Patents

Literature

43 results about "Dark brown color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chinese milk vetch soy

The invention discloses Chinese milk vetch soy. Chinese milk vetch stems and leaves rich in proteins and health care ingredients are subjected to pre-treatment, proportioning, blending, starter making, fermentation, oil sprinkling and loading. The Chinese milk vetch soy has effects of clearing heat and removing toxins, dispelling wind and improving eyesight, and invigorating spleen and tonifying qi, has a dark brown color, a thick soy fragrance and a mellow taste. The Chinese milk vetch soy can improve soil fertility, reduce a fertilizer application amount, improve a yield and effects, improve an agroecological environment, and promote new rural construction.

Owner:好记食品酿造股份有限公司

Preparation method of fragrant solomonseal rhizome vinegar

ActiveCN102229884ADark brownRich vinegarMicroorganism based processesVinegar preparationDark brown colorSweetness

The invention relates to a preparation method of fragrant solomonseal rhizome vinegar. The method takes fragrant solomonseal rhizome, fragrant solomonseal rhizome vinasse, rice and bran as the raw material, and comprises the steps of mixing, material moistening, inoculation, primary fermentation, secondary fermentation, sprinkling of vinegar, blending, sterilization, inspection and filling. The fragrant solomonseal rhizome vinegar produced through the steps of the invention has dark brown color, strong flavor, soft sourness, slight sweet taste, clear liquid state and appropriate concentration. Wherein, the adoption of fragrant solomonseal rhizome vinasse, a leftover of fragrant solomonseal rhizome wine, as the raw material makes fully use of disused resources. The fragrant solomonseal rhizome vinegar prepared in the invention takes vinegar as the carrier of fragrant solomonseal rhizome nutrients, and is characterized by wide edible scope, stable consumption amount and simple production technology, thus serving as a new member of the table vinegar family in our country. And the method of the invention is easy to master and convenient for realization.

Owner:江苏预立新能源科技有限公司

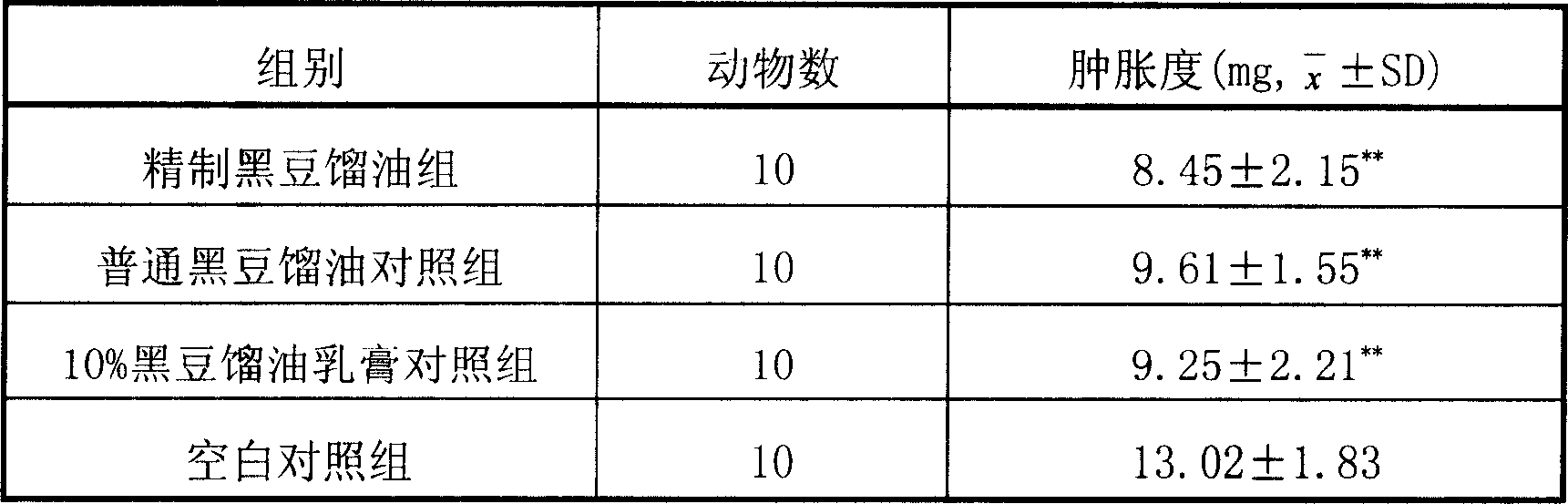

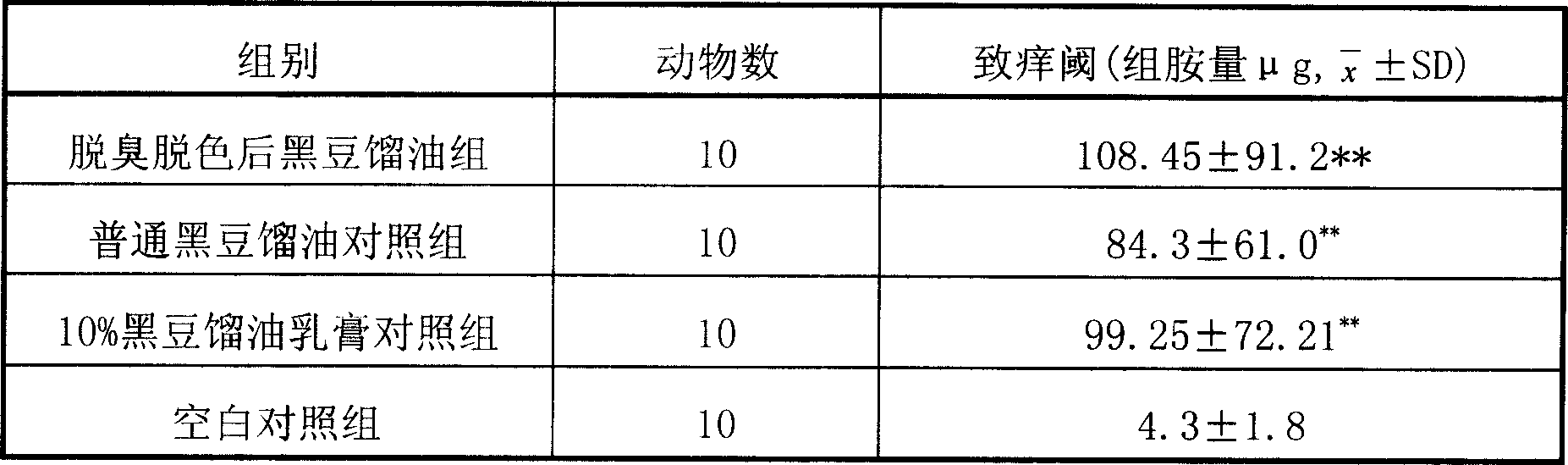

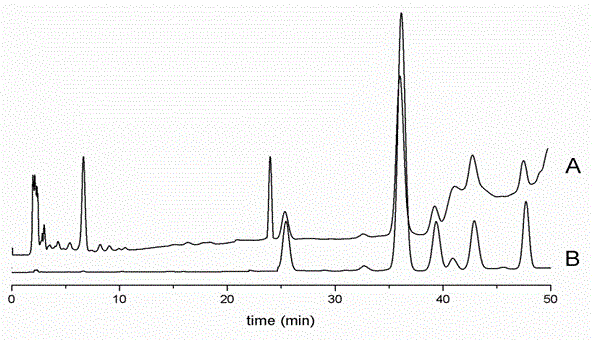

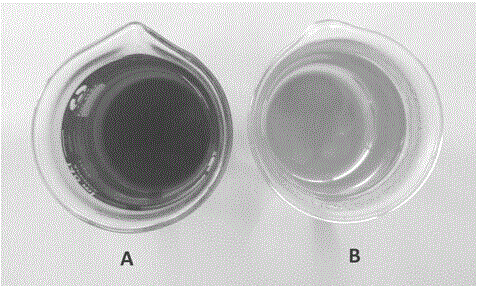

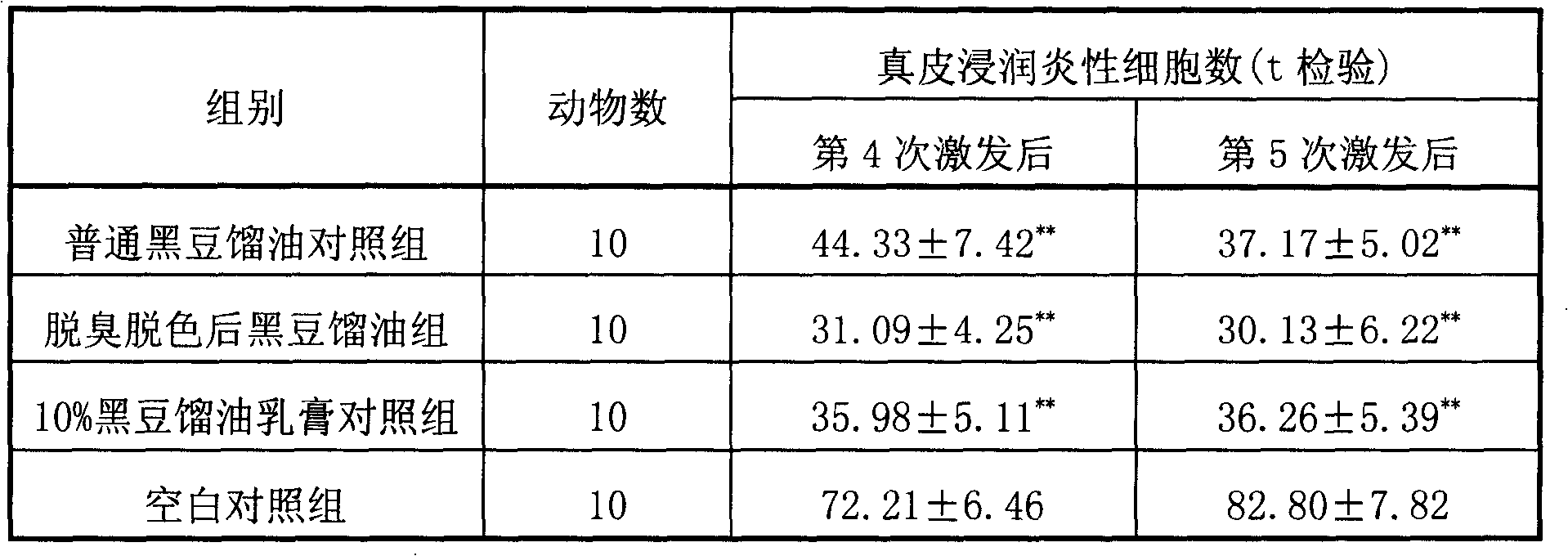

Refining method for black soya bean distillation oil

InactiveCN101015583AReduce chemical pollutionSave solventDistillation separationDermatological disorderGlycineOrganic solvent

This invention relates to a refine method for deodorizing Glycine max deflegmation oil. The invention adopts molecule short range distillation method to effectively separate component with special odour and dark brown color from Glycine max deflegmation oil, thereby obtaining light colored purified product without odour. The invention without the necessity for chemical organic solvents and specific installation has simple technology, short process time, simple operation, no enviromental pollution, and low cost; and dose not change the pharmacologic effect of processed odorless Glycine max deflegmation oil, and can improve dependance of patients.

Owner:CHONGQING HUAPONT PHARMA

Red date jelly and preparation method thereof

The invention provides a red date jelly which comprises the following components by weight percent: 8.54-10.04% of red date juice, 7.51-8.81% of jelly powder, 6.12-7.01% of soft sugar and carrageenan and the balance of water, wherein the ratio of carrageenan to jelly powder is (1:16.28)-(1:11.40). By the jelly prepared by the formula, the red date slurry has moderate viscosity and dark brown color; and the jelly has good flavor, and the finished product of jelly has a semi-transparent dark brown color; and the elasticity and the toughness are exactly proper.

Owner:YULIN UNIV +1

Soil activation and remediation fertilizer and preparation method thereof

ActiveCN101913963ANo side effectsEasy to masterFertilizer mixturesHigh concentrationNatural organic matter

The invention provides a soil activation and remediation fertilizer. The fertilizer is characterized by being formed by adding nitrogen, phosphorus and potassium fertilizers and a soil active agent into high-concentration organic matter liquid and then curing the mixture, wherein the high-concentration organic matter liquid is formed by performing biological fermentation on natural organic matters and agricultural wastes. The invention also provides a preparation method for the soil activation and remediation fertilizer. The method is characterized by comprising the following steps of: uniformly mixing the natural organic matters and the agricultural wastes; naturally fermenting the mixture in a fermentation tank at normal temperature to form organic liquid with a dark brown color and a slightly strong fish mellow flavor; filtering the obtained product and extracting supernate to obtain the high-concentration organic matter liquid; and curing the high-concentration organic matter liquid obtained by the step 1, the soil active agent and the nitrogen, phosphorus and potassium fertilizers to obtain the soil activation and remediation fertilizer. The soil activation and remediation fertilizer has the advantages of serving as fertilizer and making soil environment not deteriorated and maintaining enduring productivity.

Owner:姚乃华 +1

Fiddlehead spore seedling nursing technology

The invention relates to a fiddlehead spore seedling nursing technology. Uncracked sporangium groups in a dark brown color are selected; leaves having spores are cut down and placed in a ventilating position for natural drying; scattered spores are collected and refrigerated at the temperature of 4 DEG C; reed powder, urea formaldehyde foamed plastic, pine needle soil, bone meal, silicate bacterial fertilizer, kinetin, betaine, spermidine, inositol, vitamin B1 and vitamin B2 are mixed to form culturing substrate; the fiddlehead spores are fully flushed via sterile water, and then immersed into a mixed solution formed by zeatin and naphthylacetic acid with growth humidity remained around 82% to 85%, growth temperature of 26 to 26.5 DEG C and illumination strength of 1800 to 20001x; and when the spore infant seedling grows to 6cm, the fiddlehead spore infant seedlings on the culturing substrate are thinned. The fiddlehead spore seedling nursing technology is advantaged by high stability, strong controllability and great operability; seedling nursing period of the fiddlehead spores can be shortened; and seedling rate and rooting rate can be enhanced.

Owner:HEFEI YUANZHENG AFE SCI TECH

Secondary sedimentation tank sludge floatation alarming and controlling method for sewage treatment system

ActiveCN104710004AReduce floatingLow costWater treatment parameter controlSpecific water treatment objectivesTreatment effectThree stage

The invention discloses a secondary sedimentation tank sludge floatation alarming and controlling method for a sewage treatment system and belongs to the technical field of environmental wastewater treatment. Through awarning classification of the secondary sedimentation tank sludge floatation in the sewage treatment system is built and based on the proportion of the cover area of the secondary sedimentation tank floated sludge in the tank surface area, namely, cover degree, the occupied ratio of the black number and the dark brown color number in the activated sludge, the number of the filamentous microorganism as classifying basis, the secondary sedimentation tank floated sludge is divided into three stages and is controlled by adopting a method according to the alarming classification. According to the invention, alarming is carried out at the initial stage of the sludge floatation, the floatation of the sludge is eliminated at the initial stage by respectively adopting different strategies, so as to greatly reduce the probability of sludge floatation, and the method disclosed by the invention is a feasible, economic and effective method. Through three-stage alarming system, different control measures are adopted for sludge flotation, so that the operation cost and expense input of a sewage treatment plant are greatly reduced, and treatment effect is good.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Method for discriminating polished rice and glutinous rice

InactiveCN104914054ARapid identificationSimple methodColor/spectral properties measurementsDark brown colorHorticulture

The invention provides a method for discriminating polished rice and glutinous rice. The method comprises immersing polished rice and glutinous rice into an iodine tincture solution according to a certain mass-volume ratio for some time and then carrying out identification by observation of different colors of the rice after immersion. The immersed glutinous rice has a dark brown color and the immersed polished rice has an ianthinus color. The method is simple and easy and has discriminating accuracy of 100%.

Owner:舒城县东方粮油种植专业合作社

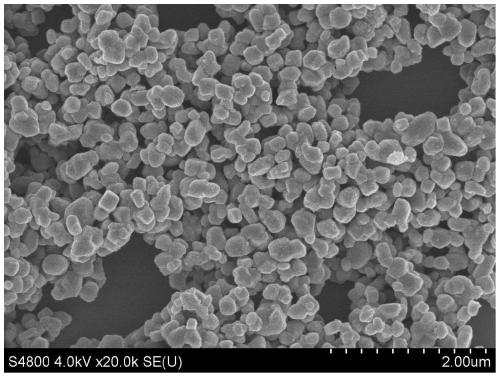

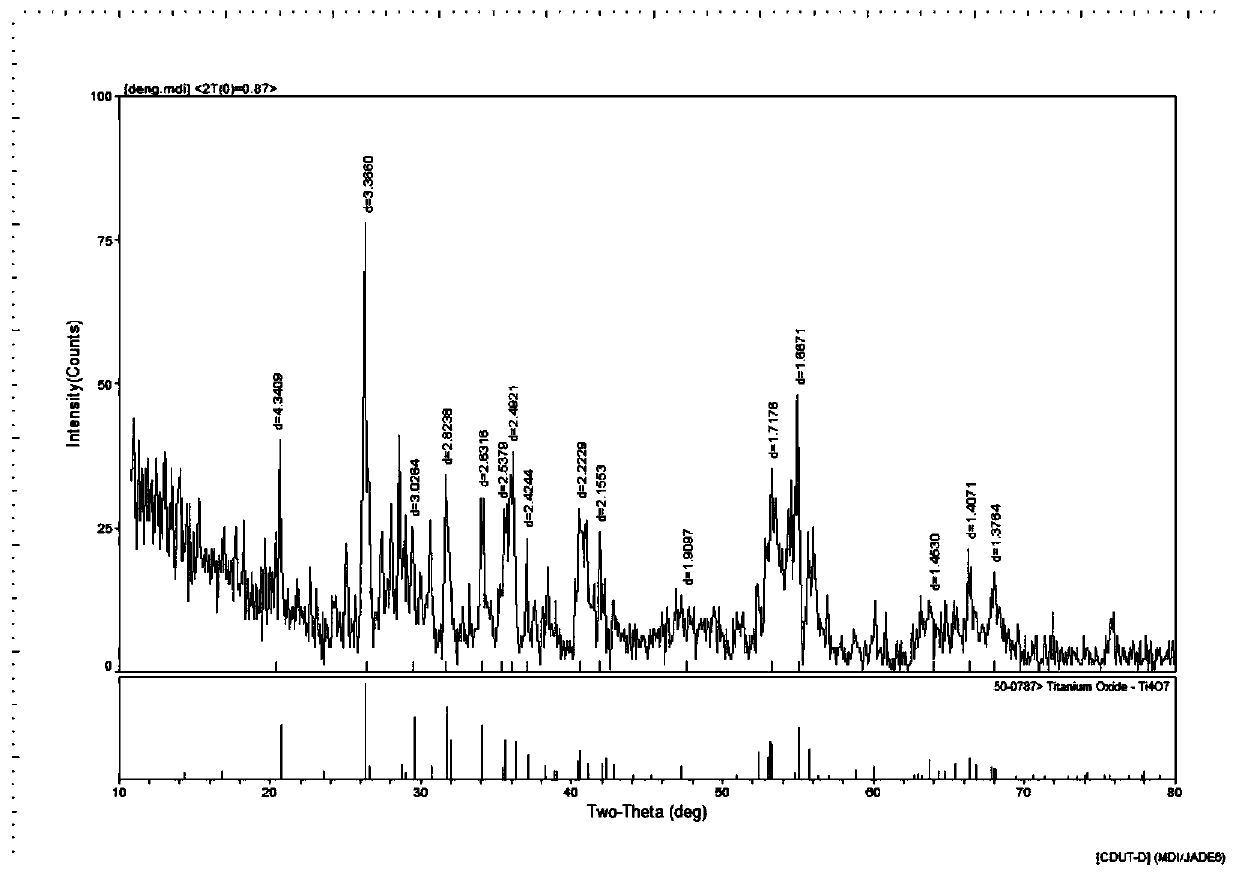

Method for preparing titanium oxide through reducing titanium-containing complexes at normal temperature

ActiveCN109879311ALow costMass productionTitanium oxides/hydroxidesTitanium oxideTitanium tetrachloride

The invention discloses a method for preparing titanium oxide through reducing titanium-containing complexes at normal temperature. The method is characterized in that reduction reaction occurs in a normal temperature liquid phase; the potential safety hazards due to mixing of reducing agents and air are eliminated; the reduction is performed in the liquid phase, the microscopic uniformity is high; the firing temperature is low; the time is short. The method has the following principle and steps that titanium sulfate or titanium tetrachloride and ammonium hydroxide or sodium hydroxide take a reaction to obtain titanic acid; the titanic acid reacts with oxalic acid or citric acid to form an oxalate oxytitanate complex-ion or oxytitanate citrate complex-ion solution; next, reaction is performed with zinc powder; the complex ions are reduced into low-valent titanium complex ions; the pH value of the solution is regulated to 12 by ammonium hydroxide; precipitates of dark brown color to dark violet color are generated; washing is performed for 3 to 5 times by 3 to 5 times of deionized water; the zin is washed away in an ion ZnO2<2-> form to obtain pure titanium hydroxide precipitates; oxalic acid is added until the pH is 0.5 to 1.5; drying is performed to 2 to 5 hours at 120 to 180 DEG C; the temperature is raised from room temperature to 820 to 950 DEG C by a muffle furnace; roasting is performed for 2 to 6 hours; titanium oxide spherical powder with the Ti4O7 content being 90 percent or higher is obtained.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Ion coloring agent for concrete and application thereof

The invention relates to an ion coloring agent for concrete and application thereof. The ion coloring agent comprises a metal inorganic salt, a solvent, an osmotic agent, a diluent and an oxidizing agent. The ion coloring agent for concrete chemically reacts with a concrete substance to produce an inorganic chromogenic substance, so an integral colored concrete structure with stable properties isformed, and the structure has resistance to water, sunlight and ageing, does not fade, and is stable in tone and natural in color. Frequently used colors include yellowish brown, brownish red, sky blue, coffee, bean green, brownish yellow, brilliant green, reddish brown and dark brown colors.

Owner:苏州金润新材料科技有限公司

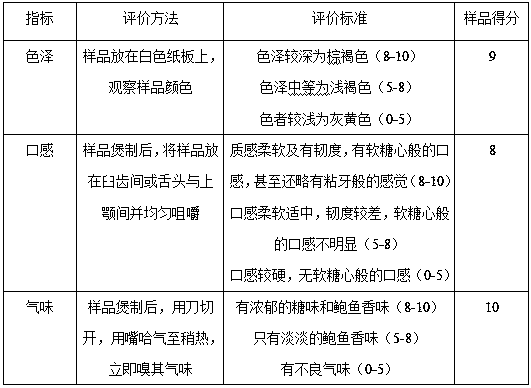

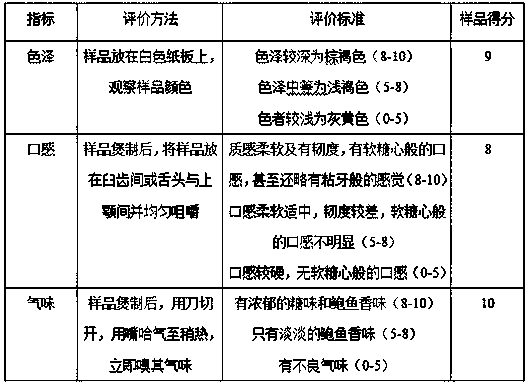

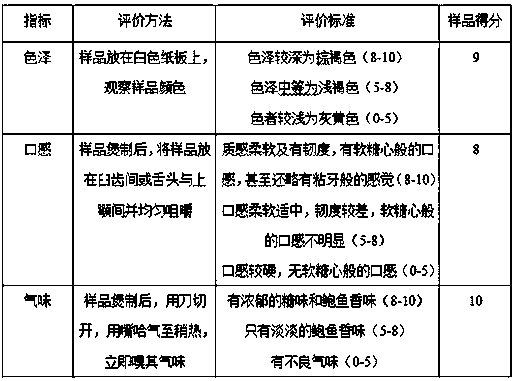

Preparation method of semifluid-center dried abalone

InactiveCN109363110AEasy to controlNot easy to influenceFood dryingFood ingredient as mouthfeel improving agentDark brown colorBiology

The invention discloses a preparation method of semifluid-center dried abalone and particularly relates to the technical field of abalone preparation. According to the method, a finished product is obtained through abalone selection, shell removal and meat taking, scrubbing, gelling treatment, precooking, pre-drying and primary tempering, setting, internal organ removal and trimming, air drying and secondary tempering, fermentation and storage. The method is not susceptible to the environment and weather, can control the temperature and humidity accurately and guarantee the sanitary conditionand is energy saving and environmentally friendly. The semifluid-center dried abalone obtained by the preparation method has darker brown color, soft texture and toughness, tastes like soft sweet cores, even tastes slightly sticky to the teeth and has the characteristics of strong sweet aroma and abalone fragrance.

Owner:福建海鳞源食品开发有限公司

Black bean soy sauce production method

InactiveCN105519921AImprove the production processIncrease productivityFood preparationWarm waterHigh pressure

The invention provides a black bean soy sauce production method, relates to a production method of a soy sauce using black beans as a main raw material, and belongs to seasoning production, wherein black beans are adopted as a raw material to brew a soy sauce, and the brewed soy sauce, garlic head, fresh ginger, green pepper and foeniculum vulgare are prepared into the product. The production method comprises: 1, soy sauce brewing: completely cooking black beans, drying in the sun for 7-10 days, placing into a fermentation tank, and adding warm water having an amount of 10-15 times the weight of the black beans, wherein the water temperature is 80-90 DEG C; 2, seasoning liquid preparation: placing 7-12% of garlic head, 3-8% of fresh ginger, 1-2% of green pepper, 0.5-0.8% of foeniculum vulgare, and the balance of water into a high pressure cooker, completely cooking, and filtering out the juice; 3, caramel salt water preparation: taking salt and sugar according to a weight ratio of 10:1, and carrying out frying stirring for 10-12 min in a 150 DEG C iron pot until the mixture presents a dark brown color; and 4, preparation blending: mixing the brewed soy sauce, the seasoning liquid and the caramel salt water according to a volume ratio of 3:3:2, fermenting for 10 days until the taste is increased, and carrying out quality inspection and packaging so as to obtain the finished product. The black bean soy sauce of the present invention has effects of beautifying and face nourishing.

Owner:郑进强

Preparation method of fragrant solomonseal rhizome vinegar

ActiveCN102229884BDark brownRich vinegarMicroorganism based processesVinegar preparationSweetnessPolygonatum lasianthum

Owner:江苏预立新能源科技有限公司

Coloring method of copper craftwork

InactiveCN106245022AEasy coloring processGood coloring effectMetallic material coating processesDark brown colorCopper

The invention discloses a copper handicraft coloring method. The process includes shape design, material selection and ingredients, coloring and baking. Before coloring, the copper handicraft is sandblasted, and the coloring can be brown, brown red and green. The invention overcomes the disadvantages of the prior art, provides convenient coloring process, good coloring effect, can keep the color bright for a long time, and the color of the whole sculpture is transparent, harmonious and rich.

Owner:罗婷元

Efficient energy-saving wine brewing method using thinned raw grains

InactiveCN106867742AComprehensive fermentation and brewing technology is feasibleEasy to operateAlcoholic beverage preparationIllicium verumDistillation

The present invention relates to an efficient energy-saving wine brewing method using thinned raw grains. The efficient energy-saving wine brewing method comprises: screening, washing and purifying raw grains such as rice, wheat and sorghum, adding a spice such as clove, illicium verum hook.f or peppermint according to a weight ratio of the raw grains to the clove of 100:1, crushing and thinning, pouring the crushed raw material into a fermentation jar, sequentially adding a raw material koji and purified water to the jar according to a weight ratio of the raw material to the koji to the purified water of 100:6-8:290-300, uniformly stirring, sealing, flipping every 2-3 days, pouring into wine distillation equipment at about the 9th day until the mash water has a dark brown color and the fermentation achieves a mature state, and distilling the wine, wherein the remaining mash water containing the low alcoholicity wine after the wine distilling can be used for rice vinegar and sauce production or re-fermentation, and the offcuts can be used for feed processing, livestock feeding, and the like. According to the present invention, the method has advantages of practicality, feasibility, fine process, easy operation, strong practicality, easy promotion, raw grain and raw material thinning, short fermentation period, excellent mash, high yield, high product quality, energy saving, mellow wine, excellent aroma, and significant comprehensive economic benefits of promotion use.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Method for increasing germination rate of grape seeds

InactiveCN109362270ASoften fastPromote absorptionBiocidePlant growth regulatorsGrape seedSalicylic acid

The invention discloses a method for increasing the germination rate of grape seeds. The method comprises the following steps: performing freeze pretreatment on plump and glossy ripe seeds with dark brown color, and standing the seeds at 20-25 DEG C until the seeds are restored to normal temperature; sequentially soaking the seeds in a complex enzyme solution and a germinating agent, taking out, and drying in the air; and mixing the germinated seeds with wet river sands, preserving in an environment having the temperature of 10-15 DEG C and relative humidity of 85-90 percent in a closed manner, wherein the complex enzyme solution is a mixed solution of ligninase, cellulose, lipase and citric acid; and the germinating agent is a mixed solution of matrine, 6-BA, salicylic acid and potassiumcarbonate. The method can destroy the seed coat structure, quickly soften the seed coats and promote seeds to absorb external nutrition, so that the germinating time of seeds can be shortened, and thebreeding efficiency of seeds can be improved.

Owner:句容市丁庄葡萄研究所

Refined spice obtained through liquid-state fermentation of flower-leaf raw materials

InactiveCN106867668AEfficient processFragrance high-end and affordableEssential-oils/perfumesFlavorDark brown color

The invention relates to a refined spice obtained through liquid-state fermentation of flower-leaf raw materials. The main preparation process comprises: weighing a raw material slurry, raw material koji and purified water according to a ratio of 100:0.6:230 when a temperature is higher than 30 DEG C, weighing a raw material slurry, raw material koji and purified water according to a ratio of 100:0.7:220 when a temperature is lower than 30 DEG C, and weighing a raw material slurry, raw material koji and purified water according to a ratio of 100:0.8:210 when a temperature is lower than 20 DEG C; weighing raw material powder, raw material koji and purified water according to a ratio of 100:0.5:250 when a temperature is higher than 30 DEG C, weighing raw material powder, raw material koji and purified water according to a ratio of 100:0.6:240 when a temperature is lower than 30 DEG C, and weighing raw material powder, raw material koji and purified water according to a ratio of 100:0.7:230 when a temperature is lower than 20 DEG C; and respectively pouring into a special fermentation jar tank, carrying out anaerobic fermentation for 10-12 days, pouring into special efficient equipment when the mash has a dark brown color and the fermentation achieves a mature state, and properly distilling to obtain the high-quality pure flower perfume.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Nanofiltration membrane separation preparation method of cosmetic-grade pueraria isoflavone

ActiveCN104523462ASolve darkeningSolve solubilityCosmetic preparationsToilet preparationsSolubilityFreeze-drying

The invention discloses a method for separating and preparing cosmetic-grade pueraria isoflavone from pueraria raw materials by using a solvent-resistant nanofiltration membrane, which comprises the following preparation steps: (1) extracting total isoflavone from pueraria raw materials to obtain a pueraria isoflavone crude product; (2) enriching the total isoflavone by a macroporous adsorption resin column; (3) performing dialysis separation by a solvent-resistant nanofiltration membrane, recovering ethanol, performing concentration, and finally performing freeze drying to obtain a pueraria isoflavone highly finished product with high content and high dissolvability. The method of the invention successfully solves a series of problems, which restrict the application in the cosmetic field, of dark brown color, poor dissolvability at normal temperature, organic solvent residue, and the like for pueraria isoflavone products produced by traditional technology, and the method has great economic value and social benefit.

Owner:HUNAN AGRICULTURAL UNIV

Externally applied Chinese medicine ointment containing pangolin scales

The invention relates to an externally applied Chinese medicine ointment containing pangolin scales, cowherb seeds, and centipedes. The raw materials comprise the following components in parts by weight: 90 parts of pangolin scales, 160 parts of cowherb seeds, and 90 parts of centipedes; the raw materials are dried and crushed into powder of 300-350 mesh sieve, the powder is placed in a porcelain bottle, millet vinegar is poured into the bottle with stirring, and the product is prepared for standby. The ointment has a dark brown color and has good treatment effects for a breast cancer disease.

Owner:孙继芝

Honey pear plantation method

The invention discloses a honey pear plantation method comprising the following steps: 1, sorting a honey pear field; 2, matrix cultivation; 3, colonization; 4, water fertilizer management; 5, flower thinning and fruit thinning; 6, spraying anti-falling agent. The plantation method is suitable for standardization honey pear planting; the planted honey pear leaves are thick and wide, fruity is fresh and no sour mouthfeel is generated, fruit size is relatively big, and the fruit is nearly spherical; the surface of the fruit is in shallow brown or dark brown color, and has light color spots; the skin is thin; pulp is crispy and tender; the fruit is juicy and has no slag, is proper in sour-sweet flavor, and high in yield; the method can effectively prevent honey pears from falling, can provide nutrient and hormone for fruit growth, can regulate tree vigor, can control nutrient and hormone balance, thus improving honey pear output; the plantation method is simple and easy to operate, and suitable for large scale popularization usage.

Owner:陈耿

New efficient wine brewing process through optimized liquid-state fermentation of a variety of raw materials

InactiveCN106867745AImprove wine qualityImprove food savingAlcoholic beverage preparationDistillationSlurry

The invention discloses a new efficient wine brewing process through optimized liquid-state fermentation of a variety of raw materials. The new process comprises equipment arrangement, raw material thinning, fine fermentation, wine distilling-quality increasing, and mass production, and specially comprises: respectively weighing washed raw grain-based rice, wheat and sorghum according to a certain ratio, crushing into a 40 mesh slurry-like raw material, respectively weighing the slurry-like raw material, koji and purified water according to a ratio of 100-90:0.8-1:280-260 (280 parts of the water is added to 0.8 part of the koji when the temperature is higher than 30 DEG C, 270 parts of the water is added to 0.9 part of the koji when the temperature is lower than 30 DEG C, and 260 parts of the water is added to 1 part of the koji when the temperature is lower than 20 DEG C), sequentially pouring into a fermentation jar, uniformly stirring, carrying out anaerobic fermentation, pouring into efficient and energy-saving wine distillation equipment at the 9th day after the mash has a light dark brown color and the fermentation achieves the mature state, distilling for 2-3 h, filling the obtained wine into a standard bottle, and sealing and storing for 13-15 days so as to obtain the high quality raw grain wine with characteristics of transparent color, refreshing and sweet taste, and natural fragrance.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

New efficient energy-saving wine brewing process using yam-based raw materials

InactiveCN106867748AAdvanced technologyCraftsmanshipAlcoholic beverage preparationDistillationManihot esculenta

The invention relates t a new efficient energy-saving wine brewing process using yam-based raw materials. The new efficient energy-saving wine brewing process comprises technical processes such as equipment arrangement, thinning and matching optimization, liquid-state fermentation, efficient wine distillation and the like, and specially comprises: respectively adding washed raw manihot esculenta crantz and washed dried manihot esculenta crantz to sweet potato according to the same ratio of 6-5:3-4, respectively carrying out weighing mixing on the obtained materials and a spice according to a ratio of 6-5:0.3-0.2, respectively crushing with a crusher to obtain a 38-40 mesh fragrant slurry-like raw material and a powdery raw material, weighing the slurry-like raw material, koji and purified water according to a ratio of 100:0.7-0.8:260-280 and the powdery raw material, koji and purified water according to a ratio of 100:0.6-0.8:280-300, respectively pouring into a fermentation tank or pool, uniformly stirring, carrying out anaerobic fermentation for 12 days, pouring the mature mash into wine distilling equipment after the mash has a dark brown color and the fermentation achieves a mature state, distilling, filling the obtained wine into a special bottle, and carrying out sealed storage and quality improvement for 13-15 days so as to obtain the yam-based wine with characteristics of rich yam flavor and mellow, fragrant and sweet taste.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Refining method for black soya bean distillation oil

InactiveCN101015583BReduce chemical pollutionSave solventMolecular distillationDermatological disorderGlycineOrganic solvent

This invention relates to a refine method for deodorizing Glycine max deflegmation oil. The invention adopts molecule short range distillation method to effectively separate component with special odour and dark brown color from Glycine max deflegmation oil, thereby obtaining light colored purified product without odour. The invention without the necessity for chemical organic solvents and specific installation has simple technology, short process time, simple operation, no enviromental pollution, and low cost; and dose not change the pharmacologic effect of processed odorless Glycine max deflegmation oil, and can improve dependance of patients.

Owner:CHONGQING HUAPONT PHARMA

Fresh meat soy sauce production method

InactiveCN105519918AImprove the production processIncrease productivityClimate change adaptationFood preparationWarm waterHigh pressure

The invention provides a fresh meat soy sauce production method, relates to a production method of soy sauce using black beans and fresh meat as main raw materials, and belongs to seasoning production, wherein soy sauce brewed by using black beans and fresh meat as raw materials, garlic head, fresh ginger and foeniculum vulgare are used to prepare the product. The production method comprises: 1, soy sauce brewing: completely cooking black beans, drying in the sun for 7-9 days, placing in a fermentation tank , and adding warm water having an amount of 10 times the weight of the black beans, wherein the water temperature is 75-85 DEG C; 2, seasoning liquid preparation: placing 7-13% of garlic head, 5-9% of fresh ginger, 0.7-0.9% of foeniculum vulgare, and the balance of water into a high pressure cooker, completely cooking, and filtering out the juice; 3, salt water preparation: taking salt and sugar according to a weight ratio of 9:1, and carrying out frying stirring for 10-11 min in a 150 DEG C iron pot until the dark brown color appears; 4, fresh meat sauce preparation: taking about 20% of fresh pork loin, mincing to obtained minced meat, steaming to achieve a cooked state, and drying in the sun; and 5, blending: mixing the brewed soy sauce, the seasoning liquid, the salt water and the fresh meat sauce according to a volume ratio of 3:1:1:1.

Owner:颜裕逸

Early warning and control method of sludge floating in secondary settling tank of sewage treatment system

ActiveCN104710004BReduce floatingLow costWater treatment parameter controlSpecific water treatment objectivesThree stageTherapeutic effect

The invention discloses a secondary sedimentation tank sludge floatation alarming and controlling method for a sewage treatment system and belongs to the technical field of environmental wastewater treatment. Through awarning classification of the secondary sedimentation tank sludge floatation in the sewage treatment system is built and based on the proportion of the cover area of the secondary sedimentation tank floated sludge in the tank surface area, namely, cover degree, the occupied ratio of the black number and the dark brown color number in the activated sludge, the number of the filamentous microorganism as classifying basis, the secondary sedimentation tank floated sludge is divided into three stages and is controlled by adopting a method according to the alarming classification. According to the invention, alarming is carried out at the initial stage of the sludge floatation, the floatation of the sludge is eliminated at the initial stage by respectively adopting different strategies, so as to greatly reduce the probability of sludge floatation, and the method disclosed by the invention is a feasible, economic and effective method. Through three-stage alarming system, different control measures are adopted for sludge flotation, so that the operation cost and expense input of a sewage treatment plant are greatly reduced, and treatment effect is good.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Blended paint for coloring surfaces of bathroom products

InactiveCN105017832AReduce processing stepsImprove aestheticsMulticolor effect coatingsLacquerPolyvinyl alcohol

The invention discloses an improved office drawer cabinet, in particular a blended paint for coloring surfaces of bathroom products. The blended paint comprises the following components in percentage by weight: 2-10% of decontamination oil, 5-15% of a diluent, 8-20% of a dark brown color paste, 5-15% of a redwood color process paint, 10-13% of a black red brown process paint, 7-13% a conditioner, 30-60% of a thinner, 5-17% of a red oxide paint, 5-10% of polyvinyl alcohol, 1-5% of sodium hydroxide, 4-15% of ammonia water and 6-9% of absolute methanol. The blended paint disclosed by the invention can be used for coating the surfaces of the bathroom products by only one time, can reduce the treatment procedures on the surfaces of the bathroom products, cannot cause corrosion to the surfaces of metal bathroom products at the same time, is richer and softer in color, and can ensure that the surfaces of the bathroom products obtain a better aesthetic extent.

Owner:NINGBO WENXIN HARDWARE PROD

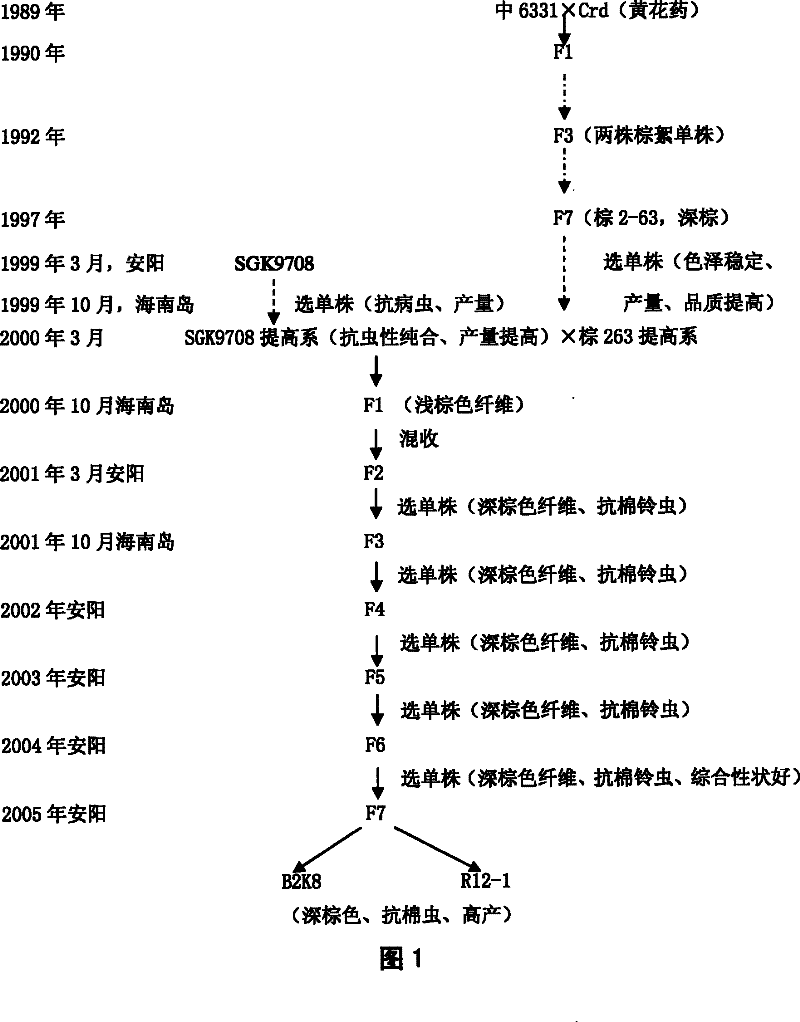

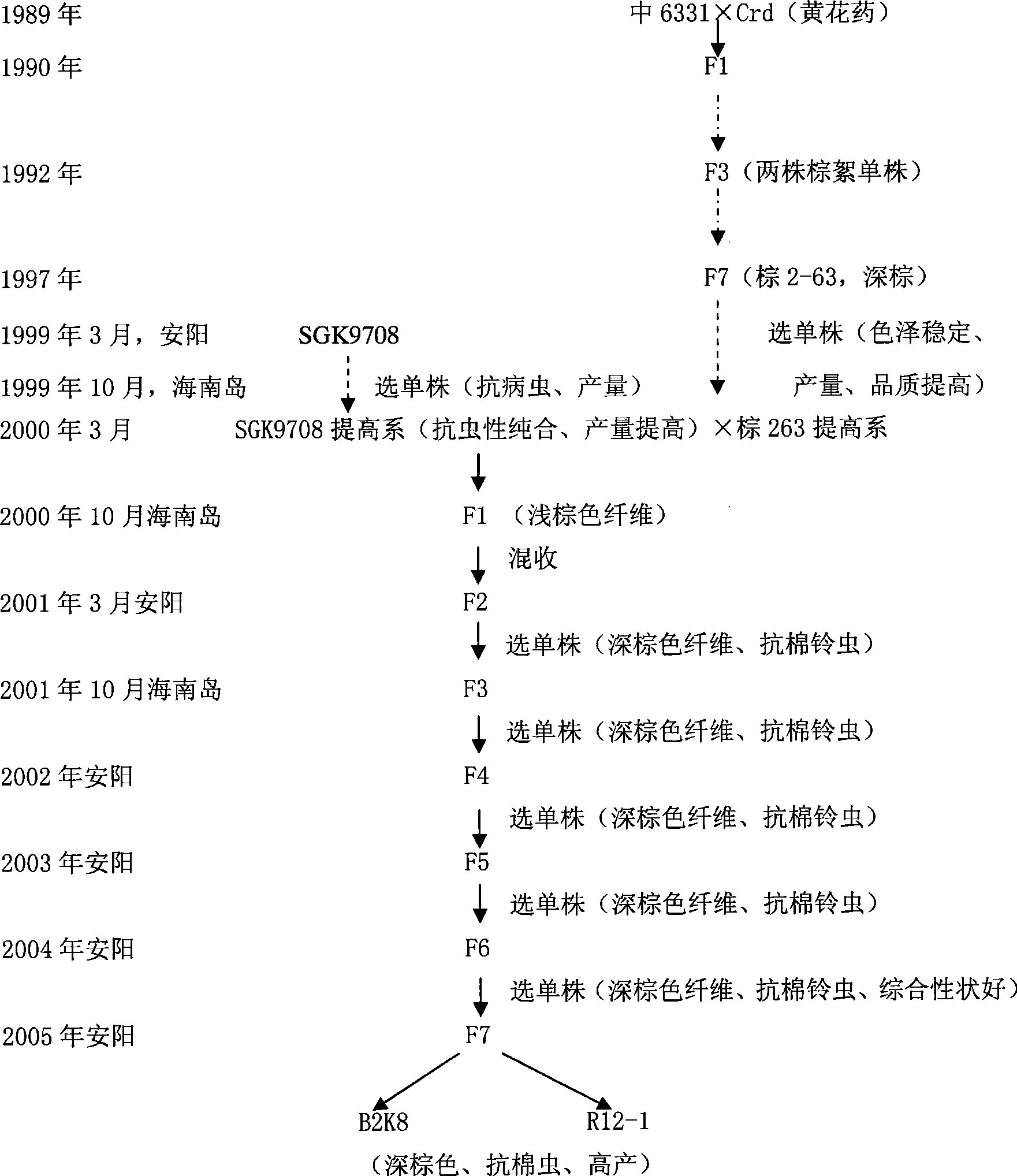

Breeding method for pest-resistant nigger-brown fibre new species of cotton

InactiveCN101427654BReduce usageReduce the cost of growing cottonPlant genotype modificationAngiosperms/flowering plantsFiberAgricultural science

The invention discloses a cotton bollworm resistant dark brown color cotton (dark brown fiber) breeding method. The transgene insect-resistant cotton strain SGK 9708 is used as basis material, and then the transgene insect-resistant cotton strain SGK 9708 improvement strain with insect-resistance homogeneity (100%), increased blight and verticillium wilt resistance, increased ginned cotton yield by about 15.0% than the raw material is obtained through breeding and identifying insect resistance. Then the transgene insect-resistant cotton strain SGK 9708 improvement strain is used as female parent to hybridize with the dark brown, high-yield, yellow anther new strain brown 263. After individual system selection for several years, a series of cotton bollworm resistant, dark brown color cotton new strains are bred, comprising B2K8, R12-1 or like. The bred dark brown color cotton not only has antlered larvae such as cotton bollworm resistance of dark brown color cotton, but also reduces pesticide consumption, protects environment, at the same time the fiber quality, ginned cotton yield are greatly increased.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

Breeding method for pest-resistant nigger-brown fibre new species of cotton

InactiveCN101427654AReduce usageReduce the cost of growing cottonPlant genotype modificationAngiosperms/flowering plantsFiberAgricultural science

The invention discloses a cotton bollworm resistant dark brown color cotton (dark brown fiber) breeding method. The transgene insect-resistant cotton strain SGK 9708 is used as basis material, and then the transgene insect-resistant cotton strain SGK 9708 improvement strain with insect-resistance homogeneity (100%), increased blight and verticillium wilt resistance, increased ginned cotton yield by about 15.0% than the raw material is obtained through breeding and identifying insect resistance. Then the transgene insect-resistant cotton strain SGK 9708 improvement strain is used as female parent to hybridize with the dark brown, high-yield, yellow anther new strain brown 263. After individual system selection for several years, a series of cotton bollworm resistant, dark brown color cotton new strains are bred, comprising B2K8, R12-1 or like. The bred dark brown color cotton not only has antlered larvae such as cotton bollworm resistance of dark brown color cotton, but also reduces pesticide consumption, protects environment, at the same time the fiber quality, ginned cotton yield are greatly increased.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

Efficient flower perfume liquid extraction method through liquid-state fermentation of raw materials

InactiveCN106867670AEfficient processFragrance high-end and affordableEssential-oils/perfumesDark brown colorSlurry

The invention relates to an efficient flower perfume liquid extraction method through liquid-state fermentation of raw materials. The main preparation process comprises: weighing a raw material slurry, raw material koji and purified water according to a ratio of 100:0.6:230 when a temperature is higher than 30 DEG C, weighing a raw material slurry, raw material koji and purified water according to a ratio of 100:0.7:220 when a temperature is lower than 30 DEG C, and weighing a raw material slurry, raw material koji and purified water according to a ratio of 100:0.8:210 when a temperature is lower than 20 DEG C; weighing raw material powder, raw material koji and purified water according to a ratio of 100:0.5:250 when a temperature is higher than 30 DEG C, weighing raw material powder, raw material koji and purified water according to a ratio of 100:0.6:240 when a temperature is lower than 30 DEG C, and weighing raw material powder, raw material koji and purified water according to a ratio of 100:0.7:230 when a temperature is lower than 20 DEG C; and respectively pouring into a special fermentation jar tank, carrying out anaerobic fermentation for 10-12 days, pouring into special efficient equipment when the mash has a dark brown color and the fermentation achieves a mature state, and properly distilling to obtain the high-quality pure flower perfume.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

New wine brewing process through liquid-state fermentation of grain-based raw materials

InactiveCN106867744AImprove wine qualityImprove food savingAlcoholic beverage preparationDistillationSlurry

The invention relates to a wine brewing technology through thinning and liquid-state fermentation of raw grains. The wine brewing technology comprises equipment arrangement, raw material thinning, fine fermentation, wine distilling and quality improvement, and batch production, and specially comprises: respectively weighing cleaned raw grains such as rough rice, wheat and sorghum according to a certain ratio, and crushing into a 40 mesh slurry-like raw material; respectively weighing the slurry-like raw material, koji and purified water according to a ratio of 100-90:0.8-1:280-260 (280 parts of the water is added to 0.8 part of the koji when the temperature is higher than 30 DEG C, 270 parts of the water is added to 0.9 part of the koji when the temperature is lower than 30 DEG C, and 260 parts of the water is added to 1 part of the koji when the temperature is lower than 20 DEG C), sequentially pouring into a fermentation jar, uniformly stirring, and carrying out anaerobic fermentation; and pouring into efficient and energy-saving wine distillation equipment at the 9th day after the mash has a light dark brown color and the fermentation achieves the mature state, distilling for 2-3 h, filling the obtained wine into a standard bottle, and sealing and storing for 13-15 days so as to obtain the high-quality raw grain wine with characteristics of transparent color, sweet and refreshing taste, and natural fragrance.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com