Patents

Literature

55results about How to "Crispy skin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crispy-skin bread rich in dietary fiber

InactiveCN103798317ACrispy skinSoft tasteDough treatmentPreservation by coatingBiotechnologyFatty acid

The invention discloses crispy-skin bread rich in dietary fiber. The crispy-skin bread is composed of crispy skin and a bread body. The crispy skin is composed of, by weight, 25 parts of white granulated sugar, 3 parts of butter, 1.5 parts of lard oil, 3 parts of eggs, 0.5 part of edible ammonium bicarbonate, 0.5 part of baking powder, 55 parts of flour, 2 parts of flaxseed powder, 1 part of wheat bran, 2 parts of oat bran, 2 parts of rice bran, 2.5 parts of milk powder and two parts of evaporated milk. The bread body is composed of, by weight, 50 parts of strong flour, 7 parts of inulin, 9 parts of white granulated sugar, 0.7 part of yeast, 1 part of table salt, 0.3 part of bread improver, 4 parts of milk powder, 20 parts of water, 4 parts of eggs and 4 parts of cream. The skin of the bread made according to the formula is crispy and tastes soft, and the bread is rich in dietary fiber, Vitamin B and Omega-3 fatty acid, delicious and nutrient.

Owner:BODA NANO SCI TECH DEHUA COUNTY

Delicious duck and preparation method thereof

The invention relates to a delicious duck and a preparation method in the food processing technology field. In the method, a crammed duck is used as raw material and a condiment containing nine Chinese herbal medicines is used as relish. A defatted delicious duck is prepared through process steps of infusion colorizing, frying and steaming. The prepared delicious duck is characterized by golden yellow appearance, crisp and lustrous sheath, crisp bone and soft meat, agreeable fatness and delicious taste, inducing people to eat more and more.

Owner:乔惠民

Processing process for fried capelins

The invention discloses a processing process for fried capelins. The fried capelins which are deeply popular with people are subjected to vacuum oil removal and gas flushing packaging so that convenient packages are formed and the original mouth feel and taste of the fried capelins are kept. The processing process is simple and practical, is convenient to operate and is suitable for industrial production application; the fried capelins obtained by the processing process have a small fishy smell, good color and luster, full taste, crispy skins, low oil content and less nutrition loss; and the quality guarantee period is prolonged while the original mouth feel and taste are kept, and the fried capelins are convenient to carry so that the great convenience is brought to people.

Owner:东莞市荷花食品有限公司

Bagel bread containing raw material of chia seeds and preparation method of bagel bread

ActiveCN104970060ASoft tasteIncrease elasticityDough treatmentPre-baking dough treatmentBiotechnologyNutritive values

The invention discloses bagel bread containing a raw material of chia seeds. The bagel bread is mainly prepared from the following raw materials: strong flour, chia seed powder, yeast, a bread modifier, sugar, cream, salt and water. The invention further discloses a preparation method of the bagel bread containing the raw material of the chia seeds. The preparation method comprises the following working procedures: preparing overnight sour dough, preparing main dough, fermenting the prepared main dough, dividing the fermented main dough, shaping the divided main dough so as to form much dough, fermenting the dough for the first time, performing decoration, fermenting the dough for the second time, cooking the fermented dough, baking the cooked dough and the like. The bagel bread prepared by the method has the characteristics that the fragrance is pure, the mouth feel is elastic and chewy, the distribution of the chia seeds is obvious, and the content of linolenic acid is high, and the nutritional value is high.

Owner:广州市传稻食品有限公司 +1

Crackling stuffing soft fried dough twist

The invention provides a method for making fried dough twist, which comprises steps of mixing allume 0.01-0.1 part, white sugar 2-4 parts, eggs 5-12 parts, flour 90-110 parts and salad oil 5-12 parts, charging cold water and diluting, adding in stuffing and placing into cooking oil pot, frying three times at oil temperature of 100-170 deg C and taking out.

Owner:王成刚

Quick-frozen fresh-keeping deep-fried dough stick and making method thereof

ActiveCN103875755AFull of nutritionPromote expansionDough treatmentPre-baking dough treatmentFrost crackQuick Freeze

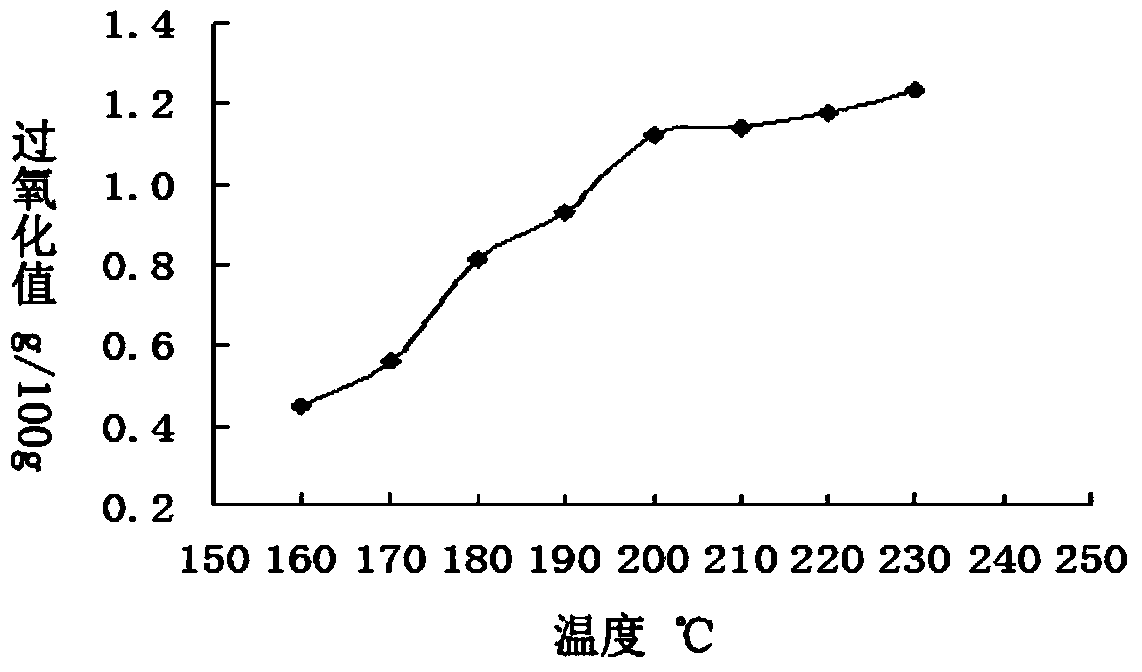

The invention discloses a quick-frozen fresh-keeping deep-fried dough stick and a making method thereof and belongs to the technical field of food processing. The quick-frozen fresh-keeping deep-fried dough stick is mainly composed of, by weight, 110-120 parts of flour special for making deep-fried dough sticks, 8-10 parts of acetylated wheat modified starch, 10-15 parts of white glutinous rice flour, 60-70 parts of water, 2-3 parts of leavening agents, 0.1-0.2 part of yeast, 3-5 parts of soybean oil, 5-10 parts of edible salt, 5-10 parts of eggs and 7-12 parts of white sugar. The flour special for making the deep-fried dough sticks, the acetylated wheat modified starch and the white glutinous rice flour are adopted, so that forming of a gluten network can be promoted, strength and gluten tenacity of the deep-fried dough stick are improved, and frost crack rate of skin of the deep-fried dough stick after quick freezing can be lowered; a low-temperature quick deep-fry method and a quick freezing method are adopted to make the deep-fried dough stick, so that water content, oil content, acid value and peroxide value of the deep-fried dough stick can be lowered, and original freshness and nutrition facts of the deep-fried dough stick can be maintained furthest.

Owner:云鹤食品有限公司

Abelmoschus esculentus filler and bakery shortening coating moon cakes and making method thereof

InactiveCN107897288AUnique flavorCrispy skinDough treatmentModified nutritive productsWater in oilNutrient

The invention discloses abelmoschus esculentus filler and bakery shortening coating moon cakes and a making method thereof, and relates to the technical field of processing of moon cakes. The abelmoschus esculentus filler and bakery shortening coating moon cakes consist of water-in-oil coatings, bakery shortening coatings and a filler, wherein the water-in-oil coatings consist of the following rawmaterials in parts by weight: 150-160 parts of middle gluten flour, 50-55 parts of lard, 10-15 parts of white sugar, 80-90 parts of water and 3-5 parts of maltodextrin; the bakery shortening coatingsconsist of the following raw materials in parts by weight: 100-110 parts of low-gluten flour and 47-52 parts of lard; and the filler consists of the following raw materials in parts by weight: 100-120 parts of abelmoschus esculentus, 5-10 parts of Chinese chestnuts, 10-15 parts of longans and 20-30 parts of navy beans. The making method of the abelmoschus esculentus filler and bakery shortening coating moon cakes comprises the following steps of preparing the water-in-oil coatings, preparing the bakery shortening coatings, preparing the filler, making dough of short crust pastry and making the moon cakes. Abelmoschus esculentus and other components are in reasonable collocation for making the filler of the moon cakes, so that the abelmoschus esculentus filler and bakery shortening coatingmoon cakes have high nutrient value and health-care efficacy, the made bakery shortening coating moon cakes are unique in flavor, crispy in coatings, clear in layering and good in mouth feel, the kinds of the bakery shortening coating moon cakes are enriched, and the abelmoschus esculentus filler and bakery shortening coating moon cakes provide a new way for processing of the abelmoschus esculentus.

Owner:合肥市绿之林农业开发有限公司

Pineapple bread

InactiveCN105248533AFull of nutritionGolden colorDough treatmentBakery productsIsomaltooligosaccharideCuticle

The invention discloses a pineapple bread comprising the following raw materials: paste raw materials: bread flour, water, soybean oligosaccharides, xylitol, eggs, mushrooms, ormosia, cream, milk powder, yeast, salt, and active soybean flour; pineapple peel raw materials: cake flour, cream, oligomerization isomaltose, lemon powder, and eggs. The pineapple bread is rich in nutrition, yellow in color, sweet and tasty, crispy in skin, smooth in quality, and elastic; the soybean oligosaccharides and xylitol can replace white sugar, so the pineapple is proper in sweetness, and bifidobacterium can grow, thus preventing fat, decayed tooth, astriction and high blood pressure; the mushroom and ormosia can lubricate the intestines and relax the bowel, can reduce blood pressure, reduce blood fat, can adjust blood sugar, can prevent cancer, and three-high patients can normally eat the bread; the pineapple peel is added with lemon powder so as to provide lemon smell, so mouthfeel is fresh, taste is sweet but not cheesy; the active soybean flour can replace an ameliorant, is safe and health, low in cost, and saves cost.

Owner:ANHUI HAOMENGYUAN FOOD CO LTD

Local flavor rice crust and making method

InactiveCN101461492ANutritional diversityBright yellow color and beautifulFood preparationVegetable oilFood flavor

The invention discloses a flavor crispy rice and preparation method thereof, belonging to the grain contained product field. The main material is rice flour and millet flour; and the auxiliary material is mainly egg, garlic extract, edible vegetable oil, starter and flavoring. The flavor crispy rice preparation method comprises: mixing the rice flour and millet flour; adding 1 / 10 the flour weight of water, and egg, proper amount of starter, flavoring and a small amount of garlic extract and perfume while stirring; compressing and slicing the kneaded dough into blanks; baking the blanks under the temperature of 100-120 degrees centigrade for 1-2 minutes to obtain the water content of 5-10%; frying in vegetable oil at 150-190 degrees centigrade for 3 minutes; cooling, detecting and packaging. The invention is made from a plurality of raw materials, has complete nutrition; and maintains the traditional crispy rice flavor; and the obtained crispy rice achieves the advantages of smooth surface, bright color, less oil adsorption, uniform and loose internal structure, crisp coat, soft core and various flavors.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Stuffed glutinous rice dumpling making process

The stuffed glutinous rice dumpling making process includes the following steps: mixing water milled glutinous rice powder with warm water and shaping into ball, injecting stuffing and rounding, sticking decoated sesame to the surface of the ball, deep frying into golden color, boiling the mixture of water, sugar, sauce and edible orange red to form syrup, and final mixing the syrup with the ball to obtain the stuffed glutinous rice dumpling. The stuffed glutinous rice dumpling has crisp outside and glutinous and soft inside, and is golden, sweet, fragrant and attractive.

Owner:何良柱

Shortening sandwich fried dough twist processing method

InactiveCN103444825AEasy to prepareCrispy skinDough treatmentBakery productsTangerine PeelFood science

The invention discloses a shortening sandwich fried dough twist processing method. Shortening sandwich fried dough twists are made through steps of making of sandwich filling, dough leavening, dough kneading, sandwich wrapping, frying and the like. The shortening sandwich fried dough twist processing method is simple, the made fried dough twists are crisp in skin and good in taste, varieties of the fried dough twists are enriched, and the fried dough twists have healthcare value due to the fact that Chinese herbal medicine extract of tangerine peels, atractylodes lancea, lagochilus leiacanthus, rhizoma bletillae and the like having spleen-fortifying stomach-nourishing functions are adopted in dough kneading.

Owner:柳培健

Processing method for keep quality and freshness of black-bone chicken meat product

The invention relates to the field of food processing, in particular to a processing method for keep the quality and freshness of a black-bone chicken meat product. The method includes the following steps of firstly, pickling, wherein after a self-made pickling material is smeared on the surface of the body and the inner wall of the lumen of a killed black-bone chicken with the feathers removed, normal-temperature vacuum pickling is carried out, and after pickling is finished, the black-bone chicken is washed with clean water and drained off; secondly, blanching, wherein the black-bone chicken is put into perilla leaf mint water to be blanched for 3-5 min; thirdly, marinating, wherein a marinating material is wrapped with gauze and put at the bottom of a pot, the chicken is put into the pot with the body immersed in water, the water is heated to 95-98 DEG C, and then braising is carried out with soft fire with the braising temperature kept at 75-80 DEG C; fourthly, frying, wherein the braised black-bone chicken is bailed out, drained off, fried for 1-2 min at 85-90 DEG C in a vacuum mode and then taken out to be cooled; fifthly, packaging and sterilization, wherein vacuum packaging is carried out, and after vacuum packaging, sterilization is carried out with a pasteurization method. By means of the method, the quality and freshness of the black-bone chicken meat product can be kept, and the original rich nutrients of the black-bone chicken can be effectively preserved.

Owner:广西河池市明达特种养殖专业合作社

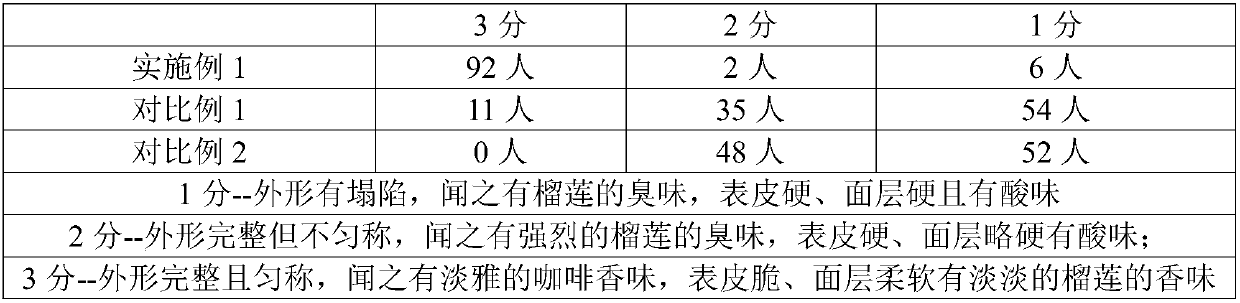

Method for preparing durian bread

InactiveCN107897262AImprove uniformityLight smellDough treatmentPre-baking dough treatmentFermentation

The invention discloses a method for preparing durian bread. The method comprises the following steps of 1, preparing fruit pulp filtrate and fruit pulp yogurt residues; 2, preparing primary fermenteddough; 3, performing secondary fermentation to prepare fermented dough; and 4, preparing a bread blank, performing several times of baking to obtain the durian bread. The bread prepared by the methodhas delicious and crispy crust and soft internal taste, has a refreshing coffee fragrance in first smelling, has light durian fragrance when being chewed carefully, and has the effects of mild moistening, blood nourishing and qi tonifying

Owner:甘宗梦

Method for making roast chicken

A preparation method for a roasted chicken comprises the following steps: 1. carefully selecting southern chick as the raw material, washing the chick and putting the chick into a conventional seasoning soup blend prepared by green onion, ginger, garlic, soy sauce, salt, sugar and soup stock to be pickled for 30 minutes; 2. fishing out the chick, drying, scalding the tegmen tight in boiling water, quickly fishing out and putting into clean water to be cooled, fishing out and drying; 3. hanging the chick in a baking oven to be roasted by low fire until the chick skin is dried, taking out and cooling thoroughly; 4. hanging the chick in the baking oven once again to be roasted by medium baking temperature until being mature, taking out and cooling thoroughly; 5. frying the chick in a hot oil pot with vigorous fire, continually dripping oil on the chick skin until the color is bright red; 6. fishing out, cooling, sterilizing, sealing and packing. The method has the advantage that, the roasted chicken prepared by the invention has bright red color and luster, crisp tegmen, fresh and rich taste, convenient eating and rich nutrients, which is a convenient food particularly suitable for household fast food.

Owner:TIANJIN YUEWEIXIAN YULEYUAN GROUP

Crisp hemp flowers with milk flavor

The invention provides crisp hemp flowers with milk flavor, belongs to a preparation formula of pasta and in particular relates to a preparation formula of hemp flowers. The invention provides a method for preparing crisp hemp flowers. The hemp flowers are characterized in that 1000g of flour is taken as the unit, materials for preparing the hemp flowers are as follows: 500-750g of bread flour, 50-100g of eggs, 50-150g of sugar, 25-100g of salad oil, 25-100g of butter, 1.5-8g of improver, 10-30g of yeast, 3-12g of sodium cyclamate, 1.5-12g of table salt and 100-250g of ghee, then 500-1000g of water is added to the materials and the mixture is blended uniformly, thus the hemp flowers can be obtained.

Owner:赵晓雁

Standardized planting method for Cnidiummonnieri

InactiveCN105393752AStrong stress resistanceFast growthPlant cultivationCultivating equipmentsSowingIrrigation

The invention discloses a standardized planting method for a Cnidiummonnieri. The standardized planting method includes the following steps of: 1) seed selecting and processing; 2) soil treatment; 3) soil sealing and weeding; (4) precise sowing and water-saving drop irrigation; 5) water dropping and germinating; 6) seedling stage irrigation; 7) soil measurement and fertilization; 8) pest and disease control during a seedling stage; and 9) harvesting. The standardized planting method for the Cnidiummonnieri can improve the yield of the Cnidiummonnieri and reduce the cost.

Owner:高洋

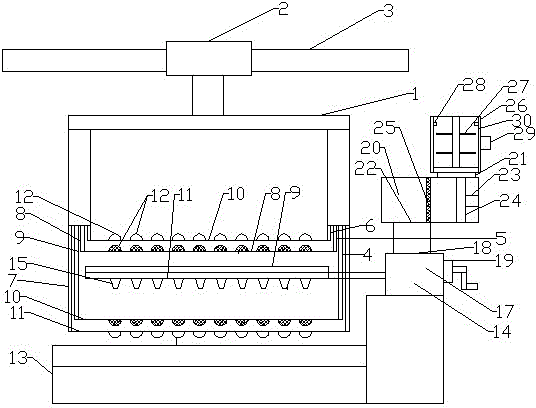

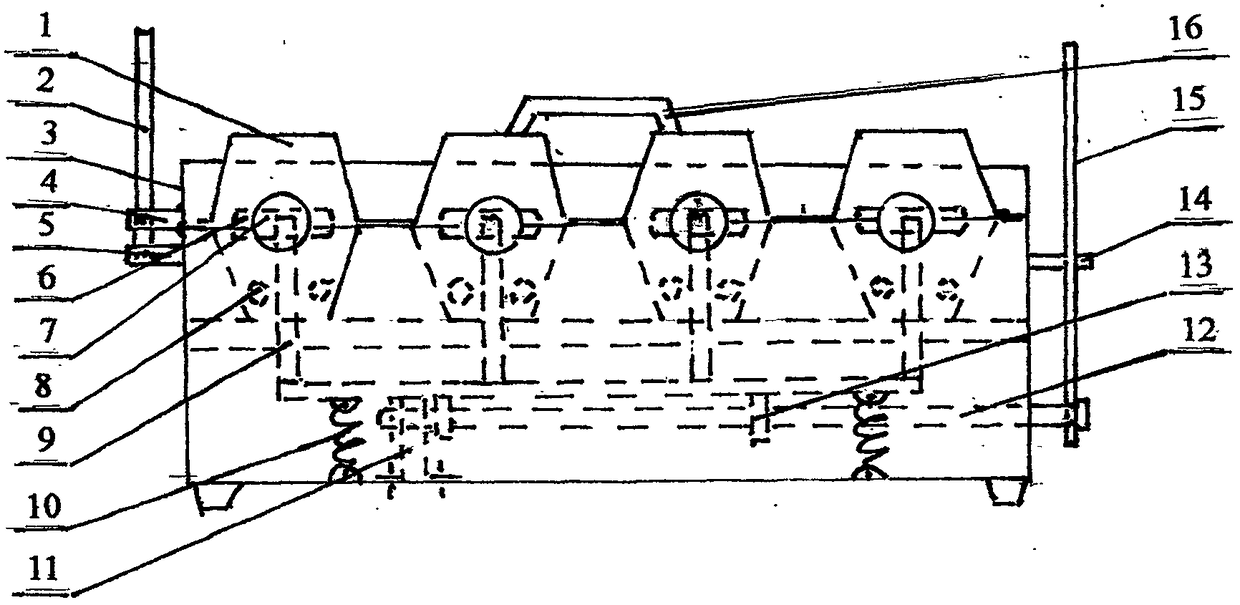

All-in-one machine for food preparation

The invention discloses an all-in-one machine for food preparation. The all-in-one machine for the food preparation comprises a stirring device, a squeezing device, a potato mash output device and a molding frying device which are connected in sequence; the stirring device is connected with the potato mash output device, and the squeezing device is connected with the potato mash output device; the stirring device comprises a stirring drum, a stirring blade is arranged in the stirring drum, and a round of nozzles are arranged on the inner ring of the stirring drum; the squeezing device comprises a squeezing box, a push rod is arranged inside the squeezing box, and a squeezing net is arranged on the other end inside the squeezing box; the potato mash output device comprises a squeeze-out nozzle, a delivery pipe and a potato mash storing box which are arrayed in a row, an opening is formed in the top portion of the potato mash storing box, a screw rod is arranged inside the potato mash storing box, and a motor is arranged on one side of the potato mash storing box; the molding frying device comprises a main lifting device, a main cross bar, four groups of associate lifting devices, a potato mash output device, a wrapping net and a molding pressing plate. By the all-in-one machine for food preparation, potatoes can be stirred into coarse mash, an appropriate amount of warm water is added during the stirring process, then the coarse mash is pressed to fine mash, the fine mash is injected into the frying net, and the fine mash is made into potato balls through the molding pressing plate.

Owner:夏利琴

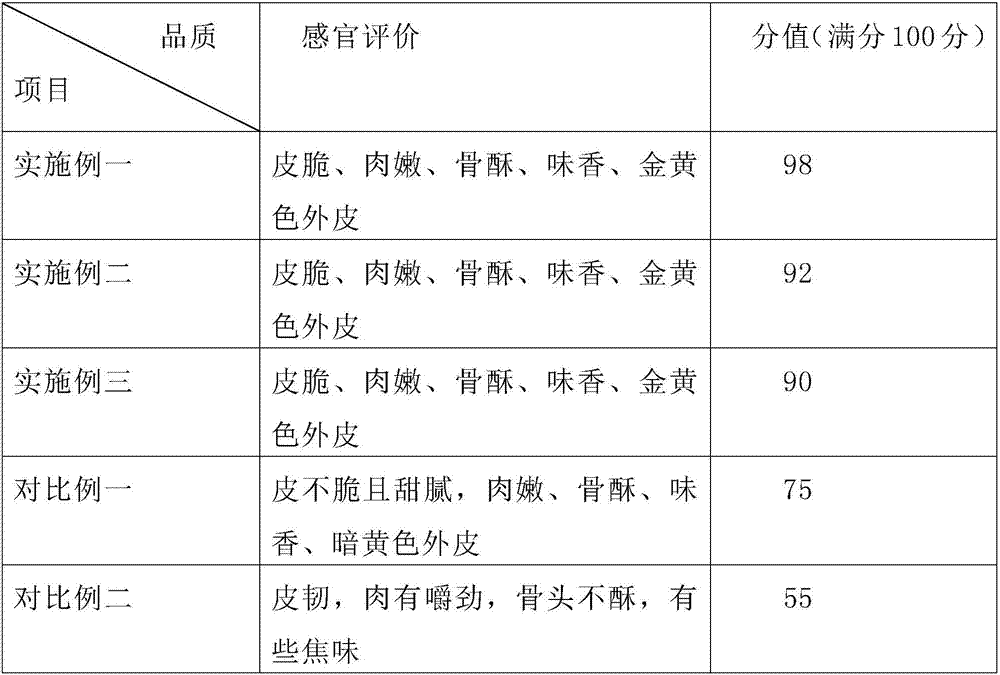

Roasted suckling pig and preparation method thereof

The invention provides a preparation method of a roasted suckling pig. The preparation method comprises the following steps: firstly, selecting materials: carefully selecting a piglet with the weight of 3 to 3.5kg; sorting; carrying out first-time pickling: mixing 3 to 5g of monosodium glutamate, 8 to 10g of table salt, 8 to 10g of oyster sauce, 8 to 10g of soy sauce, 15 to 20g of white granulated sugar, 8 to 10g of fermented red beancurd, 8 to 10g of spare rib sauce, 8 to 10g of garlic bulb, 8 to 10g of fresh ginger and 8 to 10g of anise powder, marinating and smearing a mixture in the abdominal cavity of the piglet and pickling for 4 to 5 minutes; secondly, shaping: skewering and tying iron wire on the body of the piglet; thirdly, carrying out second-time pickling: smearing the exoderm of the piglet with the soy sauce for 2 to 3 minutes; flushing: flushing the exoderm of the piglet once with the tap water and then drying in air; fourthly, carrying out first-time roasting: turning and baking for 3 to 5 minutes and then cooling at normal temperature for 30 to 40 minutes; fifthly, carrying out second-time roasting: turning and baking for 10 to 20 minutes until the pigskin turns red, then smearing sesame oil and continuously roasting; roasting in a drying oven for 10 to 15 minutes to obtain a finished product of the roasted suckling pig. The roasted suckling pig roasted by the method disclosed by the invention has the characteristics of perfect combination of color aroma and taste, and mouth feel of crisp skin, tender meat, crisp bone and nice taste.

Owner:王睿

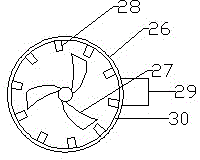

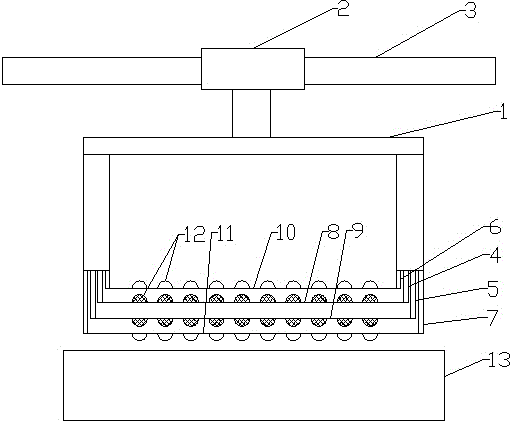

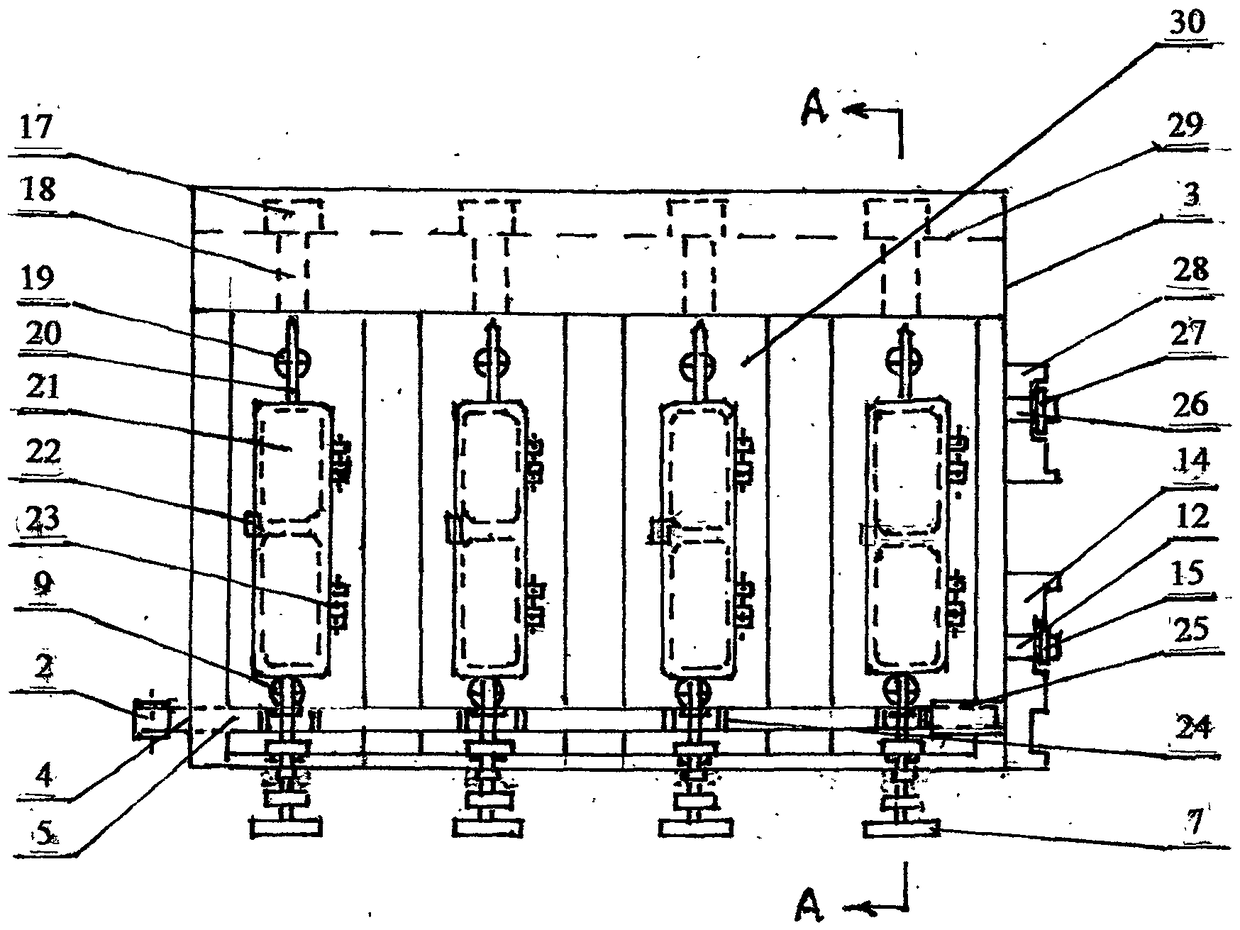

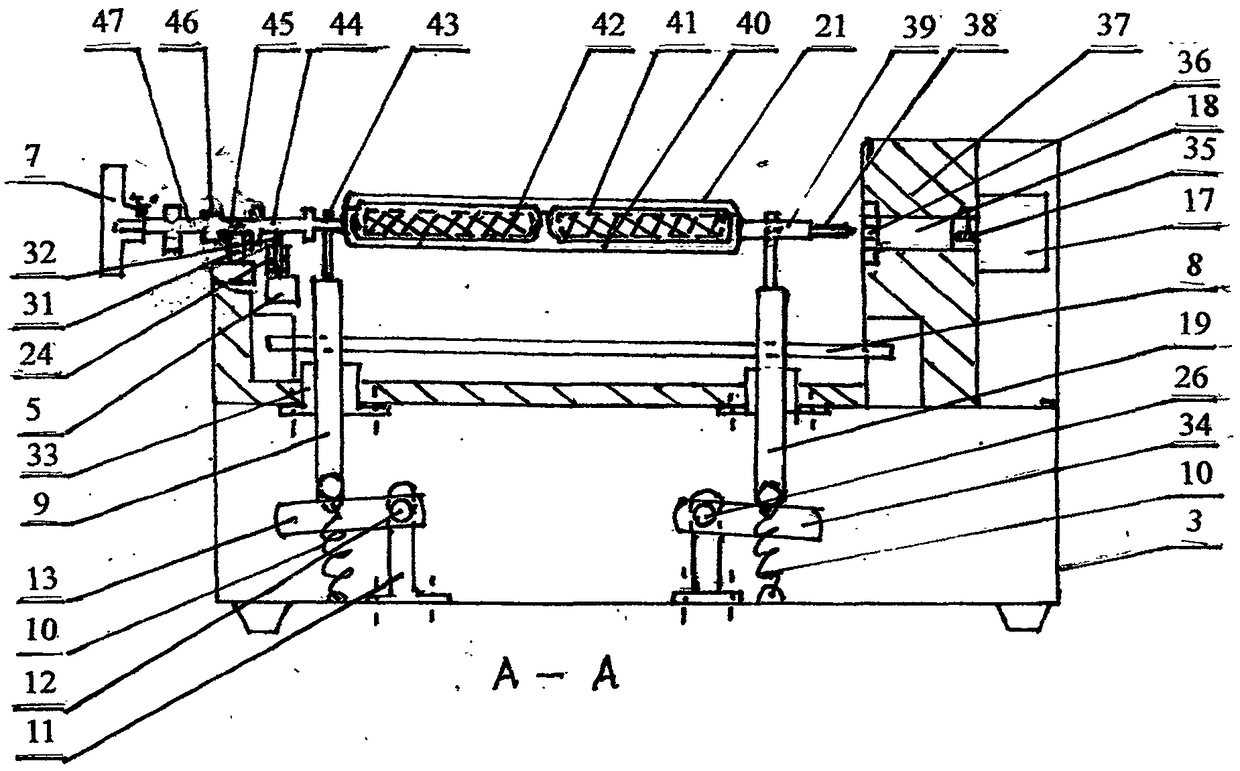

Frying device of potato balls

PendingCN104664283AHigh forming and frying efficiencyCoated evenlyFood preparationEngineeringForming pressure

The invention discloses a frying device of potato balls. The frying device comprises a frying tank, a main lifting device, a main cross rod, four groups of electric push rods, an upper wrapping net, a lower wrapping net, an upper forming pressure plate and a lower forming pressure plate, wherein the upper forming pressure plate, the upper wrapping net, the lower wrapping net and the lower forming pressure plate are sequentially arranged from top to bottom, and the four groups of electric push rods comprise a first group of electric push rods, a second group of electric push rods, a third group of electric push rods and a fourth group of electric push rods. Through the device, mashed potato balls can be formed in a batch, mashed potato is wrapped through the wrapping nets for keeping the original ball shape of the potato balls unchanged in a frying process, high-temperature hot oil can uniformly wrap and heat the potato balls from meshes, the fried potato balls are golden in color and luster and crispy in outer skins, the forming and frying efficiency is high, and a large number of potato balls can be fried once by a single person.

Owner:杨振波

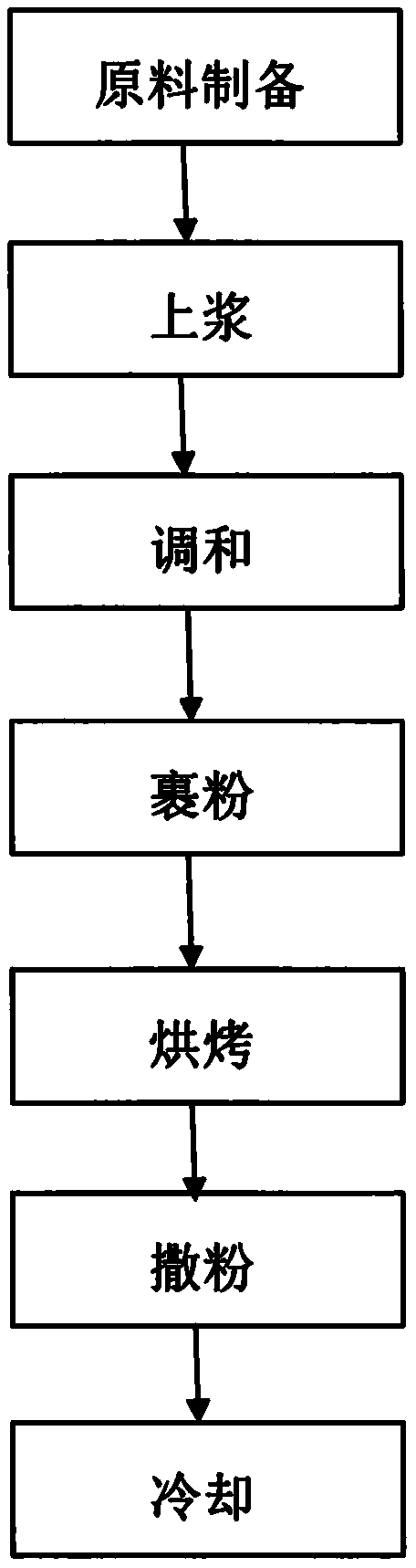

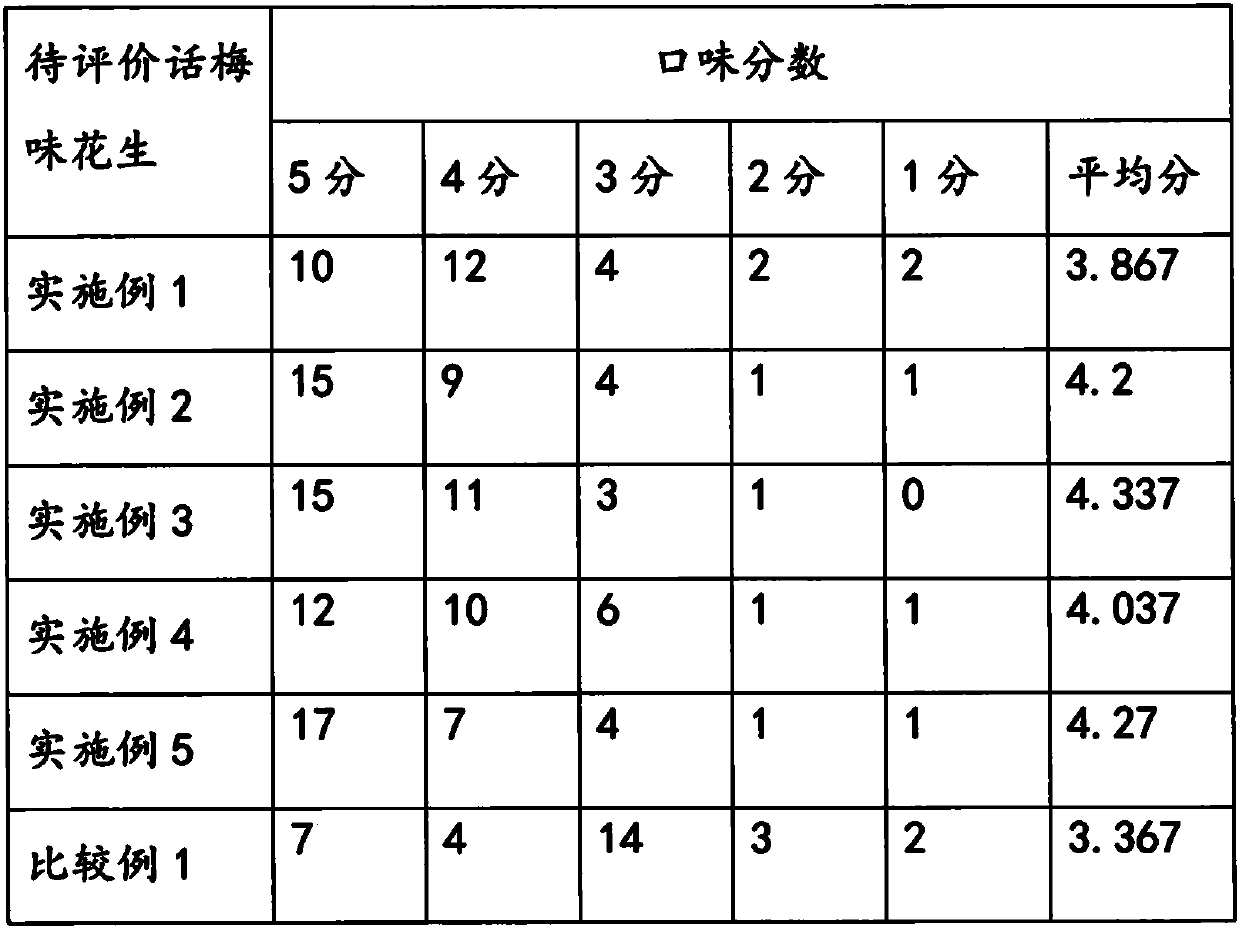

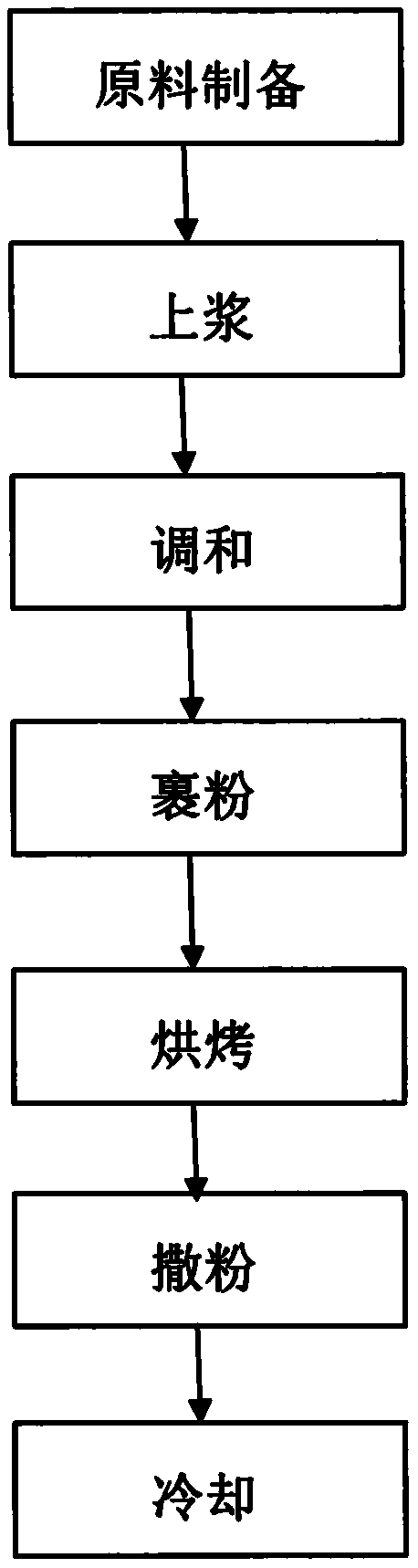

Plum-flavored peanut and making method thereof

The invention relates to a plum-flavored peanut and a making method thereof. The plum-flavored peanut is prepared by sizing, blending, powder-coating, baking, and mixing 100 parts by weight of peanut.The sizing slurry is 1.5 to 2.5 parts by weight, the slurry powder is stirred by the spice powder, edible salt, monosodium glutamate, starch and the water; a syrup is prepared by mixing white granulated sugar, water and seasoning, and the seasoning includes salt and monosodium glutamate. The flour used for blending is 25 to 40 parts by weight. During powder coating, 70 to 150 parts by weight of the coating powder and 85 to 130 parts by weight of the syrup are used. During mixing, 2 to 8 parts by weight of the plum-flavored seasoning powder and 3 to 6 parts by weight of the edible oil are used. The plum-flavored peanut made by the invention maintains the freshness of the peanut itself, the outer skin of the peanut is made more crispy by sizing and powder coating, the above combination makes the plum-flavored peanut delicious but not greasy, the taste is layered, the taste is unique, and the plum-flavored peanut is loved by various consumer groups.

Owner:正阳新地食品工业有限公司

Rapid chili fermentation method

The invention relates to the technical field of chili snack food, in particular to a rapid chili fermentation method. Chilies are treated with the steps of softening, seasoning and fermenting, so that prepared pickled chilies are delicious in taste, the outer skin of the chilies is soft and crisp, and the taste of the pickled chilies is improved; particularly, the pickled chilies have a sweet aftertaste after being put into the mouth and eaten while having the slightly-spicy flavor, and the flavor of the pickled chilies is unique; besides, the pickled chilies diffuse a fresh scent, and can promote digestion of the intestines and the stomach and enhance the appetite of eaters.

Owner:贵州省石阡和记绿色食品开发有限公司

Machine for frying corn pancake with filling

ActiveCN109221309ACrispy skinImprove insufficient intake of coarse grains and vegetablesHollow article bakingEngineering

The invention relates to a dining utensil. The purpose is to solve the problem that a corn pancake is made by pouring batter on a circular heating flat iron plate for forming in the prior catering industry and a machine for frying a corn pancake with filling does not exist in the market. The upper middle position of a heating zone 30 is provided with a mould assembly 6, a hinge 23 is arranged between a mould bottom 40 and a mould cover 21, a toggle plate 24 is fixed on the upper part of a moving rod 5, a motor fixing plate 29 is fixed on two sides of the front inner part of a shell 3, and a motor 17 is fixed on the motor fixing plate 29; the machine has the advantages that the machine saves the manual wrapping process, and the outer peel of the corn pancake can be crisp and soft and glutinous according to different batters and baking time, and the corn pancake is suitable for people at different ages; a finished product is thin in peel and large in filling, the batter is mainly made ofcoarse cereals, the filling is mainly made of vegetables, the problem of insufficient intake of coarse grains and vegetables for prior people can be effectively improved, and the corn pancake is beneficial to sub-healthy people. The corn pancake is suitable for a catering net point, a dining hall and a snack vehicle, and is an optional device for re-starting a business for laid-off and re-employment people.

Owner:泰安金冠宏食品科技有限公司

Chicken liver cored meat ball making method

InactiveCN103504342ARich and deliciousIncrease added valueFood freezingFood thermal treatmentFlavorAdditional values

The invention discloses a chicken liver cored meat ball making method which comprises the following steps: (1) preparing raw material for a chicken liver cored meat ball, (2) preparing chicken breast meat pulp, (3) preparing chicken liver paste, (4) pouring the chicken breast meat pulp and the chicken liver paste respectively into a material jar of a cored meat ball forming machine for forming, wherein the formed cored meat ball is added into the hot water with the temperature of 50-60 DEG C to be heated for 10-15 minutes and then added into the hot water with the temperature of 80-90 DEG C to be heated for 10-15 minutes, and is then taken out, cooled and quickly frozen. The chicken liver cored meat ball is crisp and tender in the outer skin, the chicken liver paste in the meat ball is smooth, fragrant and glutinous, the flavor of the chicken liver is aromatic, and the chicken liver is delicious. The quickly frozen chicken liver product is better eaten by people, and is better stored and transported. According to the invention, the chicken liver is deeply processed, and the additional value of the chicken liver is increased.

Owner:河南省淇县永达食业有限公司

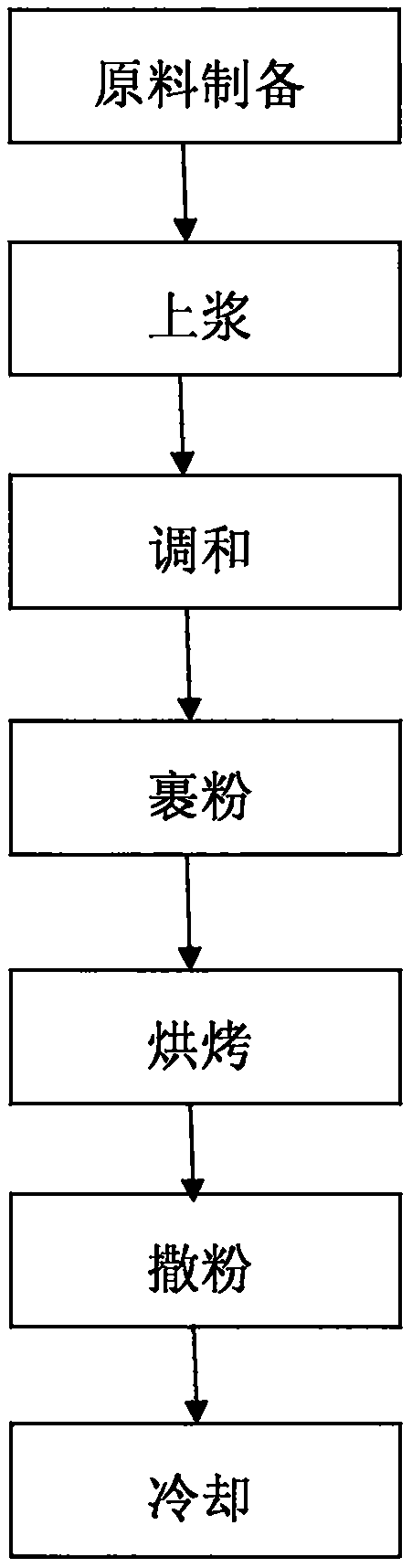

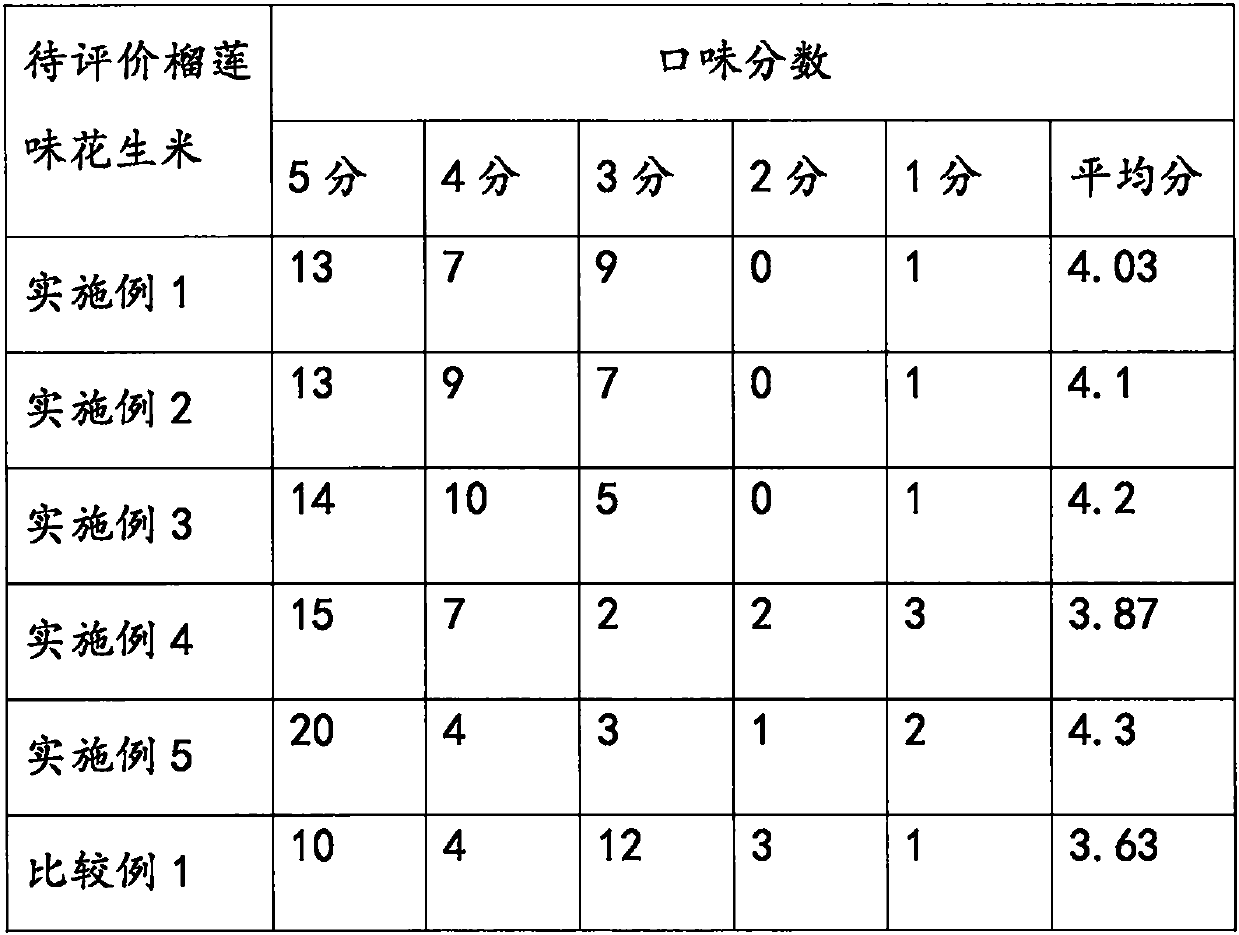

Durian-flavored peanut and making method thereof

The invention relates to a durian-flavored peanut and a making method thereof. The durian-flavored peanut is prepared by sizing, blending, powder-coating, baking, and mixing 100 parts by weight of peanut. The sizing slurry is 1.5 to 2.5 parts by weight, the slurry powder is stirred by the spice powder, edible salt, monosodium glutamate, starch and the water; a syrup is prepared by mixing white granulated sugar, water and seasoning, and the seasoning includes salt and monosodium glutamate. The flour used for blending is 25 to 40 parts by weight. During powder coating, 70 to 150 parts by weightof the coating powder and 85 to 130 parts by weight of the syrup are used. During mixing, 3 to 9 parts by weight of the durian-flavored seasoning powder and 3 to 6 parts by weight of the edible oil are used. The durian-flavored peanut made by the invention maintains the freshness of the peanut itself, the outer skin of the peanut is made more crispy by sizing and powder coating, the above combination makes the durian-flavored peanut delicious but not greasy, the taste is layered, the taste is unique, and the durian-flavored peanut is loved by various consumer groups.

Owner:正阳新地食品工业有限公司

Alaska cod steak and preparation method thereof

The invention discloses an Alaska cod steak and a preparation method thereof. The Alaska cod steak is prepared by processing an Alaska cod, a marinade, a paste and a coating powder material; relativeto 100 parts of an Alaska cod raw material by mass, the marinade comprises the following raw materials in parts by mass: 5-20 parts of ice water, 0.5-1.8 parts of table salt, 1-5 parts of white granulated sugar, 0.01-0.04 part of ethyl maltol, 1-5 parts of salad oil, 0.2-0.8 part of monosodium glutamate, 1-3 parts of modified cassava starch, 1-6 parts of corn starch, 1-5 parts of plant oil, 0.5-4parts of garlic powder and 0.2-1 part of white pepper powder. The Alaska cod steak has the beneficial effects as follows: the Alaska cod steak prepared by using the marinade having a scientific matching ratio is rich in nutrition, crispy in outer skin and fresh and tender in meat; through mutual cooperation of various components in ingredients, a unique mouth feel and a unique flavor are formed; apreparation technology is fine and controllable, and achievement of industrial production is facilitated; under the premise that the taste and the quality are guaranteed, the cost is effectively controlled.

Owner:NEW HOPE LIUHE

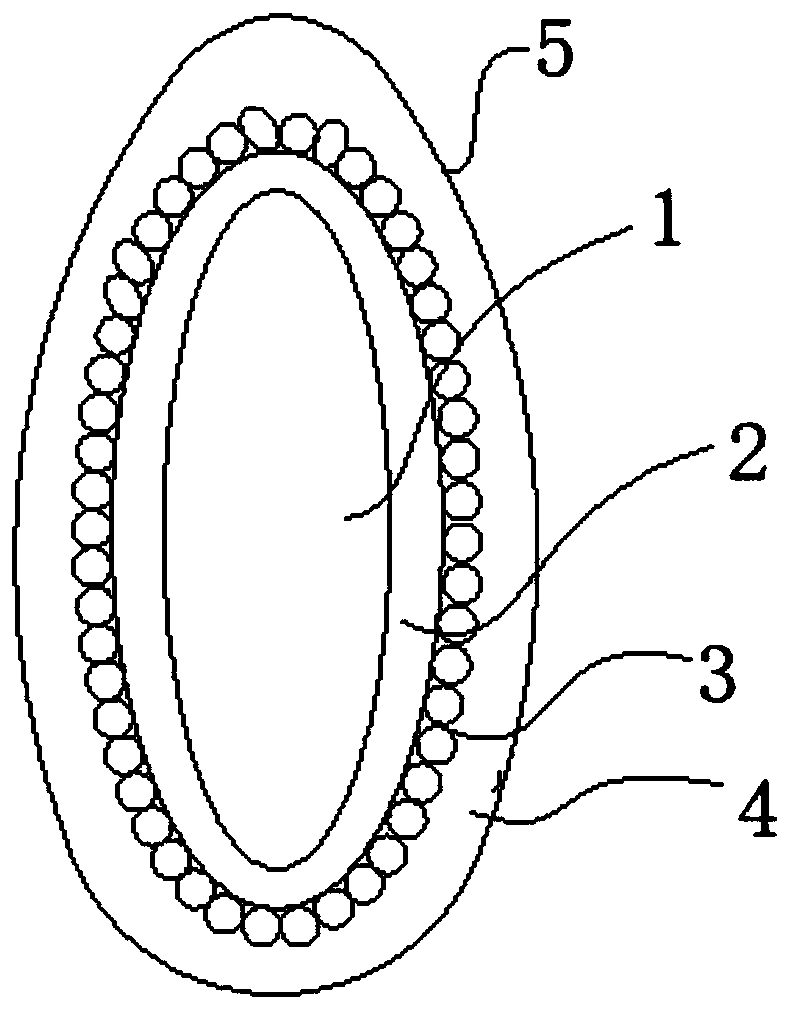

Layered chocolate shelled melon seeds and processing method thereof

PendingCN111543613ARich tasteImprove experienceFood ingredient as antioxidantEdible seed preservationHorticultureFood processing

The invention discloses layered chocolate shelled melon seeds and a processing method thereof, and belongs to the field of food processing. According to the layered chocolate shelled melon seeds, theouter surface of baked shelled melon seeds is coated with a chocolate inner layer, a popping candy layer and a chocolate outer layer from inside to outside; the popping candy layer is embedded betweenthe two chocolate layers, so that the fixing effect is good, the popping candy layer is not easy to fall off, the taste of the shelled melon seeds is enriched, the taste of the popping candy is three-dimensional when the popping candy jumps in the mouth, and the aftertaste is more lasting in the specific reaction process. The problem that existing chocolate shelled melon seeds are monotonous in taste and lack of three-dimensional taste is solved.

Owner:CHACHA FOOD CO LTD +1

Preparation method of buttered crispy fried dough twists

The invention discloses a preparation method of buttered crispy fried dough twists and relates to a preparation method of deep-fried dough twists. The preparation method of buttered fried dough twists comprises the following steps: (1) thoroughly mixing and stirring 6.5 Kg of anhydrous shortenings, 13 Kg of flour and 8 Kg of cerealose until being crispy and soft, to obtain a stuffing; (2) mixing flour, water and yeast, and leavening to obtain leaven flour; (3) thoroughly mixing 50 Kg of leaven flour, 50 Kg of flour, 10 Kg of soft white sugar, 5 Kg of eggs, 5 Kg of cooked sesame oil, 0.4 Kg ofbaking powder, 0.5 Kg of dietary alkali, 0.4 Kg of table salt and 13 Kg of warm water, to obtain dough; (4) wrapping the stuffing with the dough, and processing into dough twists; and (5) deep-fryingthe dough twists in 170 DEG C to 185 DEG C oil in a cooking pot. Compared with the prior art, the dough is made from leaven flour and hot sesame oil, the method is simple, and the twist foods are crispy and palatable, are available in different types, and are easy to be preserved.

Owner:神池县东海食品有限责任公司

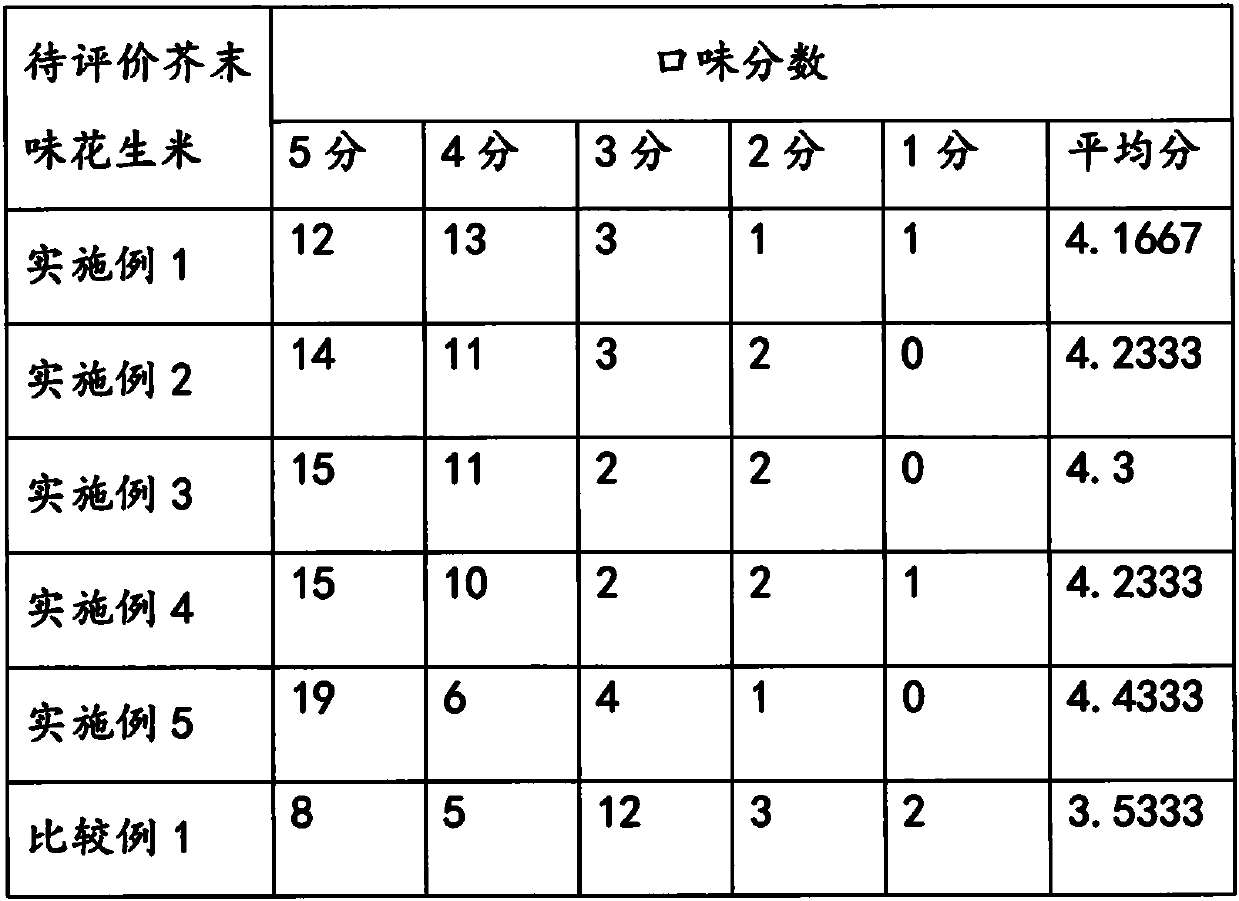

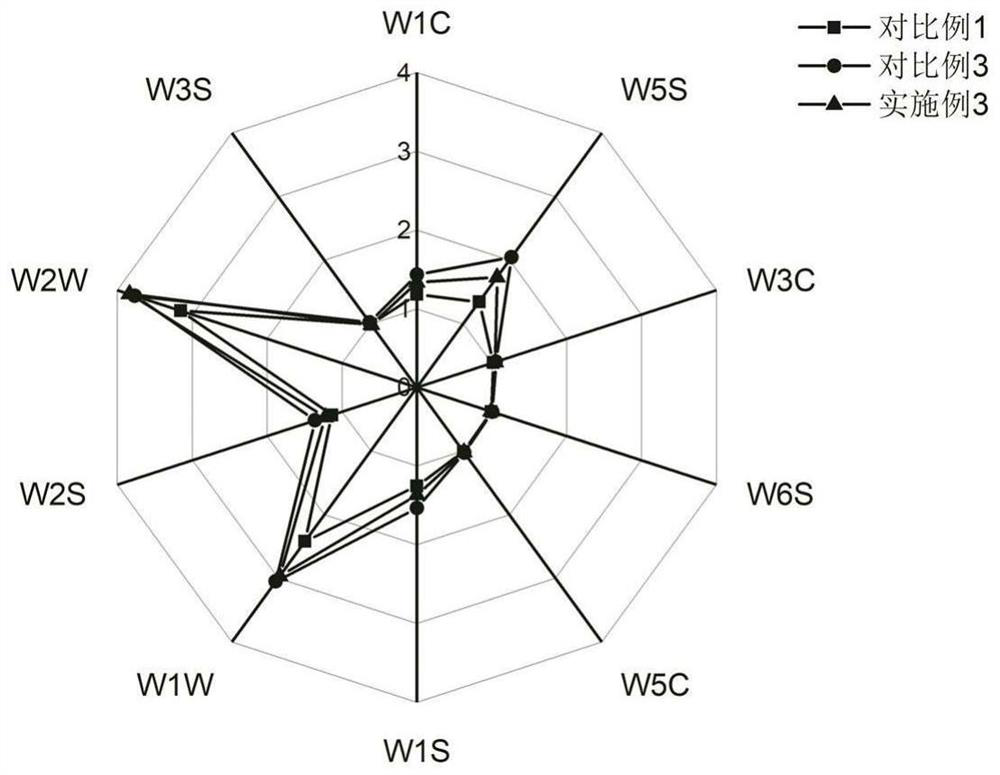

Mustard-flavored peanut and making method thereof

The invention relates to a mustard-flavored peanut and a making method thereof. The mustard-flavored peanut is prepared by sizing, blending, powder-coating, baking, and mixing 100 parts by weight of peanut. The sizing slurry is 1.5 to 2.5 parts by weight, the slurry powder is stirred by the spice powder, edible salt, monosodium glutamate, starch and the water; a syrup is prepared by mixing white granulated sugar, water and seasoning, and the seasoning includes salt and monosodium glutamate. The flour used for blending is 25 to 40 parts by weight. During powder coating, 70 to 150 parts by weight of the coating powder and 85 to 130 parts by weight of the syrup are used. During mixing, 3 to 9 parts by weight of the mustard-flavored seasoning powder and 3 to 6 parts by weight of the edible oilare used. The mustard-flavored peanut made by the invention maintains the freshness of the peanut itself, the outer skin of the peanut is made more crispy by sizing and powder coating, the above combination makes the mustard-flavored peanut delicious but not greasy, the taste is layered, the taste is unique, and the mustard-flavored peanut is loved by various consumer groups.

Owner:正阳新地食品工业有限公司

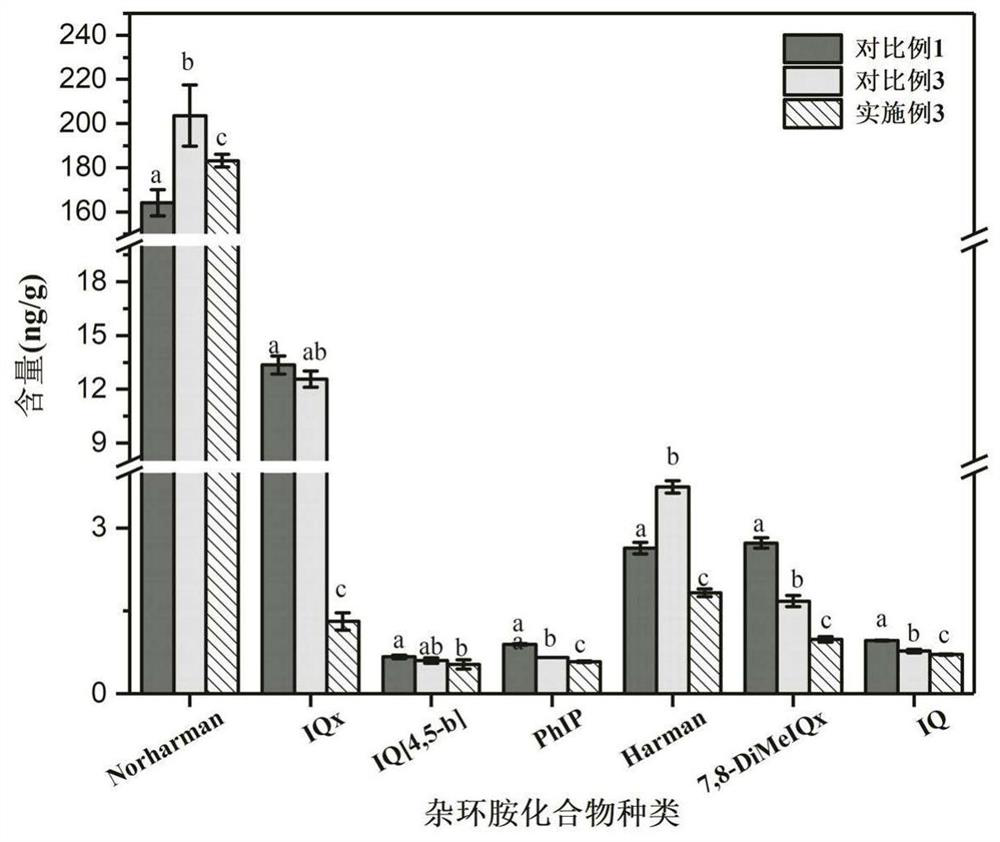

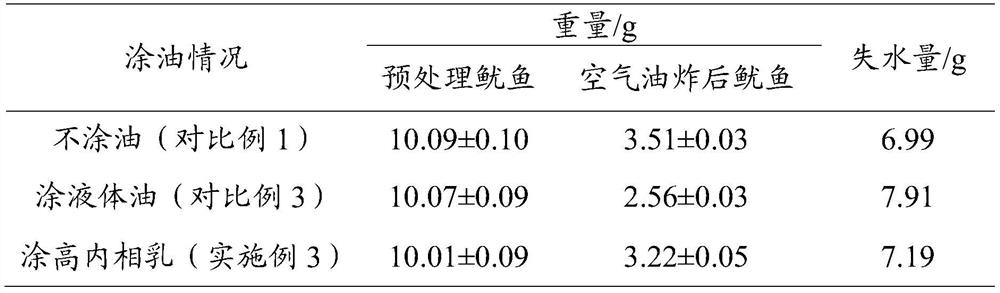

Method for air-frying seafood based on immobilized grease

The invention discloses a method for air-frying seafood based on immobilized grease. The method comprises the following steps: smearing casein-stabilized high internal phase emulsion on the surface ofthe seafood for air-frying to obtain the air-fried seafood. By utilizing the immobilization effect of the high internal phase emulsion on the grease, the flowability of the grease is changed, and thegrease coating uniformity is ensured; and the appearance and the texture of the air-fried low-fat-content seafood are improved. The obtained product is uniform in surface color, crispy in surface andrich in elasticity inside. Meanwhile, the production of heterocyclic amine can be effectively reduced; the high-internal-phase emulsion shows physical properties such as spreadability and plasticityin application, and can be widely applied to food baking and deep-frying to replace hydrogenated oil and ester exchange grease.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Dumplings secretly made by a barbecue process

The invention belongs to dumplings secretly made by a barbecue process, wherein the preparation components comprise: 45% of flour, 5% of Chinese prickly ash, 2% of fine salt, 13% of egg white, 6% of egg yolk, 5% of edible oil, 2% of starch, 1% of cuminum cyminum l, 4% of perilla oil and the balance of purified water. The preparation method comprises the following steps: mixing and dough making, auxiliary liquid preparing, dipping and baking. According to the invention, dumplings can be baked for eating; and compared with boiled dumplings and fried dumplings, the dumplings prepared by the method of the invention have crisp wrapper, tender interior and scorched exterior.

Owner:周志胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com