Automatic rice preparation and processing system

A processing system and automatic preparation technology, applied in applications, grain processing, agriculture, etc., can solve the problems of wasting manpower, single implementation, and endangering the life of manufacturing equipment, and achieve the effect of efficient handover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

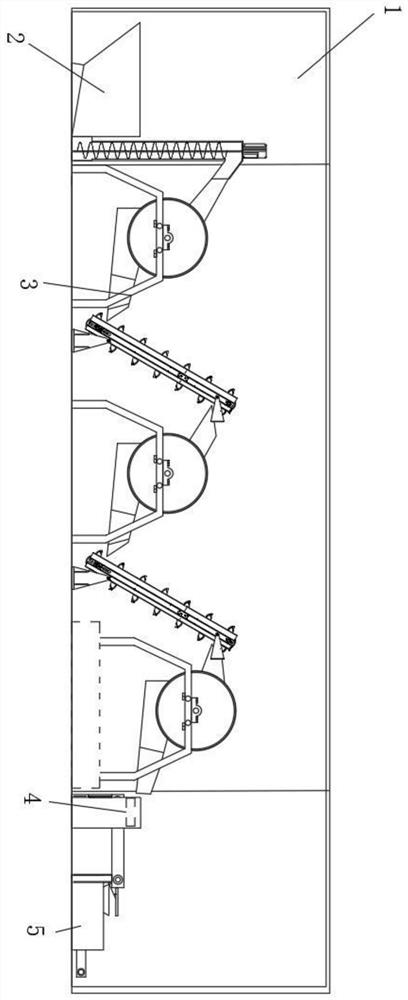

[0026] Such as figure 1 Shown, a kind of rice automatic preparation and processing system comprises:

[0027] The frame is provided with three closed and independent processing chambers inside, and the first processing chamber, the second processing chamber and the third processing chamber are sequentially along the path of the rice;

[0028] The feeding module is arranged in the first processing chamber, and is used to put in the processed rice;

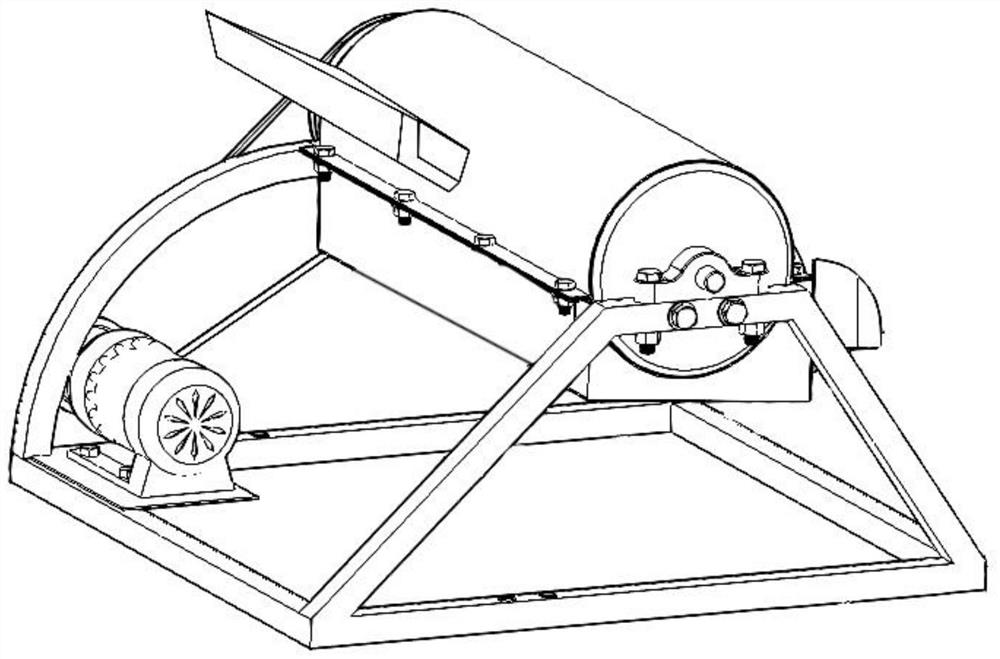

[0029] The hulling module is arranged in the second processing chamber, and is used to remove the chaff from the rice;

[0030] The filtering impurity removal module is arranged in the second processing chamber, and is used to recover and filter out the detached chaff and impurities;

[0031] The packaging module is arranged in the third processing room, and is used for bagging and packaging the post-filtered rice;

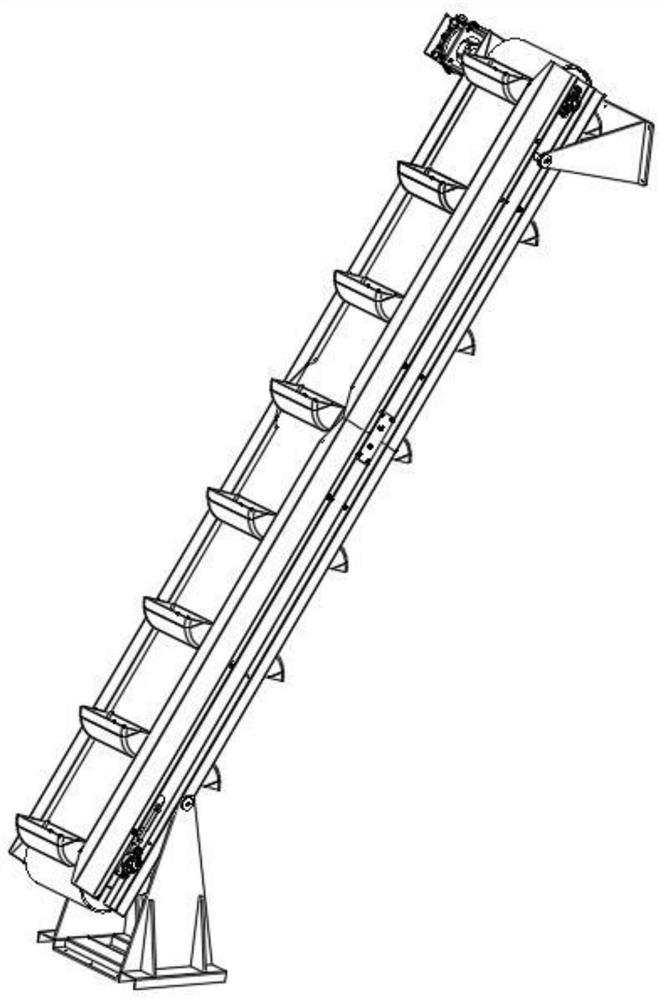

[0032] The feed module includes a feed hopper, a lifting mechanism and a storage bin, the feed hopper is arranged ...

Embodiment 2

[0036] Embodiment 2. This embodiment is a further description of the above-mentioned embodiment. It should be understood that this embodiment includes all the above-mentioned technical features and further detailed description:

[0037] With the gradual increase of my country's rice production and consumers' demand for refined rice, many rice processing enterprises have developed rapidly. Now people require higher and higher quality requirements for refined rice, so the requirements for the rice preparation process will gradually increase. The existing rice preparation process mainly includes processes such as cleaning, husking, and rice milling.

[0038] The existing processing system often performs a single function separately, and then transports the semi-finished product by manpower to complete the next process. This method undoubtedly wastes a lot of manpower. Benign recycling will have adverse effects on the production environment and equipment in the same production env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com