A polyamide composition resistant to high temperature thermal oxygen aging and its preparation method

A polyamide composition and polyamide technology, applied in the field of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] 1. Preparation of nano-polyamide masterbatch: the nano-polyamide masterbatch in Examples 1 to 5 of the present invention is a self-made product, and each material component includes polyamide, nanoparticle, silane coupling agent, lubricant, antioxidant Add additives and other additives to the high-mixing equipment, control the temperature at 80-160°C, stir for 3-15 minutes, and rotate at a speed of 500-2000RP / min. Add the mixed materials through the main feeding port of the twin-screw extruder. Under the process conditions of 210-280°C, vacuum at -0.05~-0.08MPa, and rotating speed of 300-500RP / min, it is melted and extruded through a twin-screw extruder, and granulated to obtain granular nano-polyamide masterbatches.

[0025] 2. The preparation method of the polyamide composition resistant to high temperature thermal oxygen aging: Weigh each raw material component by weight, and use a high-speed mixer to mix the dried polyamide, nano-polyamide masterbatch, heat stabilize...

Embodiment 1

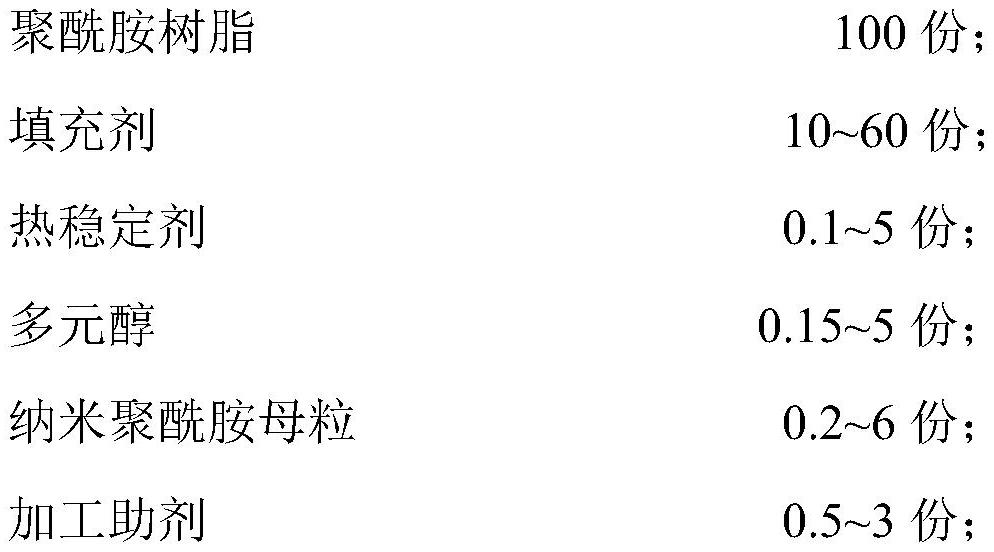

[0027] A high-temperature thermal-oxidative aging-resistant polyamide composition, which comprises the following raw material components in parts by weight:

[0028]

[0029]

[0030] Among them, the polyamide resin is PA6; the content of nanoparticles in the nano-polyamide masterbatch is 25% wt, and the type of nanoparticles is magnesium oxide; the filler is E-type glass fiber, and the diameter of the glass fiber is 7 μm; the heat stabilizer is iodide copper; polyol is dipentaerythritol; processing aids include N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, tris(2,4 - a mixture of di-tert-butylphenyl) phosphite and 2,4-dihydroxybenzophenone in a weight ratio of 1:1:1.

Embodiment 2

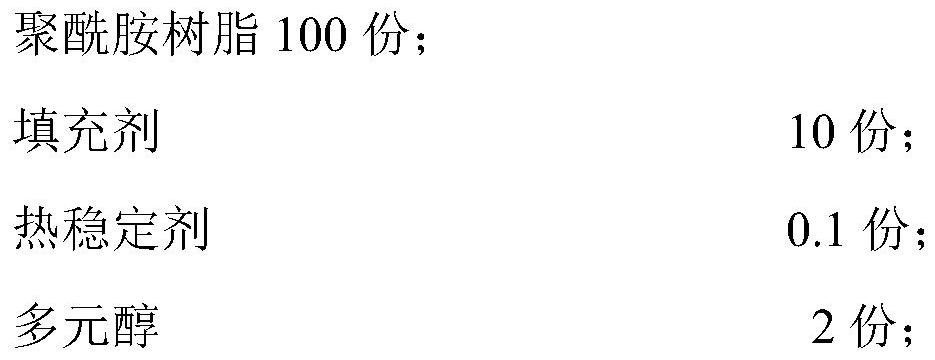

[0032] A high-temperature thermal-oxidative aging-resistant polyamide composition, which comprises the following raw material components in parts by weight:

[0033]

[0034] Among them, the polyamide resin is PA66 / PA6; the content of nanoparticles in the nano-polyamide masterbatch is 25% wt, and the type of nanoparticles is zinc oxide; the filler is E-type glass fiber, and the diameter of the glass fiber is 10 μm; the heat stabilizer is Potassium iodide; polyol is trimethylolethane; processing aids include N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexanediamine, tris A mixture of (2,4-di-tert-butylphenyl) phosphite mixture and zinc stearate in a weight ratio of 1:1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com