Patents

Literature

271results about How to "Consistent appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

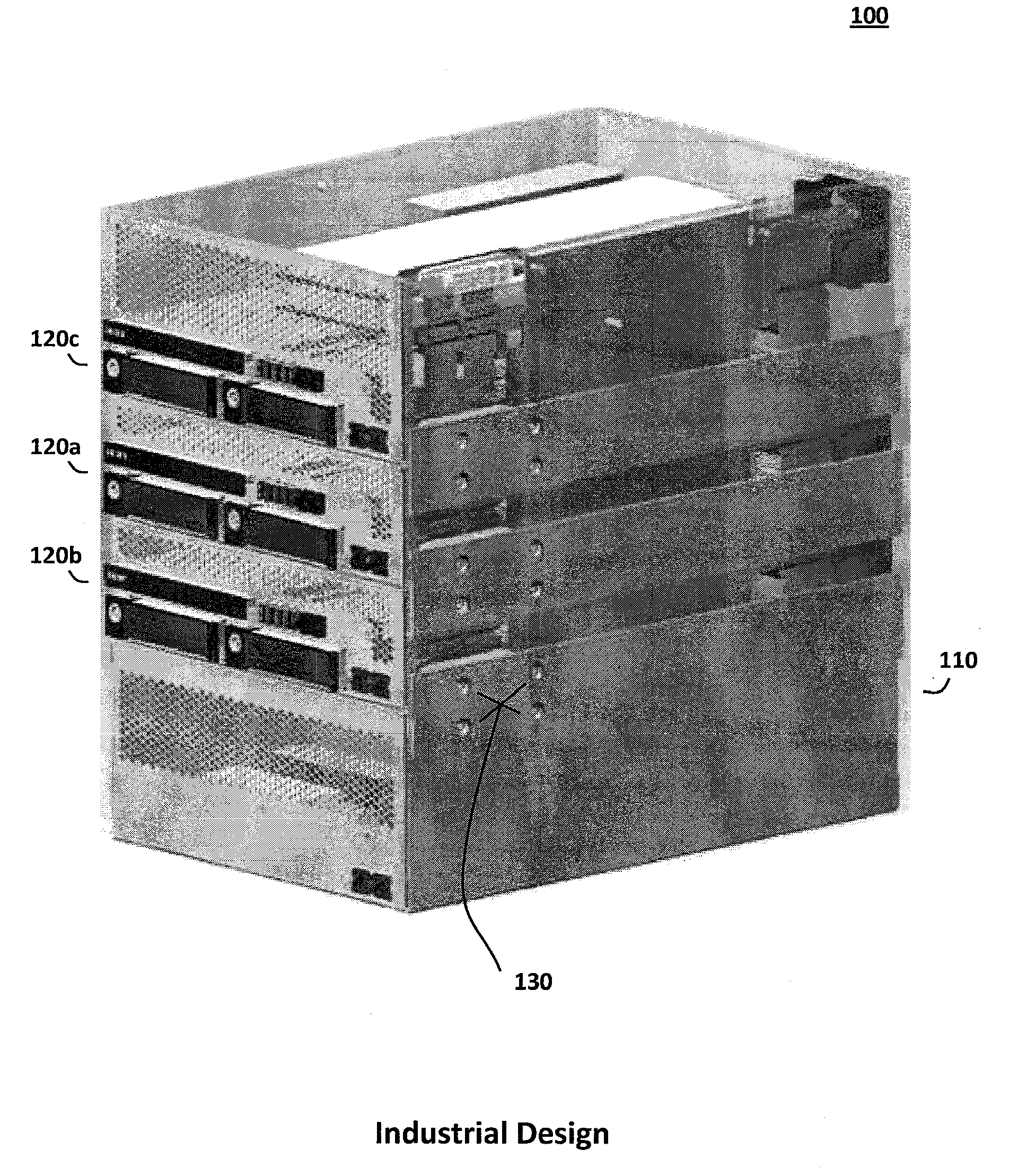

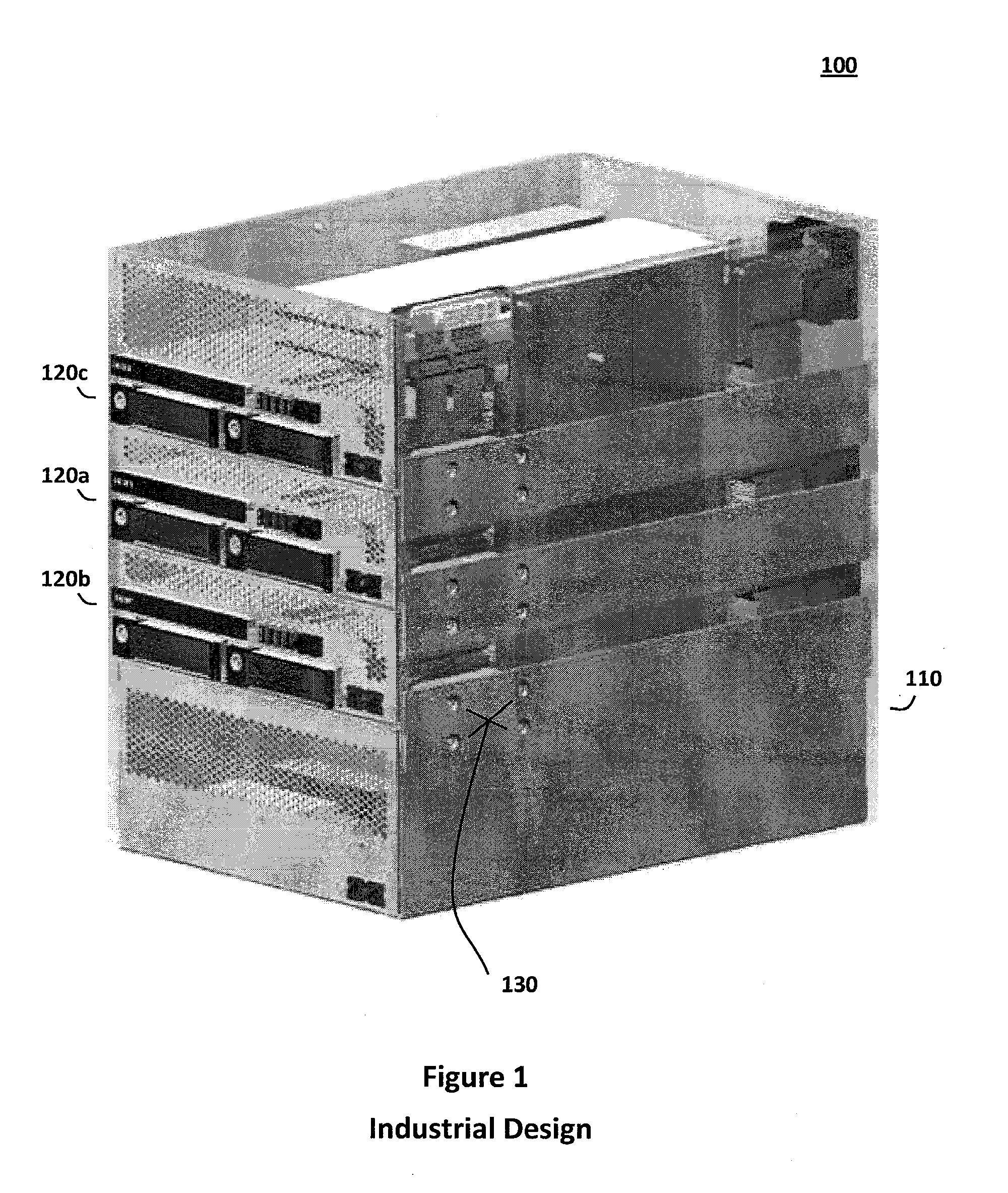

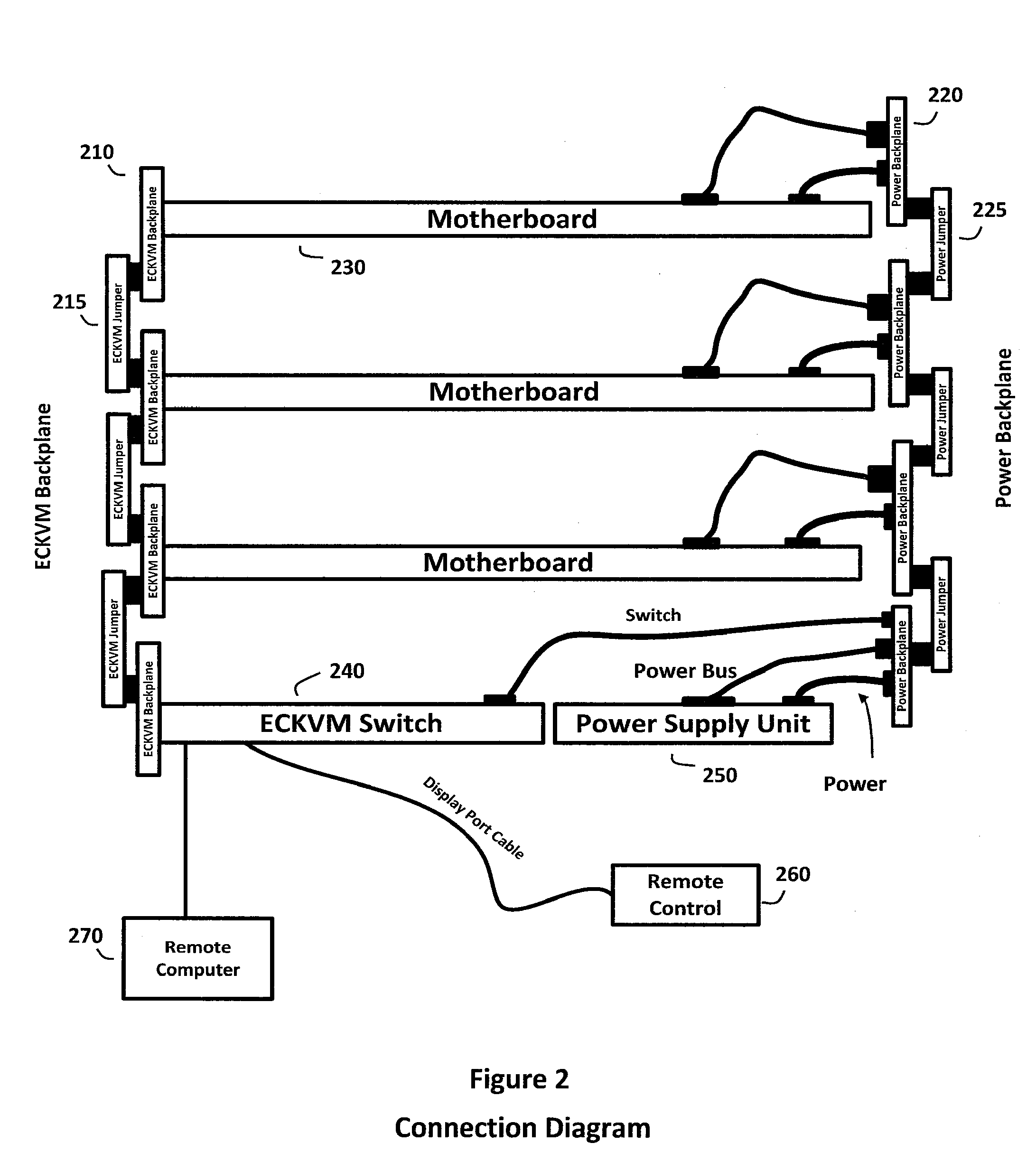

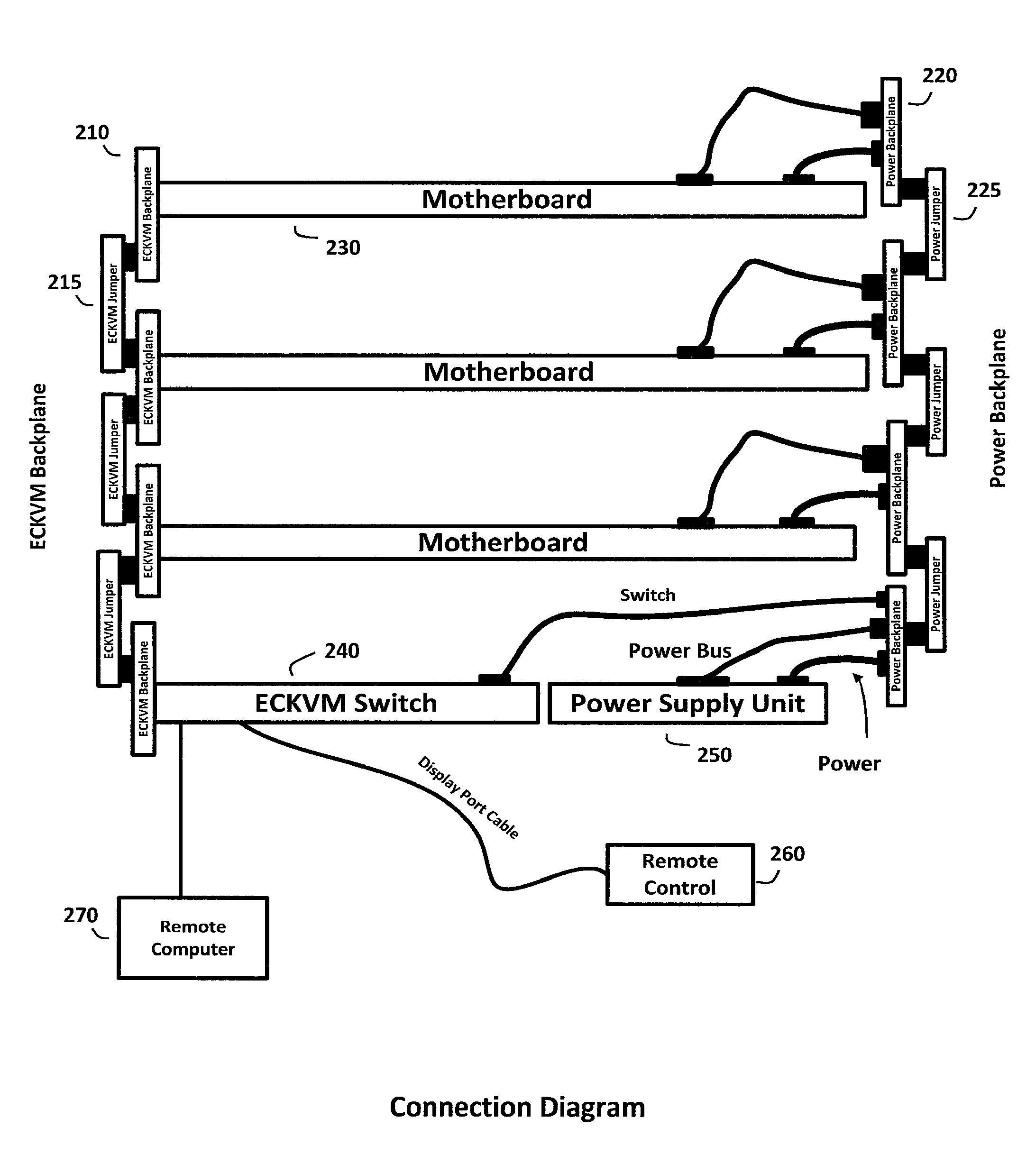

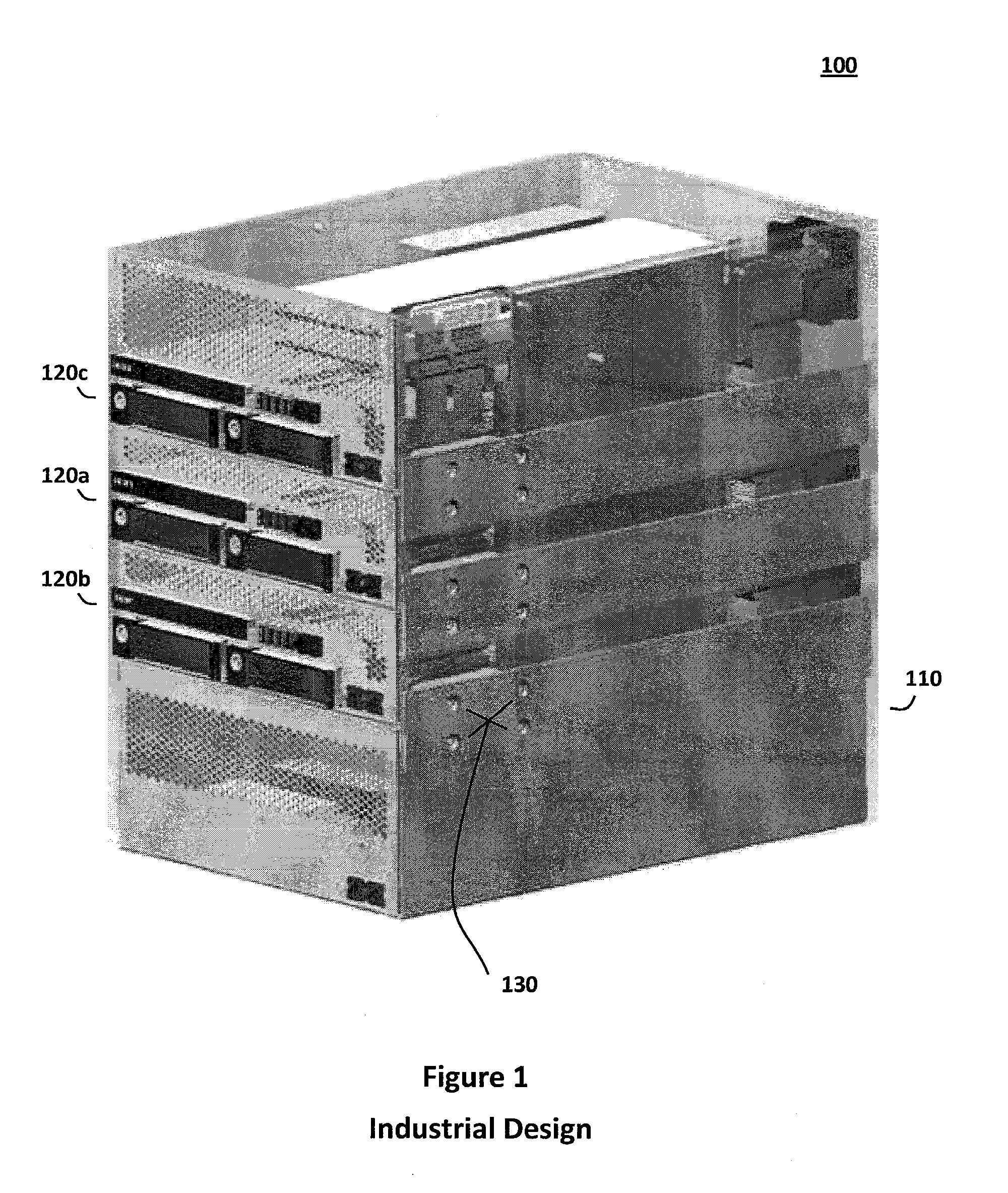

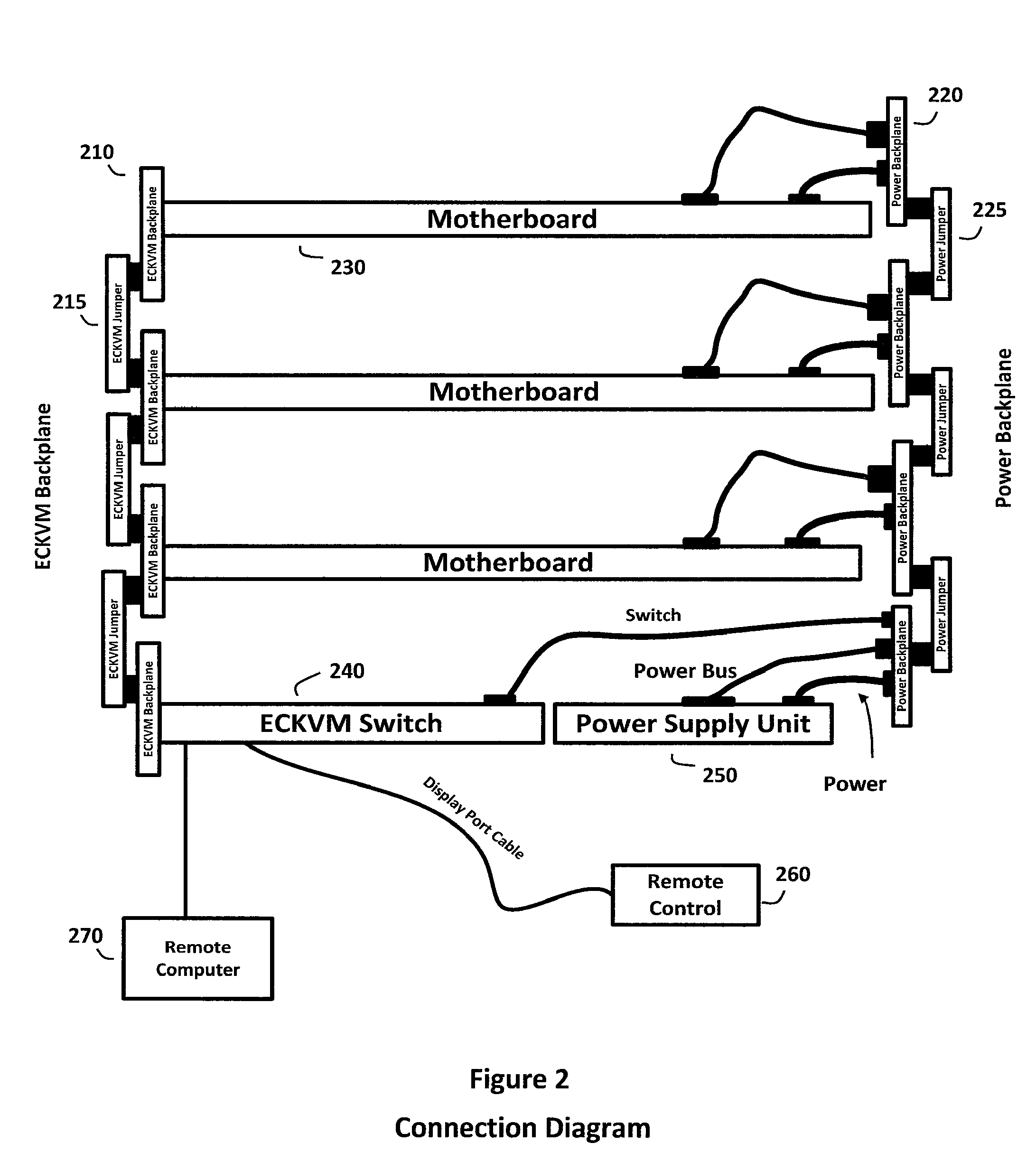

Adaptive computing system with modular control, switching, and power supply architecture

InactiveUS20120243160A1Low initial costSimple to deployCasings with display/control unitsPower supply for data processingModularityAdaptive computing

The adaptive computing system described herein may generally include a modular control, switching, and power supply architecture. In particular, the adaptive computing system may provide a platform supporting multiple independent desktop computer modules that occupy less physical space than a standalone commercial computer, provide performance density comparable to current server solutions, and address concerns relating to stability, safety, productivity, performance, assembly, service, and other factors important to diverse desktop computer user communities. Moreover, mechanical, electrical, and functional components associated with the adaptive computing system may have various certifications or otherwise be relied upon to demonstrate compliance with criteria in regulatory, environmental, consumer safety, and other contexts.

Owner:NCS TECH

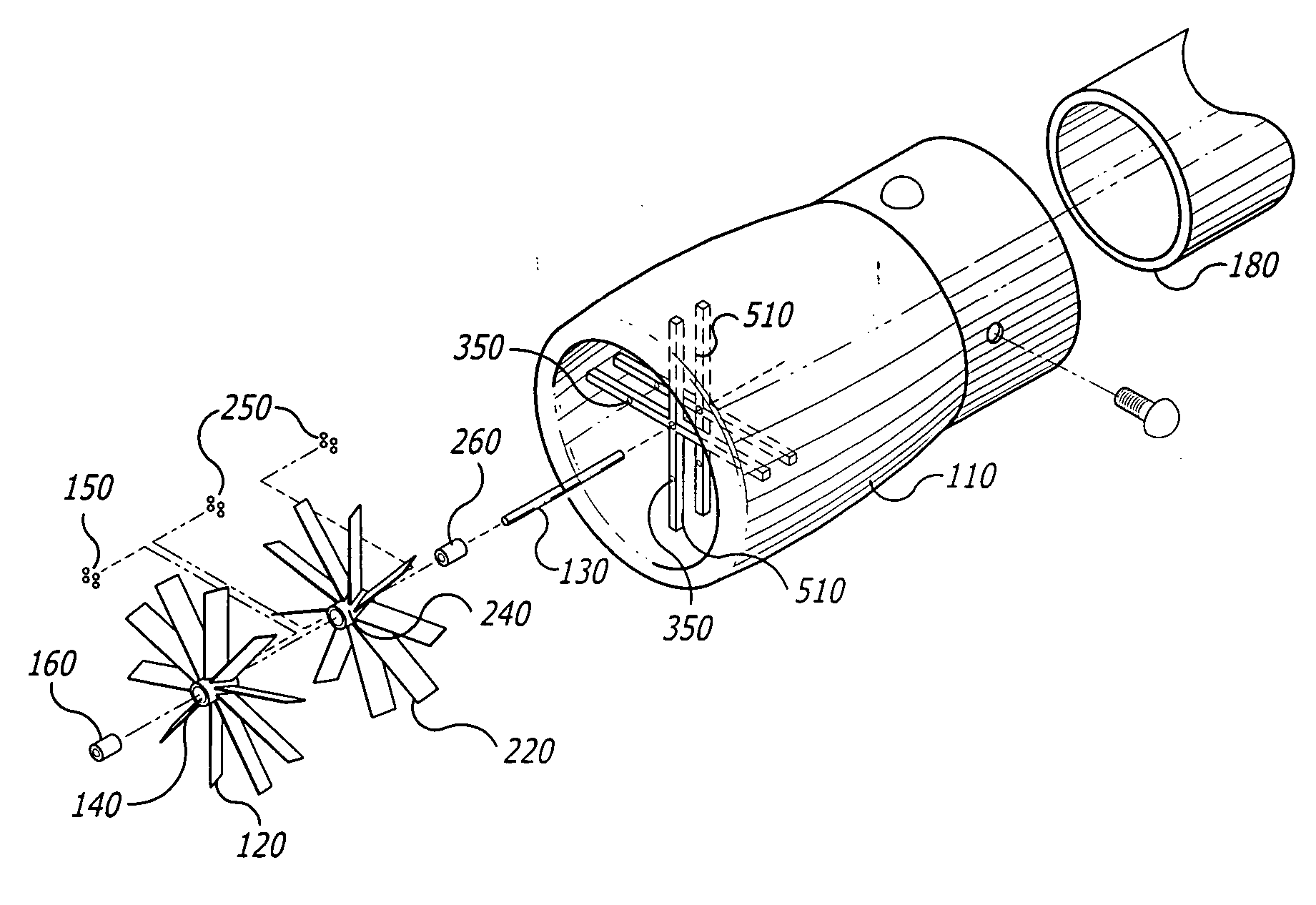

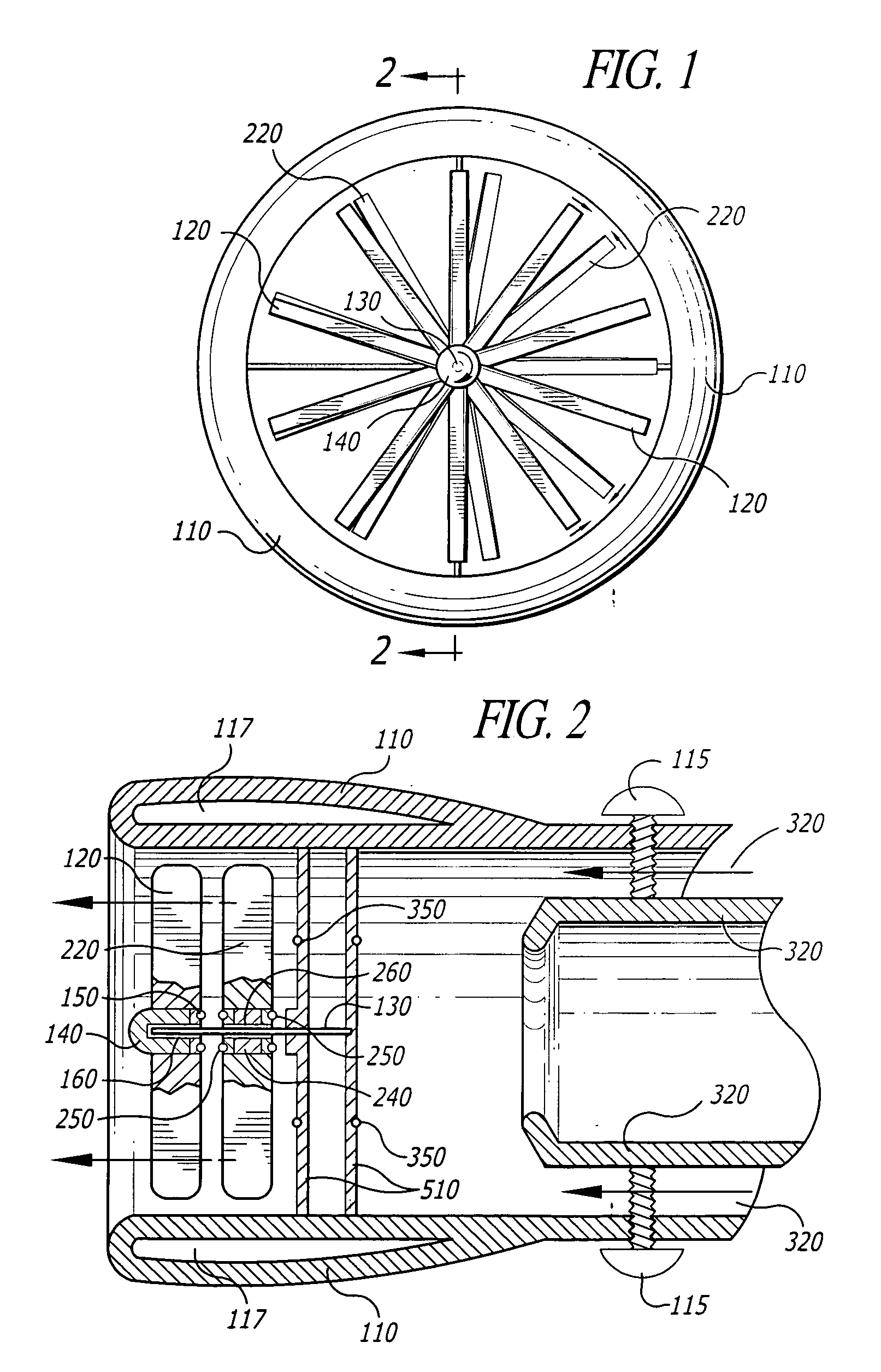

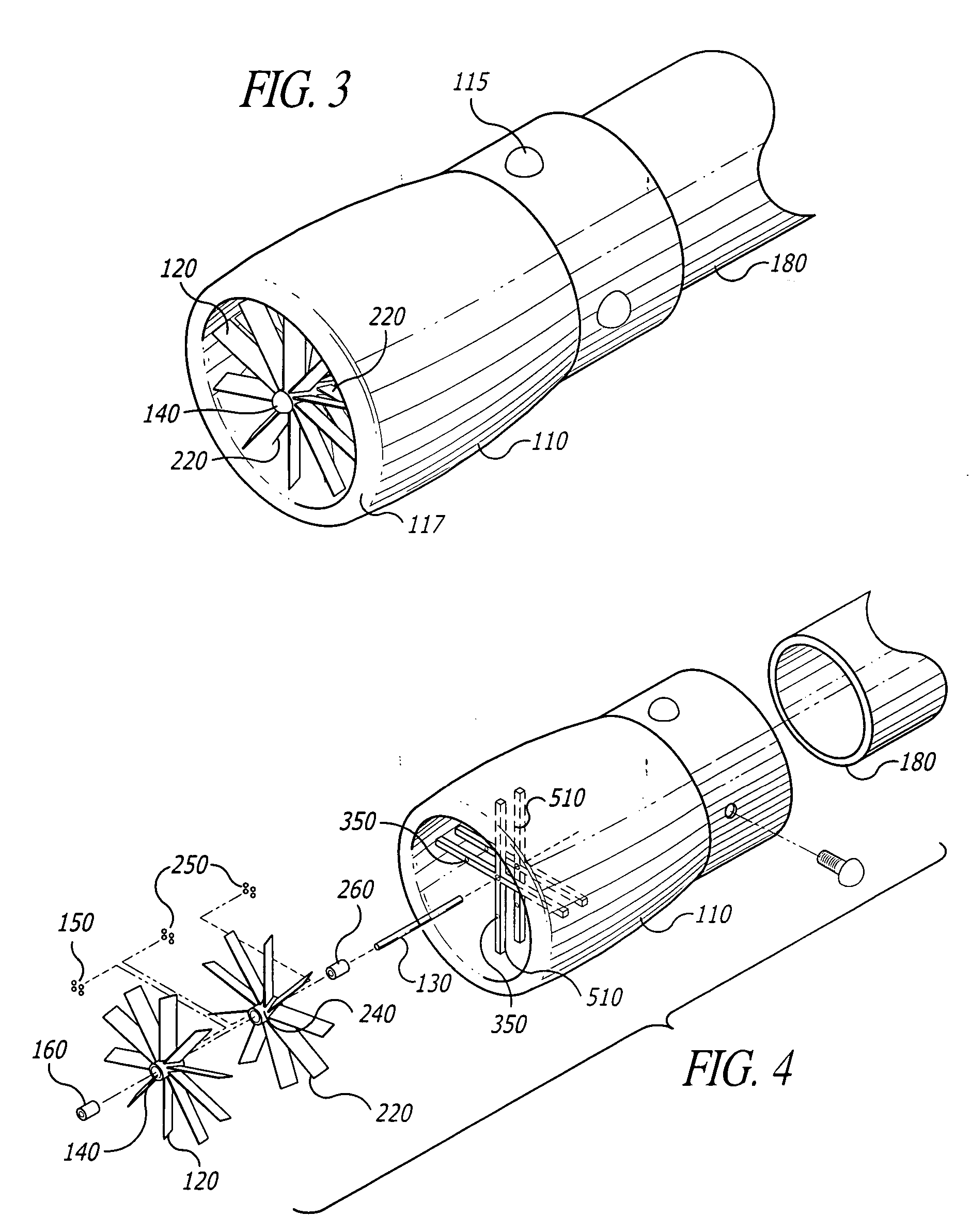

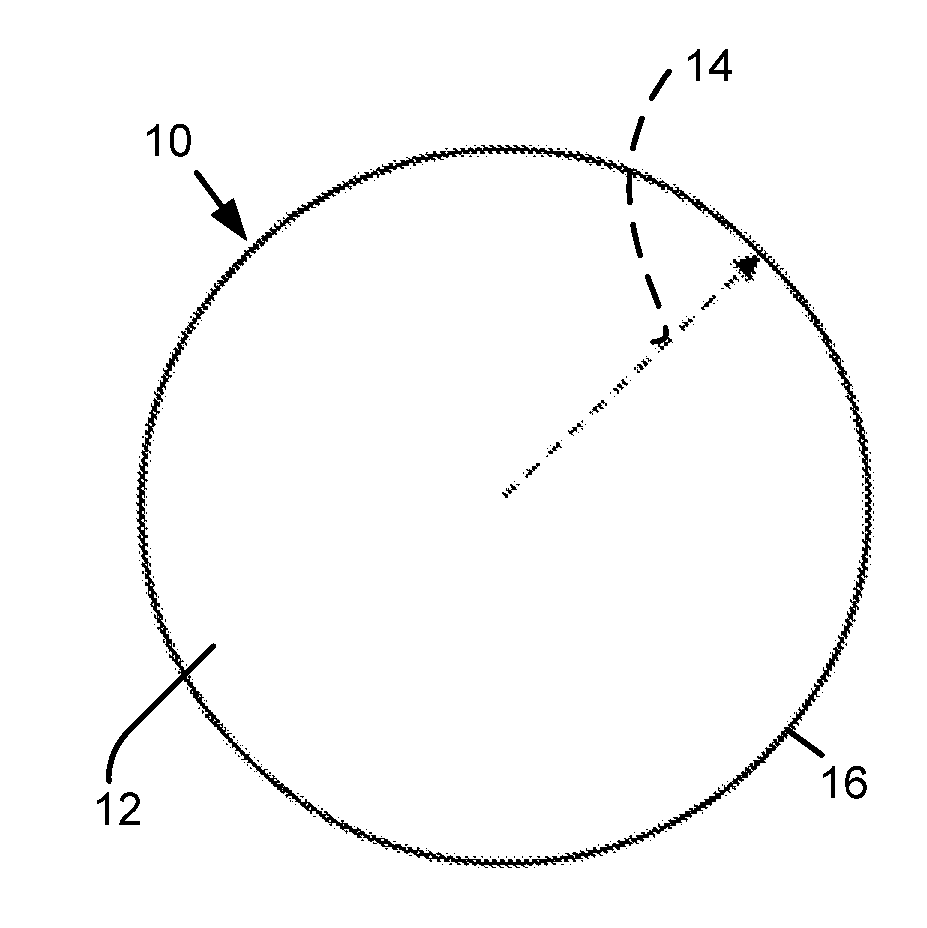

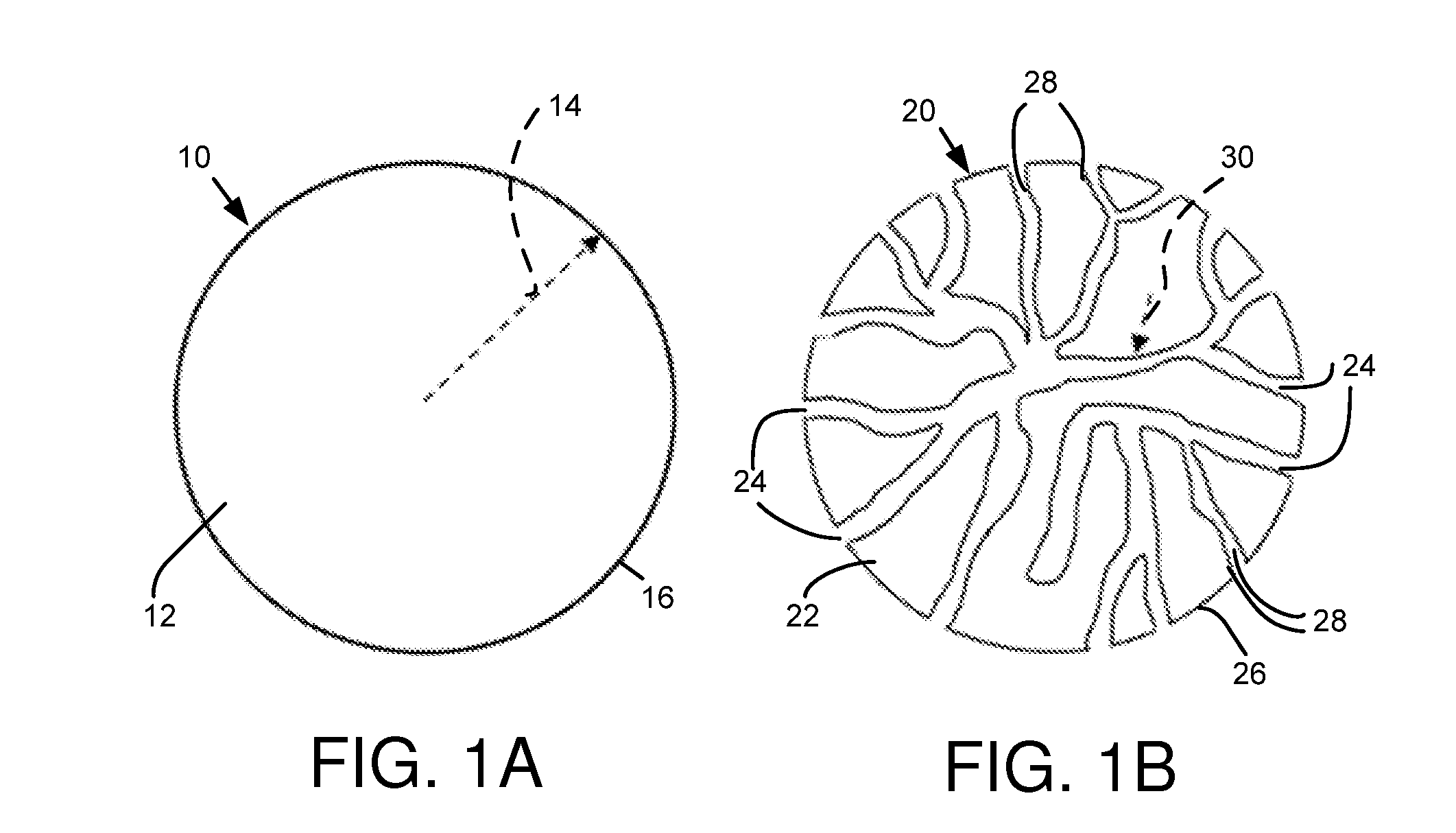

Tailpipe decoration

InactiveUS20060092621A1Appearance is closeConsistent appearanceInternal combustion piston enginesLighting support devicesTurbine bladeEngineering

A tailpipe decoration has a hollow tubular housing, an axle mounted within the housing, and a first and second set of turbine blades. Each set of turbine blades has a hub with a number of radially mounted turbine blades. The first and second sets of turbine blades are mounted on the axle. Housing connectors mounted on the housing connect the housing to a tailpipe when the housing connectors are engaged. The tailpipe decoration can also have a plurality of electric generators, each with a coil portion and a magnet portion, the magnet portion mounted on either the first or second hub and the coil portion mounted on the housing or a hub so that electric current is generated with the rotation of a hub for illuminating LEDs or the like within the housing.

Owner:LAI MARCOS YU SIN

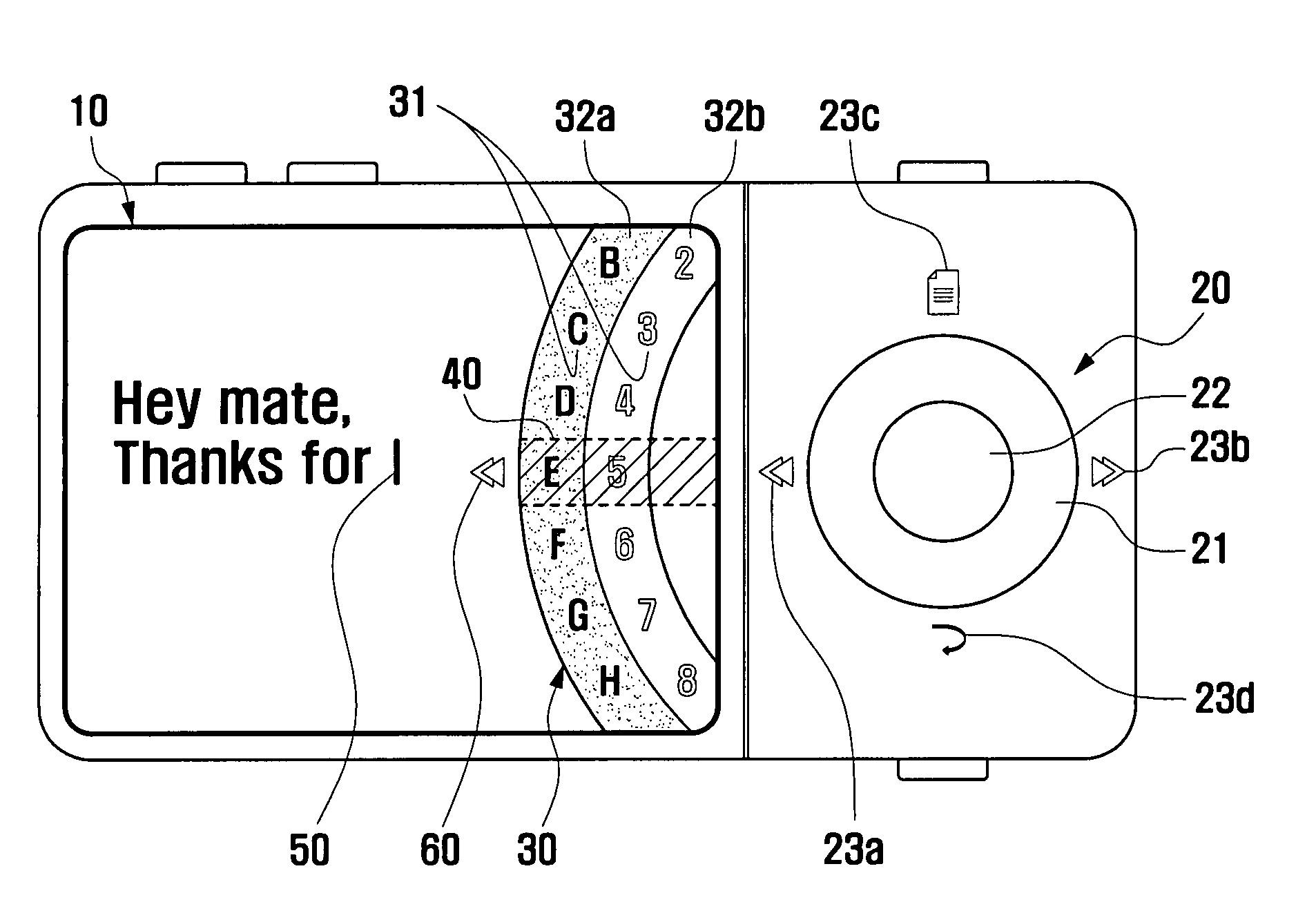

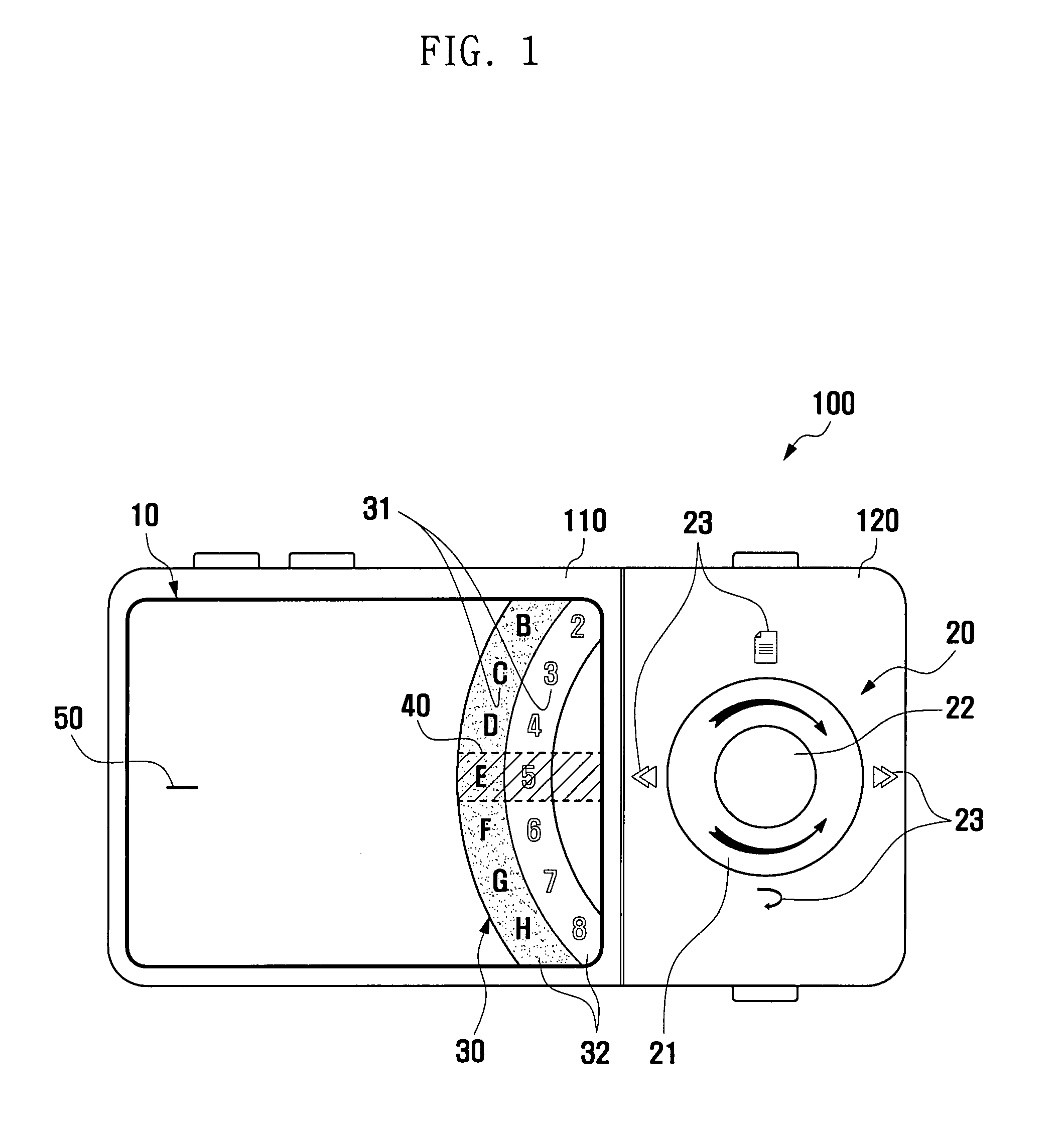

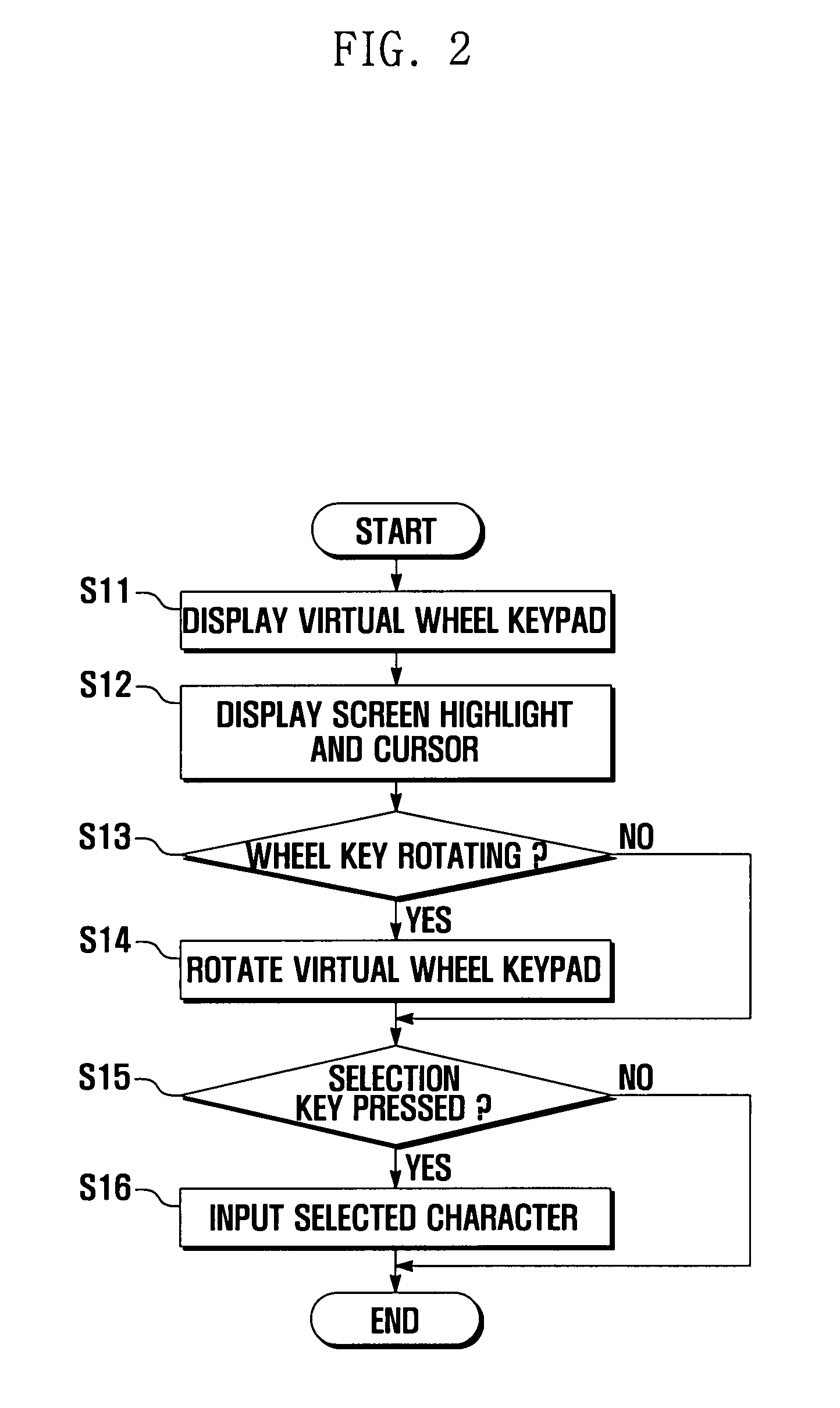

Virtual wheel interface for mobile terminal and character input method using the same

InactiveUS8223127B2Good user interfaceConsistent appearanceInput/output for user-computer interactionCathode-ray tube indicatorsHuman–machine interfaceComputer terminal

Owner:SAMSUNG ELECTRONICS CO LTD

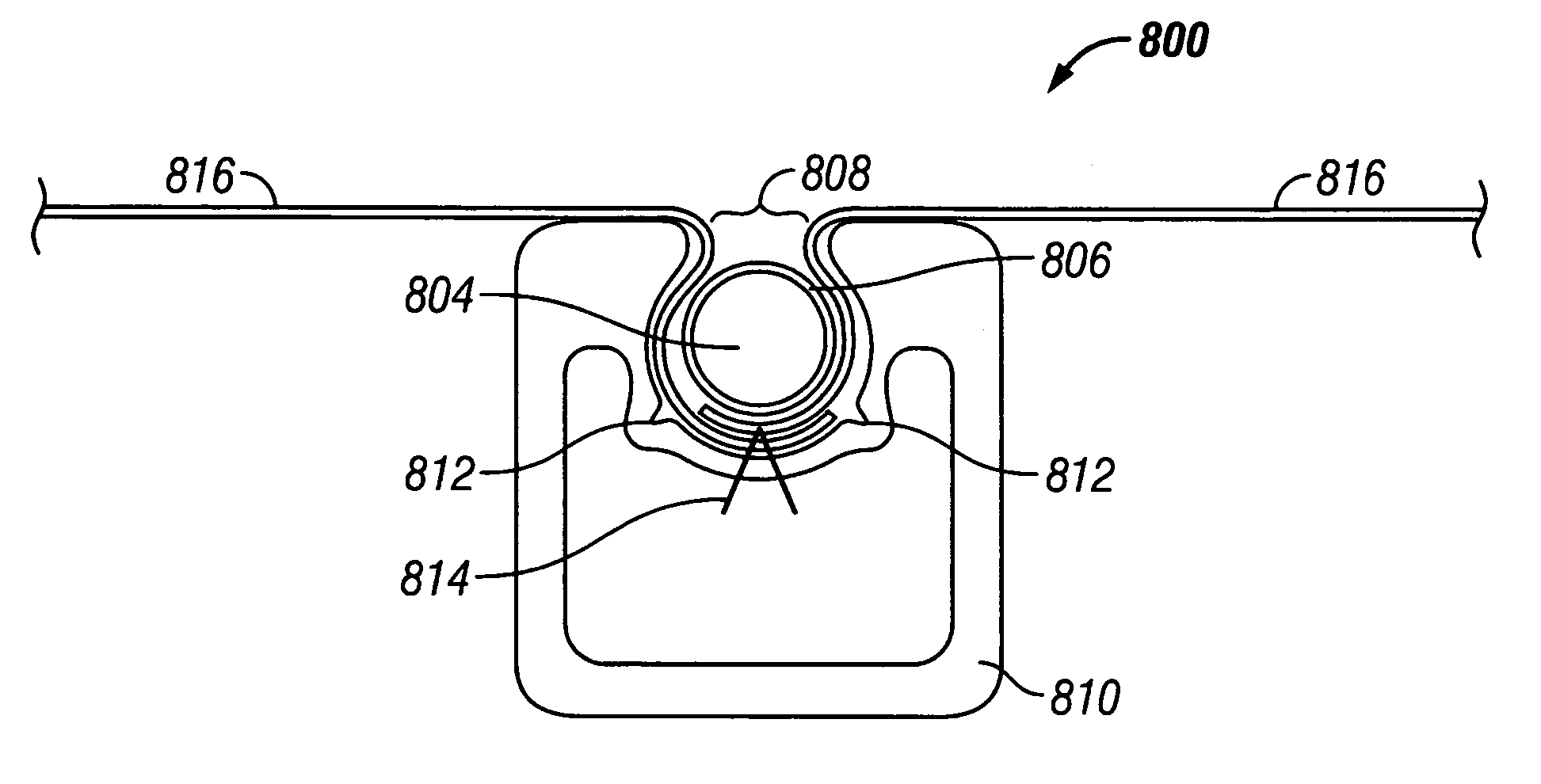

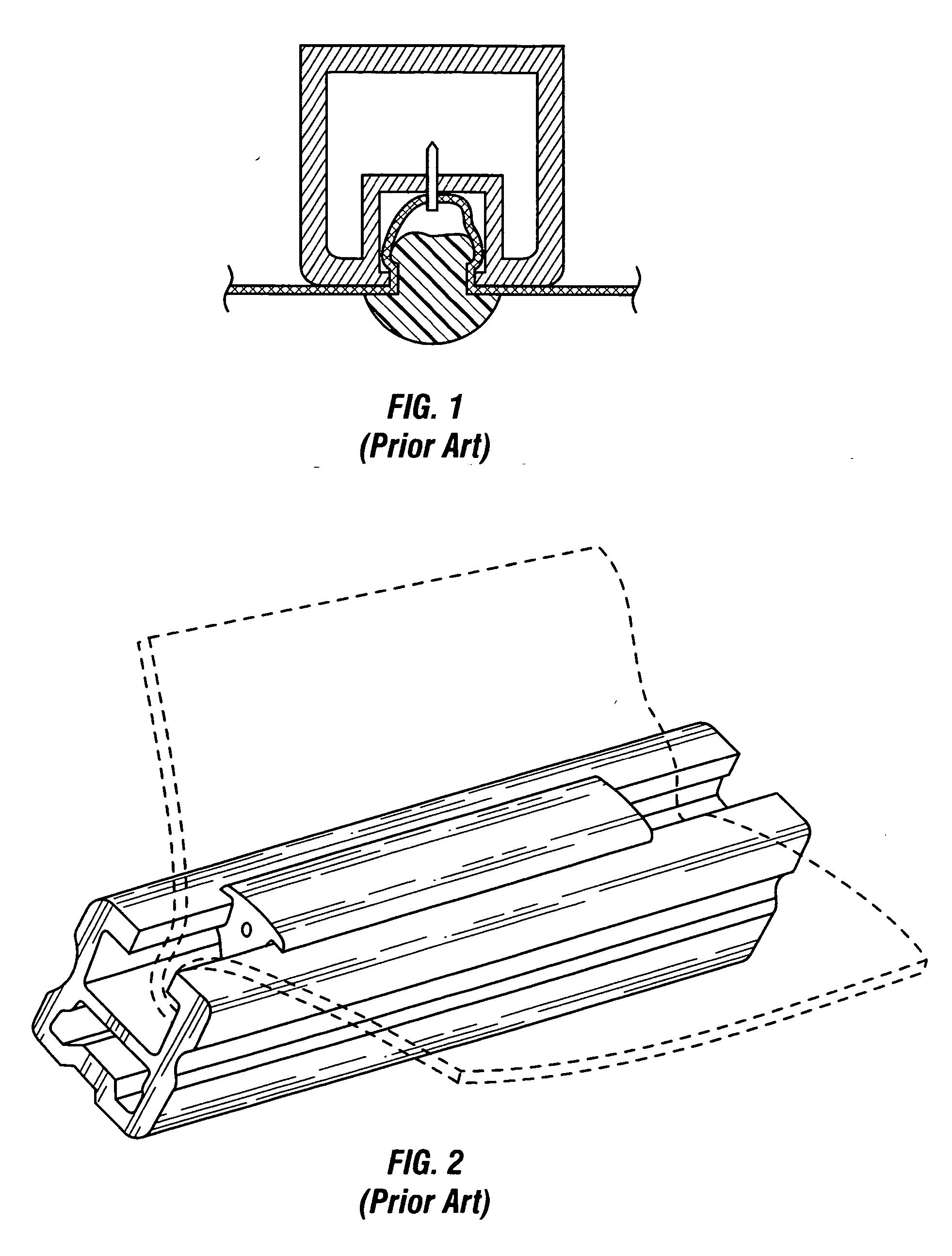

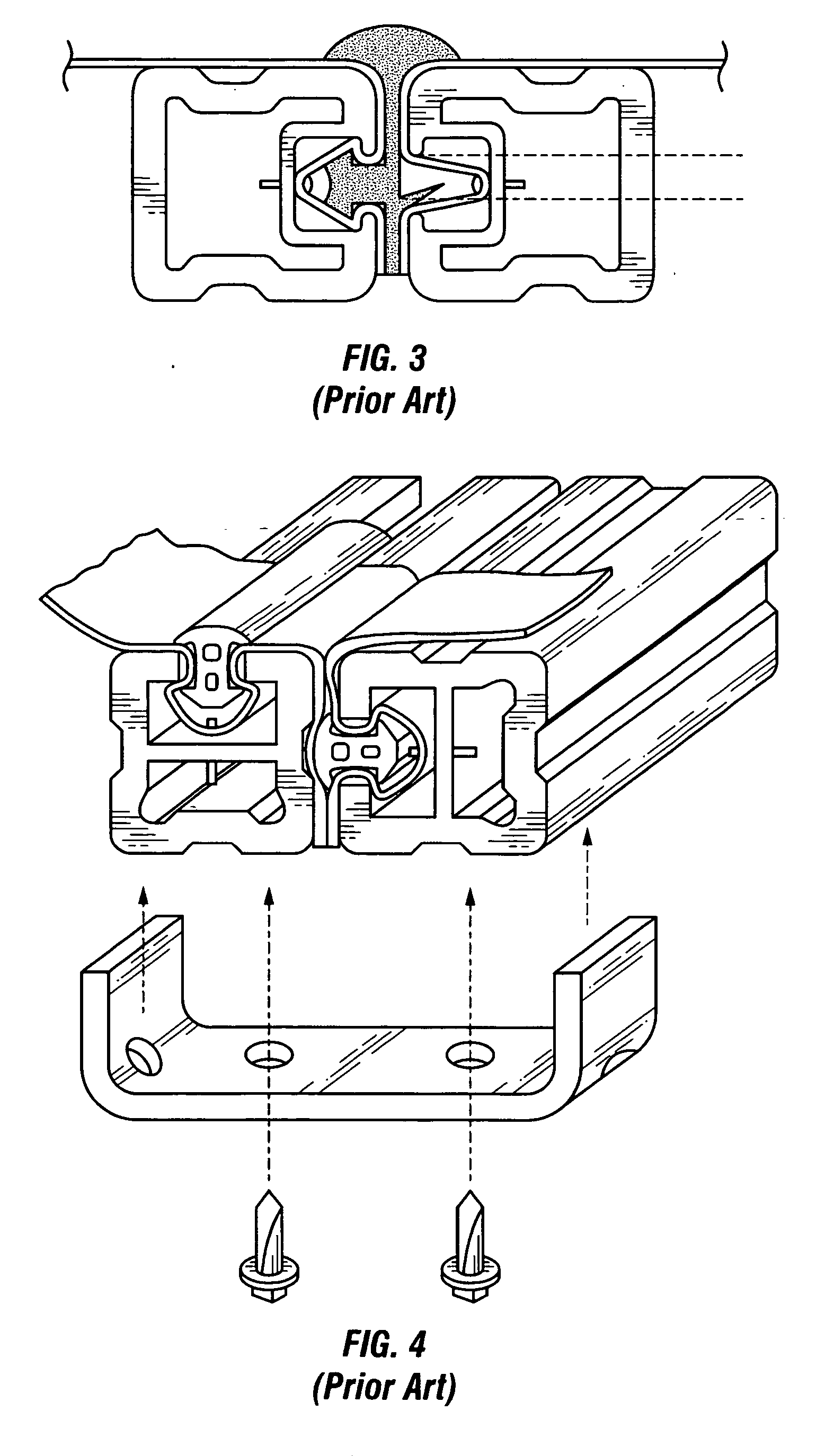

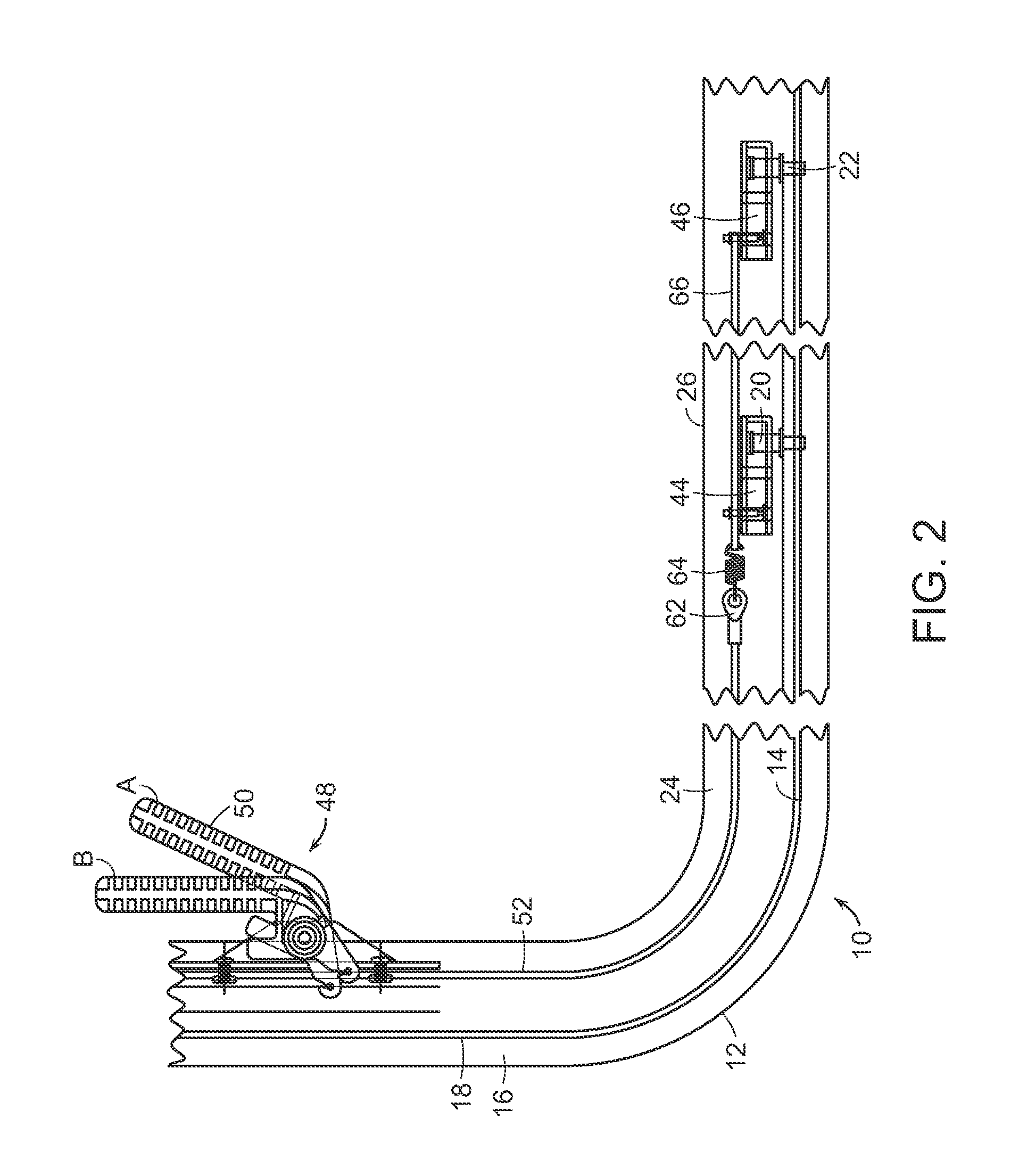

Awning bead and staple system

InactiveUS20060219374A1Consistent appearanceEfficient use ofSunshadesTents/canopiesVisual appearanceAwning

An improved system of virtually seamless connected awning sections with a consistent visual appearance between the sections. A recessed awning bead encased with the fabric covering material chosen for the awning is contoured to, and fit into, a novel channel in the awning frame members. The awning bead allows for uniform weathering and fading of all visible awning parts. Such an improved awning is more aesthetically pleasing because no part of the seam protrudes above the plane of the awning surface. A narrowed neck of the channel in the awning frame member maintains the awning bead within the channel and thus slightly below the exterior awning surface in order to maintain a consistent surface between panel sections.

Owner:SABIC INNOVATIVE PLASTICS IP BV

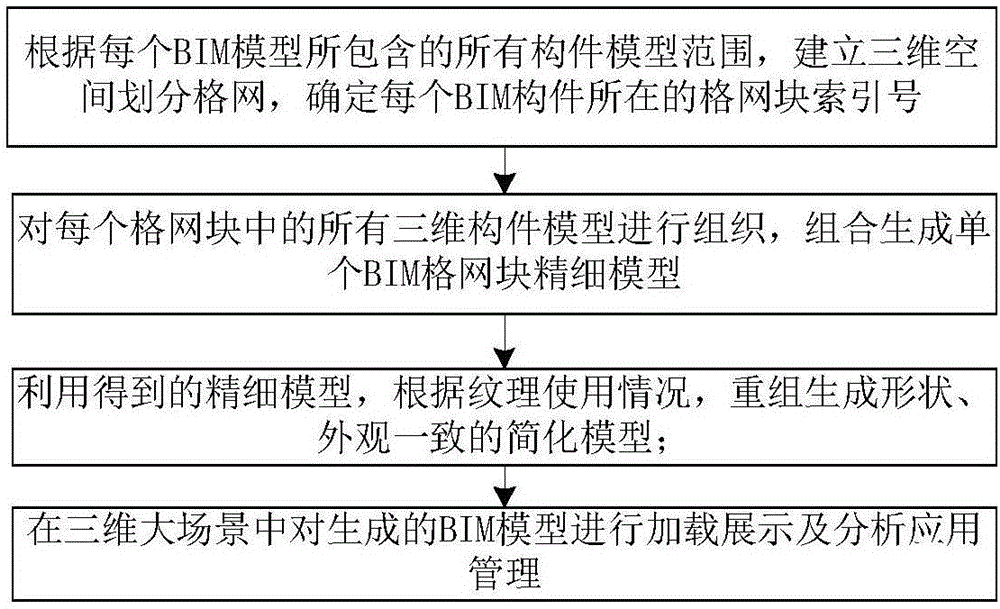

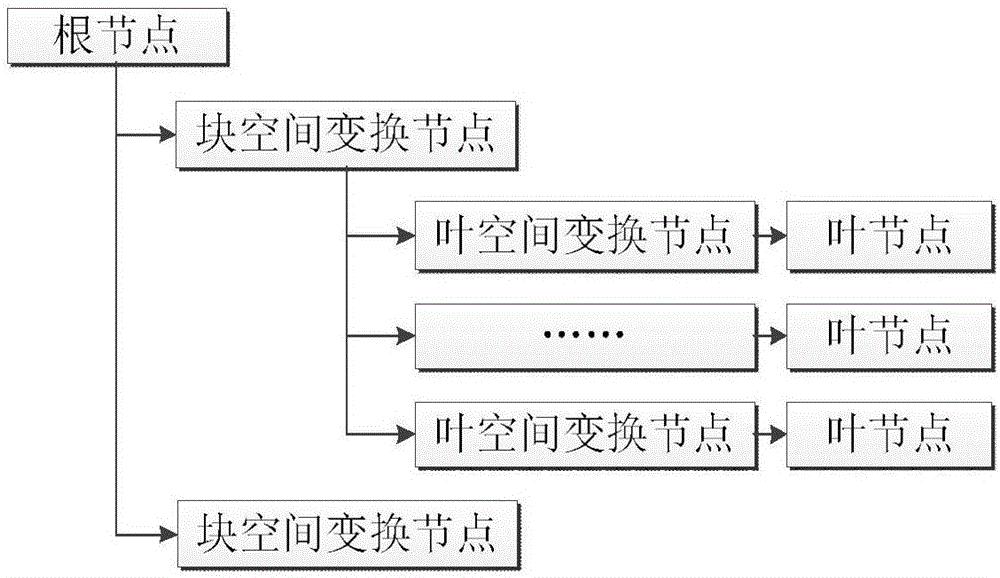

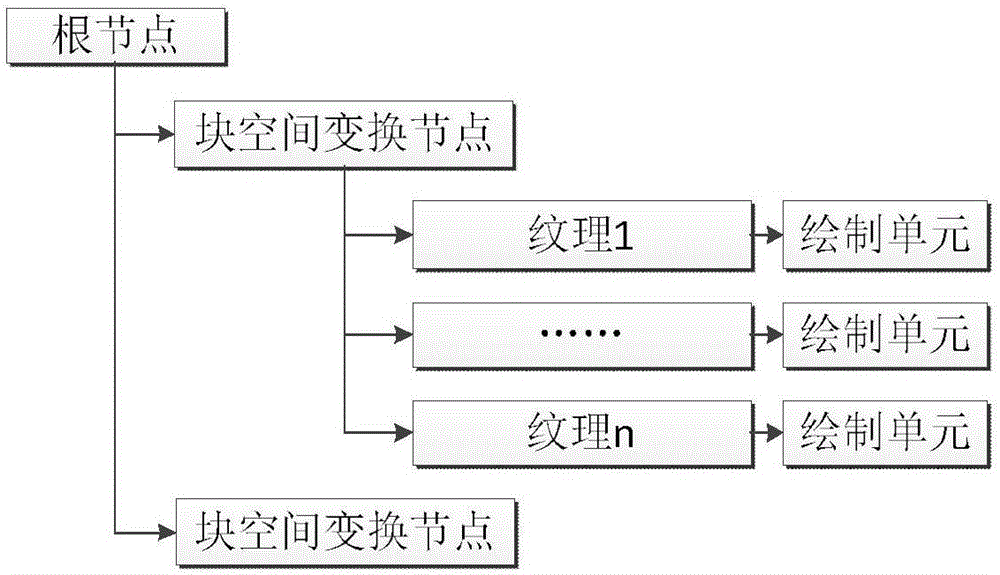

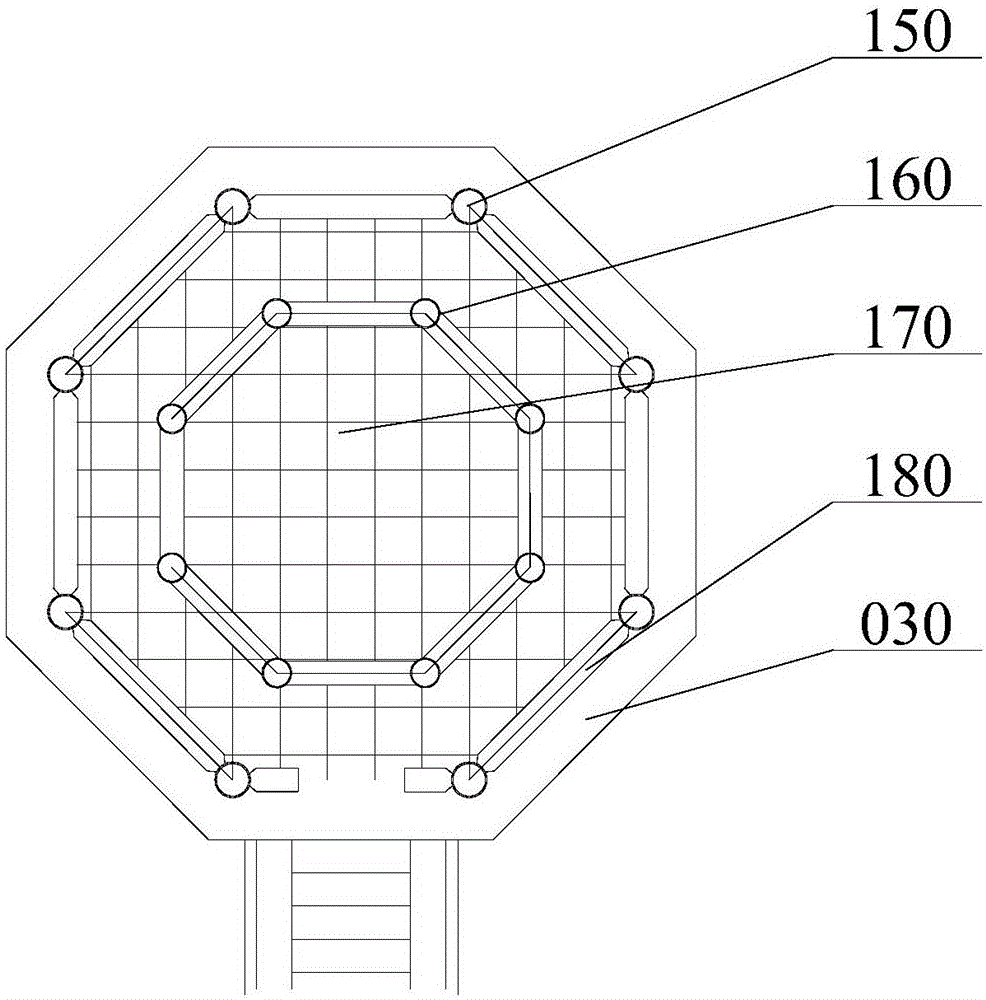

Visual implementation method of BIM model in three-dimensional large scene

ActiveCN106599493AReduce in quantityImprove display efficiencyGeometric CADSpecial data processing applicationsReduced modelThree-dimensional space

The invention discloses a visual implementation method of a BIM model in a three-dimensional large scene, and relates to the field of building information model visualization. The visual implementation method comprises the following steps: firstly, establishing a three-dimensional space division grid according to the dimension of a range of all member models contained in each BIM model; then organizing the member models in each grid block to combine and generate a precise model of a single grid block; recombining and generating a simplified model with consistent shape and appearance according to vein use conditions by using the obtained precise model; and finally, loading and displaying the precise model or the simplified model of the BIM model in the three-dimensional large scene according to a selected display mode and an index number. According to the visual implementation method disclosed by the invention, on the basis of guaranteeing the application of the BIM model, all members of each BIM model are divided according to the three-dimensional space division grid by means of the space grid idea, and the members in the grid are merged to reduce the number of the models of the index and improve the loading efficiency of the BIM model.

Owner:CHONGQING SURVEY INST

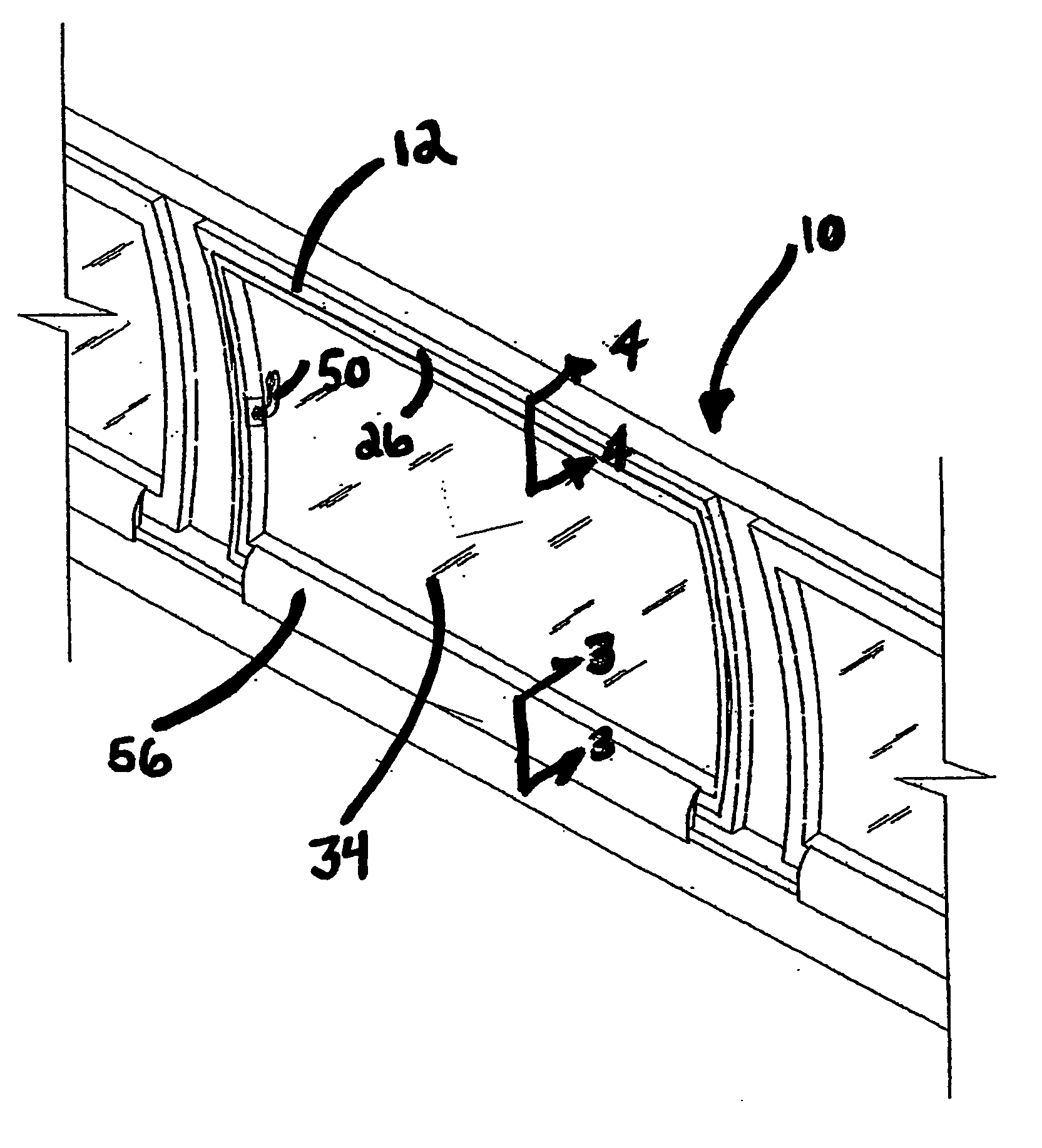

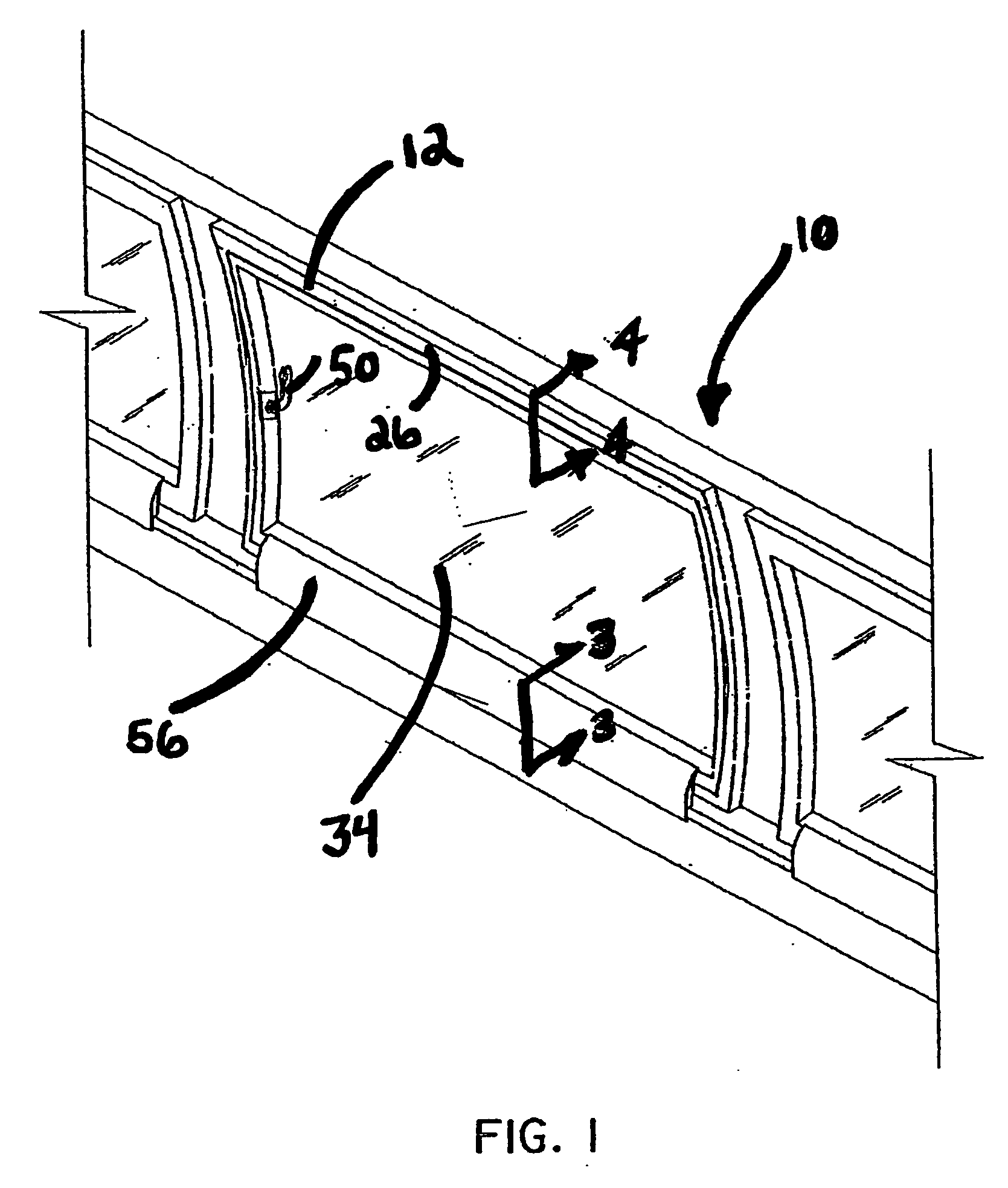

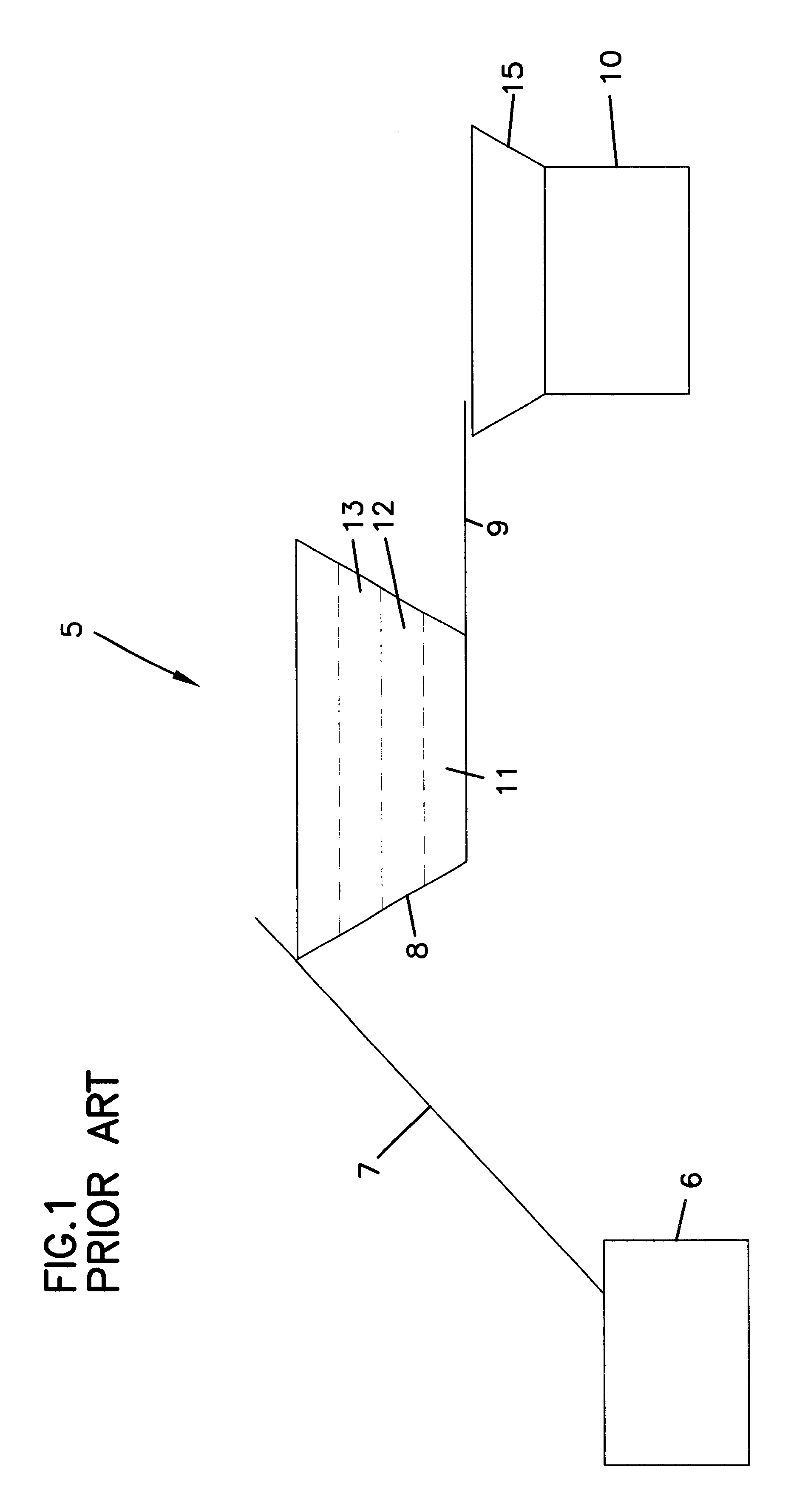

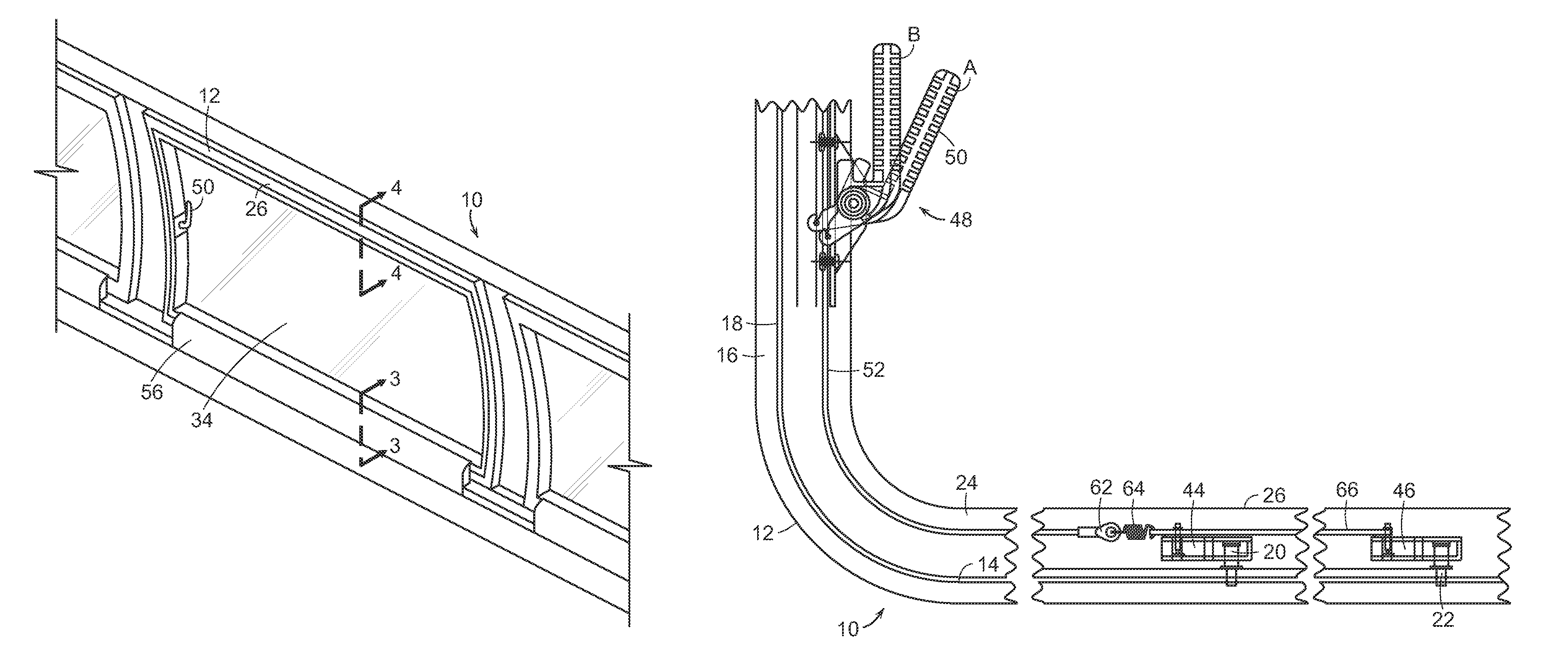

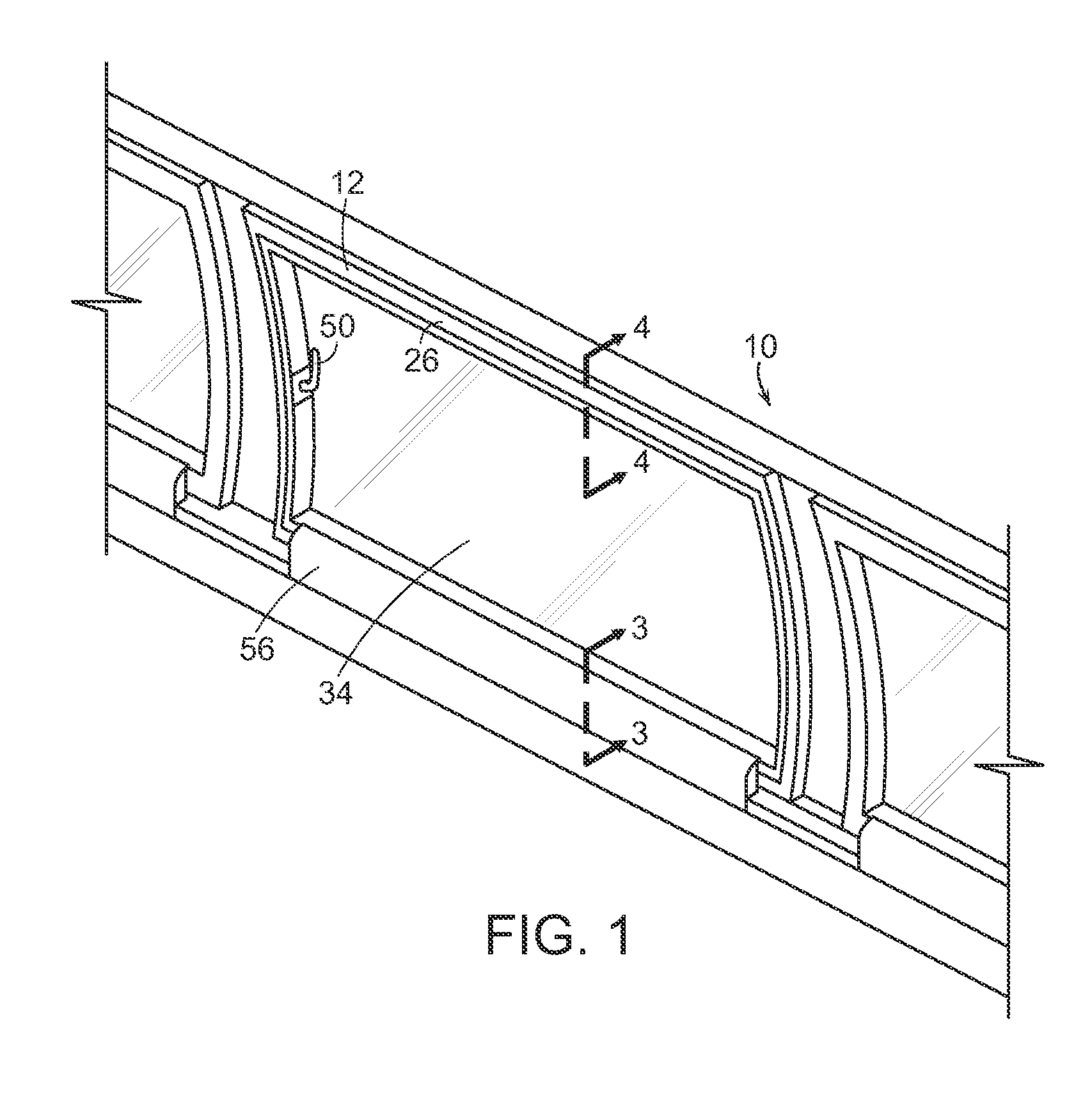

Motor vehicle egress window

ActiveUS20060175866A1Reduce adverse effectsReduce penetrationWindowsWindscreensEngineeringMotorized vehicle

A motor vehicle egress window comprises a circumferential outer frame forming an auxiliary egress opening for a motor vehicle passenger compartment and an inner frame unit. The outer frame has an outer frame member with an inner surface and at least a first striker pin. The inner frame unit is mounted to the outer frame for movement between closed and open positions has a circumferential inner frame, a glazing pane mounted to the inner frame, at least a first egress latch mounted to the inner frame, and a release mechanism. The egress latch is operative to latch to the striker pin to hold the inner frame unit in the closed position. The release mechanism includes a manually operative release handle, preferably mounted at an elevated position on a vertical side portion of the inner frame, and release linkage comprising at least a first link from the release handle to the first latch. In certain embodiments the inner and outer frames overlap radially for improved functionality.

Owner:PLASMAN US HOLDCO LLC

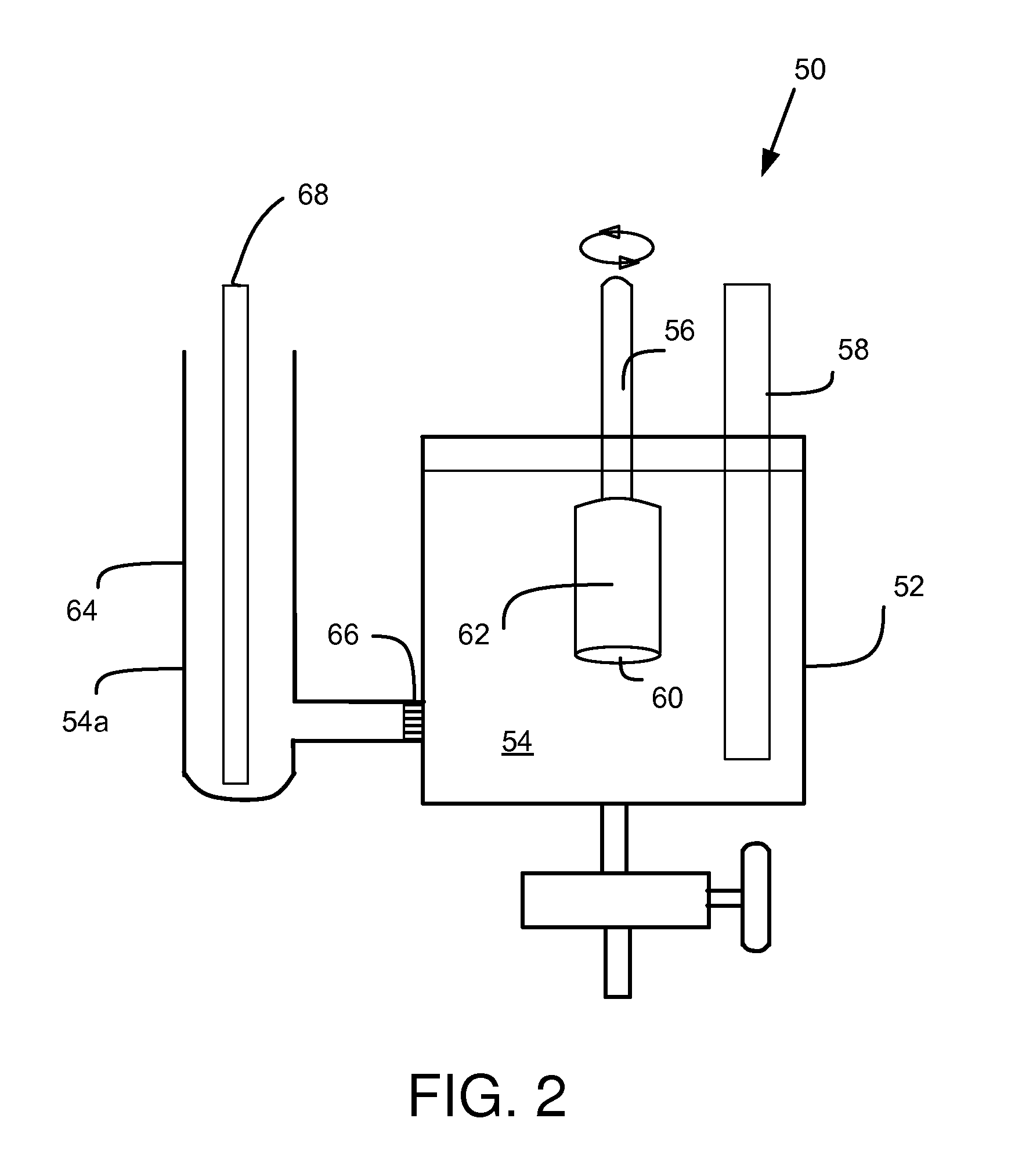

Processing method of deproteinized rice

ActiveCN103211163APromote dissolutionImprove removal effectFood preparationFlavorReaction temperature

The invention provides a processing method of deproteinized rice. The processing method comprises the following steps of: (1) washing and removing impurities; (2) carrying out enzymolysis and fermentation: in a reaction tank, adding processed rice, purified water, proteolytic enzyme and lactic acid bacteria according to proportion, wherein the weight proportion of rice to purified water is 1:(5-20), the reaction temperature is 10-60 DEG C, the reaction time is 3-20 hours, the initial pH of reaction liquid is between 4.5 and 9.5, the using amount of proteolytic enzyme accounts for 0.1% to 5% of total weight of rice, and the dropping amount of lactic acid bacteria is as follows: 109-1014 bacteria is added in every ton of reaction liquid; and (3) after enzymolysis and fermentation, leaching, washing and drying to obtain the deproteinized rice. According to the method, the technology is simple, the cost is low, the appearance, the color, the flavor and the taste of the deproteinized rice processed by adopting the technology are the same as those of ordinary rice; and the protein removal ratio can be more than 95% at most.

Owner:成都东洋百信制药有限公司

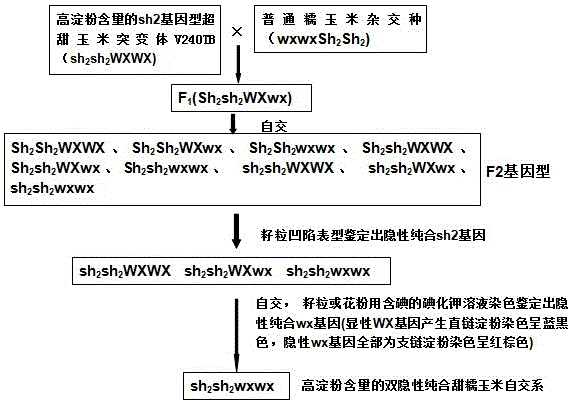

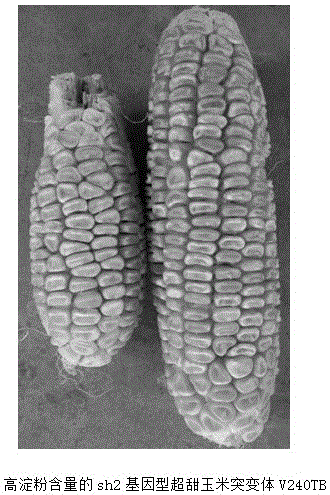

Method for breeding double recessive homozygous sweet-waxy maize hybrid through sh2 gene type super-sweet maize mutant with high starch content

InactiveCN105075856ASolve the shortcomings of low germination rateConsistent appearancePlant genotype modificationWaxy cornAgricultural science

The invention discloses a method for breeding double recessive homozygous sweet-waxy maize hybrid through a sh2 gene type super-sweet maize mutant with high starch content. The collection number of the sh2 gene type super-sweet maize mutant V240TB with the high starch content is CGMCC No.10410. The sh2 gene type super-sweet maize mutant V240TB with the high starch content is hybridized with ordinary waxy maize, and a double recessive homozygous sweet-waxy maize inbred line with the high starch content is obtained. Two double recessive homozygous sweet-waxy maize inbred lines with the high starch content are matched, and the double recessive homozygous sweet-waxy maize hybrid is obtained and has higher sugar content than the ordinary waxy maize and higher starch content than ordinary super-sweet maize, and the starch is all amylopectin. The bred double recessive homozygous sweet-waxy maize hybrid inbred line and hybrid with the high starch content integrate respective advantages of sweet maize and waxy maize, the sweetness is high, the waxiness is good, the maize kernels have identical appearance and maturity, and meanwhile, the seed germination percentage reaches the standard of ordinary maize.

Owner:FOOD CROPS RES INST YUNNAN ACAD OF AGRI SCI

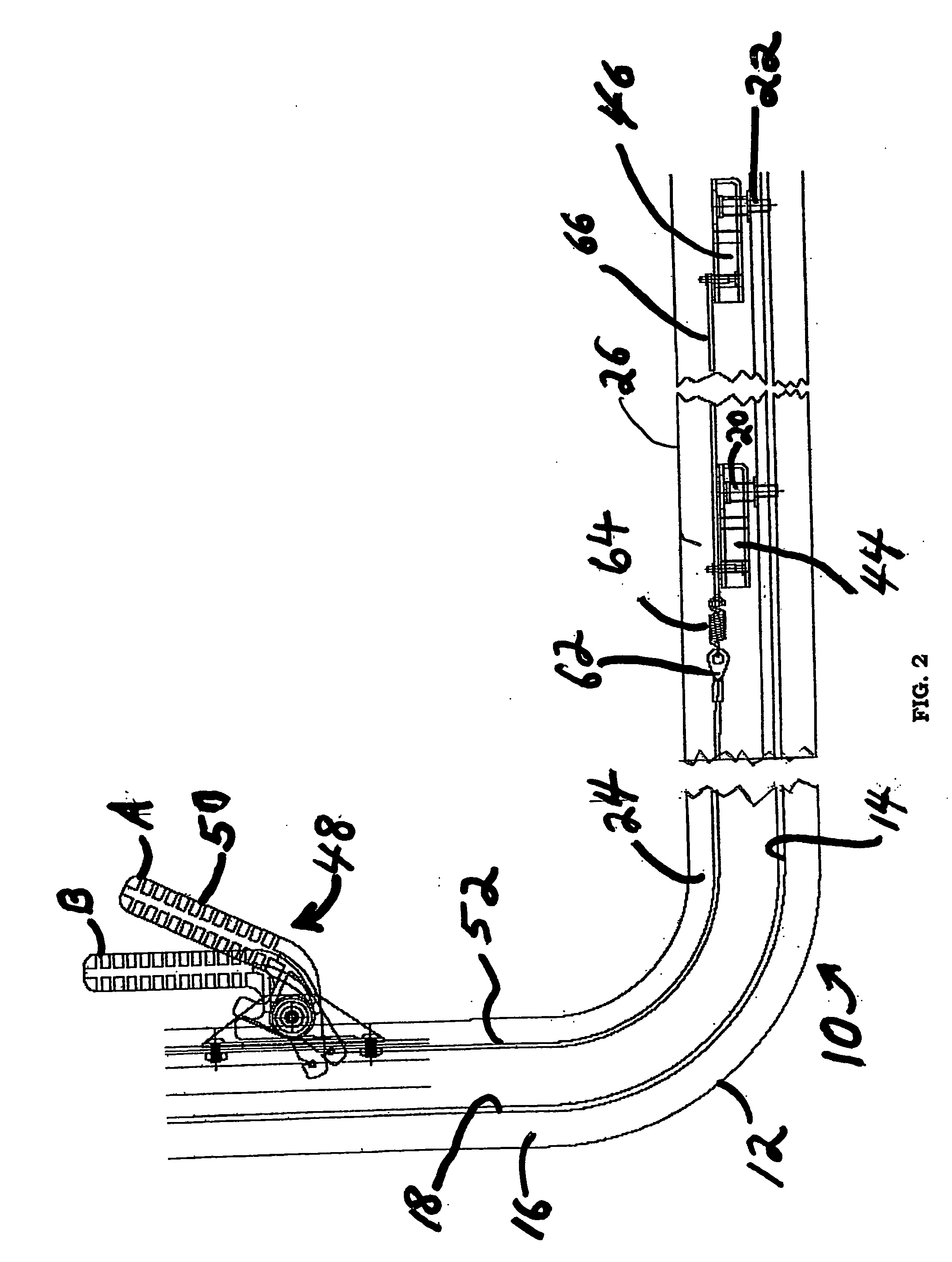

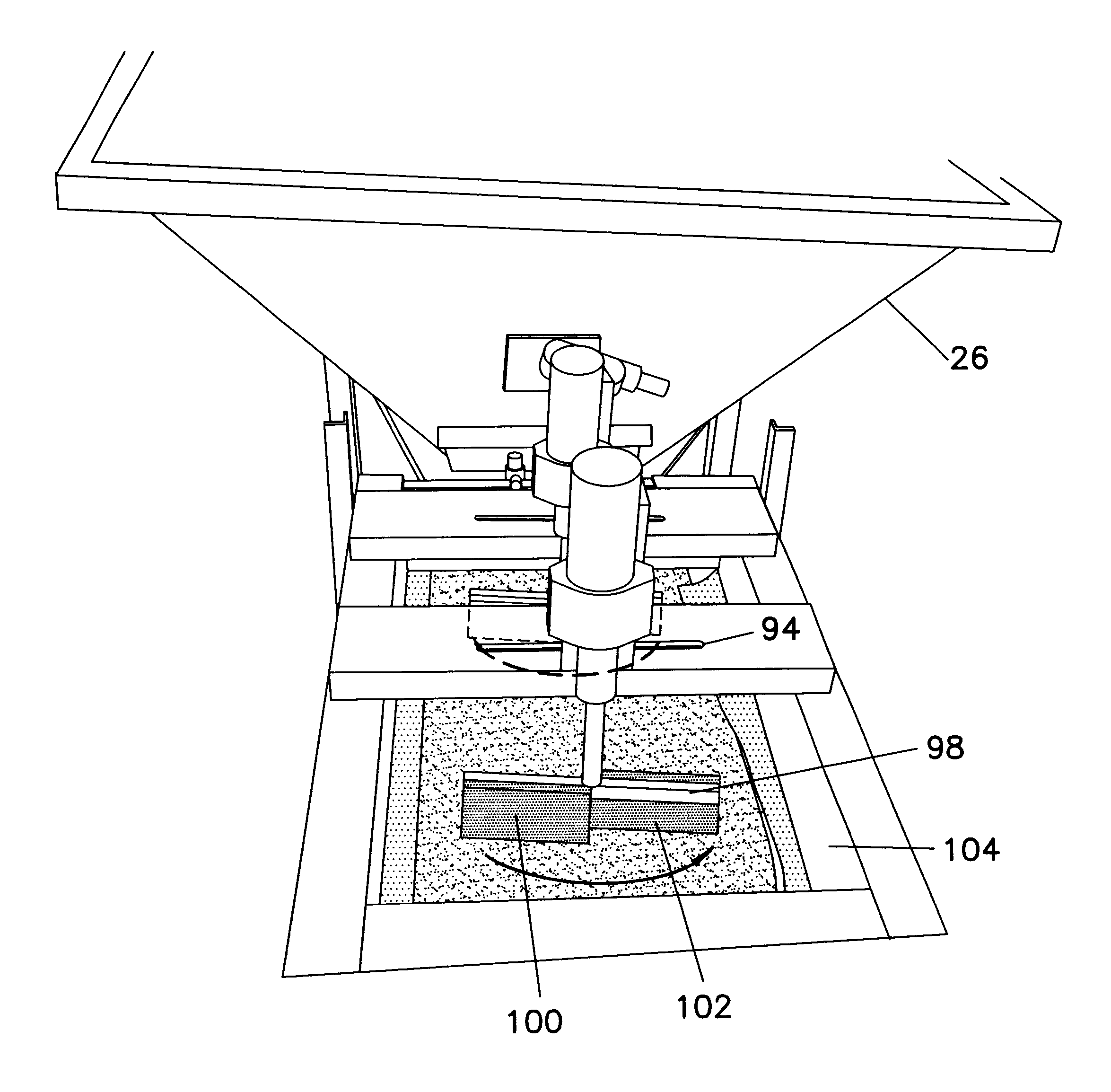

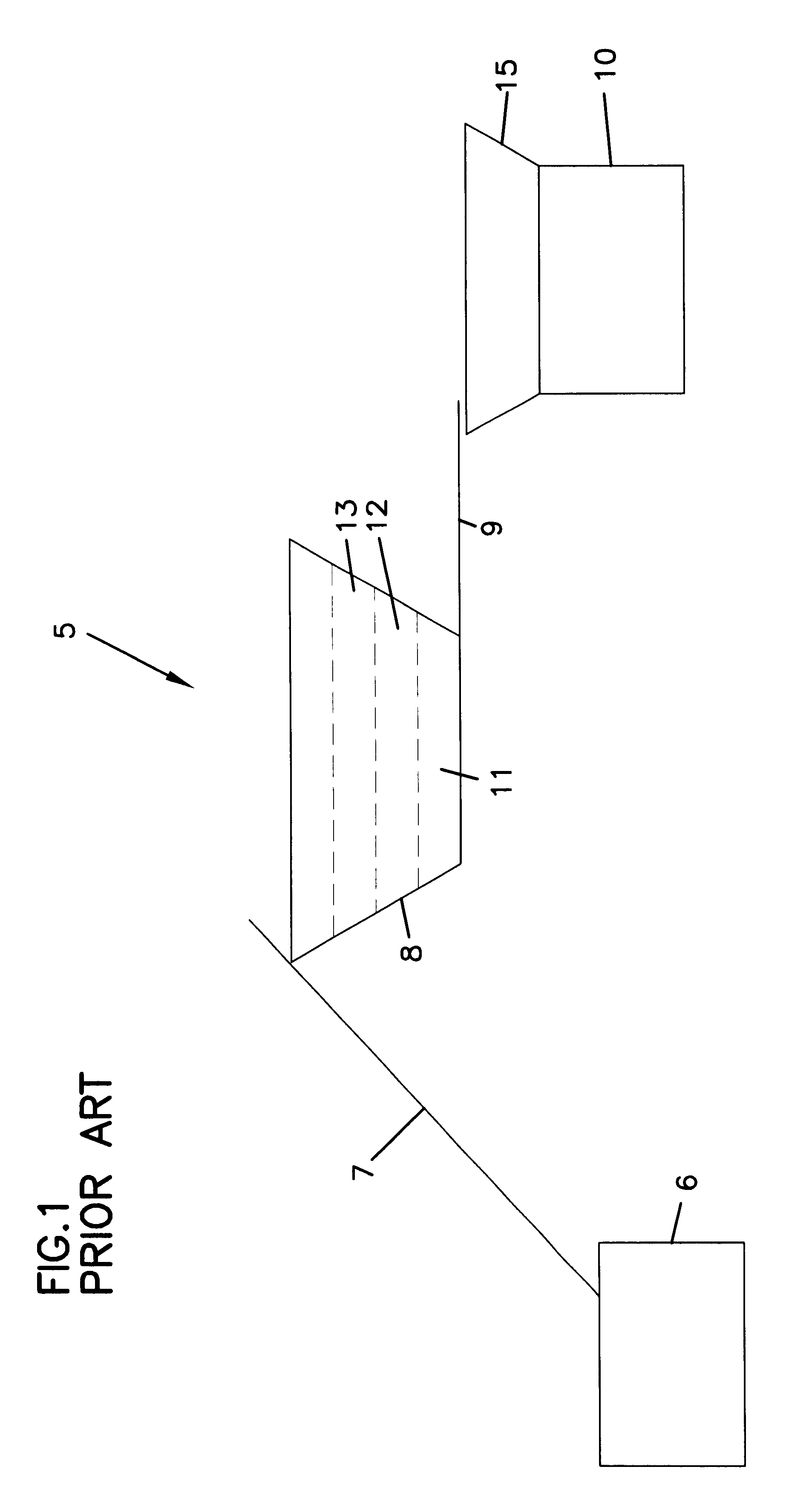

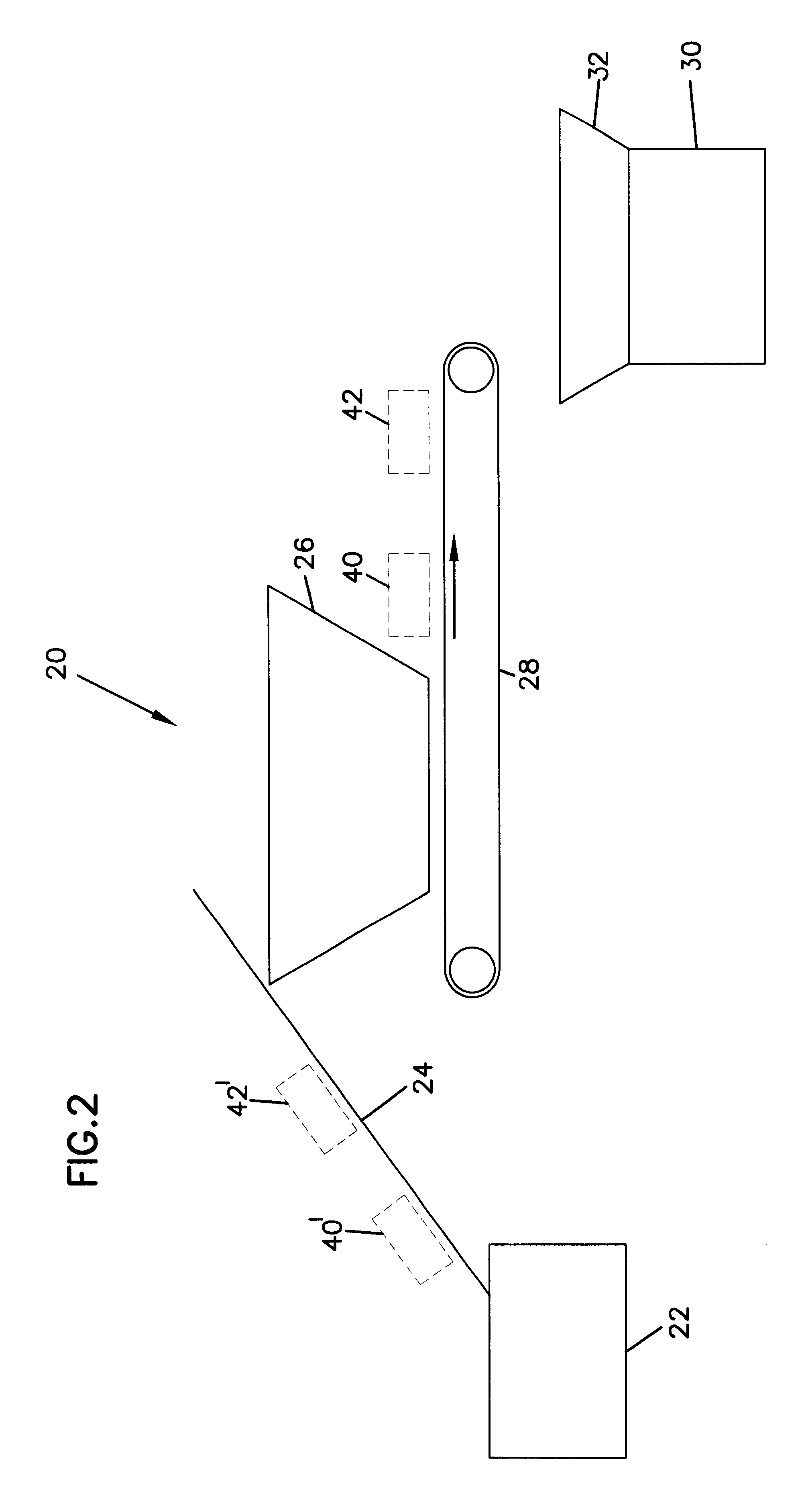

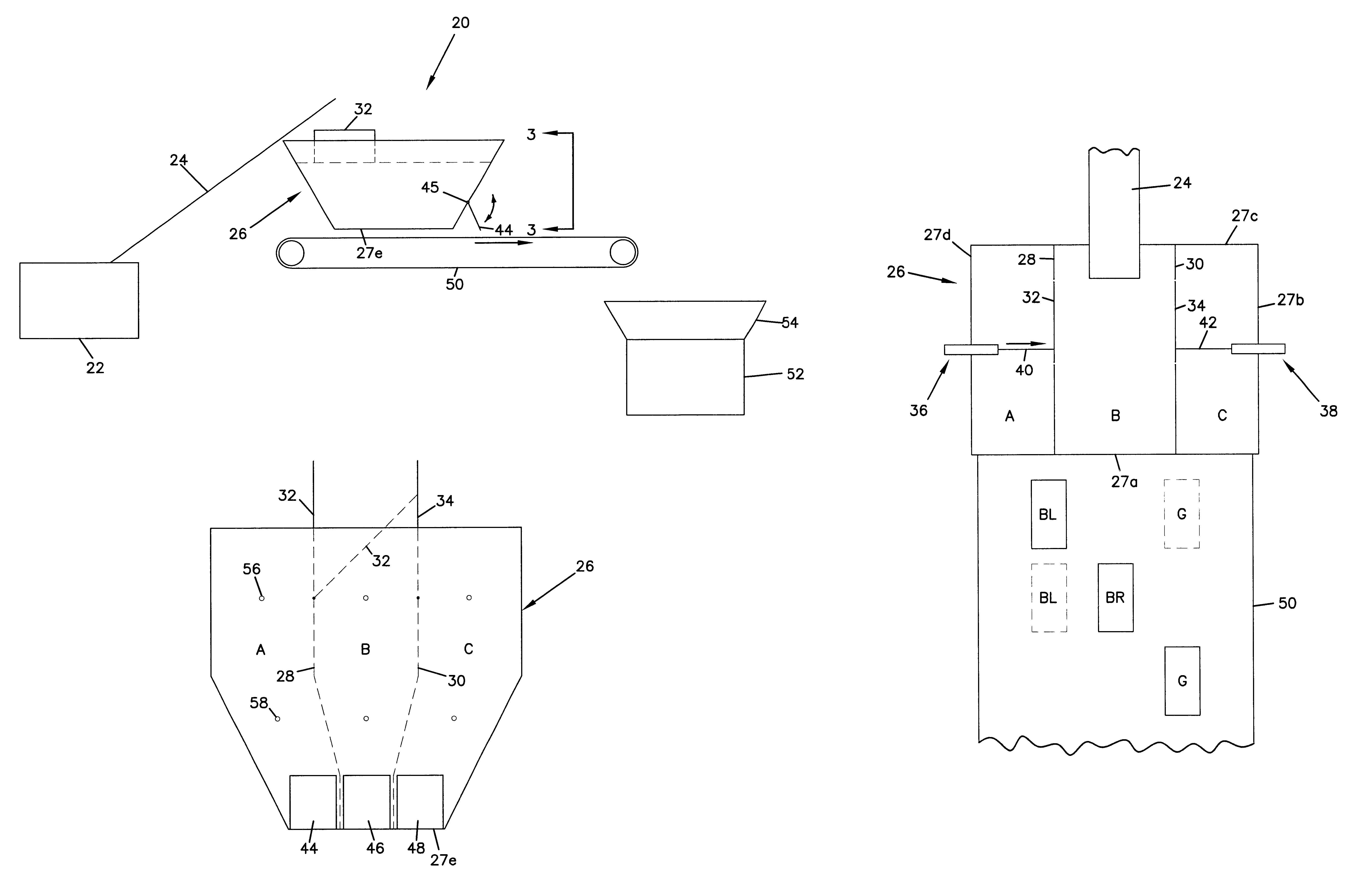

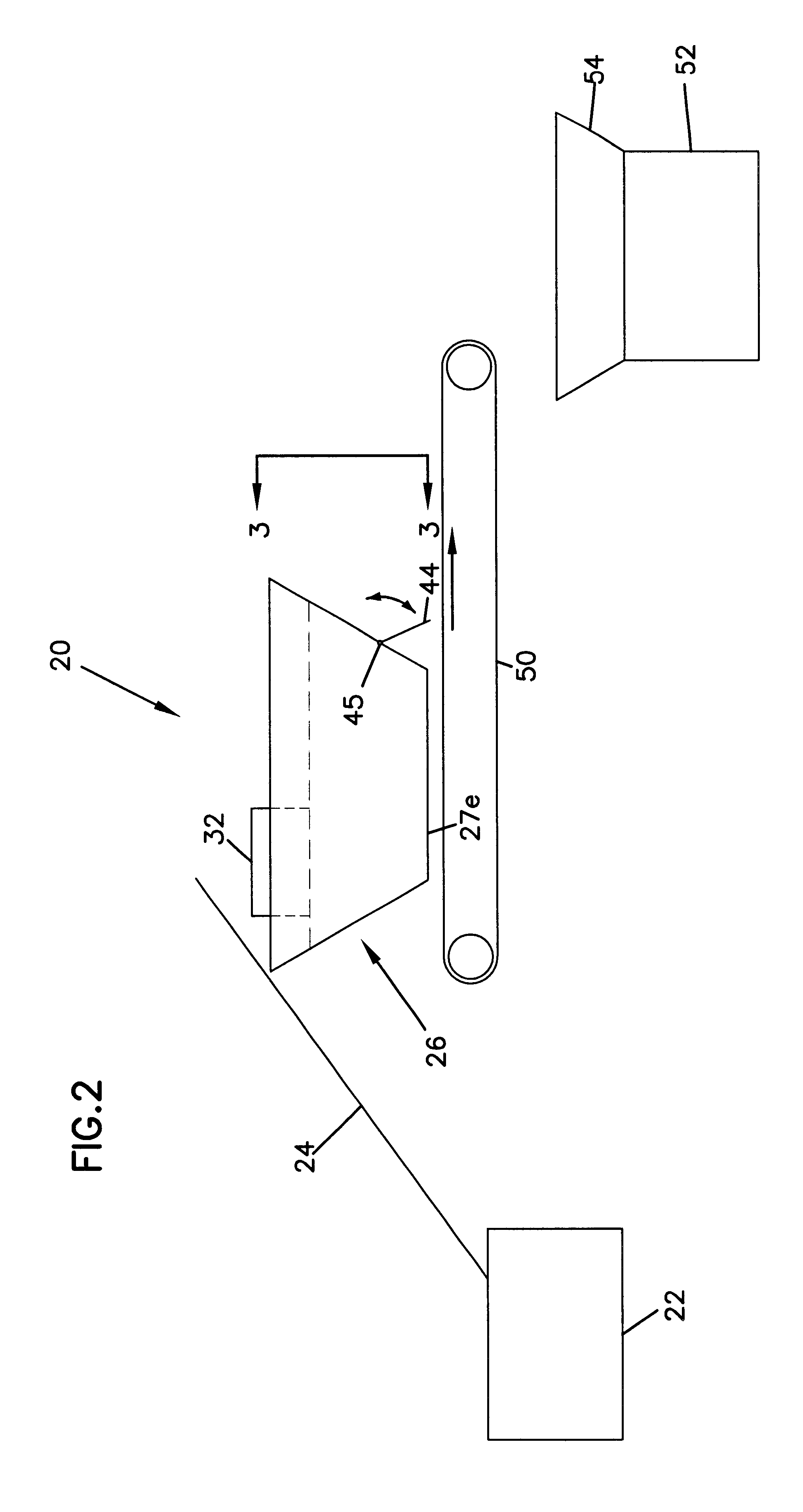

Process and equipment for producing concrete products having blended colors

InactiveUS6910796B2Easy to changeResulting appearance of the visible surfaces of the concrete products can be readily alteredFrozen sweetsConfectioneryBrickRetaining wall

A process and equipment for producing multi-color concrete products, including architectural concrete blocks, concrete bricks, modular concrete products that are suitable for use in landscaping applications, such as retaining wall blocks, concrete pavers, and concrete slabs. The invention includes a spray mechanism that sprays liquid pigment onto concrete discharged from a hopper. The concrete then proceeds to a blending mechanism which blends the pigment into the concrete to produce a multi-color concrete blend. The concrete blend is then used to produce multi-colored concrete products.

Owner:ANCHOR WALL SYST

Process and equipment for producing concrete products having blended colors

InactiveUS6923565B2Resulting appearance of the visible surfaces of the concrete products can be readily alteredReduce colorMixing operation control apparatusFeeding arrangmentsBrickEngineering

A process and equipment for producing multi-color concrete products, including architectural concrete blocks, concrete bricks, modular concrete products that are suitable for use in landscaping applications, such as retaining wall blocks, concrete pavers, and concrete slabs. The invention includes a hopper that is divided into separate sections, with each section intended to contain a differently colored concrete. Each hopper section includes a controllable discharge opening that permits precise control of the amount of each concrete color that is discharged from the hopper. The colored concrete is then transported to and dumped into a hopper of a concrete product production machine, where the concrete is blended into a multi-color concrete blend for use in producing the concrete products.

Owner:ANCHOR WALL SYST

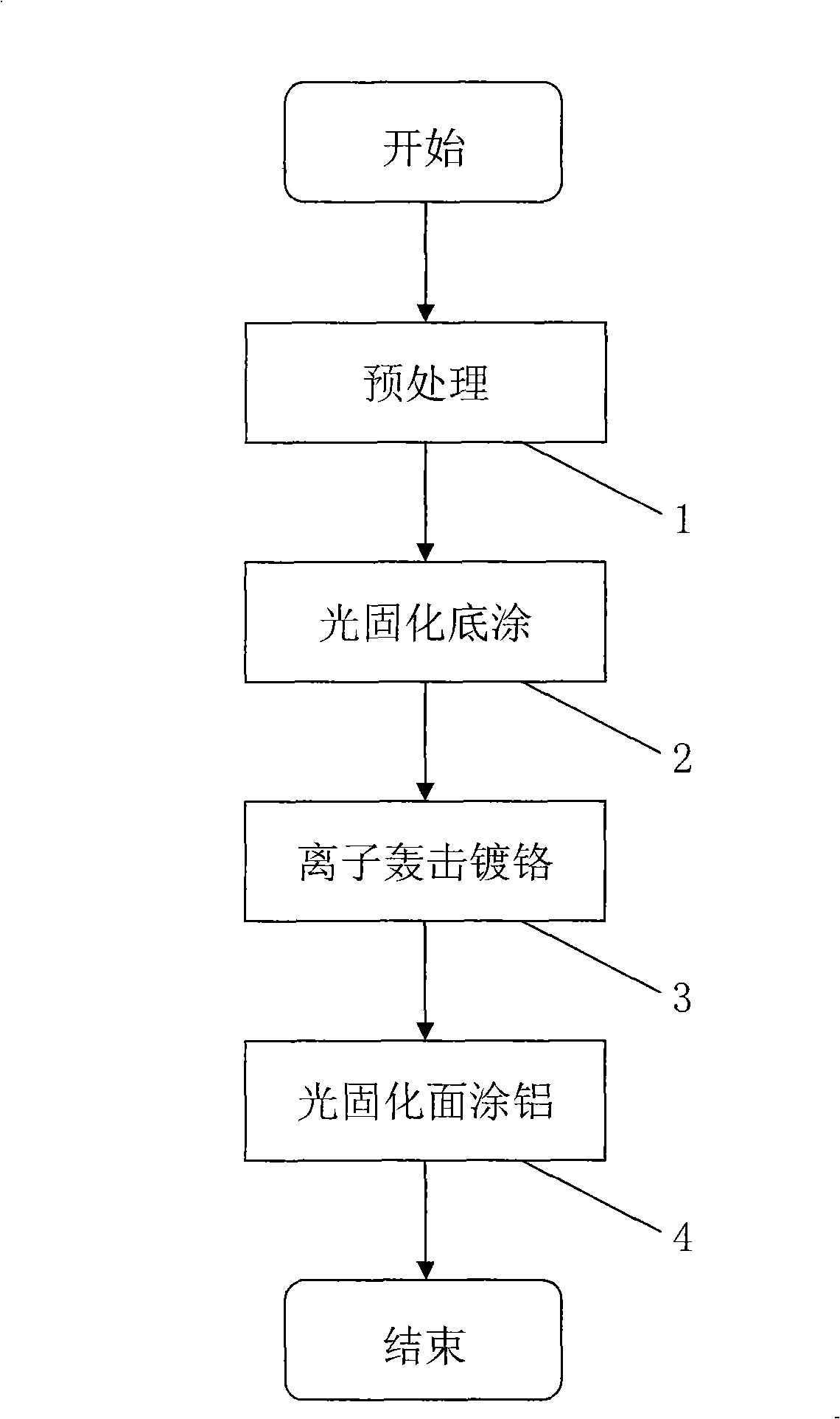

Coating method of automobile hub cover

InactiveCN101338409AConsistent bindingConsistent usabilityVacuum evaporation coatingSputtering coatingPhysical well beingEngineering

The invention discloses a membrane-plating method for a hub cover of a vehicle which includes the steps of pre-processing, bottom coating through light curing, chromeplating through ion bombardment, surface coating through light curing, etc. The invention adopts a dry plating to replace the traditional wet electric plating and adopts an aluminum layer to replace the traditional metal coat of Ni-Cu-Cr. The dry plating method does not contain poison matters, does not have the problem of three wastes, does not need three-waste processing, has a simple technique process and has no pollution to the environment. The working condition of a worker is good; the effect to the body health is small. The noble metals like Cu, Ni and Cr are not needed to be used; only less aluminum is used, thus greatly reducing the cost. The technique is simple; the working procedures are less; the production cost is low. The power consumption is about one fifths to one sevenths of the electric plating; the water consumption is about one tens to one twentieths of the electric plating. The integral production cost is about one seconds of the electric plating. The method of the invention has a high economic benefit; besides, nano-ceramics particles are added in the surface coating material of light curing which improves the techniques of dispersing and mixing as well as remarkably improves the surface wear-resistance.

Owner:HUZHOU JINTAI PLATING IND

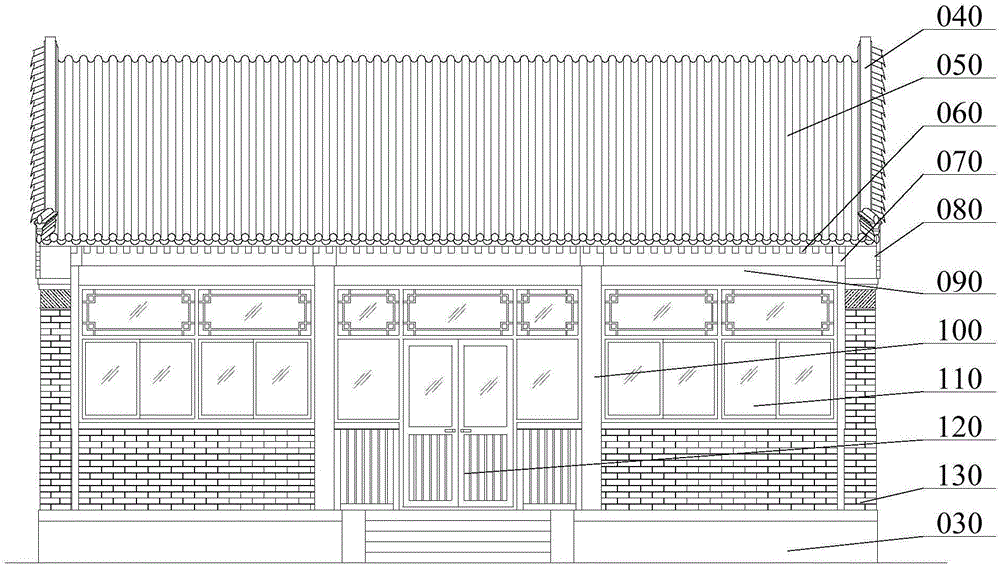

Archaistic building and manufacturing method thereof

ActiveCN106382023AConstruction rationalizationStable physical propertiesBuilding roofsRoof covering using tiles/slatesWater seepageBuilding construction

The invention provides an archaistic building and a manufacturing method thereof, relating to the technical field of manufacturing of historic buildings. The archaistic building comprises a ground foundation, a main body steel structure, archaistic upright pillars and archaistic joint tiles, wherein the archaistic joint tiles and the archaistic upright pillars are made of modified cement and are factory prefabricates with lifelike forms and excellent assembling and archaistic effects. Besides, the steps of the manufacturing method are simple, and the manufactured archaistic joint tiles are scientific in physical dimension design and reasonably butted and have the advantages that water seepage and rain leakage are avoided, the texture is real, the durability is good, and the appearance and the proportion are accordant with traditional tiles. According to the manufacturing method, the technical problems of long construction cycle and short service life in the prior art are solved, the construction of the archaistic building is relatively reasonable, and the application of the archaistic building is relatively wide.

Owner:BEIJING JUXING COMPOSITE MATERIAL TECH DEV

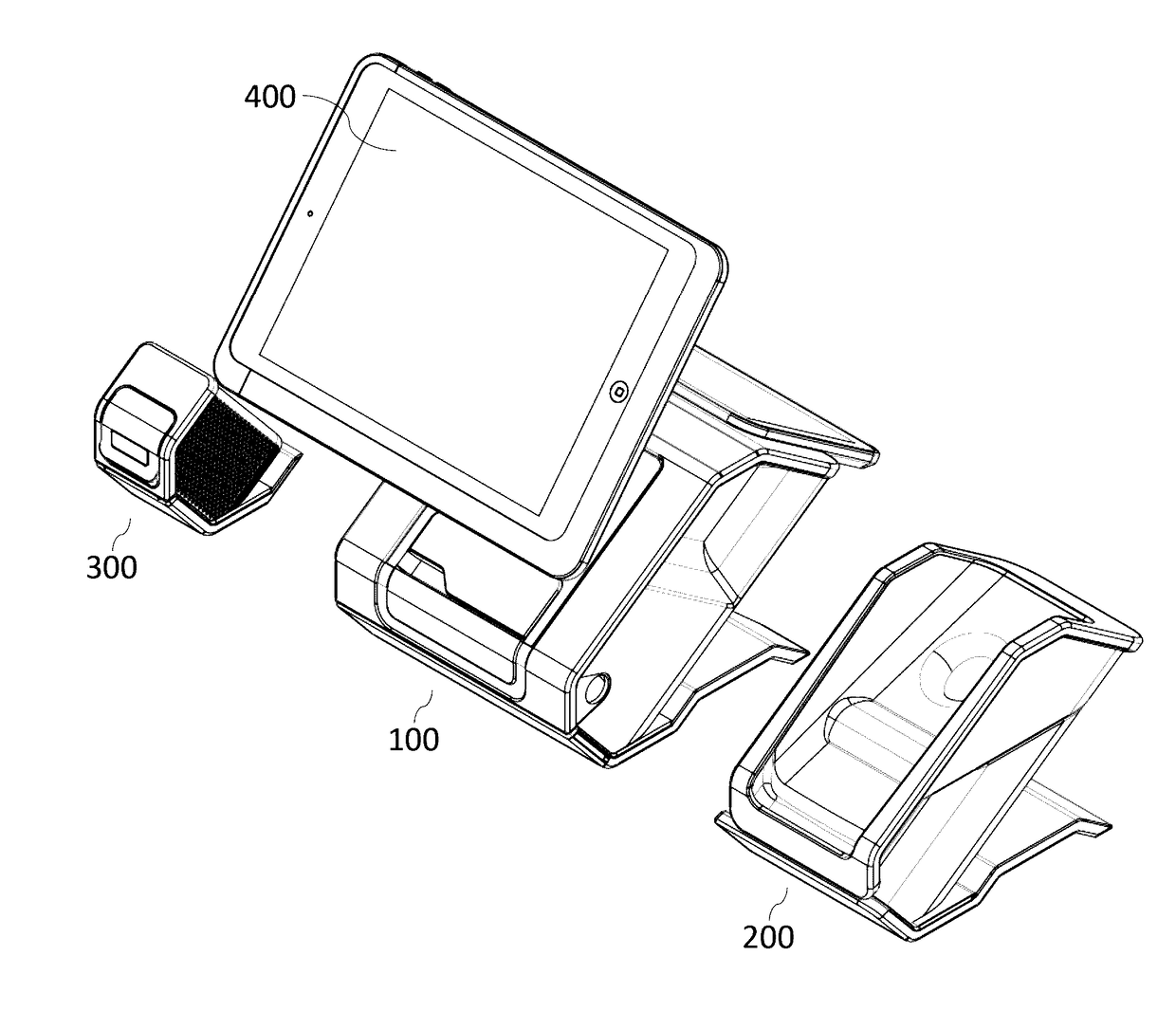

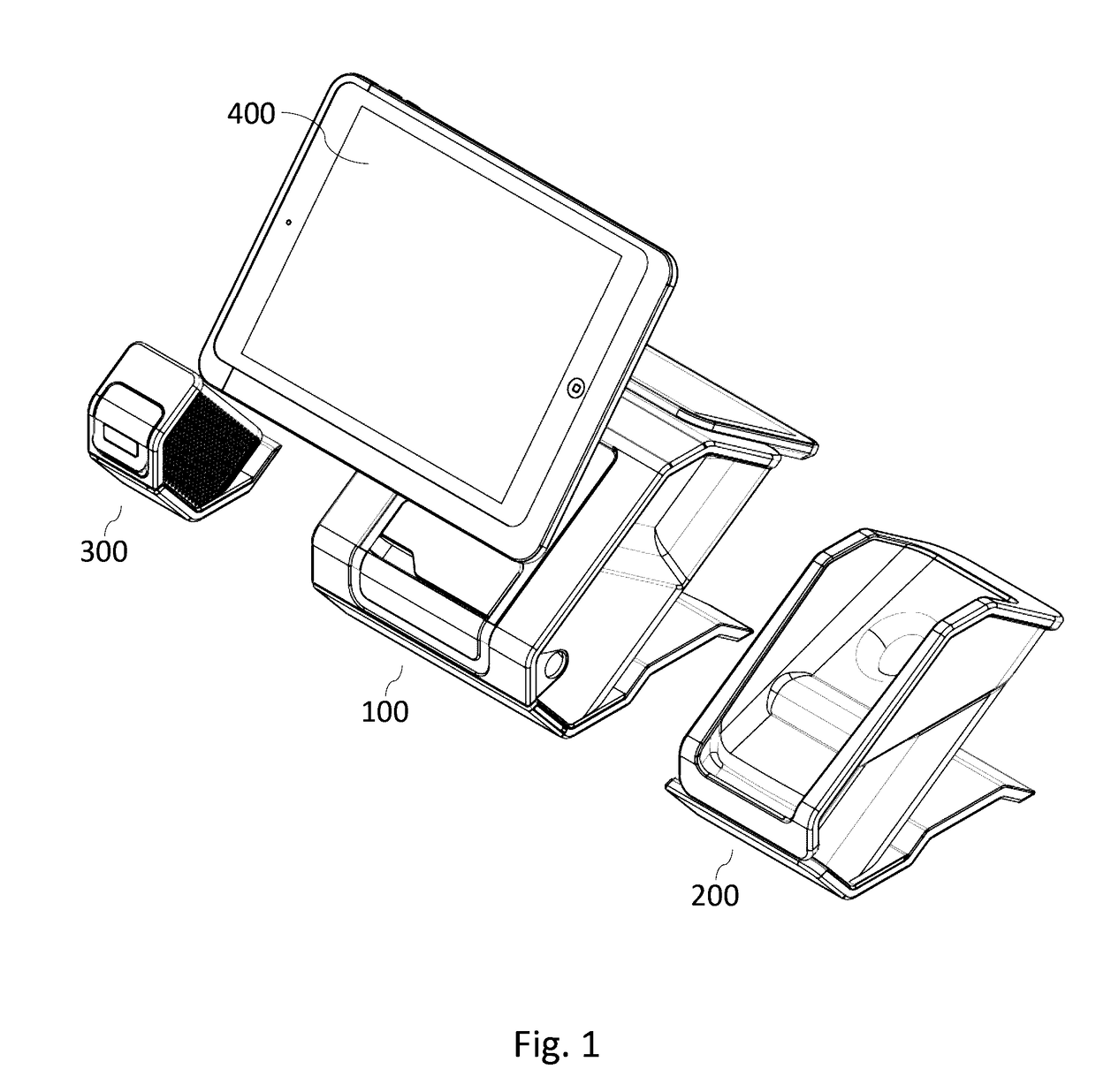

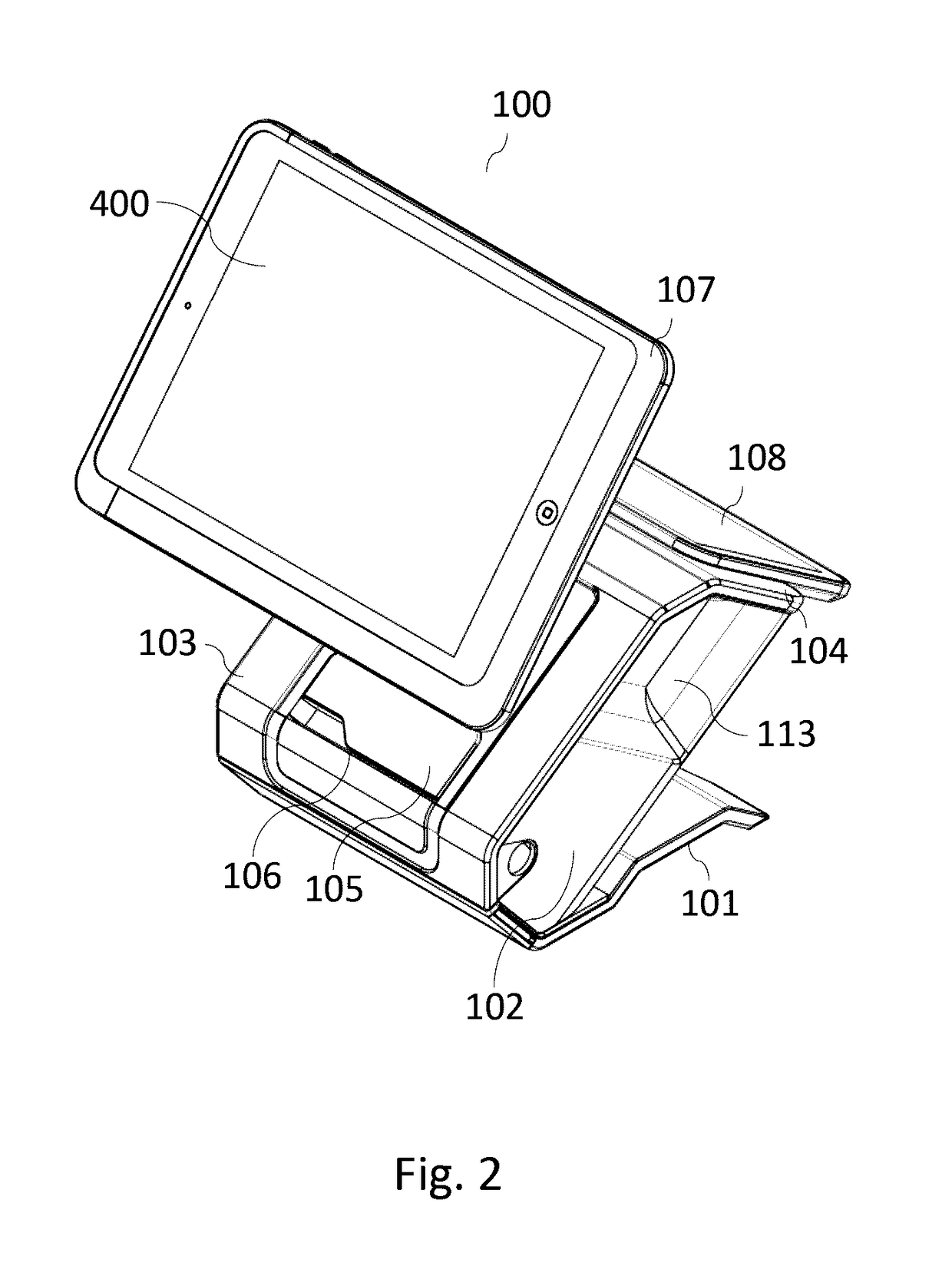

Modular cash register

InactiveUS20170140615A1Achieve modularityAccurately heldCash registersPoint-of-sale network systemsTouchpadModularity

The proposed technique relates to cash register implemented by means of a tablet type digital touchpad device (400). The digital touchpad device (400) is fixed to a main module (100) that comprises:a central unit (102);an interchangeable support (107) adapted to maintaining said digital touchpad device (400);a hinged arm (110), of which one of the extremities, called a first extremity, is linked by a first pivot link (111) to said central unit (102), and of which the other extremity, called a second extremity, is linked by a second pivot link (112) to a receiving plate to which said interchangeable support (107) is fixed.The proposed cash register is modular, and it optionally comprises an optical reader module and / or a payment module on which a payment terminal is positioned.

Owner:CIE IND & FINANCIERE DINGENIERIE (INGENICO)

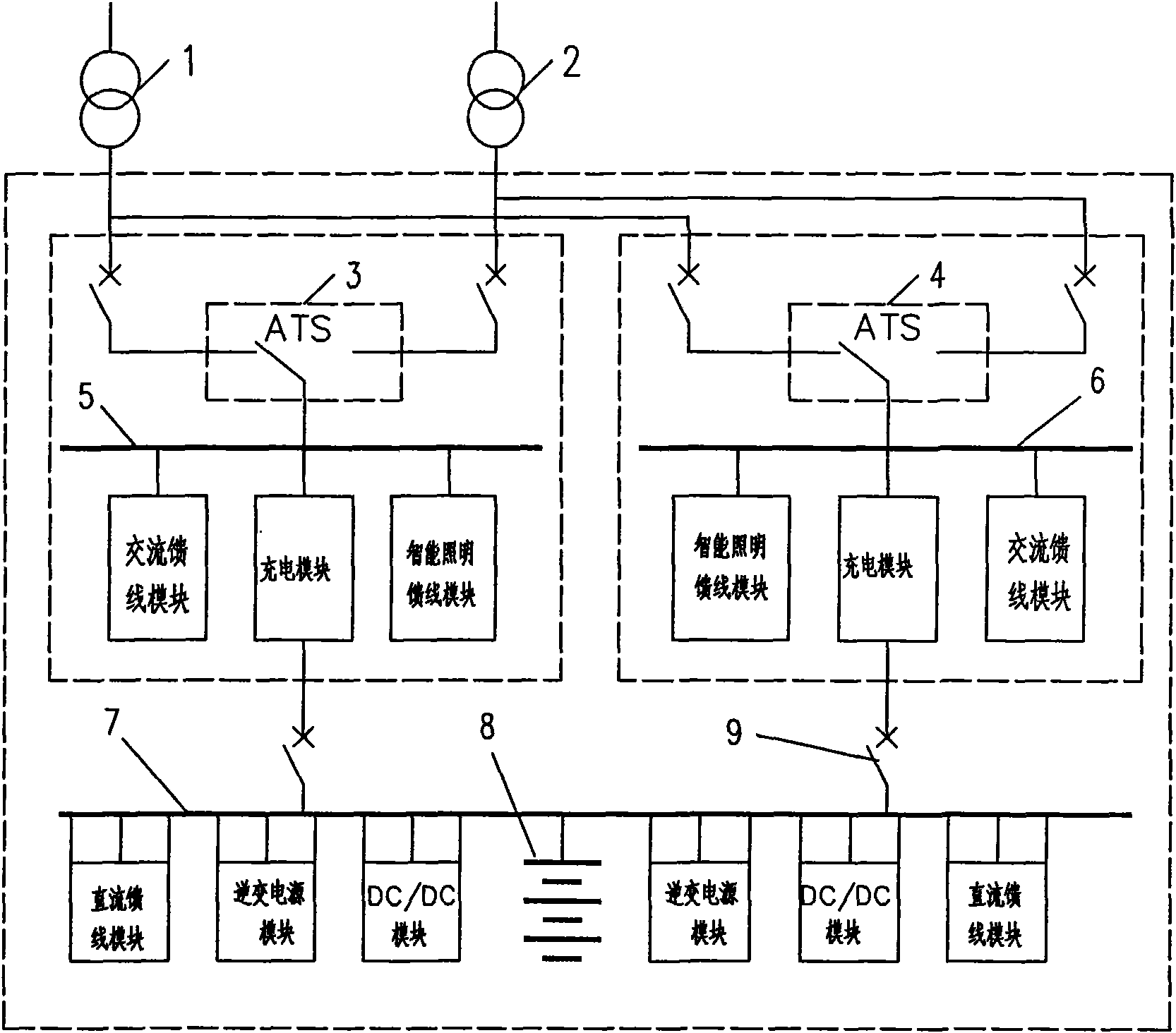

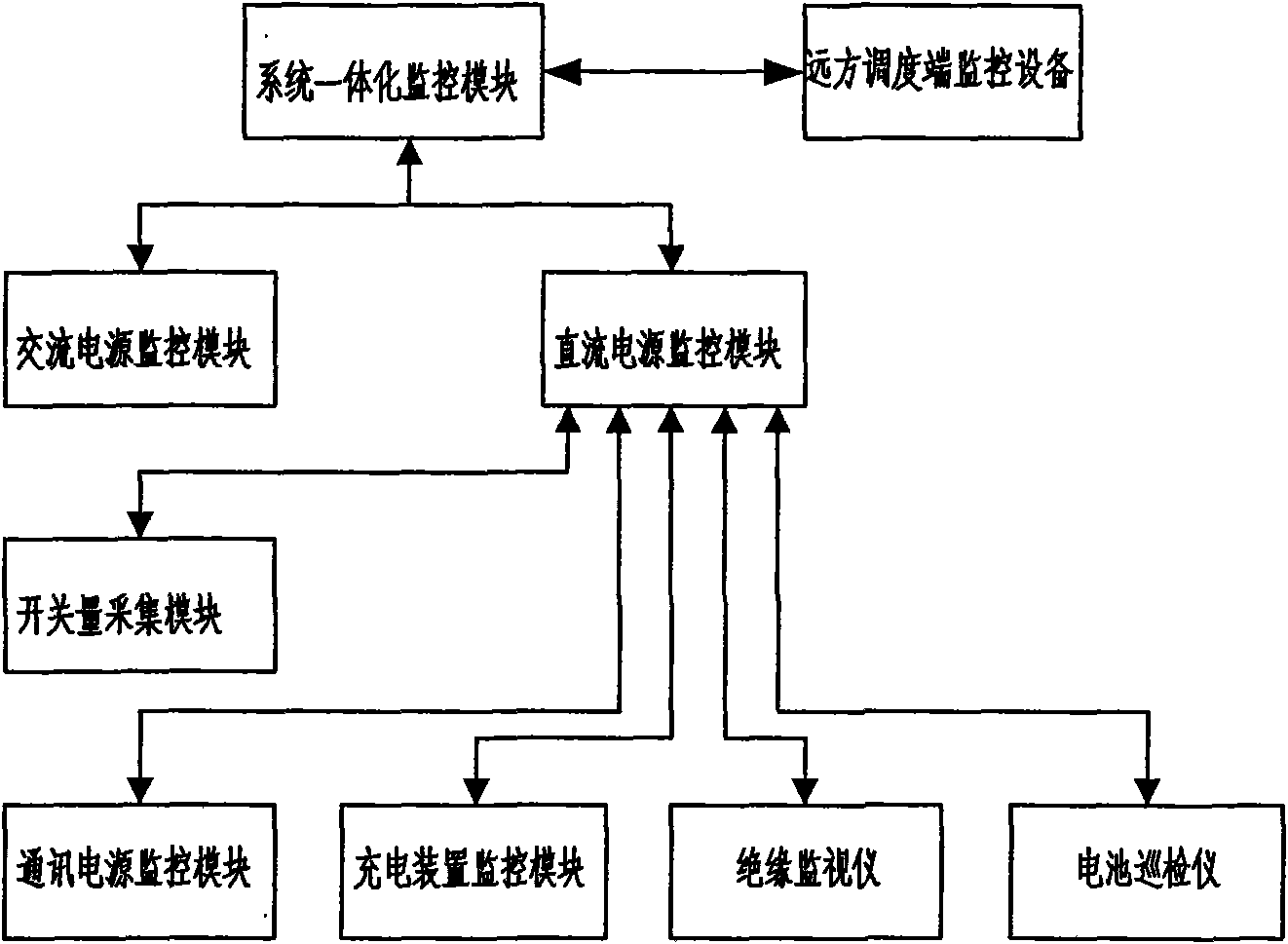

Power supply device for transformer substation

The invention relates to a power supply device for a transformer substation, which comprises two transformers (1,2) and two ATS switches (3,4), wherein ATS switches are connected with sections of alternating current buses (5,6) respectively; each section of the alternating current bus is connected with an alternating current feeder module, a charging module, an intelligent lighting feeder module and the like; and each charging module is connected with the same alternating current bus (7), and the alternating current buses are connected with two sets of the direct current feeder modules, two sets of inversion power modules, two sets of DC-DC modules and one set of accumulators (8) respectively. The power supply device has the advantages that: all the switches are intelligently modularized and integrated in a chassis; a switch programming control hardware platform is established and modules are integrated into the network through network communication technology, so the power switch for the transformer substation has the functions of activating preset programs and completing programmed operation besides the conventional manual control, remote control and protective control according to related information triggering conditions.

Owner:HUAIBEI POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER +1

Adaptive computing system with modular control, switching, and power supply architecture

InactiveUS8576570B2Easy to deployEasy to operateCasings with display/control unitsPower supply for data processingPhysical spaceComputer users

The adaptive computing system described herein may generally include a modular control, switching, and power supply architecture. In particular, the adaptive computing system may provide a platform supporting multiple independent desktop computer modules that occupy less physical space than a standalone commercial computer, provide performance density comparable to current server solutions, and address concerns relating to stability, safety, productivity, performance, assembly, service, and other factors important to diverse desktop computer user communities. Moreover, mechanical, electrical, and functional components associated with the adaptive computing system may have various certifications or otherwise be relied upon to demonstrate compliance with criteria in regulatory, environmental, consumer safety, and other contexts.

Owner:NCS TECH

Acetate plasticizer for improving smoking property of cigarette and method for preparing same

InactiveCN1994164AQuality improvementHigh fullnessTobacco smoke filtersVegetal fibresFlavorPlasticizer

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

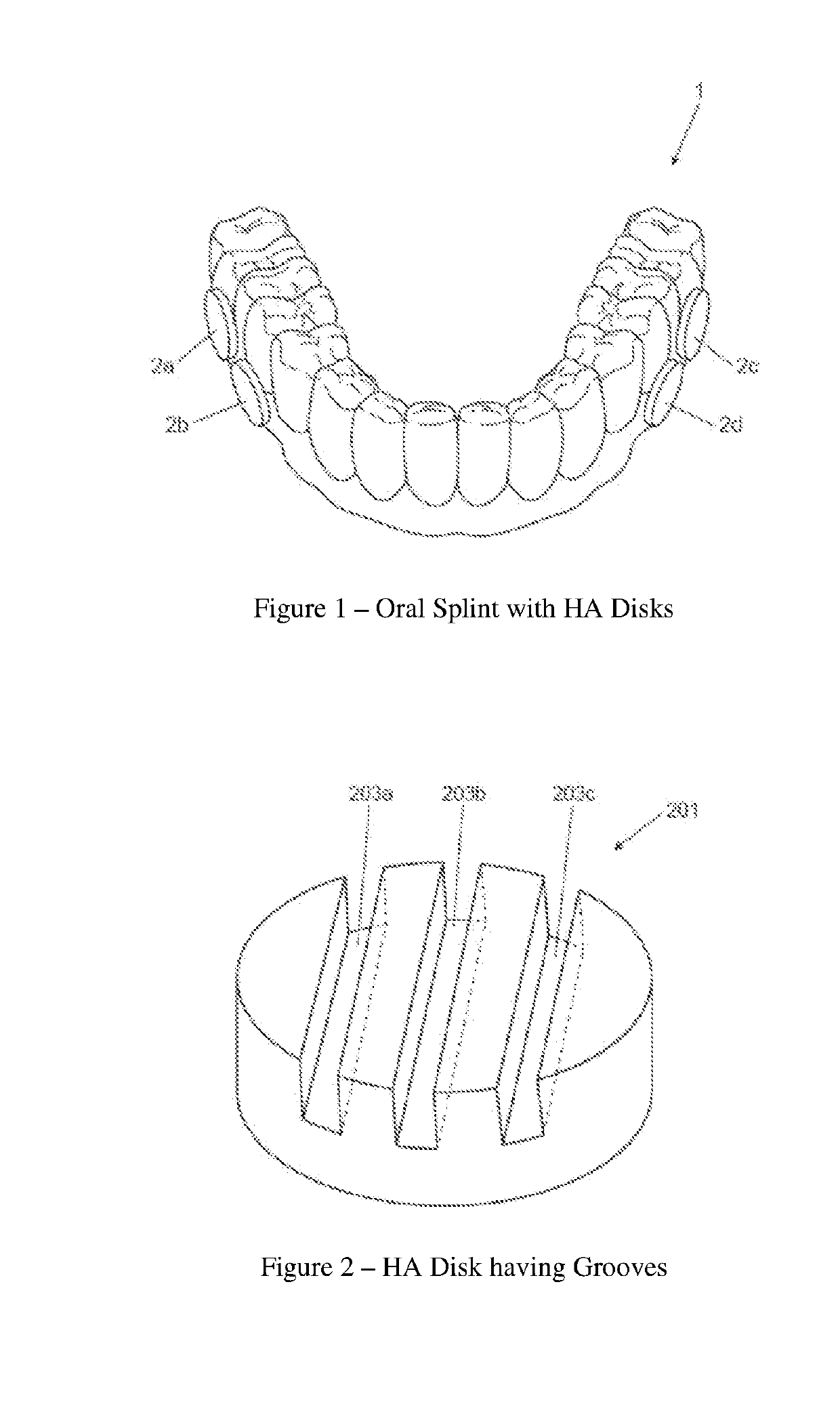

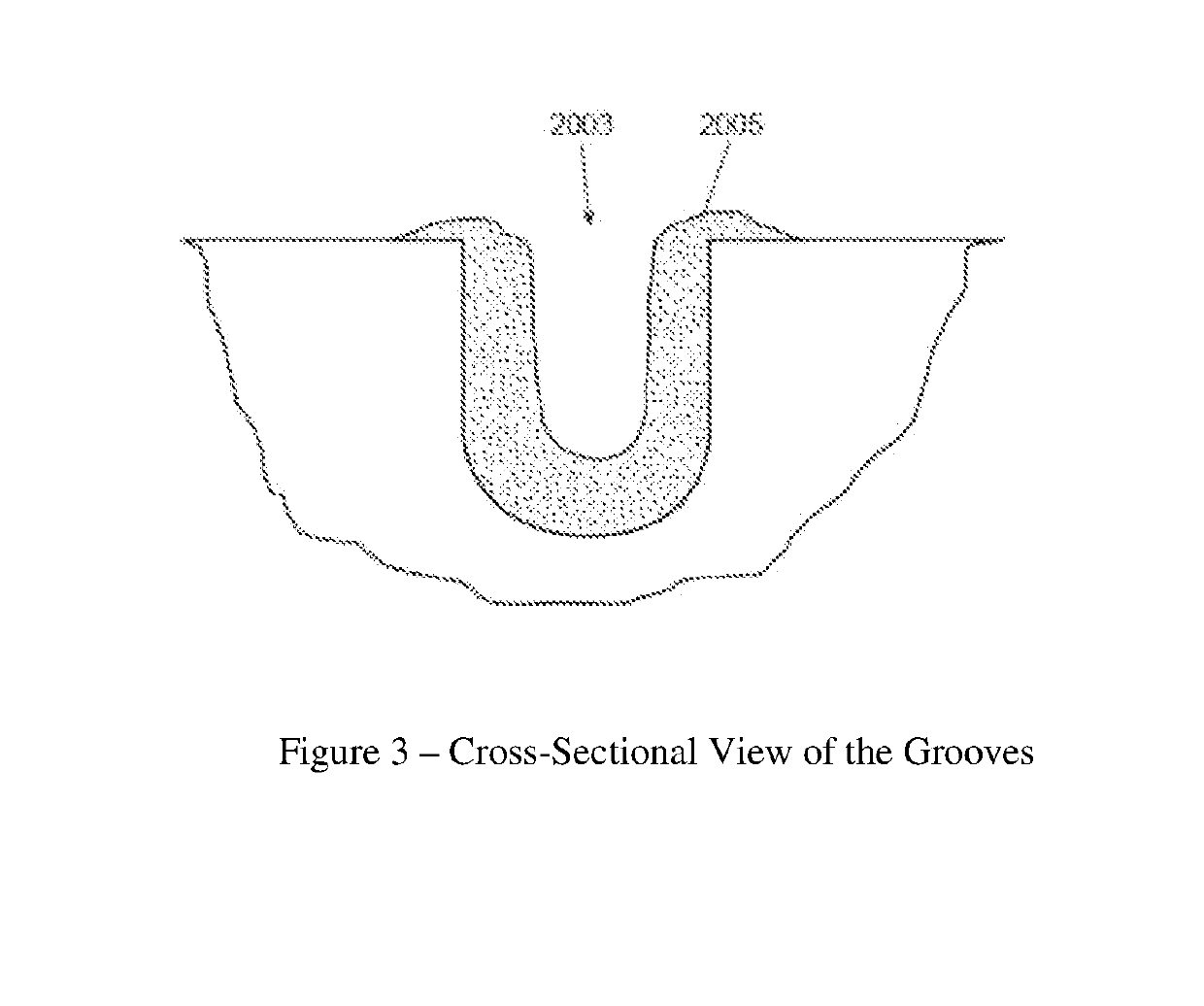

Oral care compositions for promoting gum health

ActiveUS20190298636A1Improved Gum Health benefitDeep penetrationCosmetic preparationsToilet preparationsMedicineChewing gum

Oral care compositions comprising an amino acid and stannous ion source, especially in the absence of zinc ion source, are provided for promoting Gum Health of a user.

Owner:THE PROCTER & GAMBLE COMPANY

Microwave vacuum freeze-drying method for rhizoma gastrodiae

InactiveCN107308350ANutrients are not destroyedAppearance color is not damagedDrying solid materials with heatDrying solid materials without heatFreeze-dryingAdditive ingredient

The invention discloses a microwave vacuum freeze-drying method for rhizoma gastrodiae. The microwave vacuum freeze-drying method comprises the following steps: firstly, cleaning and draining fresh rhizoma gastrodiae; secondly, pre-freezing the rhizoma gastrodiae at the temperature of 10 DEG C below zero to 30 DEG C below zero for 1 hour to 1 year; thirdly, slicing and pricking the rhizoma gastrodiae obtained in the second step; fourthly, putting the pricked rhizoma gastrodiae into a microwave freezing dryer, and freezing at the pressure of 5 to 20 Pa and the temperature of 35 DEG C below zero to 40 DEG C below zero for 1 to 3 hours; introducing nitrogen, controlling the pressure at 20 to 100 Pa, controlling microwave power at 100 to 300 w / kg when the time reaches 0 to 3 hours, controlling the microwave power at 300 to 500 w / kg when the time reaches 3 to 6 hours, controlling the microwave power at 100 to 200 w / kg when the time reaches 6 to 8 hours, and warehousing to obtain freeze-dried rhizoma gastrodiae slices. The method disclosed by the invention has the advantages of short production period and low energy consumption and cost for freeze drying; in addition, effective ingredients, nutritional ingredients, appearance, color and luster of the fresh rhizoma gastrodiae are sufficiently protected from being damaged, original shapes of crude products are maintained, and the rhizoma gastrodiae slices are crisp and tasty in mouthfeel.

Owner:ZHEJIANG JIANFENG HEALTH TECH

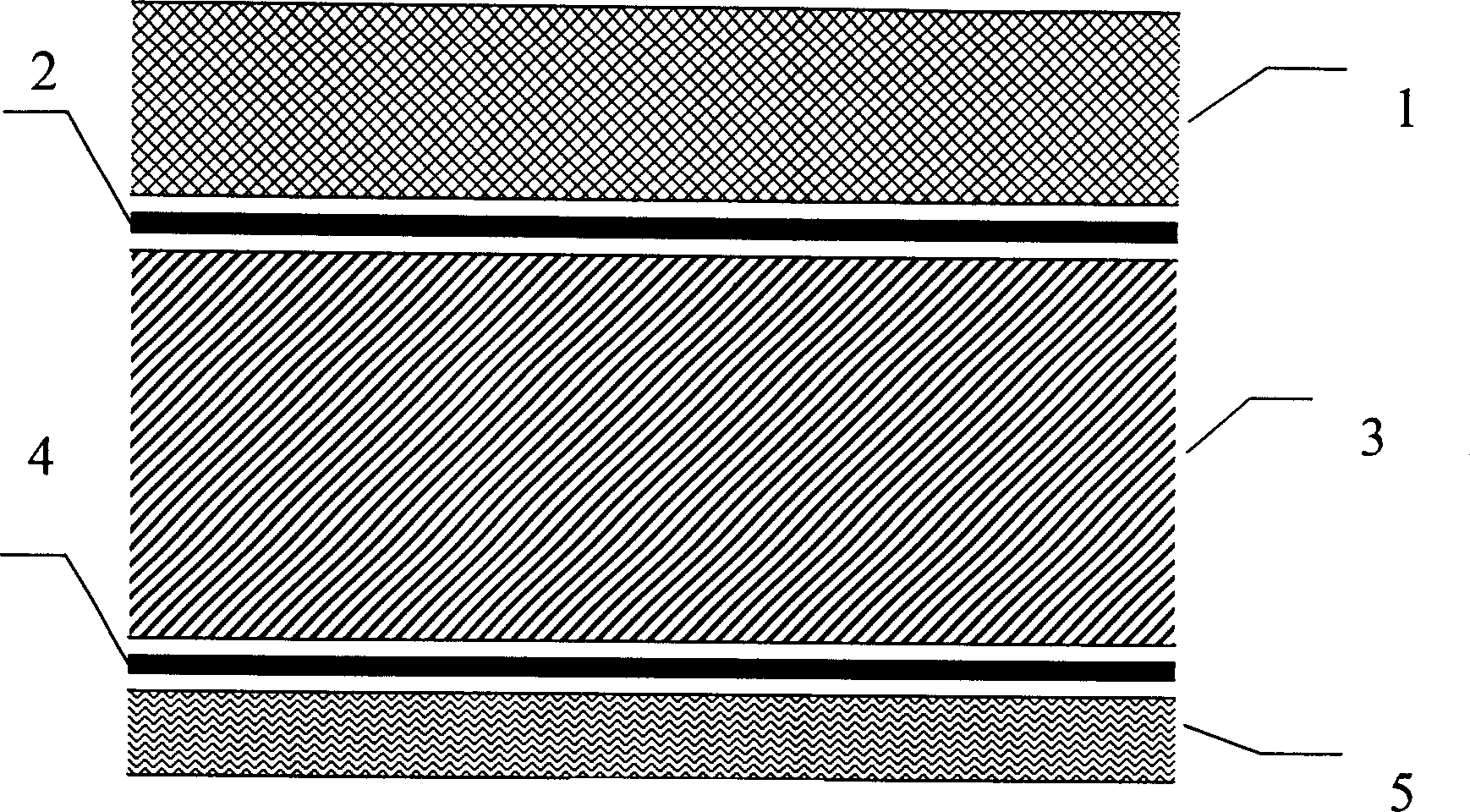

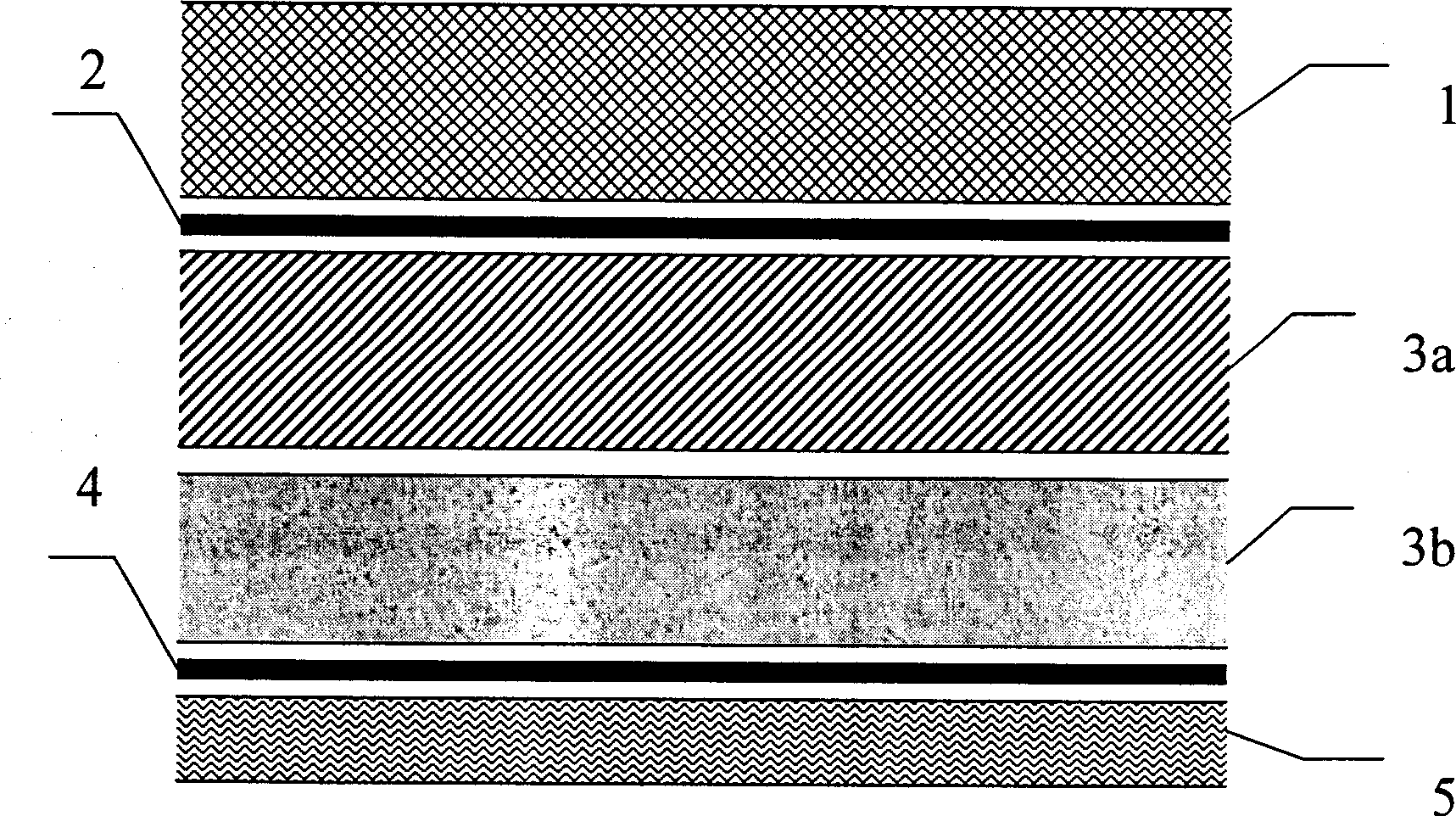

Composite material for interior decoration of automobiles and manufacturing method thereof

ActiveCN1799827ALow investment costLow costLamination ancillary operationsLaminationSurface layerIn vehicle

The invention relates to a composite material used in vehicle inner decoration and relative producing method. Said composite material is formed by five or six non-woven sheets as surface layer, de-molding layer, filled layer, de-molding layer and base material layer. Wherein, the filled layer can be formed by hot-melt felt (3a) and polypropylene felt (3b). The producing method comprises that using the de-molding layer (4) as lower layer, the filled layer (3) as intermediate layer and the de-molding layer (2) as upper layer to be piled and arranged between the upper and lower heating plates of heat device; adhering said three layers after low-pressure high-temperature heating into the frame of soft-sandwich type; moving said frame into the lower mould of molding mould and above the base material layer (5); coating the surface layer (1) on the frame; closing the mould to be pressurized and shaped; cutting the hole and edge; and lifting upper mould to attain the final product. The invention has the advantages of lower cost, un-deformed product, high strength, impact resistance, welding availability, short producing process and high efficiency.

Owner:上海汽车地毯总厂有限公司

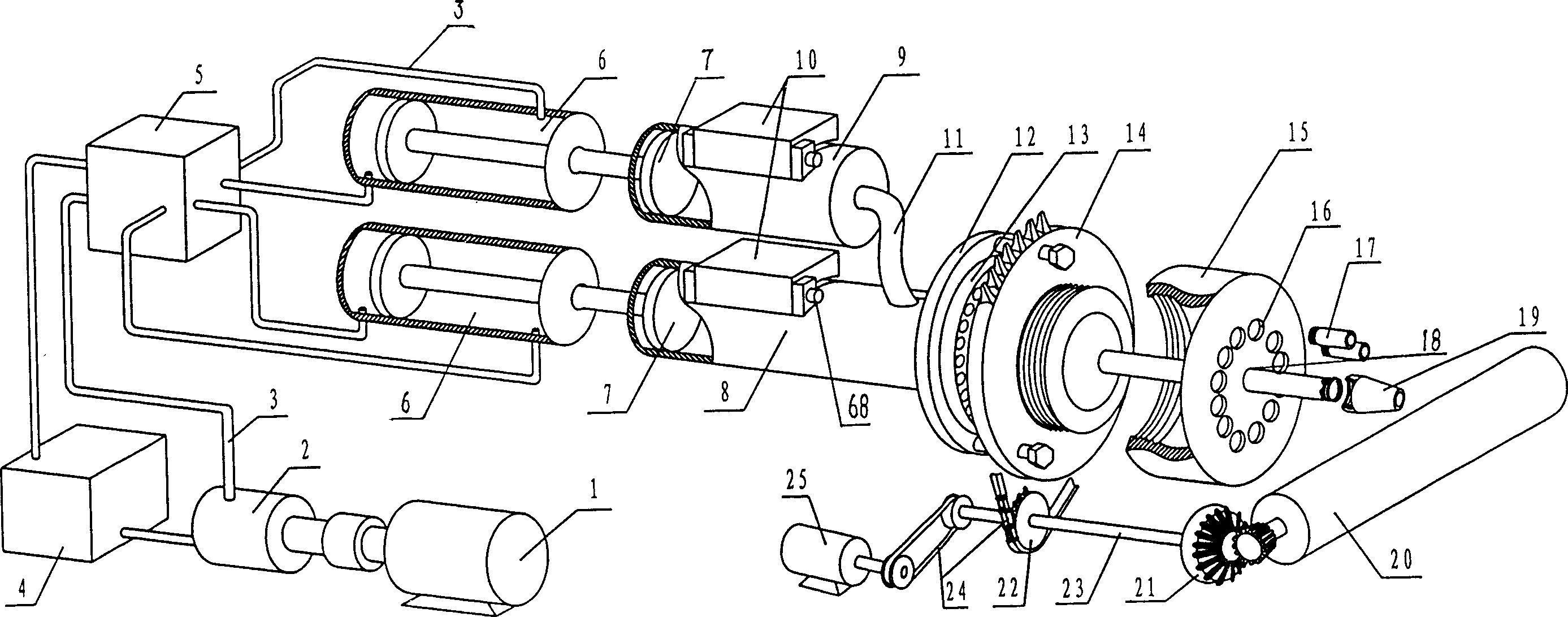

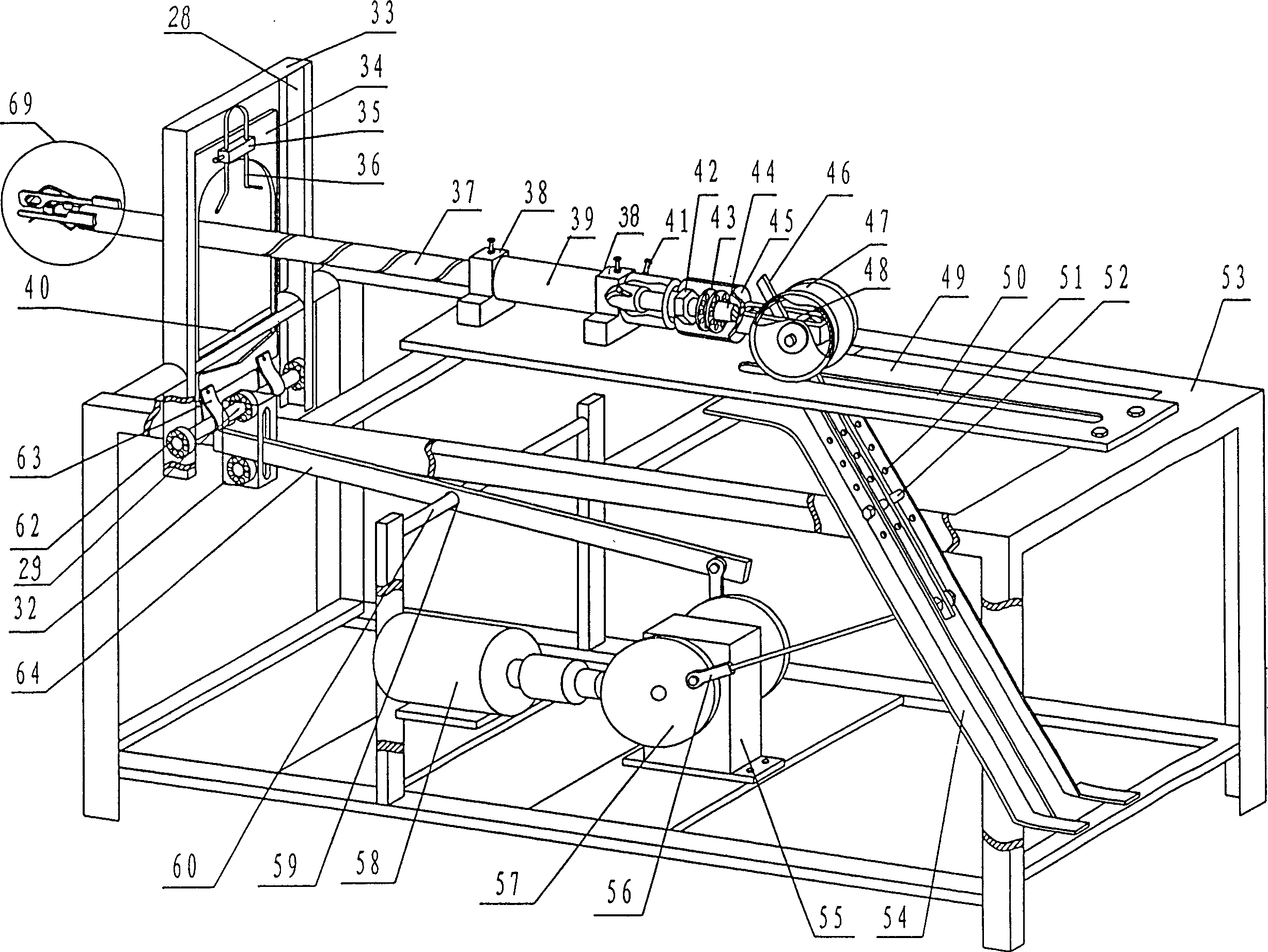

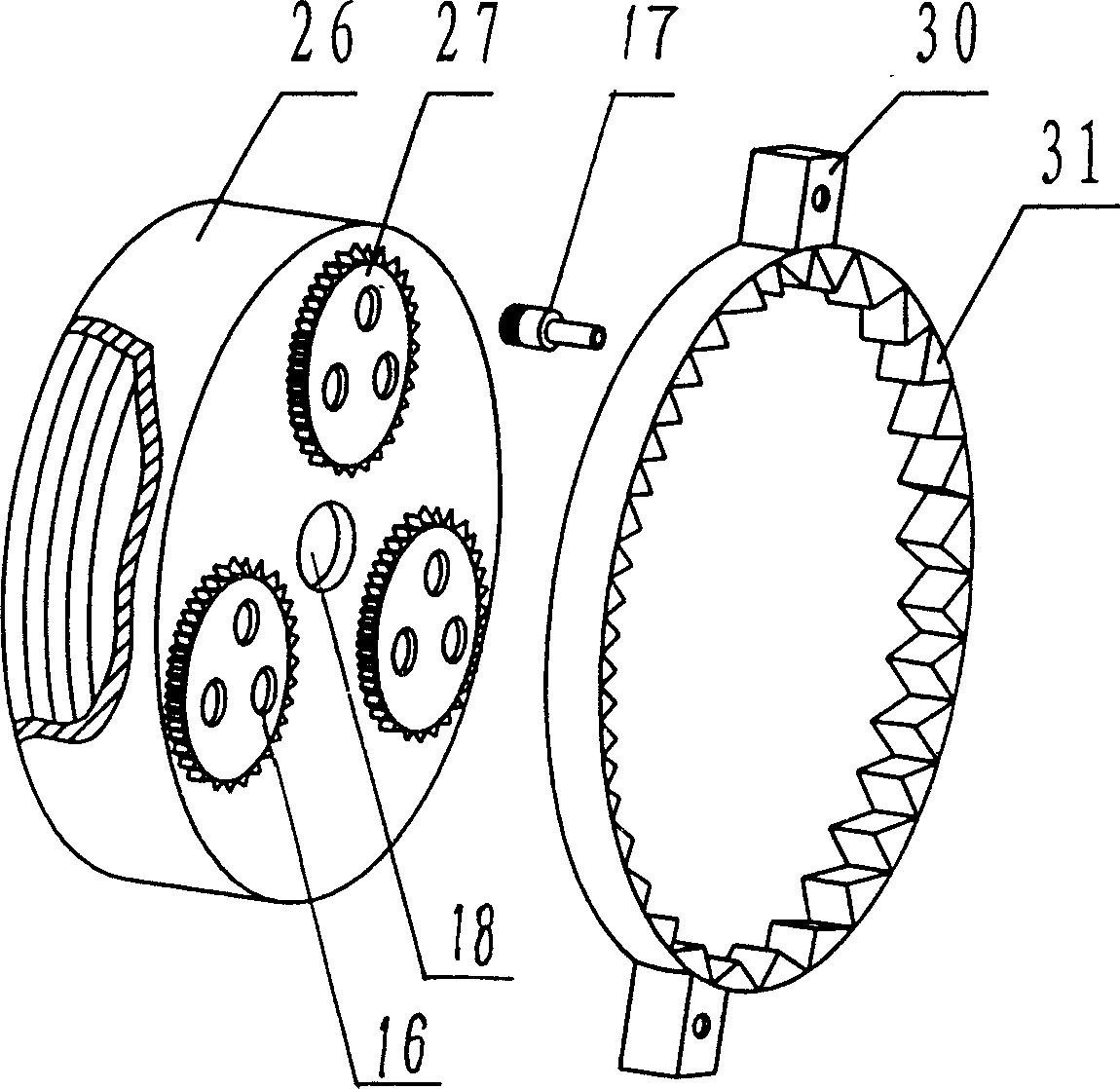

Automatic fried dough twist shaping machine

InactiveCN1602695AMake uniformUnified production standardsDough strip twisting machinesElectricityGear wheel

This invention relates to a machine roll paste into pretzel automatically, including hydraulic pressure drive and roll mould machine, electricity drives hydraic pressure crock piston and then force the stuffing crock and paste crock operation in whole machine. The output of paste crock is a compose tray. There are stuffing hole and paste hole on it. There is out pipe on the stuffing crock, through the paste crock connected the stuffing output hole. The timing electromotor drives the compose tray rotating through the transmission machine. It is connected with umbrella gear in disguised from connected the parallel compose roller before the composing tray through transmission machine. On the other hand, the timing electromotor jointed two output reducers. The two output reducer: connected to the manipulator machine and orientation falchion machine, on the uphold frame. The manipulator nip, drawer, collapse and screw pretzel stick to the orientated falchion, and then press the pretzel and cut to sects. This pretzel machine operated easy sanitation, high quality, and high affection. The products consistent with handcraft in the special style, multiplicity sculpt, fit for the industrialization.

Owner:徐志兴

Motor vehicle egress window

ActiveUS7730668B2Reduce adverse effectsReduce penetrationWindowsWindscreensMobile vehicleEngineering

A motor vehicle egress window comprises a circumferential outer frame forming an auxiliary egress opening for a motor vehicle passenger compartment and an inner frame unit. The outer frame has an outer frame member with an inner surface and at least a first striker pin. The inner frame unit is mounted to the outer frame for movement between closed and open positions has a circumferential inner frame, a glazing pane mounted to the inner frame, at least a first egress latch mounted to the inner frame, and a release mechanism. The egress latch is operative to latch to the striker pin to hold the inner frame unit in the closed position. The release mechanism includes a manually operative release handle, preferably mounted at an elevated position on a vertical side portion of the inner frame, and release linkage comprising at least a first link from the release handle to the first latch. In certain embodiments the inner and outer frames overlap radially for improved functionality.

Owner:PLASMAN US HOLDCO LLC

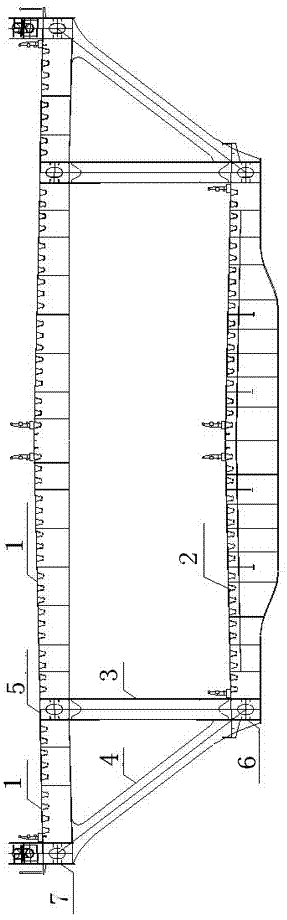

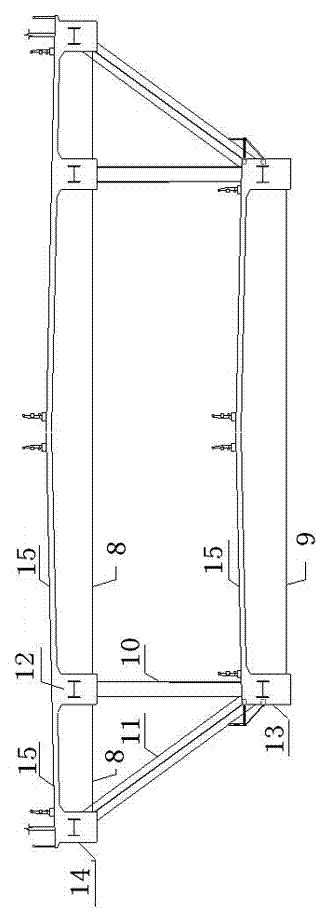

Main girder structure system of double-layer bridge deck cable-stayed bridge

InactiveCN104499415AImprove economic indicatorsShorten the lengthTruss-type bridgeCable stayedBridge deck

The invention discloses a main girder structure system of a double-layer bridge deck cable-stayed bridge. The structure system comprises a mid-span main girder and a side-span main girder, and is characterized in that the mid-span main girder adopts the combination of a plate truss and a steel truss girder, and the side-span main girder adopts a structure system of a composite truss girder. The structure system can effectively shorten the side-span span to prevent the side-span weight, keeps the appearance consistency of the whole bridge main girder, and has higher promotion values on such aspects as economy, bridge landscape and driving comfort.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

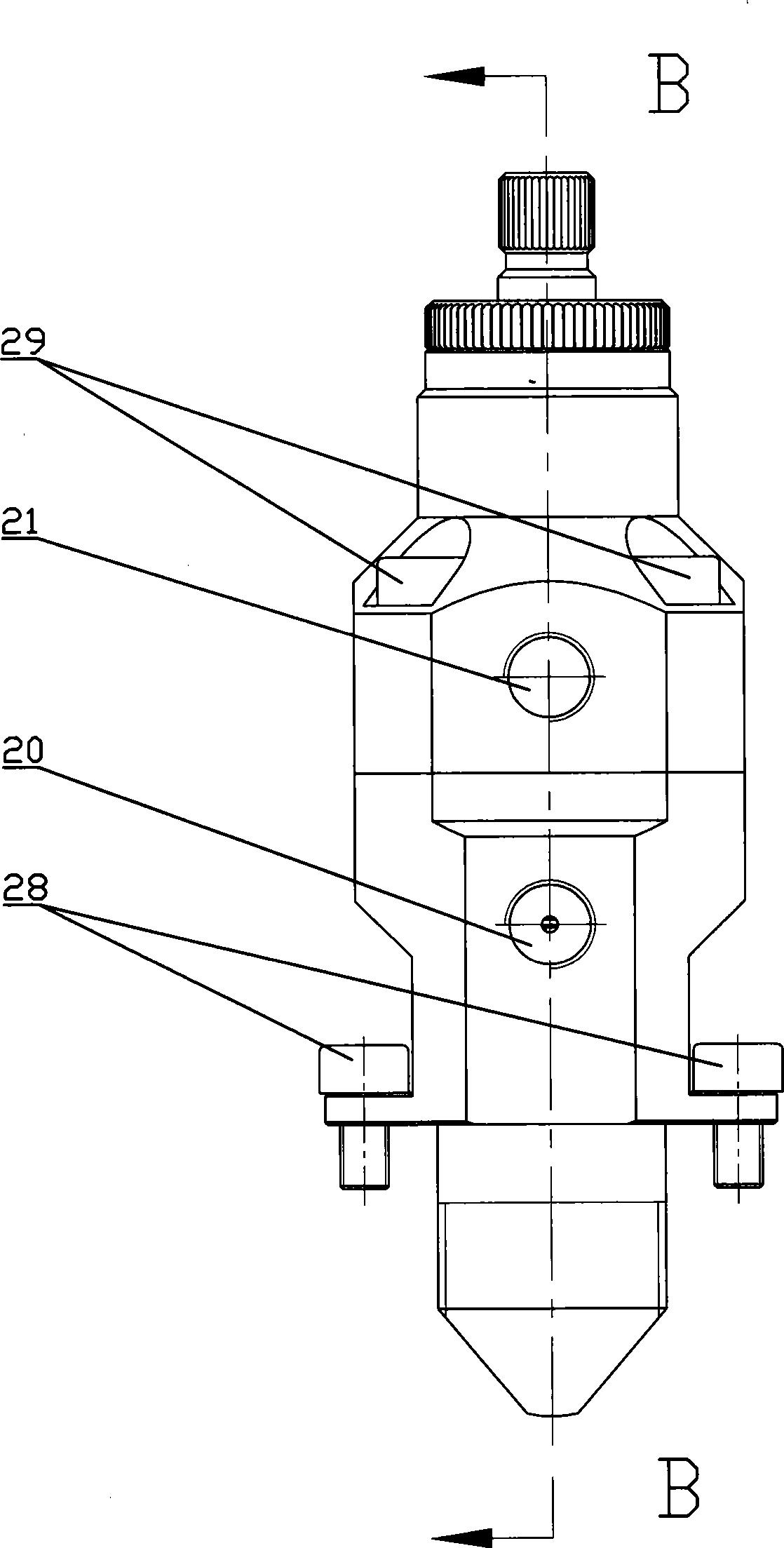

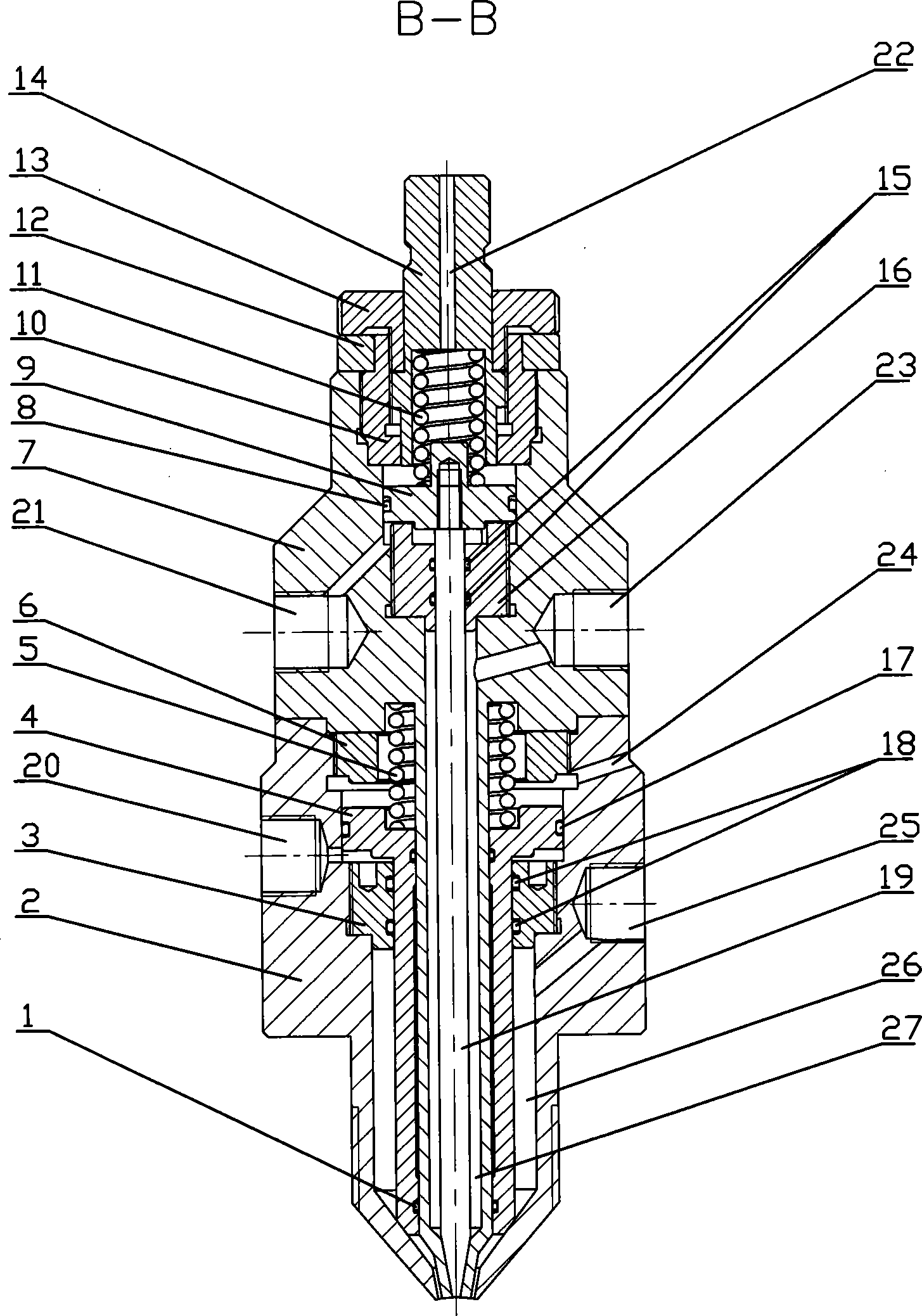

Trace dual-tube needle valve

ActiveCN104390036AImprove performanceConsistent appearanceRotary stirring mixersTransportation and packagingDouble tubeAdhesive

The invention provides a trace dual-tube needle valve and relates to a needle valve for gluing equipment, in particular to a trace dual-tube needle valve for dual-component polyurethane. The trace dual-tube needle valve comprises a needle valve base, a seal plug, a piston A, a spring A, a baffle ring, a valve body, a piston B, an inner sleeve and the like, wherein the valve body is fixedly connected with the needle valve base; the baffle ring and the seal plug are respectively and fixedly arranged in the needle valve base by virtue of threads; a piston part of the piston A is arranged between the baffle ring and the seal plug; the piston A is used for closing or opening a glue passage A; the inner sleeve and a seal head are respectively arranged at the upper part of the valve body by virtue of threads; a washer is arranged at the upper end of the inner sleeve; external threads of an adjusting nut and an adjusting screw are sequentially connected with internal threads of the inner sleeve; a valve needle is used for closing or opening a glue passage B. The trace dual-tube needle valve is relatively accurate in measuring accuracy, applicable to trace dual-component polyurethane gluing, especially applicable to trace foaming dual-component polyurethane gluing and also applicable to other trace dual-component adhesive gluing, and the measuring accuracy of the trace dual-component polyurethane inlet glue can be easily controlled.

Owner:DALIAN HUAGONG INNOVATION TECH

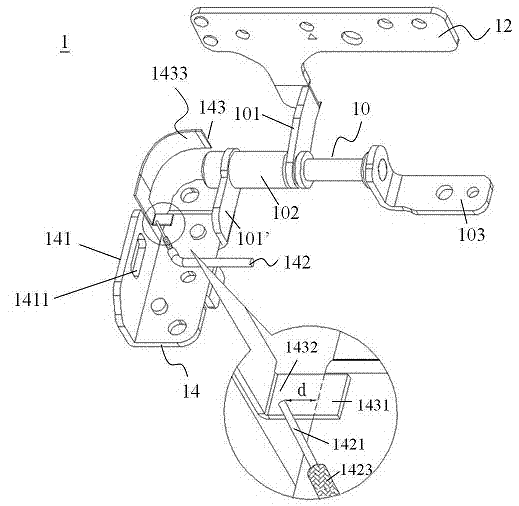

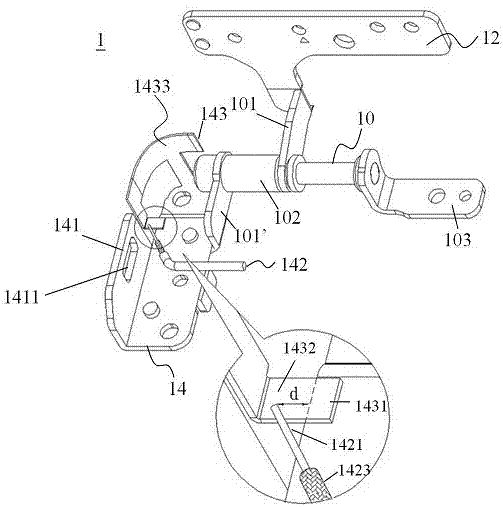

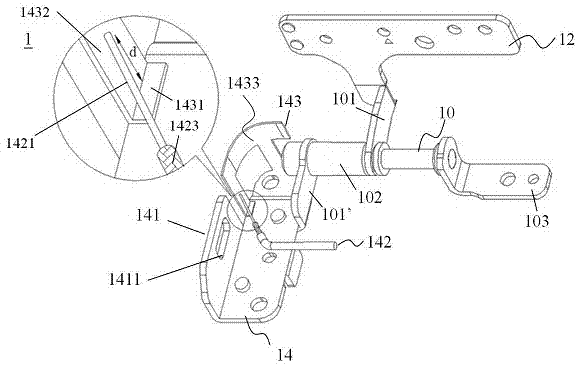

Bearing antenna and laminated type electronic device with the same

ActiveCN103904419AStable structureEasy to assembleAntenna supports/mountingsRadiating elements structural formsInterior spaceElectrical conductor

A hinge antenna comprises a metal hinge, a first metal connecting plate and a second metal connecting plate. The hinge antenna further comprises a microwave substrate, a signal feeding line, and a conductor, wherein the conductor is electrically connected to the microwave substrate and extended from the microwave substrate. Furthermore, the feed line of the signal feeding line is electrically connected to the microwave substrate and the ground line of the signal feeding line is electrically connected to the metal hinge, the first metal connecting plate, the second metal connecting plate, and an outside metal shield so that the metal hinge, the first metal connecting plate, the second metal connecting plate, and the outside metal shield can serve as a ground. The aforementioned configuration is utilized to form an antenna loop. In addition, the configuration of this antenna can be built in the interior space of the foldable electronic device.

Owner:昆山展腾电子科技有限公司

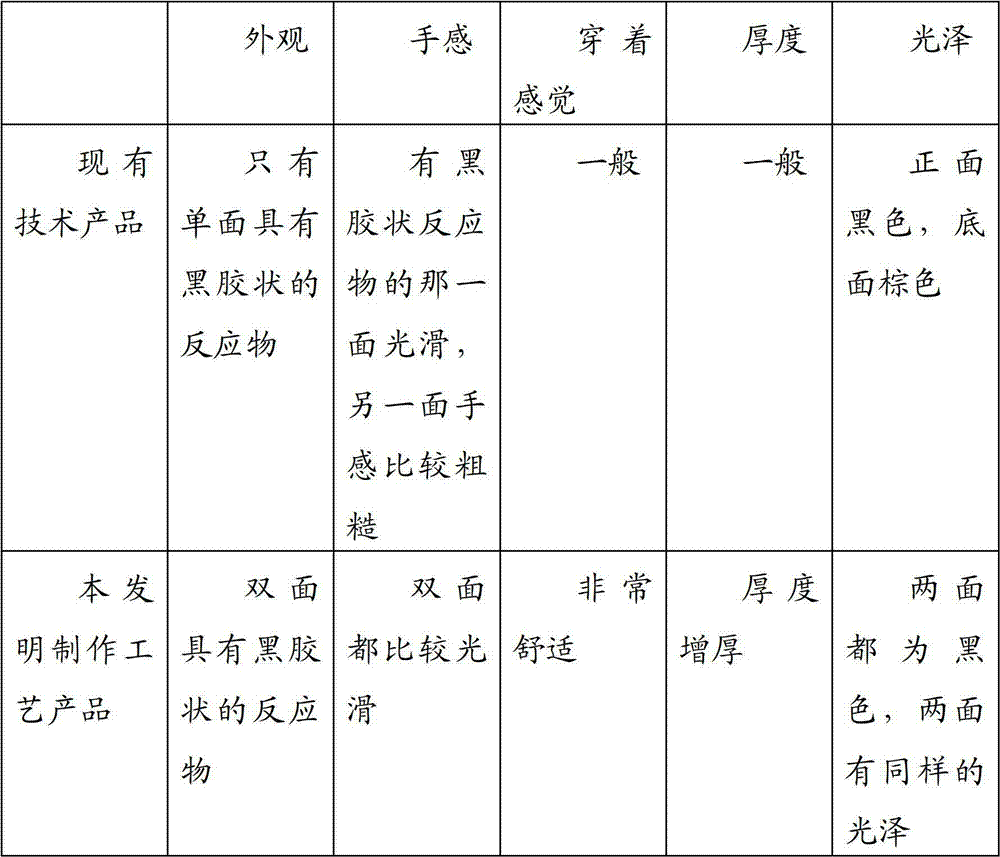

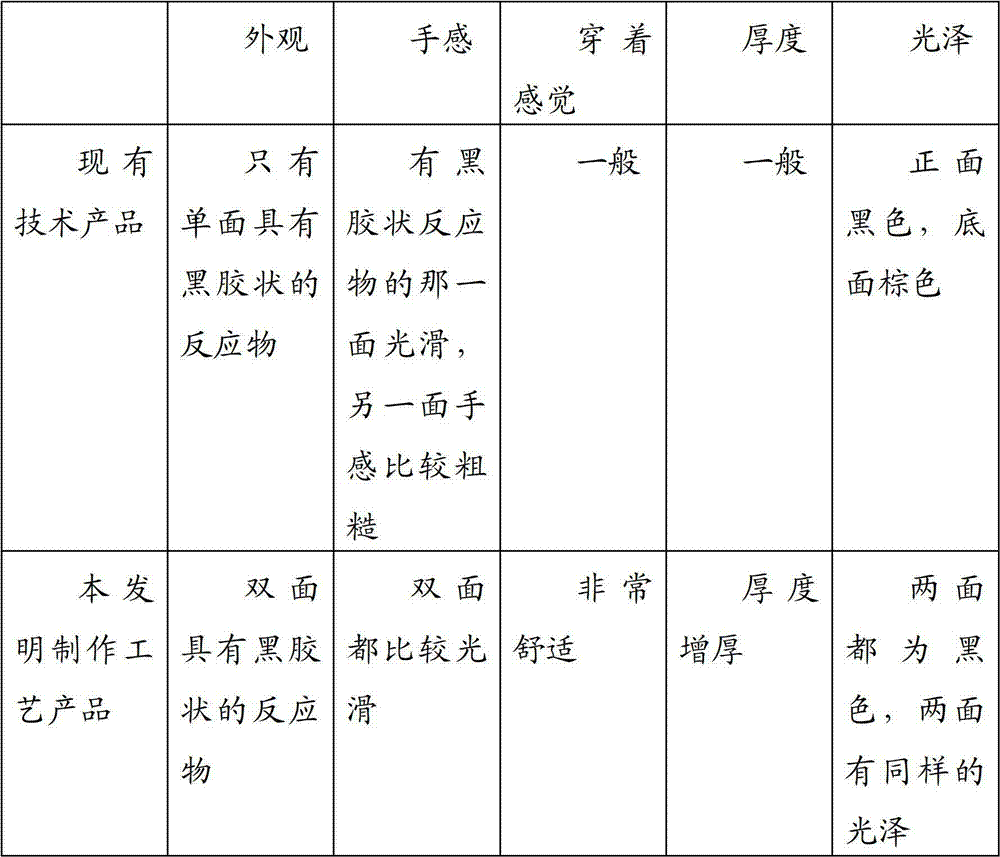

Process for producing double-sided gambiered Guangdong silk

ActiveCN102733182ASame inner and outer fabricConsistent appearanceDyeing processAnimal fibresState of artChemistry

The invention discloses a process for producing double-sided gambiered Guangdong silk, which comprises the following steps: (1) preparing greige; (2) preparing Chinese pennisetum water; (3) stamping the greige (soaking the greige in the Chinese pennisetum water for the first time); (4) sprinkling the Chinese pennisetum water on the greige; (5) soaking the greige in the Chinese pennisetum water; (6) soaking and drying the greige in the sun; (7) boiling the greige; (9) removing mud; (10) soaking the greige in the Chinese pennisetum water which obtained by filtering for the second time and drying the greige in the sun; (11) soaking and drying the back surface of the greige in the sun; (12) spreading mud on the back surface of the greige; and (13) soaking the back surface of the greige in the Chinese pennisetum water which obtained by filtering for the second time and drying the back surface of the greige in the sun. Two surfaces of the product produced by adopting the process are provided with black jellied ferrous tannate, the front surface and the back surface have the same qualities, internal and external cloth qualities are same, and appearances of two surfaces are consistent. Compared with the prior art, the product produced by adopting the process has a smooth back surface so that the product is conformable to wear. The product is thick and has good handfeel. In addition, two surfaces of the product have shiny gloss and the characteristics of the gambiered Guangdong silk.

Owner:佛山市顺德区顺熙贸易有限公司

Composite battery separator

ActiveUS20120270110A1Increase resistanceDifficult and costly to produceCell seperators/membranes/diaphragms/spacersAcid electrolytesPorosityPolyolefin

A microporous silica-filled polyolefin separator (80) has a material composition that includes a fraction of cured rubber powder exhibiting low or no porosity. The cured rubber powder is a material derived from one or both of passenger and truck tires. The cured rubber powders exhibit the properties of increasing hydrogen evolution overpotential on the negative lead electrode and of decreasing the effect of antimony deposited on the negative electrode of the lead-acid battery. Incorporation of these cured rubber powders into the formulation of a microporous silica-filled polyethylene separator results in improved electrochemical properties in deep-cycle lead-acid batteries.

Owner:AMTEK RES INT

Method for preparing black tea drink

InactiveCN101589746AConsistent tasteMellow tastePre-extraction tea treatmentTea extractionBlack teaDigestion

The invention provides a method for preparing a tea drink, and particularly relates to a method for preparing a black tea drink. The method is characterized in that: the method adopts the drink preparing steps of preparation of original tea, washing of original tea, taste burning, baking, warm soaking, low-fire cooking, steaming, cooling, stirring, filtering, temperature adjusting, filtering, degassing, sterilization, re-cooling, refiltering, heating and canning, quality inspection and the like; by the method, the original healthcare functions of degreasing, reducing fat, aiding digestion and benefiting intestines and stomach of the black tea are maintained, and no chemical additive is added; moreover, the black tea drink prepared by the method is red-yellow, has concentrated fragrance and tastes fresh and good, and the method provides a black tea original juice drink conveniently drunk by people.

Owner:ANHUA GOAM ERXI TEA DEV

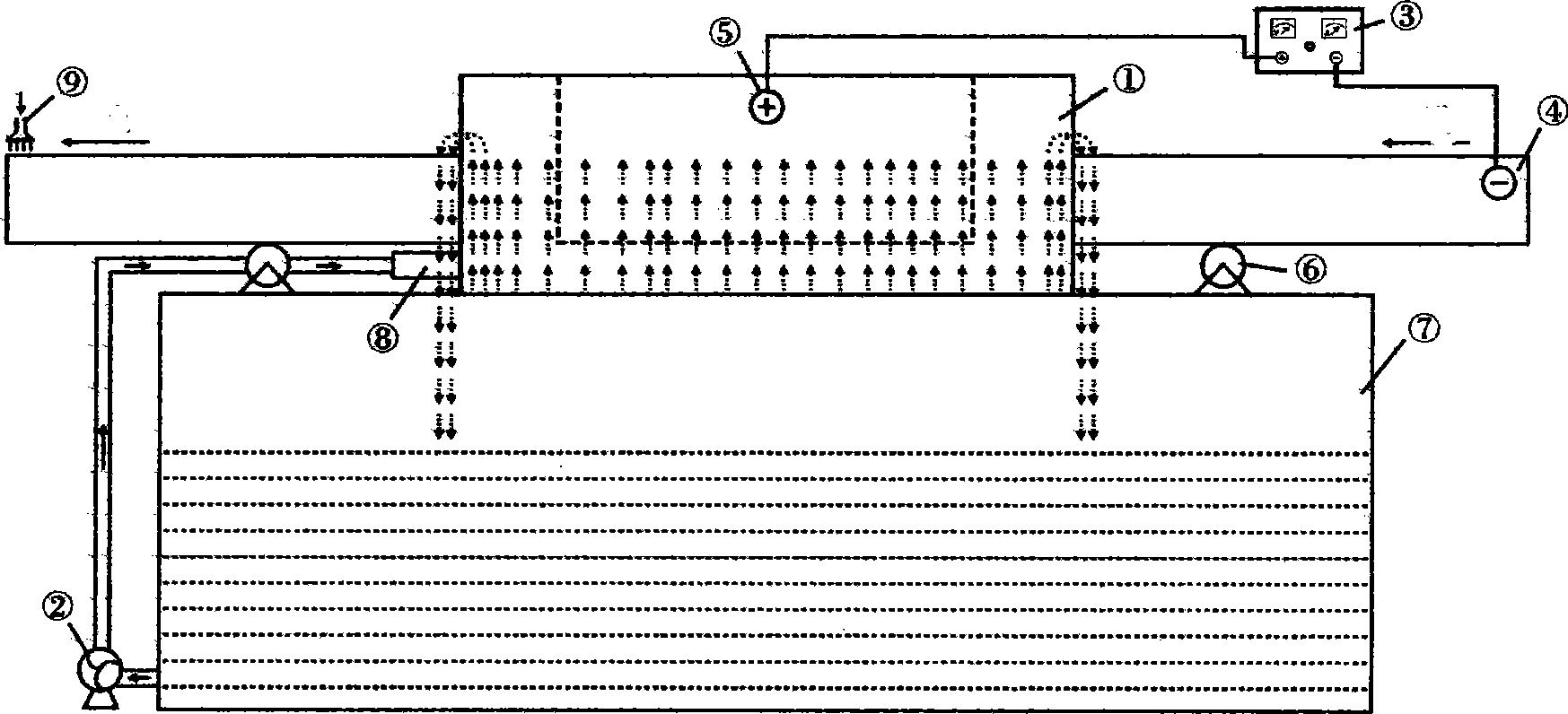

Long copper row continuous moving jet tin plating method and device

The process of shifting long copper bar continuously and tin plating with jet flow includes passing the long copper bar through a miniature electroplating bath, and jetting plating solution to the copper bar in high speed upwards with jetting pipes for electroplating the four surfaces of the copper bar in continuous moving. The process has high homogeneity of plating solution and great allowed current density. The present invention has the advantages of low investment, simple operation, capacity of realizing complete plating and local plating, high plating quality, etc.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

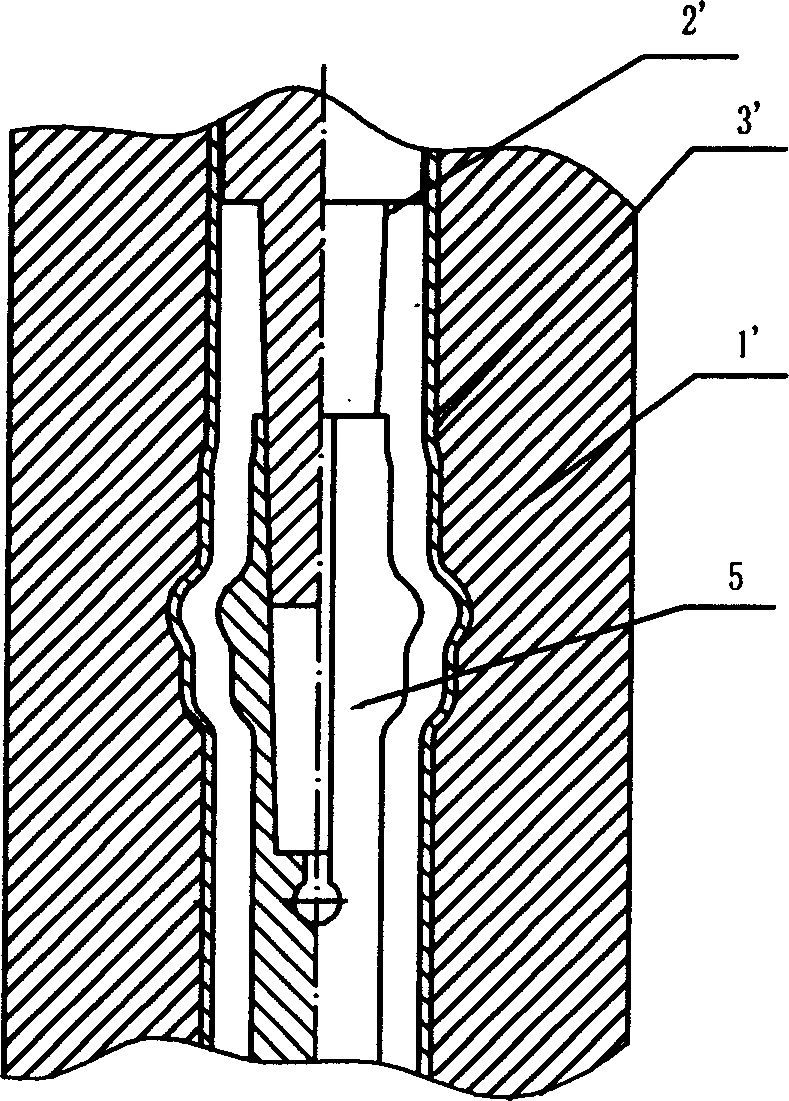

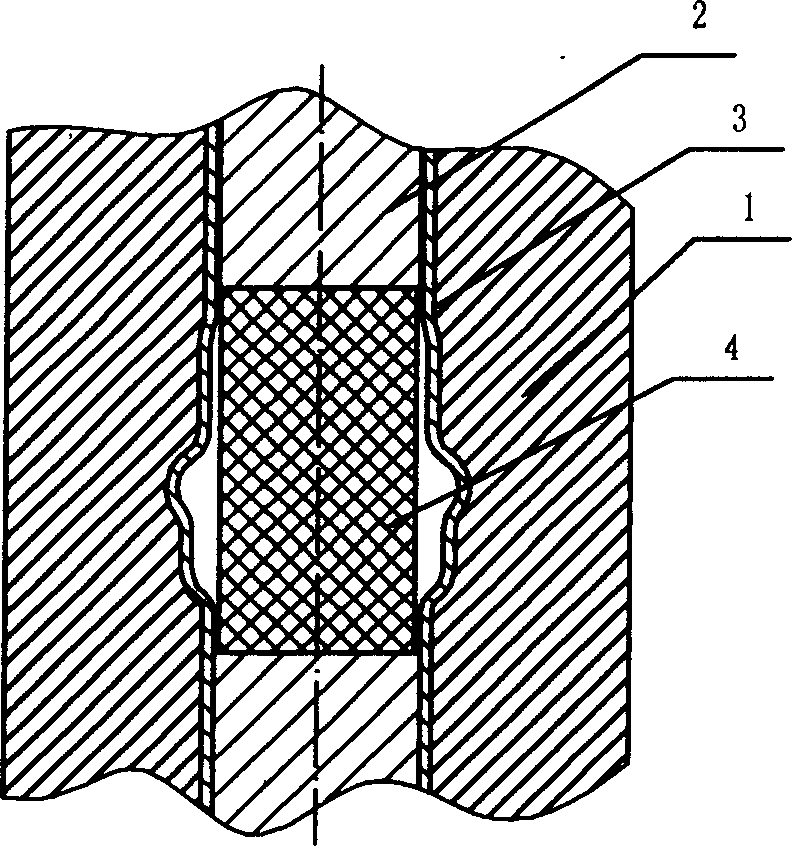

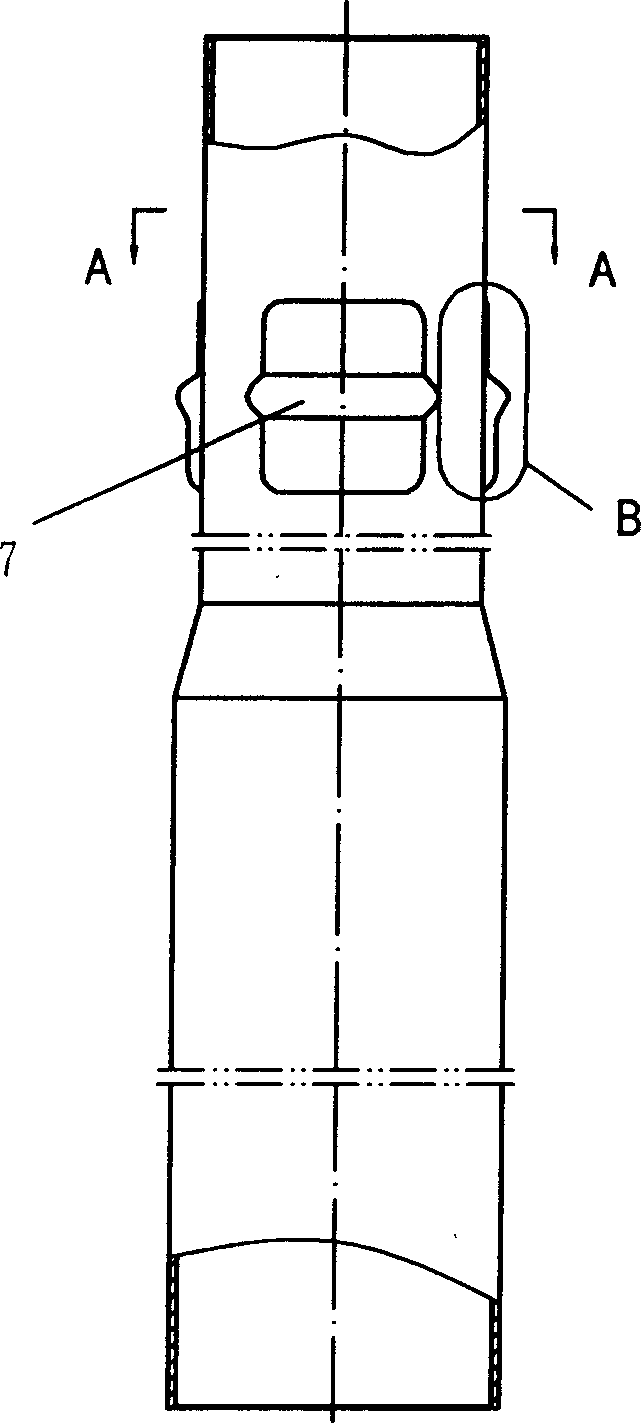

Three-boss flexible expanding die of vibration damper liquid-storage cylinder and expanding process

The invention discloses a three protruding platform bulge mould for processing the liquid tube of shock-reducer. The bulge mould includes a bulge die and a upper press die. The shape of bulge model cavity is matching with the shape of the three-projection-platform on the liquid storage tube. The characteristic is that there is bugle soft die in the bulge shape cavity and the bugle soft die is under the upper pressing die and it is made up of flexible material. The process of bulging shape is: put preparative workpiece straight into bulge die cavity, and put the soft die into the workpiece and then tighten the bulge die; The upper press soft die extrudes the workpiece to make workpiece full of bugle die and the workpoece is deformed along shape of bulge die. The invention has the characteristic of reasonable design, reduced production cost, advanced eligibility of product, simple process of machining, short machining cycle.

Owner:杭州福鼎交通器材有限公司

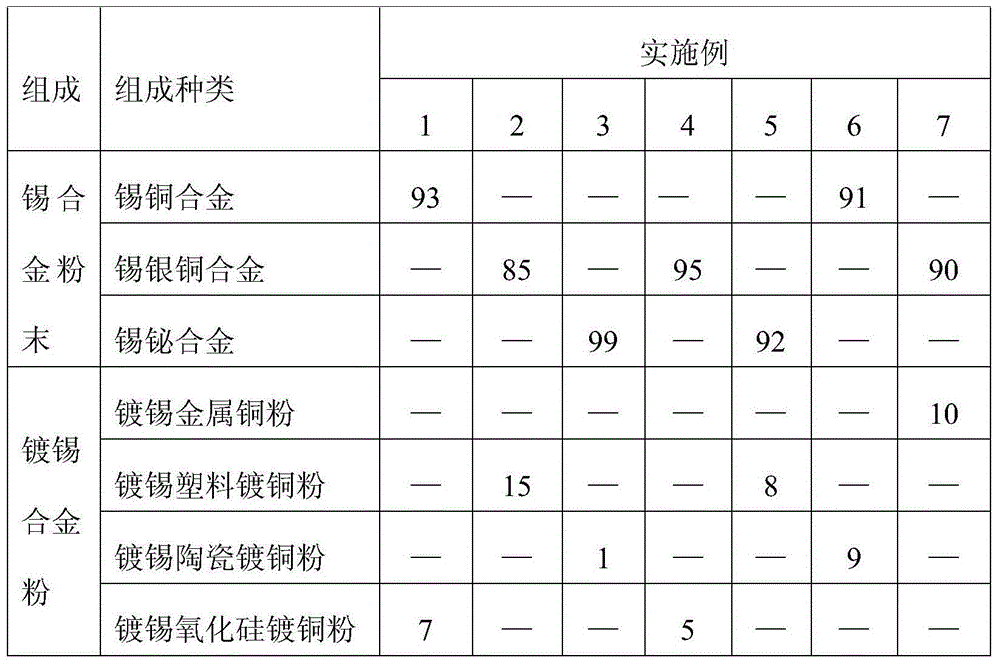

Solder powder doped with tin-plated alloyed powder and soldering paste containing solder powder

ActiveCN104785949ASolder paste soldering effect is excellentLow costLiquid/solution decomposition chemical coatingWelding/cutting media/materialsTinningCopper plating

The invention discloses solder powder doped with tin-plated alloyed powder and soldering paste containing the solder powder. The tin-plated alloy powder is obtained by plating surfaces of metal copper powder, plastic copper-plated powder, ceramic copper-plated powder and silicon oxide copper-plated powder with tin, the tin-plated alloyed powder is mixed with tin alloy powder frequently seen and sold on the present market to form the solder powder to be used in the soldering paste, the wettability between the tin-plated alloyed powder and the tin alloy powder is high, the bonding force is large, the appearance is constant after welding, it is avoided that small tin balls appear on welded points obtained after welding or left outside a welding disc, the tin soldering effect of the soldering paste containing the solder powder is superior to that of tin soldering powder sold on the market, the soldering paste can be used for assembling of PCB electronic components and the reflow soldering process of other metal elements, and the cost of the soldering paste can be greatly reduced.

Owner:昆山成利焊锡制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com