Preparation method of soil conditioner

A technology of soil improver and active agent, which is applied in the field of fertilizer preparation, can solve the problems of pollution sources, insufficient understanding of the value of organic fertilizers, and the decline of the effect of organic fertilizers, so as to improve the utilization rate, inhibit growth and reproduction, and be full of vitality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

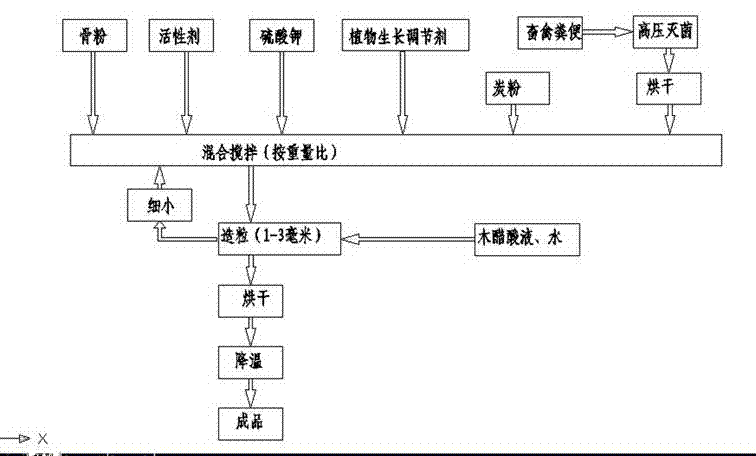

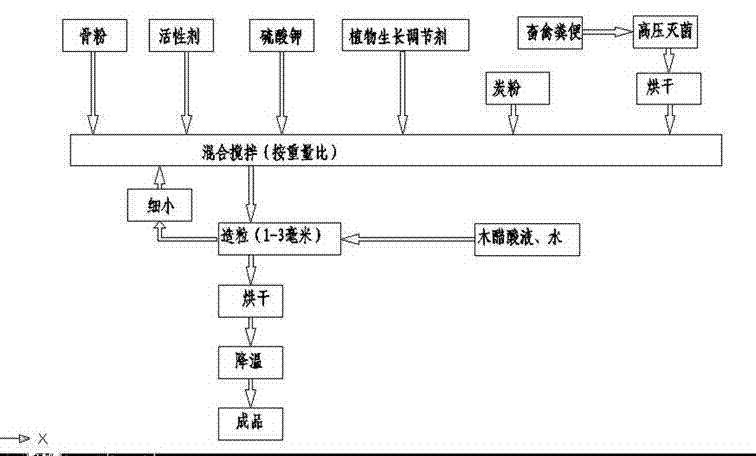

[0028] Preparation method step of the present invention is as follows:

[0029] a. Prepare charcoal powder: sinter the plant straw into 80-120 mesh charcoal powder for later use;

[0030] b. Pretreatment of poultry and livestock manure: put poultry and livestock manure into an autoclave, sterilize it under 2 steam pressures for two hours to become mold-free poultry and livestock manure, and dry the mold-free poultry and livestock manure naturally until the moisture content is less than When it is 12%, it is crushed and passed through a 60 mesh sieve for subsequent use;

[0031] c. according to parts by weight, plant charcoal, poultry manure, bone meal, potassium sulfate,

[0032] Put the plant growth regulator and the active agent into the stirring tank, and stir evenly to obtain a pasty mixture;

[0033] d. Granulation and packaging: put the pasty mixture into a granulator for granulation, add 2 to 8 parts by weight of wood acetic acid solution to the pasty mixture during g...

Embodiment 1

[0035] Example 1: by weight

[0036] 1. Prepare charcoal powder: sinter the crop straw into 80-120 mesh charcoal powder for later use;

[0037] 2. Pretreatment of poultry and livestock manure: put poultry and livestock manure into an autoclave tank, and sterilize it under 2 steam pressures for two hours to become mold-free poultry and livestock manure, take out the mold-free poultry and livestock manure and dry it naturally to the moisture content When it is less than 12%, it is crushed through a 60-mesh sieve, and its particles are used for later use.

[0038] 3. Put 55kg of plant charcoal powder into the 500L stirring tank, 5kg of poultry manure; 15kg of bone meal less than 1 mm; 18kg of potassium sulfate; A mixture is prepared.

[0039] 4. Sampling and testing the mixture to check whether the mixing degree is uniform, and granulate after passing the test.

[0040] 5. Granulation and packaging: Put the mixture into a granulator for granulation. When granulating, add 5 kg ...

Embodiment 2

[0041] Example 2: by weight

[0042] 1. Prepare charcoal powder: sinter the crop straw into 80-120 mesh charcoal powder for later use;

[0043]2. Pretreatment of poultry and livestock manure: put poultry and livestock manure into an autoclave tank, and sterilize it under 2 steam pressures for two hours to become mold-free poultry and livestock manure, take out the mold-free poultry and livestock manure and dry it naturally to the moisture content When it is less than 12%, it is crushed through a 60-mesh sieve, and its particles are used for later use.

[0044] 3. Put 260kg of plant charcoal powder (crushed into 80-200 meshes), 80kg of poultry manure, 60kg of bone meal, 72kg of potassium sulfate, 60kg of production-increasing amine, and 4kg of sodium a-naphthalene acetate into a 500L stirring tank and stir evenly , to produce a mixture.

[0045] 4. Sampling and testing the mixture to check whether the mixing degree is uniform, and granulate after passing the test.

[0046] 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com