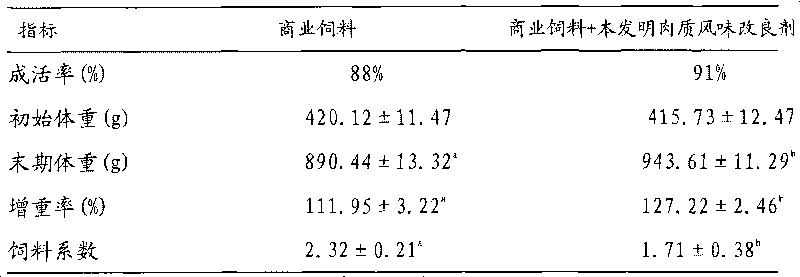

Meat quality flavor modifying agent for grass carp or carp and preparation method thereof

ActiveCN101744145BIncrease attractivenessImprove immunityAnimal feeding stuffAquaculture industryCarp

The invention relates to a feed additive of aquaculture industry, in particular to a meat quality flavor modifying agent for grass carp or carp and a preparation method thereof. Each kilogram of modifying agent comprises the following components: 30 to 50g of seaweed extract, 10 to 20g of combination of inosinic acid and guanylic acid, 20 to 30g of carnitine, 15 to 30g of glycin, 10 to 20g of alanine and the balance of zeolite powder. The preparation method comprises the following steps: firstly, crushing solid materials in the seaweed extract, the combination of inosinic acid and guanylic acid, the carnitine, the glycin, the alanine and the zeolite powder materials and sieving the crushed solid materials through a sieve with 80 to 100 meshes for later use; and secondly, mixing and stirring the crushed solid materials in the proportion to ensure that the coefficient of variation CV of the uniformity is less than 5 percent to obtain the product. The modifying agent can effectively improve protein content, content of total amino acids, content of essential amino acids and content of delicious amino acid in muscles of the grass carp and the carp.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

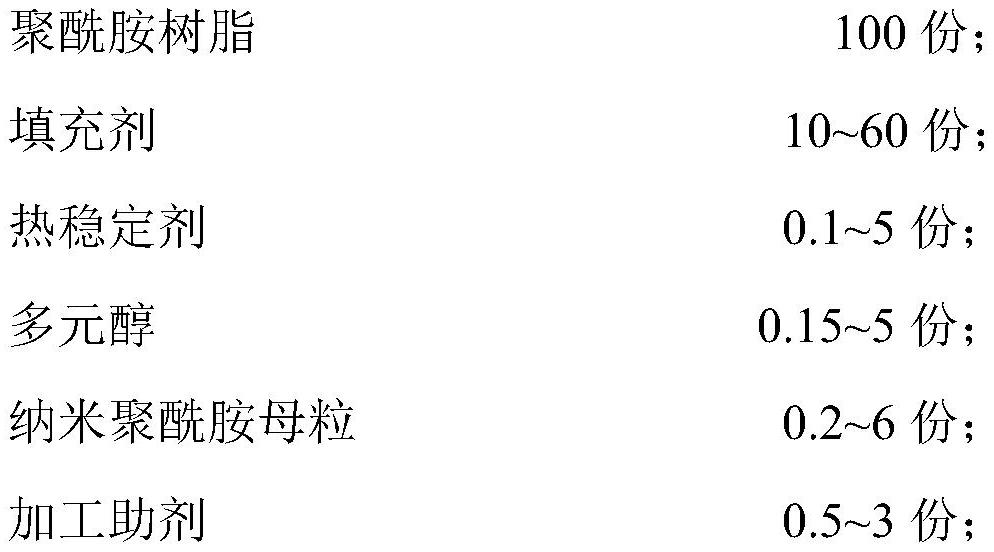

A polyamide composition resistant to high temperature thermal oxygen aging and its preparation method

The invention discloses a high-temperature thermo-oxidative ageing resistant polyamide composition and a preparation method thereof. The high-temperature thermo-oxidative ageing resistant polyamide composition is prepared from the following raw-material components in parts by weight: 100 parts of polyamide resin, 10 to 60 parts of filling agent, 0.1 to 5 parts of heat stabilizer, 0.15 to 5 parts of polyol, 0.2 to 6 parts of nano polyamide master batch and 0.5 to 3 parts of processing aid, wherein the nano polyamide master batch is a self-made product; the content of a nano particle is in a range of 25%wt. The high-temperature and thermo-oxidative ageing resistant polyamide composition selects and uses the proper heat stabilizer and is supplemented by the polyol and the nano particle; all the components interact; meanwhile, the corresponding processing aid is added; the high-temperature thermo-oxidative ageing resistant polyamide composition is obtained; the high-temperature thermo-oxidative ageing resistant polyamide composition has excellent chemical performance, size stableness performance and high-temperature thermo-oxidative ageing resistant performance. The surface performanceof a sample piece of the polyamide composition prepared by the preparation method is excellent; no floating fiber is accumulated on a surface; the performance maintenance and the size stableness canbe good in a high-temperature condition, and the high-temperature thermo-oxidative ageing resistant polyamide composition is applicable to the fields of the use as high-temperature accessories on theperipheries of automobile engines and for other high-temperature-resistant materials.

Owner:合肥圆融新材料有限公司

Quantitative description method for surface color of galvanized sheet

ActiveCN103544403BImprove work efficiencyGood surface colorSpecial data processing applicationsSurface roughnessBrightness perception

The invention provides a method for quantitatively describing the surface color of a galvanized sheet. Steps: 1) Establish the functional relationship between surface roughness Ra and diffusion parameter σ; 2) Select at least 5 galvanized sheets with different degrees of light and shade, measure their surface roughness Ra and diffusion parameter σ respectively, and obtain the formula for determining the undetermined coefficient ; 3) Select a galvanized sheet with a normal surface and measure the surface roughness Ra 0 , the diffusion parameter σ is calculated by the formula 0 , and use this as a benchmark; 4) For galvanized sheets with color difference, measure the surface roughness Ra n , and then calculate the diffusion parameter σ by the formula n ; 5) put σ n with σ 0 Compared to: σ n -σ 0 The value of σ is a positive number, that is, it is brighter, and the greater the deviation of the value, the brighter the color; σ n -σ 0 The value of is negative, that is, darker, and the greater the deviation of the value, the darker the color. The invention utilizes the surface roughness of the galvanized steel sheet to quantitatively determine the color difference level of the surface of the galvanized steel sheet on-line, the operation is simple and practical, and the work efficiency is high.

Owner:武汉钢铁有限公司

High strength powder metallurgy material

InactiveCN108145147AHigh strengthQuality improvementTransportation and packagingMetal-working apparatusMixing ratioAntimony

The invention provides a high strength powder metallurgy material comprising, by mass, 80-100 parts of iron, 5-6 parts of titanium, 2-3 parts of stibium, 2-3 parts of calcium, 1-2 parts of aluminum, 3-5 parts of carbon, 0.5-1 parts of graphite, 1-2 parts of molybdenum disulfide, 0.5-1 parts of strengthened nickel, and 2-3 parts of a lubricant. According to the high strength powder metallurgy material, multiple metal raw materials and additives such as the carbon, the molybdenum disulfide, and the lubricant are utilized to produce according to a specific mixing ratio, and the fusion performanceis good. A workblank obtained by using the powder metallurgy material is easy to demold, the surface quality is good, and the quality is uniform and fine.

Owner:LUOYANG SHENJIA KILN

Olive salting liquid and method for preventing production of olive precipitate

ActiveCN106820006APrevents brown polymers or polyphenol-protein polymersSpeed up replacementClimate change adaptationFood preservationEpicuticular waxChemistry

The invention provides olive salting liquid and a method for preventing production of olive precipitate. The olive salting liquid is prepared from the following raw materials in parts by weight: 100 parts of water, 12 to 16 parts of sodium chloride, 0.6 to 1.2 parts of sodium metabisulfite, and 0.2 to 0.6 part of citric acid. The method for preventing the production of the olive precipitate comprises the following steps of 1, beating and flattening the olives after the epicutile wax layer is removed; 2, boiling the beat and flattened olives in water for 5 to 10min at the temperature of 80 to 100 DEG C; 3, soaking the boiled olives into the olive salting liquid. The method for preventing the production of the olive precipitate has the advantages that by performing beating and flattening, boiling, and controlling of component of olive salting liquid, the production of the olive precipitate is effectively prevented; the method is simple, the condition is controllable, the operability is strong, the salting time and the preserved olive processing cycle are greatly shortened, and the production cost is reduced.

Owner:FUJIAN AGRI & FORESTRY UNIV

Electric vehicle body varnish baking process

InactiveCN111112021AOptimizing recipe ratiosEasy to adjust viscosityPretreated surfacesCoatingsElectric carsElectric vehicle

The invention provides an electric vehicle body varnish baking process. A varnish baking resin formula proportion is optimized, meanwhile, a lubricating agent is added for use, convenience is providedfor subsequent varnish mixing, and varnish viscosity can be more easily adjusted.

Owner:江苏爱派电动车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com