Method for preparing titanium oxide through reducing titanium-containing complexes at normal temperature

A technology of titanium complex and titanium suboxide, applied in the direction of titanium oxide/hydroxide, etc., can solve the problems of high price, small output and high manufacturing cost of titanium suboxide, and achieve the elimination of explosion hazards, low raw material cost, high temperature and the effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

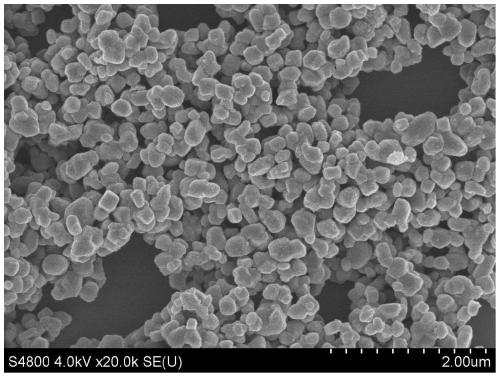

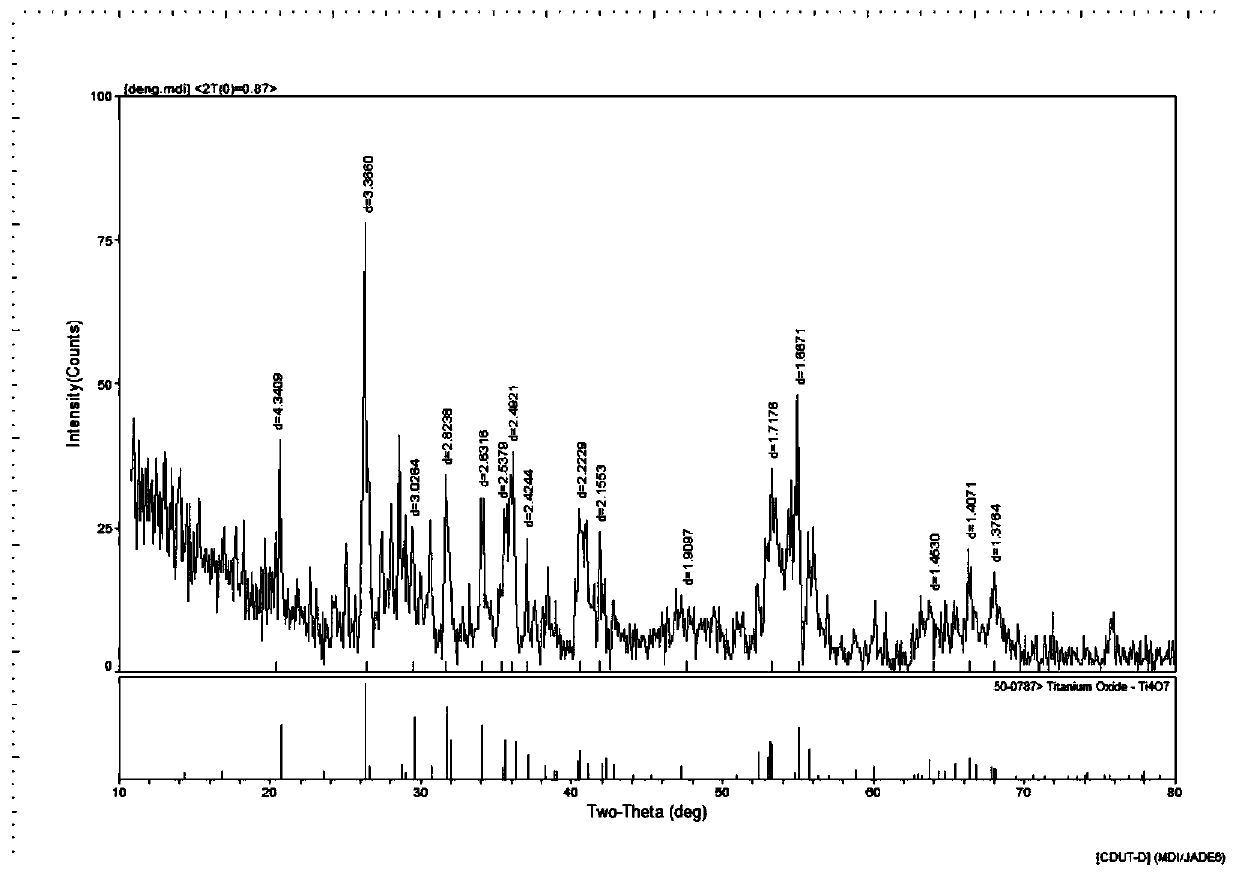

[0031] Embodiment 1: Get the titanium sulfate solution that measures 1 mole with titanium dioxide, add ammoniacal liquor to observe that precipitation is complete, pH7, obtain orthotitanic acid white precipitation; The above-mentioned orthotitanate Ti(OH) 4 Wash the precipitate with 5 times the volume of deionized water to remove sulfate and ammonium ions to obtain pure orthotitanic acid; add 2.5 moles of oxalic acid and 5 times the volume of deionized water, add pure orthotitanic acid, and stir Slowly dissolve completely; add 1 mole of zinc powder, stir the reaction until no bubbles are generated, and react for 5 hours; obtain a black solution; slowly add ammonia water to adjust the pH value of the solution to 12, and then produce a brown to dark purple-black precipitate , washed 5 times with 5 times deionized water to obtain pure titanium hydroxide precipitate mainly composed of purple trivalent titanium; add oxalic acid and stir until the pH is 0.5; The precipitate was drie...

Embodiment 2

[0032] Embodiment 2: Get the titanium sulfate solution that measures 1 mole with titanium dioxide, add ammoniacal liquor to observe that precipitation is complete, pH8, obtain orthotitanic acid white precipitation; The above-mentioned orthotitanate Ti(OH) 4 Wash the precipitate with 4 times the volume of deionized water to remove sulfate and ammonium ions to obtain pure orthotitanic acid; add 2 moles of oxalic acid and 3.5 times the amount of deionized water, put in pure orthotitanic acid, and stir Slowly dissolve completely; add 0.5 mole of zinc powder, stir the reaction until no bubbles are generated, react for 4 hours; obtain a black solution; slowly add ammonia water to adjust the pH value of the solution to 12, and then produce a brown to dark purple-black precipitate , washed 4 times with 4 times deionized water to obtain pure titanium hydroxide precipitate mainly composed of purple trivalent titanium; add oxalic acid and stir until the pH is 1.0; The precipitate was dri...

Embodiment 3

[0033] Embodiment 3: Get the titanium sulfate solution that measures 1 mole with titanium dioxide, add sodium hydroxide to observe that precipitation is complete, pH9, obtain orthotitanic acid white precipitation; The above-mentioned orthotitanate Ti(OH) 4 Wash the precipitate with 5 times the volume of deionized water to remove sulfate and sodium ions to obtain pure orthotitanic acid; add 2.5 moles of citric acid to 5 times the volume of deionized water, add pure orthotitanic acid, and stir Add 1 mole of zinc powder, stir the reaction until no bubbles are produced, and react for 5 hours; obtain a black solution; slowly add ammonia to adjust the pH value of the solution to 12, and then produce brown to deep purple black Precipitate, washed 5 times with 5 times deionized water to obtain pure titanium hydroxide precipitate mainly composed of purple trivalent titanium; add oxalic acid and stir until the pH is 0.5; The titanium precipitate was dried at 180°C for 3 hours until no o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com