Patents

Literature

46 results about "Rice Preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Follow These Steps Boil water and add salt. Pour water (for every cup of rice, use 1¾ cups of water) into a large saucepan with a tight-fitting lid. Pour in rice. Add it to the boiling water. Stir once, or just enough to separate the rice. Use a wooden spoon to separate any clumps. Cover the pot and simmer. Be sure the lid fits tightly on the pot.

Fish rice dumpling and processing method of fish rice dumping

InactiveCN102823817AGuaranteed food safetyWell preservedFood preparationMaterials preparationAdditive ingredient

The invention discloses a fish rice dumpling and a processing method of the fish rice dumping. The processing method comprises the steps of raw material preparation, dumping making, dumping boiling and package, wherein the material preparation comprises three parts including 1, fish preparation, 2, seasoning sticky rice preparation, and 3, rice dumping leaf preparation. The fish rice dumpling processed according to the method provided by the invention belongs to novel fish type nutrition food suitable for both old people and young people, and fish in the fish rice dumping can be boiled along with the major ingredients of sticky rice, so the nutrition substance preservation condition is good, and particularly, when fish meat of freshwater fish (such as carps and four major Chinese carps) is used as stuffing, the nutrition is richer. In addition, any fishbone does not exist in the stuffing of the fish rice dumping, and the eating safety of the fish rice dumping is ensured.

Owner:扬州常天水产科技有限公司

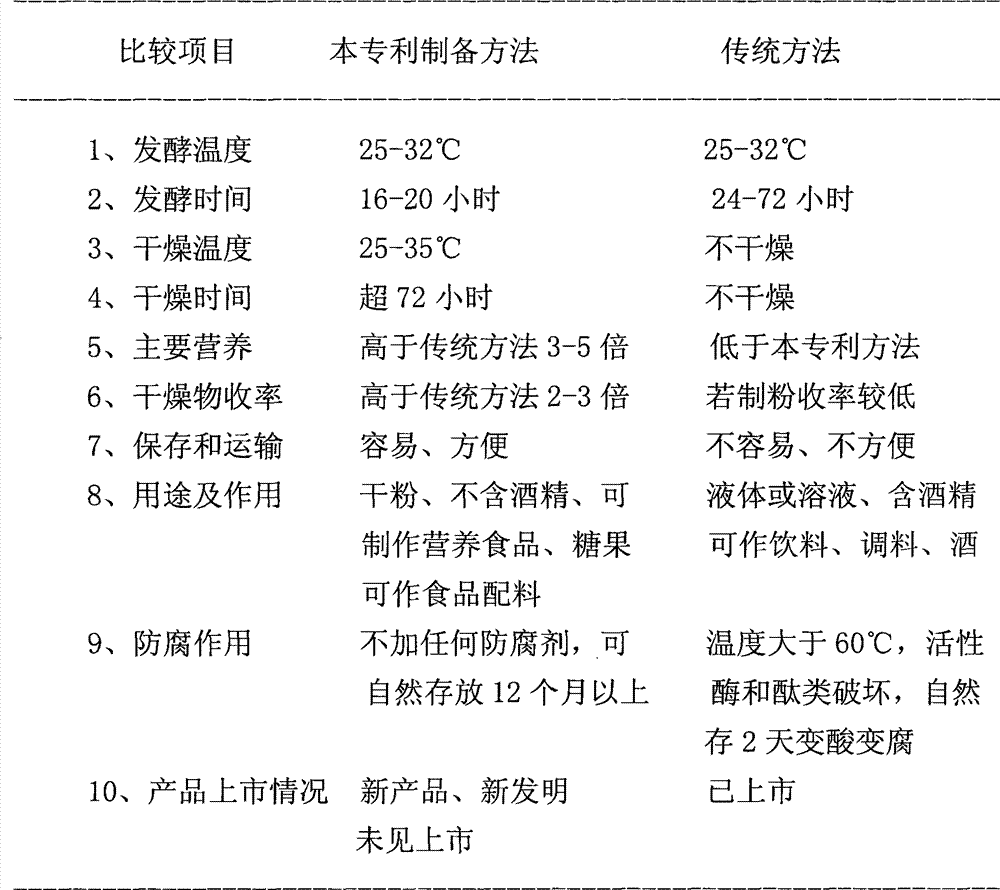

Two-step fermentation preparation method and application of sweet fermented-rice nutrient or brewing nutrition products

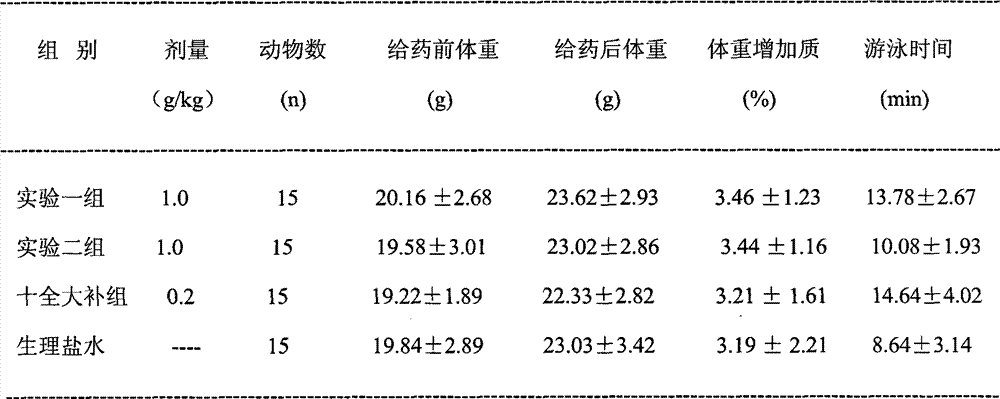

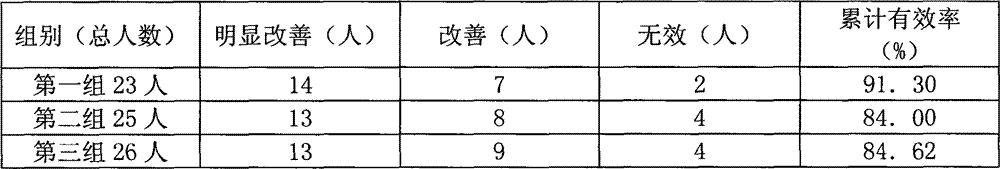

The invention relates to a two-step fermentation preparation method and application of sweet fermented-rice nutrient or brewing nutrition products with extremely high values. The two-step fermentation preparation method comprises the following steps of: (1) fermenting raw materials to prepare initial sweet fermented-rice or fermenting products according to a sweet fermented-rice preparation process or a conventional brewing process; and (2) performing drying fermentation or drying during fermentation on the initial sweet fermented-rice or the initial brewing fermentation products in a low-temperature mode, or performing drying fermentation on the initial sweet fermented-rice or the initial brewing fermentation products for a certain time to directly prepare a nutrient solution on the basis of the step (1). The main nutritive components of the powder or substance are obviously higher than those of sweet fermented-rice prepared by a traditional method by 3-5 times, the total protein of the powder is close to 30 percent, and the content of essential amino acids of a human body is over 20 percent; and moreover, the product does not contain alcohol and can be naturally preserved for over 12 months. The product has the effects of resisting fatigue, enhancing immunity, improving sleep quality, improving sexual function, and promoting growth of white blood cells and development of infants. The product can be prepared into foods, health-care foods and medicines of various dosage forms by traditional methods and also can serve as ingredients of foods, health-care foods and medicines.

Owner:黄家章

Novel environmentally-friendly preboiled rice preparation method

The invention discloses a novel environmentally-friendly preboiled rice preparation method which produces preboiled rice by carrying out hydrothermal treatment on brown rice. The novel environmentally-friendly preboiled rice preparation method is characterized by comprising the following preparation steps: cleaning and rice hulling; soaking; steaming; drying, cooling and grinding. The novel environmentally-friendly preboiled rice preparation method has the purposes that according to the method for carrying out hydrothermal treatment on the brown rice serving as a raw material, unhusked rice is replaced for production of the preboiled rice; by the use of the preparation method for producing the preboiled rice, effective use of energy in production can be increased, the production technological process and technological conditions can be simplified, and the processing period is short; furthermore, the nutritional quality of the preboiled rice is improved, the color and the smell of the preboiled rice are improved, and the use quality of the preboiled rice is improved.

Owner:JIANGSU VOCATION & TECHNICAL COLLEGE OF FINANCE & ECONOMICS

Processing method for Tujia oil tea soup

The invention discloses a processing method for Tujia oil tea soup. The method is implemented by totally 8 procedures of primary oil tealeaves pretreatment, parched rice preparation, accessory preparation, ginger-pepper oil preparation, oil tea preparation, garlic oil preparation, mixing and bagging. When the Tujia oil tea soup is drunk, a small oil tea soup bag is torn, so that oil tea soup is poured in a bowl and mixed with boiling water, and a bowl of delicious Tujia oil tea soup is made after 1 to 2 minutes, wherein the parched rice can be replaced with oil-fried soybeans, crisp fat and oily bean curds. The processing method has the benefits that the tealeaves and various accessories are fried, organic tealeaves rich in elementary selenium in a Tujia mountainous area, wild camellia oil, the parched rice and the like are selected, and garlic sprouts and parched rice perfectly matched with oil tea soup are matched, so that the Tujia oil tea soup is delicious, and can be drunk after being mixed with boiling water; the oil tea soup has tea fragrance, attractive soup color and endless aftertaste, and tastes delicious, memories of people about conventional food can be increased, and a health food material with a nostalgia flavor is provided for Tujia people spread all over the world and other people fond of oil tea soup.

Owner:范才成

Local flavor rice crust and making method

InactiveCN101461492ANutritional diversityBright yellow color and beautifulFood preparationVegetable oilFood flavor

The invention discloses a flavor crispy rice and preparation method thereof, belonging to the grain contained product field. The main material is rice flour and millet flour; and the auxiliary material is mainly egg, garlic extract, edible vegetable oil, starter and flavoring. The flavor crispy rice preparation method comprises: mixing the rice flour and millet flour; adding 1 / 10 the flour weight of water, and egg, proper amount of starter, flavoring and a small amount of garlic extract and perfume while stirring; compressing and slicing the kneaded dough into blanks; baking the blanks under the temperature of 100-120 degrees centigrade for 1-2 minutes to obtain the water content of 5-10%; frying in vegetable oil at 150-190 degrees centigrade for 3 minutes; cooling, detecting and packaging. The invention is made from a plurality of raw materials, has complete nutrition; and maintains the traditional crispy rice flavor; and the obtained crispy rice achieves the advantages of smooth surface, bright color, less oil adsorption, uniform and loose internal structure, crisp coat, soft core and various flavors.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Pollen fermented glutinous rice preparation method

The invention aims at the limitations of fermented glutinous rice products and the market blank of pollen fermented glutinous rice and discloses a method for fermenting pollens and glutinous rice mixtures into fermented glutinous rice by using yeasts for fermented glutinous rice. The method comprises the steps of: selecting high-quality glutinous rice and adding a certain proportion of pollens tomake cooked glutinous rice, adding a proper amount of sterile water with temperature being approximate 20 DEG C, containing the mixture in a container and fermenting for 3-4 days at 27-33 DEG C to obtain pollen spore fermented glutinous rice. The preparation method is economic, practical and simple; compared with the traditional fermented glutinous rice, the nutrients are richer and the healthcare function is better; the cell walls of the pollens of the product is easy to broken and the nutrients are easy to absorb; the pollens are mixed with the product after fermentation, all nutrients of the pollens are merged with the fermented glutinous rice and are eaten and the full-value high-efficiency utilization of the pollens are realized; and more minor ingredients with a healthcare function are not added aiming at special people, the fermented glutinous rice is a general food and is particularly suitable for old and weak people, women and children to eat, and the market capacity is larger.

Owner:FANGJIAPUZI PUTIAN GREEN FOOD

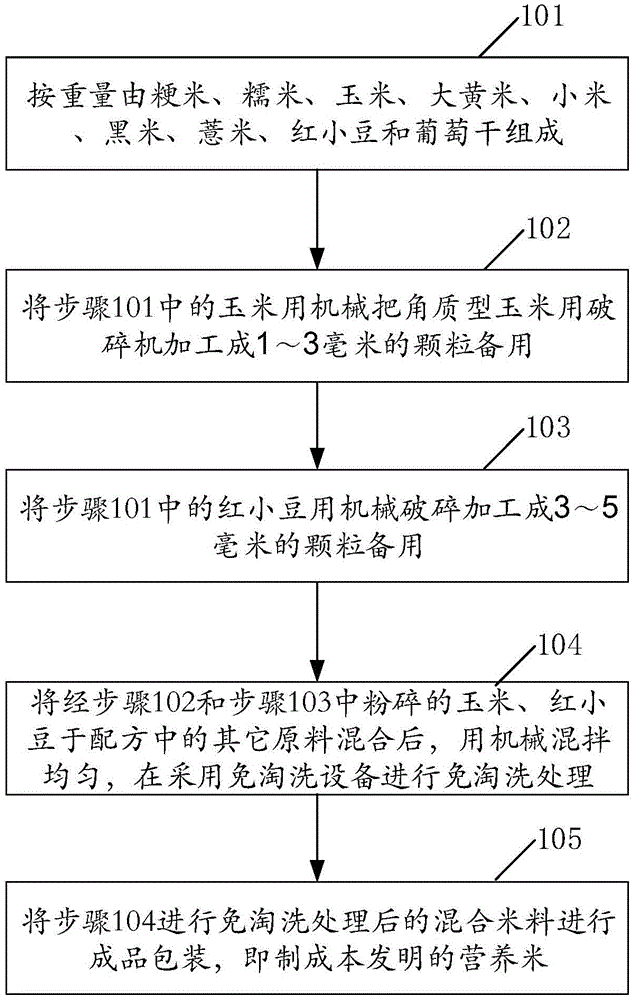

Nutrition rice preparation method

InactiveCN106387626AFull of nutritionTaste is flexible and chewyFood ingredient functionsTrace elementBiology

The present invention relates to the field of food processing, and discloses a nutrition rice preparation method. According to the present invention, according to the difference of the trace elements contained in the existing cereals and beans, combined complementation and matching is performed to supplement the balanced nutrition intake of an eater, and through multiple formula preparation and eating, the novel formula nutrition rice with characteristics of rich nutrition, flexible taste, chewing resistance, fresh aroma and wide application range is prepared, wherein the rice is safe and convenient, has a dietary therapy effect, can provide effects of disease prevention and nutrition health after long-term consumption, and further has effects of endocrine balancing, fatigue eliminating, blood enriching, qi benefiting, brain tonifying, kidney strengthening, and longevity.

Owner:CHONGQING XIPU AGRI DEV CO LTD

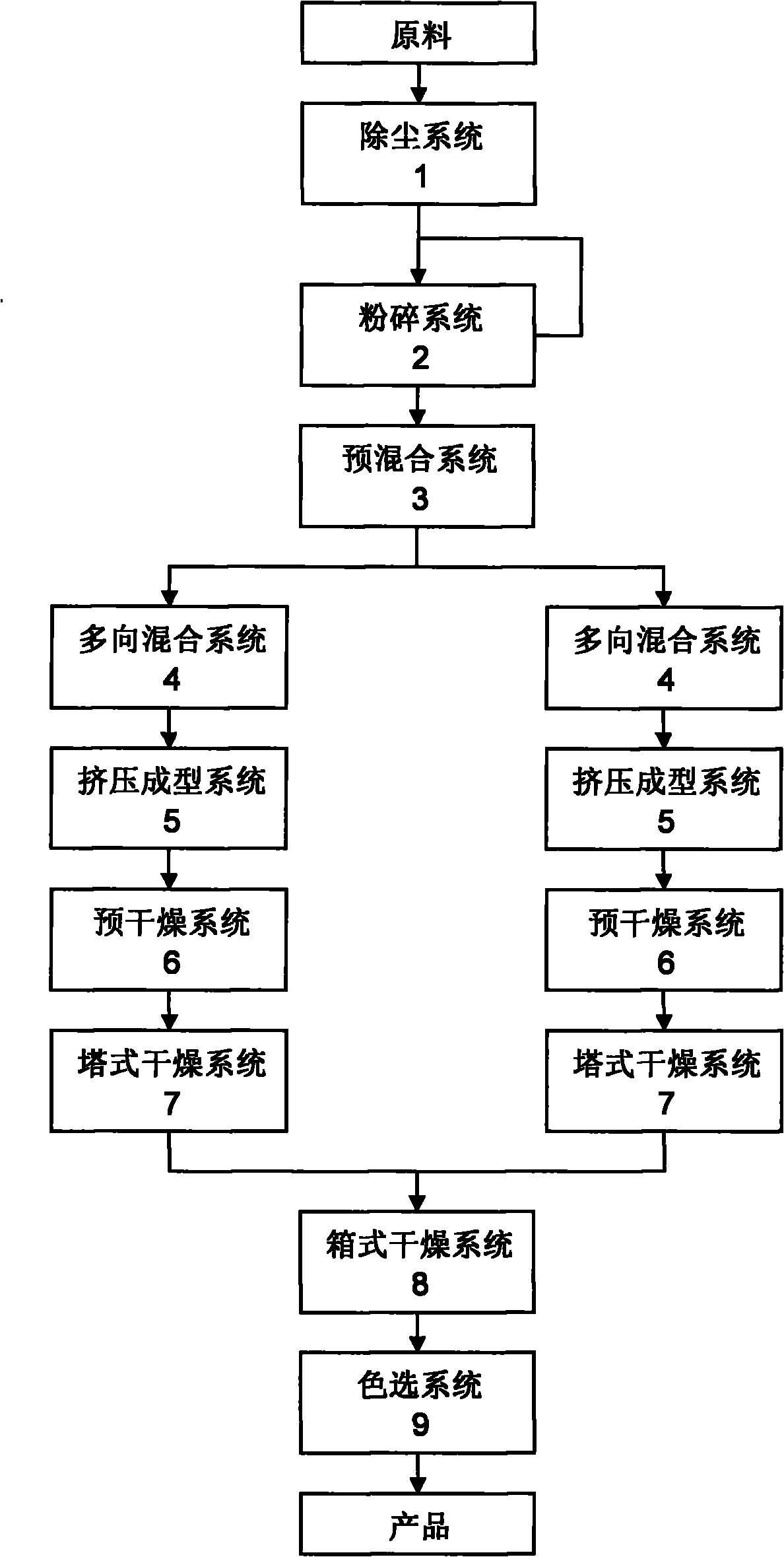

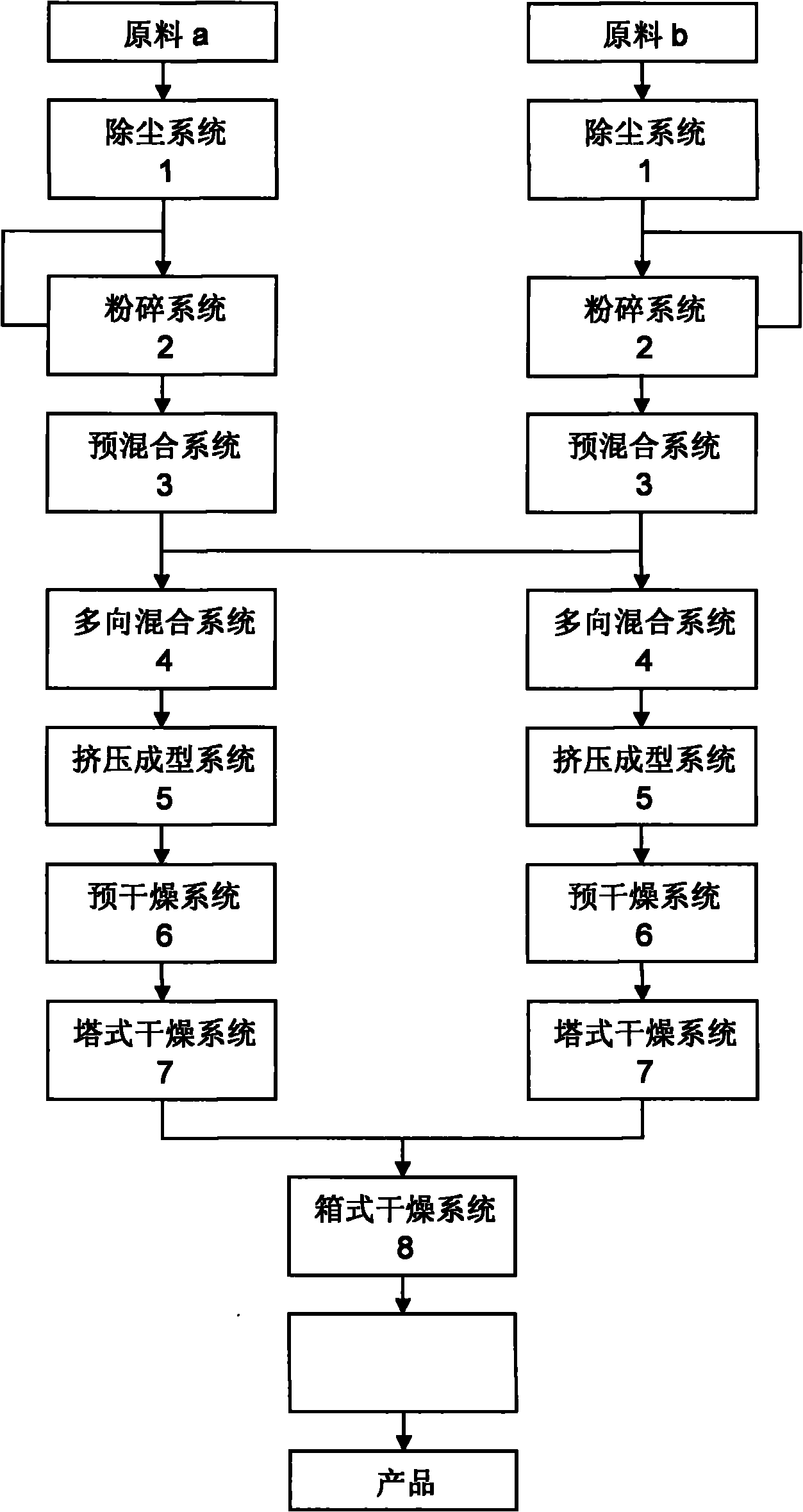

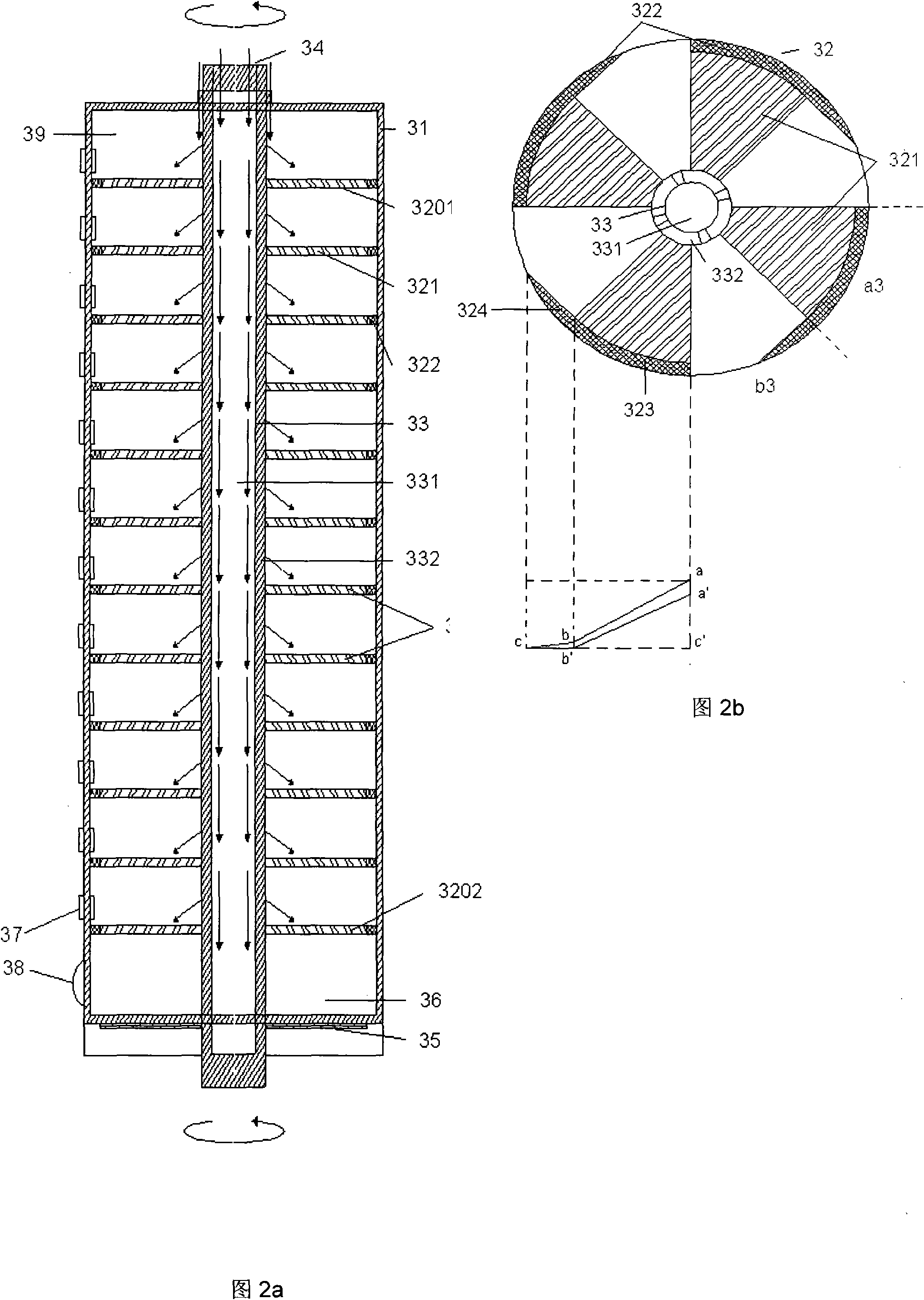

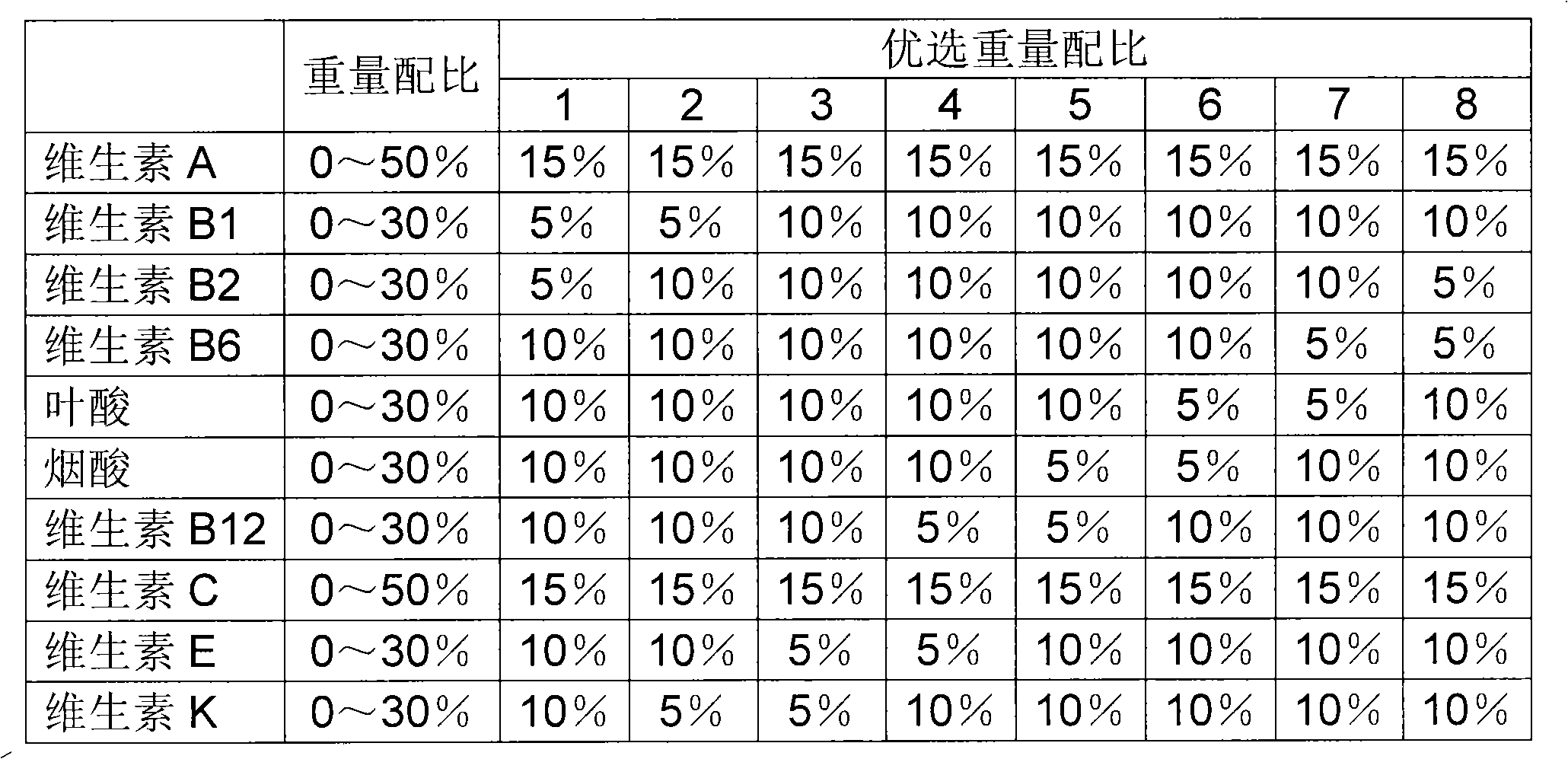

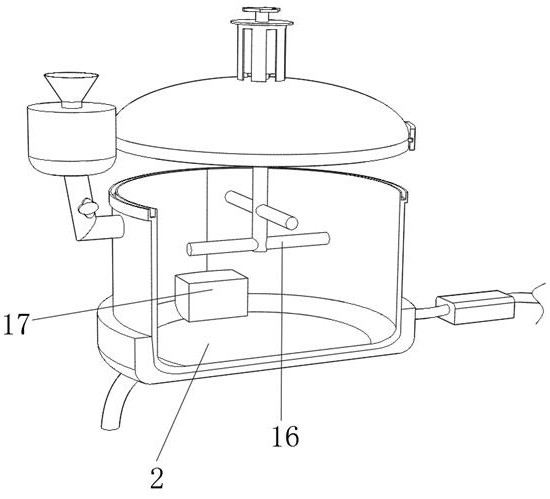

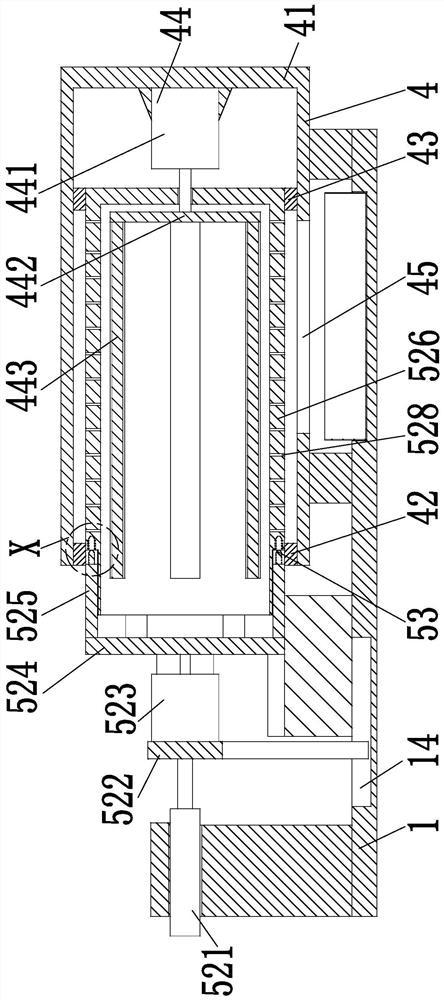

Reconstituted rice preparation plant

The invention discloses a reconstituted rice preparation plant. Along the material flow direction, the reconstituted rice preparation plant orderly comprises a dust-removal system, a pulverizing system, a premixing system, a multiway mixing system, an extrusion molding system, a predrying system, a tower type drying system, a box-type drying system and a color selection system, wherein the premixing system is a staggered combined type mixing reaction kettle, and the multiway mixing system is a horizontal three-chamber multiway mixing device; the extrusion molding system is a screw extruder and is provided with 2-4 multisection temperature-control heating type screws which mesh with each other and can rotate in reverse directions, and each screw is provided with at least 2 connecting sections, at least 2 thermal insulation sections, at least 1 first mixing section, at least 1 second mixing section, at least 1 third mixing section and a discharge section; the predrying system is a drier with multiple dispersion structures; the tower type drying system is a drying tower with a forward-backward distribution structure; and the box-type drying system is a multistage drier with gas agitation function.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

Preparation method of red kojic rice with high color value

The present invention discloses a preparation method of red kojic rice with a high color value and belongs to the technical field of red kojic rice preparation. Firstly, monascus purpureus seed liquid is prepared, then rice is subjected to hot soaking and freezing pre-treatment, then a variety of accessory materials are combined, the rice is boiled using a high-pressure cooker to obtain ripen rice with full of granules, the ripen rice is mixed with the monascus purpureus seed liquid to conduct fermentation, and thus the red kojic rice with the high color value is obtained. The method is unique, the technology is convenient, the ripening accessory materials are added during the cooking process, so that the cooked rice is more penetrated, stickiness and agglomeration are avoided, the red kojic rice is easy to be used by microorganisms, the production period is shortened, the red kojic rice with the high color value can be obtained in a short time, the cost is saved, the red kojic rice is suitable for industrial mass production, and the red kojic rice has significant economic benefits.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

Potato rice preparation method

A method for preparing potato rice. Specifically include: select common rice as raw material, and process the rice into powdery rice flour and rice milk; ~40% of the mixed material, and then use the rice grain forming machine to press the mixed material into rice-shaped potato rice, and finally dry and pack it into commercial potato rice. By implementing the invention, the rice and the potato are integrated, and the ordinary rice and the potato are turned into health-care rice rich in nutrition. Eating its rice not only enables people to obtain nourishment and health care in daily eating, but also effectively avoids many discomforts caused by eating potatoes. In addition, the value of rice and potatoes has been greatly increased, and the benefits are extremely significant.

Owner:黄秀英

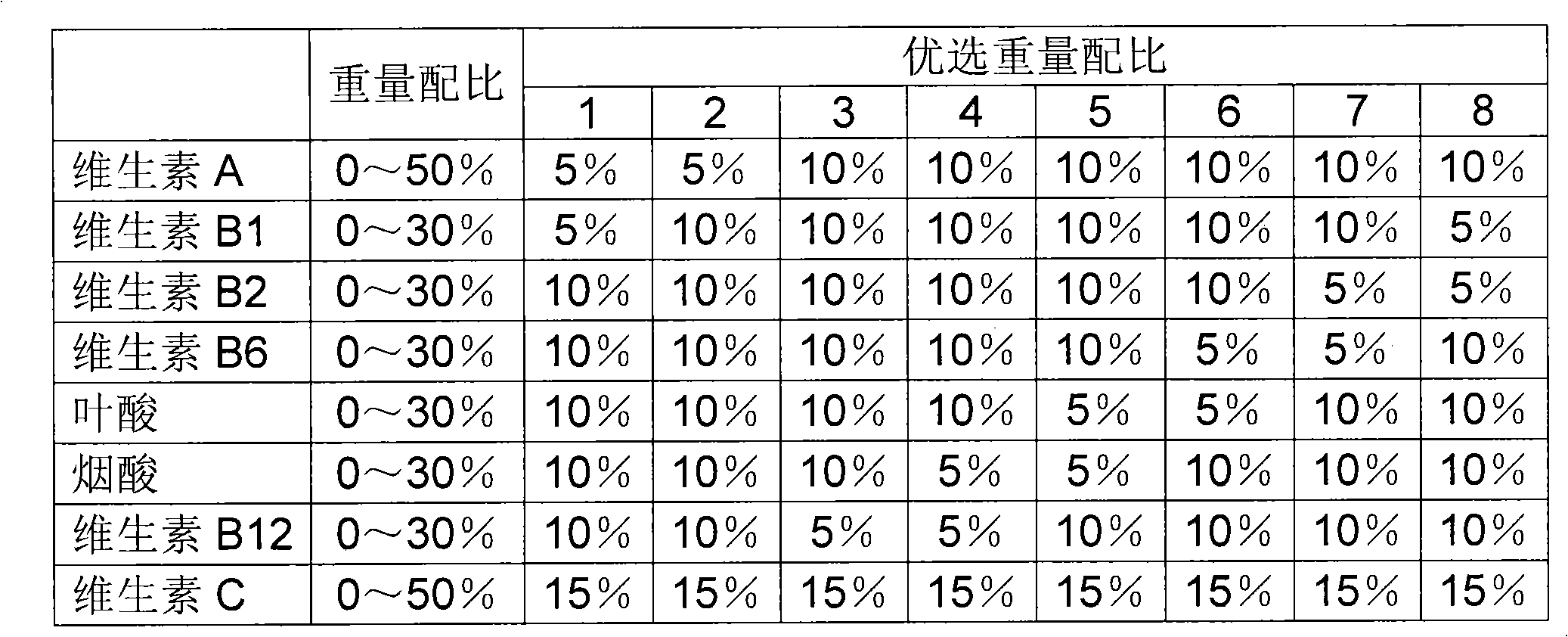

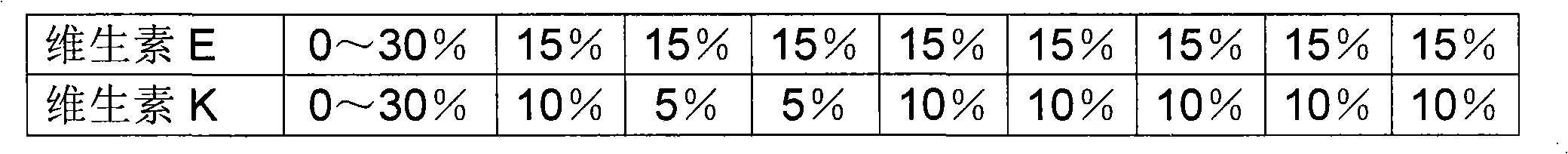

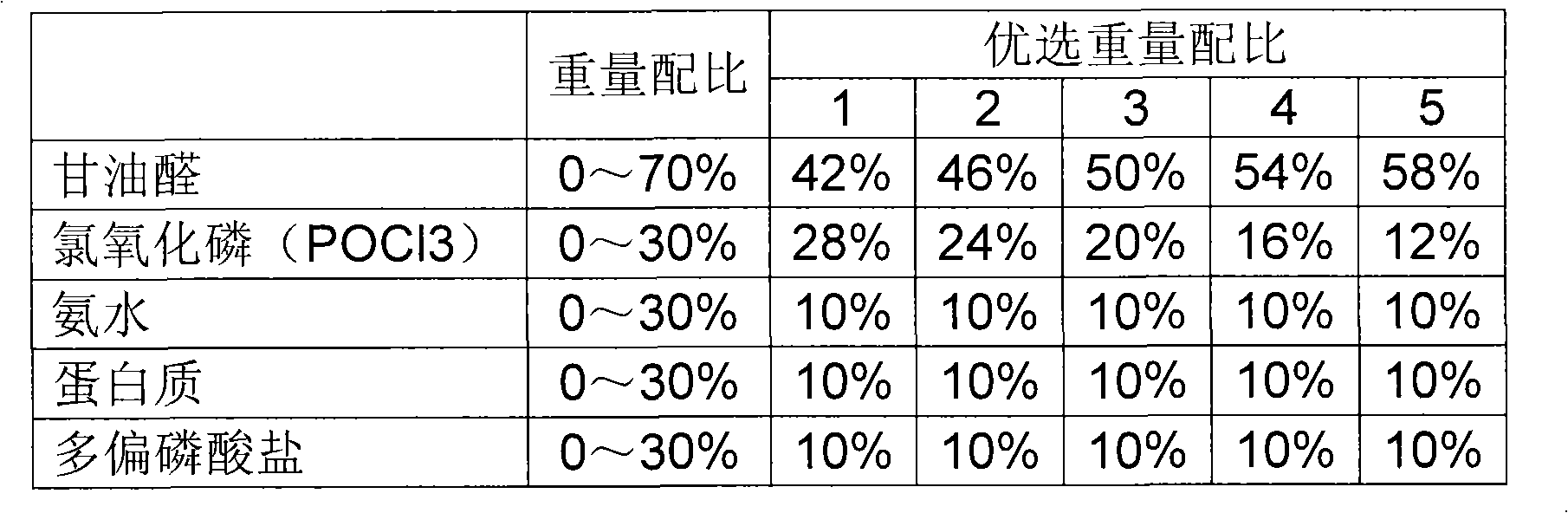

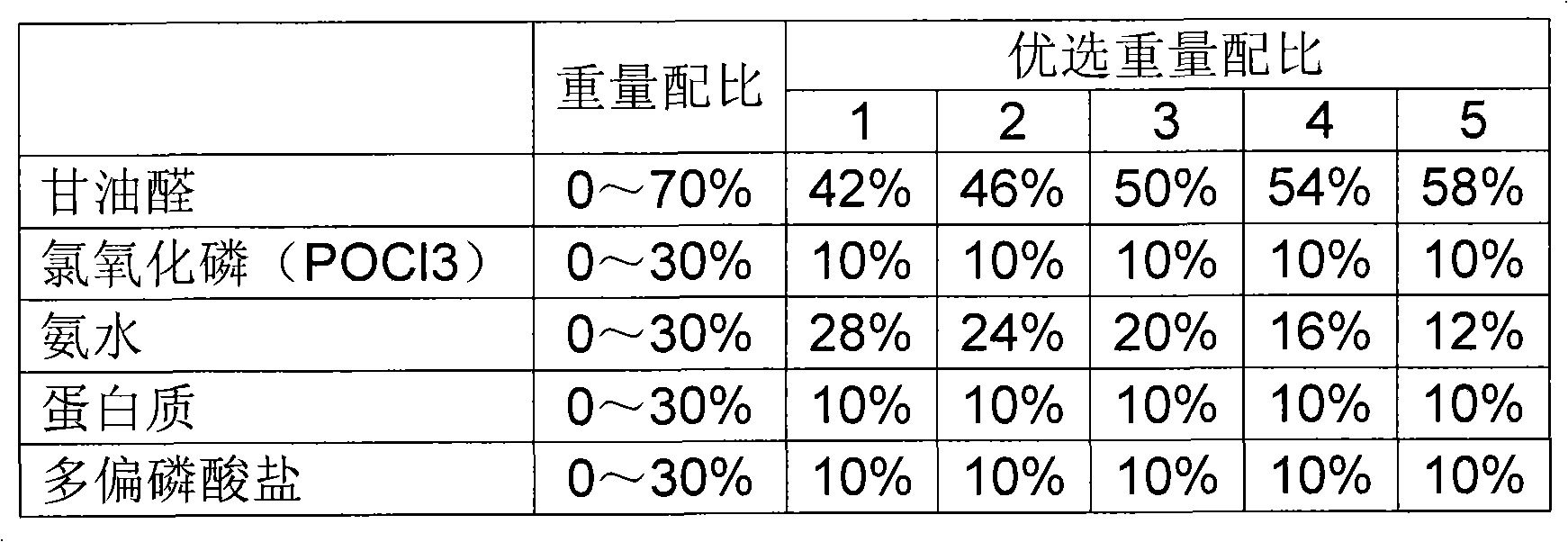

Nutrient substance in nutrition rice preparation process

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

Crosslinking agent for synthetic rice preparation technique

InactiveCN101856087APromote cross-linking reactionIncrease elasticityFood preparationSal ammoniacGlyceraldehyde

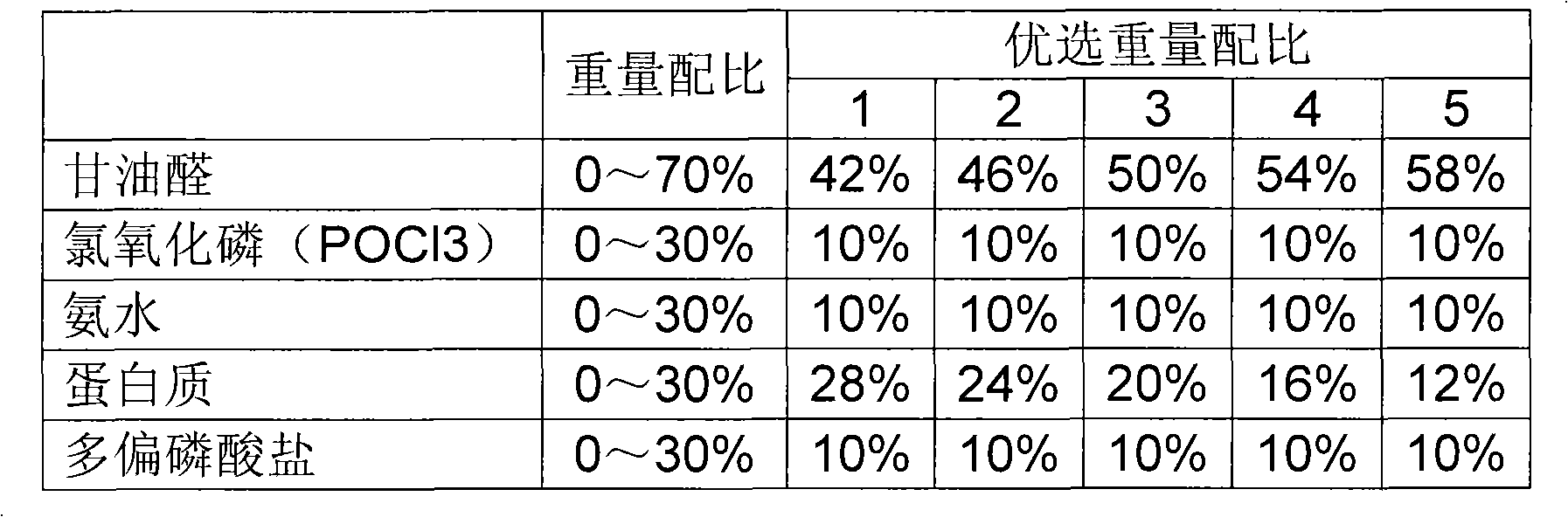

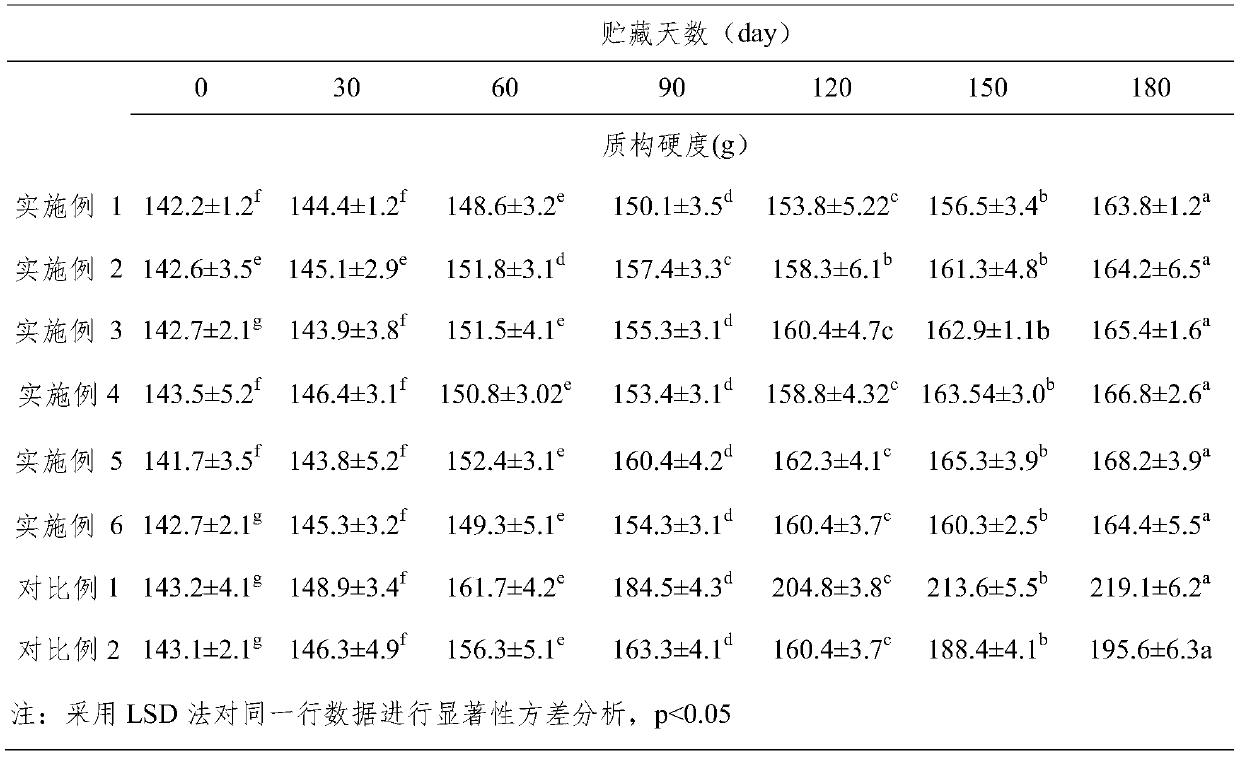

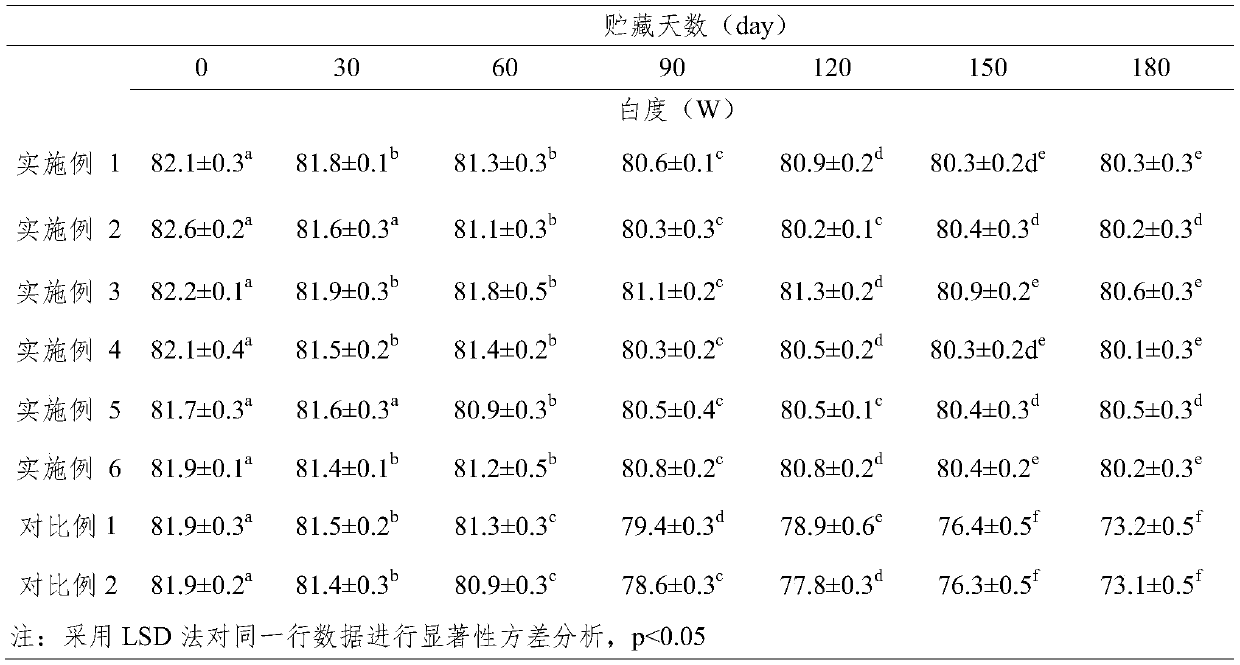

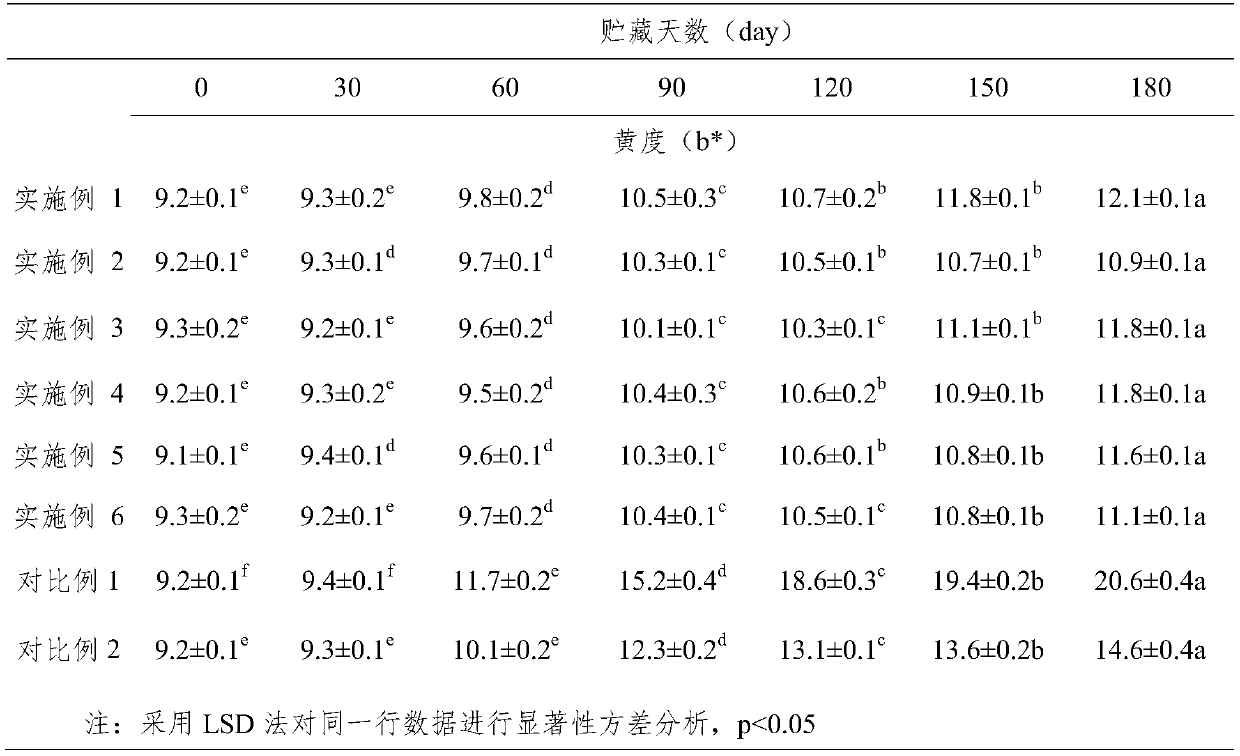

The invention discloses a crosslinking agent for a synthetic rice preparation technique, which comprises one or more of glyceraldehyde, glutaraldehyde, phosphorus oxychloride (POCL3), ammonia, protein and multi-metaphosphate, wherein glyceraldehyde, glutaraldehyde, phosphorus oxychloride (POCL3), ammonia, protein and multi-metaphosphate are respectively 0-70%, 0-70%, 0-30%, 0-30%, 0-30%, 0-30% and 0-30% in weight proportion.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

Cooked glutinous rice preparation method

The present invention discloses a cooked glutinous rice preparation method which comprises the following steps: (1) processing glutinous rice: washing the glutinous rice and soaking the glutinous rice in an immersed manner, removing the glutinous rice out and steaming the glutinous rice until the glutinous rice is done, adding salt and chicken essence into the steamed glutinous rice with a ratio of steamed glutinous rice to salt to chicken essence being 50 : 0.6 : 0.1-0.2, and stirring the mixture evenly to obtain the cooked glutinous rice; (2) processing meat: a, adding water in ginger and boiling the mixture until the total amount of water is reduced to 1 / 4 to obtain the ginger water, and cooling the ginger water to room temperature; b, cutting fresh lean meat into cubes and adding 1.5-2% of salt by weight of the fresh lean meat and 2-3% of ginger water to conduct pickling; c, taking fresh water to conduct boiling, putting the pickled lean meat into the water in an immersed manner, cooking the meat until the meat is done, taking out the meat and draining the water; and d, taking lard and cooking the lard until the lard is medium to almost heated, putting the drained cooked meat into the cooked lard and frying the meat into a golden brown color, and removing the fried meat and slicing the fried meat; and (3) mixing 160-170 grams of the cooked glutinous rice obtained in the step 1 and 30-40 grams of the sliced meat obtained in the step 2, thereby obtaining the finished product. The finished product of the cooked glutinous rice is not greasy, and has delicious taste and unique flavor.

Owner:GUIZHOU PSN FOOD CO LTD

Ready-to-eat rice soak solution and high-quality ready-to-eat soft rice preparation method

ActiveCN109907220ASolve the technical problem that only L-cysteine can be used as the soaking solutionOvercoming technical biasClimate change adaptationFood preservationReady to eatRice dishes

The invention discloses ready-to-eat rice soak solution and a high-quality ready-to-eat soft rice preparation method. The ready-to-eat rice soak solution refers to acidic solution containing L-tyrosine. The preparation method includes steps of pearl rice and jasmine rice compounding, washing, soaking in fermentation liquid, enzyme preparation adding, pre-gelatinization, recurrence inhibitor adding, normal-pressure cooking and aging, cooling, sterilization and storage to obtain ready-to-eat soft rice. By adoption of a slightly acidic and L-tyrosine-rich fermentation liquid soaking and cooking process, yellowing of rice in a storage period is effectively inhibited, and texture hardness increasing of rice in the storage period is reduced.

Owner:FUJIAN AGRI & FORESTRY UNIV

Preparation method of nutritional and healthy tea rice

The invention relates to a method of tea auxiliary material manufacture and tea rice preparation. The preparation method comprises following steps: preparing tea auxiliary materials: removing impurities in the fresh tea, washing and cleaning the tea, drying the tea by putting the tea in a cool and dry place until the content of water is less than 5%; then putting the tea in a grinder, grinding the tea until the sizes of the tea powder are in the range of 30 meshes to 40 meshes, then putting the tea powder into a planetary ball mill, and controlling the ball material ratio (mass ratio) in the range of 6 to 8 :1, the rotary speed of rotation plate in the range of 250 to 350 r / min, and the grinding time in the range of 8 to 10 hours to obtain the tea auxiliary materials; preparing the tea rice: mixing the tea auxiliary materials, rice and water together according to the mass ratio of tea auxiliary materials to rice to water of 10 to 15 : 100 : 150 to 170, evenly mixing and then permitting the solution to stand still for 2 to 4 minutes, putting the mixed tea rice into an automatic electric cooker to boil, maintaining the temperature for 15 to 20 minutes after the tea rice is boiled thoroughly, evenly mixing the rice in the cooker, and eating the rice when the temperature of the rice cools to 45 to 50 DEG C. The tea rice is added with the flavor of rice, overcomes the shortage of single nutrition of the rice by adding functional components in the tea auxiliary materials, and has a healthy function on human bodies.

Owner:长沙医食健康科技有限公司

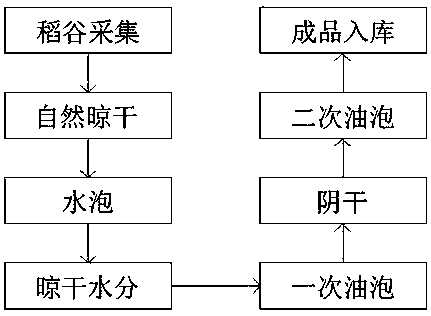

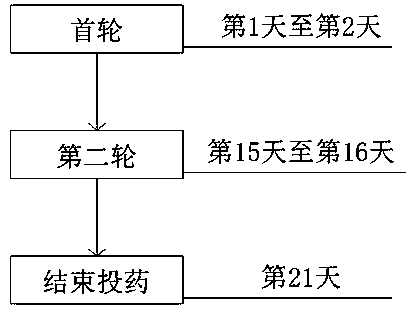

Vitamin D3 rice product for deratization and preparation process and use method thereof

InactiveCN111066786AEffective food attractorEffective controlBiocideAnimal repellantsBiotechnologySurface moisture

The invention discloses a vitamin D3 mouse rice preparation process and a use method thereof. The process comprises the following steps: collecting enough fresh rice by a purchaser; naturally airing the purchased fresh rice until the moisture in the rice does not exceed 11%; putting the rice into a soaking pool to be soaked for five hours; fishing out the soaked unhulled rice in sequence, and placing and airing the unhulled rice; slowly pouring the rice of which the surface moisture is air-dried into 500,000 units of VD3 oil, and soaking for 10 hours; taking out the rice soaked for ten hours through fishing equipment and placing in a shade drying field to be dried in the shade; putting the unhulled rice dried in the shade into 500,000 units of VD3 oil again, and soaking for 5 hours; and fishing the rice subjected to secondary soaking through fishing equipment, and putting the fished rice into a shade-drying field for shade-drying to obtain the finished product mouse rice. Compared withthe traditional raticide, the rice has enough safety performance and can prevent and treat rats with drug resistance and effectively shortens the death time of rats, and the rice has enough phagostimulant to rats due to the adoption of rice as a raw material.

Owner:广州市益高有害生物防治有限公司

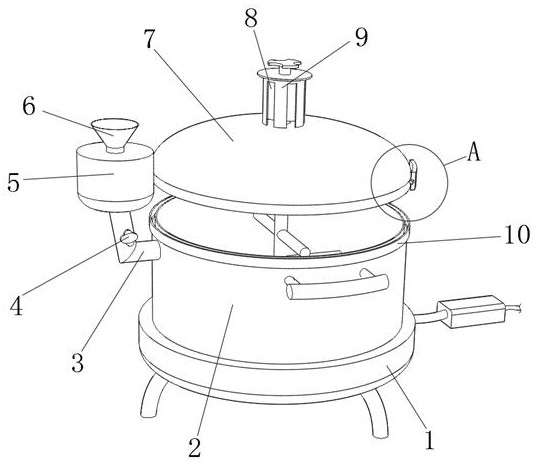

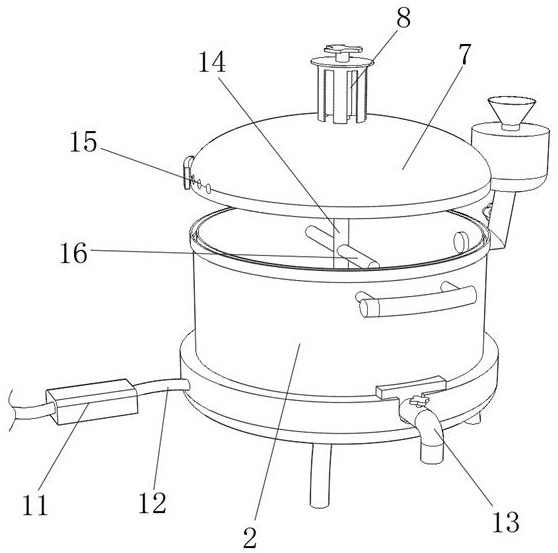

Making method of abalone juice rice

PendingCN114504090AReduce odorGreat tasteClimate change adaptationFood scienceRice dishesRice Preparation

The invention relates to the technical field of abalone juice rice, and discloses an abalone juice rice making method, which comprises: S1, raw material preparation: completely preparing 80-100 parts of soup-stock, 5-12 parts of sea cucumber, 1-3 parts of oyster sauce, 2-5 parts of chicken juice, 0-3 parts of edible salt, 1-5 parts of rock candy, 10-18 parts of braising juice, 4-10 parts of starch and other raw materials, and placing aside for spare; the invention further provides an abalone juice rice preparation device which comprises a heating base, a heating pot is arranged in the heating base, a feeding port is formed in one side of the heating pot, and a feeding pipe is fixedly connected to one side of the feeding port, the abalone juice rice preparation device not only can reduce peculiar smell of sea cucumbers and improve the taste of the sea cucumbers, but also can enable abalone juice to be more ornamental after being prepared, and the abalone juice rice preparation device is worthy of popularization and application. Meanwhile, the phenomenon that the taste of the abalone juice is disordered due to uneven stirring can be prevented, the eating state of the abalone juice is increased, the original taste of the abalone juice can be greatly reserved, evaporation of water is reduced, and the taste of the abalone juice is prevented from becoming heavy.

Owner:福建省渔家翁食品有限公司

Glutinous rice flavored bean paste manufacturing method

InactiveCN107373620ADelicate tasteRich in nutritional valueAlcoholic beverage preparationFood ingredient as flavour affecting agentBiotechnologyFlavor

The invention belongs to the technical field of food processing, discloses a glutinous rice flavored bean paste manufacturing method and aims to solve the problem of poor taste of existing bean paste. The method includes steps of chili paste preparation, fermented glutinous rice preparation, bean fermentation and bean paste preparation and particularly includes: removing stems of peppers, cleaning, mixing with salt, fermenting for 3 months, and adopting an automatic mixer to process into small pieces; subjecting glutinous rice to cooking, steaming, swelling, re-cooking and fermenting; subjecting broad beans to screening, stone removing, shelling, soaking in water, fermenting with yeast, and adding fermented glutinous rice water to ferment; proportionally mixing the chili paste and beans to obtain the bean paste. The glutinous rice flavored bean paste is unique in mellow flavor, delicate in taste and rich in contents of vitamins, trace elements, amino acids and the like, and the paste is reddish brown, bright, glossy, moderate in viscosity and freeness of mildew and impurities.

Owner:泸县海潮中心供销合作社酱园酿造厂

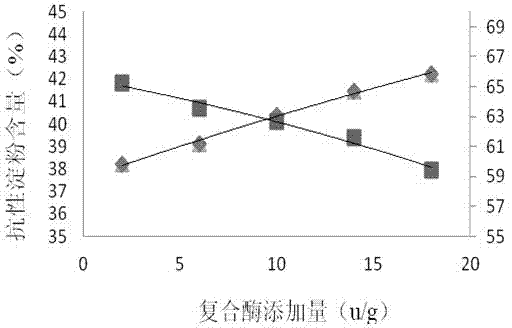

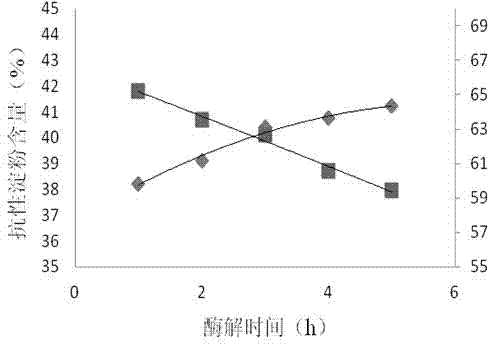

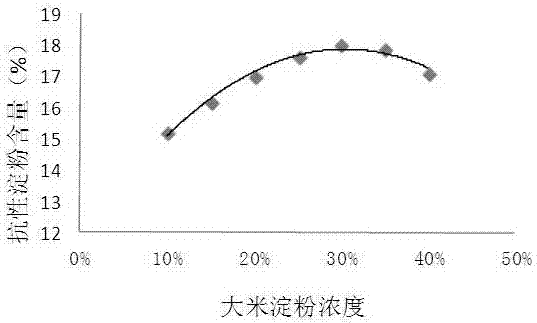

Preparation and Production Method of Rice Resistant Starch

ActiveCN103918872BImprove the utilization level of deep processingIncrease incomeProtein foodstuffs working-upAmylaseResistant starch

The invention relates to a production technology of resistant rice starch. A production method for preparing resistant rice starch comprises the following steps: firstly, gelatinizing, debranching and crystallizing the rice starch, and then drying the extracted resistant rice starch to obtain the resistant rice starch; improving the content of amylase in the rice starch by debranching treatment; controlling the concentration of the gelatinized rice starch at 20-50%, the debranching enzyme content at 12-25U / g, the debranching temperature at 45-55 DEG C and the debranching time at 12-20 hours; crystallizing under the condition of 2-12 DEG C after debranching is ended, and then extracting the resistant rice starch, and drying under the condition of 50-70 DEG C. The excessive rice resources such as broken rice and early indica rice can be reasonably utilized, the economic value of the potential resources is increased, and the produced resistant rice starch can overcome the defects of the traditional dietary fibers. By adopting the production method disclosed by the invention, the deep processing utilization level of the rice starch in China can be improved, and the method has important significance on development of grain storage enterprises and rural economy.

Owner:HENAN MINGYE BIOTECH

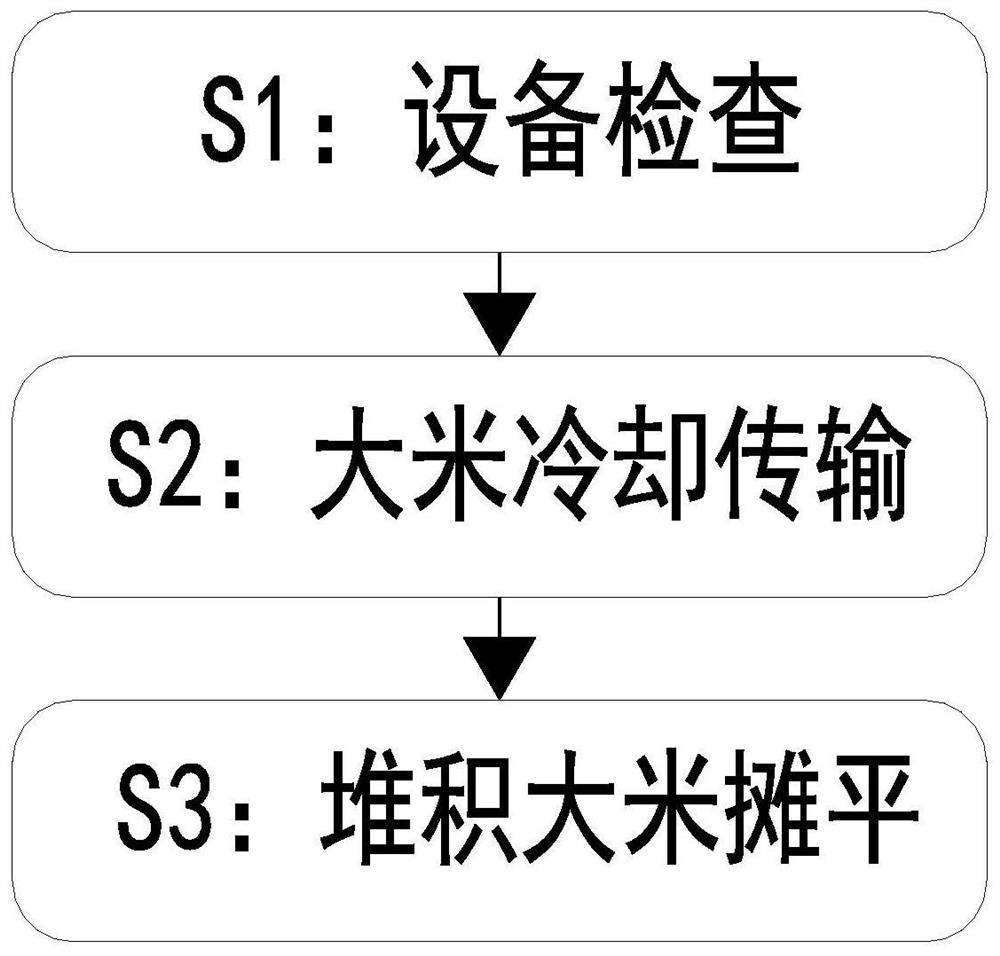

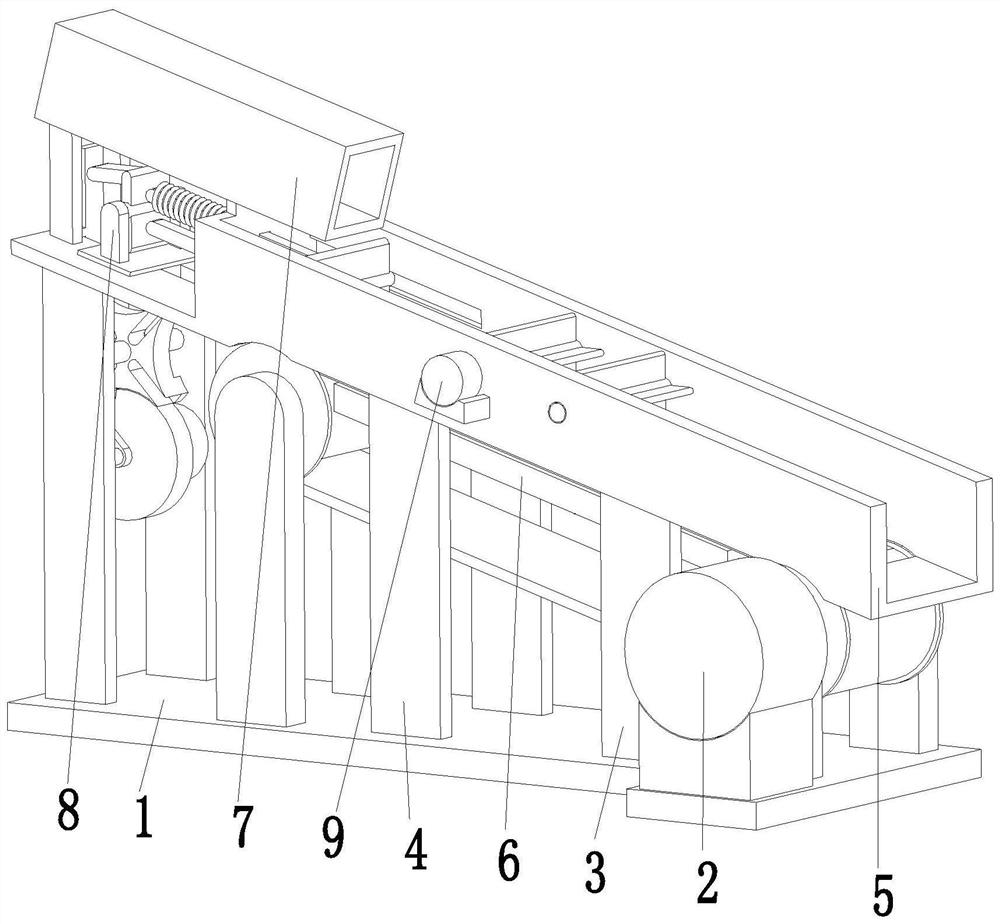

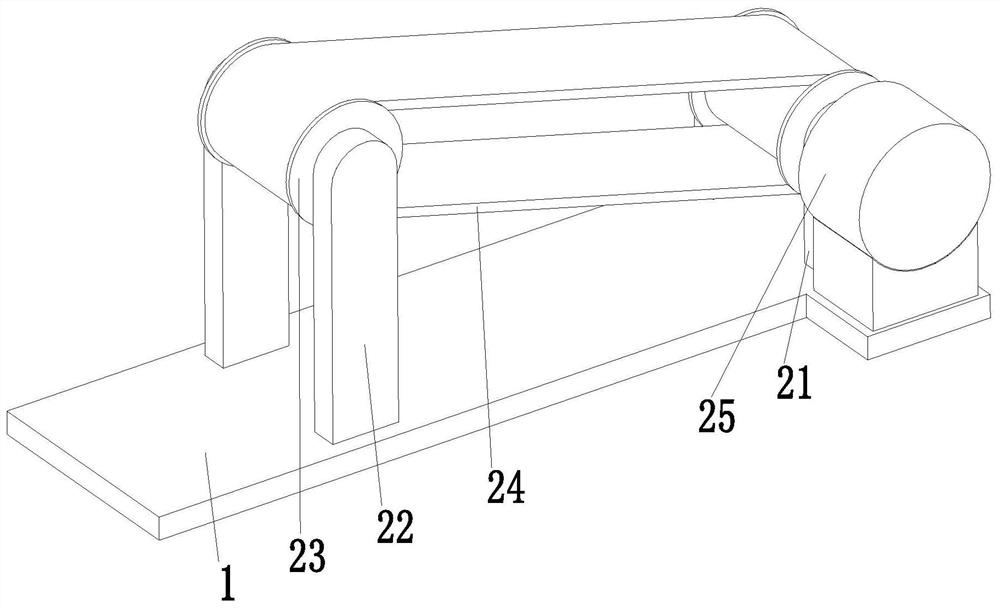

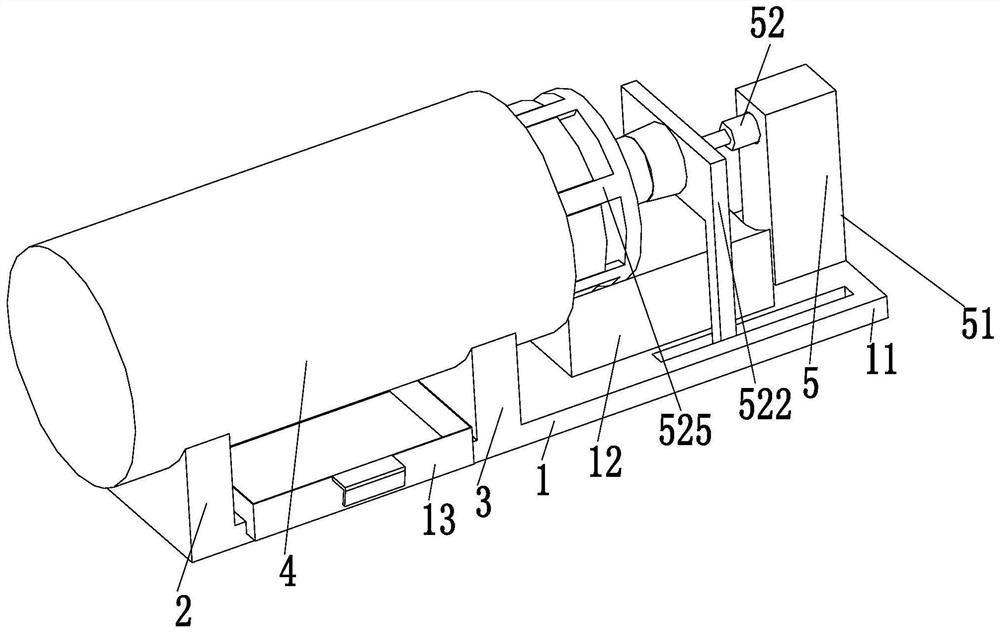

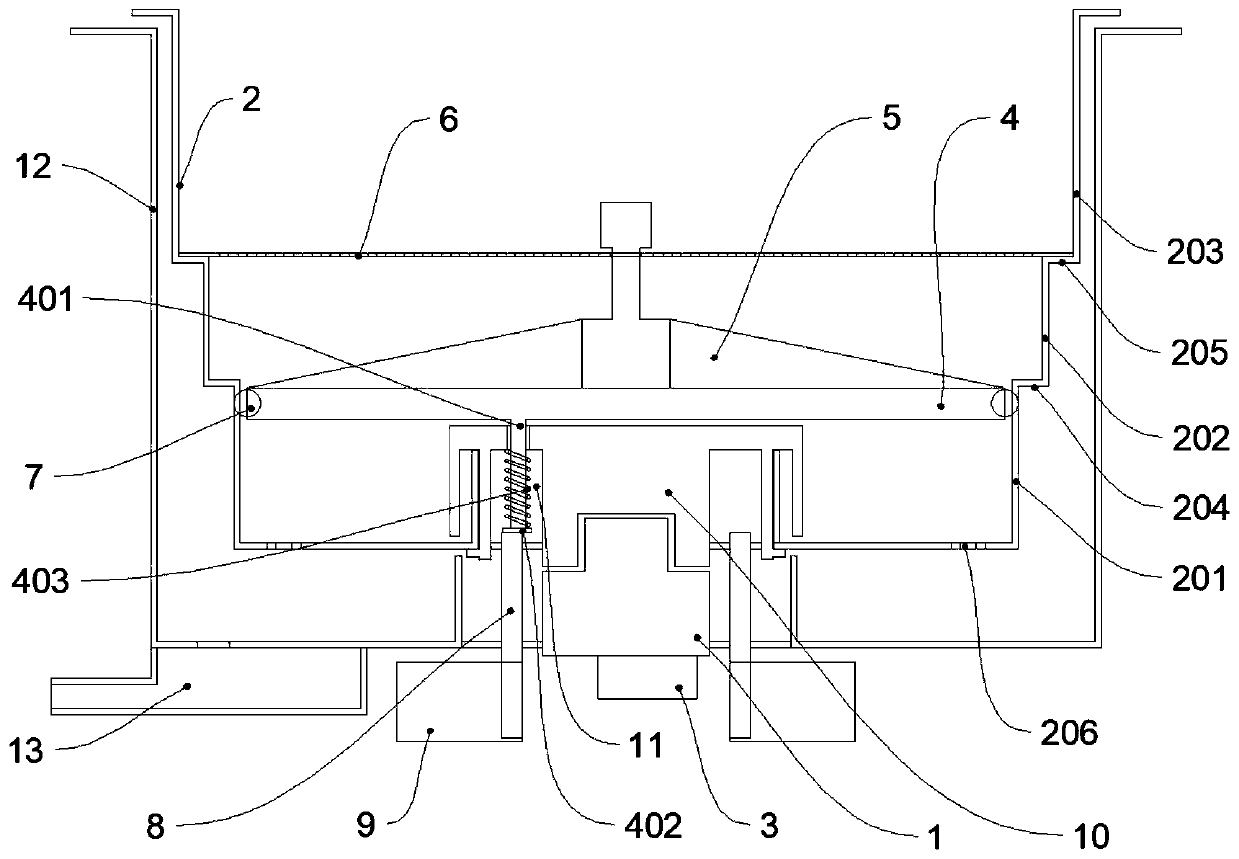

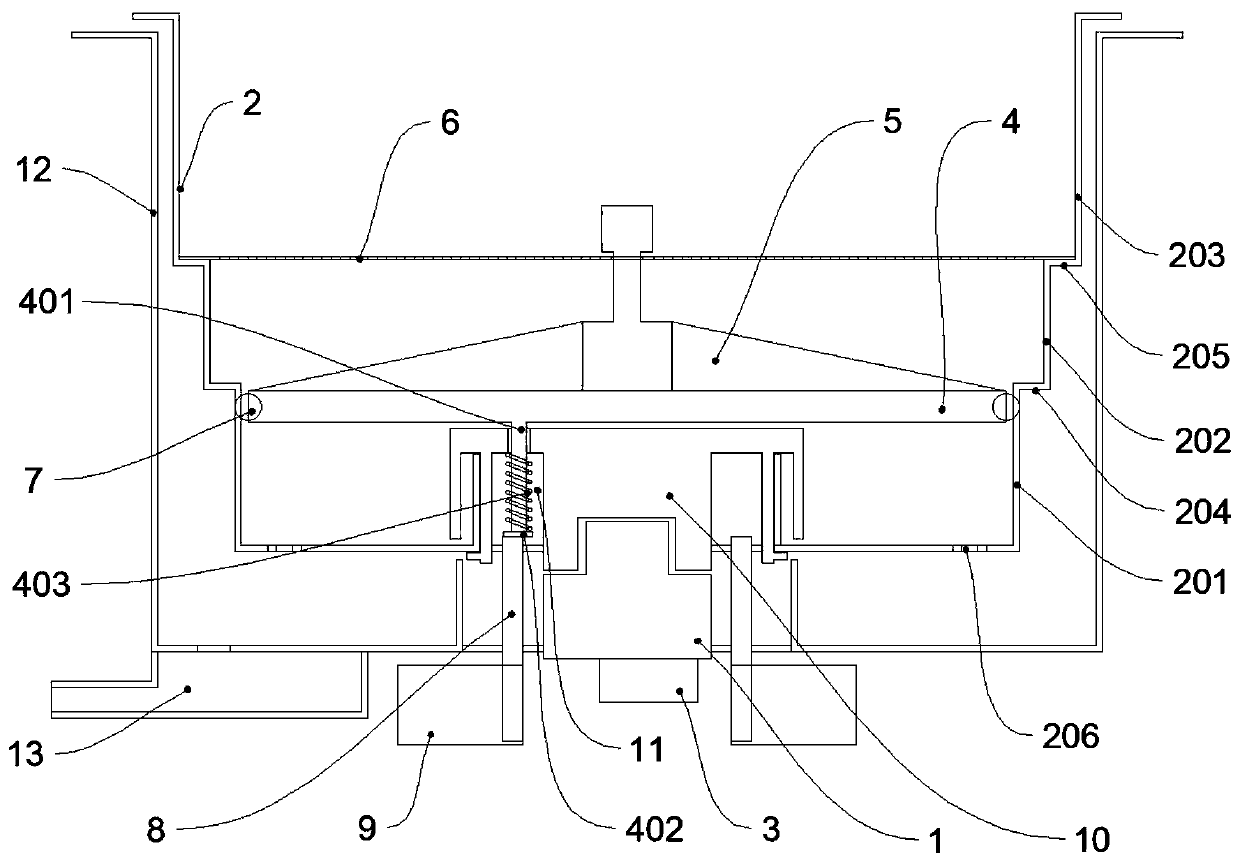

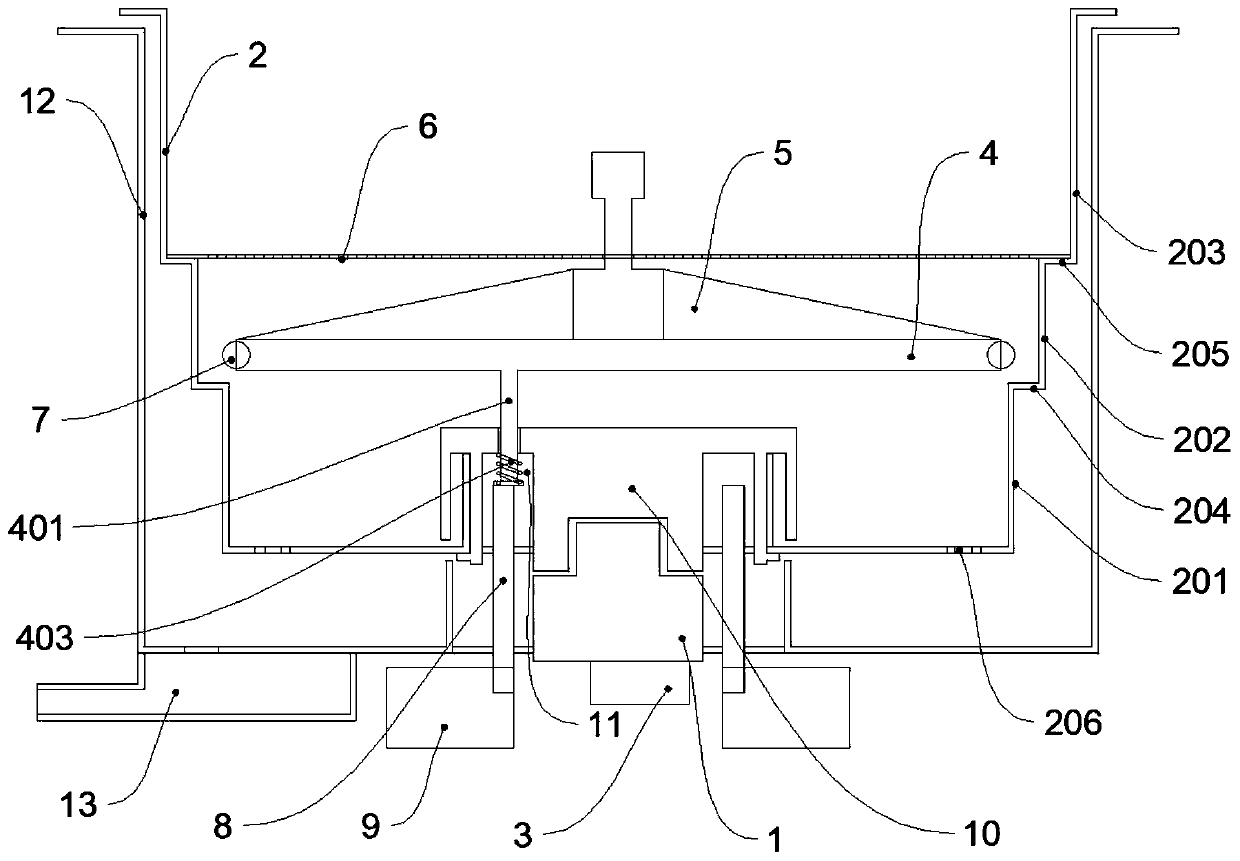

Dispersion and cooling process for rice preparation and rice milling

ActiveCN111790487BReduce cooling efficiencyEffective coolingGrain treatmentsAgricultural engineeringMechanical engineering

The invention relates to a dispersive cooling process for rice preparation and milling. The dispersive cooling process for rice preparation and milling adopts the following dispersive cooling device for rice preparation and milling. A transmission mechanism is installed on the upper end surface of the base, and the upper end surface of the base A transmission trough is installed through the first support plate and the second support plate, a cooling block is installed between the first support plate and the second support plate, a guide tube is installed on the upper left side of the transmission trough, and a pushing mechanism is installed on the left side of the transmission trough , the transmission tank is provided with a toggle mechanism; the present invention can solve the problem existing in the process of using fans to cool down the rice that has just passed through the rice milling process: the fan can only blow to the rice on the upper layer of the conveyor belt, and the rice on the lower layer of the conveyor belt Rice cannot be effectively cooled; due to the unstable output of the rice milling machine, it is easy to cause small-scale accumulation of rice when it falls on the conveyor belt, and it is easy to cause problems such as heating of rice due to the ineffective cooling of the accumulation.

Owner:江苏聚仁农业科技有限公司

Processing method of carefully selected red beans

The invention provides a processing method of carefully selected red beans. The processing method comprises the steps as follows: (1) removal of impurities from rice; (2) magnetic screening processing; (3) rice bran separation; (4) graded polishing of brown rice; (5) rice cooling and sterilization; (6) whitening, polishing and red bean color selection for fine processing; (7) rice preparation; (8)secondary sterilization treatment; and (9) packaging. The processing method comprises clear and reasonable steps, the selection process is simple, selected red beans have good taste and high quality,and the selection efficiency of raw red beans can be substantially improved with the processing method.

Owner:程诚

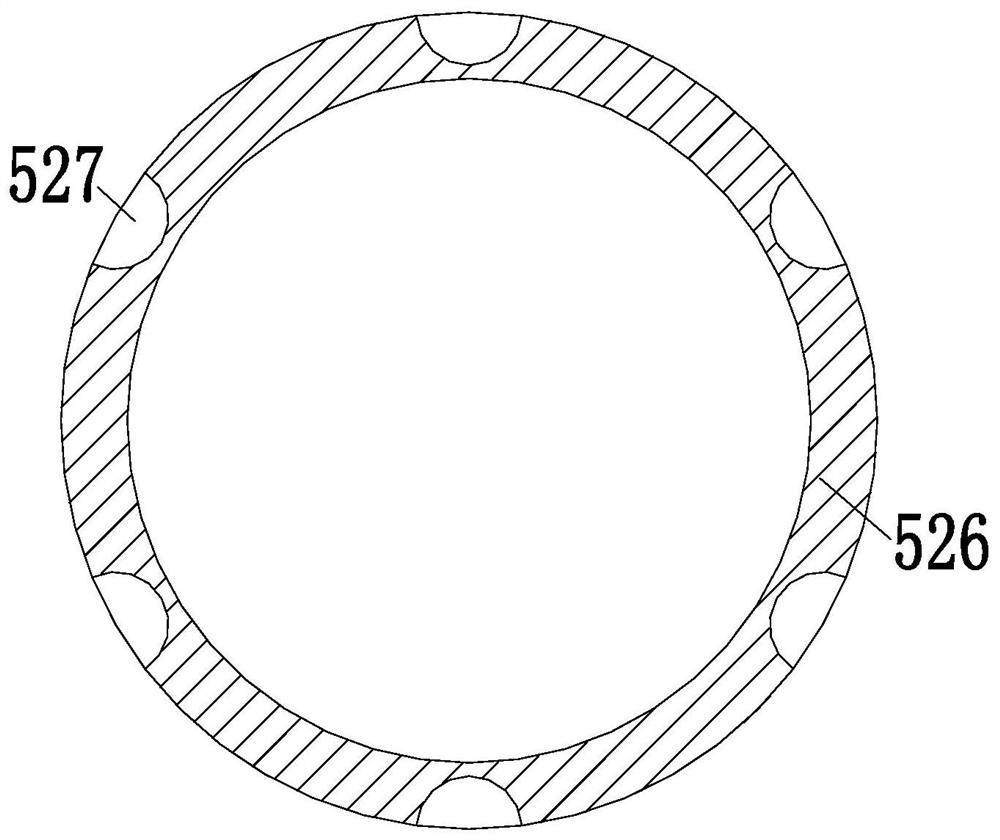

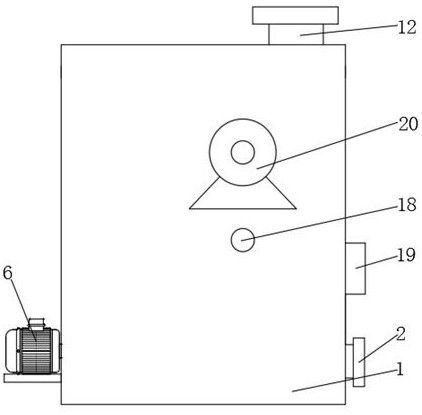

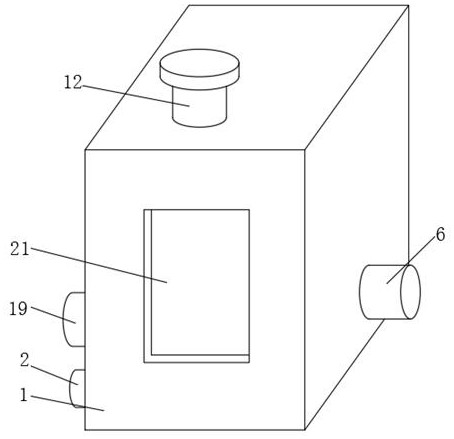

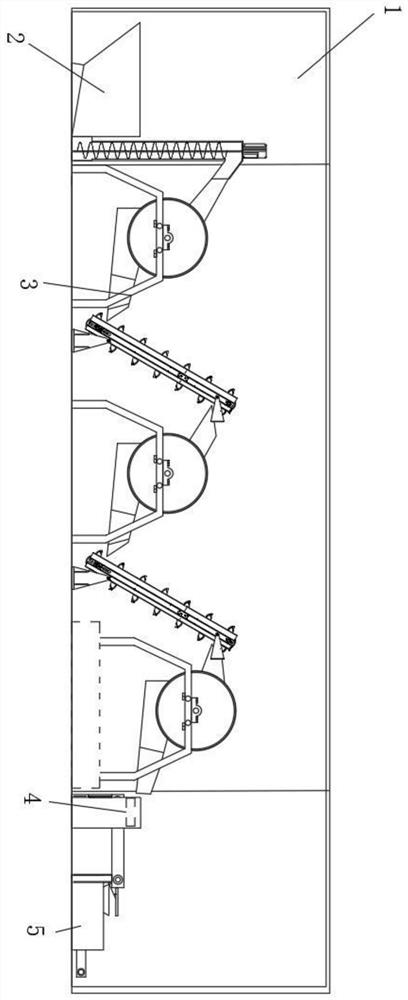

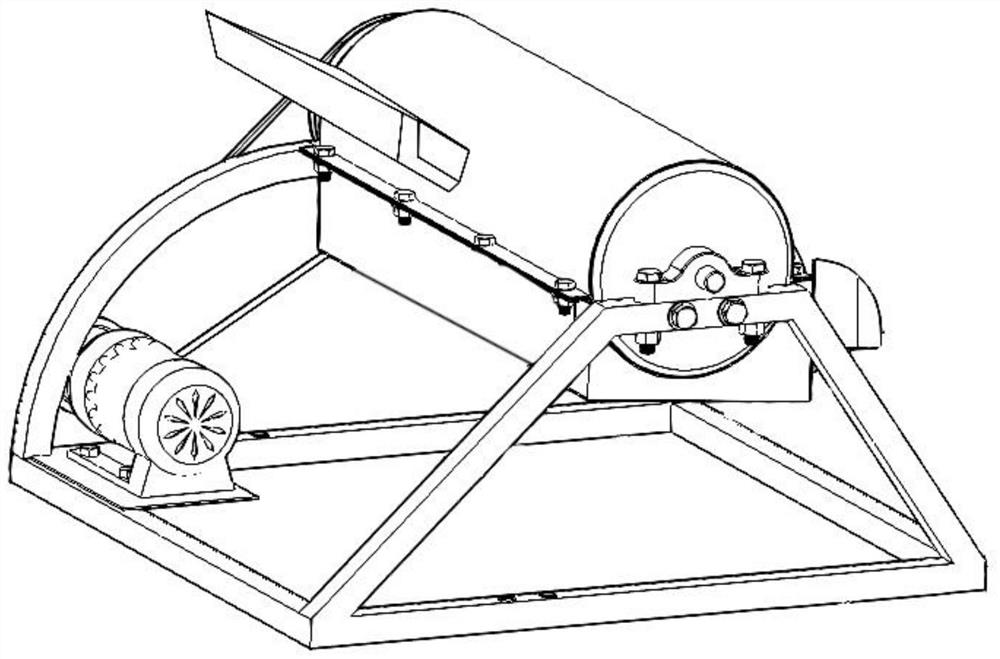

Rice preparation and processing precision standard grading classificator and grading selection process

The invention relates to a rice preparation and processing precision standard grading classificator and grading selection process. The rice preparation and processing precision standard grading classificator comprises a fixed base, a first mounting table, a second mounting table, a mounting cylinder and a centrifugal screening device, the first mounting table is fixed to the left side of the upperend of the fixed base, and the second mounting table is mounted in the middle of the upper end of the fixed base; the upper ends of the first mounting table and the second mounting table are connected through the mounting cylinder, and the centrifugal screening device is arranged at the right side of the upper end of the fixed base; and a rotating motor drives a rotating roller to rotate, then small broken rice and impurities are separated from whole rice through centrifugal force, and the grading efficiency is improved.

Owner:张纪彬

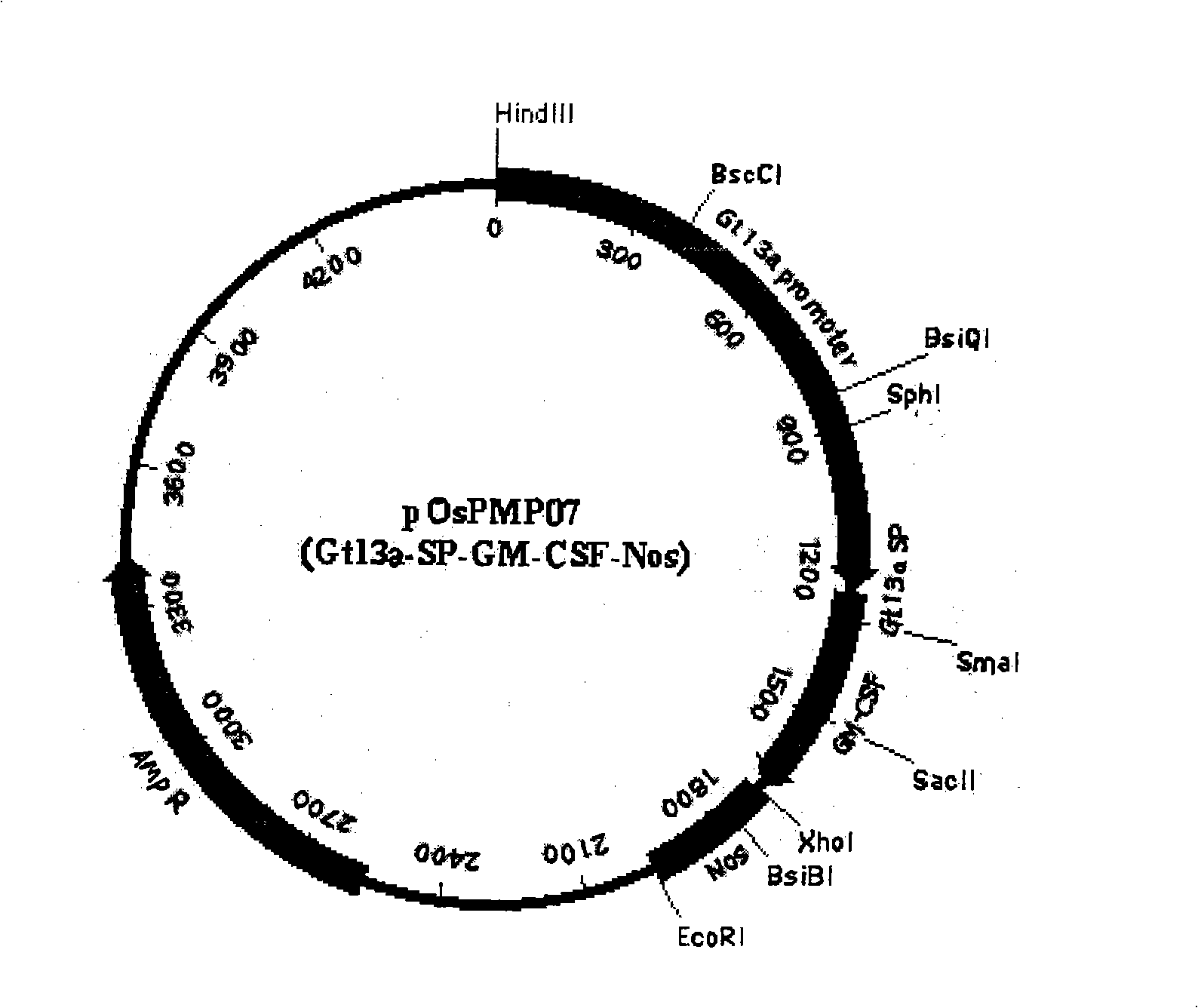

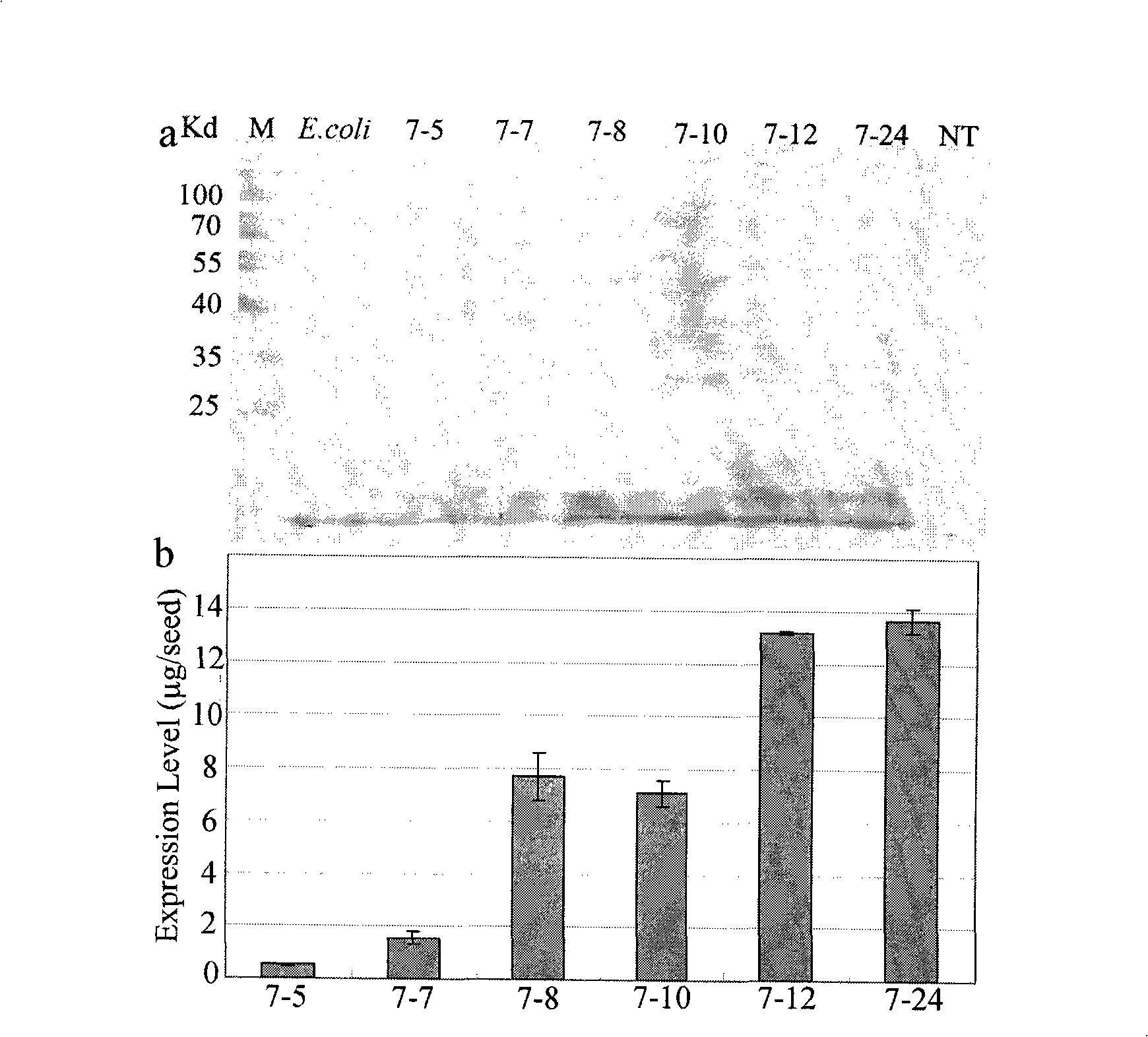

Method for preparation of transgenic rice preparation and use thereof

InactiveCN101255421ASimple purification processNo pollution in the processPowder deliveryPill deliveryGenetically modified riceSide effect

The invention discloses preparation for a genetic modified rice formulation and usage thereof. The preparation includes steps of: A. acquiring specific promoter for rice and semaphore peptides thereof; B. obtaining human GM-CSF gene of rice's genetic codon; C. genetically transforming rice gene and highly expressing selection of genetic modified plant; D. processing seeds of genetic modified rice. An application of genetic modified rice seed as medicament for treating or preventing leucocytopenia is also disclosed. The invention is simple in process, low in cost, good in safety property and curative effect, and has no side effect. Because recombinant rhGM-CSF is stored in rice flour, and rice is main food of human, any purification steps are not needed in tablet preparation, and the tablet contains no pathogenic bacteria and virus of human, the invention is safe and reliable. The tablet has functions to stimulate proliferation of leukocyte, improve immunologic competence in vivo, recover lowered immunologic competence resulted by reduction of leucopenia induced by chemotherapy and radiotherapy of cancer.

Owner:WUHAN HEALTHGEN BIOTECHNOLOGY CORP

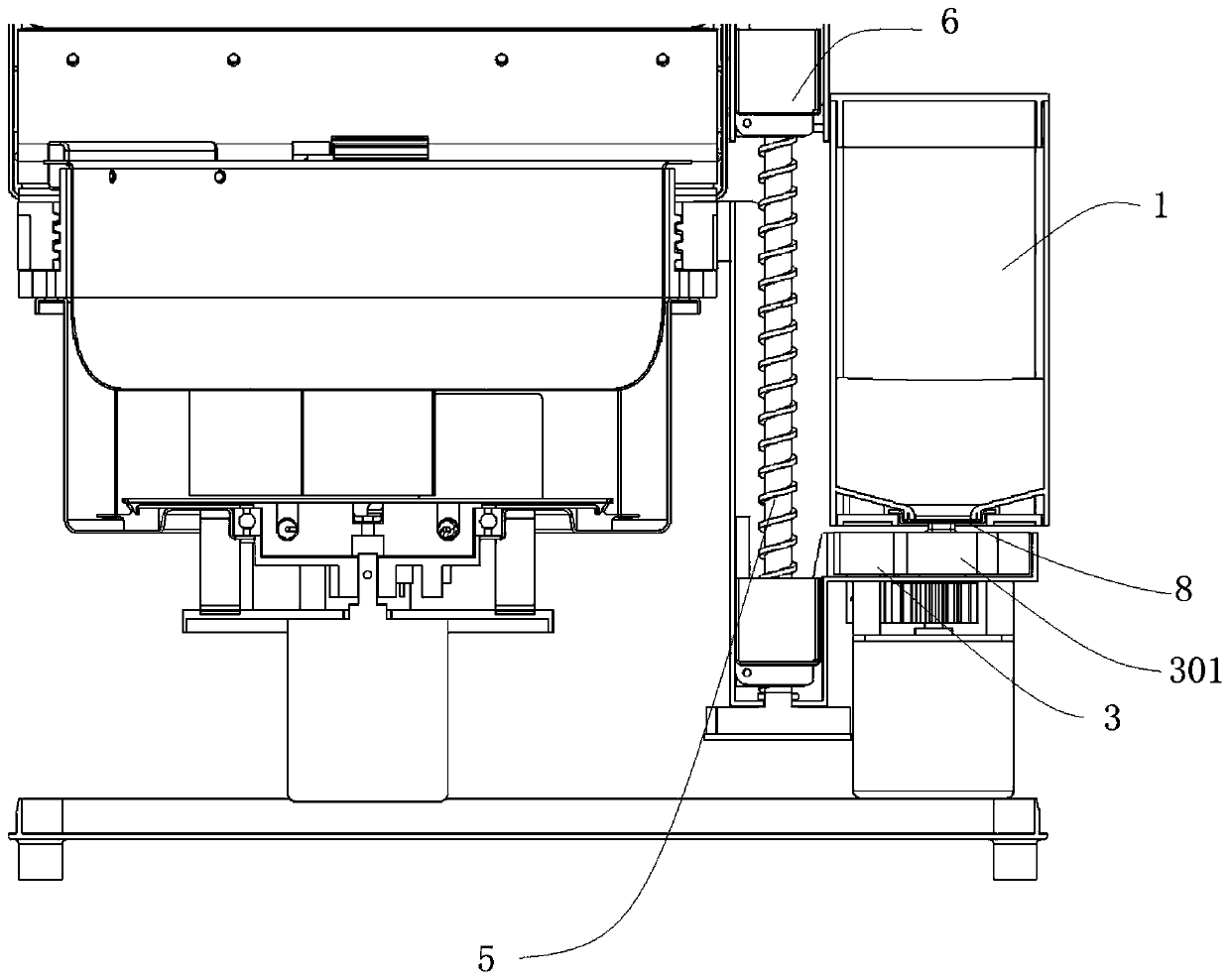

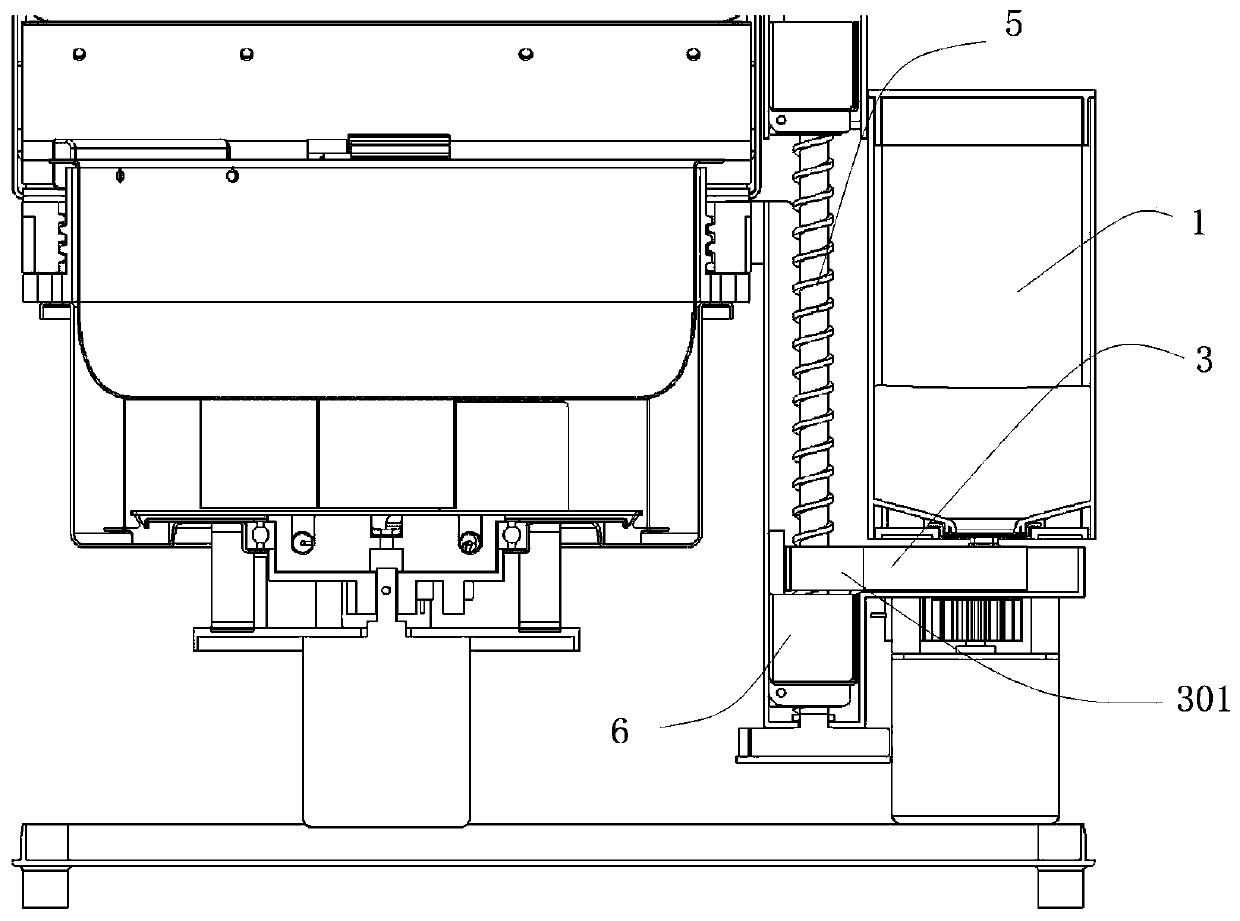

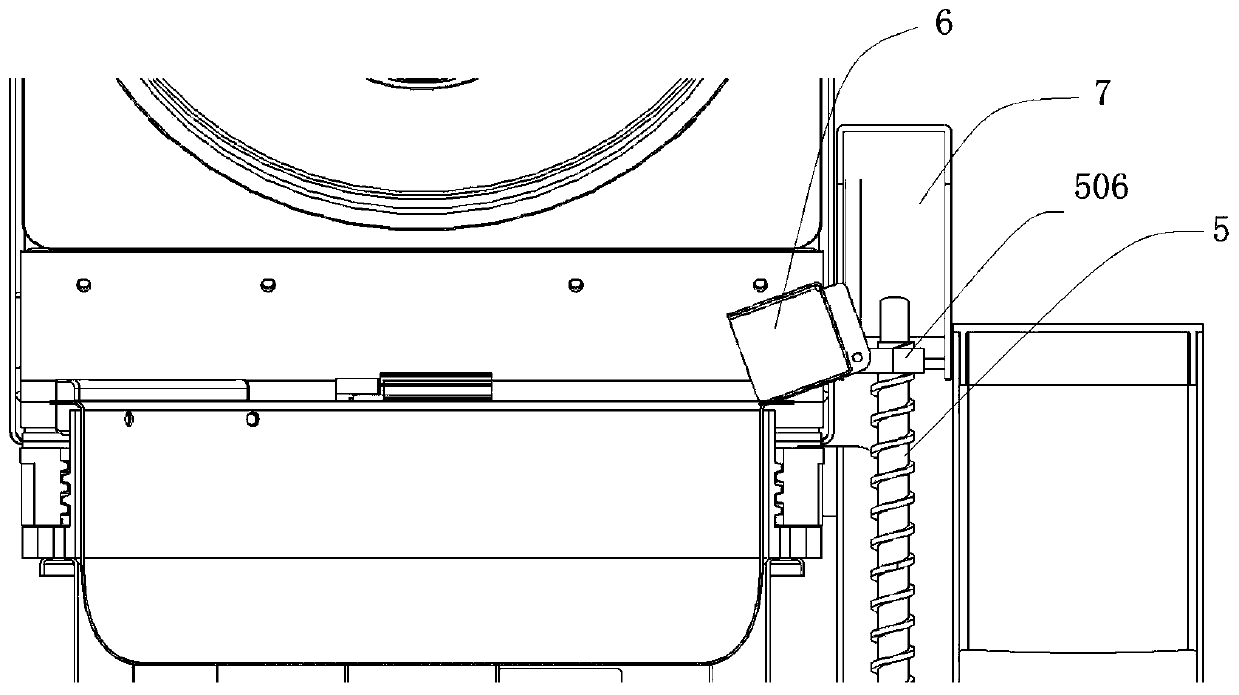

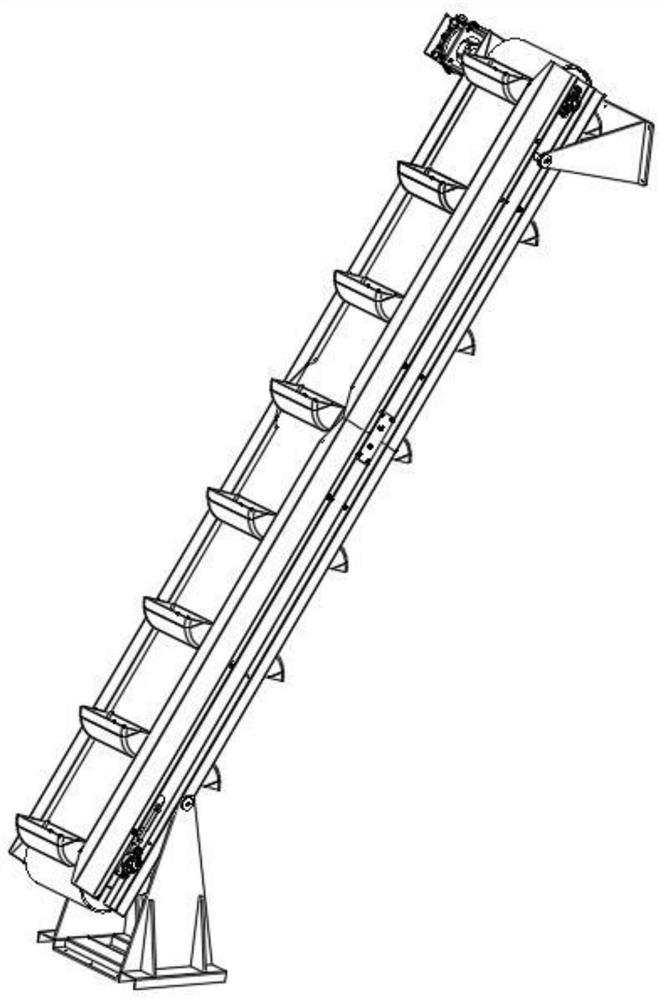

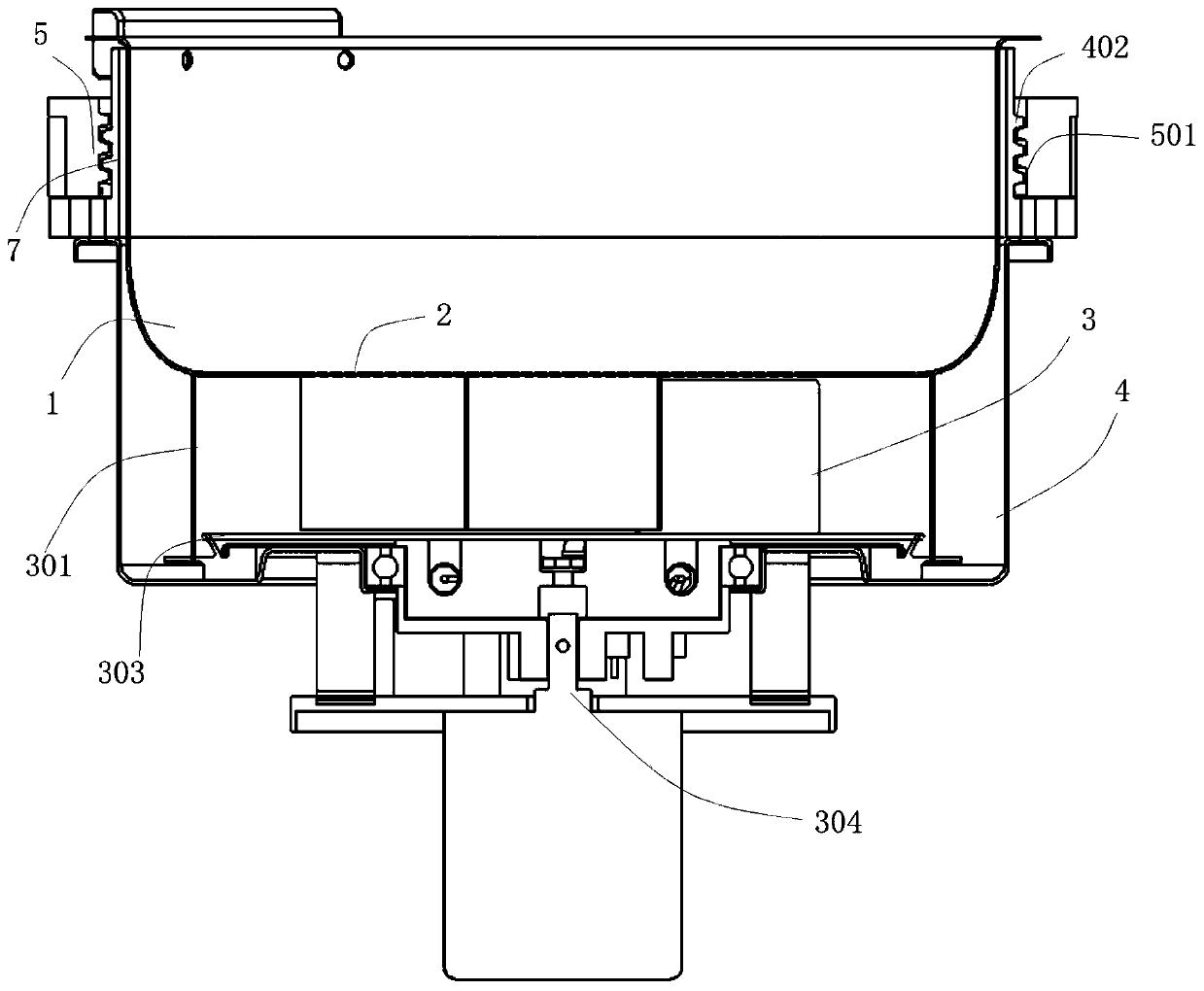

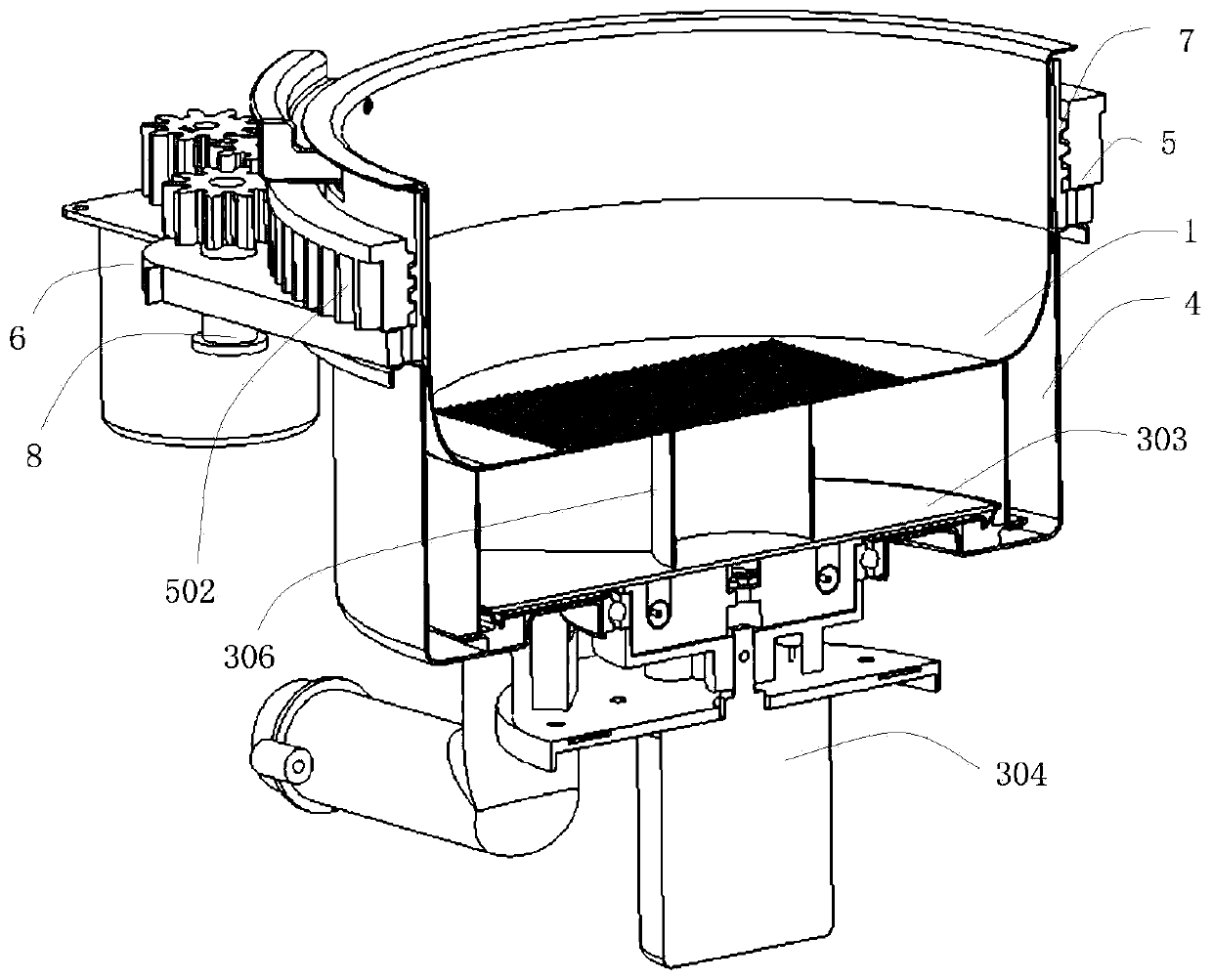

Rice adding, measuring and conveying mechanism for rice preparation device

PendingCN111166187AHigh degree of automationAutomated quantificationCooking vesselsRice dishesAgricultural engineering

The invention discloses a rice adding, measuring and conveying mechanism for a rice preparation device. Compared with the prior art, the rice adding, measuring and conveying mechanism for the rice preparation device comprises a rice moving rotating shaft located below a rice bin; a rice measuring block structure arranged on the rice moving rotating shaft; a rice supporting plate structure positioned below the rice measuring block structure; a rice measuring through hole formed in the rice measuring block structure; a rice measuring driving mechanism connected with the rice moving rotating shaft and used for driving the rice measuring block structure to rotate; a rice conveying transmission mechanism located on the side, close to an inner container of a cooker body, of the rice bin; a riceconveying hopper mounted on the rice conveying transmission mechanism; a rice conveying driving mechanism used for driving the rice conveying hopper to move up and down along the rice conveying transmission mechanism; and a rice pouring driving mechanism used for driving the rice conveying hopper to tilt towards the inner container of the cooker body to pour rice; the rice measuring through hole has a first state of receiving rice below the rice bin and above the rice supporting plate structure and a second state of dropping the rice by rotating to be above the rice conveying hopper and separated from the rice supporting plate structure; compared with the prior art, the rice adding, measuring and conveying mechanism for the rice preparation device has the advantages that automatic quantitative rice adding and conveying can be achieved, and the automation degree of the rice preparation device is increased.

Owner:株洲田螺姑娘智能科技有限公司

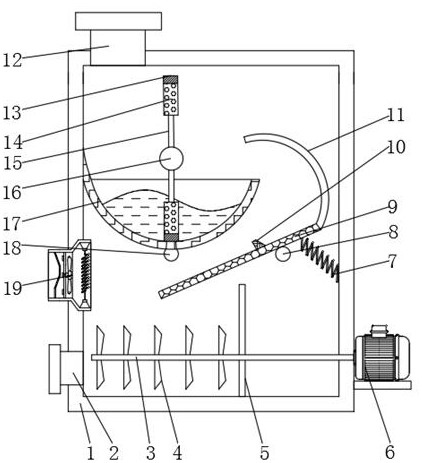

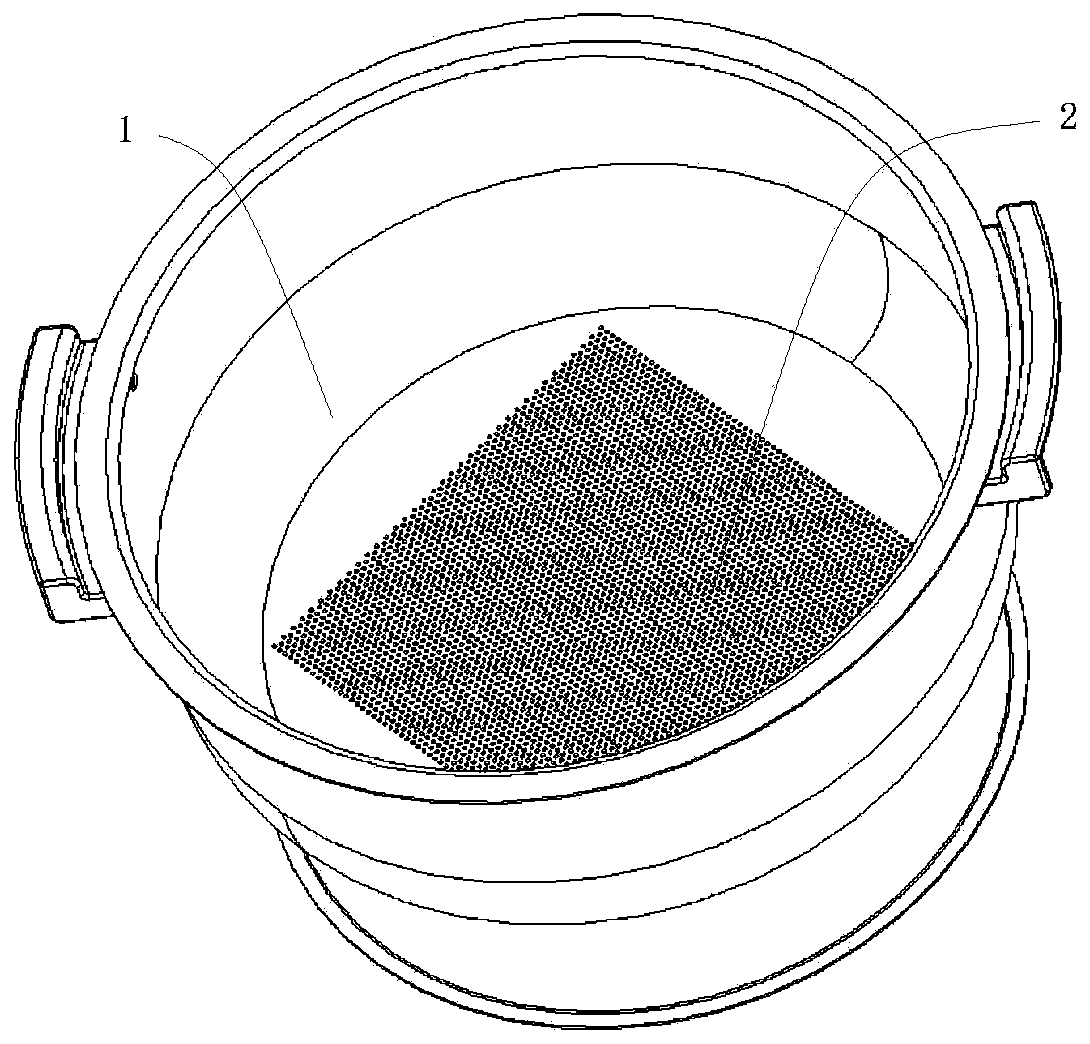

Integrated rice washing heating and draining device and rice draining preparation system

PendingCN110150963AImprove production efficiencyShorten the timeWarming devicesCooking vessel constructionsProcess engineeringRice Preparation

The invention discloses an integrated rice washing heating and draining device. Compared with the prior art, the integrated rice washing heating and draining device includes a pot body liner, a heating body, a cleaning structure , and a filtering mechanism, wherein a draining hole is formed in the bottom of the pot body liner, and the heating body is mounted in the pot body liner; the cleaning structure is arranged on the upper part of the heating body, and the filtering mechanism is arranged above the heating body; and a sealing structure is arranged between the side walls of the heating bodyand the pot body liner. Compared with the prior art, the integrated rice washing heating and draining device can realize rice washing, heating, cooking and draining in the same device in the processof rice preparation, time of a user is saved, and the rice preparation efficiency is improved. The invention further relates to a rice draining preparation system. The same beneficial effects are achieved.

Owner:株洲田螺姑娘智能科技有限公司

Preparation device and preparation method for instant rice

PendingCN114557423ARich variety of flavorsAvoid affecting tasteDrying gas arrangementsLipidic food ingredientsAgricultural scienceAgricultural engineering

The invention relates to the technical field of instant rice preparation, and discloses an instant rice preparation device which comprises a box body, the top of the box body is fixedly connected with a feeding pipe, one side of the box body is fixedly connected with a discharging pipe, the outer wall of one side of the box body is fixedly connected with a first motor, and one end of an output shaft of the first motor is fixedly connected with a first transmission rod; the invention also provides a preparation method of the instant rice, which comprises the following steps: S1, preparing the following raw materials in parts by weight: 70-90 parts of rice, 2-5 parts of corn starch, 1-3 parts of soybean oil, 10-30 parts of millet and 0.1-1 part of sesame; and S2, crushing. The instant rice cleaning device can enrich the taste types of instant rice, provide people for selection, improve the diversity of the instant rice, improve the density of the instant rice, improve the taste of the instant rice, stir the rice in the cleaning cylinder during cleaning, improve the cleaning quality, stir the rice out of the cleaning cylinder, and improve the functional diversity of the instant rice cleaning device.

Owner:福建省渔家翁食品有限公司

Automatic rice preparation and processing system

InactiveCN112756035AEfficient handoverFull scraping and shellingGrain treatmentsAgricultural engineeringProcess engineering

The invention provides an automatic rice preparation and processing system applied to the field of rice preparation. The system comprises a rack, a feeding module, a shelling module, a filtering and impurity removing module and a packaging module, the rack is provided with three processing chambers, and each working room can perform relatively independent operation; meanwhile, separated glumes and impurities can be recycled in the second processing chamber and cannot fall into other processing chambers to pollute the environment; the shelling module is arranged, and scraping teeth with different widths and diameters can be arranged, so that the rice is fully scraped and shelled; a transmission mechanism of a conveying structure is arranged between shelling mechanisms, so that efficient connection between the shelling mechanisms is achieved, and waste caused by falling of a large number of materials in the machining process is avoided; by arranging the filtering and impurity removing module, the glumes and the other impurities can be fully recycled; and by arranging the packaging module, the processed rice can be packaged and delivered, so that a complete processing chain is formed.

Owner:常德振邦米业有限公司

Preparation method of nutritional and healthy tea rice

The invention relates to a method of tea auxiliary material manufacture and tea rice preparation. The preparation method comprises following steps: preparing tea auxiliary materials: removing impurities in the fresh tea, washing and cleaning the tea, drying the tea by putting the tea in a cool and dry place until the content of water is less than 5%; then putting the tea in a grinder, grinding the tea until the sizes of the tea powder are in the range of 30 meshes to 40 meshes, then putting the tea powder into a planetary ball mill, and controlling the ball material ratio (mass ratio) in the range of 6 to 8 :1, the rotary speed of rotation plate in the range of 250 to 350 r / min, and the grinding time in the range of 8 to 10 hours to obtain the tea auxiliary materials; preparing the tea rice: mixing the tea auxiliary materials, rice and water together according to the mass ratio of tea auxiliary materials to rice to water of 10 to 15 : 100 : 150 to 170, evenly mixing and then permitting the solution to stand still for 2 to 4 minutes, putting the mixed tea rice into an automatic electric cooker to boil, maintaining the temperature for 15 to 20 minutes after the tea rice is boiled thoroughly, evenly mixing the rice in the cooker, and eating the rice when the temperature of the rice cools to 45 to 50 DEG C. The tea rice is added with the flavor of rice, overcomes the shortage of single nutrition of the rice by adding functional components in the tea auxiliary materials, and has a healthy function on human bodies.

Owner:长沙医食健康科技有限公司

Production method of nutritional health-care rice

InactiveCN114158688AFull of nutritionHas health benefitsFood ingredient as taste affecting agentNatural extract food ingredientsAMERICAN GINSENG ROOTAngelica Sinensis Root

The invention discloses a production method of nutritional health-care rice, which comprises the following steps: 1) rice preparation: taking 350-400 parts by mass of rice; 2) preparation of a nutrient solution: taking 8-12 parts by mass of American ginseng, 2-5 parts by mass of angelica sinensis, 3-7 parts by mass of radix paeoniae alba, 3-5 parts by mass of red dates, 3-5 parts by mass of Chinese wolfberry fruits and 3-5 parts by mass of honeysuckle flowers, performing crushing, and then performing reflux filtration to obtain an extracting solution; (3) concentrating and filtering the extracting solution to obtain a nutrient solution; 4) mixing and soaking the nutrient solution, water and rice according to a ratio of (3-5): (3-5): 1; 5) performing moisture volatilization in a low-temperature drying manner; (6) carrying out polishing and color sorting on the dried rice; 7) sterilizing: sterilizing and disinfecting the polished and color-sorted rice by using an ultraviolet lamp; and 8) vacuum packaging.

Owner:靖州县振宏米业有限责任公司

Rotary rice washing mechanism and rice preparation device

PendingCN111110012AGood quality and effectRealize flush cleaningSteam cooking vesselsAgricultural scienceRice dishes

The invention discloses a rotary rice washing mechanism. Compared with the prior art, the rotary rice washing mechanism comprises a cooker body inner container, water passing sieve holes formed in thelower part of the cooker body inner container, and a negative-pressure water stirring mechanism arranged below the cooker body inner container and communicated with the cooker body inner container, wherein the negative-pressure water stirring mechanism is used for injecting water for washing rice grains into the cooker body inner container through the water passing sieve holes and absorbing waterflowing out of the cooker body inner container through the water passing sieve holes. Compared with the prior art, the rotary rice washing mechanism provided by the invention can realize continuous rice washing and cooking, improves the quality effect of rice washing, and improves the automation degree of the rice preparation device. The invention also relates to the rice preparation device whichalso has the above beneficial effects.

Owner:株洲田螺姑娘智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com