Nano titanium dioxide modified electrophoretic resin and its electrophoretic paint with high fullness and antibacterial and antiviral properties

A technology of nano-titanium dioxide and electrophoretic resin, applied in biocide-containing paints, electrophoretic coatings, conductive coatings, etc., can solve the problems of unsatisfactory anti-ultraviolet radiation ability, achieve good antibacterial and anti-virus capabilities, high yield, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

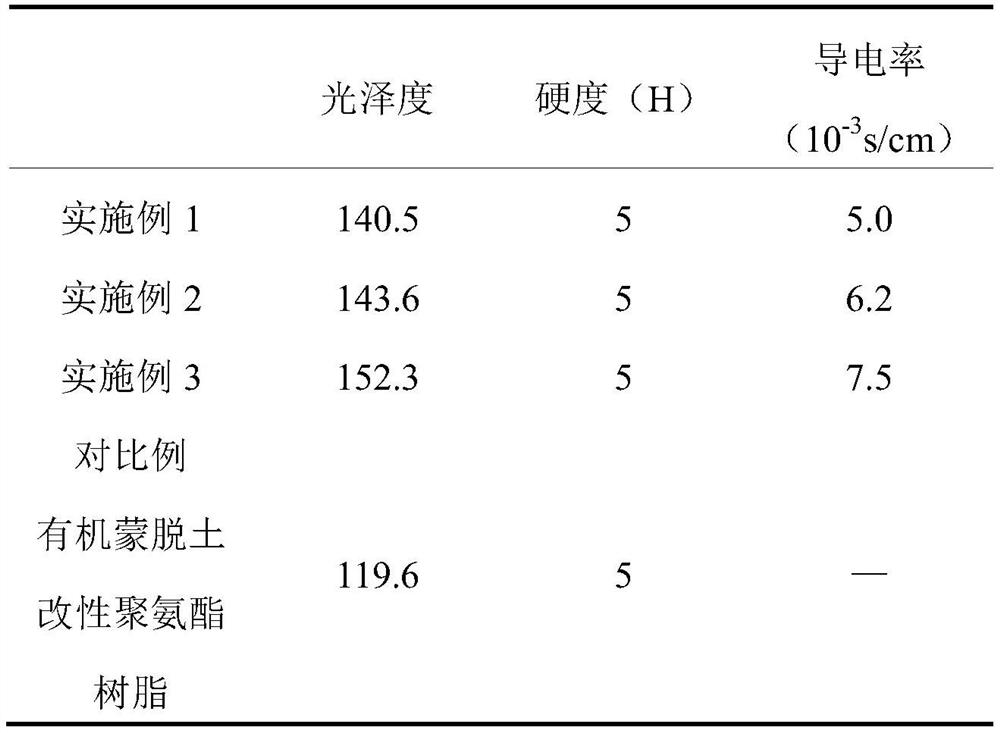

Examples

Embodiment 1

[0036] The preparation process of a polyurethane resin containing hydroxyl functional groups is as follows, which includes adding 2.27% trimethylolpropane, 35.4% epoxy resin, and 4% 1,4-butanediol to the reaction kettle in mass percentages, and the temperature is raised to 55°C , constant temperature reaction for 1 to 3 hours, then continue to drop 43.38% of isophorone diisocyanate into the reactor, keep warm for 1 to 3 hours, add 14.95% of glacial acetic acid, continue to keep warm for about 2 hours, and cool down to obtain a polyurethane resin containing hydroxyl functional groups . The yield reaches 90%.

[0037] The preparation process of a nano-titanium dioxide modified polyurethane resin is as follows, the nano-titanium dioxide with a mass percentage of 45% is dispersed in deionized water at a temperature of about 25°C until uniform; then continue to add 15% propylene glycol, after the dispersion is uniform, slowly drop Add 25% of the hydroxyl functional group-containin...

Embodiment 2

[0039] The preparation process of a polyurethane resin containing hydroxyl functional groups is as follows, which includes adding 3.76% trimethylolpropane, 33.3% epoxy resin, and 0.8% 1,4-butanediol into the reaction kettle in mass percentages, and heating up to 60°C , constant temperature reaction for 1 to 3 hours, then continue to drop 43.38% toluene diisocyanate into the reactor, keep warm for 1 to 3 hours, add 19.03% glacial acetic acid, continue to keep warm for about 2 hours, and cool down to obtain a polyurethane resin containing hydroxyl functional groups. The yield reached 91.2%.

[0040] The preparation process of a kind of nano-titanium dioxide modified polyurethane resin is as follows, the nano-titanium dioxide with a mass percentage of 65% is dispersed in deionized water at a temperature of about 25°C until uniform; then continue to add 3% propylene glycol, after the dispersion is uniform, slowly Add 10% of the hydroxyl functional group-containing polyurethane res...

Embodiment 3

[0042] The preparation process of a polyurethane resin containing hydroxyl functional groups is as follows, which includes adding 3.05% trimethylolpropane, 34.2% epoxy resin and 3.5% 1,4-butanediol into the reaction kettle in mass percentage, and heating up to 60°C , constant temperature reaction 1~3h, then continue to drip the mixture 41.50% of toluene diisocyanate and isophorone diisocyanate in reactor, wherein, the mol ratio between toluene diisocyanate and isophorone diisocyanate is 1: 1. Heat preservation reaction for 1-3 hours, add 17.75% glacial acetic acid, continue heat preservation for about 2 hours, and cool down to prepare polyurethane resin containing hydroxyl functional groups. The yield reached 90.5%.

[0043] The preparation process of a kind of nano-titanium dioxide modified polyurethane resin is as follows, take the nano-titanium dioxide with a mass percentage of 50% and disperse it into the deionized water with a temperature of about 25°C until uniform; then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com