Reconstituted rice preparation plant

A preparation device and rice recovery technology, applied in the field of mechanical equipment, can solve the problems of reduced extrusion effect, affecting product output efficiency, product uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

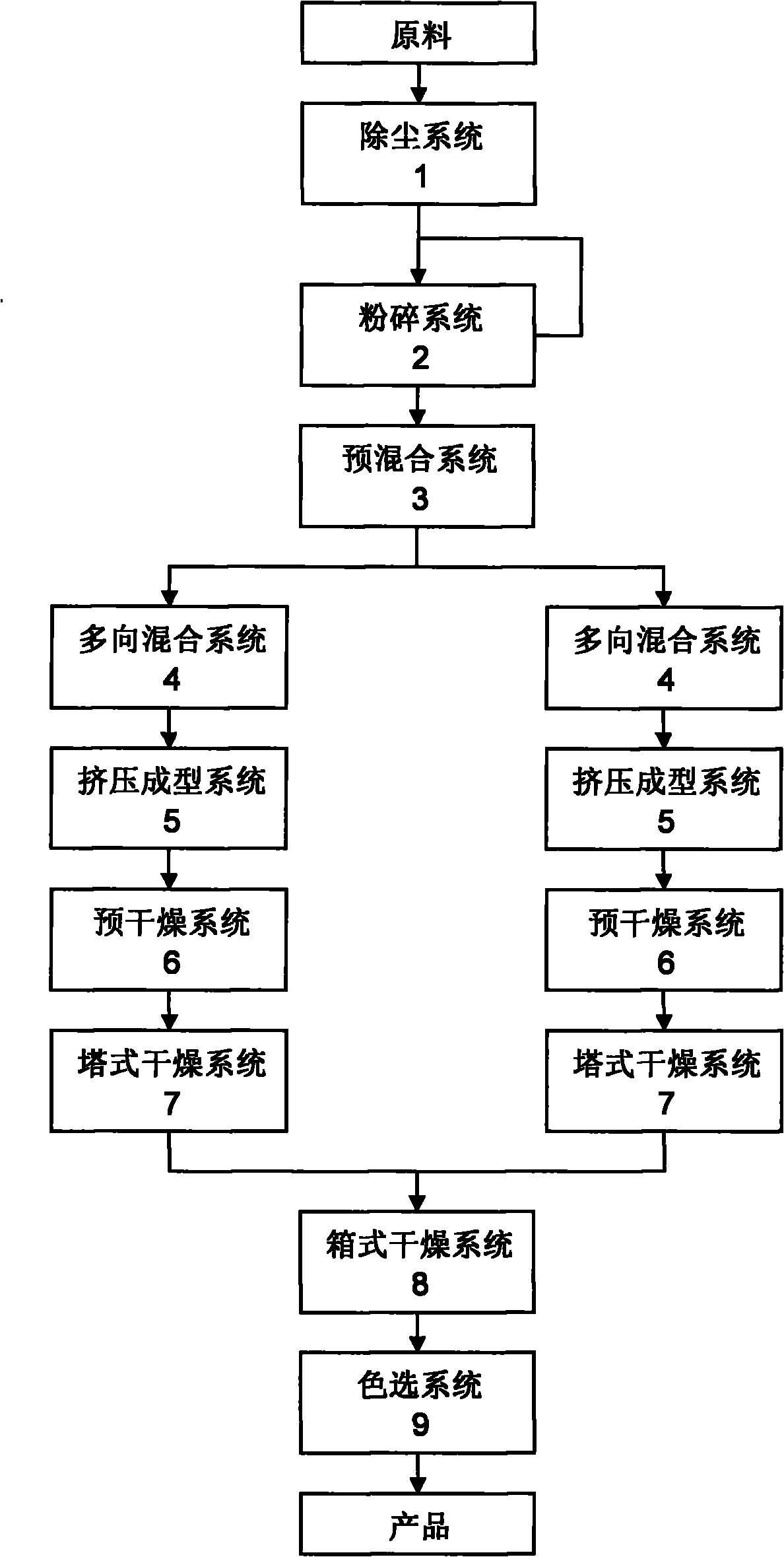

[0143] like Figure 1a As shown, the present invention discloses a reconstituted rice preparation device, which includes a dust removal system 1, a crushing system 2, a pre-mixing system 3, a multi-directional mixing system 4, an extrusion molding system 5, a pre-drying system 6, a tower along the material flow direction in sequence. Type drying system 7, box type drying system 8, color sorting system 9.

[0144] The premixing system 3 is correspondingly configured with at least two multidirectional mixing systems 4 . The at least one dust removal system and the at least one pulverization system are connected to the premixing system 3 . Each of the multidirectional mixing systems 4 is correspondingly configured with an extrusion molding system 5 , a pre-drying system 6 , and a tower drying system 7 . Each tower drying system 7 of each multidirectional mixing system 4 is connected to one box drying system 8 . The box drying system 8 is connected to at least one color sorting ...

Embodiment 2

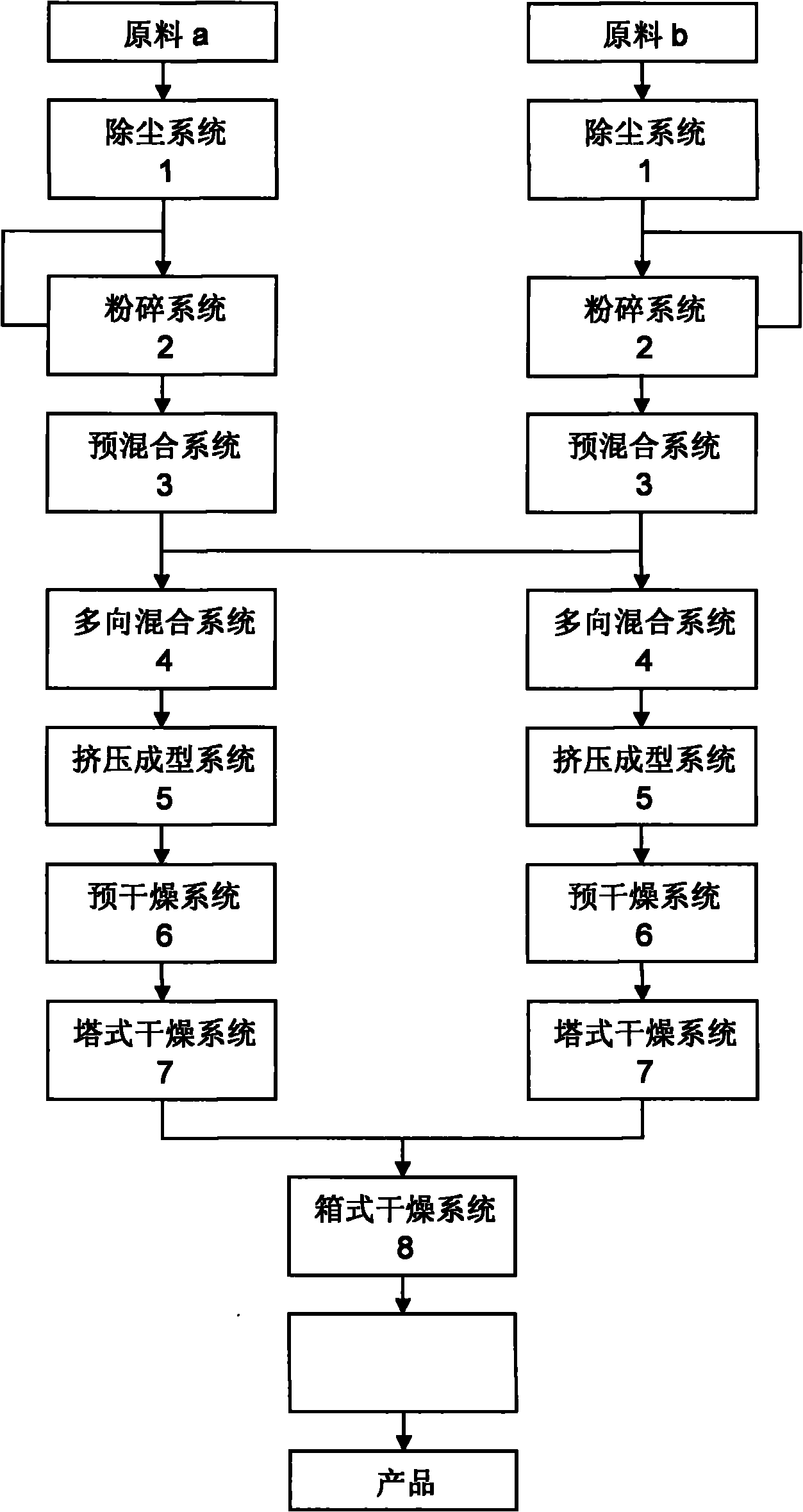

[0146] like Figure 1b As shown, the present invention discloses a reconstituted rice preparation device, which includes a dust removal system 1, a crushing system 2, a pre-mixing system 3, a multi-directional mixing system 4, an extrusion molding system 5, a pre-drying system 6, a tower along the material flow direction in sequence. Type drying system 7, box type drying system 8, color sorting system 9.

[0147] The reconstituted rice preparation device includes at least 2 pre-mixing systems 3 and at least 2 multi-directional mixing systems 4 . The at least one dust removal system and the at least one pulverization system are connected to the premixing system 3 . The premixing systems 3 are respectively connected to the multidirectional mixing systems 4 , so that the materials provided by the premixing systems 3 are further mixed in the multidirectional mixing systems 4 . Each of the multidirectional mixing systems 4 is correspondingly configured with an extrusion molding s...

Embodiment 3

[0149] The following is specifically described as Figure 1a , Figure 1b The specific structure of the reconstituted rice preparation apparatus shown and described in Example 1 and Example 2.

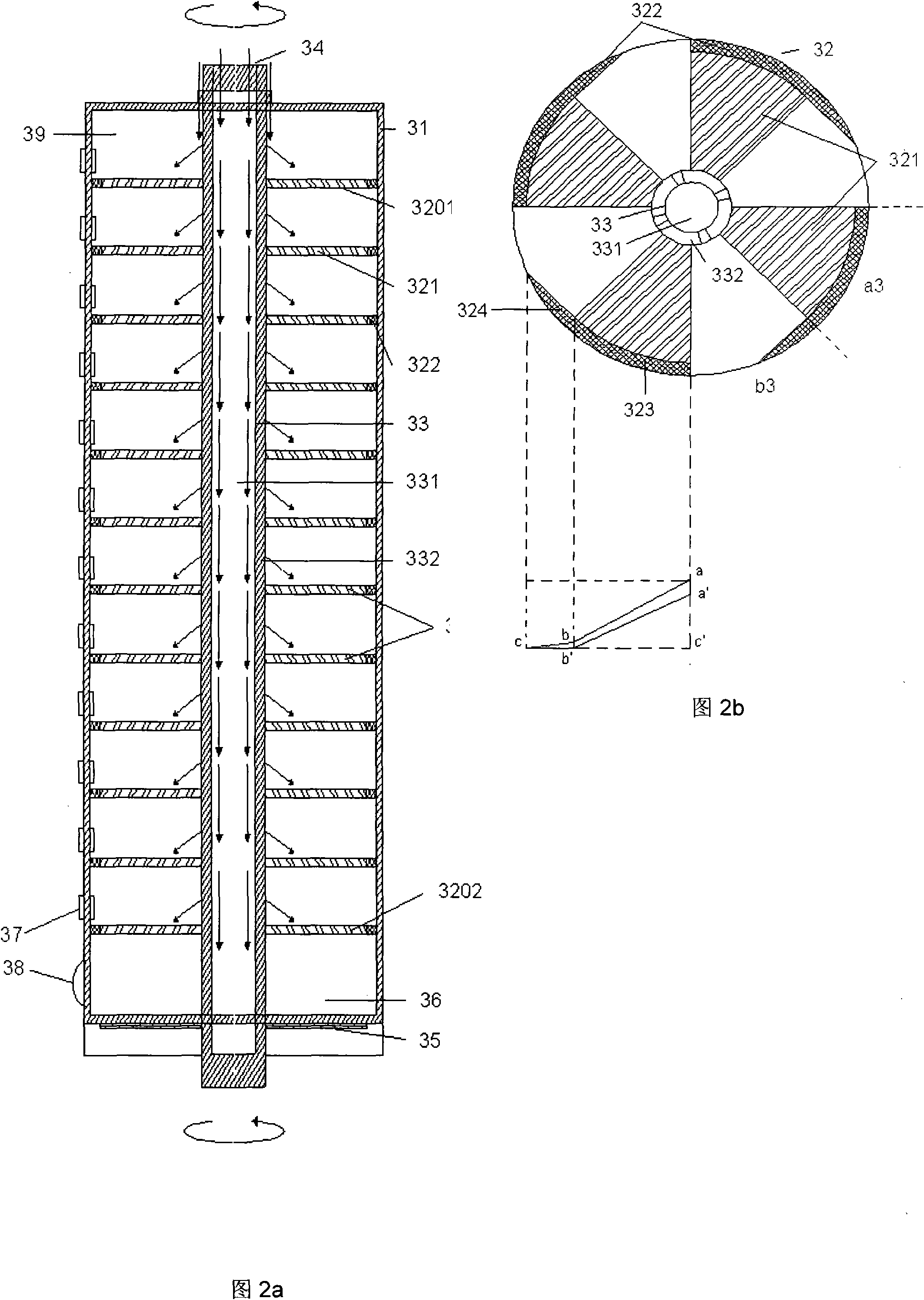

[0150] like Figures 2a to 2f As shown, the premixing system 3 is a staggered combined mixing reactor, including a mixing system 310, a staggered tray system 320 located inside the mixing system 310, a high-pressure gas injection system 330, a material storage system 360, and a mixing system located in the mixing system 310. 310 Feed system 340 at the top and discharge system 350 at the bottom.

[0151] The mixing system 310 is a cylindrical tower-type mixing reactor formed by the shell 31, which is used for mixing solid and liquid materials. The high-pressure gas injection system 330 has a vertical rotating shaft 33 located at the center of the shell 31, and the rotating shaft 33 drives the interlaced tray system 320 connected thereon to rotate. The feeding system 340 is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Center angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com