Bonding equipment and bonding method

A bonding and equipment technology, applied in semiconductor/solid-state device testing/measurement, semiconductor devices, electrical components, etc., can solve problems such as complex structure, low yield, and inconvenient electrical wiring of visual systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

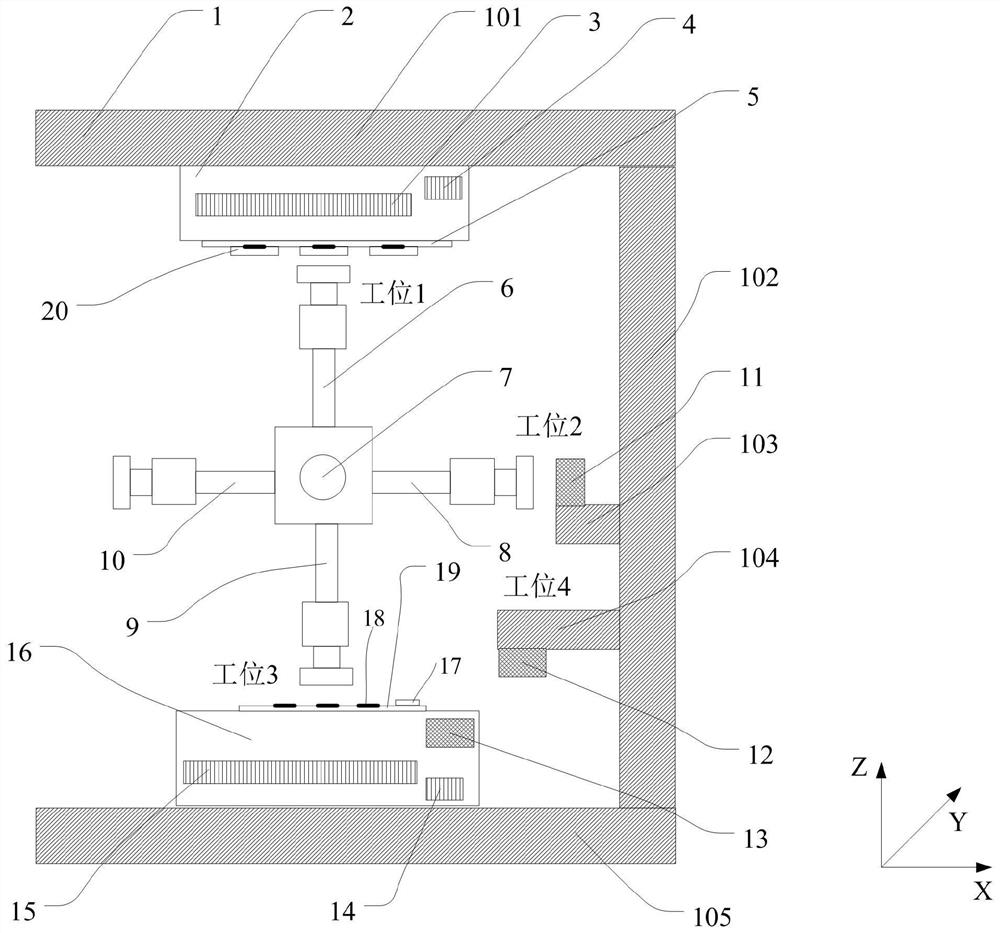

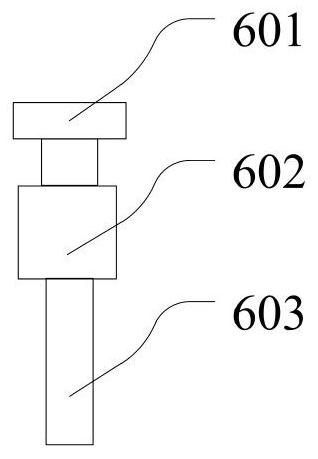

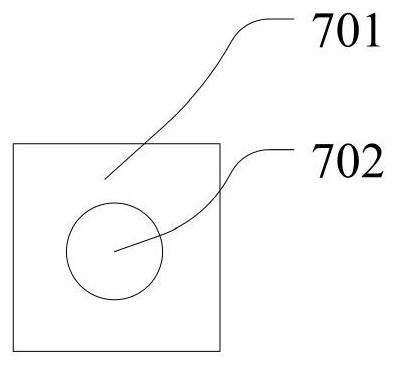

[0066] refer to figure 1 , which is a schematic structural diagram of the bonding equipment in Embodiment 1 of the present invention, the bonding equipment includes a supply motion table 2, a transmission system, a bonding motion table 16 and an alignment measurement system; the transmission system includes a rotation unit 7 and A plurality of chip bonding units uniformly arranged on the rotating unit 7, the rotating unit 7 drives the chip bonding unit to go back and forth between the chip picking station, the chip position measuring station and the chip bonding station in sequence The described supply motion table 2 carries some first chips, and the bonding motion table 16 carries some second chips; the chip bonding unit is used to pick up the first chip from the supply motion table 2, and The first chip is transferred and handed over to the corresponding second chip; and the alignment measurement system includes a first alignment measurement unit 11, a second alignment measu...

Embodiment 2

[0112] The chip alignment mark 18 is located on the side of the second chip facing away from the bonding motion table 16, and the chip identification mark can be located on the side of the first chip facing the supply motion table, or can also be located on the back side of the first chip. On the side facing the feeding motion table, when the chip identification mark is located on the side of the first chip facing away from the feeding motion table, the first alignment measurement unit 11 and the third alignment measurement unit 13 are the back side Align the measuring system. Specifically, see 14, Figure 14 It is a schematic structural diagram of the bonding equipment in Embodiment 2 of the present invention. Compared with Embodiment 1, the structural composition of the bonding equipment is different in that: the first alignment measurement unit 11 is a backside alignment measurement system, and its light source can be An infrared light source is used, which can penetrate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com