Patents

Literature

133results about "Dough strip twisting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

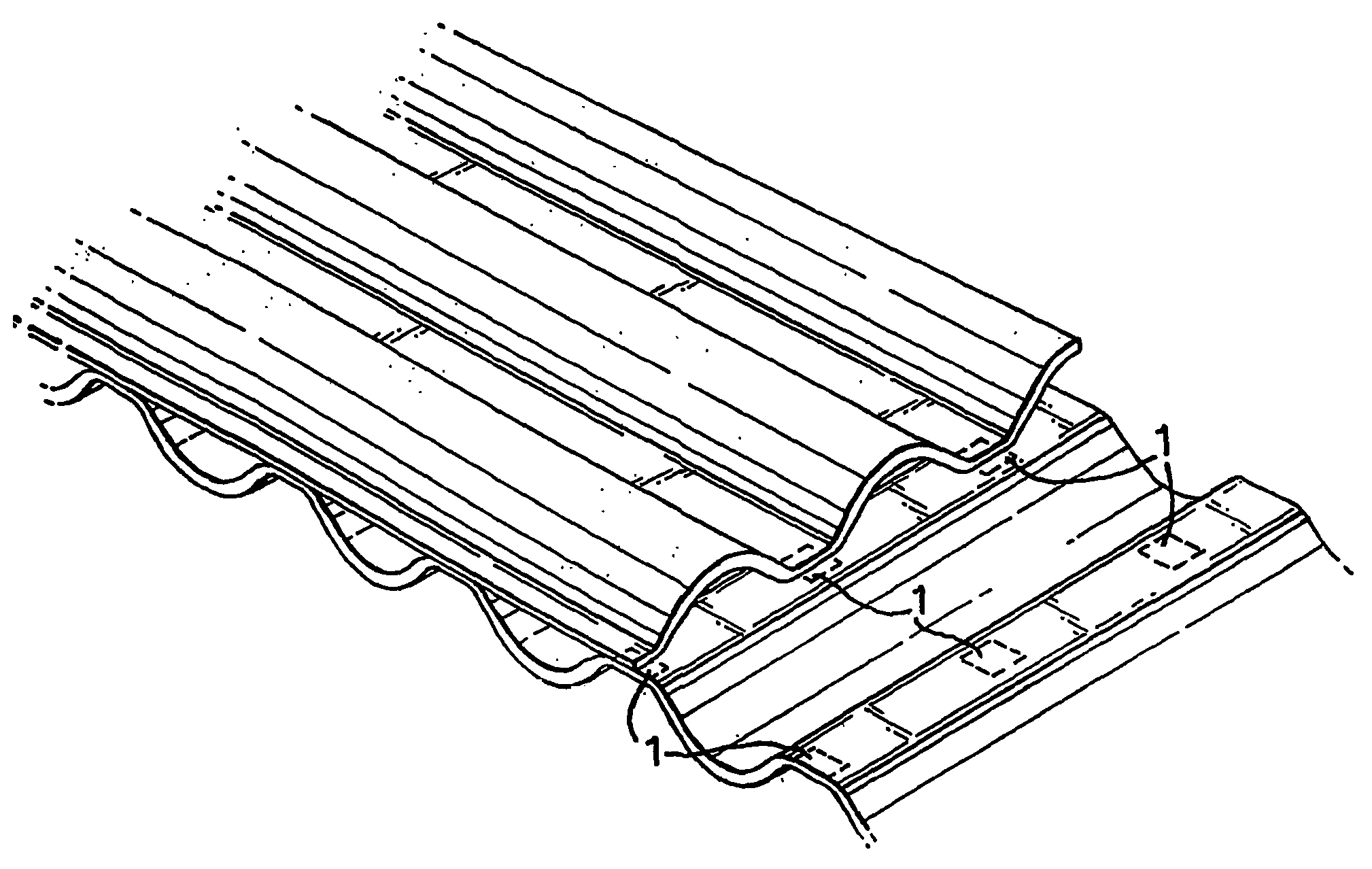

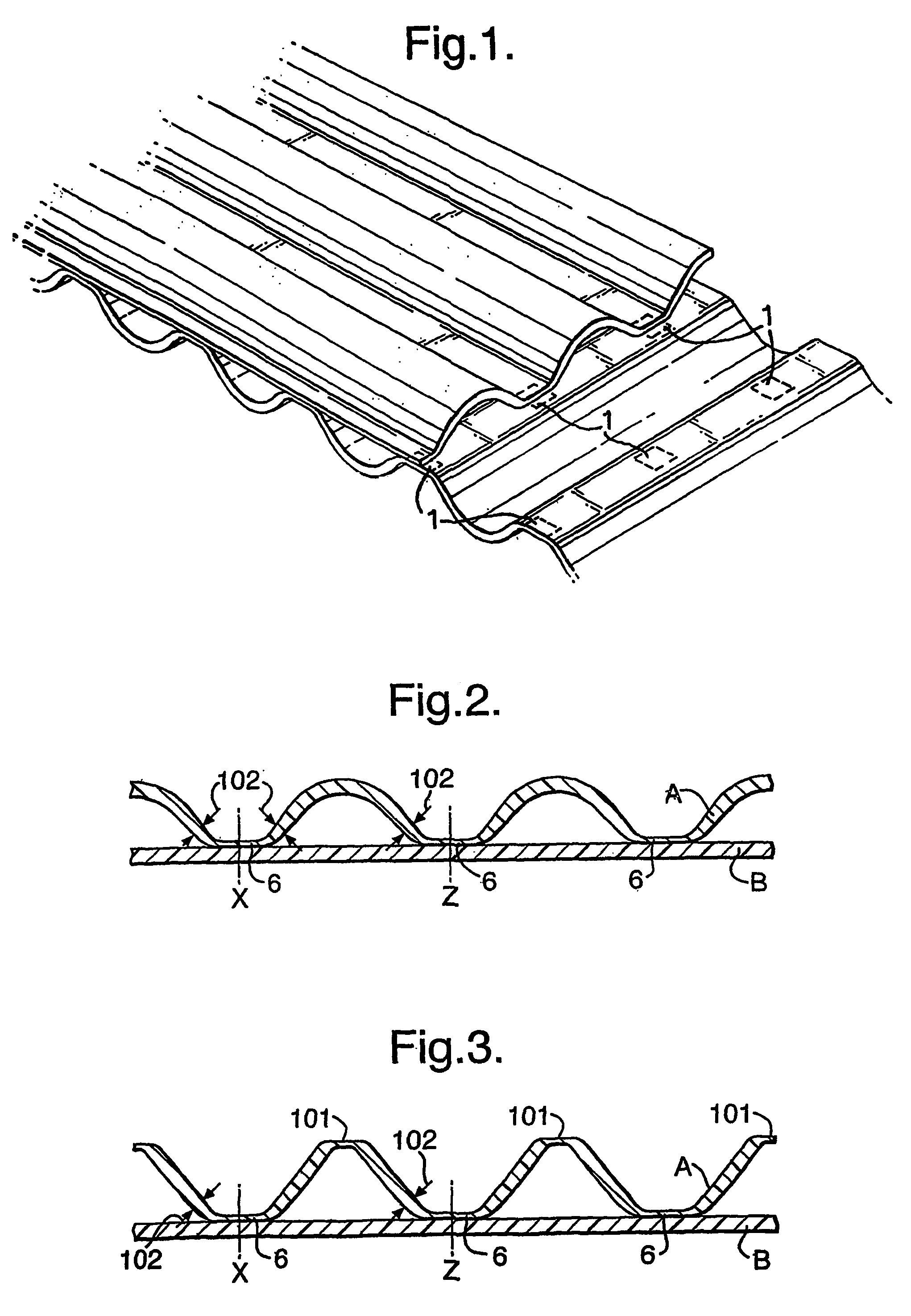

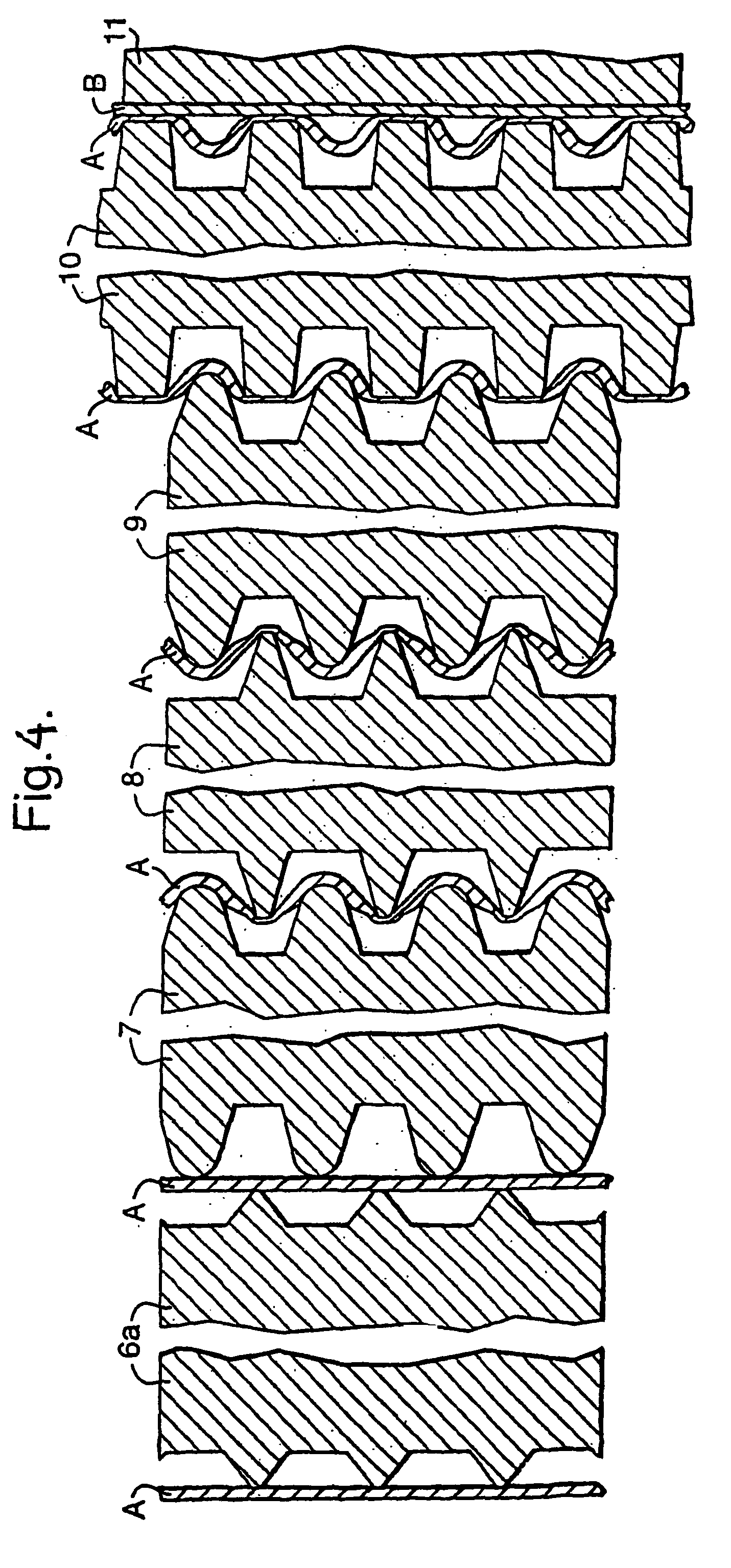

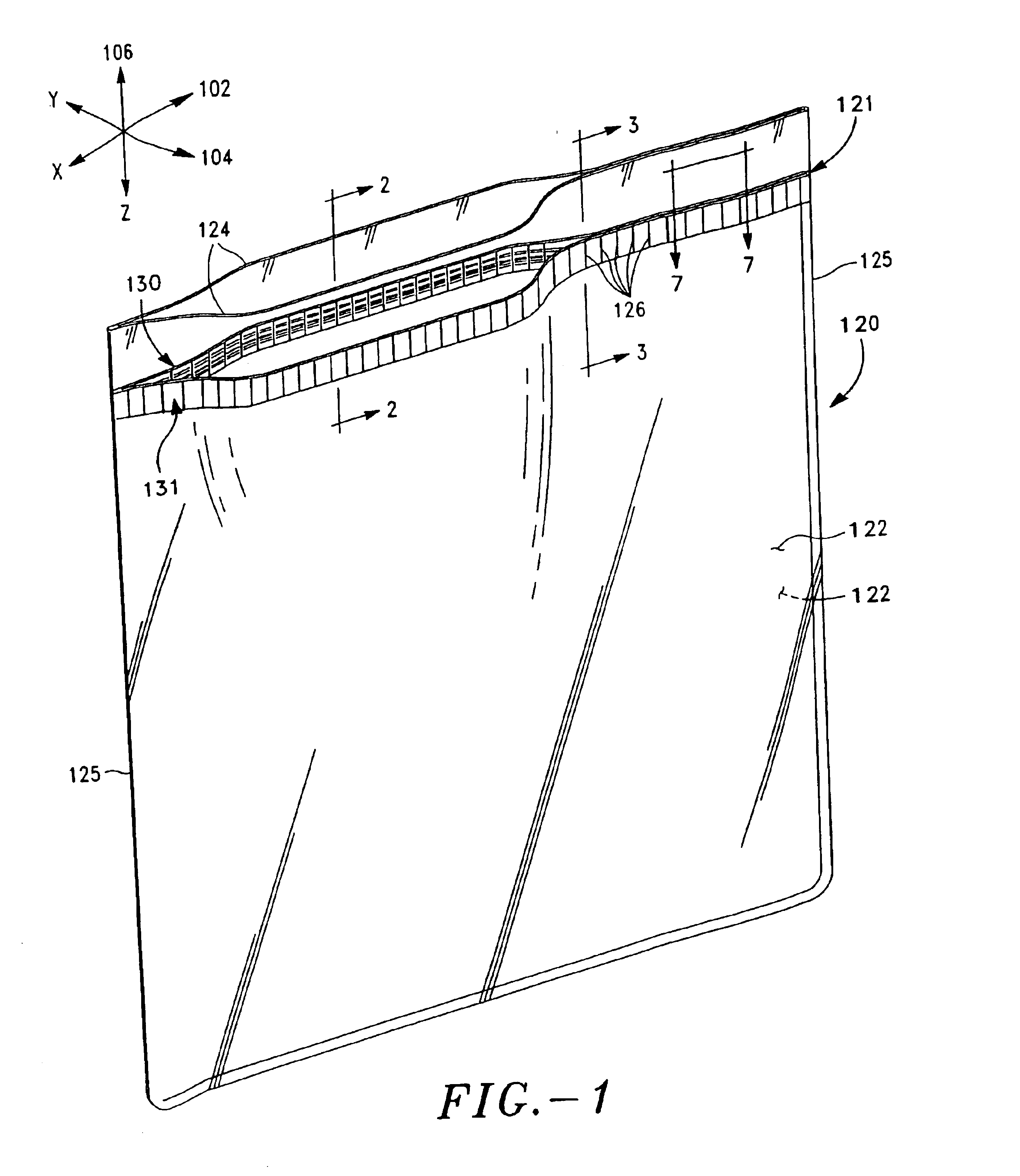

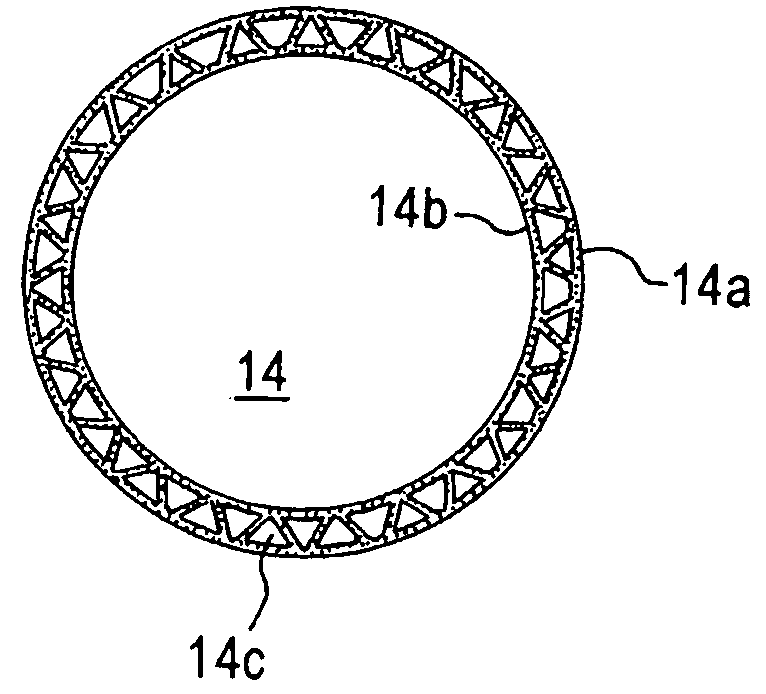

Laminates of films having improved resistance to bending in all directions and methods and apparatus for their manufacture

InactiveUS7901758B2Increase stiffnessEnhance resilienceMechanical working/deformationPersonal careFluteEngineering

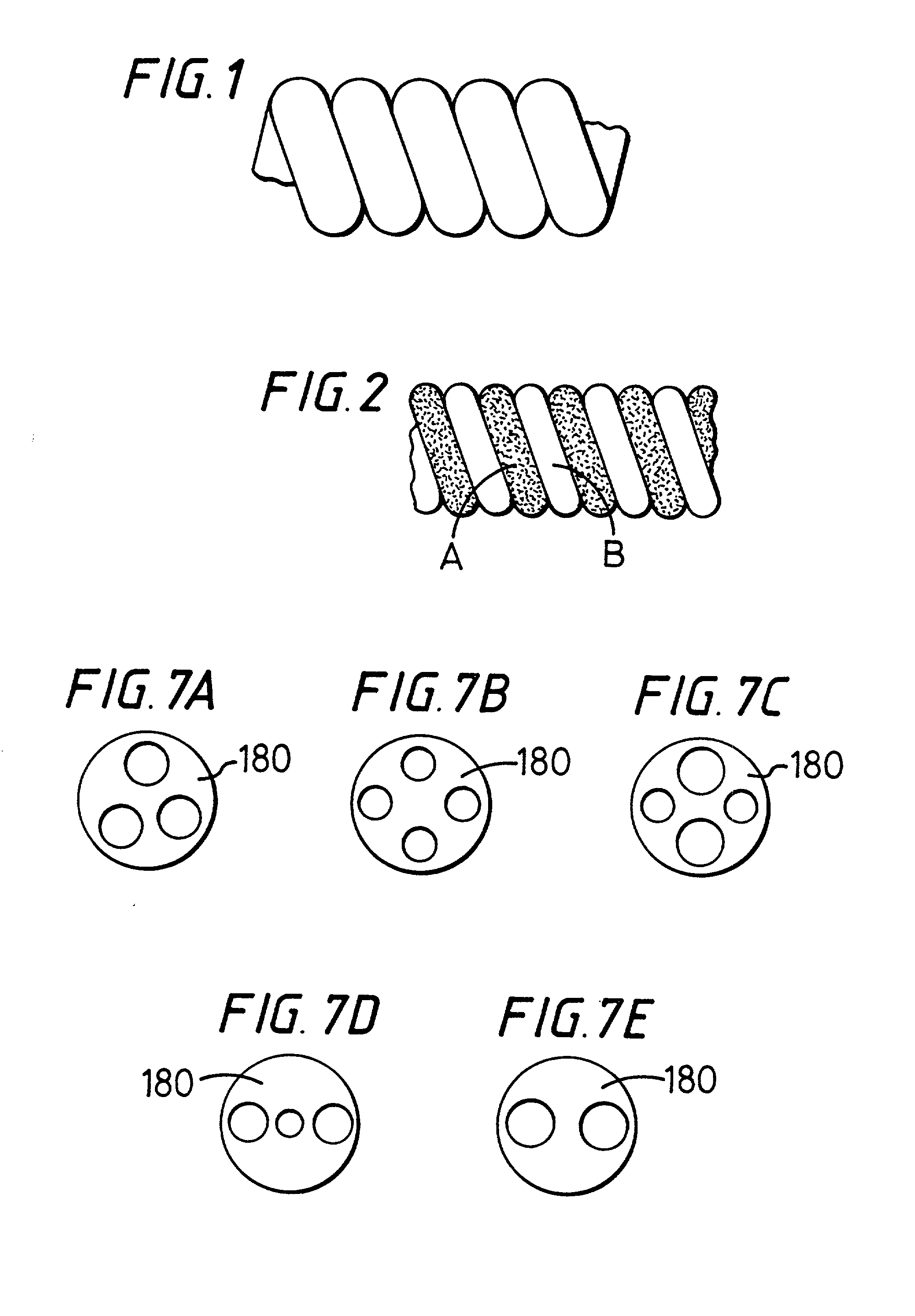

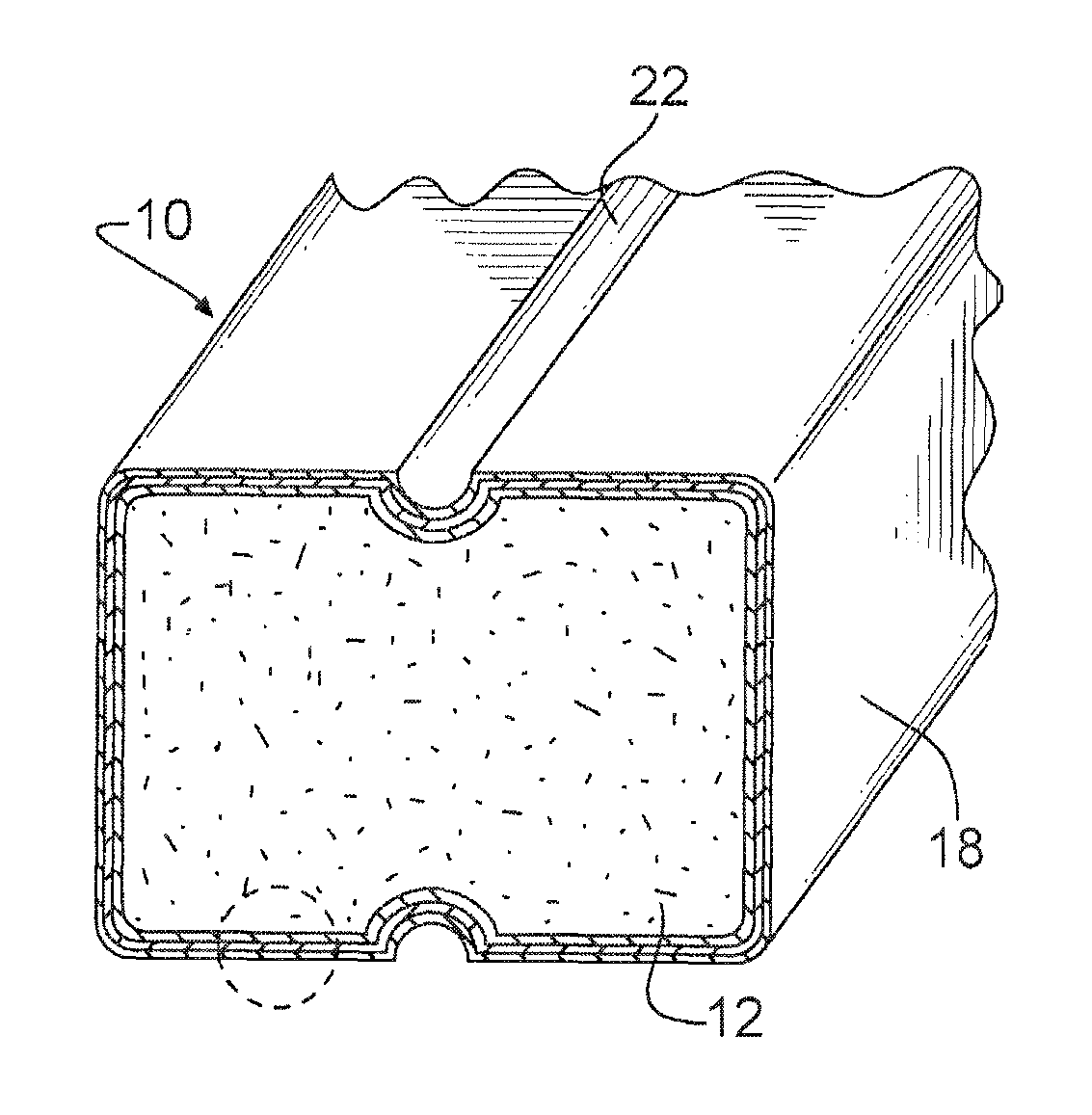

The present invention relates to a flexible laminate of films of thermoplastic polymer material mainly for applications in which relatively high yield strength and ultimate tensile strength is required, and a method and apparatus for its manufacture. The laminate comprises a monofilm formed or multifilm-formed ply (A) and another monofilm-formed or multifilm formed ply (B) both mainly consisting of orientable thermoplastic polymer material, in which A has a fluted configuration and B on a first side is adhesively bonded in bonding zones to the crests on a first side of A, in which B also has a fluted configuration, the flute direction of B forming an angle from generally about 30° up to and including 90° to the flute direction of A and the said bonding zones being on the crests of the first side of B to produce spot bonding with the crests on the first side of A, the wavelengths of the flutes in A and / or B are no longer than 5 mm, and the wavelengths of the flutes in both A and B are less than 10 mm.

Owner:RASMUSSEN OB

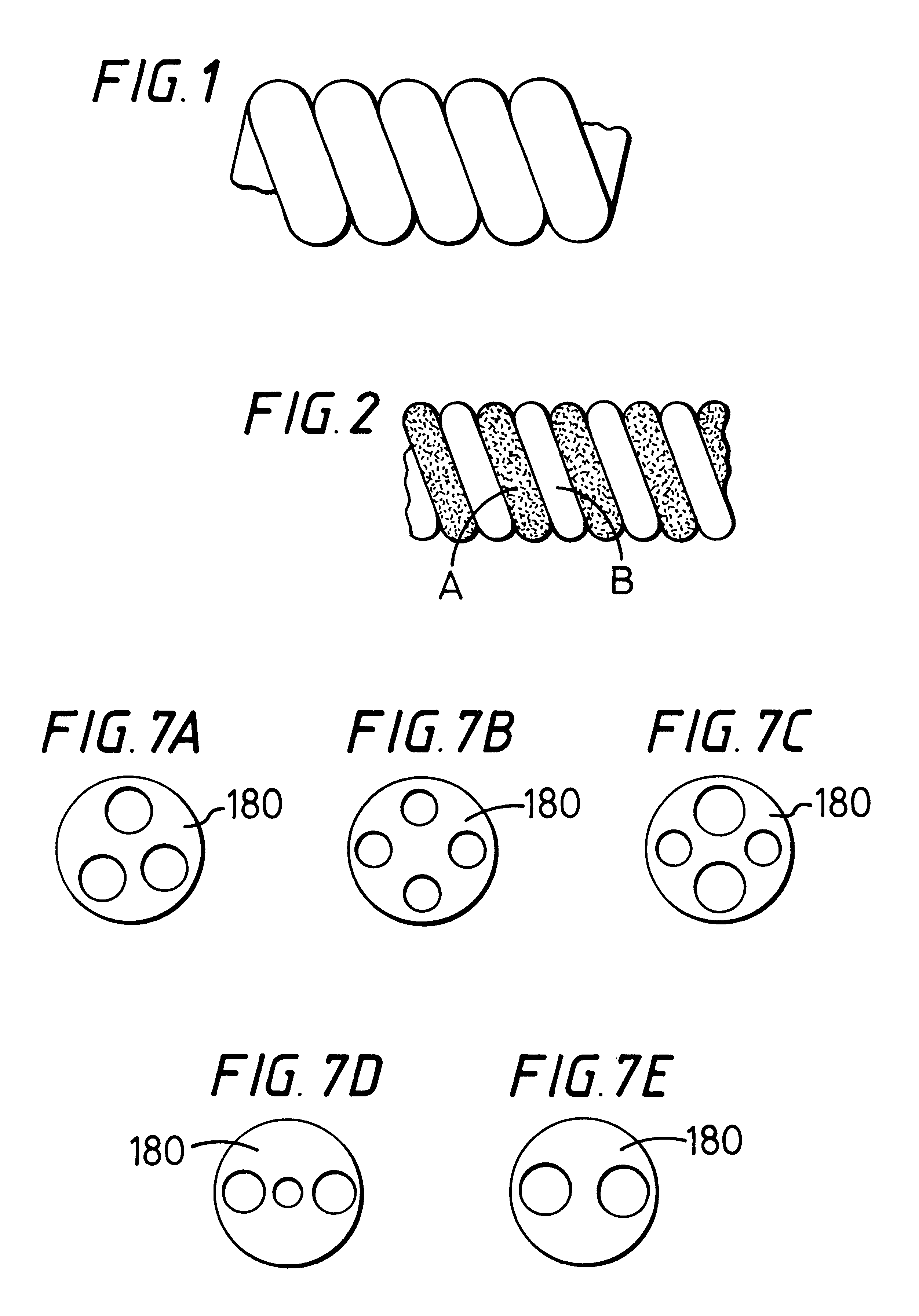

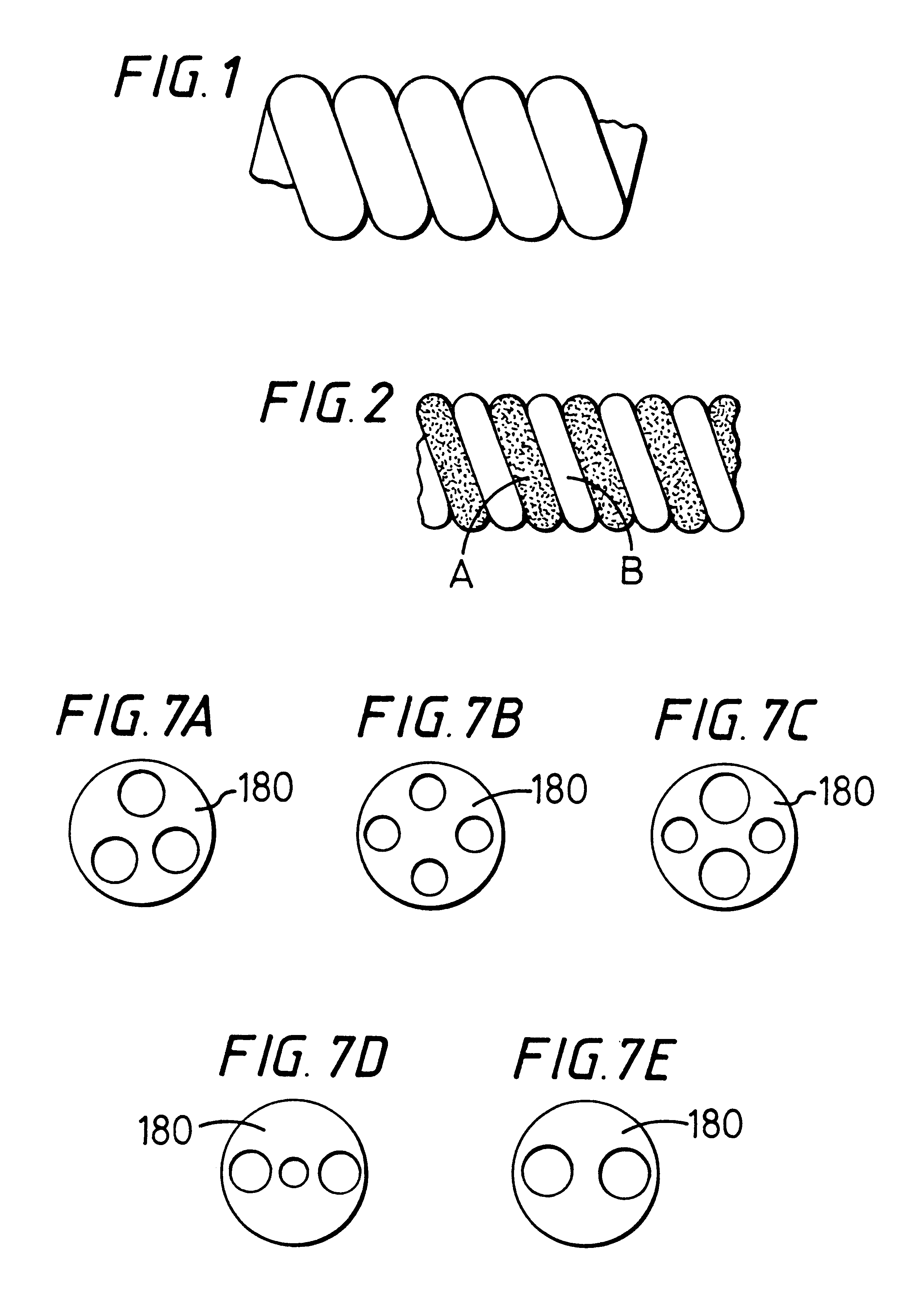

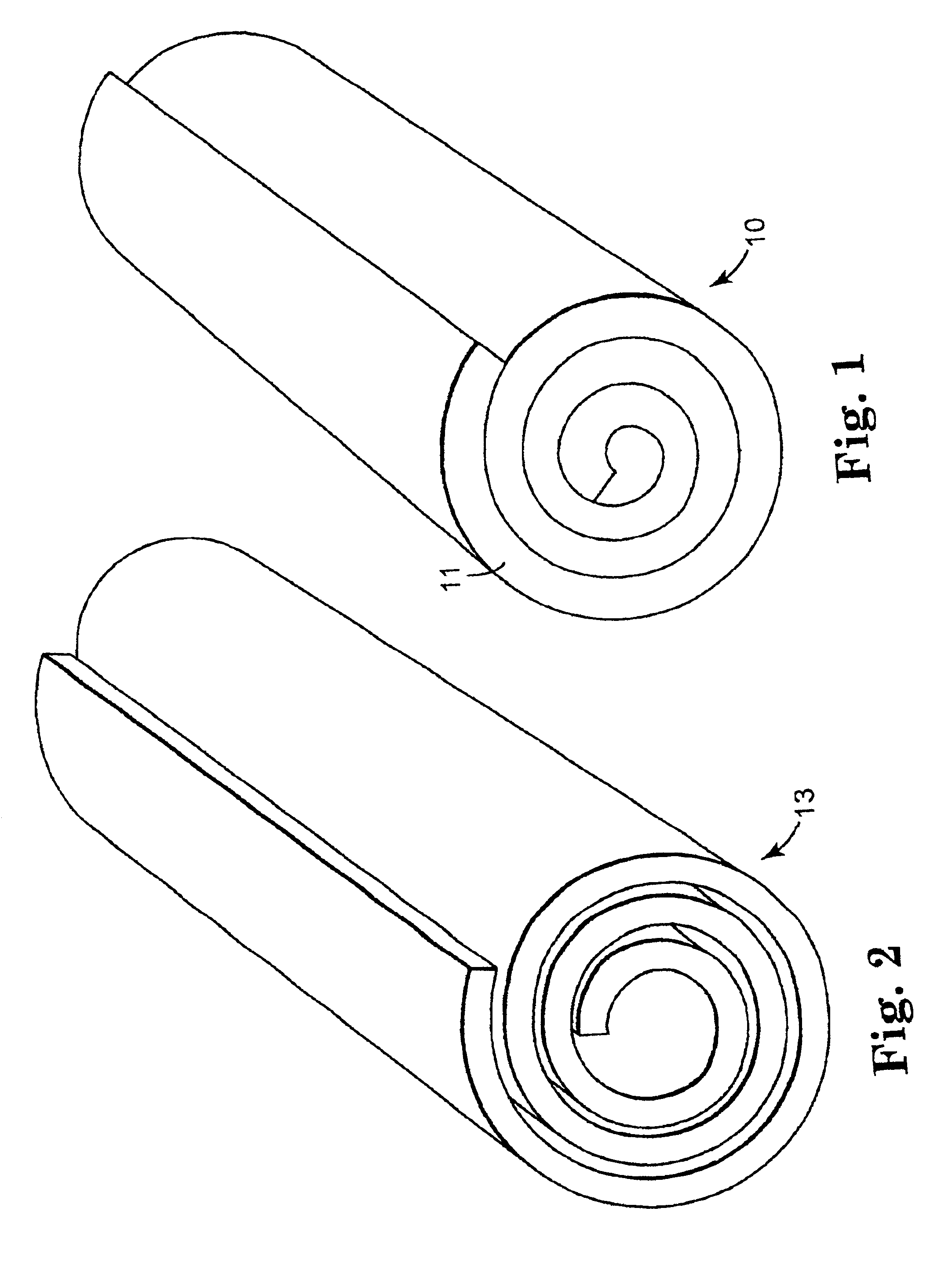

Helical food product

A food product comprising one or more plastic food substrates is formed into a helical configuration and coated with a fluid barrier agent to prevent reannealing of adjacent turns of the product. The fluid barrier agent may be an edible vegetable oil such, for example, as hydrogenated vegetable oil, Soya oil, rape oil, sunflower oil, safflower oil, peanut oil or a mixture of such oils. The product may define a single helix or a multiple helix, e.g. a double or triple helix.

Owner:BERNARD MATTHEWS FARMS

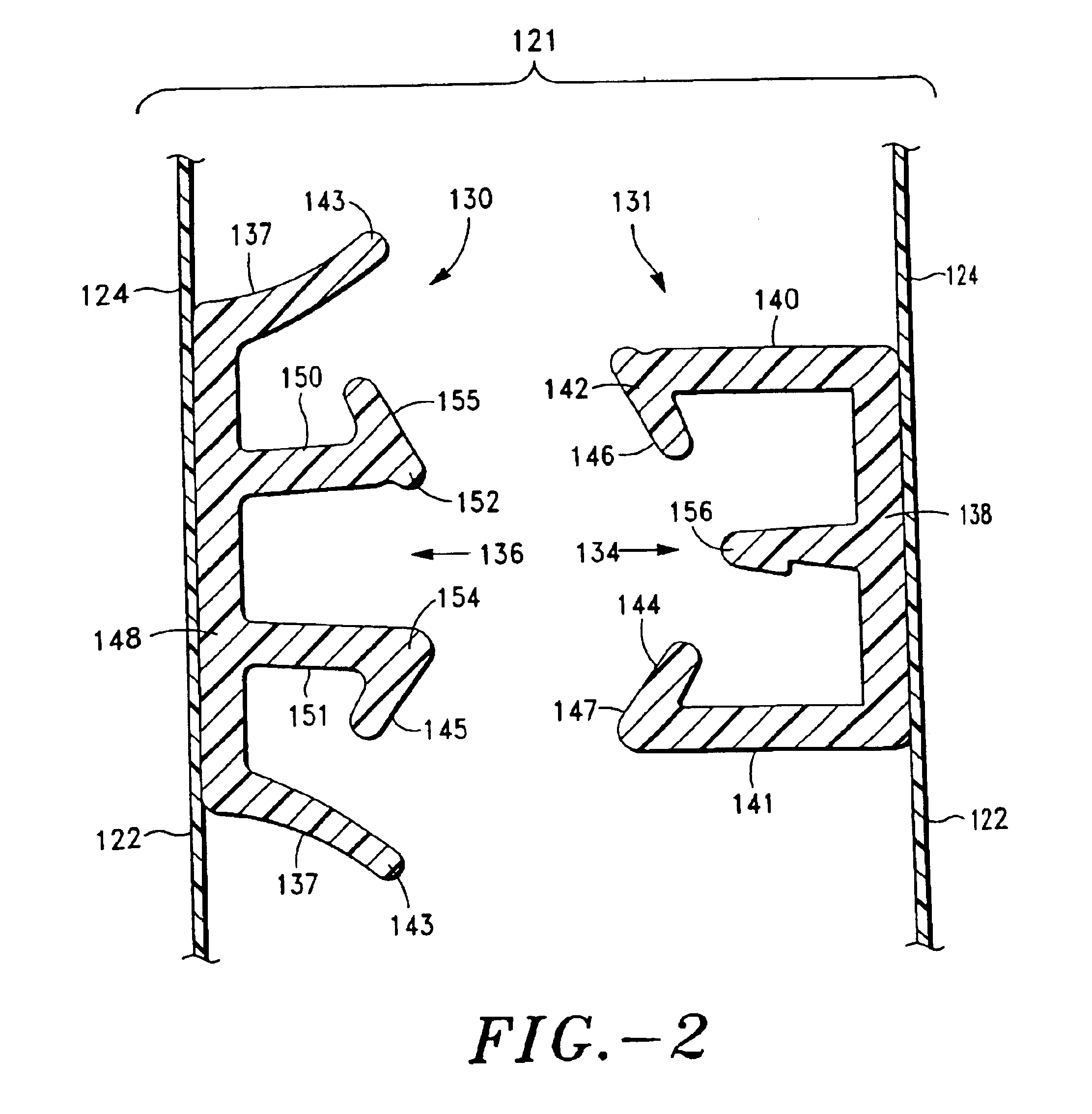

Interlocking closure device

InactiveUS6953542B2Improve leak-proof effectDesired audible and/or tactile effectsSnap fastenersMechanical working/deformationThermoplasticCold formed

A closure device for a thermoplastic bag which includes two opposing, longitudinally extending interlockable male and female fastening strips having respective male and female closure elements or profiles that are deformed to interdigitate and produce an audible clicking sound and or tactile effect that is perceptible to the touch as the closure device is opened and closed. Interdigitation of the two profiles is achieved by cold forming the profiles while interlocked. The shape of the cold form is a stepped deflection of both profiles so that their shapes are generally congruent. The stepped deflections provide a change in the occlusion and peel force of the interlocking closure device thereby resulting in an audible clicking or popping sound as the closure device is opened and closed and a tactile effect that is perceptible to the touch as the closure device is closed.

Owner:WATER KINETICS LTD

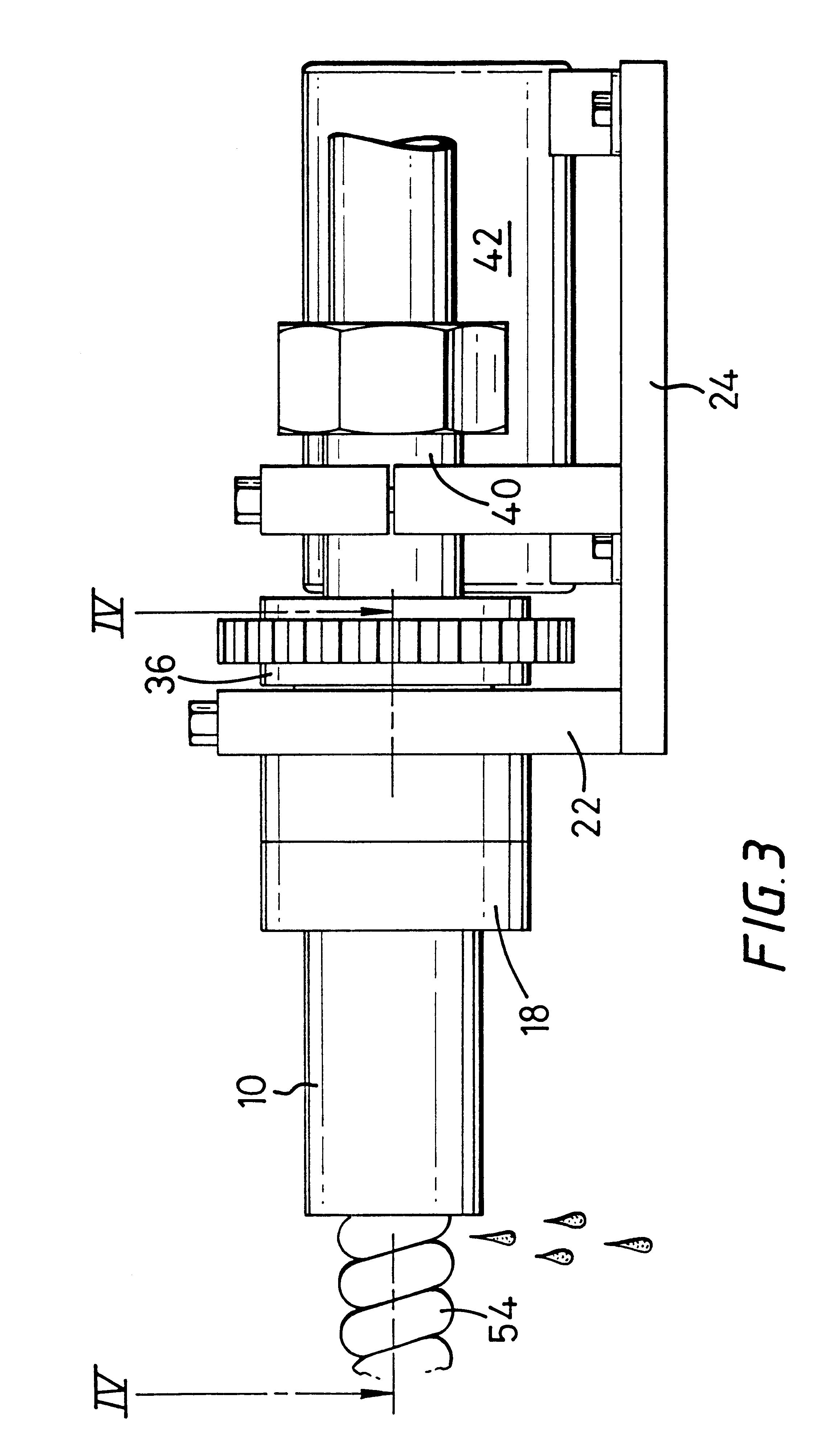

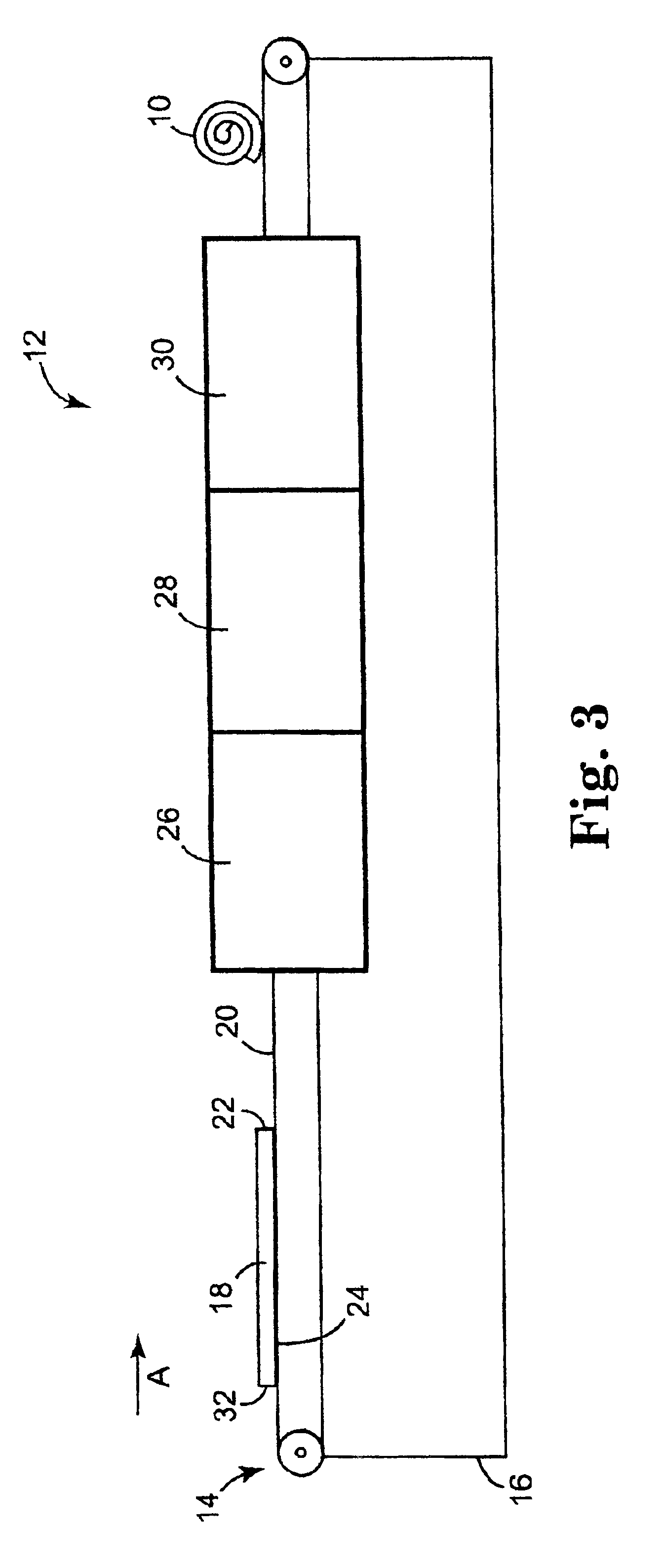

Method and apparatus for making an helical food product

Owner:BERNARD MATTHEWS FARMS

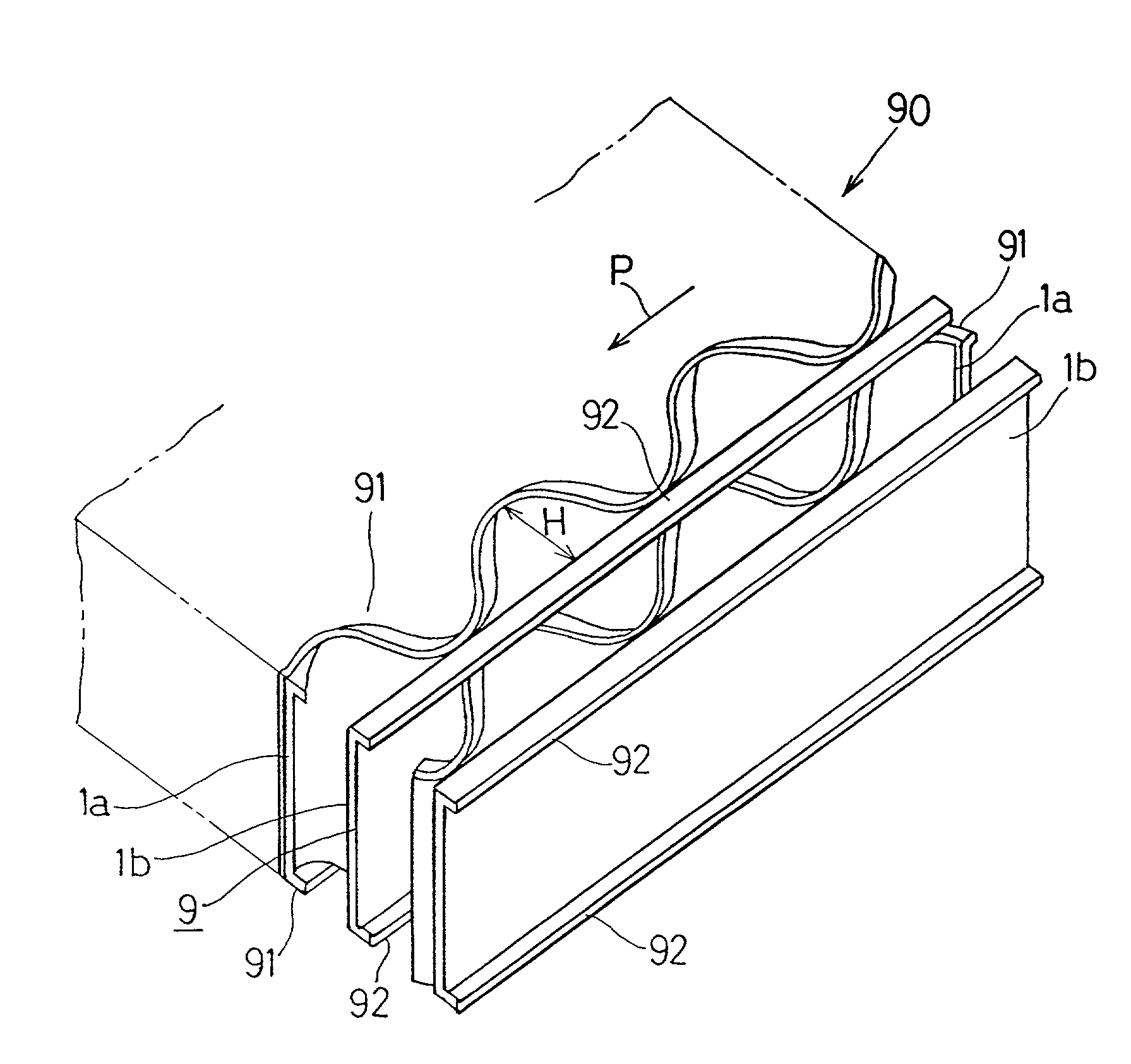

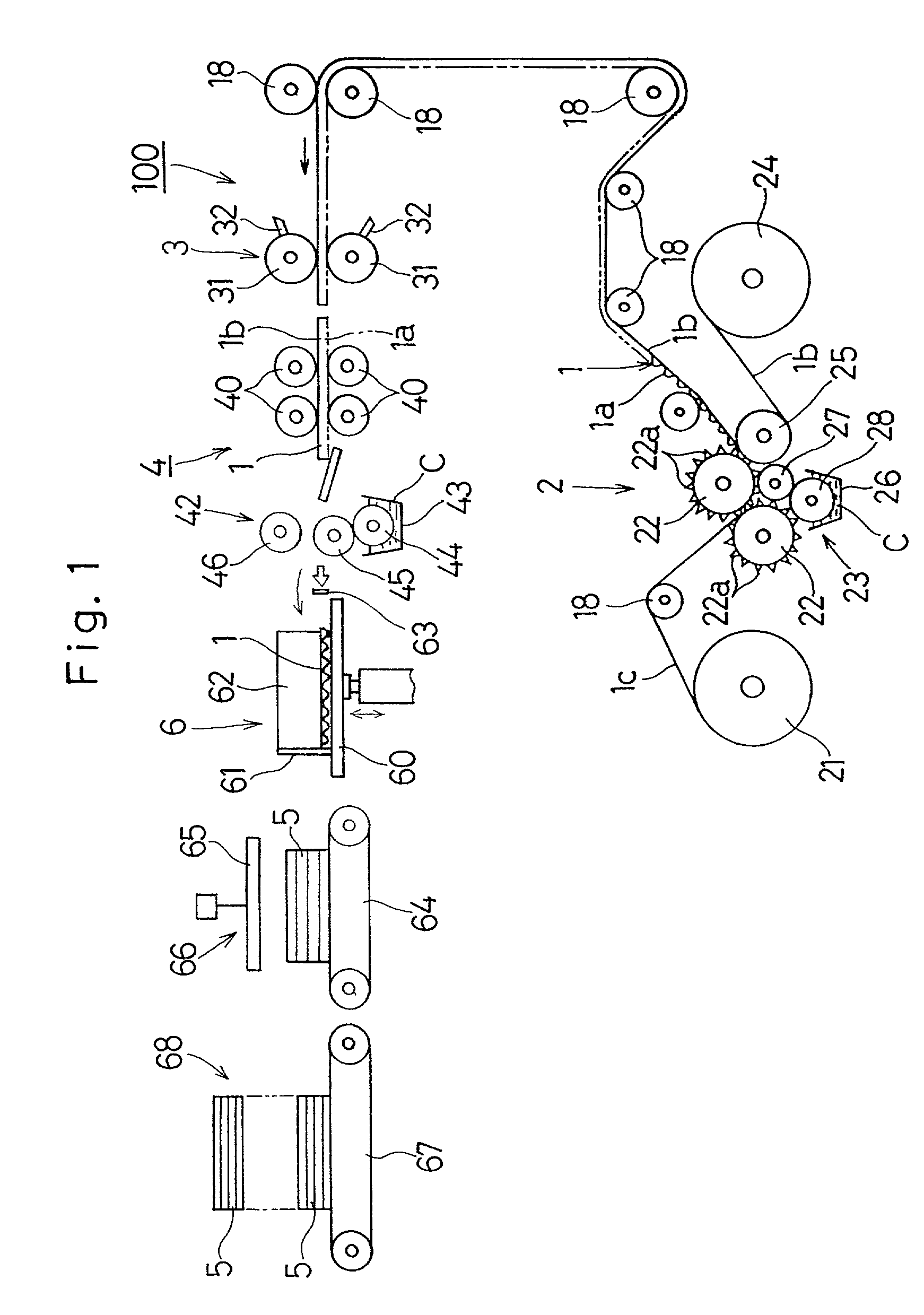

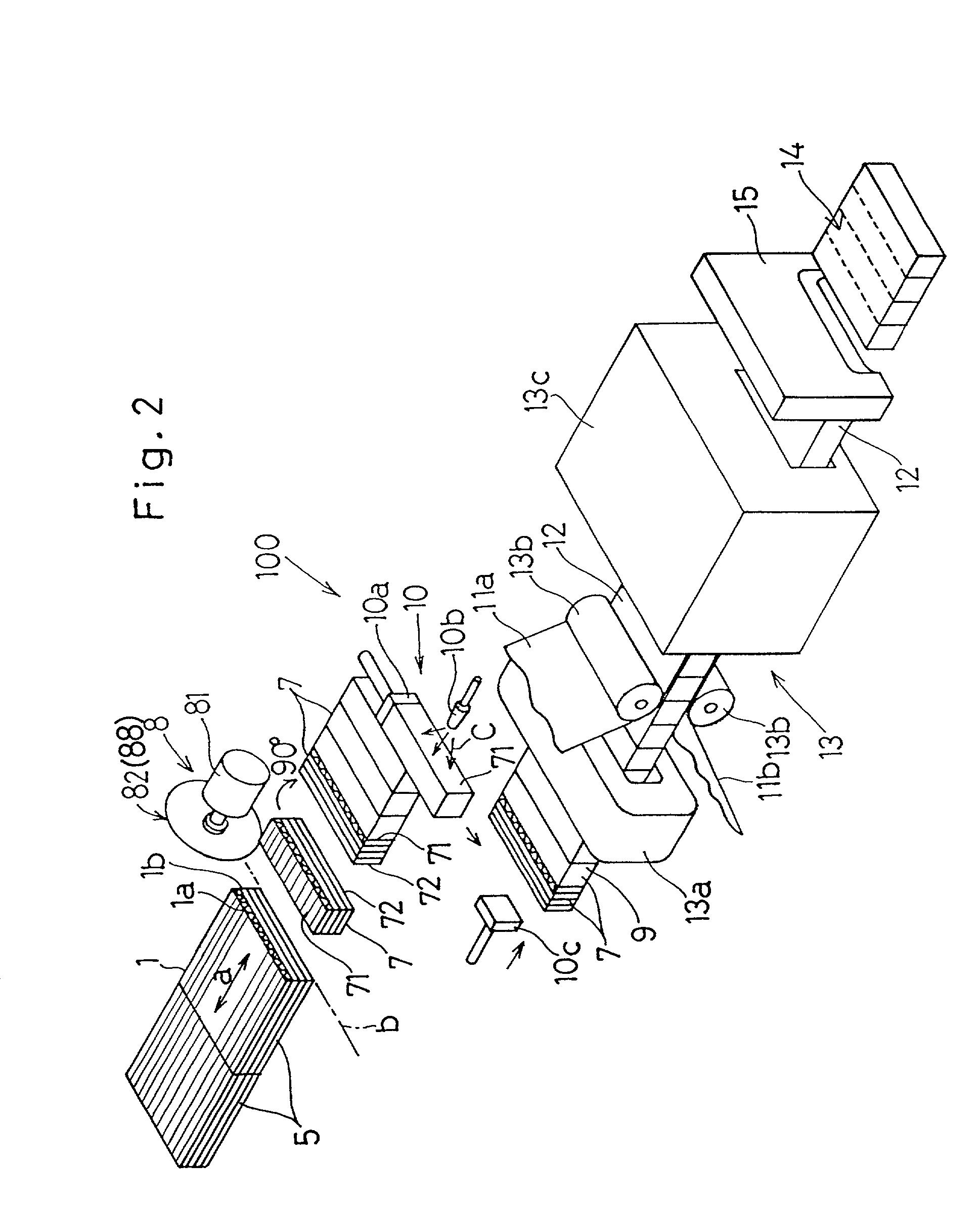

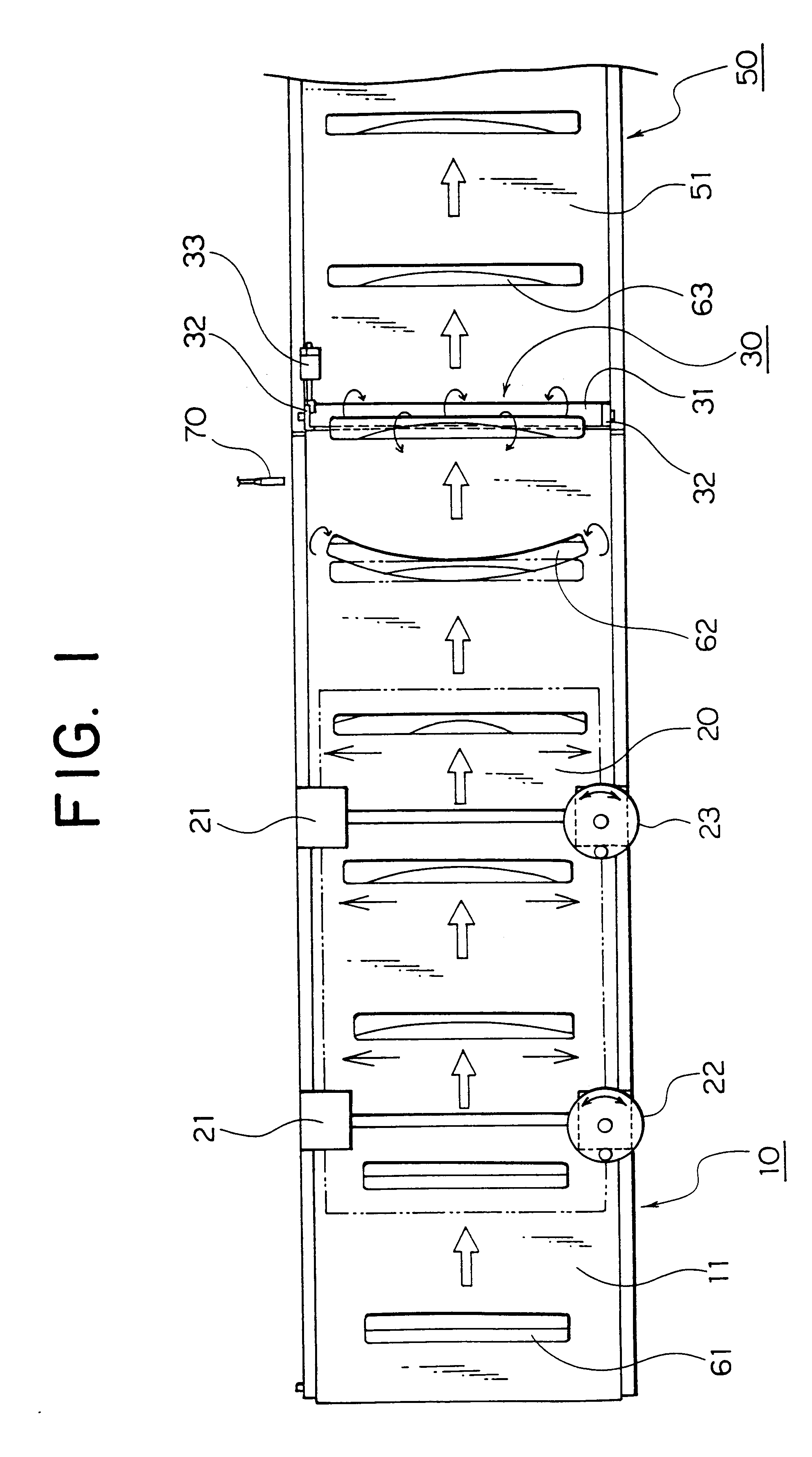

Corrugated cardboard plates, method of and apparatus for making the same

InactiveUS20020064629A1Low costExcellent heat and sound insulationMechanical working/deformationPaper/cardboard articlesCardboardEngineering

Corrugated cardboard plates are made by laminating and bonding corrugated cardboards 1, each including a corrugated sheet 1a and at least one liner sheet 1b bonded to the corrugated sheet 1a, to provide a corrugated cardboard laminate 5, which is in turn cut along a plurality of cutting lines b lying perpendicular to a direction parallel to ridge lines a of the corrugated sheet 1a to provide a plurality of corrugated blocks 7. The corrugated blocks 7 are then arrayed in a line to provide an elongated flat corrugated plank 9 in which the top face of one of the corrugated blocks 7 is bonded to the bottom face of the next adjoining corrugated block 7. At least one backing sheet 11a or 11b, made of paper, to one of opposite surfaces of the elongated flat corrugated plank 9 and is subsequently cut into a plurality of corrugated cardboard plates 14 of a predetermined size. In this way, the corrugated cardboard plates 14 or 90 can be obtained at a reduced cost, each of the plates 14 or 90 having an excellent heat insulation, a sound insulation and being lightweight and robust.

Owner:TAIZEN CO LTD

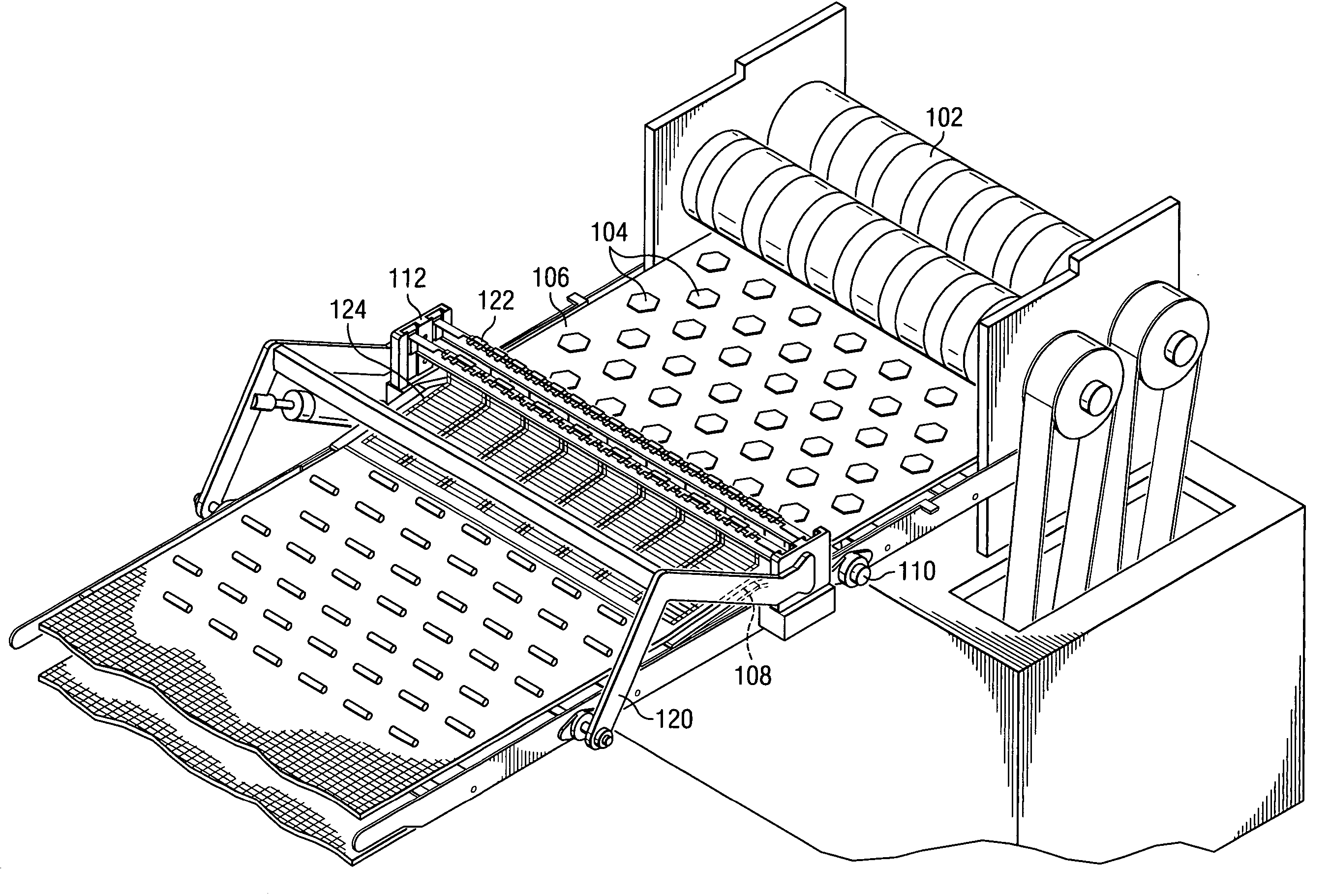

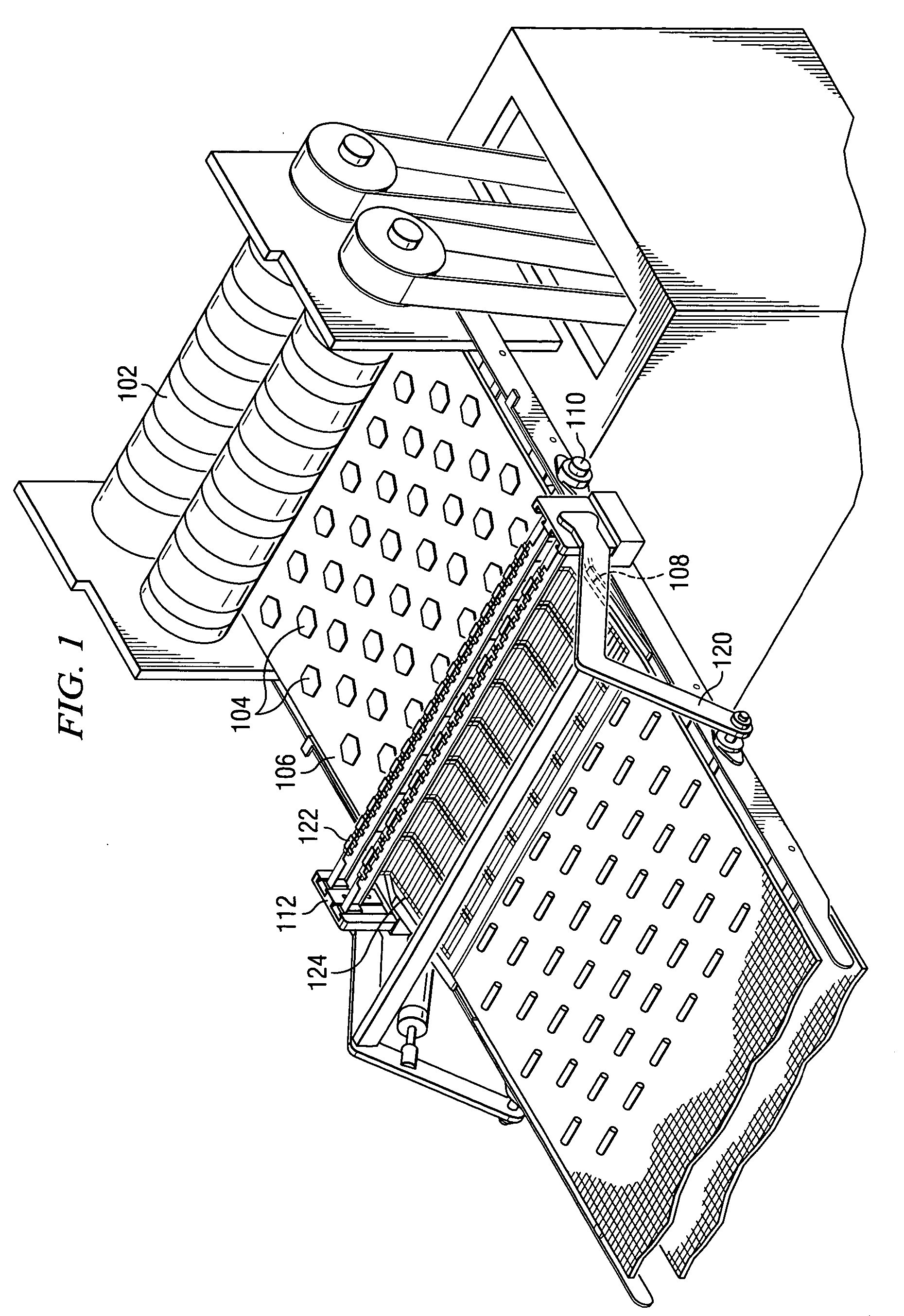

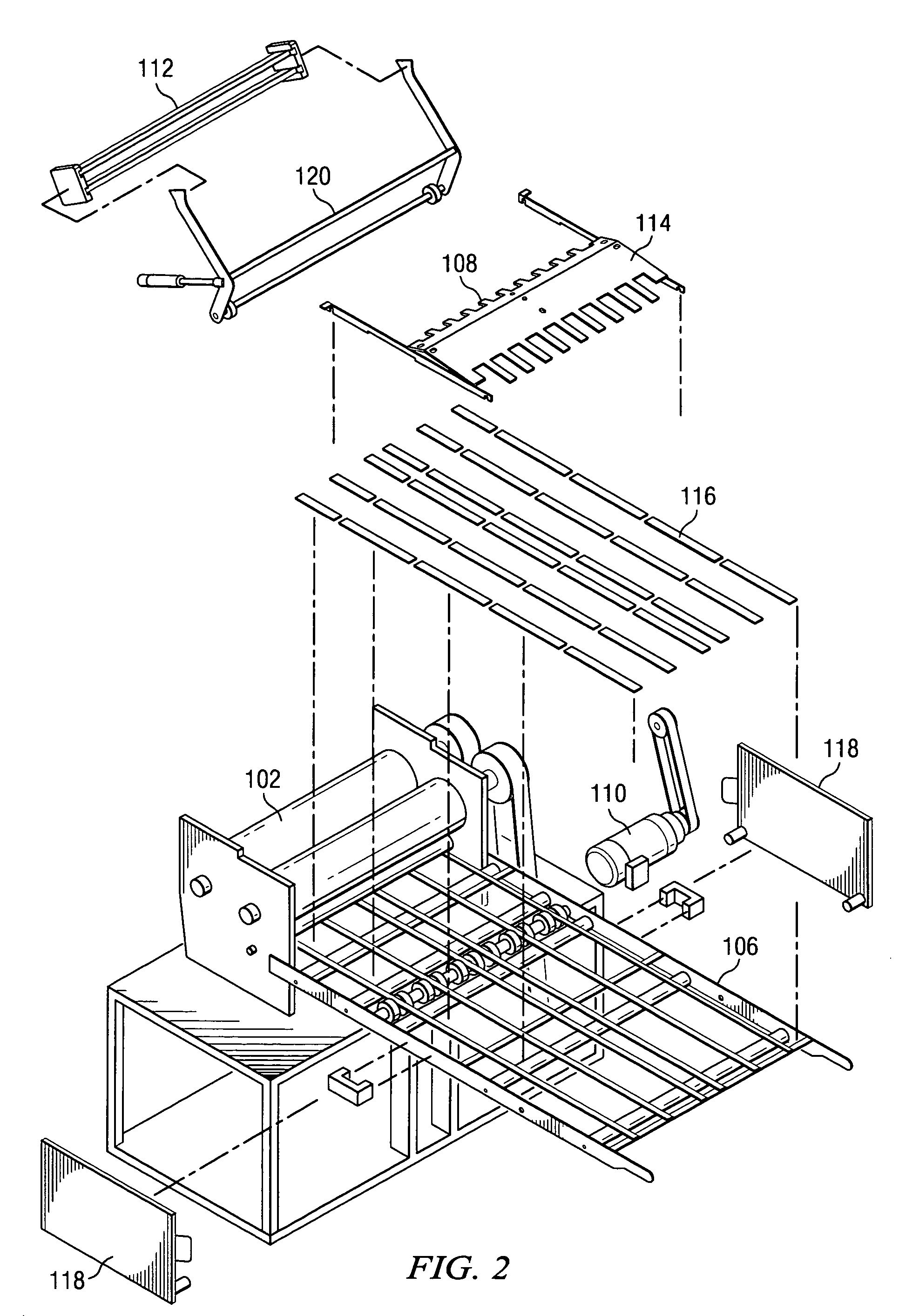

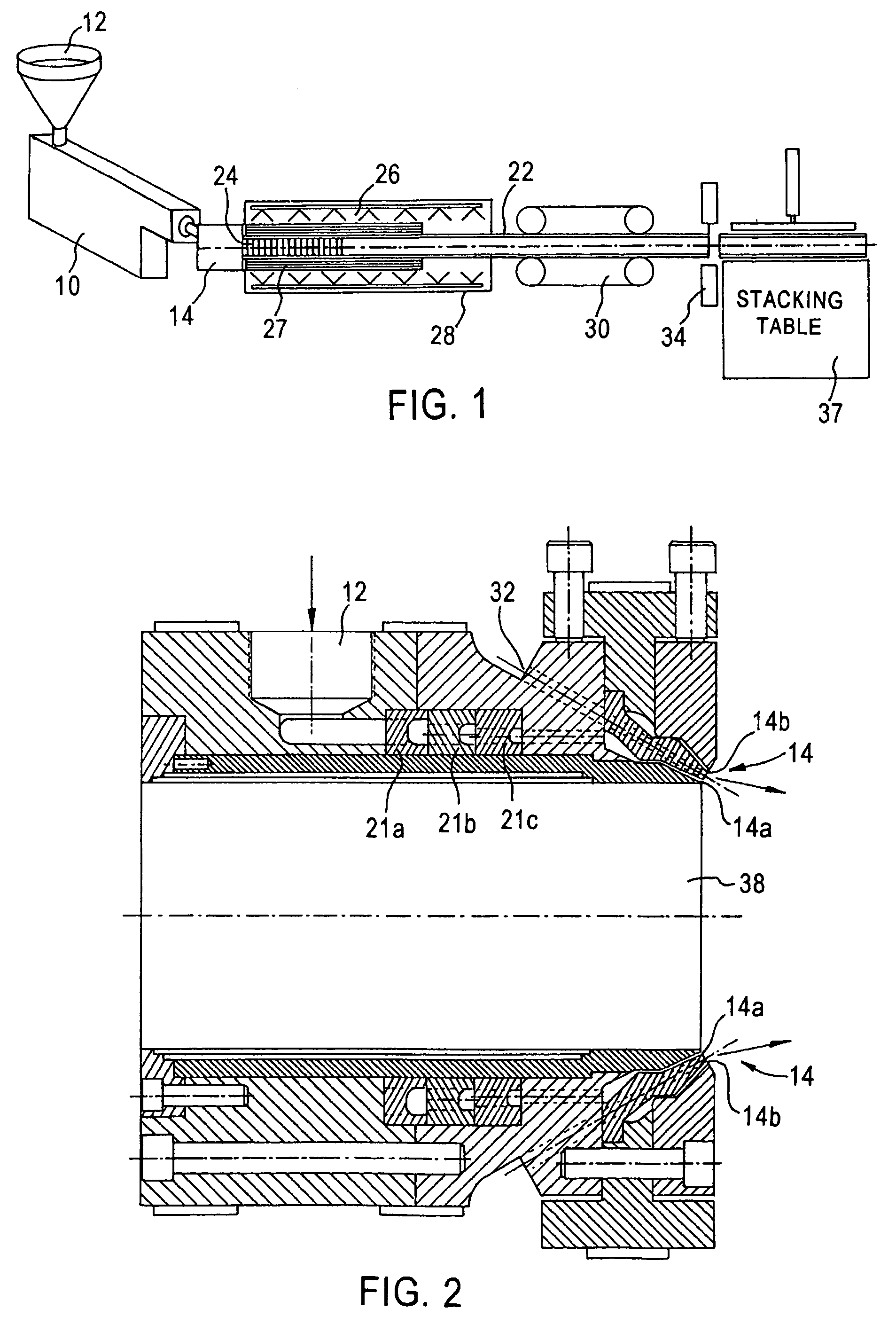

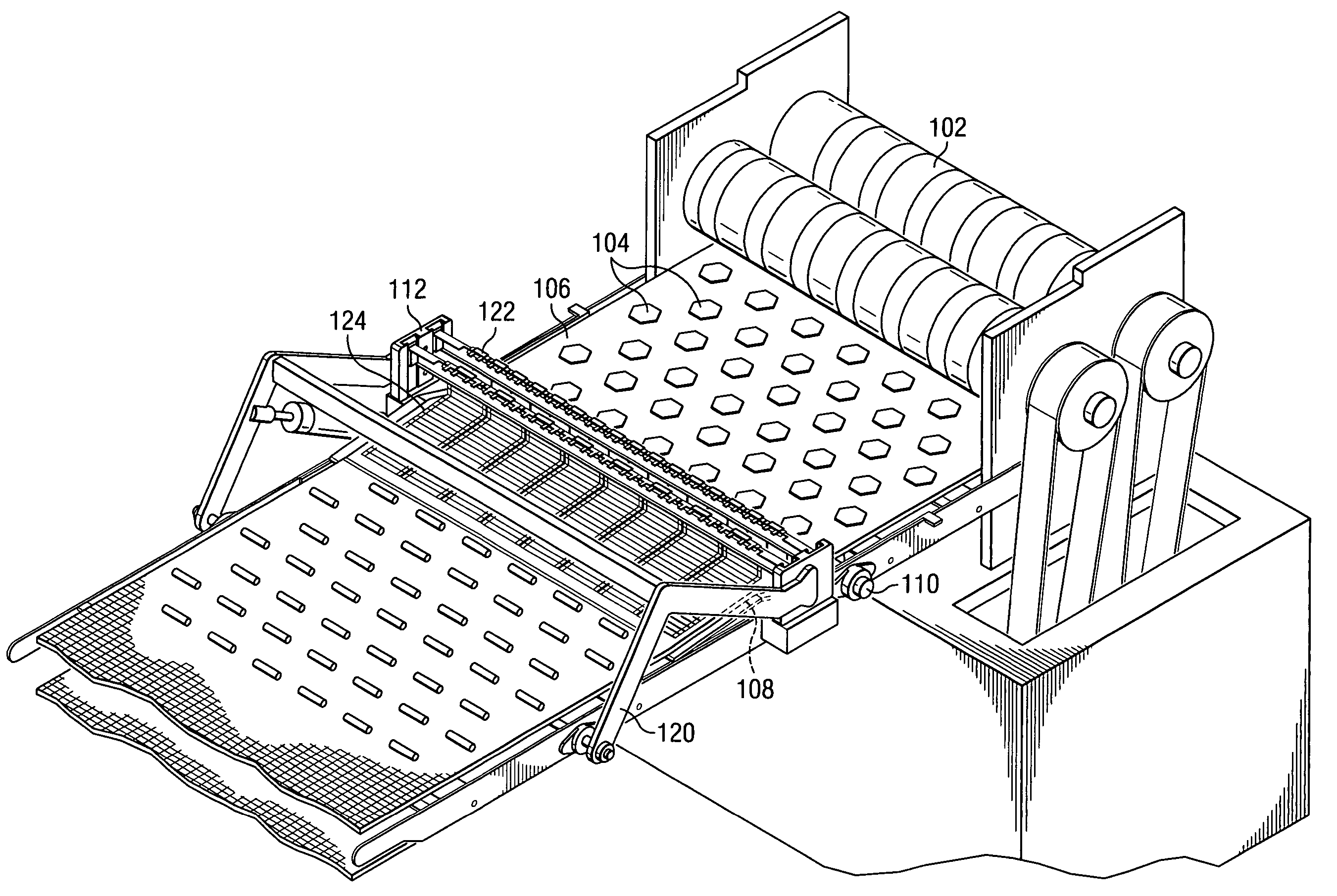

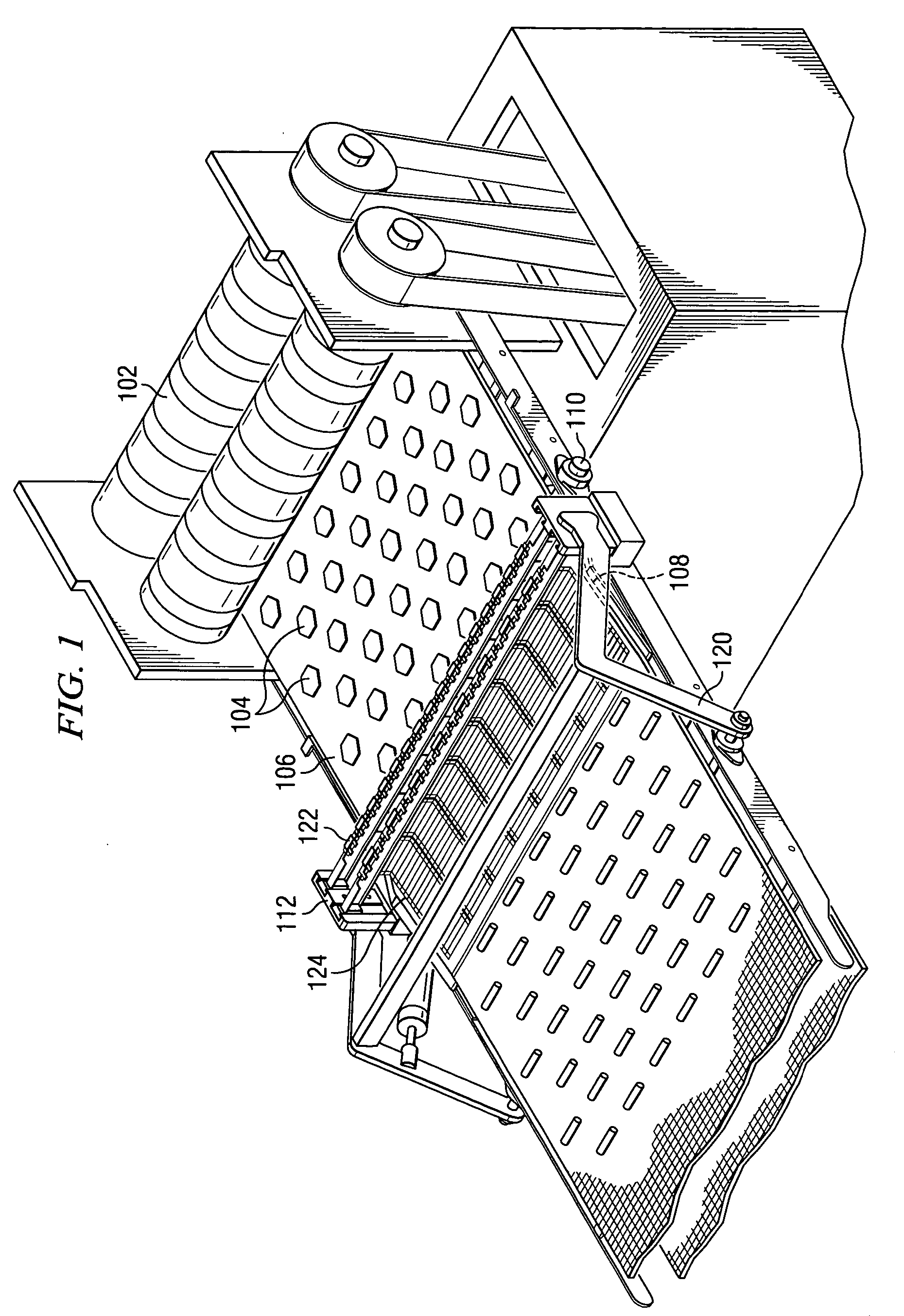

Dough rolling apparatus and method

An improved dough-rolling apparatus and method for rolling sheeted dough. The proposed invention comprises a dough-rolling apparatus having a dough sheeter, a sheeting conveyor having a ramped section, a roll-initiating curtain positioned above the ramped section, and a roll-completing curtain positioned above the conveyor and downstream from the roll-initiating conveyor. Sheeted and cut dough pieces are deposited onto a steel mesh, partially-ramped sheeter belt, where two wire-mesh rolling curtains are draped onto the sheeter belt to induce rolling of the dough pieces.

Owner:FRITO LAY NORTH AMERICA INC

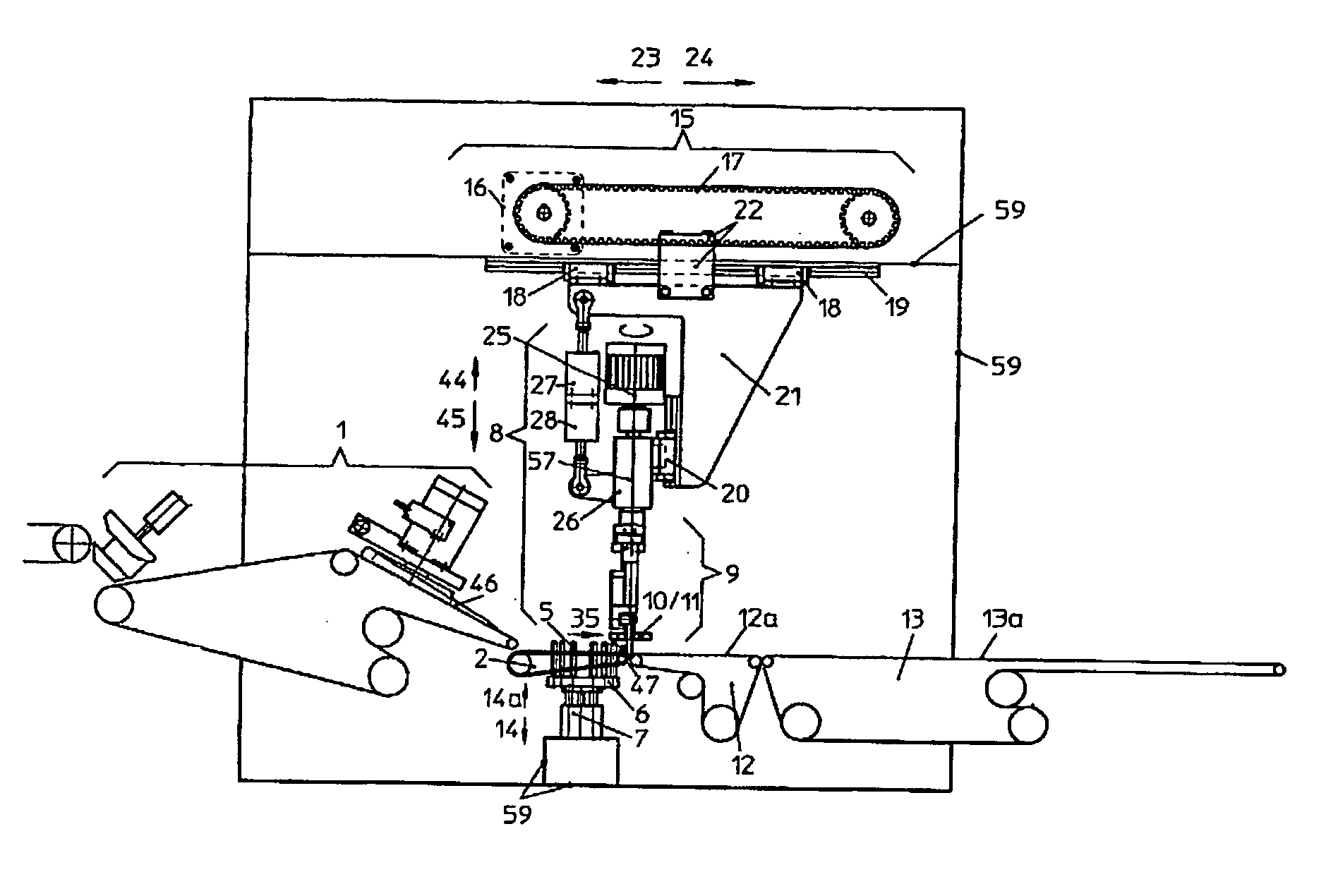

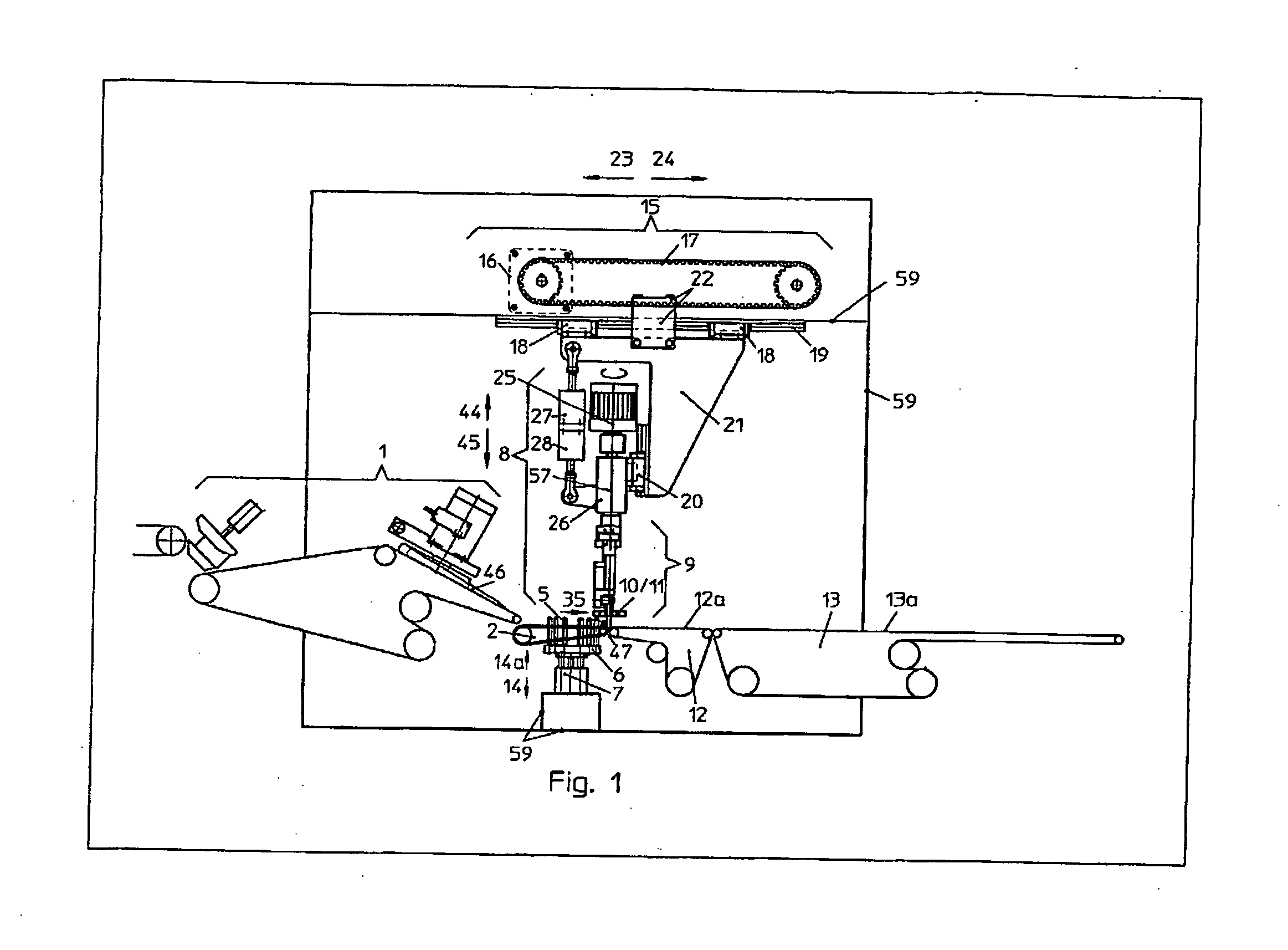

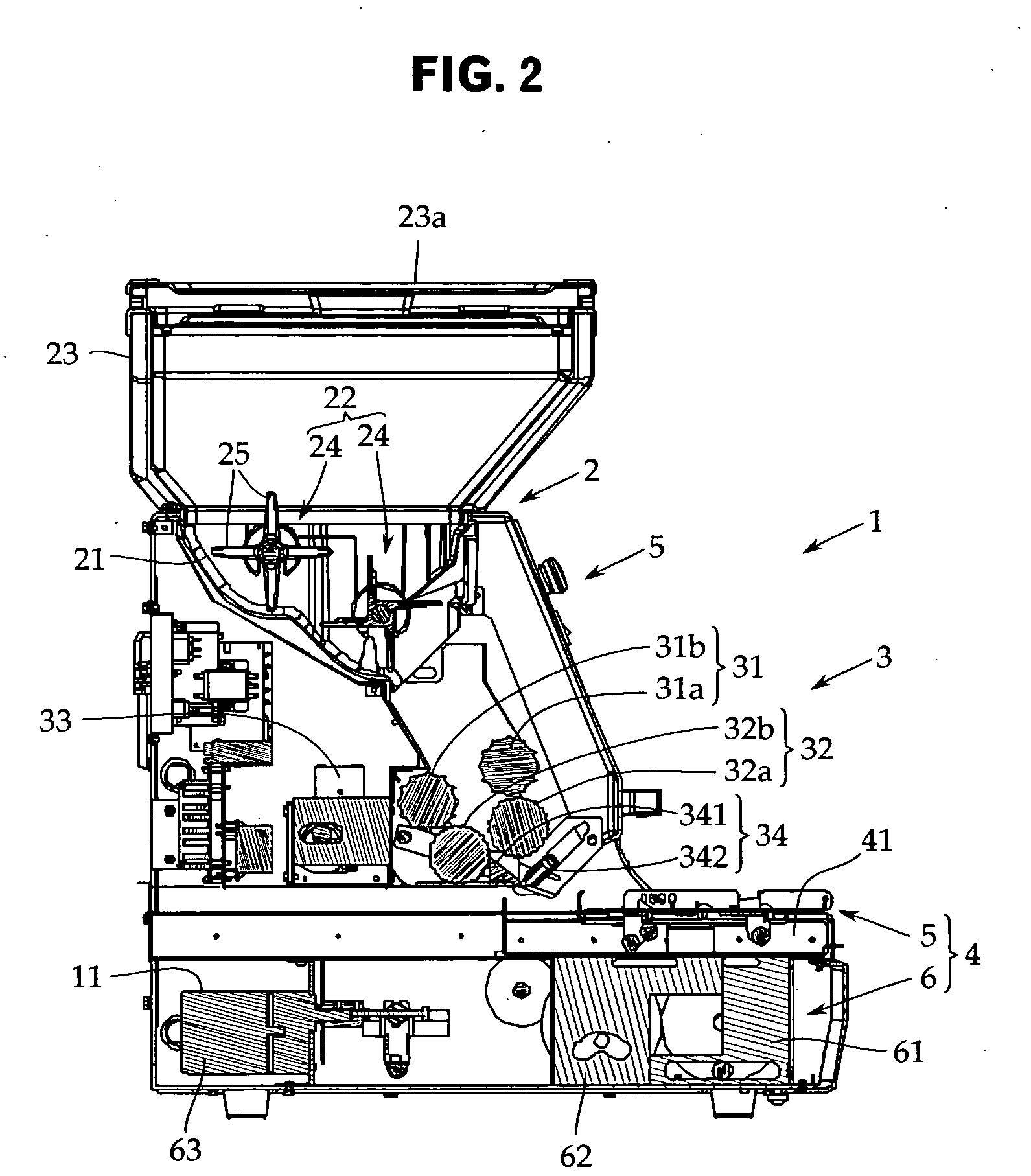

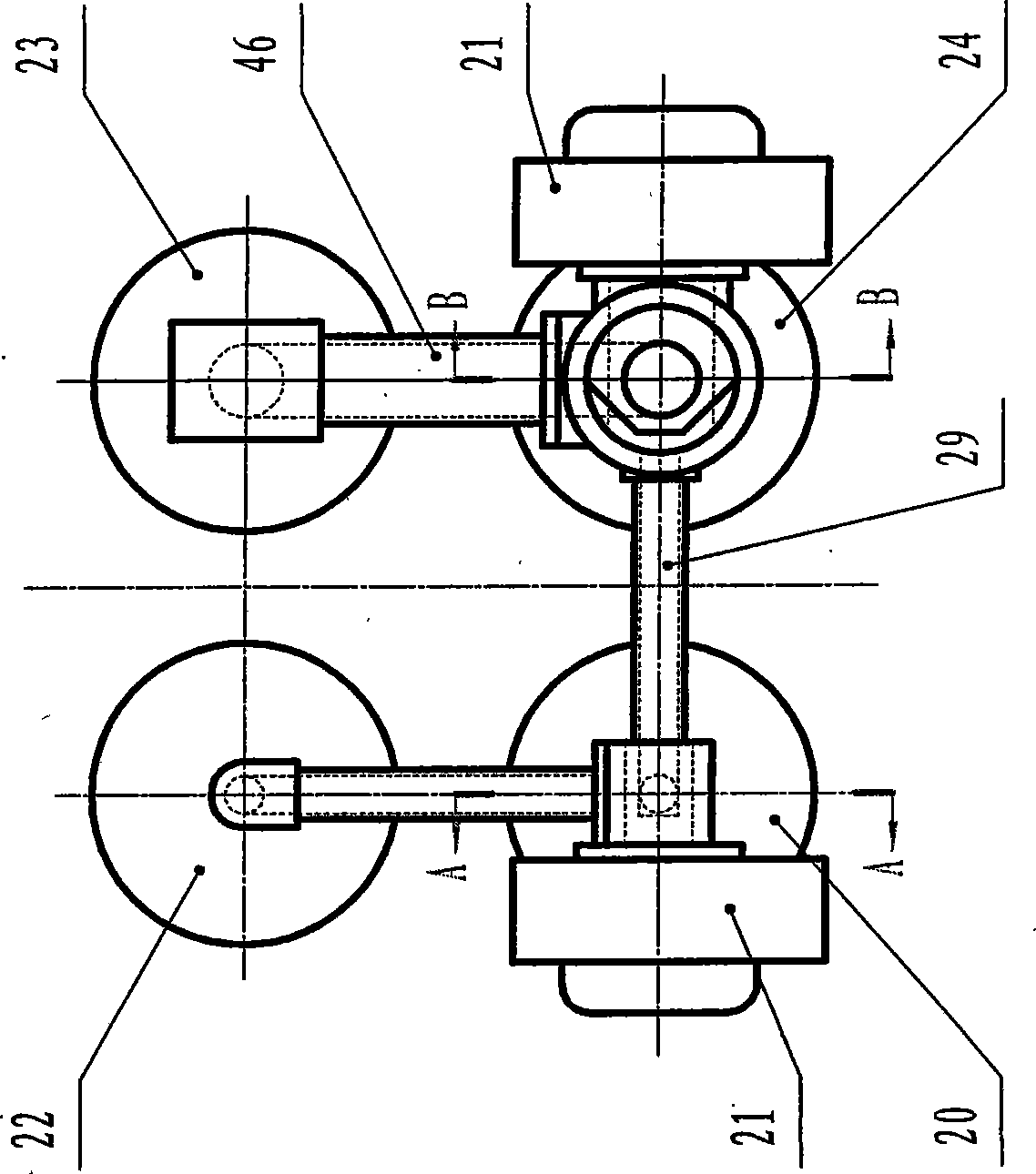

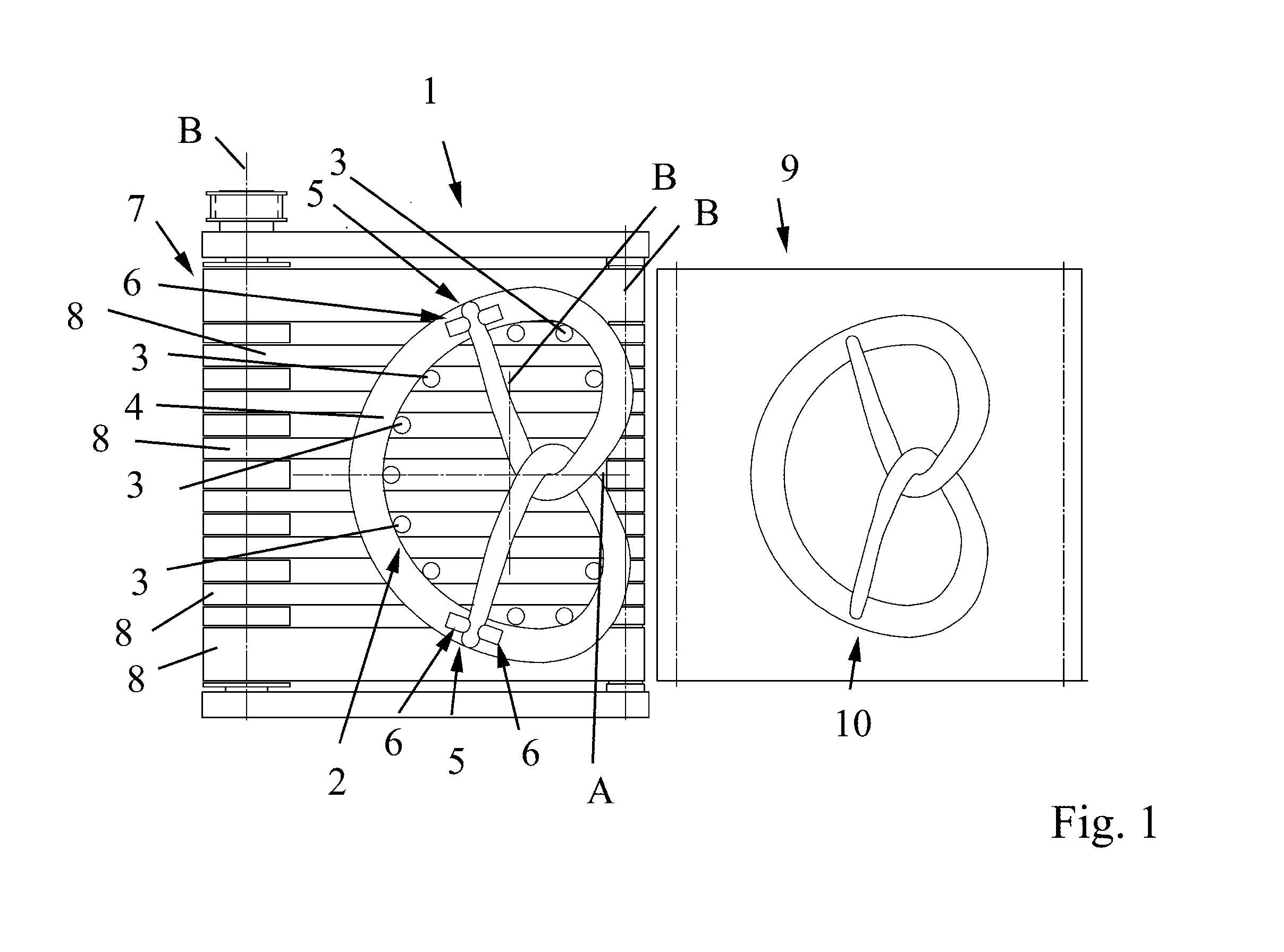

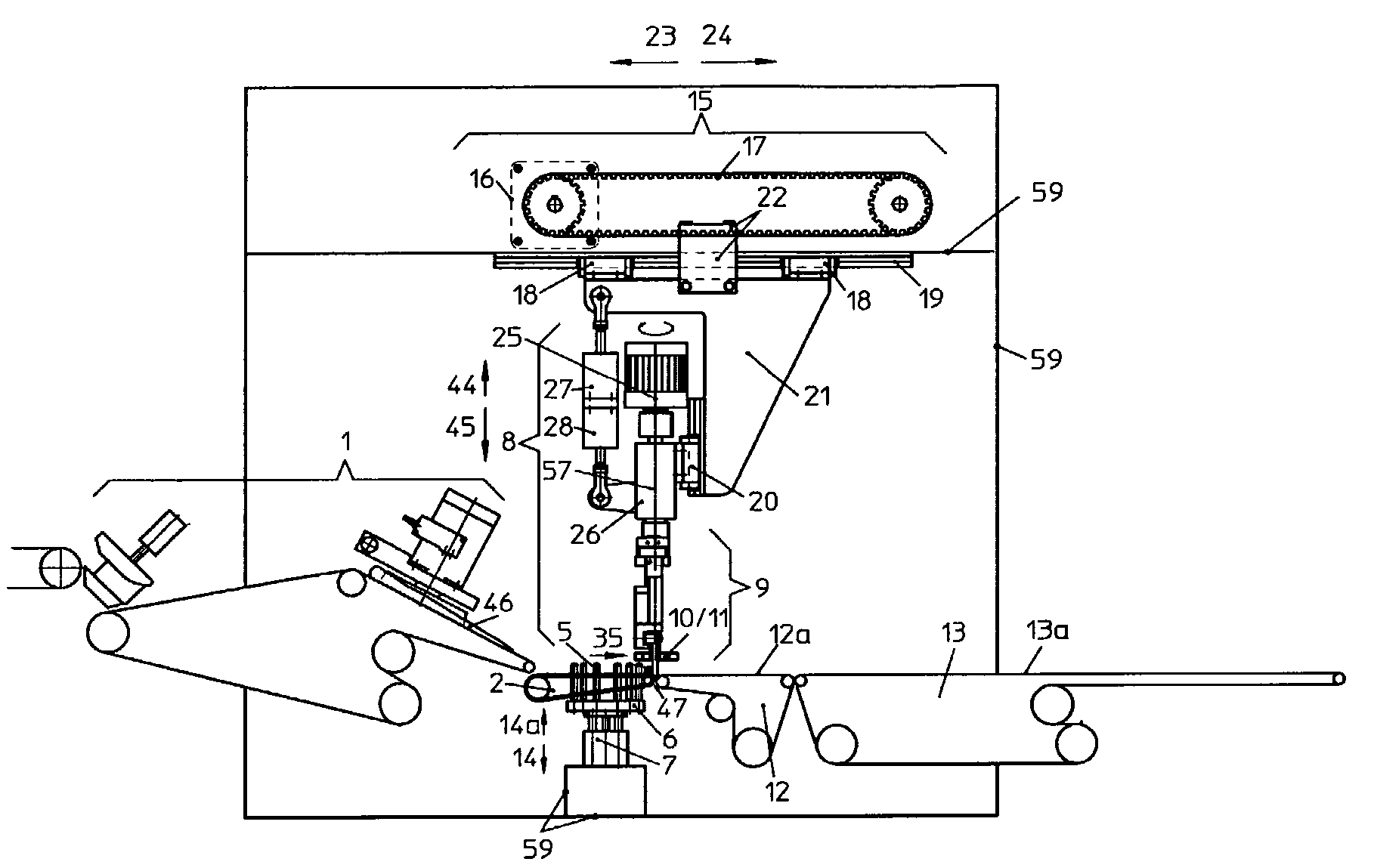

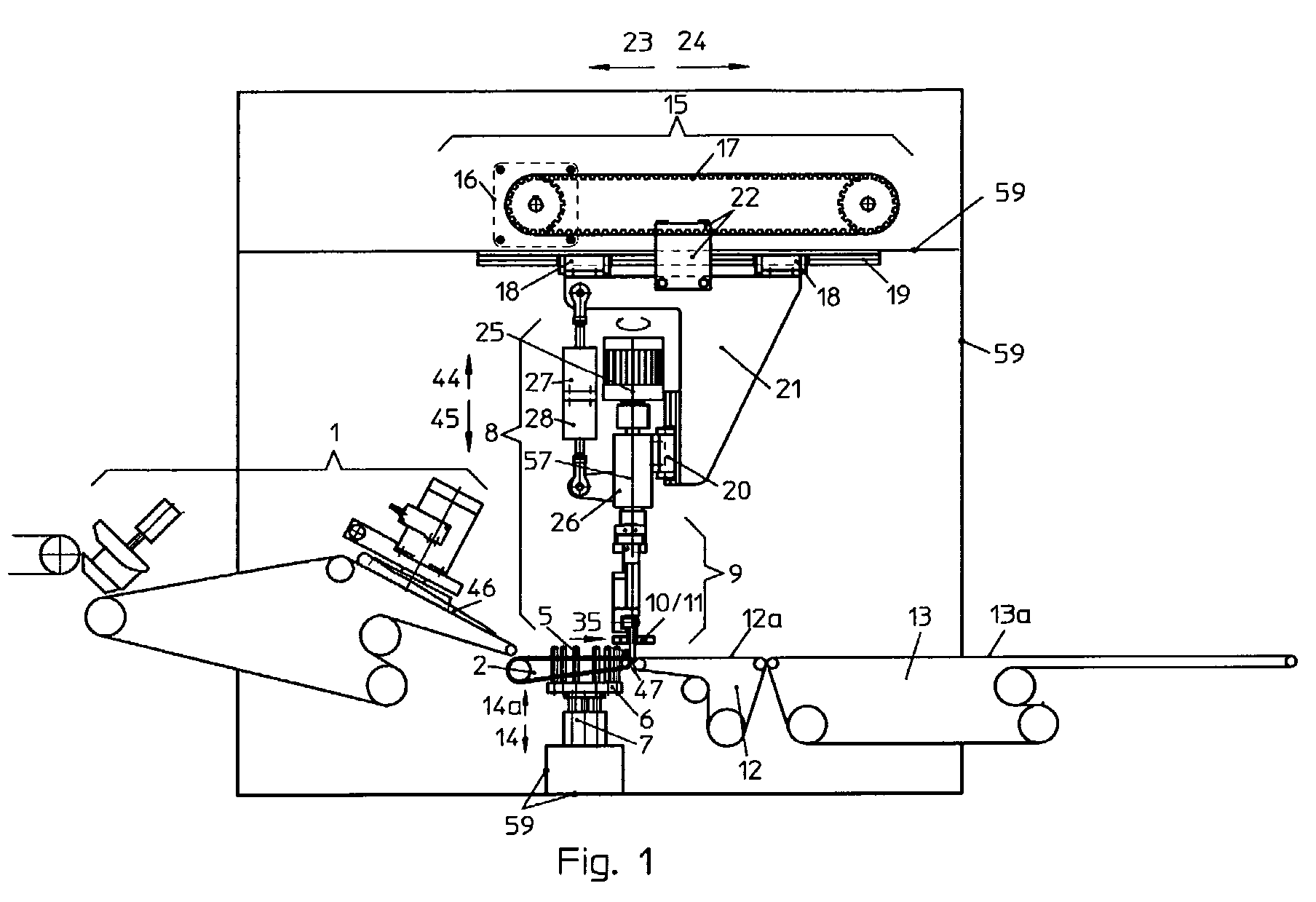

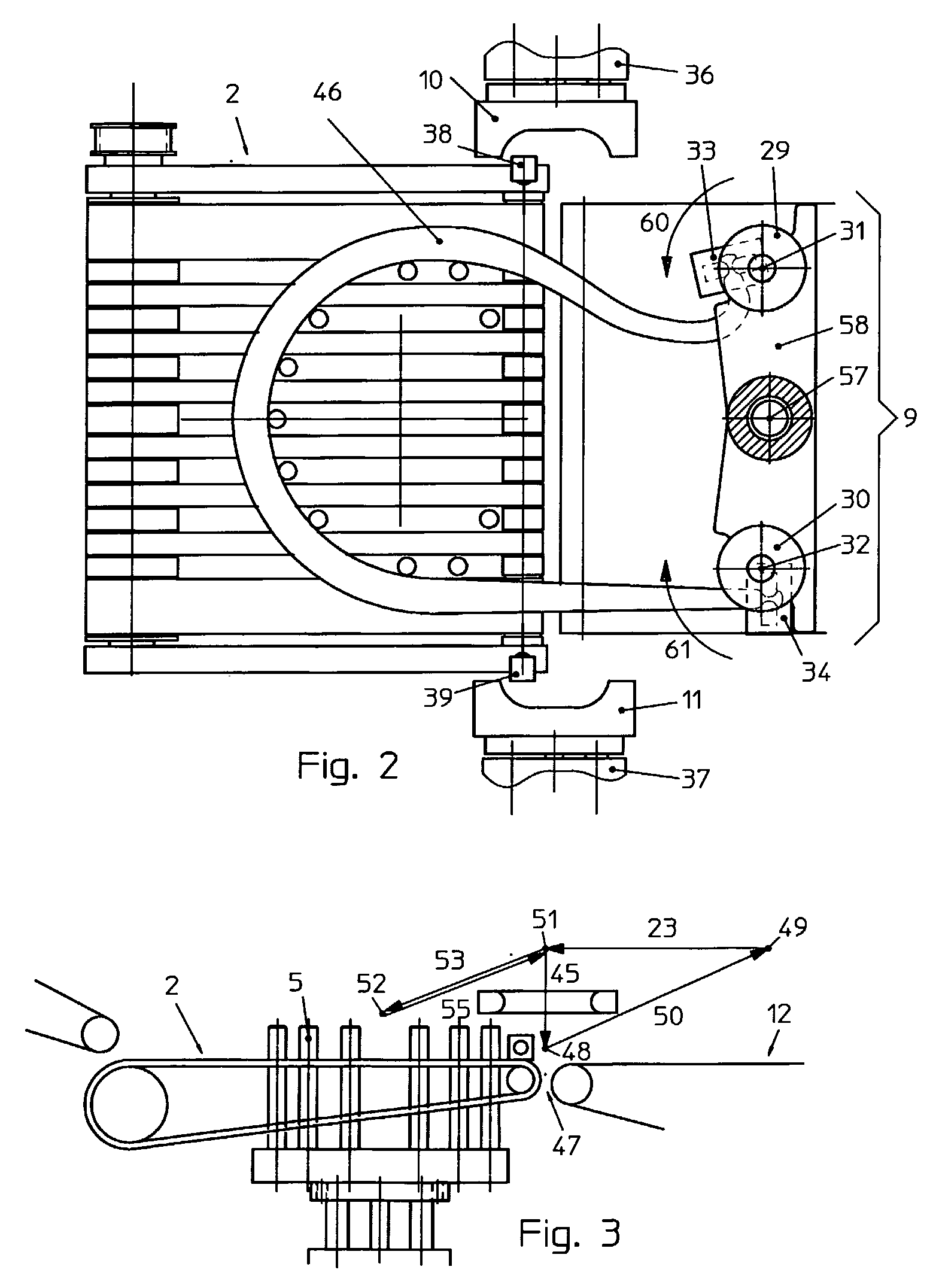

Knotting system for a dough strand

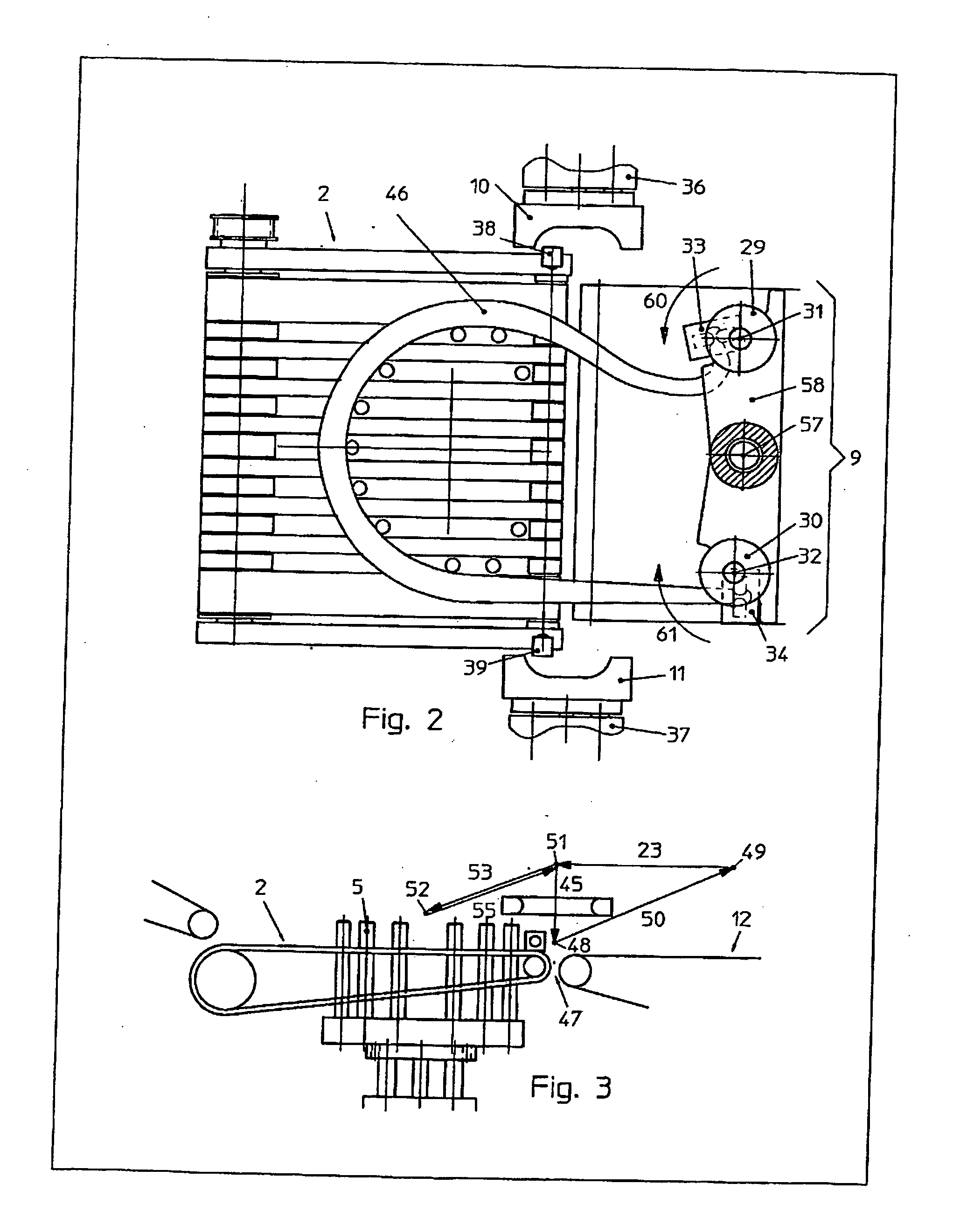

InactiveUS20070048423A1Increase distanceReduce frictionDough treatmentDough strip twisting machinesEngineering

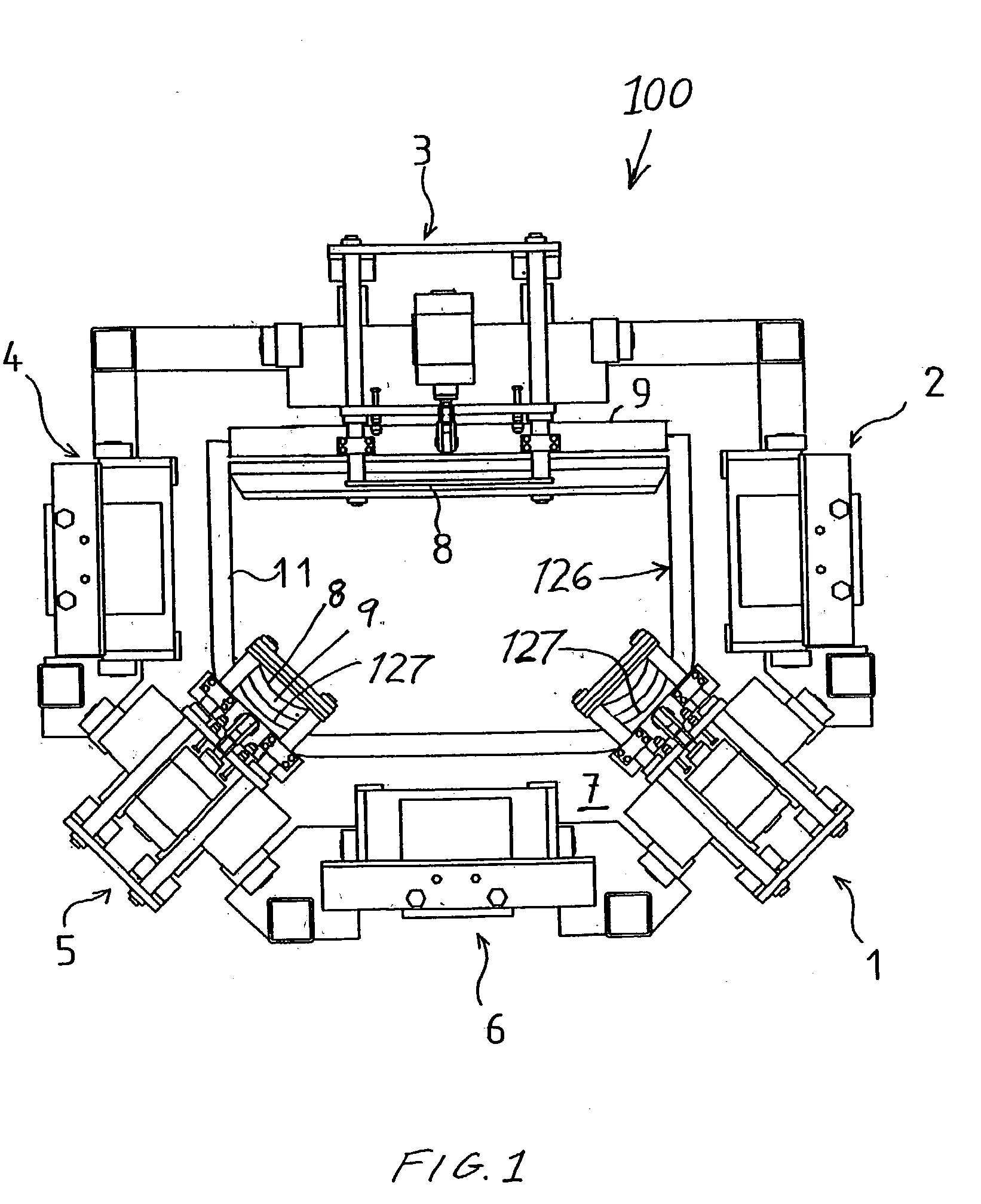

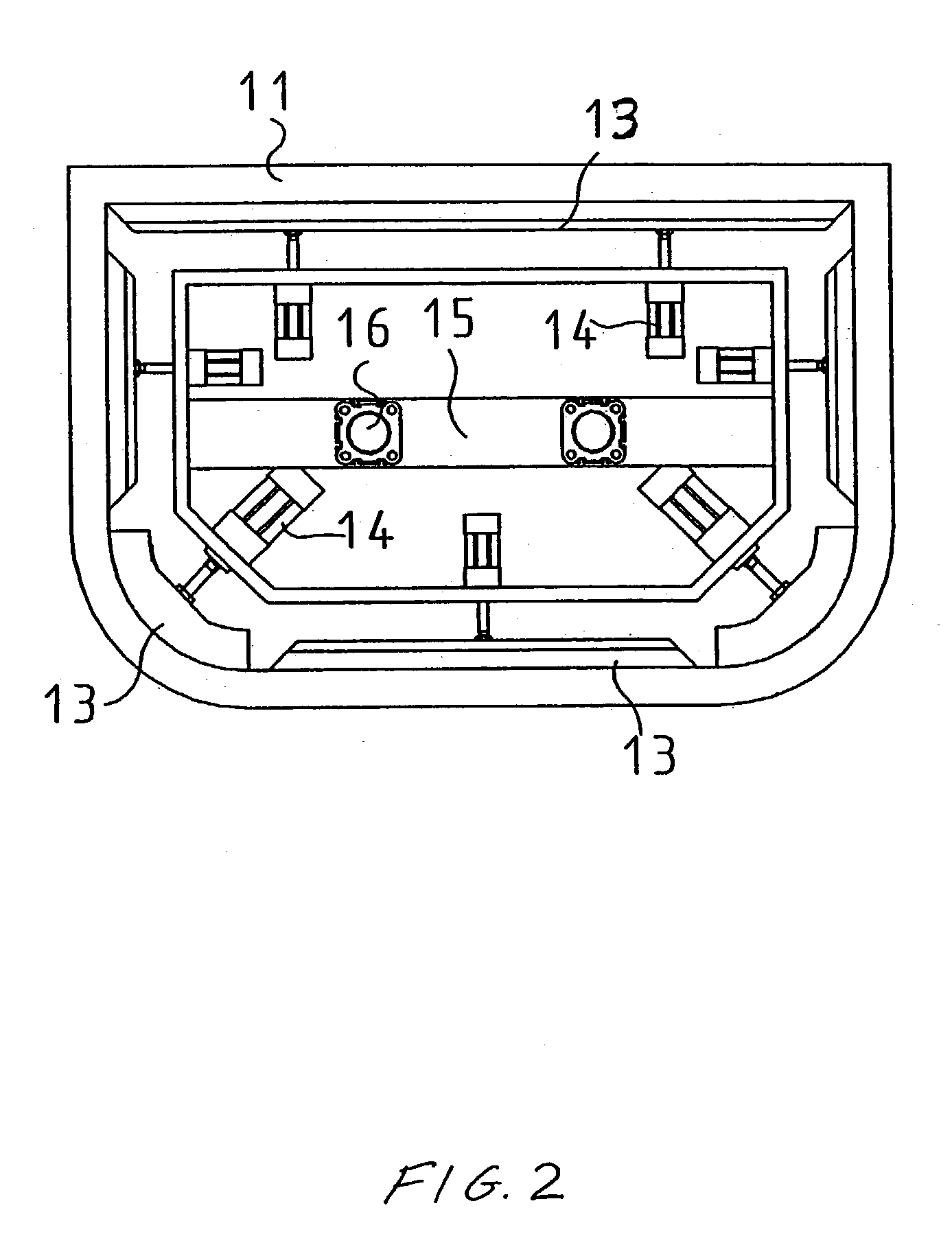

The invention relates to a device and a method for the automated production of knotted dough products, in particular pretzels. Said device comprises: a shaping table (2) for horizontally supporting a U-shaped bent dough strand (46); a shaping tool (6) that can be activated to vertically support the U-shaped bent dough strand (46), the shaping table (2) and activated shaping tool (6) forming a common stop for the U-shaped bent strand (46); and a knotting head (9) for seizing the ends of the dough strand and for knotting said strand (46). According to the invention, the knotting head (9) can be displaced from a seizing position (48), in which the ends of the U-shaped bent dough strand (46) are seized, into an extension position (49), in which the dough strand is extended, then into a knotting position (51), in which the dough strand is knotted and finally into a placing position 52, in which the ends of the dough strands are placed on the central part of the dough strand. In addition, the common shaping stop is configured to be stationary, in particular on the horizontal displacement plane.

Owner:FRITSCH GMBH

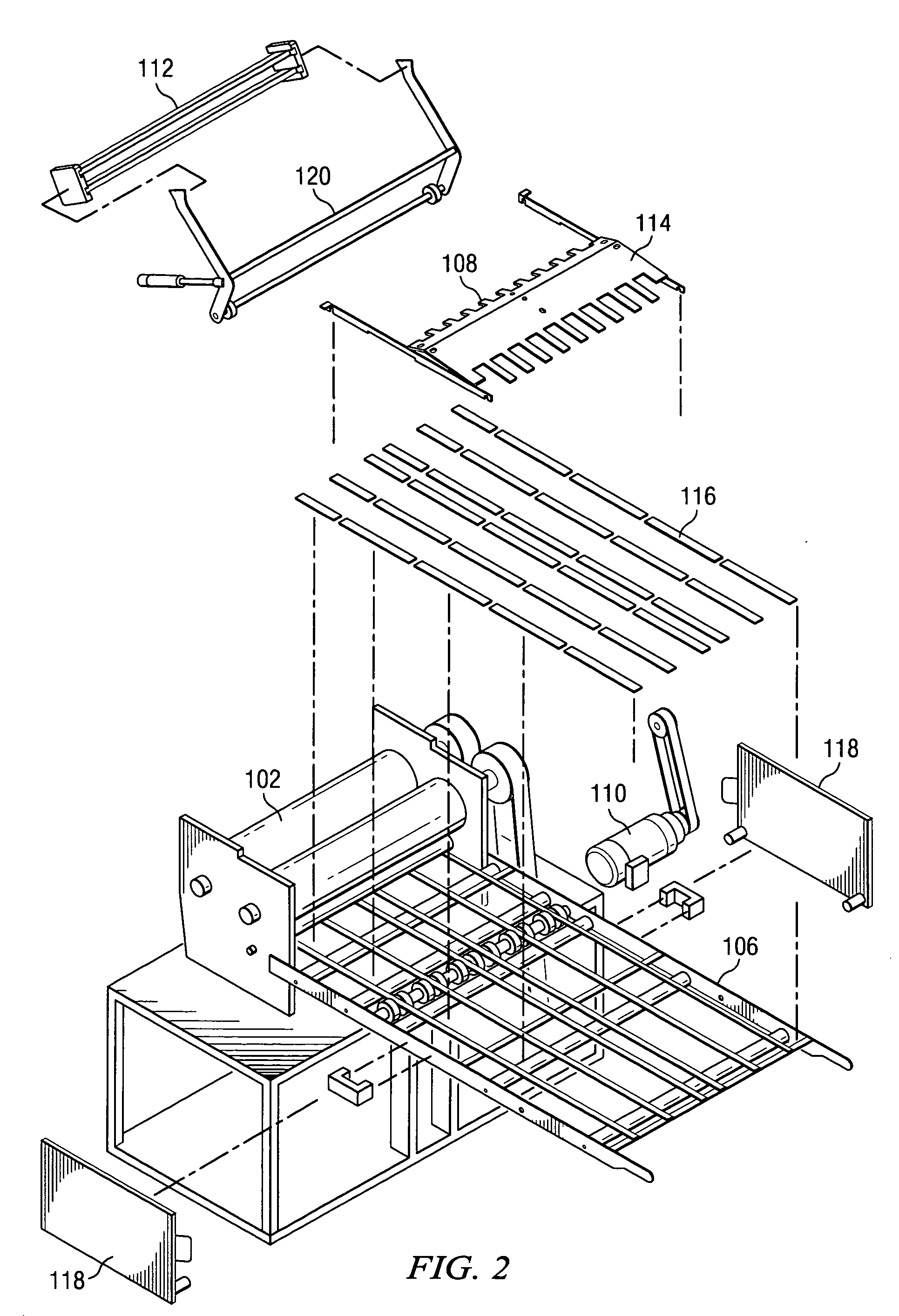

Dough product rolling apparatus and method for rolling dough products

InactiveUS6838105B2Increase engagementImprove abilitiesDough treatmentFrozen sweetsLeading edgeEngineering

The leading edge of a sheet of dough product impacts an impacting feature and causes the leading edge to roll over onto itself thereby initiating a roll. Engagement enhancement is utilized to increased to increase the ability of the sheet of dough product to resist sliding upon impacting the impacting feature. This provides a tighter rolled dough product having a consistent size and shape. Thus, in accordance with one specific aspect of the present invention, rolled dough products for subsequent packaging into containers may be formed that have a repeatable size and shape. By providing rolled dough products having a repeatable size and shape a more efficient and economical process results. This is because the size and shape of the rolled dough product is controlled with respect to the size of the container.

Owner:GENERAL MILLS MARKETING INC

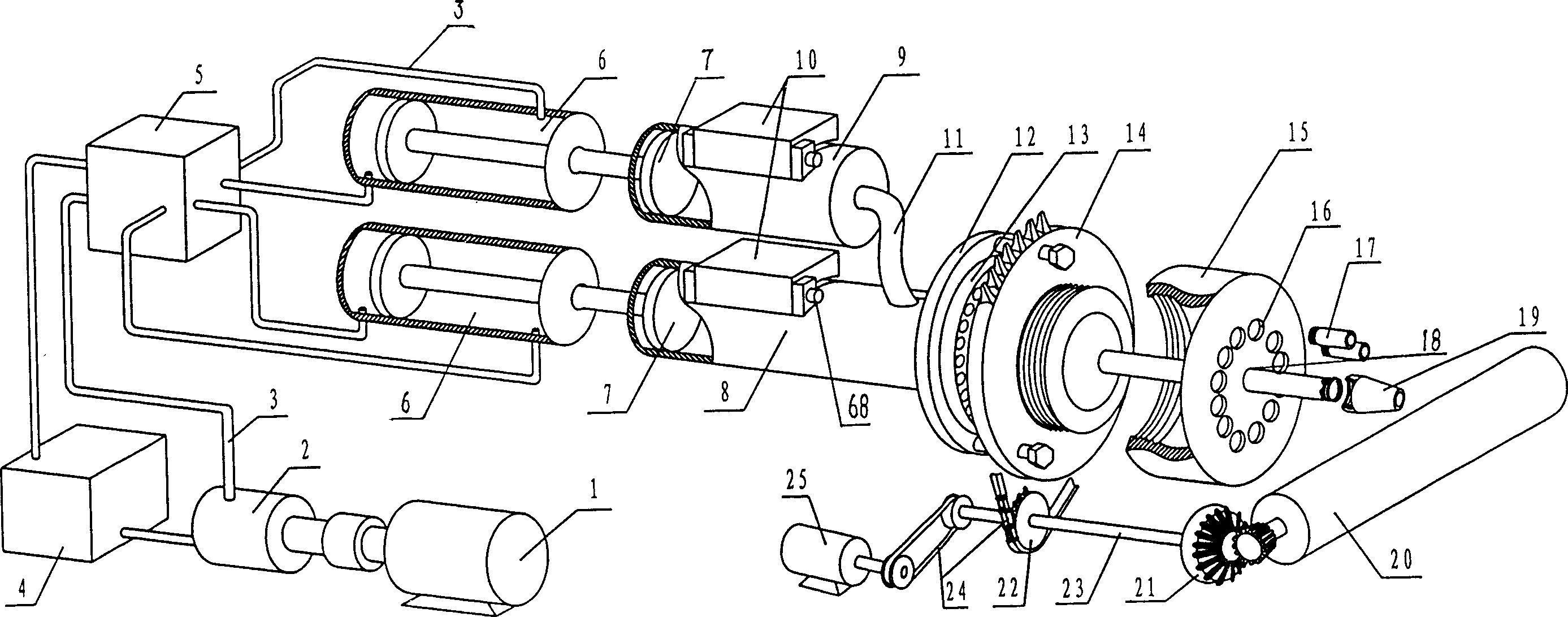

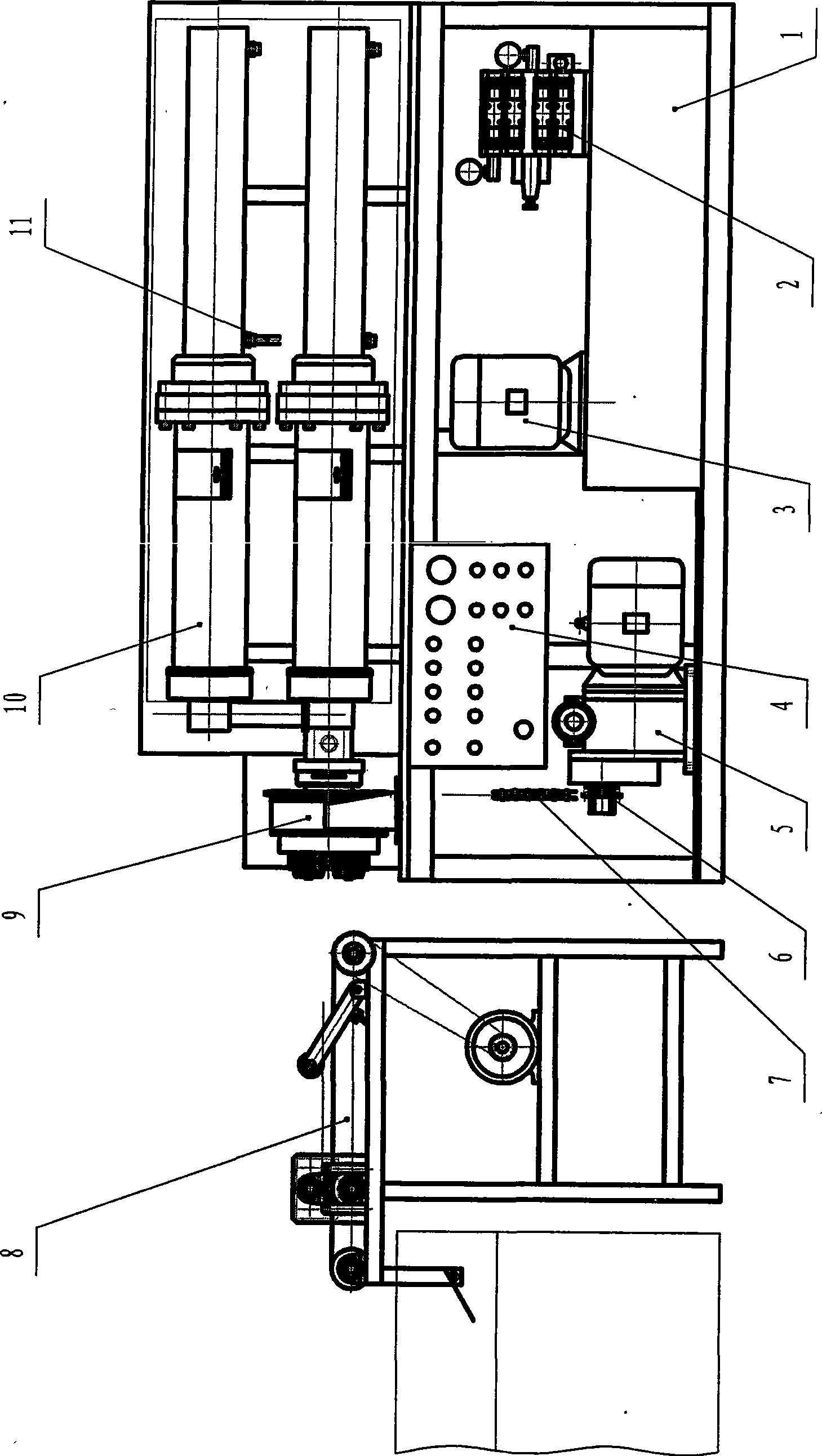

Automatic fried dough twist shaping machine

InactiveCN1602695AMake uniformUnified production standardsDough strip twisting machinesElectricityGear wheel

This invention relates to a machine roll paste into pretzel automatically, including hydraulic pressure drive and roll mould machine, electricity drives hydraic pressure crock piston and then force the stuffing crock and paste crock operation in whole machine. The output of paste crock is a compose tray. There are stuffing hole and paste hole on it. There is out pipe on the stuffing crock, through the paste crock connected the stuffing output hole. The timing electromotor drives the compose tray rotating through the transmission machine. It is connected with umbrella gear in disguised from connected the parallel compose roller before the composing tray through transmission machine. On the other hand, the timing electromotor jointed two output reducers. The two output reducer: connected to the manipulator machine and orientation falchion machine, on the uphold frame. The manipulator nip, drawer, collapse and screw pretzel stick to the orientated falchion, and then press the pretzel and cut to sects. This pretzel machine operated easy sanitation, high quality, and high affection. The products consistent with handcraft in the special style, multiplicity sculpt, fit for the industrialization.

Owner:徐志兴

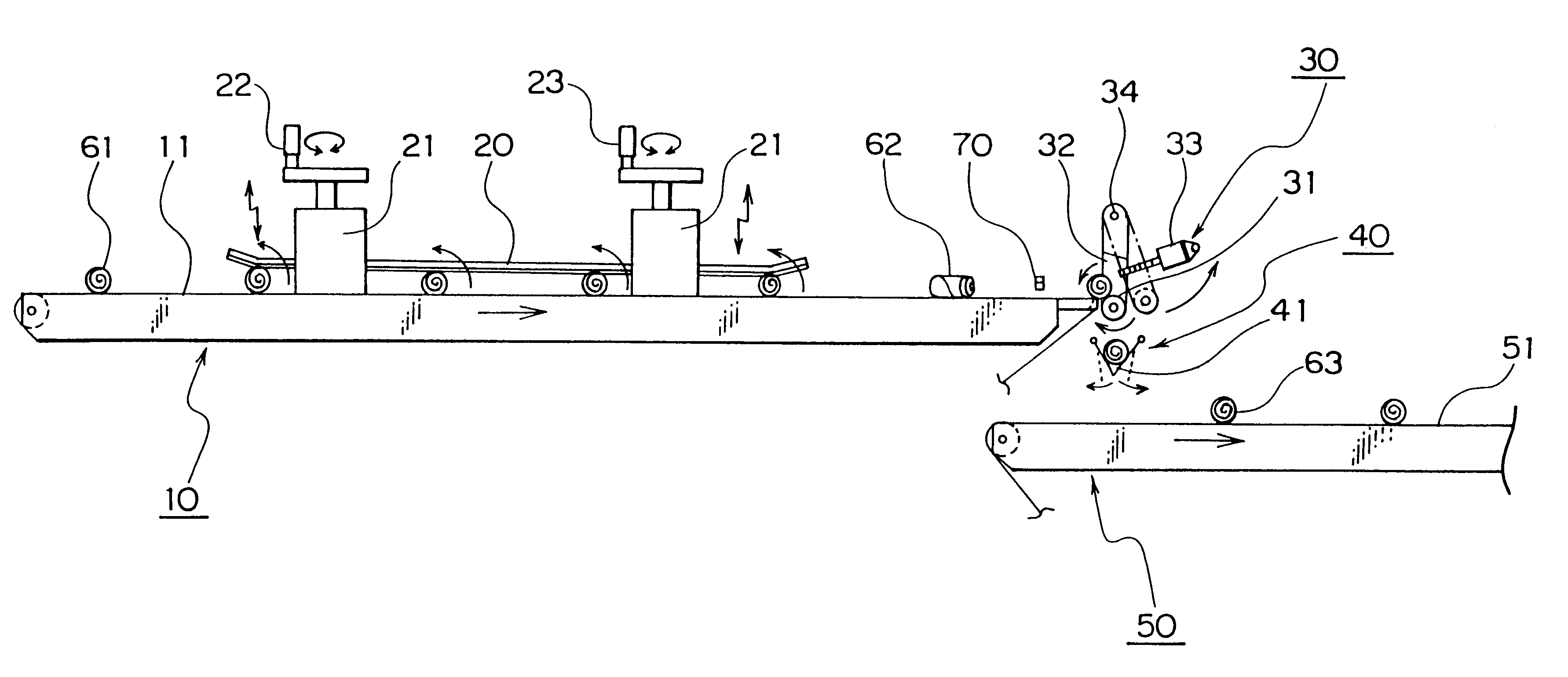

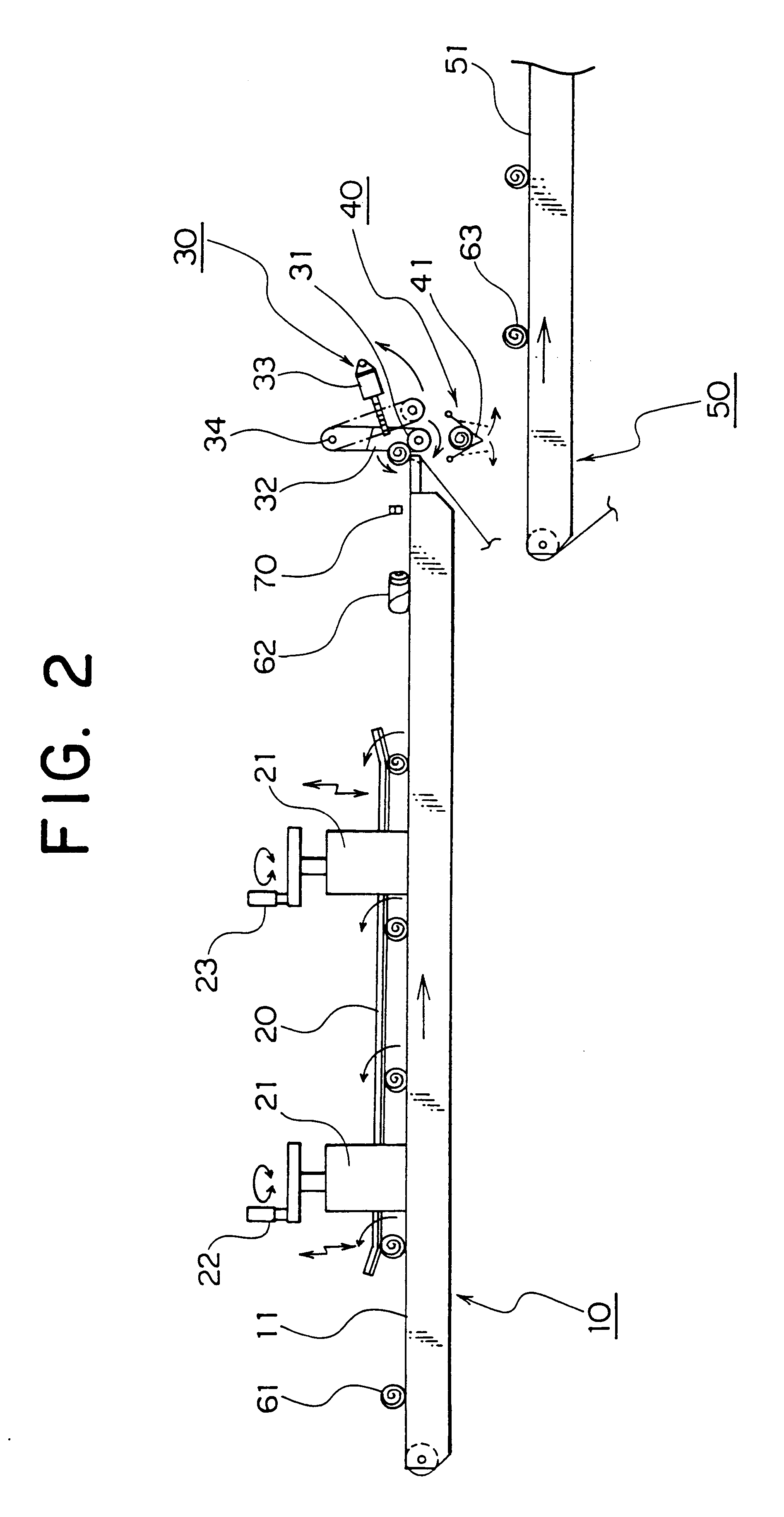

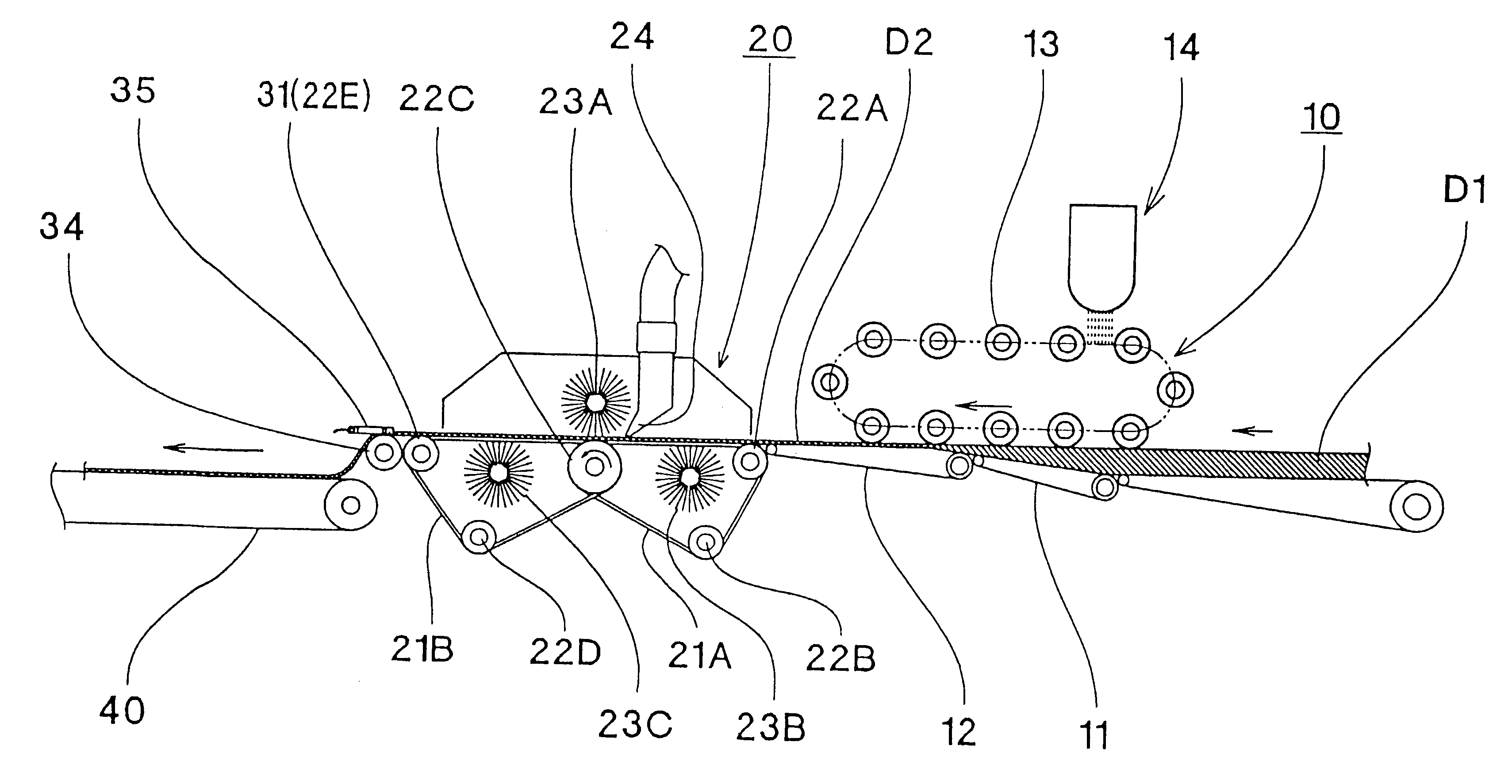

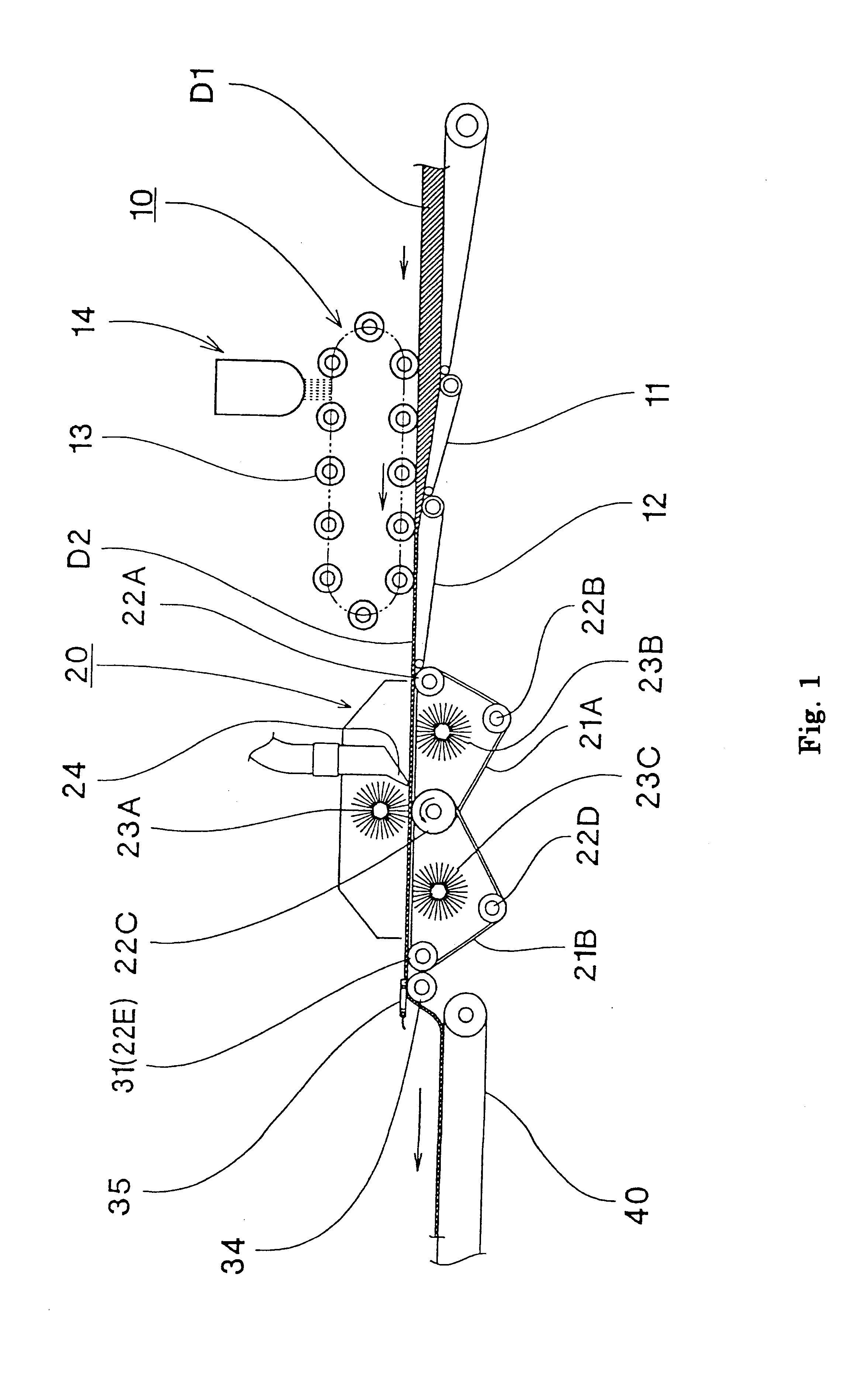

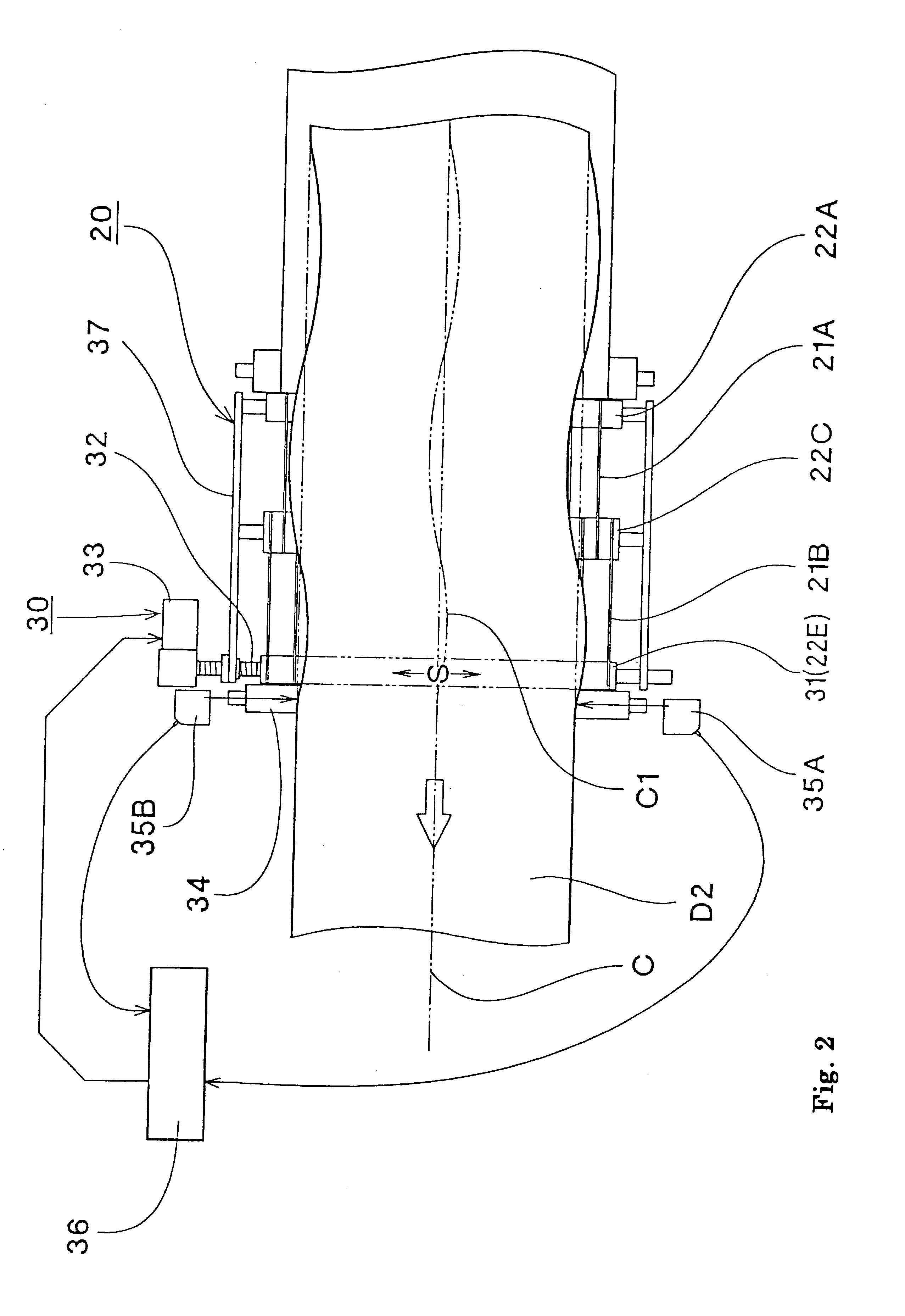

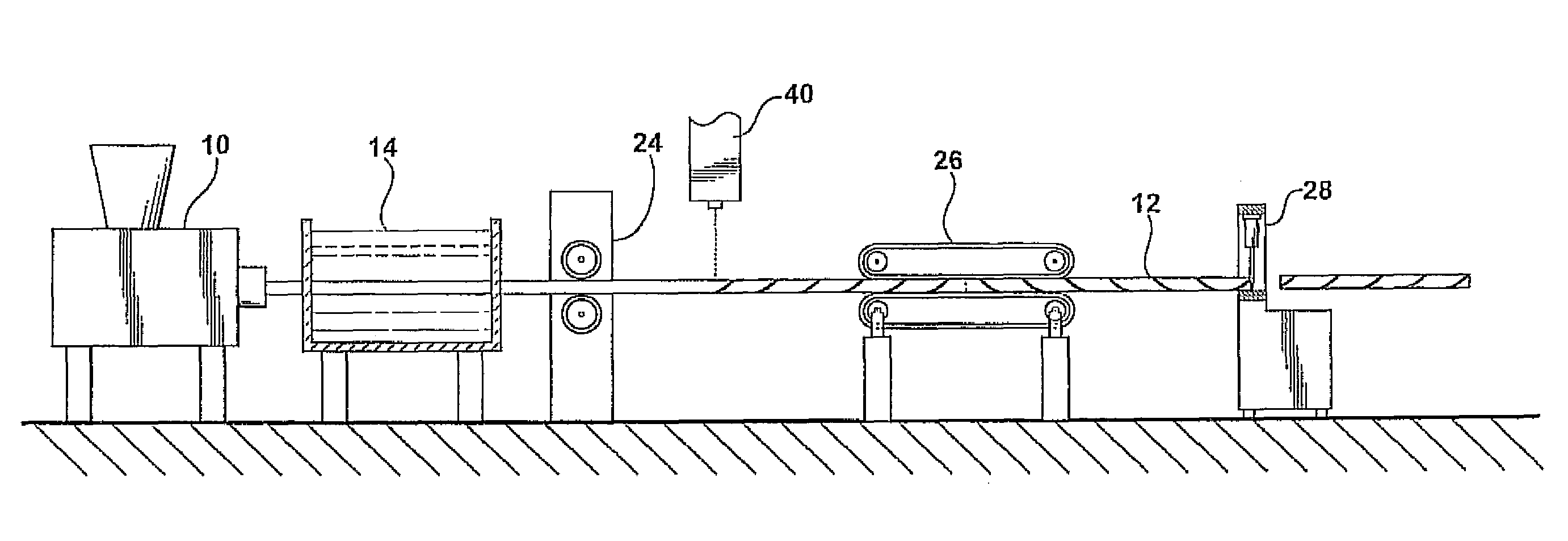

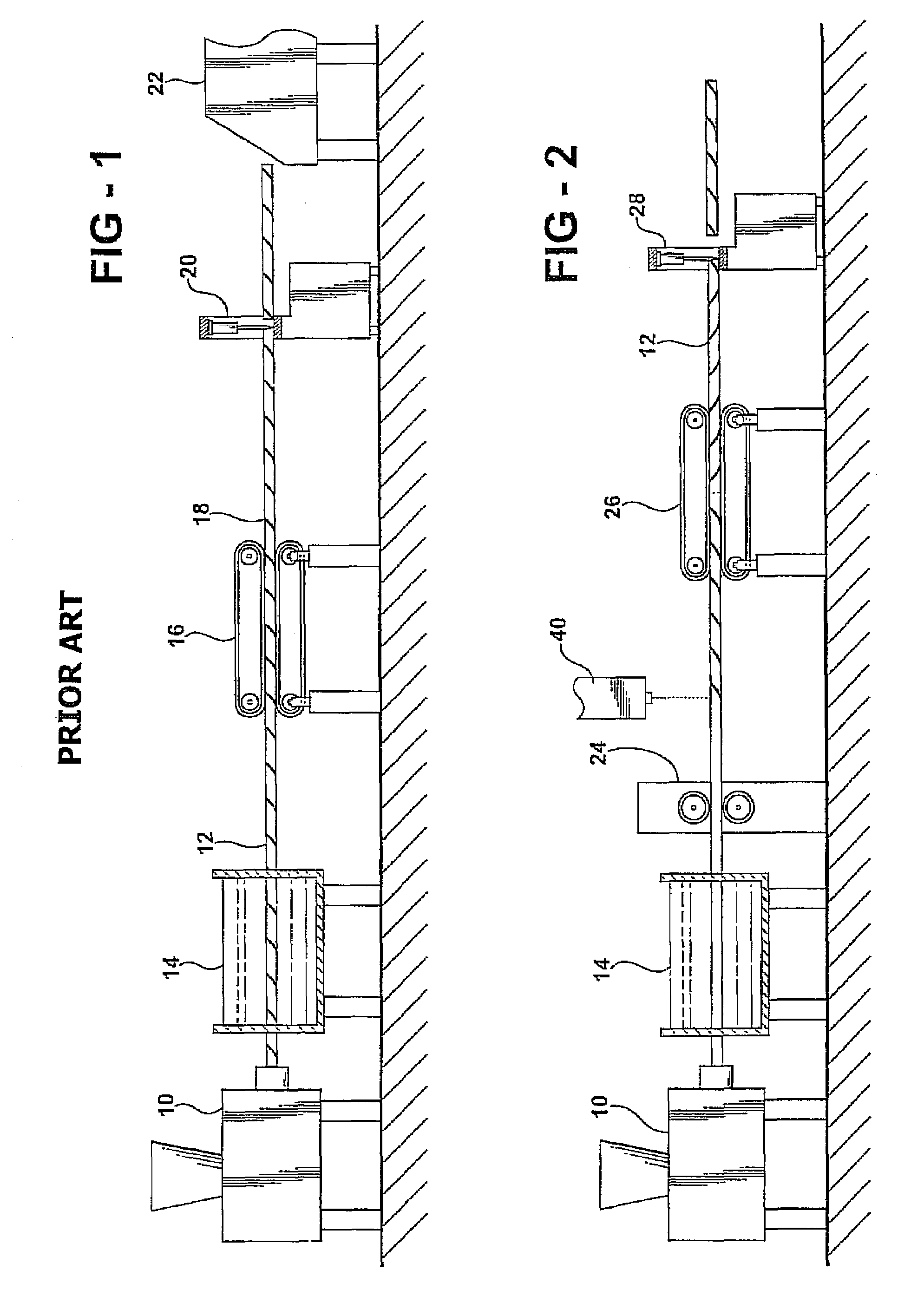

Method and apparatus for conveying bar-like bread dough pieces

Owner:RHEON AUTOMATIC MASCH CO LTD

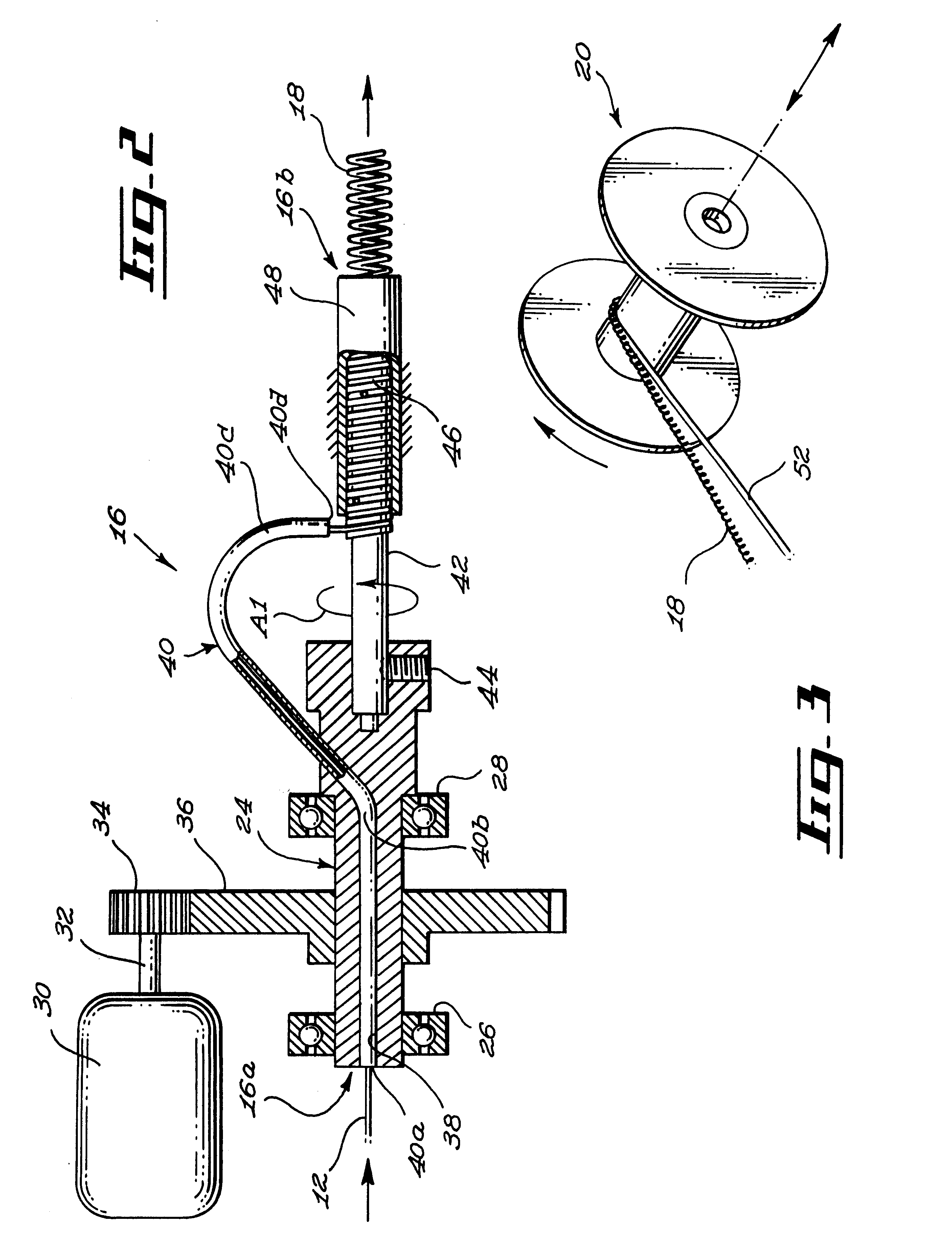

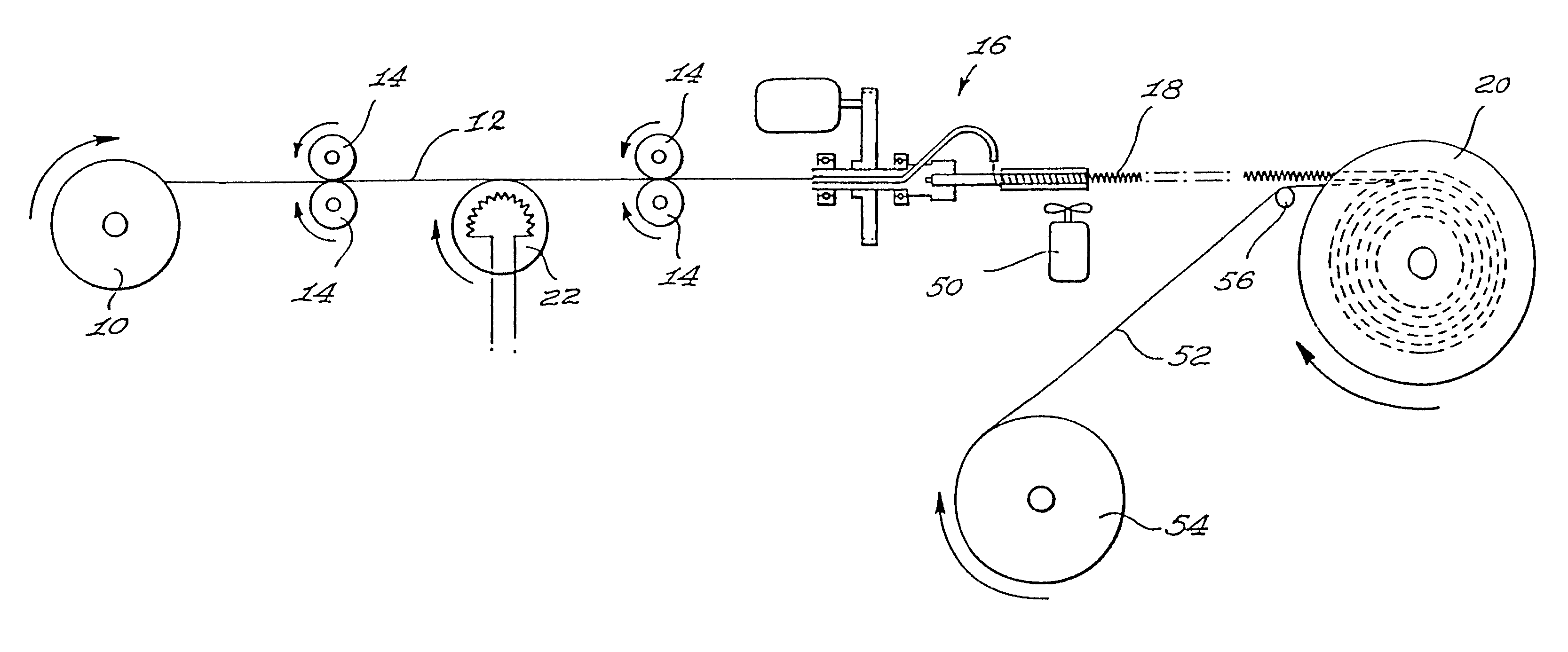

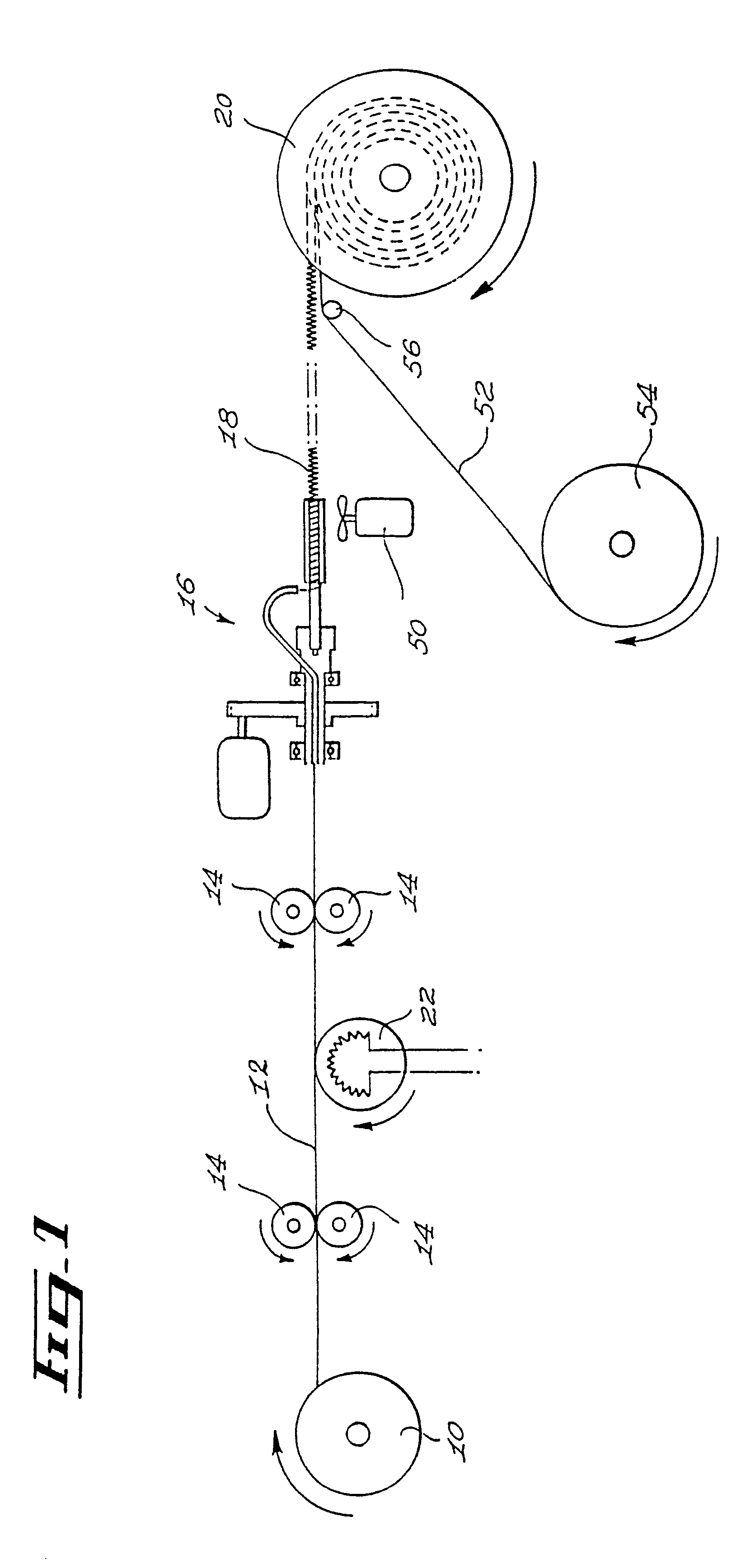

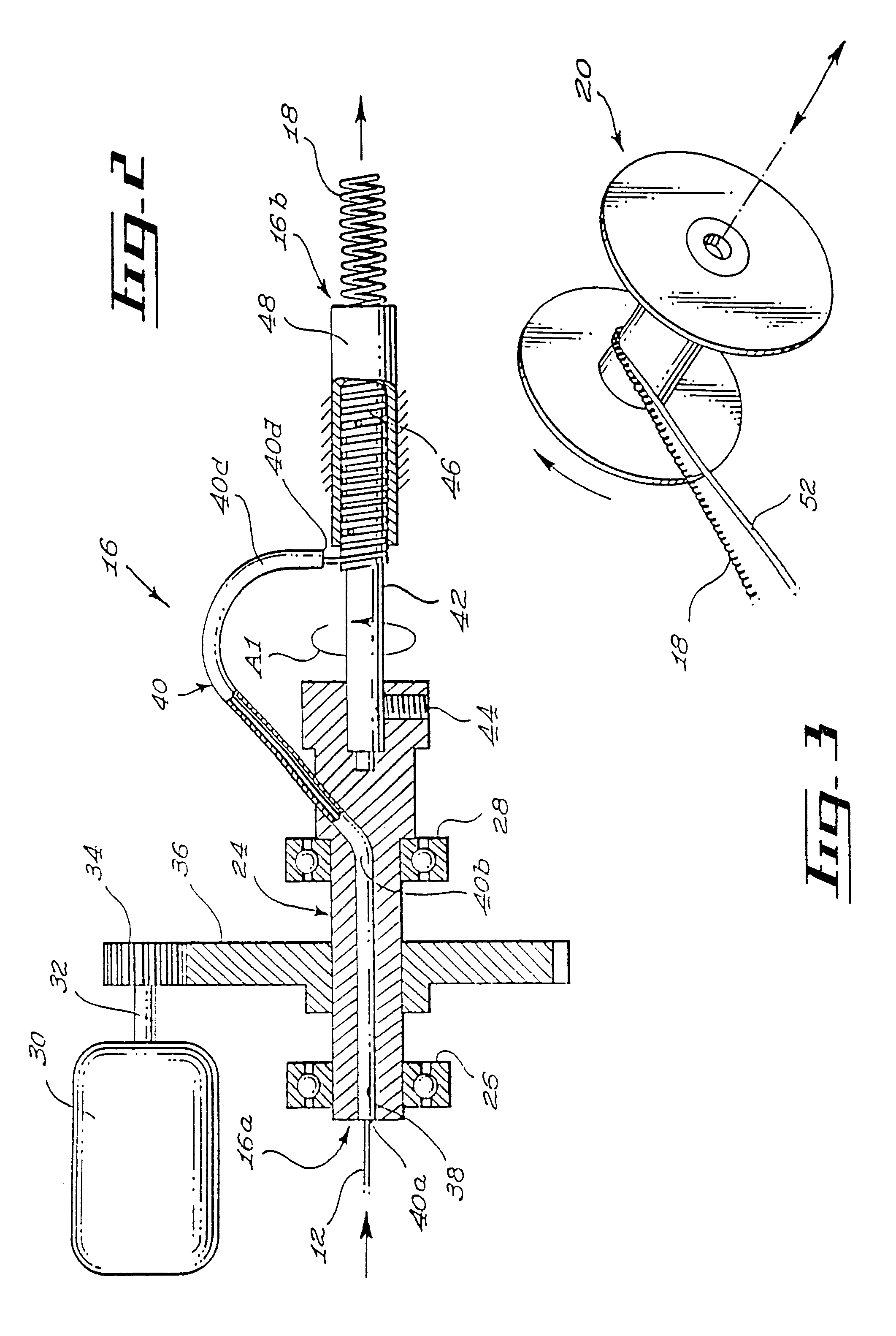

Method and apparatus for forming plastic coils

Owner:2751 3654 QUEBEC

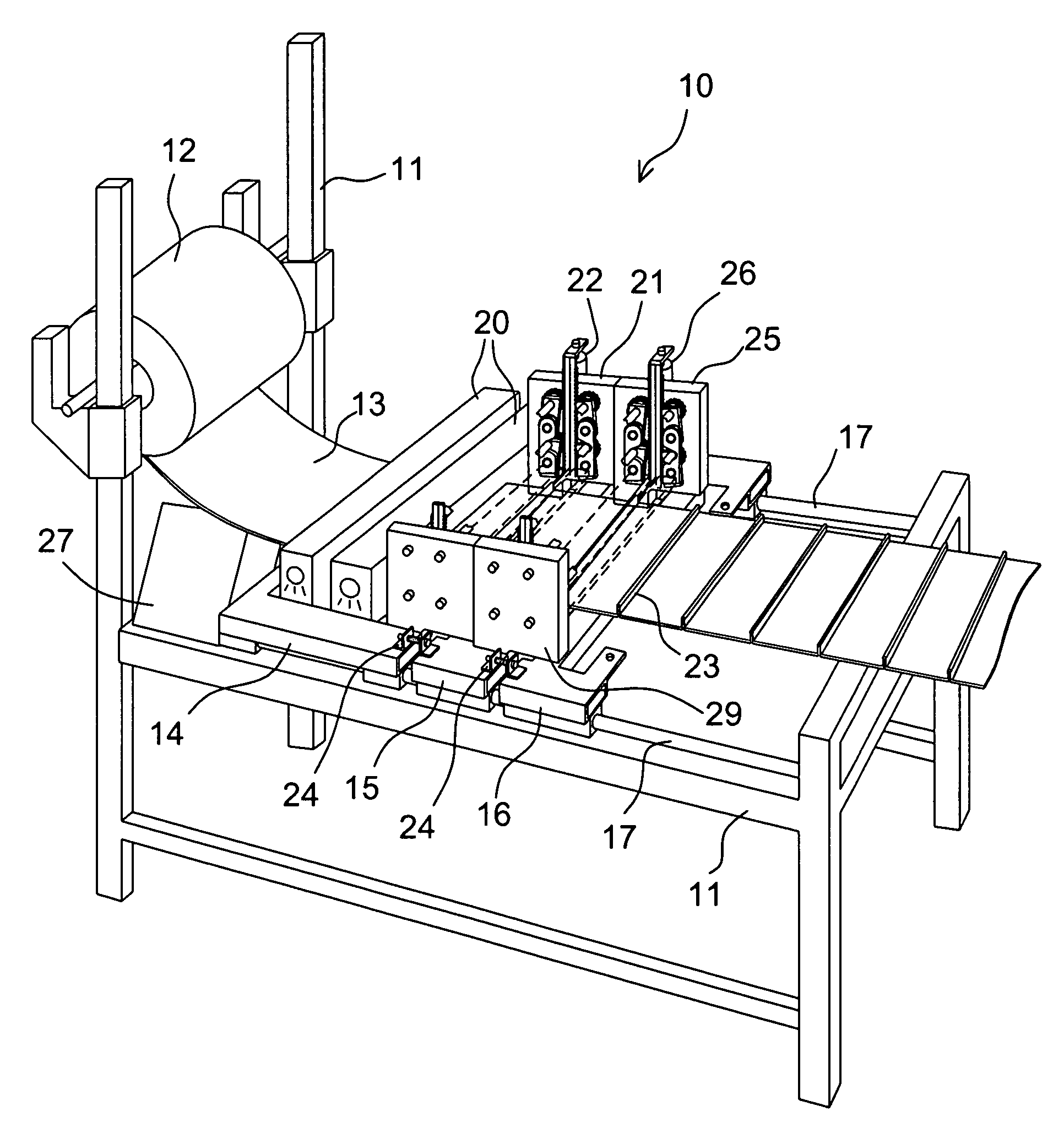

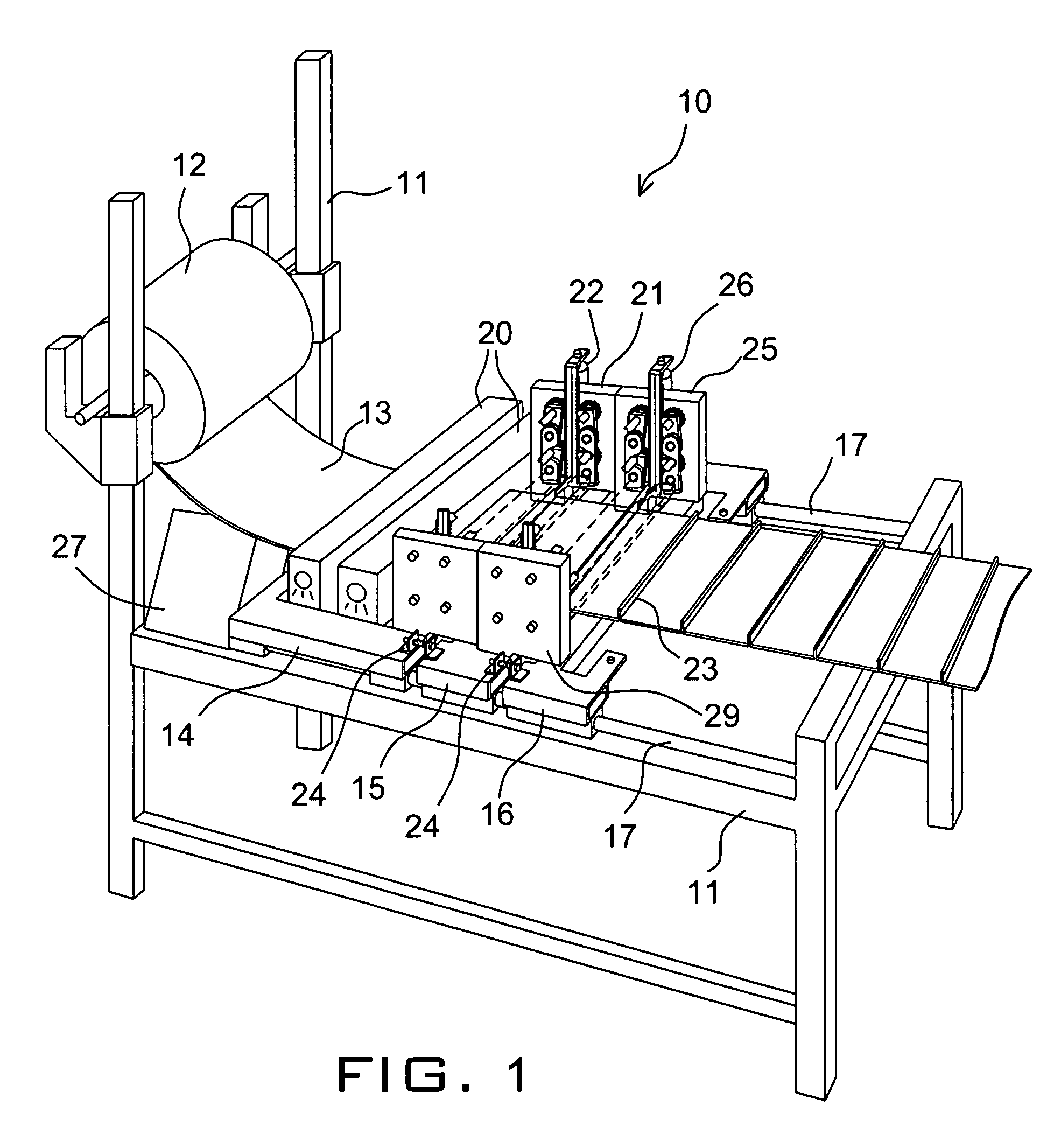

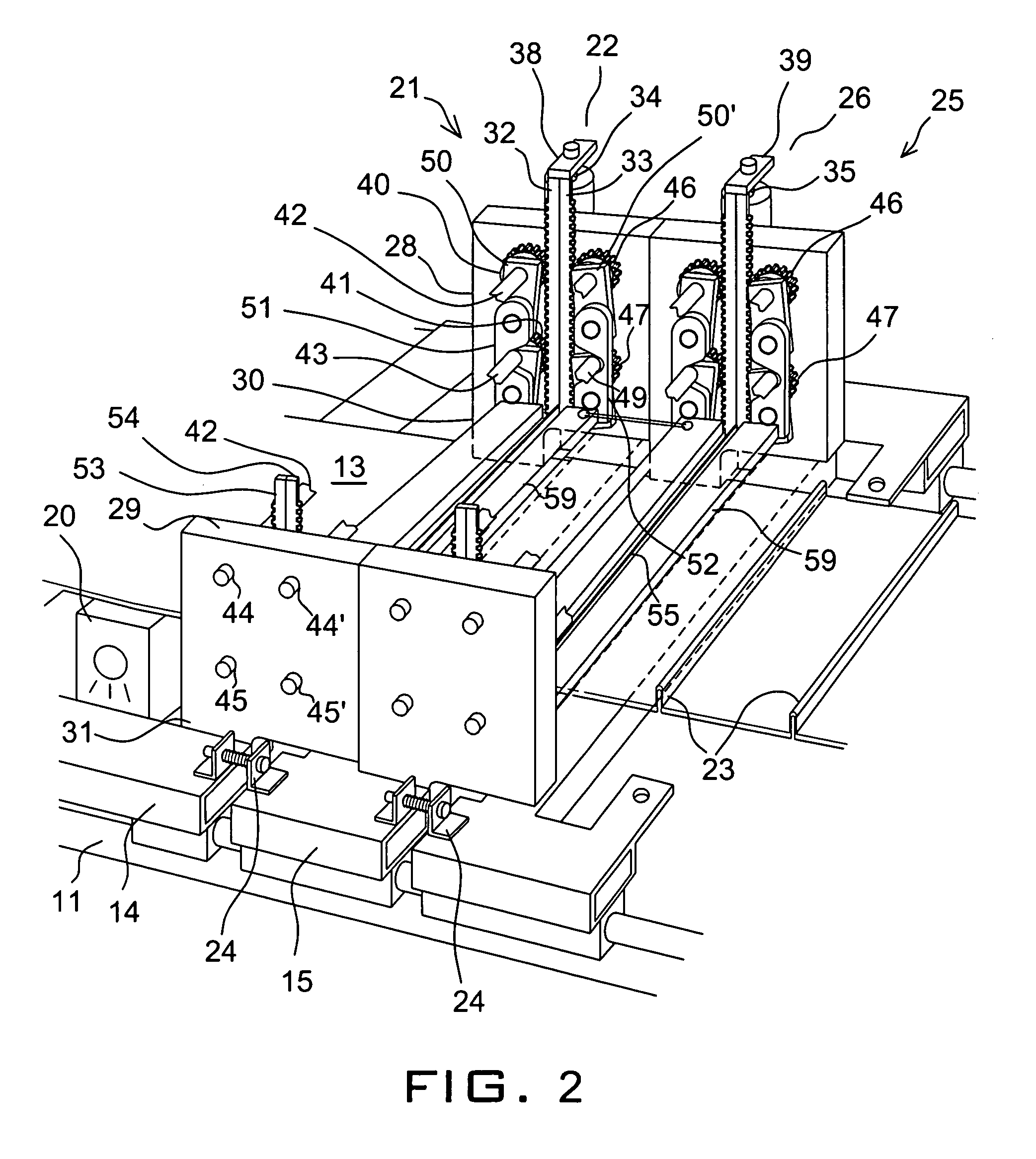

Method and apparatus for making an helical food product

The present invention provides a food product comprising one or more plastic food substrates formed into a helical configuration and coated with a fluid barrier agent to prevent reannealing of adjacent turns of the product. The fluid barrier agent may be an edible vegetable oil such, for example, as hydrogenated vegetable oil, Soya oil, rape oil, sunflower oil, safflower oil, peanut oil or a mixture of such oils. The product may define a single helix or a multiple helix, e.g. a double or triple helix. The invention also provides a method and apparatus for making such a helical food product.

Owner:BERNARD MATTHEWS FARMS

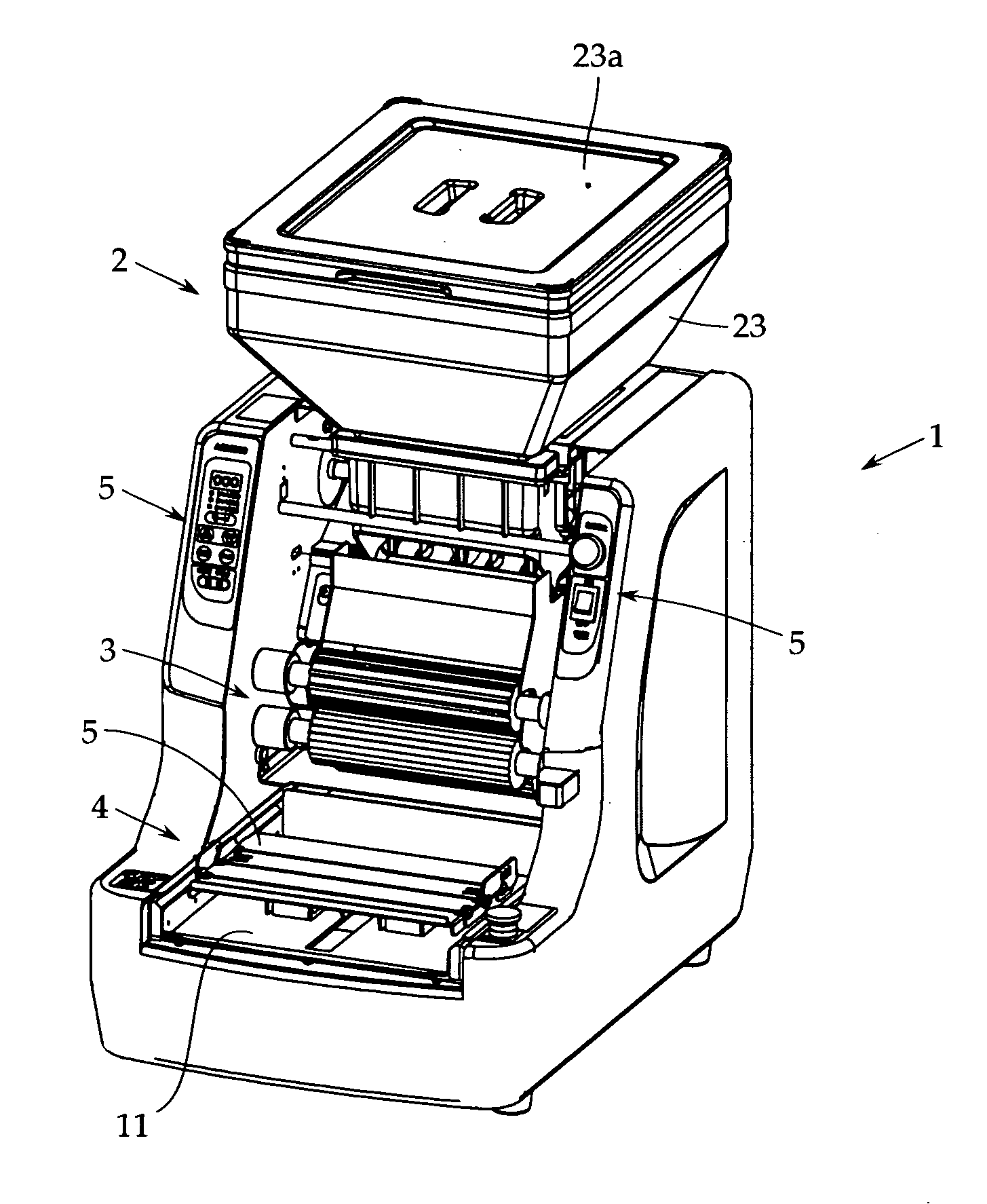

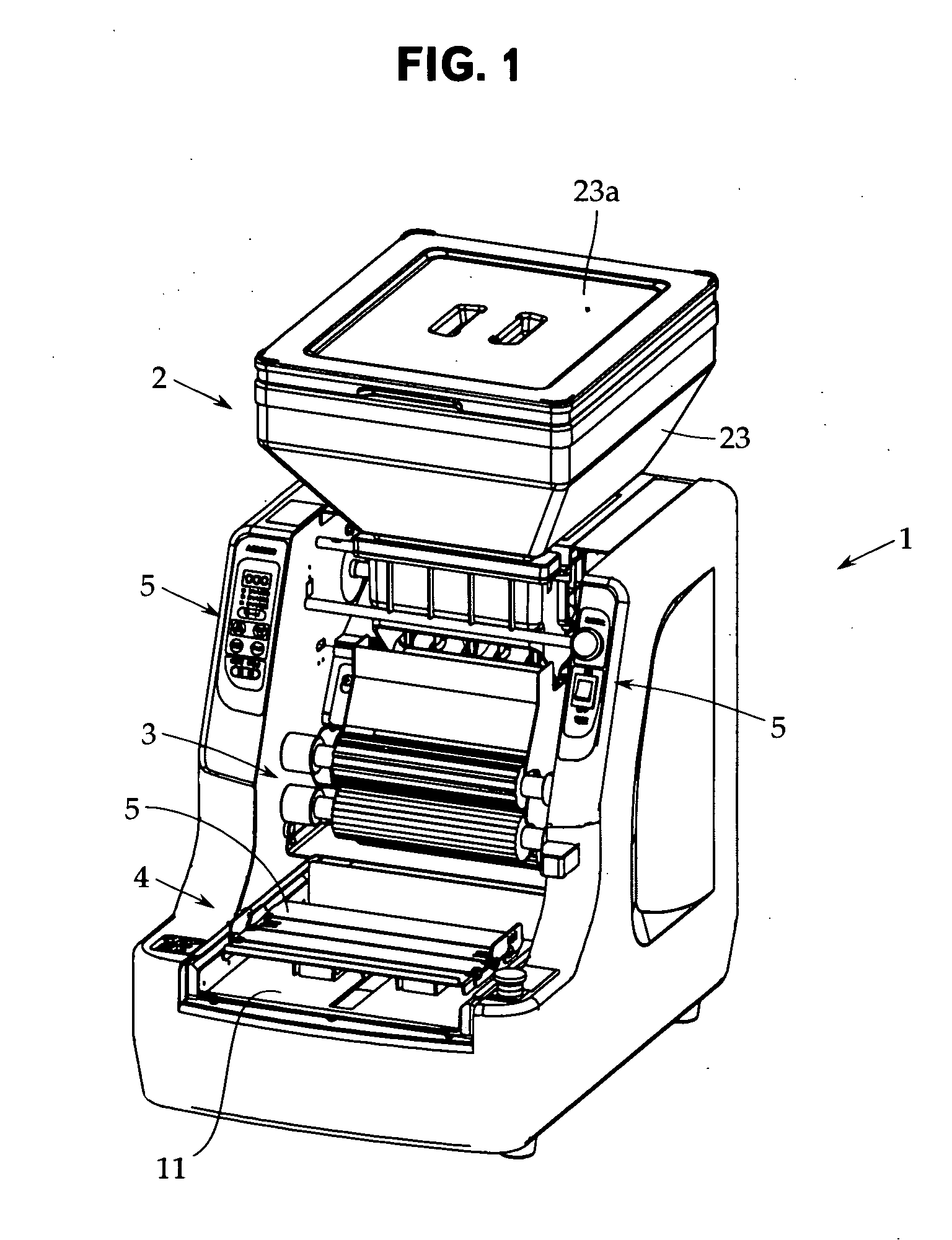

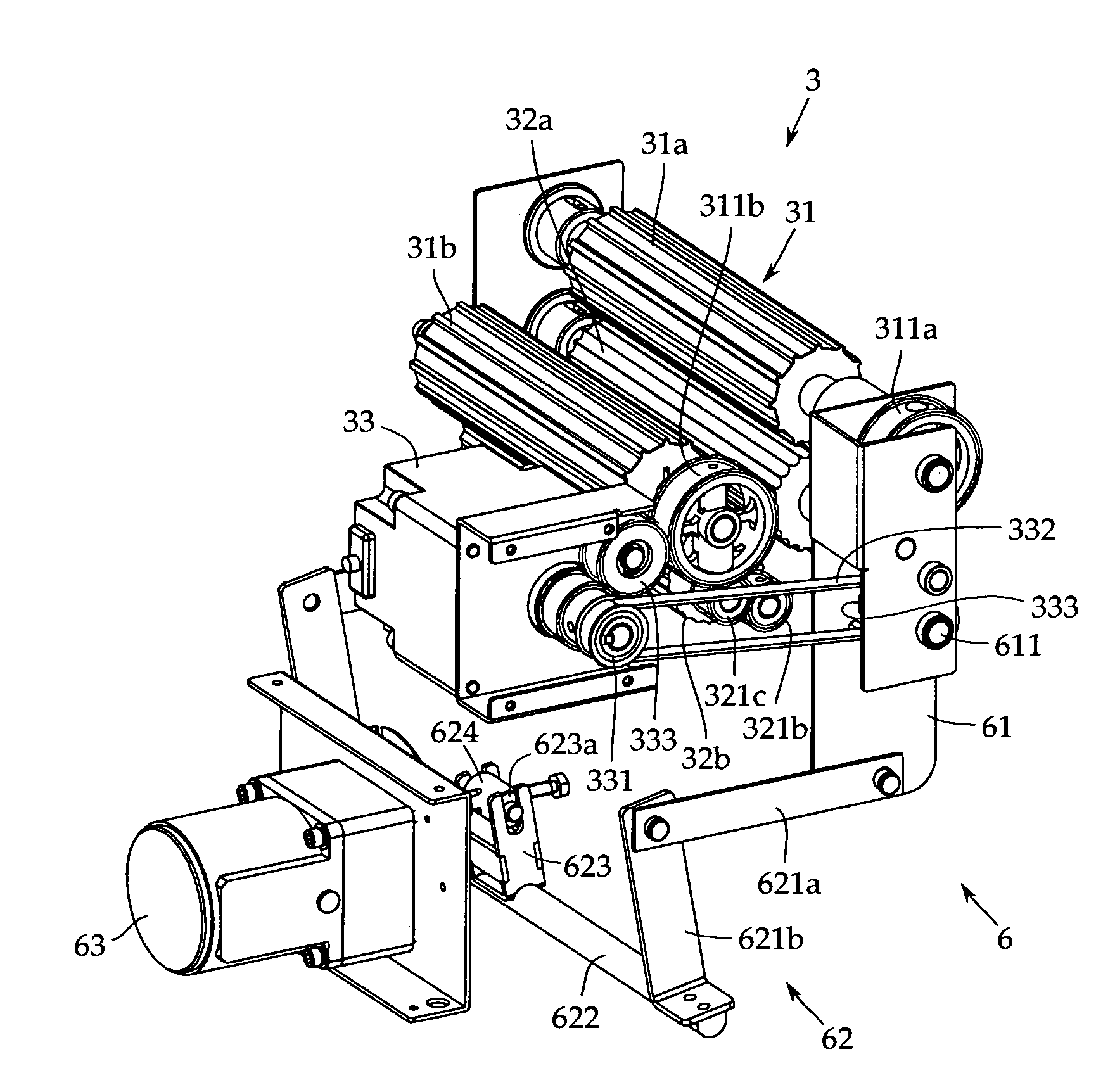

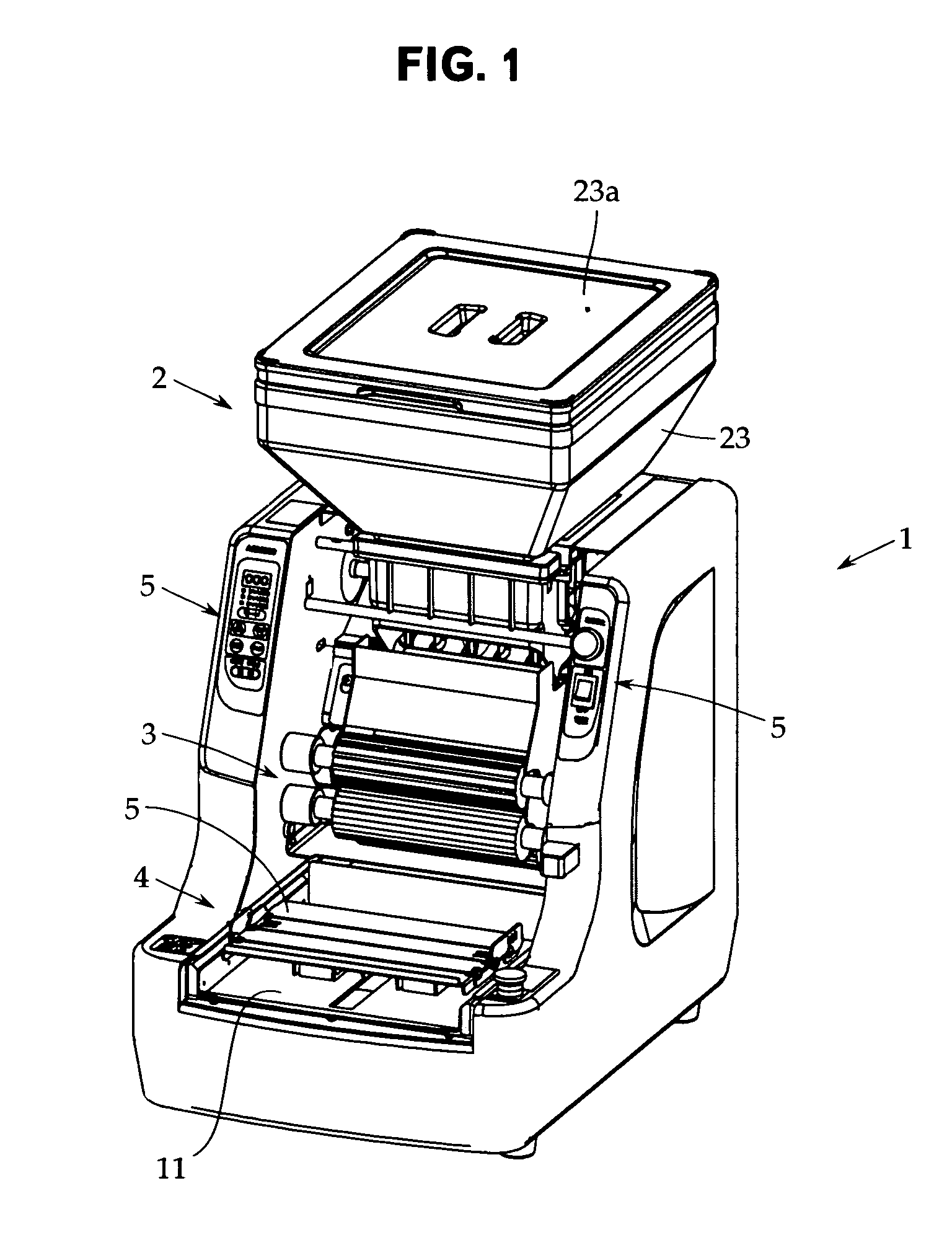

Cooked rice mold apparatus

ActiveUS20080206389A1Complex feed mechanismImprove maintainabilityConfectioneryPress rollersMechanical engineeringExit side

Provided is a cooked rice mold apparatus that can easily adjust the supply amount of sushi rice. The roller spacing of a top rolling roller pair 31 arranged on the exit side of a hopper 2 of a rolling section 4 is variable.

Owner:AUDIO-TECHNICA

Method and apparatus for forming a bent or folded edge rim of a self-supporting thin-walled molded component

InactiveUS20030232160A1Easy to operateAvoid the needEnvelopes/bags making machineryDough sheet coiling machinesFree edgeEngineering

An apparatus includes several bending units for forming a singly-bent or doubly-folded edge rim around the perimeter of a molded component, e.g. a laminated contoured interior trim component for a motor vehicle. Each bending unit includes an electrically heatable cutting or impressing tool, and a bending tool. A workpiece holder clamps the component into a forming mold. The heated impressing tool melts and presses one or two grooves forming weakened zones and corresponding bending lines in the edge rim of the component. The bending tool then presses and bends the edge rim flange back along the bending line. Optionally, the bending tool additionally bends the free edge flange portion down along the second bending line to form the doubly-folded rim. The portions of the rim folded against each other are melt-bonded together and then cooled to permanently fix the bonded and folded configuration of the rim.

Owner:R S TECHN

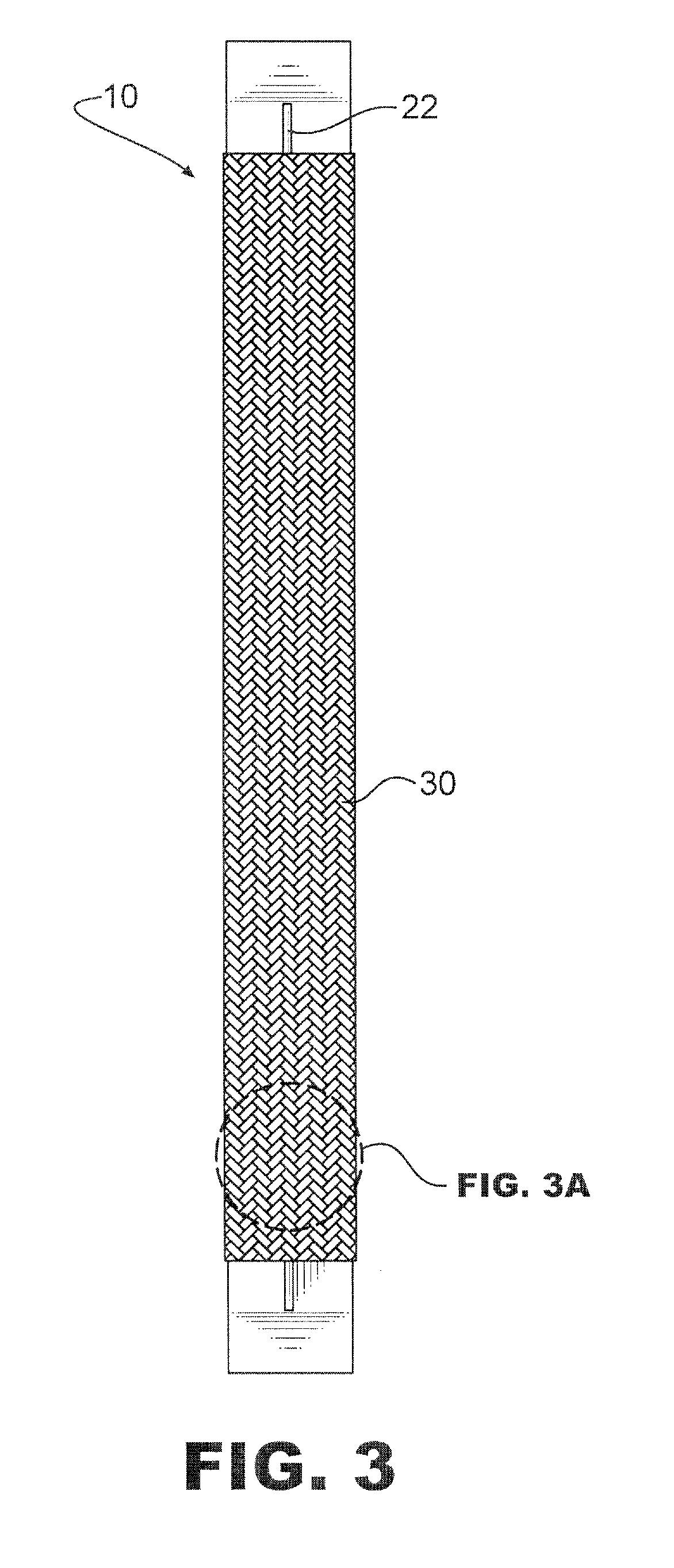

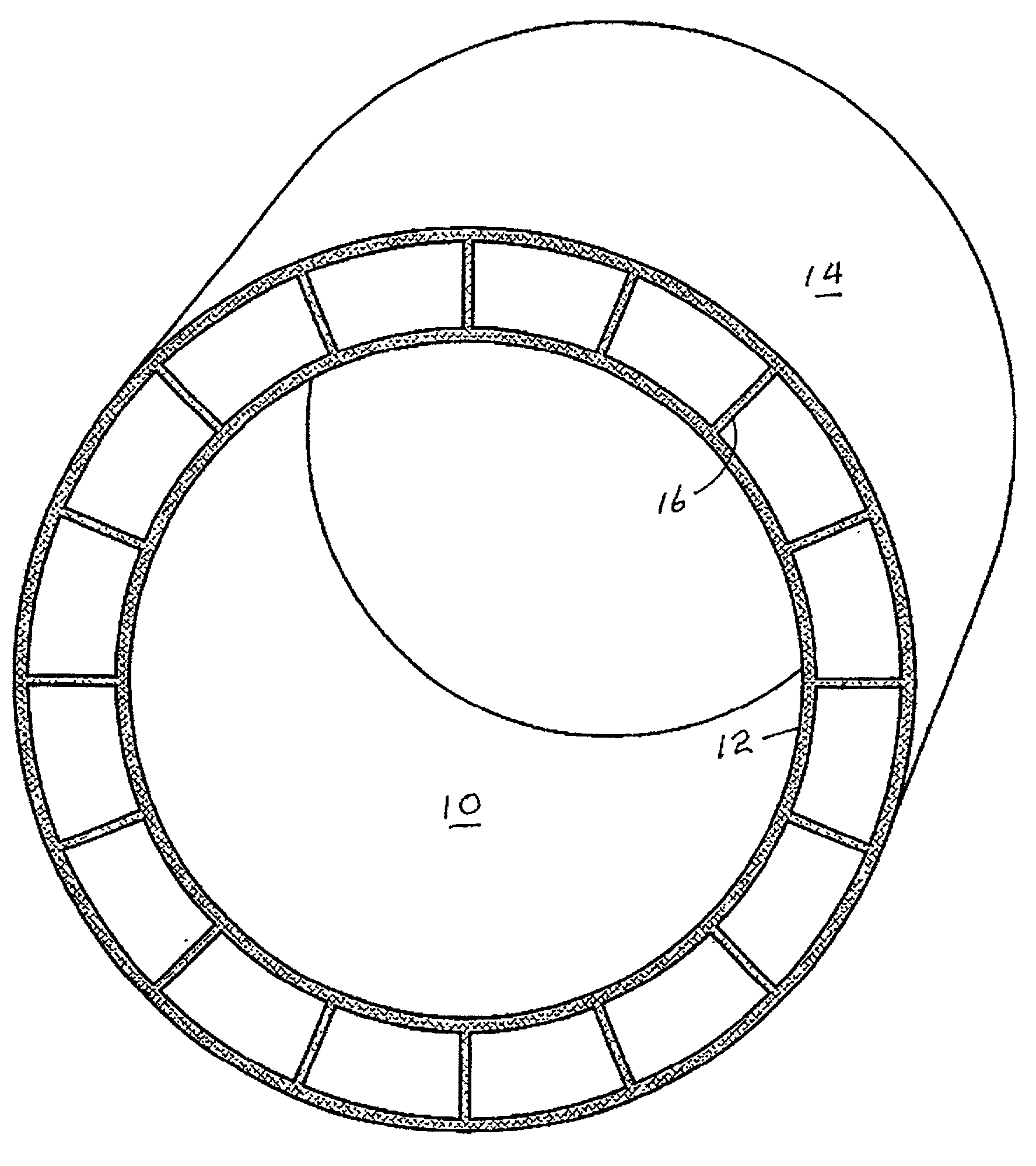

Composite mandrel

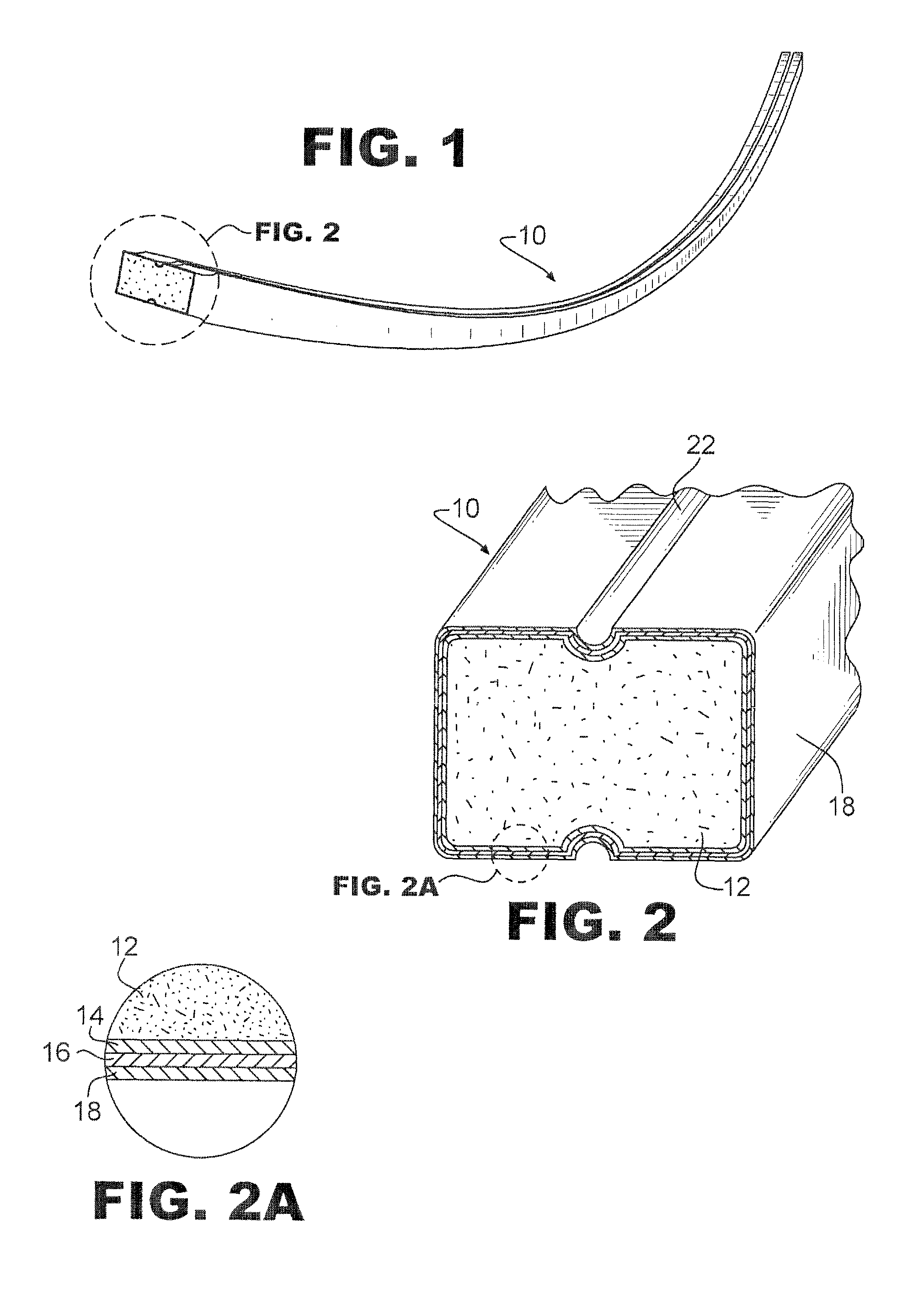

InactiveUS7815160B2Increase stiffnessReduce weightDough sheet coiling machinesLaminationGlass fiberFiber

A mandrel for use as a substrate in the manufacture of woven or braided articles may comprise an inner core of foam; at least a first intermediate layer of carbon fiber-reinforced resin; and an outer layer of glass fiber-reinforced resin. The foam core may comprise a high density, closed cell polyurethane foam that is formed of a desired size and shape. The fibers in the intermediate layer and outer layer may be, for example, chopped fibers, continuous longitudinally aligned fibers, circumferentially wound fibers, obliquely aligned fibers, or the fibers may have a woven or braided pattern. Multiple mandrel may be joined together to form complex mandrel shapes such as curves, ovals, and circles.

Owner:A&P TECH

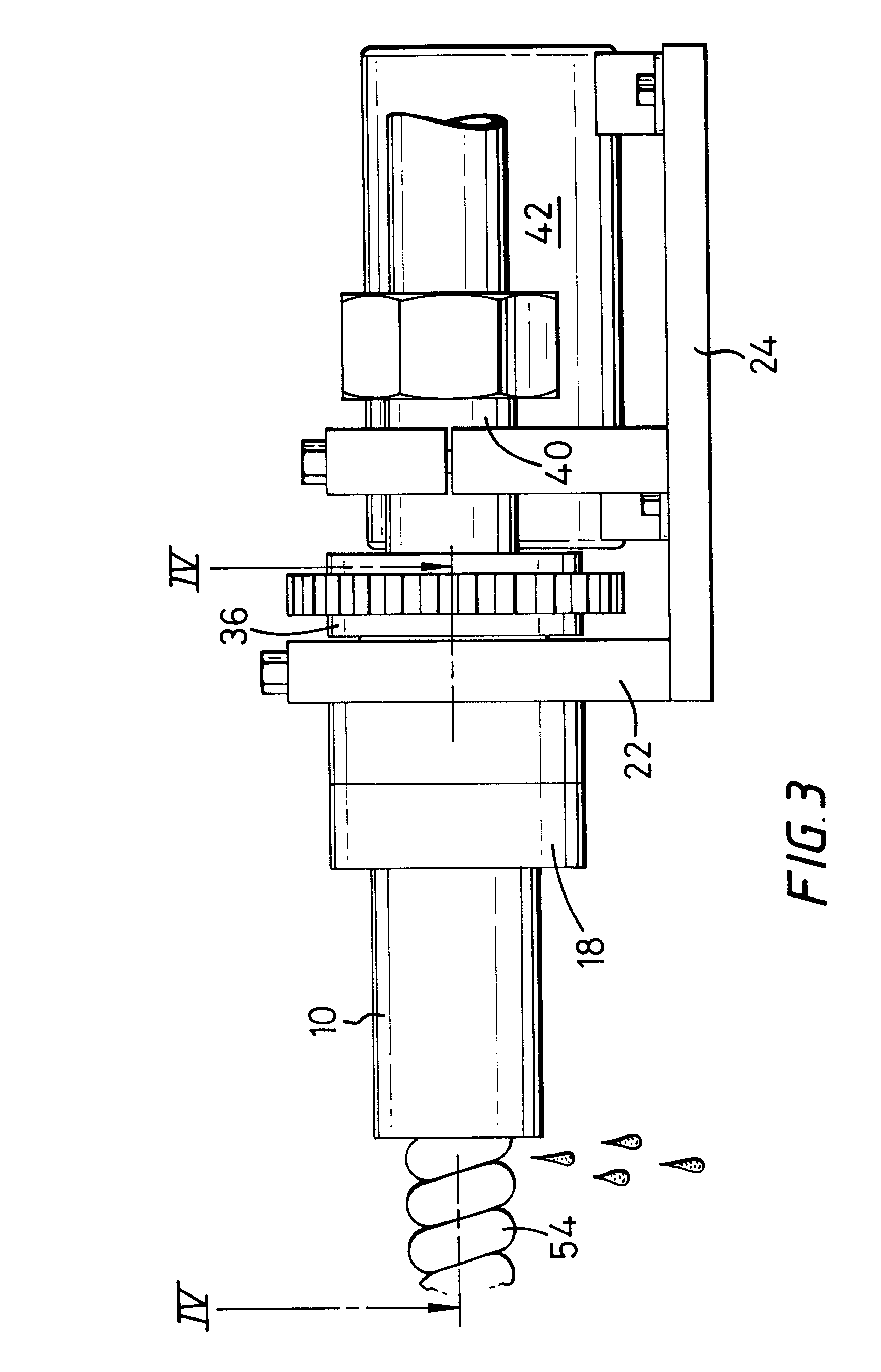

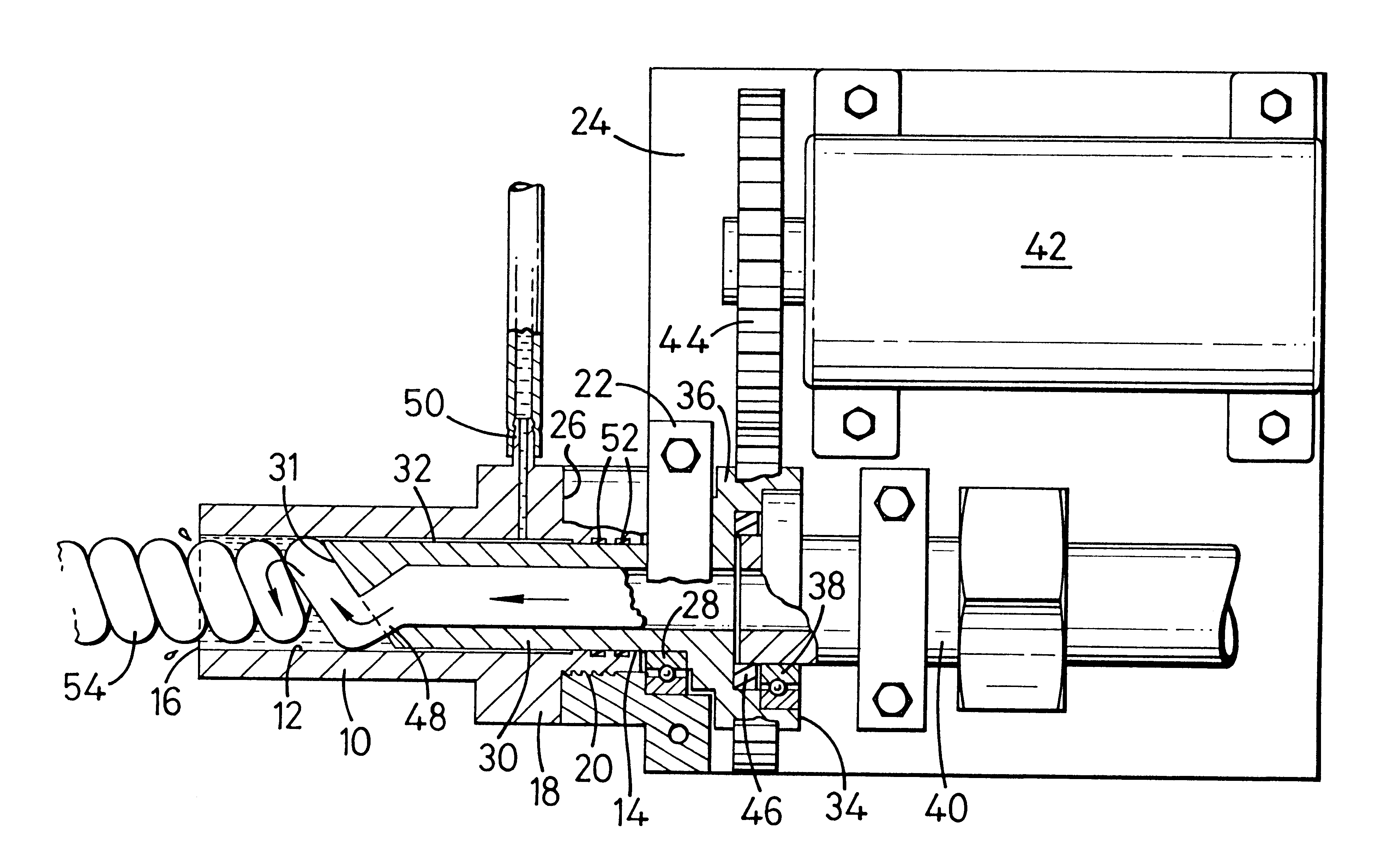

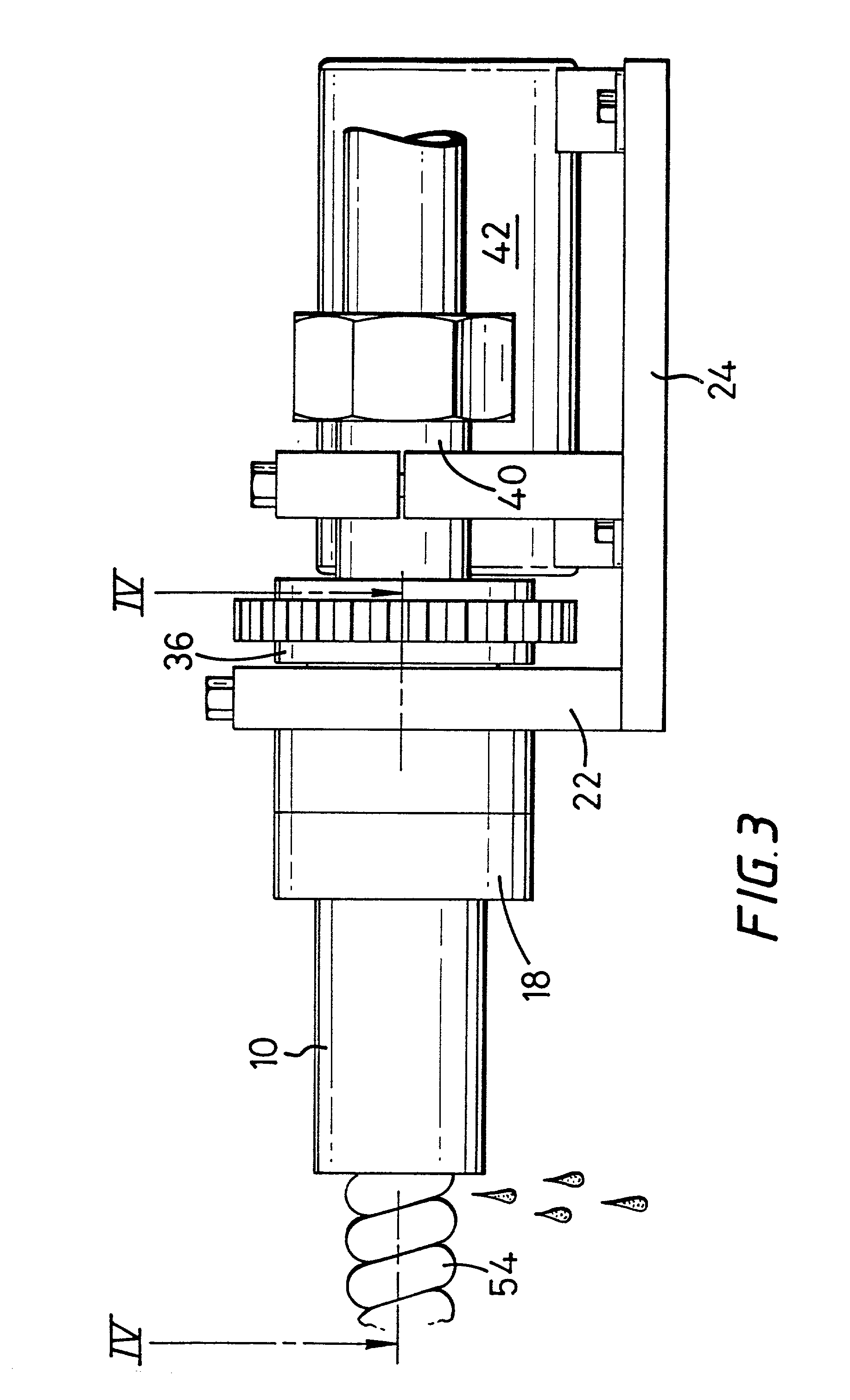

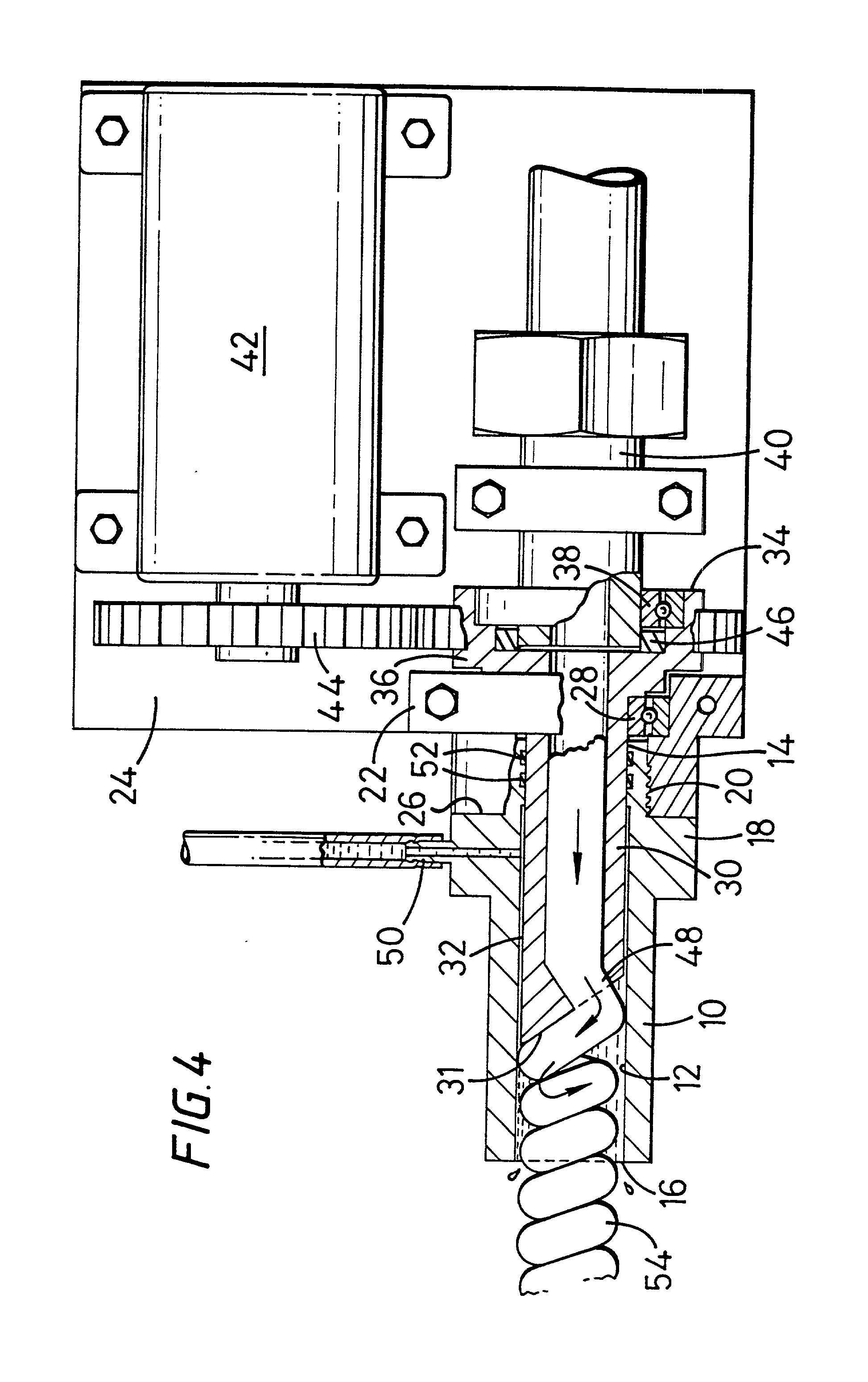

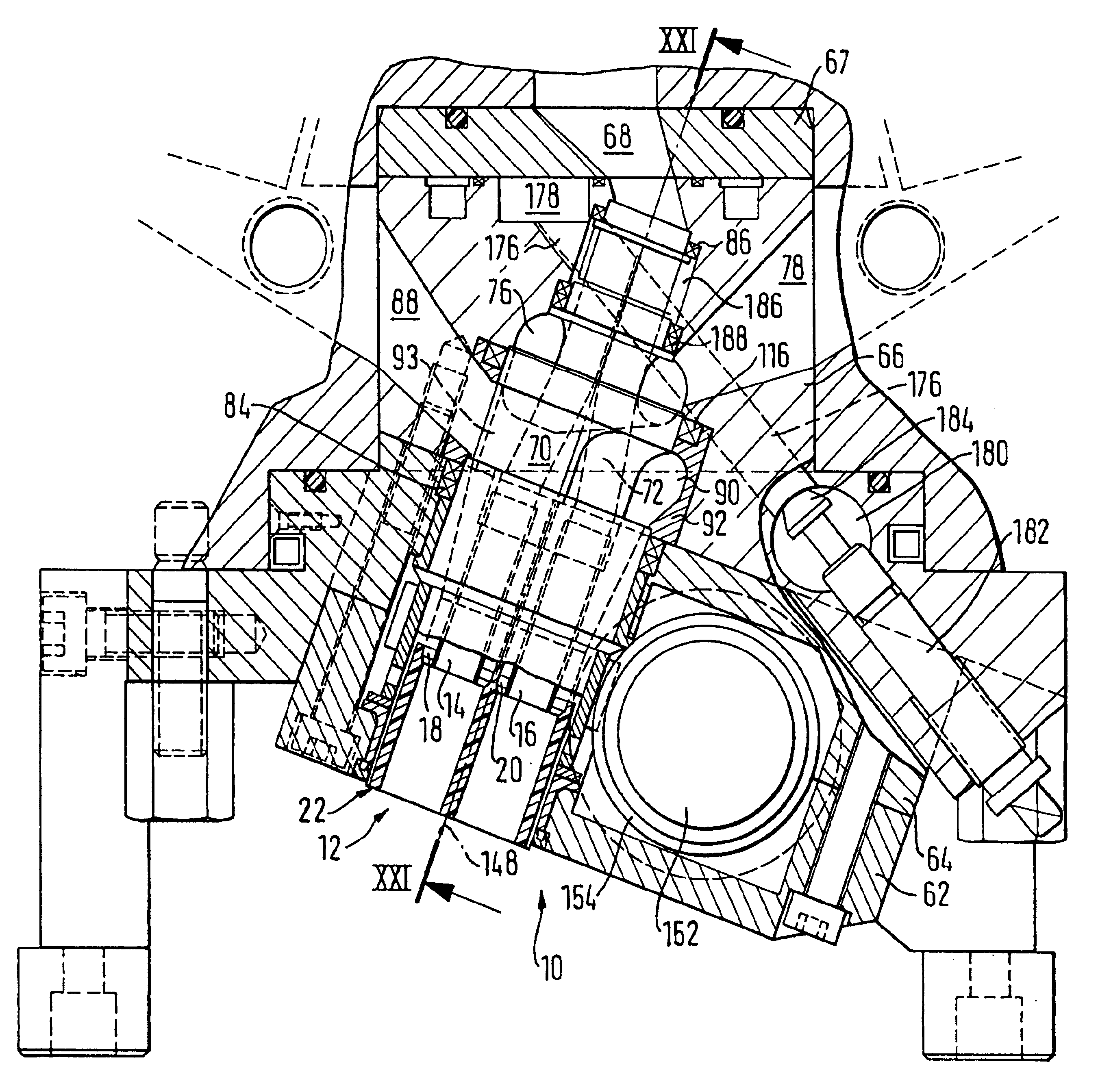

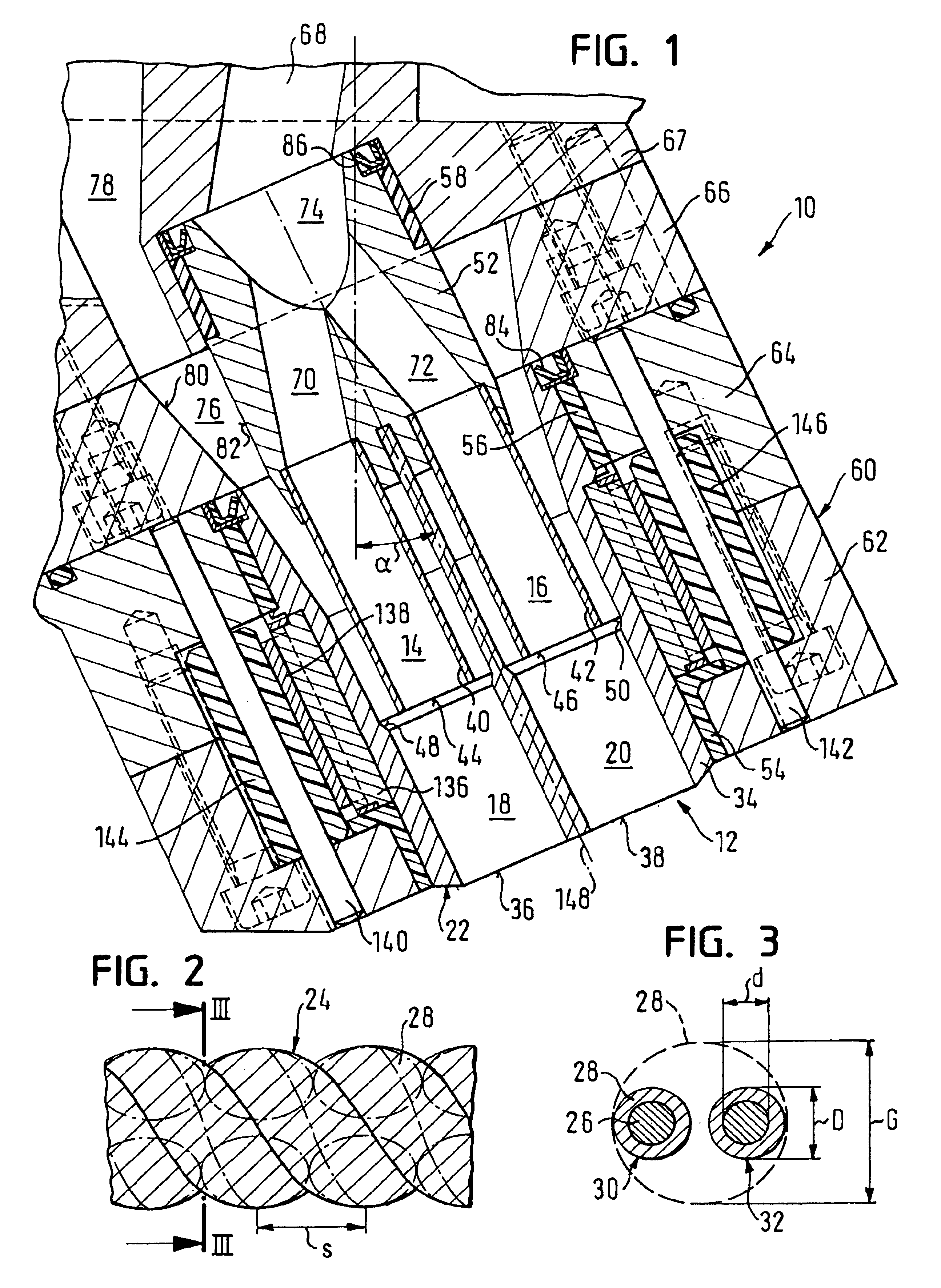

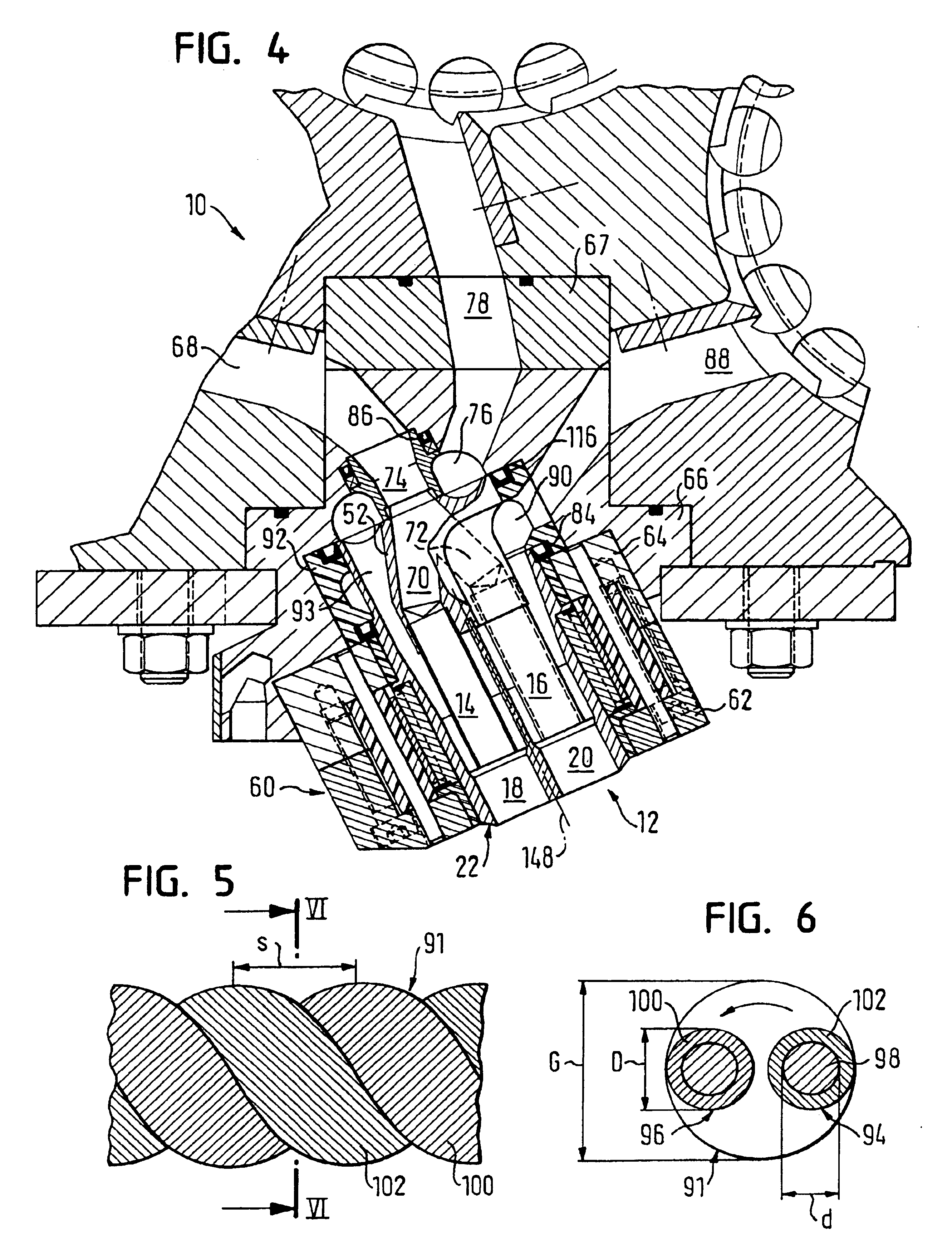

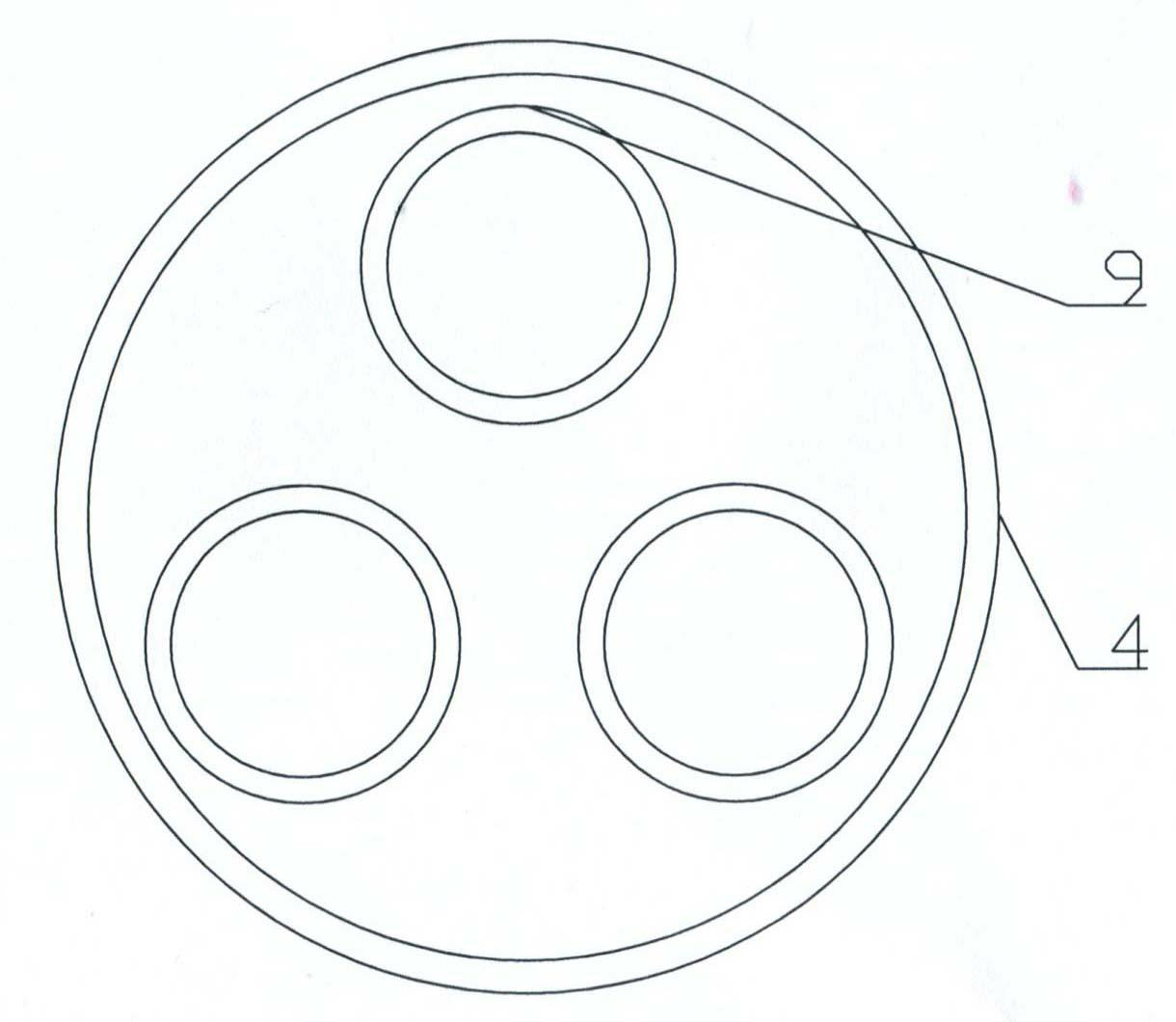

Nozzle arrangement, nozzle carrier and device for extruding doughy substances

InactiveUS6896504B2Improve accuracyHigh precisionPower operated devicesFrozen sweetsEngineeringNozzle

For producing coiled bakery products comprising two strands each made of an outer and an inner doughy substance, a nozzle arrangement (12) comprises two inner nozzles (14, 16), which are each surrounded by an outer nozzle (18, 20), wherein all of the nozzles (14, 16, 18, 20) are rotatable about a common axis of rotation (148).

Owner:HOSOKAWA BEPEX

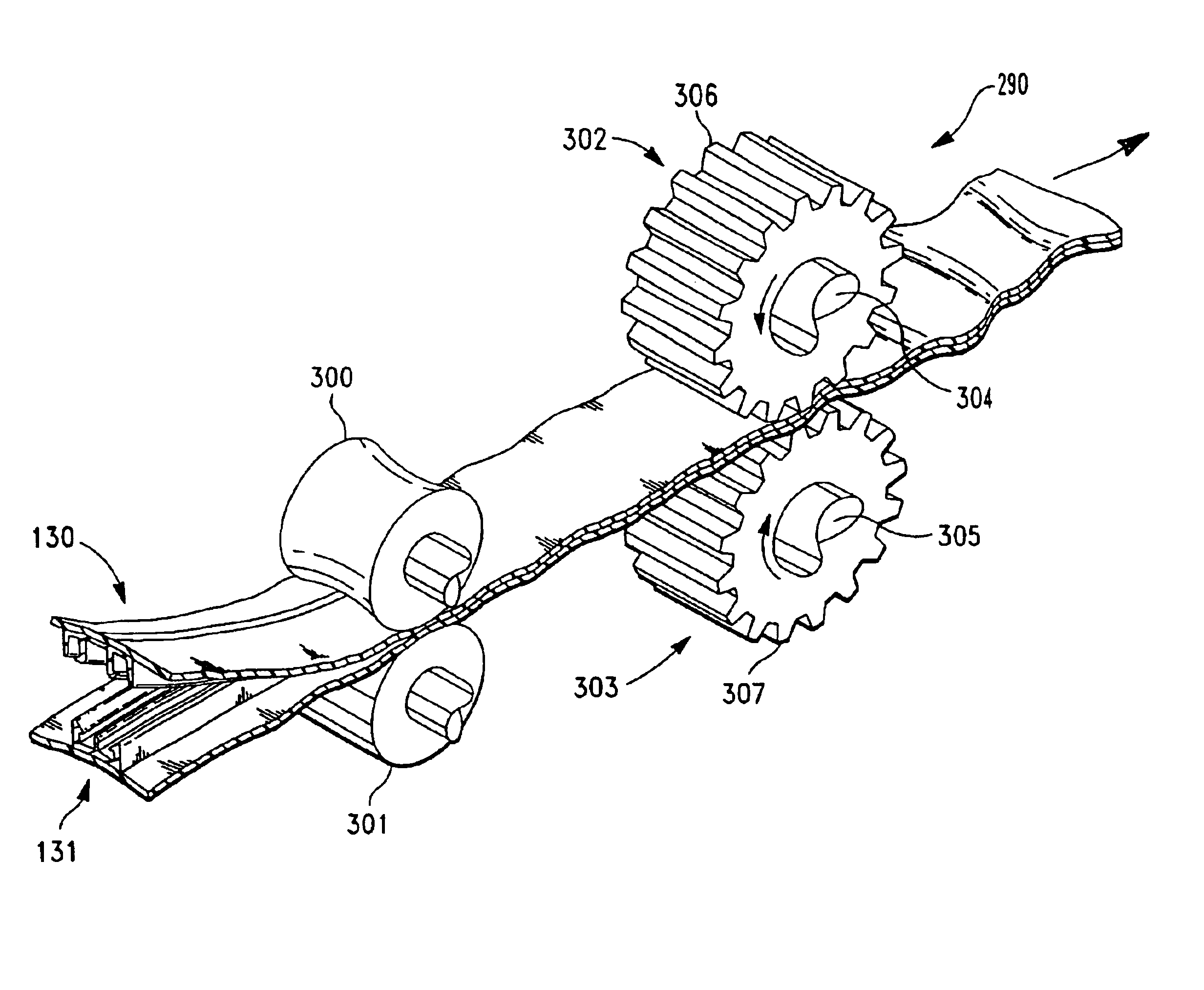

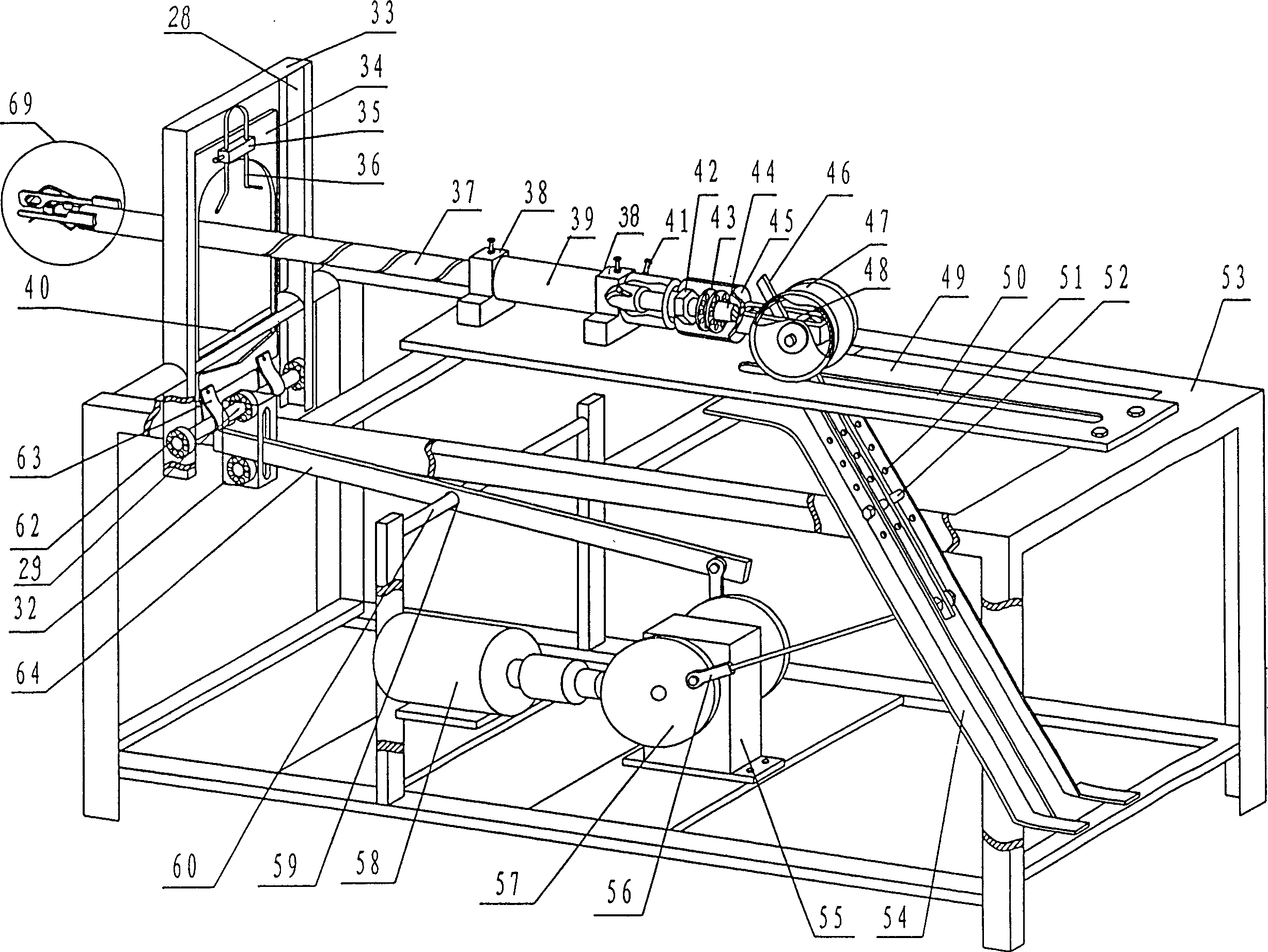

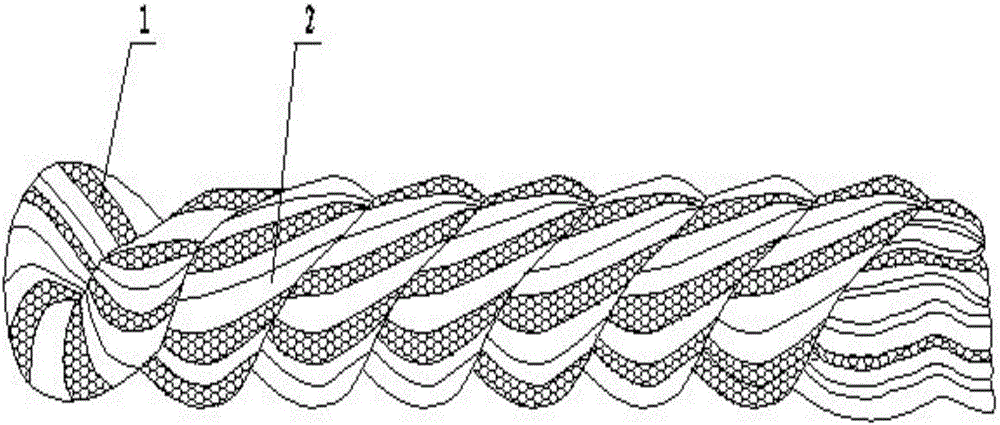

Machine for making double-stranded farci fried dough twists

InactiveCN101461412AIngenious ideaReasonable designBakery productsDough shaping and dividing combinationHydraulic cylinderMotor drive

The invention relates to a double strand stuffing wrapped fried dough twist machine, which comprises a hydraulic four-cylinder full automatic feeding and shaping mechanism, adopts PLC program-controller to realize full-automatic circular continuous production. In the mechanism, the motor drives the oil pump which promote the hydraulic cylinder piston to drive the two dough cylinders and the two stuffing cylinders of the hydraulic four-cylinder feeding mechanism to operate alternatively. The two single strand screw shaping heads in the shaping mechanism rotates under the effect of the revolving chain wheel driving and the ring gear, to make the extruded a plurality of flour strips and a stuffing strip into two single strand screws with the flour strips round the stuffing strip; the revolving of the shaping mechanism drive the two single screws to enwind with each other into a complex screw; when the complex screw is conveyed to the cutting tool position by a conveyor belt, the rotating cutting tool cuts it into dough twists blank, and moves it forward; then the conveyor belt conveys the cut dough twist blanks into a fryer for frying to obtain the product which is same as the fried dough twist made by Tianjin traditional handwork method. The invention achieves the advantages of reasonable structure, energy saving, high efficiency and sanitary, and can make the fried dough twists with standard good appearance.

Owner:徐志兴

Crackling stuffing soft fried dough twist

The invention provides a method for making fried dough twist, which comprises steps of mixing allume 0.01-0.1 part, white sugar 2-4 parts, eggs 5-12 parts, flour 90-110 parts and salad oil 5-12 parts, charging cold water and diluting, adding in stuffing and placing into cooking oil pot, frying three times at oil temperature of 100-170 deg C and taking out.

Owner:王成刚

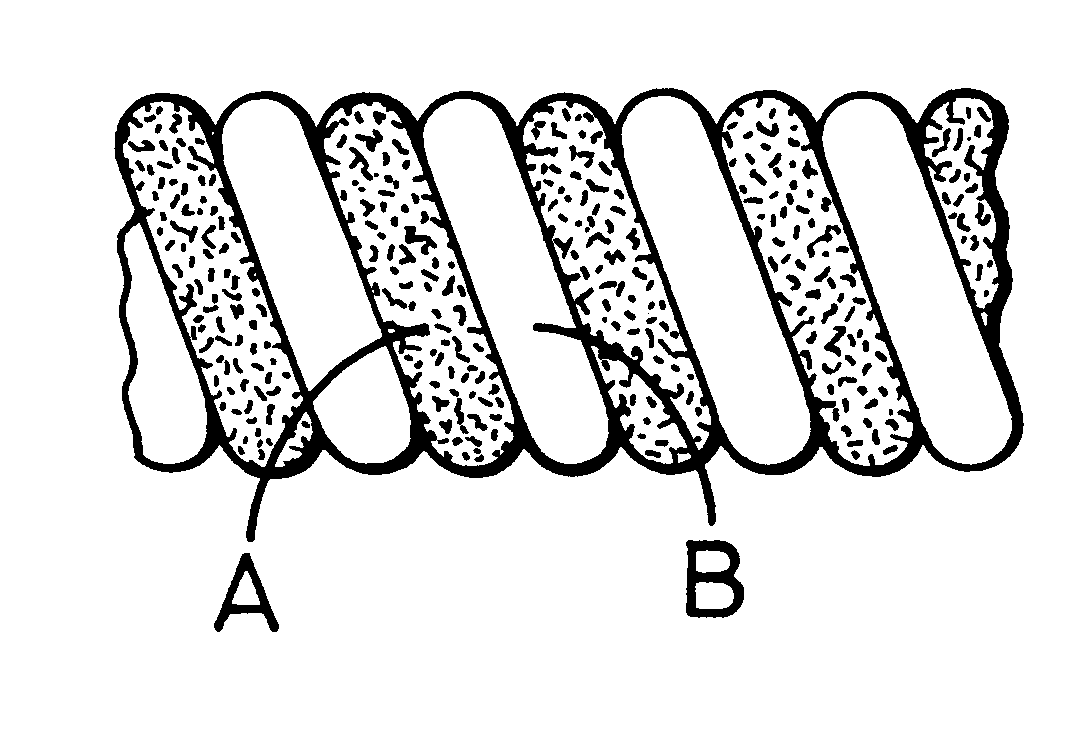

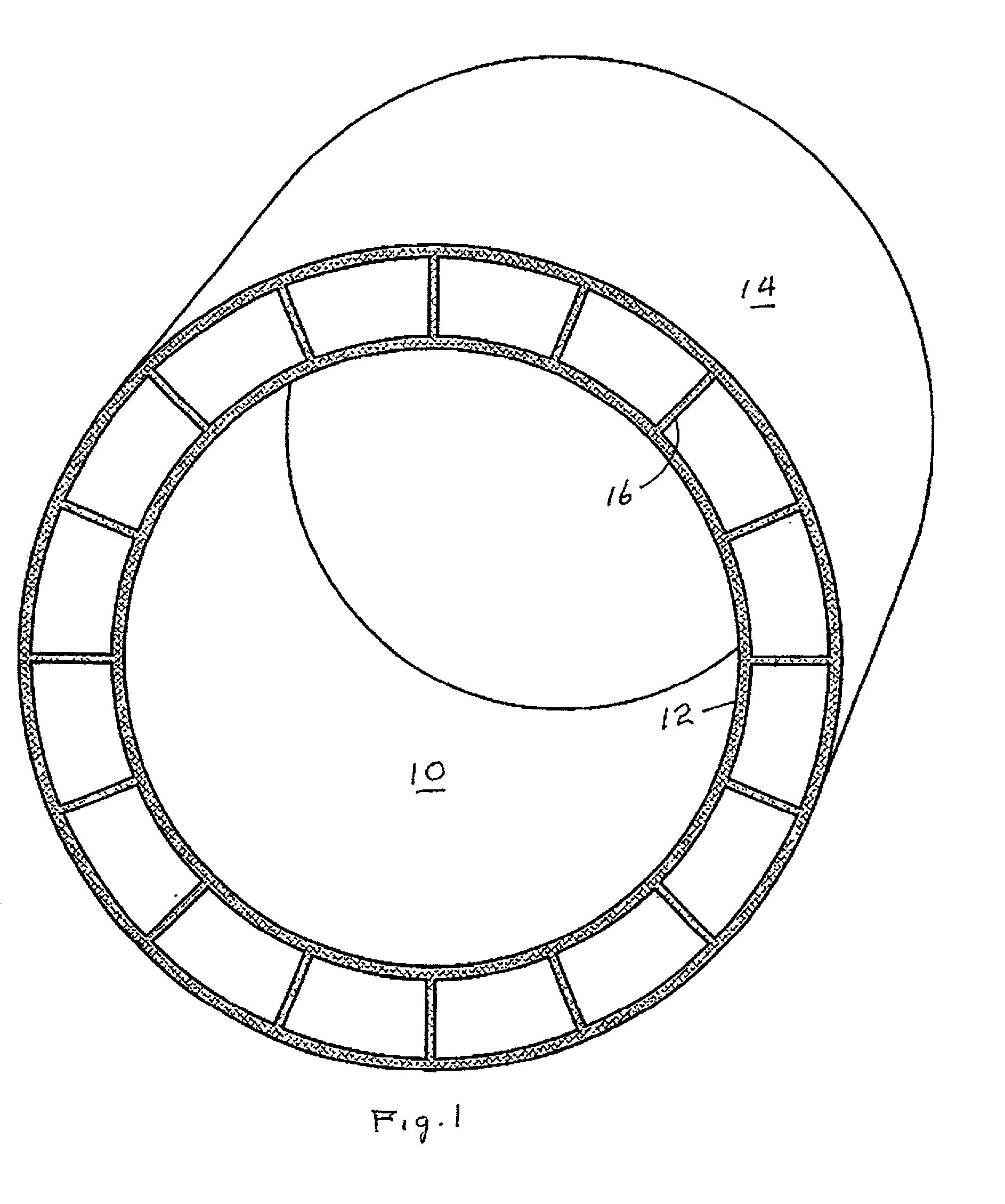

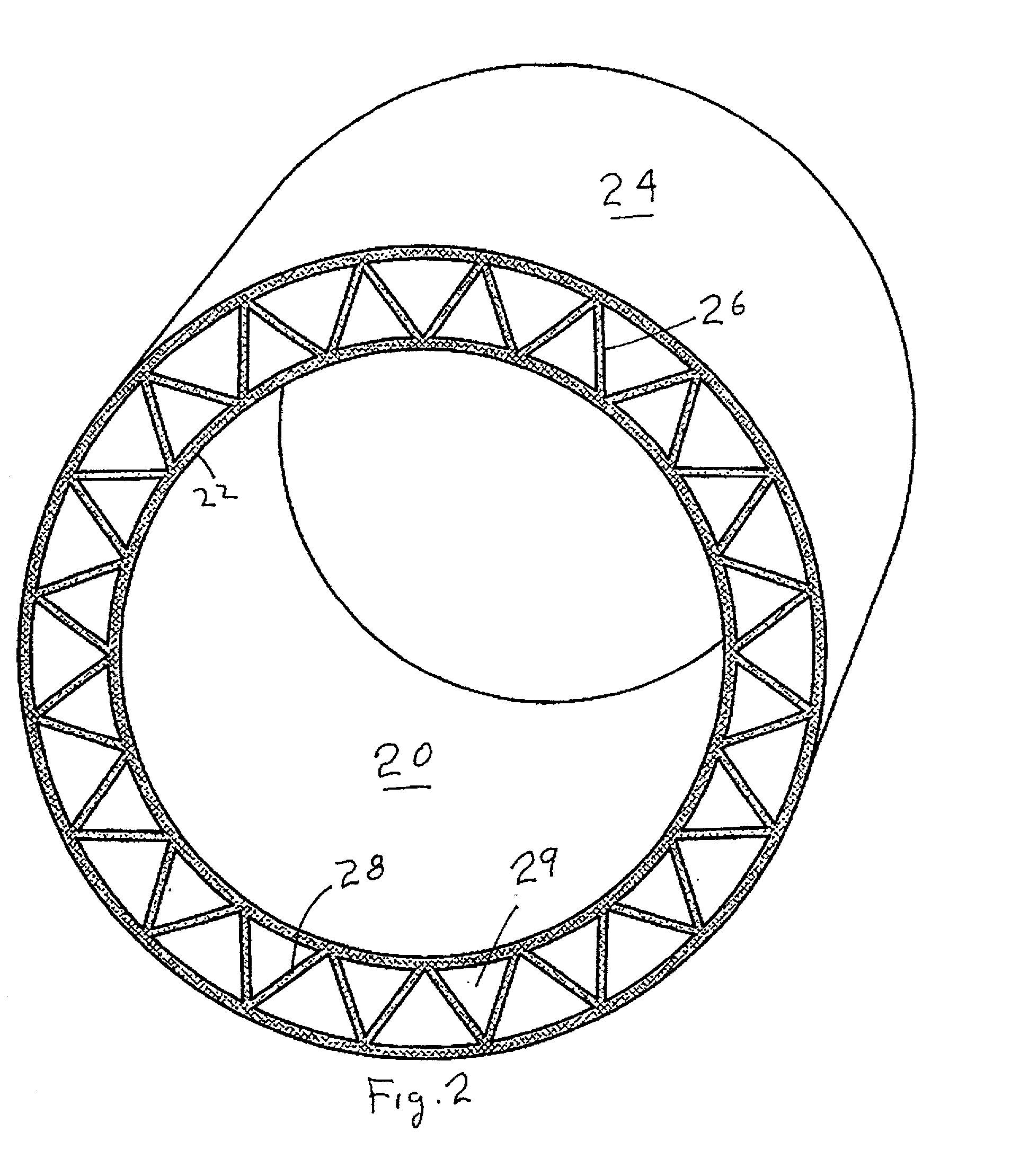

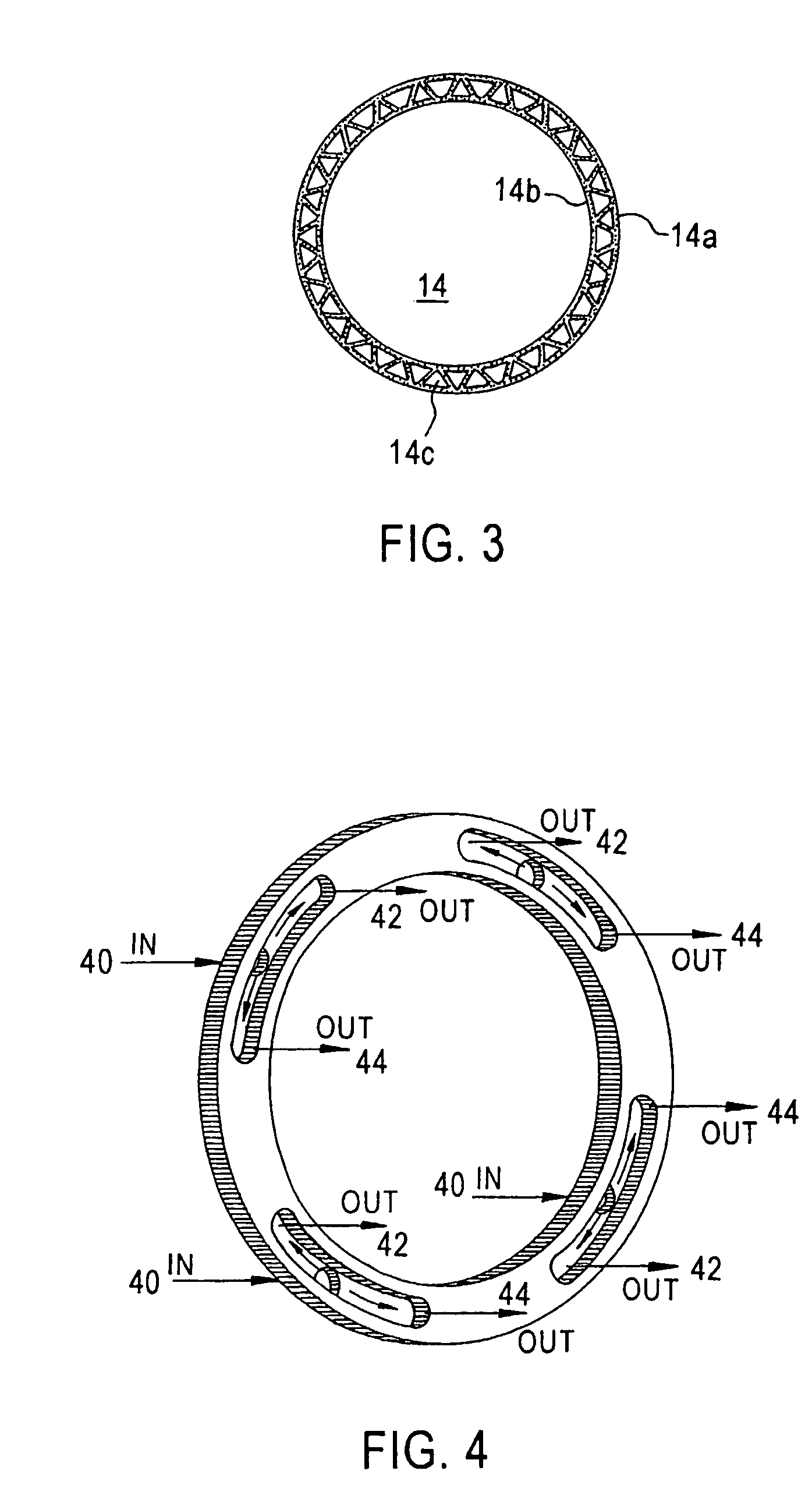

Ribbed core dual wall structure

InactiveUS20020125607A1Improve roundnessConsistent spacingCeramic shaping apparatusHollow wall articlesDouble wallEngineering

An elongated composite tube made up of an inner tube 42 and an outer tube 44 (see FIG. 3) with a plurality of elongated helical ribs disposed between the inner tube and the outer tube in a supporting relationship to both. A slinky like toy made from the composite tube is also disclosed, as is a method of making both.

Owner:PROTEUS

Transporting apparatus

Owner:RHEON AUTOMATIC MASCH CO LTD

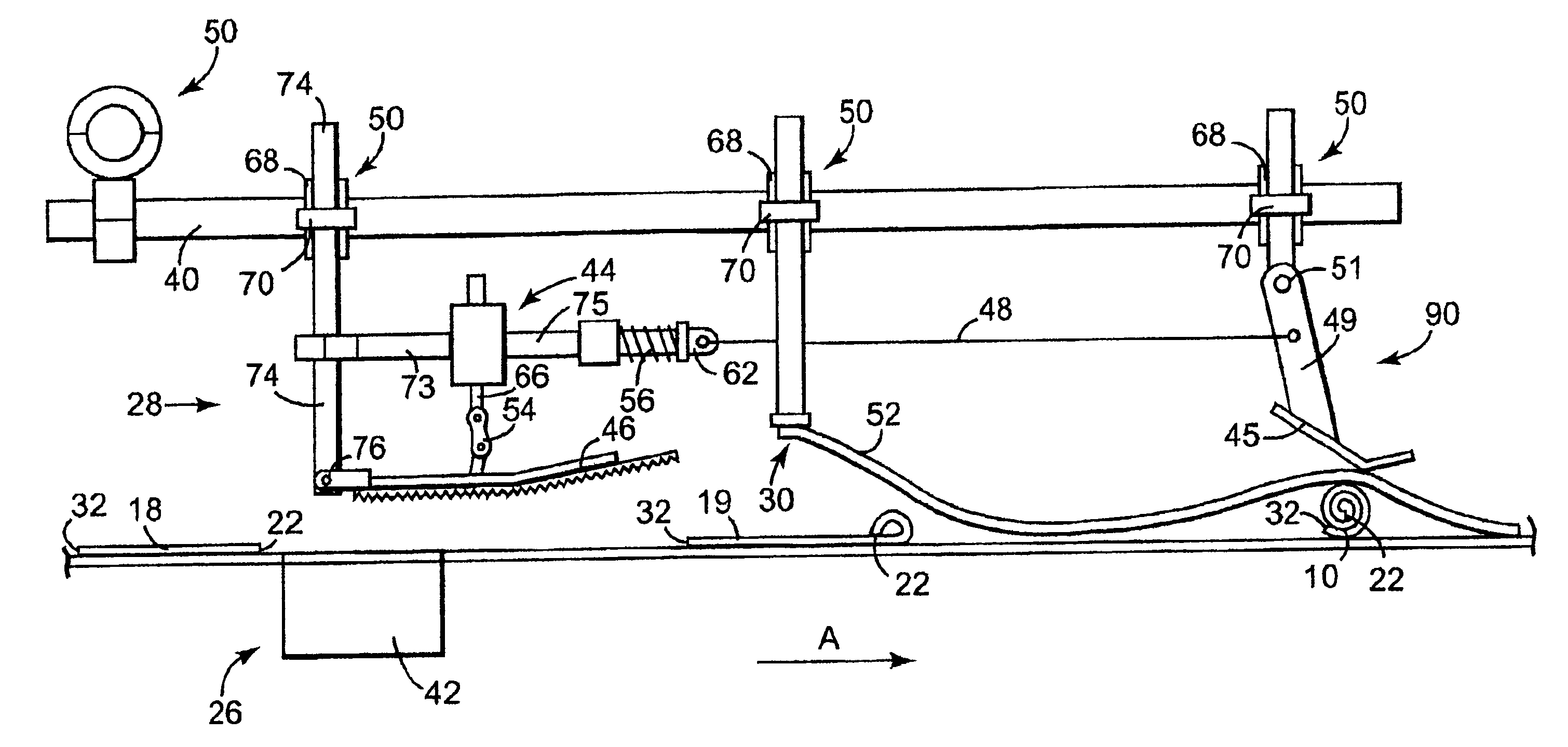

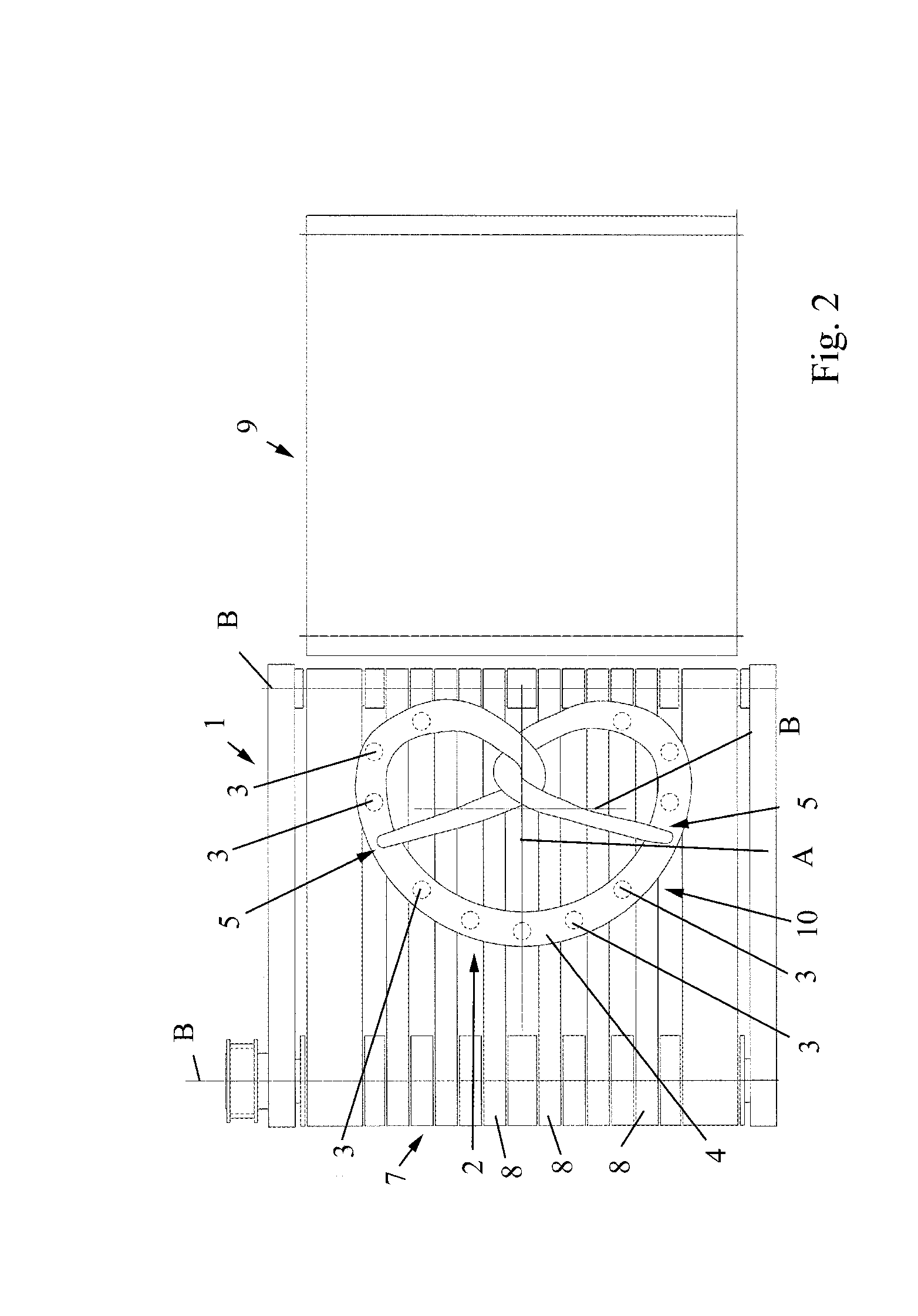

Process For Knotting A Dough Strand Into A Desired Form, Especially Knotting A Dough Strand In A Pretzel Form, Plus Related Apparatus

InactiveUS20100159098A1Increase the lengthQuality improvementDough treatmentDough sheet coiling machinesEngineeringActual length

Process for the knotting of a dough strand into a desired form, particularly for the knotting of a dough strand into a pretzel form, wherein the dough strand subject to stretching of the dough strand length is knotted around a form element that provides the desired form for a dough strand with larger starting length than the actual length of the dough strand and / or the desired form with an increased form size, whereupon the form element that establishes the desired form is removed, at least partially, so that the dough strand that was placed into the desired form contracts into a final size.

Owner:FRITSCH GMBH

Plastic coil and method of forming same

Owner:2751 3654 QUEBEC

Method for producing a helically shaped, seamless multi-walled cylindrical article

InactiveUS7550102B2Good strength propertiesReduce the overall diameterCeramic shaping apparatusTube shearing machinesMechanical engineeringHelix

A method of making a composite tubular article made up of at least two concentric members, the outer of said members being tubular and the inner of said members being at least cylindrical and preferably tubular, and struts disposed in supporting and positioning orientation between the inner and outer members, by extruding a moldable material into the desired profile; stretching the inner tubular member over a cooling mandrel and disposing a cooling sleeve over the outer tubular member under conditions sufficient to solidify the article; twisting and longitudinally pulling the solidified article, so that it rotates over the cooling mandrel and inside the cooling sleeve while it is moving down stream across the cooling mandrel, whereby causing the extrudate to be twisted into a helical shape.

Owner:PROTEUS

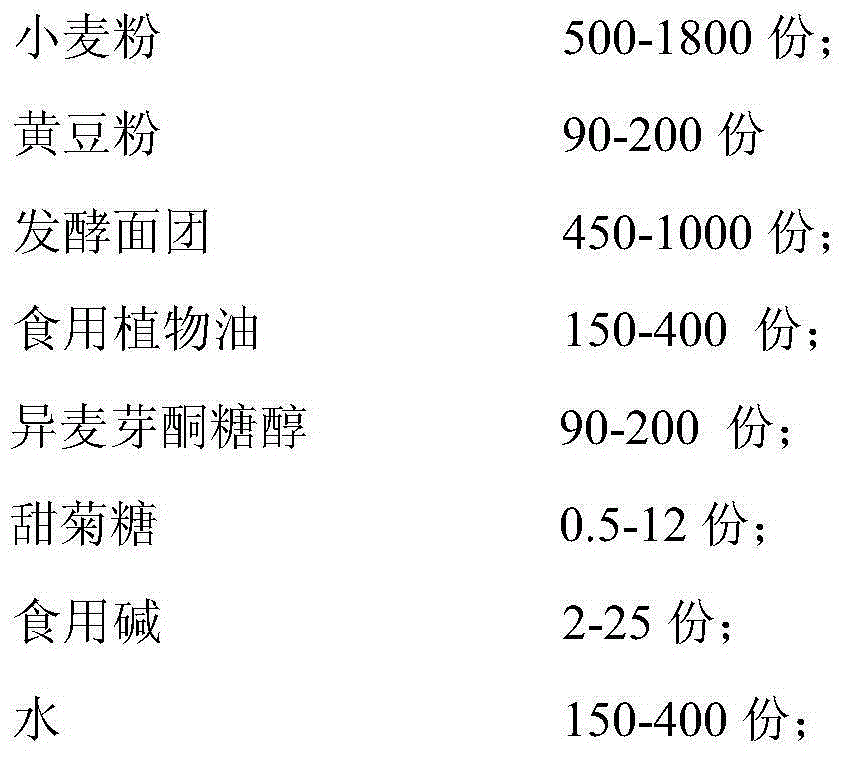

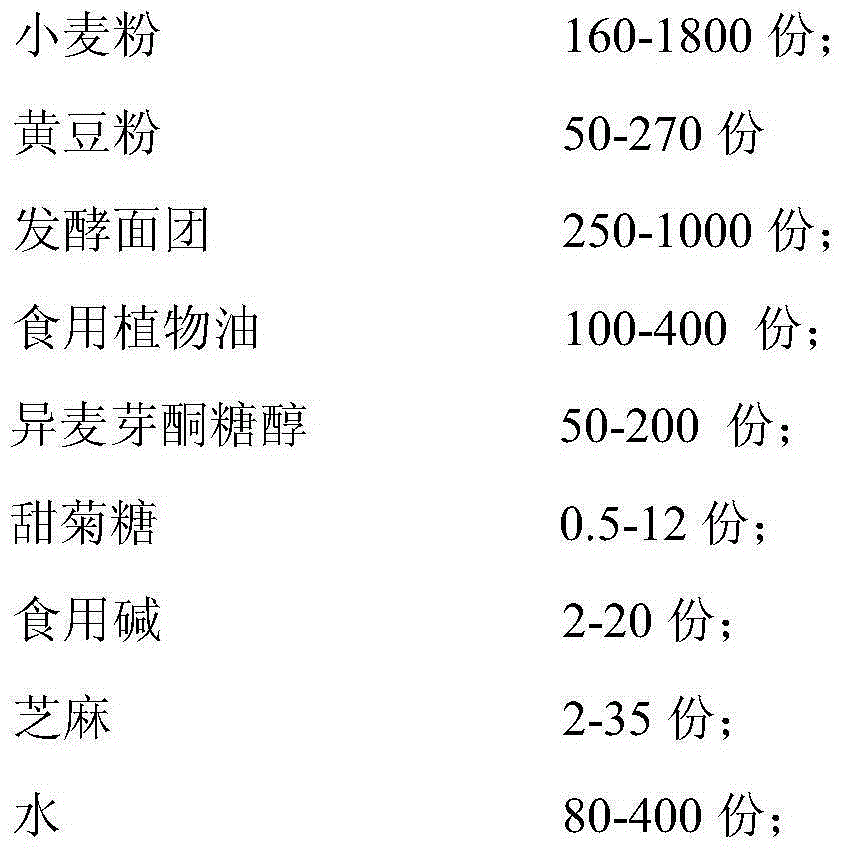

Stuffed Chinese doughnut low in GI value and preparing method thereof

ActiveCN104982476AReduce glucoseAvoid eatingDough strip twisting machinesBlood glucose increasedIsomalt

The invention relates to a stuffed Chinese doughnut low in GI value, namely a low-glycemic index stuffed Chinese doughnut. The stuffed Chinese doughnut comprises Chinese doughnut noodles, sesame strips and stuffing, wherein the sum of the mass of Chinese doughnut noodles and the mass of sesame strips to the mass of stuffing is 12 to 1-8.5. Wheatmeal is replaced with soybean meal low in GI value, saccharose is not added, and isomaltitol and stevioside in appropriate proportion are added. The stuffed Chinese doughnut prepared with the method belongs to low-GI food with a GI value of 49. It is guaranteed that diabetics do not eat saccharose, the hidden worry that GI value might increase due to amylolysis of flour can be effectively relieved, and dual insurance is provided for inhibiting blood glucose increase. The method for preparing the stuffed Chinese doughnut enables the characteristics of traditional Chinese doughnuts of being sweet, crisp and capable of staying crisp after being stored for a long time to be reserved, the stuffed Chinese doughnut is suitable for diabetics and people who have the requirement for a low-GI-value diet and value nutrition and health, the range of users of the stuffed Chinese doughnut is enlarged, and the stuffed Chinese doughnut is the pioneer in sugar alcohol food technology improvement in China.

Owner:天津桂发祥十八街麻花食品股份有限公司

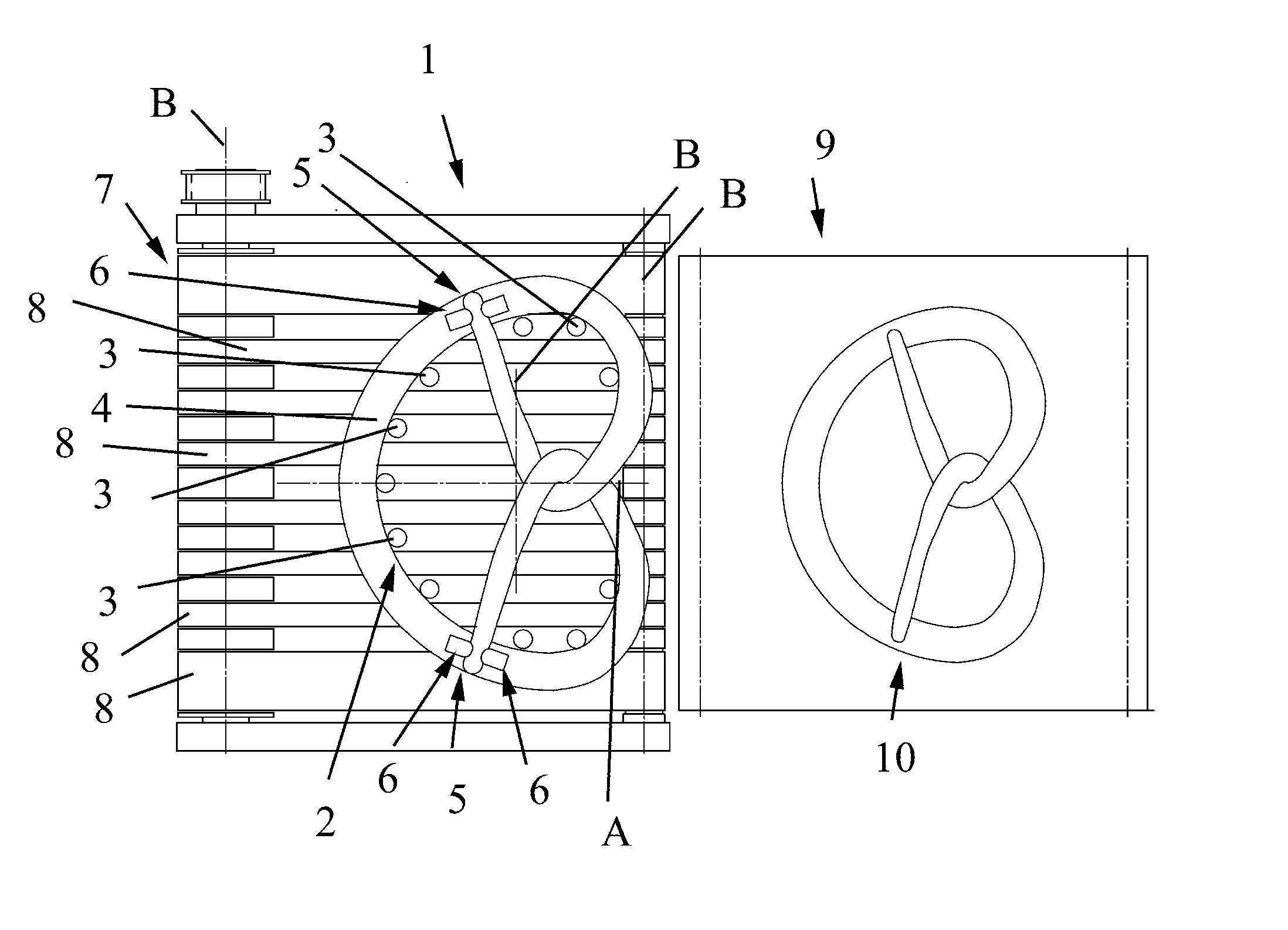

Knotting system for a dough strand

ActiveUS8173191B2Increase distanceReduce frictionDough treatmentDough sheet coiling machinesEngineering

The invention relates to a device and a method for the automated production of knotted dough products, in particular pretzels. Said device comprises: a shaping table (2) for horizontally supporting a U-shaped bent dough strand (46); a shaping tool (6) that can be activated to vertically support the U-shaped bent dough strand (46), the shaping table (2) and activated shaping tool (6) forming a common stop for the U-shaped bent strand (46); and a knotting head (9) for seizing the ends of the dough strand and for knotting said strand (46). According to the invention, the knotting head (9) can be displaced from a seizing position (48), in which the ends of the U-shaped bent dough strand (46) are seized, into an extension position (49), in which the dough strand is extended, then into a knotting position (51), in which the dough strand is knotted and finally into a placing position 52, in which the ends of the dough strands are placed on the central part of the dough strand. In addition, the common shaping stop is configured to be stationary, in particular on the horizontal displacement plane.

Owner:FRITSCH BAKERY TECH GMBH & CO KG

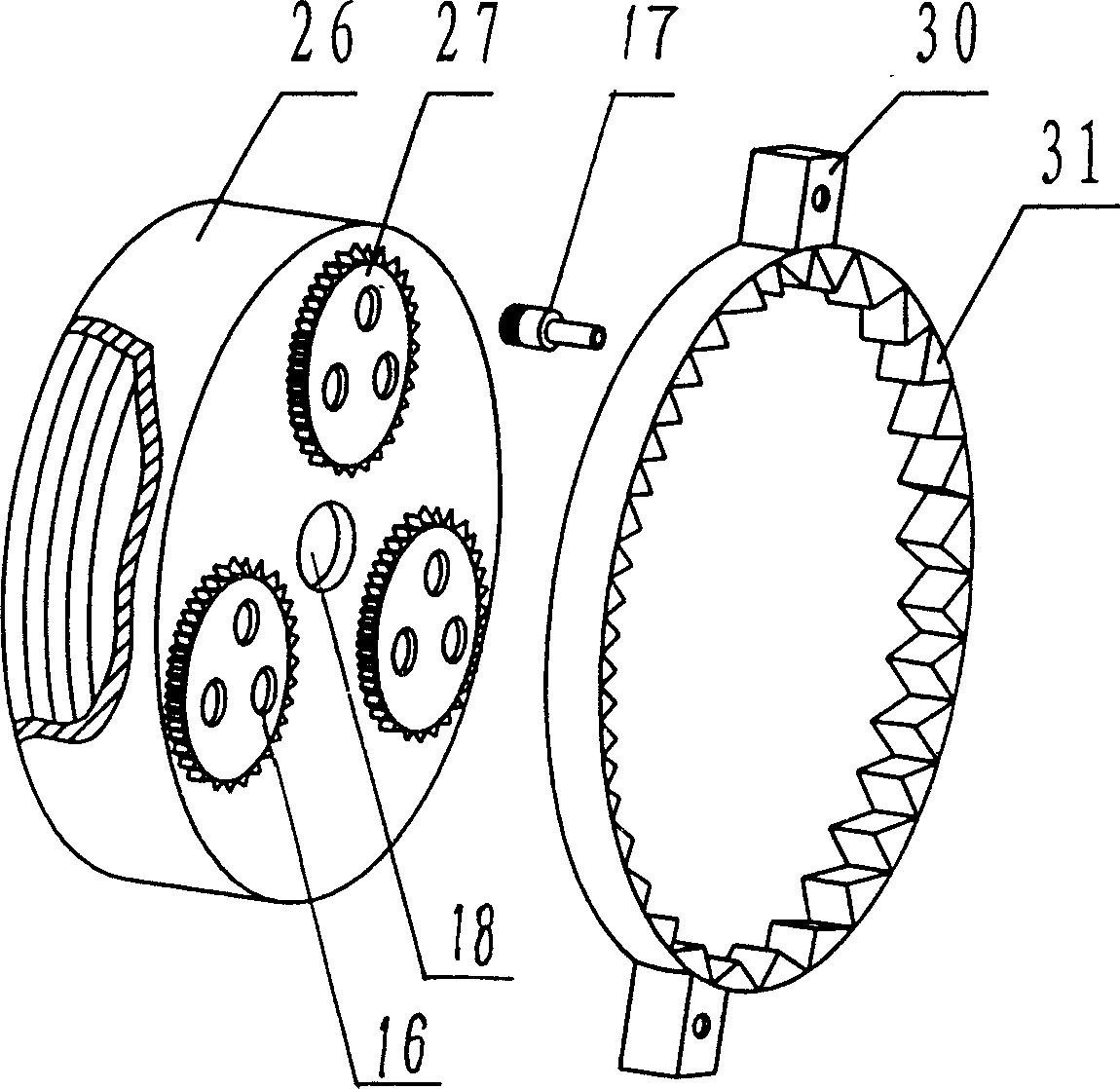

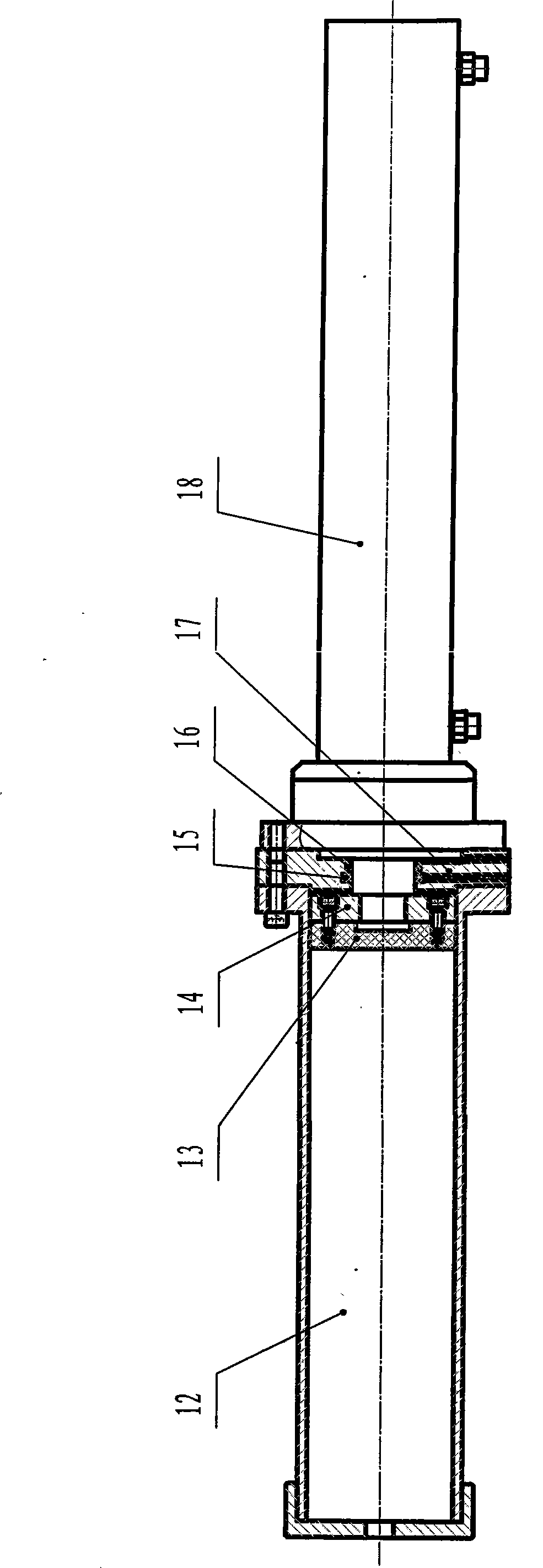

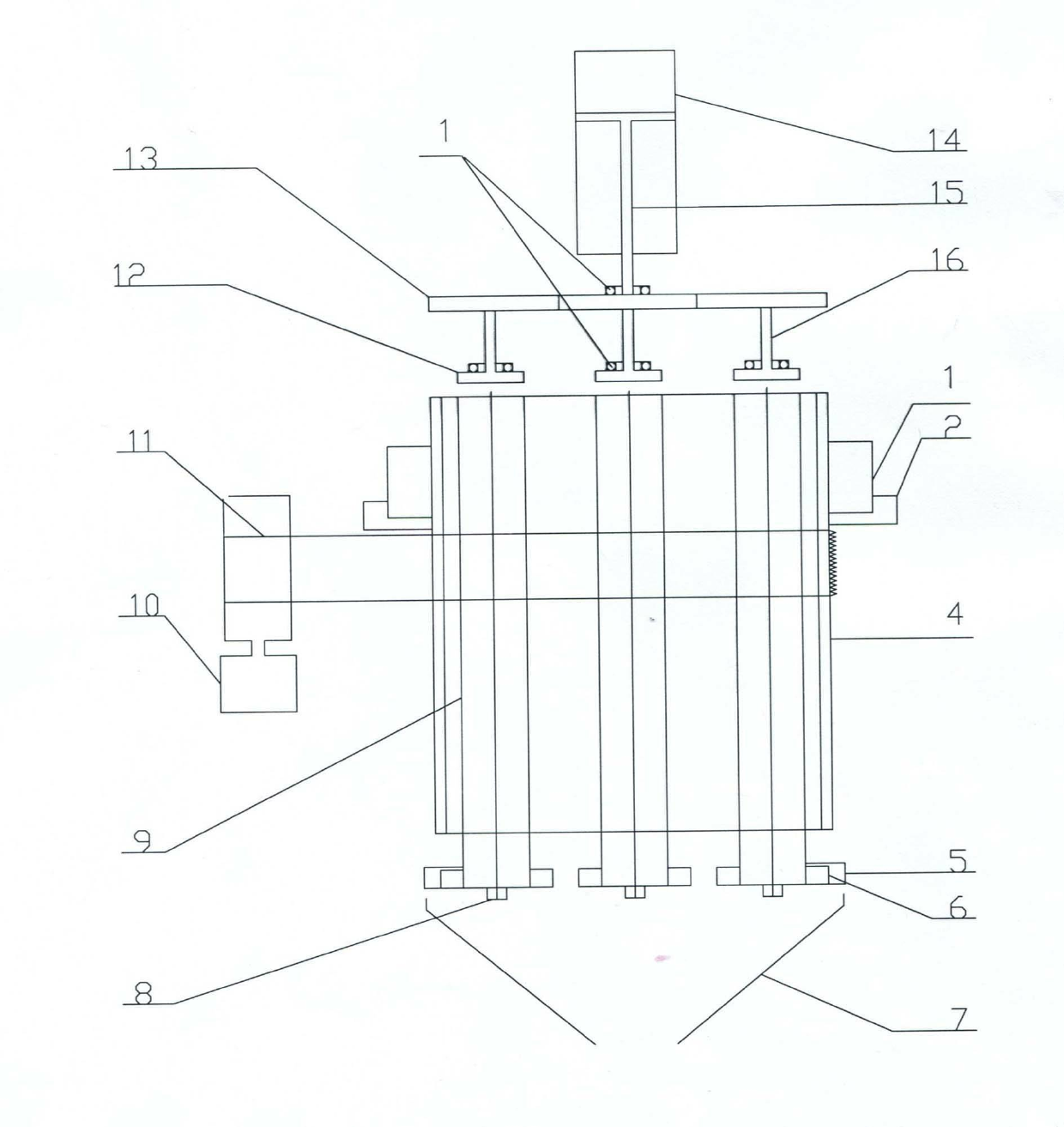

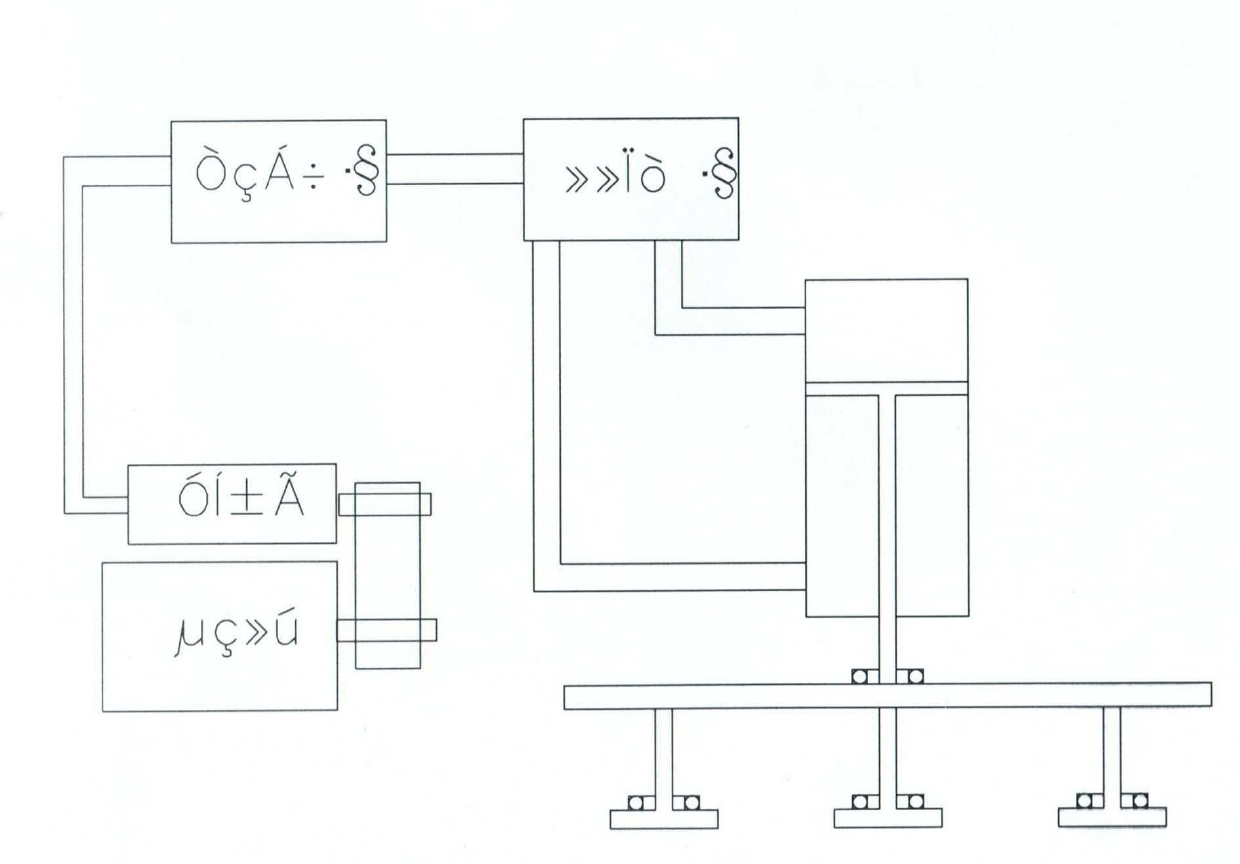

Sub-cylinder type rotary cylinder static pressure fried dough twist making machine

InactiveCN102428980ALow failure rateAvoid damageDough strip twisting machinesFailure rateHydraulic motor

The invention discloses a sub-cylinder type rotary cylinder static pressure fried dough twist making machine and relates to a food processing machine which can solve the problems of dough leakage and heating of the conventional fried dough twist making machine. The sub-cylinder type rotary cylinder static pressure fried dough twist making machine disclosed by the invention is characterized in that a rotary connecting disc of a dough pressing and shaping device is connected with a push rod of an oil cylinder through a bearing, a rotary dough pressing sheet is connected with a connecting support rod of the rotary connecting disc through the bearing, a rotary dough cylinder is fixed in a rotary cylinder through a pressure bearing, the rotary cylinder is fixed on a platform through the bearing, a shaping mold sheet is arranged at the lower end of the rotary dough cylinder, the lower part of the rotary dough cylinder is connected with an external gear, the external gear is meshed with an internal gear disc, the internal gear disc is fixed on a frame, a fried dough twist synthesis bucket is arranged below the internal gear disc, and the rotary cylinder is directly driven by a hydraulic motor. The sub-cylinder type rotary cylinder static pressure fried dough twist making machine disclosed by the invention has the advantages that failure rate is reduced during operation of a mechanism, heating generated by relative motion is prevented from damaging the internal structure of a fermented dough and the quality of fried dough twists is improved.

Owner:韩学珍

Dough rolling apparatus and method

An improved dough-rolling apparatus and method for rolling sheeted dough. The proposed invention comprises a dough-rolling apparatus having a dough sheeter, a sheeting conveyor having a ramped section, a roll-initiating curtain positioned above the ramped section, and a roll-completing curtain positioned above the conveyor and downstream from the roll-initiating conveyor. Sheeted and cut dough pieces are deposited onto a steel mesh, partially-ramped sheeter belt, where two wire-mesh rolling curtains are draped onto the sheeter belt to induce rolling of the dough pieces.

Owner:FRITO LAY NORTH AMERICA INC

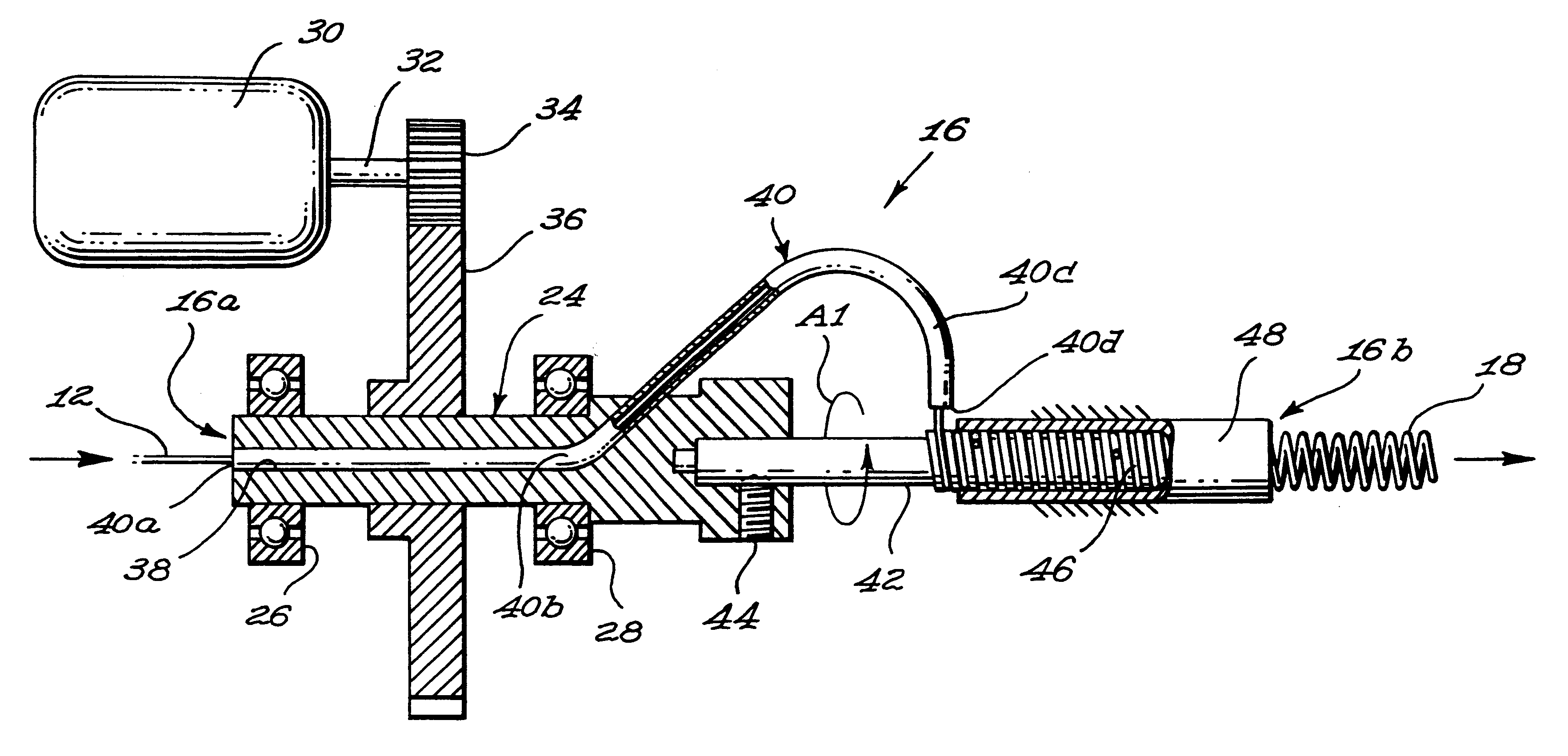

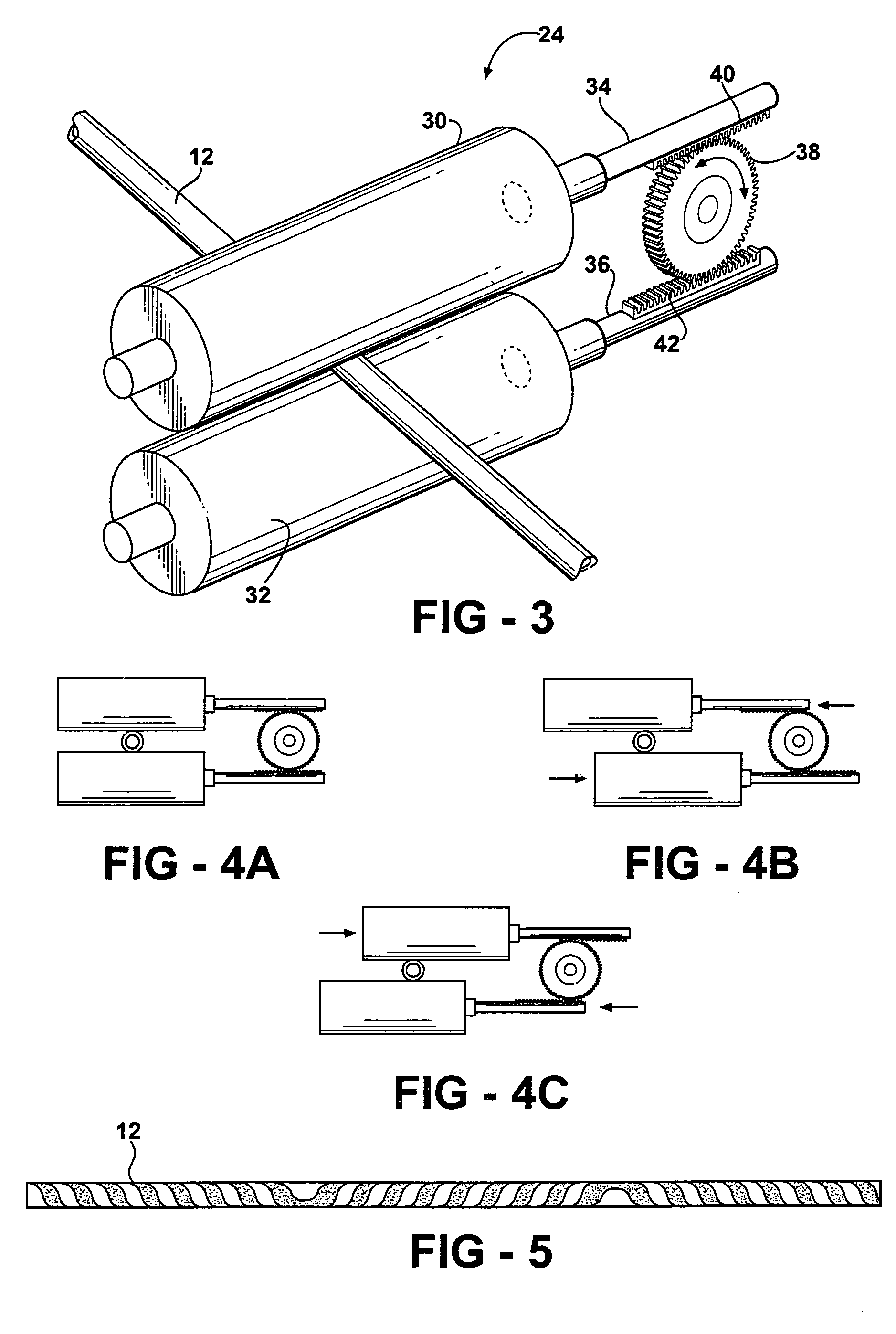

Striped drinking straw and method of making the same

Extruded, striped drinking straws are formed by coextruding at least two polymers of different color through a common extruder to form an elongated tube. An oscillator consisting of a pair of rolls supported for rotation about their central axes, extending normally to the extension of the tube, bear against opposed sides of the tube and are reciprocated in opposing directions so as to rotate the tube by a gear and spline mechanism. A straight puller draws the tube out of the extruder and through the twisting oscillator and a cutter forms the tube into straw lengths at the output of the puller.

Owner:LIPSON ERIK

Cooked rice mold apparatus

ActiveUS7581940B2Reduce the amount of solutionHigh densityConfectioneryPress rollersEngineeringMechanical engineering

Provided is a cooked rice mold apparatus that can easily adjust the supply amount of sushi rice. The roller spacing of a top rolling roller pair 31 arranged on the exit side of a hopper 2 of a rolling section 4 is variable.

Owner:AUDIO-TECHNICA

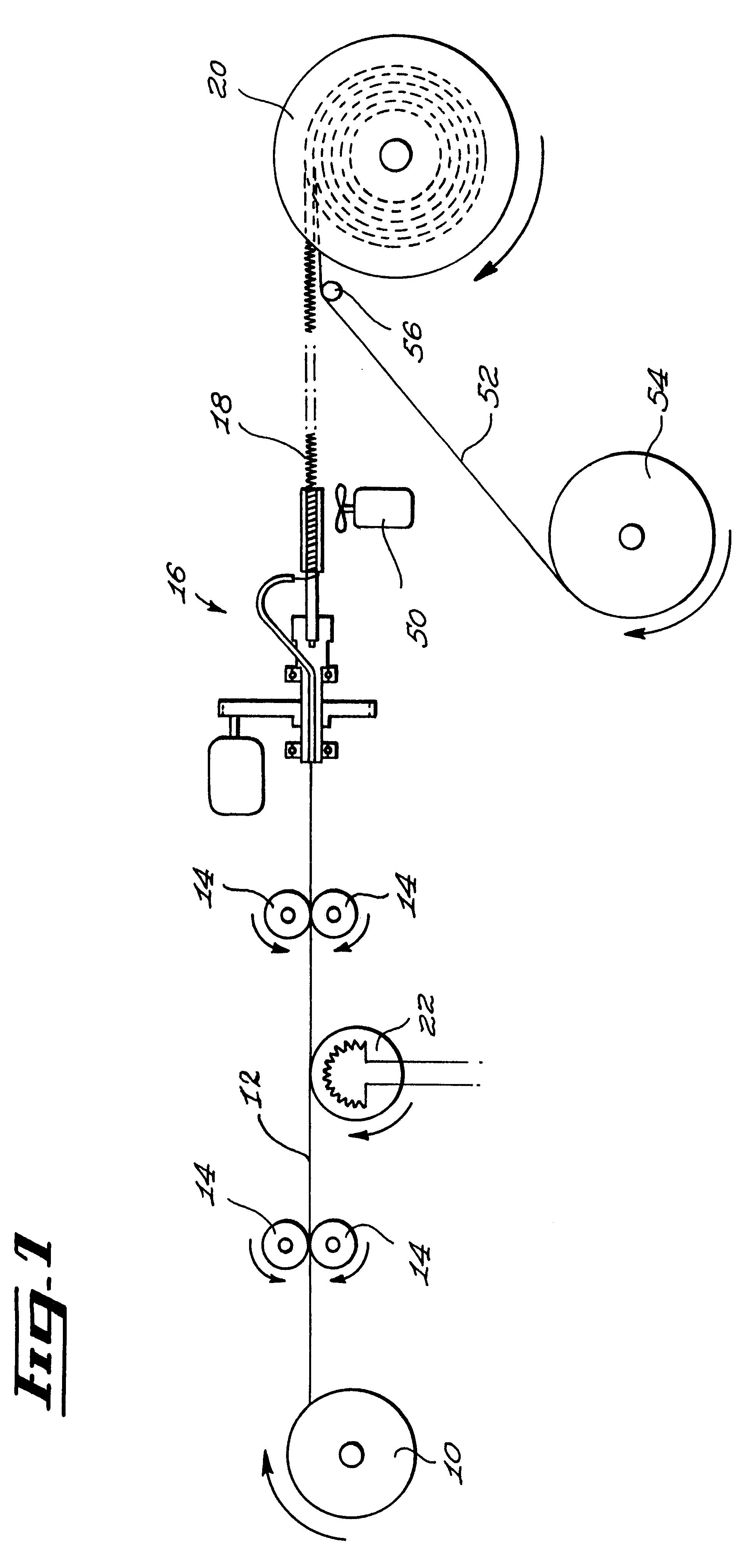

Rib forming apparatus and method

InactiveUS7695267B2Increase distanceLess floor spaceMechanical working/deformationConfectioneryEngineeringSheet material

A rib forming apparatus has an elongated support table, a supply of thermoplastic sheet material over the table, a transporting means having at least two transverse carriages mounted on the table to slide along longitudinal edges thereof, a thermal means mounted on one of the carriages for locally heating the sheet material in preparation of a molding press, and at least one press module mounted on another carriage and having a reciprocating press blade positioned at one flat side of the sheet material and a couple of swiveling press blades positioned at the opposite flat side of the sheet material and movable toward the reciprocating press blade to mold the heated section of the sheet material by closing the above three press blades toward each other, whereby a series of vertical rib folds are formed transversely of the sheet material and advanced by the transport means through the closed press blades.

Owner:CENTURY PROD A DBA OF CENTURY TREE SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com