Making method of abalone juice rice

A production method and rice technology, which are applied in the field of abalone sauce rice, can solve the problems that the ingredients of abalone sauce cannot be fully mixed, affect the taste of eating, etc., and achieve the effects of beautiful appearance, reduced water evaporation, and reduced peculiar smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

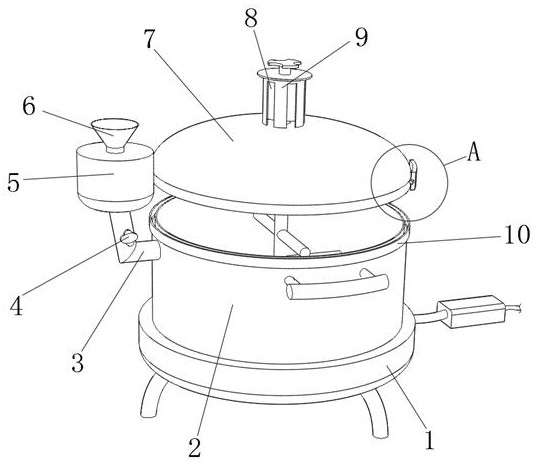

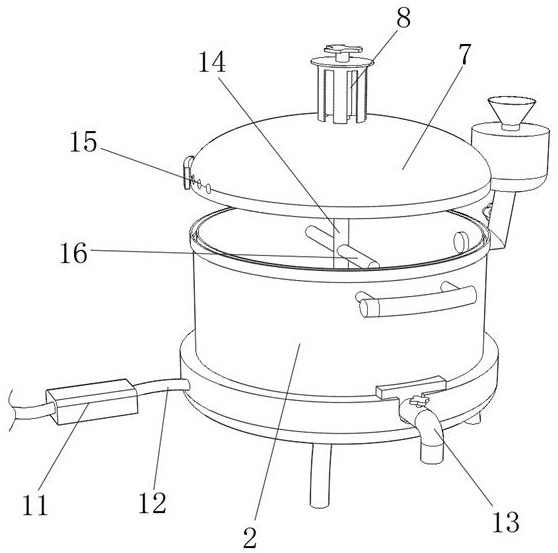

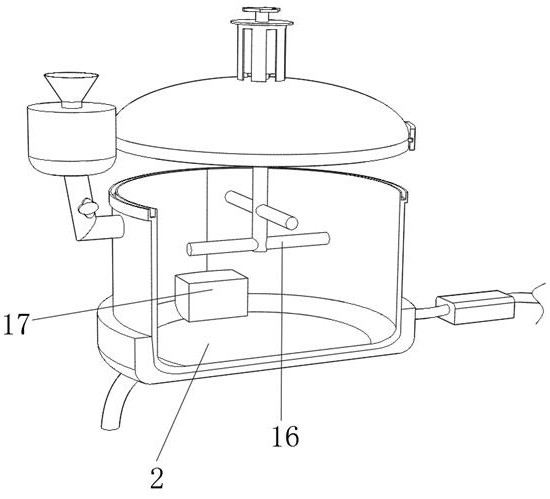

[0039] refer to Figure 1-Figure 5 , a method for making rice with abalone sauce, comprising the following steps:

[0040] S1: Raw material preparation, 80-100 parts of broth, 5-12 parts of sea cucumber, 1-3 parts of oyster sauce, 2-5 parts of chicken broth, 0-3 parts of edible salt, 1-5 parts of rock sugar, 10-18 parts of braised sauce and 4-10 parts of starch and other raw materials are ready, put aside for later use;

[0041] S2: Sea cucumber treatment, remove the viscera of fresh sea cucumbers, the removal of viscera helps to reduce the perception of sea cucumbers, and then clean the surface of sea cucumbers with a brush, then put the sea cucumbers in boiling water for 1-5 minutes and pick them up for later use;

[0042] S3: Starch thickening, put an appropriate amount of pure water into the thickening bucket, then add starch, and then use a stirring spoon to stir the mixture for 3-8 minutes until there is no foamy starch in the bucket and it is thin and fluid, then put i...

Embodiment 2

[0051] refer to Figure 1-Figure 5 , a method for making rice with abalone sauce, comprising the following steps:

[0052] S1: Raw material preparation, 80-90 parts of broth, 5-10 parts of sea cucumber, 1-2.5 parts of oyster sauce, 2-5 parts of chicken broth, 1-3 parts of edible salt, 1-4 parts of rock sugar, 11-16 parts of braised sauce and 4-8 parts of starch and other raw materials are ready, put aside for later use;

[0053] S2: sea cucumber treatment, remove the viscera of fresh sea cucumbers, the removal of viscera helps to reduce the perception of sea cucumbers, and then clean the surface of sea cucumbers with a brush, then put the sea cucumbers in boiling water for 1-4 minutes and pick them up for later use;

[0054] S3: Starch thickening, put an appropriate amount of pure water into the thickening bucket, then add starch, and then use a stirring spoon to stir the mixture for 3-6 minutes until there is no foamy starch in the bucket and it is thin and fluid, then put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com