Durian-flavored peanut and making method thereof

A technology of peanuts and durians, applied in the direction of food science, etc., can solve the problems of limited taste, high oil content and deterioration of deep-fried products, and achieve the effect of rich taste, unique taste and crispy skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

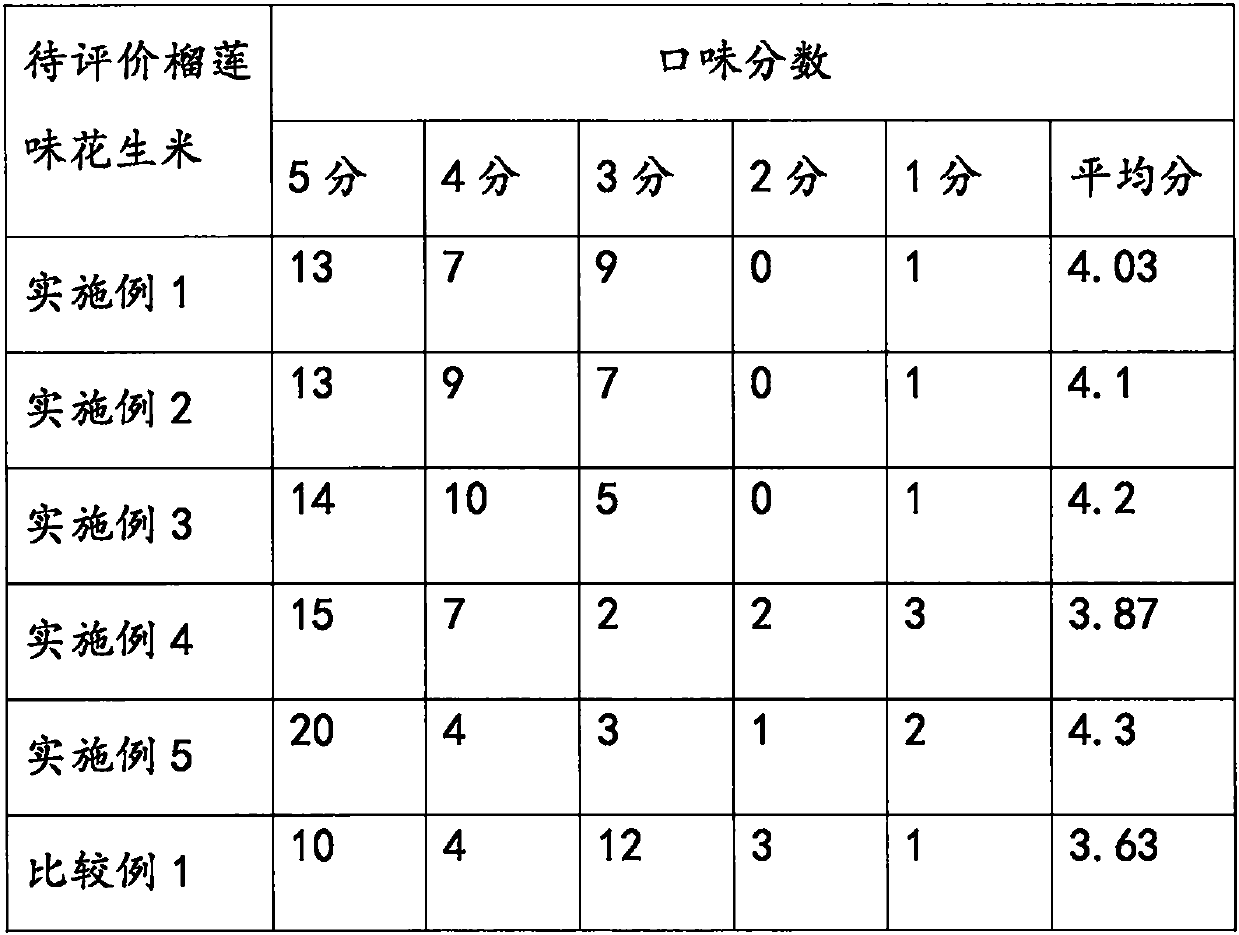

Examples

preparation example Construction

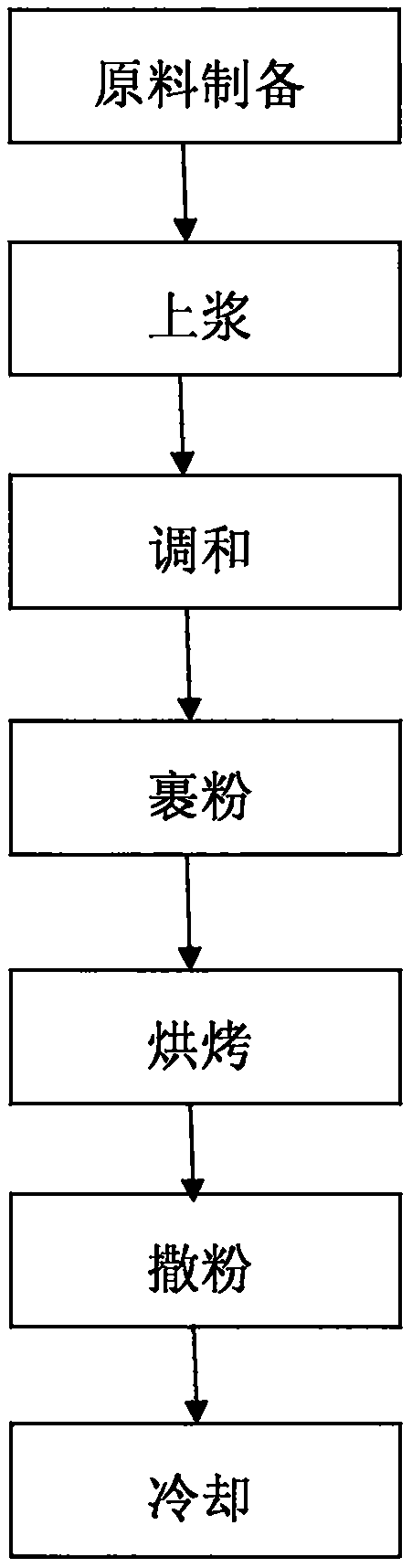

[0034] The preparation method of the above-mentioned peanuts is described below. Including the following steps:

[0035] Step 1: Raw material preparation. The raw materials include peanuts and other required materials. Specifically:

[0036] 100 parts by weight of peanuts, 25-40 parts by weight of flour, 3-9 parts by weight of durian-flavored seasoning powder and 3-6 parts by weight of edible oil are selected.

[0037] 1.5-2.5 parts by weight of slurry, 70-150 parts by weight of powder coating and 85-130 parts by weight of syrup are prepared.

[0038] The slurry is formed by stirring allspice powder, edible salt, monosodium glutamate, edible cornstarch and water (preferably hot water); the mass ratio of fivespice powder, edible salt, monosodium glutamate, and edible cornstarch in the slurry powder is 1:2.5:2.5 : 40.

[0039] The syrup sprayed during the powder coating is composed of white granulated sugar, water (preferably hot water), and seasoning in a mass ratio of 1:1...

Embodiment 1

[0050] Prepare 100 parts by weight of peanuts; 2.5 parts by weight of slurry; 150 parts by weight of coating powder, 40 parts by weight of flour for blending, 130 parts by weight of syrup, 9 parts by weight of durian flavored seasoning powder, and 6 parts by weight of edible oil.

[0051] The outer layer of peanuts is evenly wrapped with a layer of artificially prepared slurry, then mixed with flour, and then coated with flour to ensure that the peanuts are completely coated with flour, then the excess flour is sieved off, and baked in a rotary oven. The first stage uses 140°C, and the baking time is about 20 minutes. In the second stage, the temperature is raised to 170°C, and the baking time is about 30 minutes. Season the durian seasoning powder until it is evenly mixed and put it in the cooling area.

Embodiment 2

[0053]100 parts by weight of peanuts; 1.5 parts by weight of slurry; 70 parts by weight of breading powder, 25 parts by weight of flour for blending, 85 parts by weight of syrup, 3 parts by weight of durian-flavored seasoning powder, and 3 parts by weight of edible oil.

[0054] The outer layer of peanuts is evenly wrapped with a layer of artificially prepared slurry, then mixed with flour, and then coated with flour to ensure that the peanuts are completely coated with flour, then the excess flour is sieved off, and baked in a rotary oven. The first stage uses 130°C, and the baking time is about 25 minutes. In the second stage, the temperature is raised to 160°C, and the baking time is about 35 minutes. Season the durian seasoning powder until it is evenly mixed and put it in the cooling area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com