Patents

Literature

43results about How to "Improve micro-uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal deformation rare-earth permanent magnet material and preparation method thereof

ActiveCN106548844APromote formationEasy to optimizeInductances/transformers/magnets manufactureMagnetic materialsMass ratioRare earth

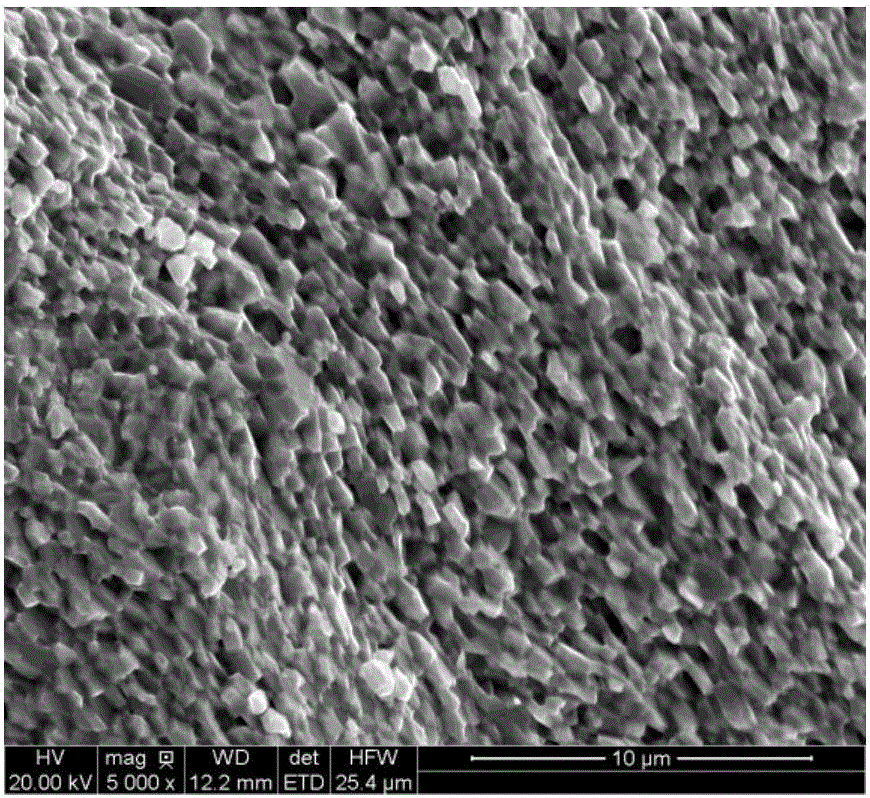

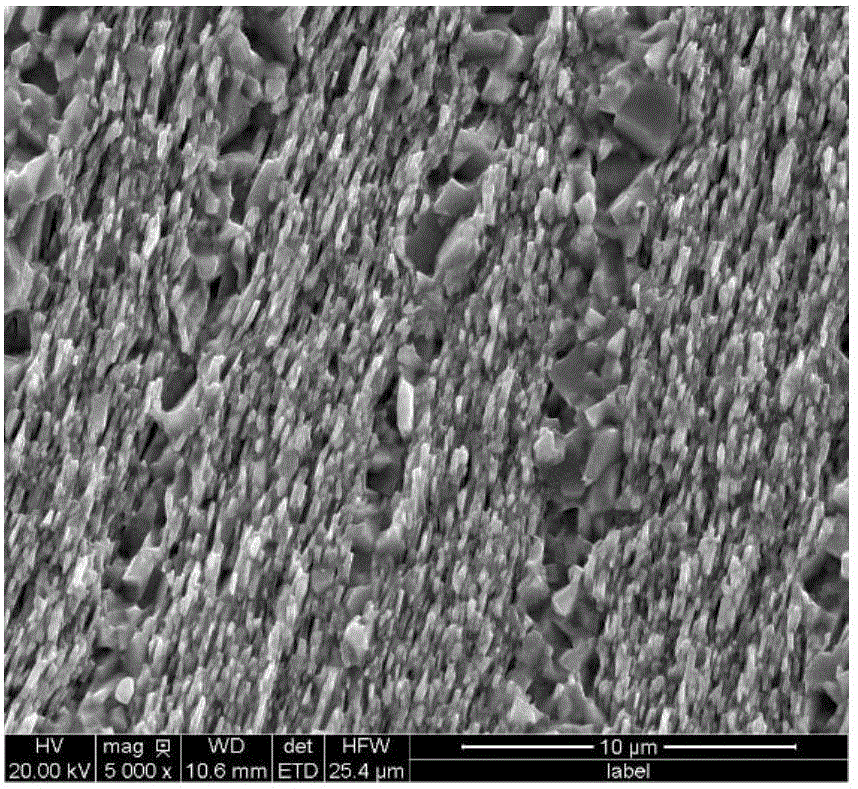

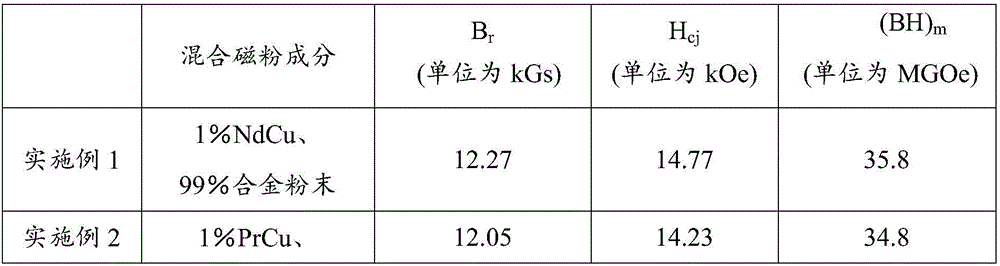

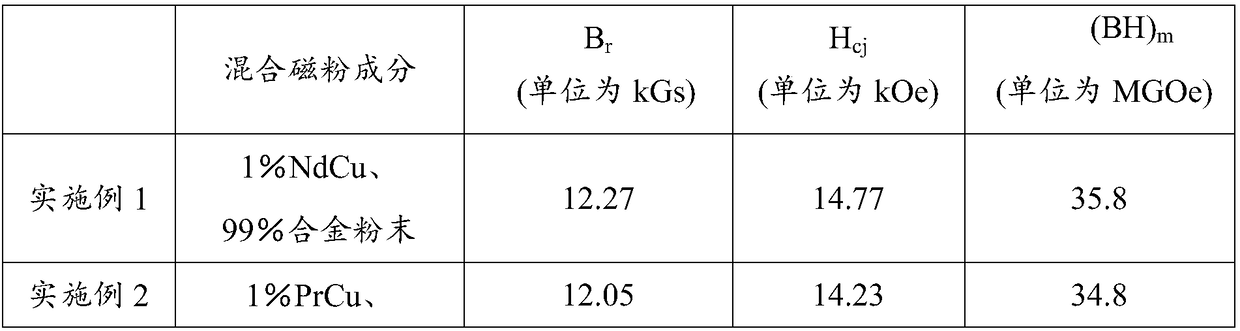

The invention relates to a preparation method of a thermal deformation rare-earth permanent magnet material. The method comprises the following steps of (1) providing main magnetic powder and low-melting-point alloy powder separately, wherein a chemical formula of the main magnetic powder is Re<x>Fe<100-x-y-z>M<y>B<z> according to the mass percent, the chemical formula of the low-melting-point alloy powder is ReCu<100-a>, Re is one or more of Nd, Pr, Dy, Tb, La and Ce and a is smaller than or equal to 90 and greater than or equal to 60; (2) mixing the main magnetic powder with the low-melting-point alloy powder evenly to obtain mixed magnetic powder, wherein the mass ratio of the low-melting-point alloy powder in the mixed magnetic powder is greater than 0 and smaller than or equal to 10%; (3) carrying out hydrogenation-disproportionation-dehydrogenation-recombination treatment on the mixed magnetic powder and diffusing a low-melting-point alloy in the treatment process to obtain HDDR magnetic powder; and (4) sequentially carrying out hot-press molding and deformation molding on the HDDR magnetic powder to obtain the thermal deformation rare-earth permanent magnet material. The invention further provides the thermal deformation rare-earth permanent magnet material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

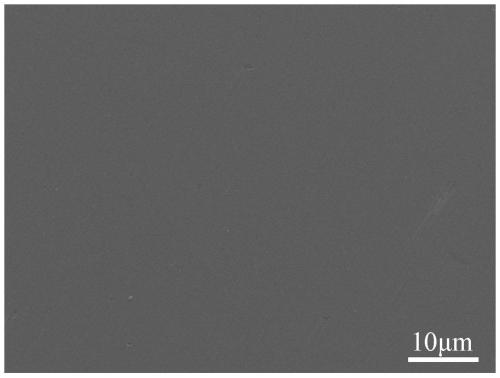

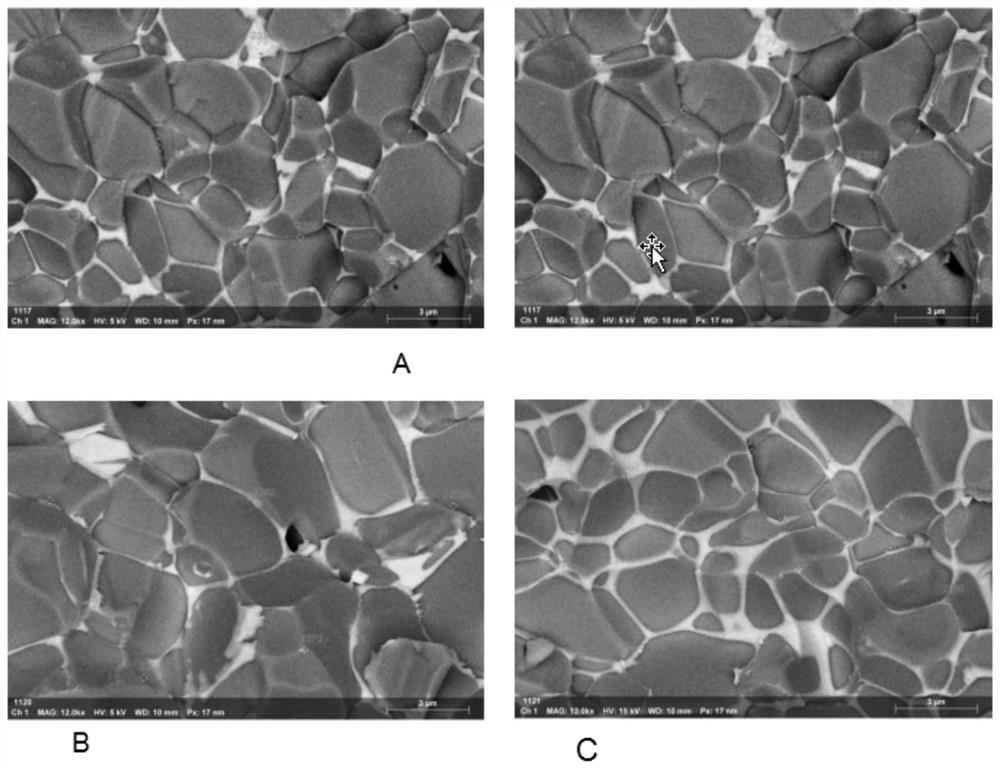

Method for preparing high-compact ITO target material through two-step sintering

ActiveCN106977179AShort sintering timeImprove micro-uniformityAir atmosphereUltimate tensile strength

The invention discloses a method for preparing a high-compact ITO target material through two-step sintering. The method comprises the following steps: firstly manufacturing the raw material into a biscuit, keeping warm and degreasing under the air atmosphere, directly placing under the air atmosphere to warm to 800-1300 DEG C after the degreasing and keeping warm for 5-30 hours to perform the first step of pre-sintering; placing the pre-sintered green body on a sintering bearing plate, warming to 1500-1600 DEG C and keeping warm for 5-30 hours under the oxygen atmosphere so as to perform the second step of sintering; stopping introducing the oxygen 1-5 hours before finishing the sintering; and performing furnace cooling to obtain an ITO target sintering body. The pre-sintering is performed under the air atmosphere so that the sintering time of the oxygen atmosphere can be shortened, the production energy consumption is greatly lowered; the degreasing and the pre-sintering process are integrated so that the sintering total time is saved; the pre-sintering enables the particles in the green body to be further homogenized, the abnormal crystal grain growth is avoided, and the microscopic homogeneity of the target is improved, and the strength and the thermal shock resistance are improved; the prepared ITO target density reaches to 7.128g / cu.cm and more.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

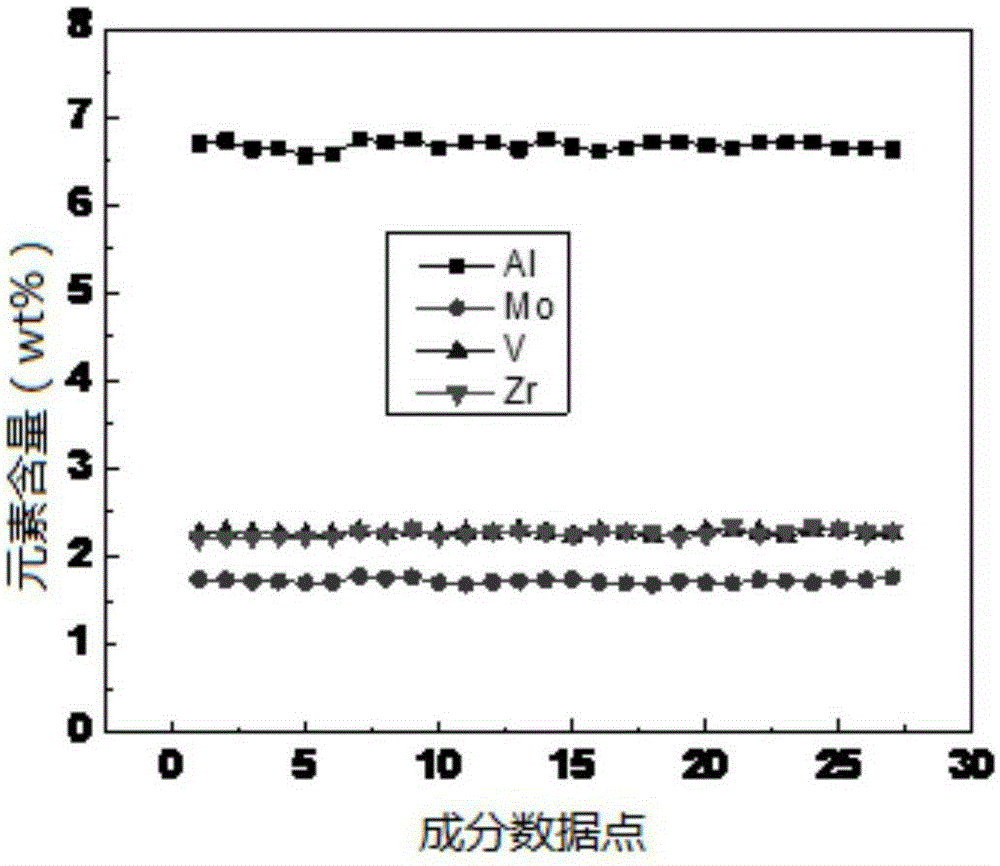

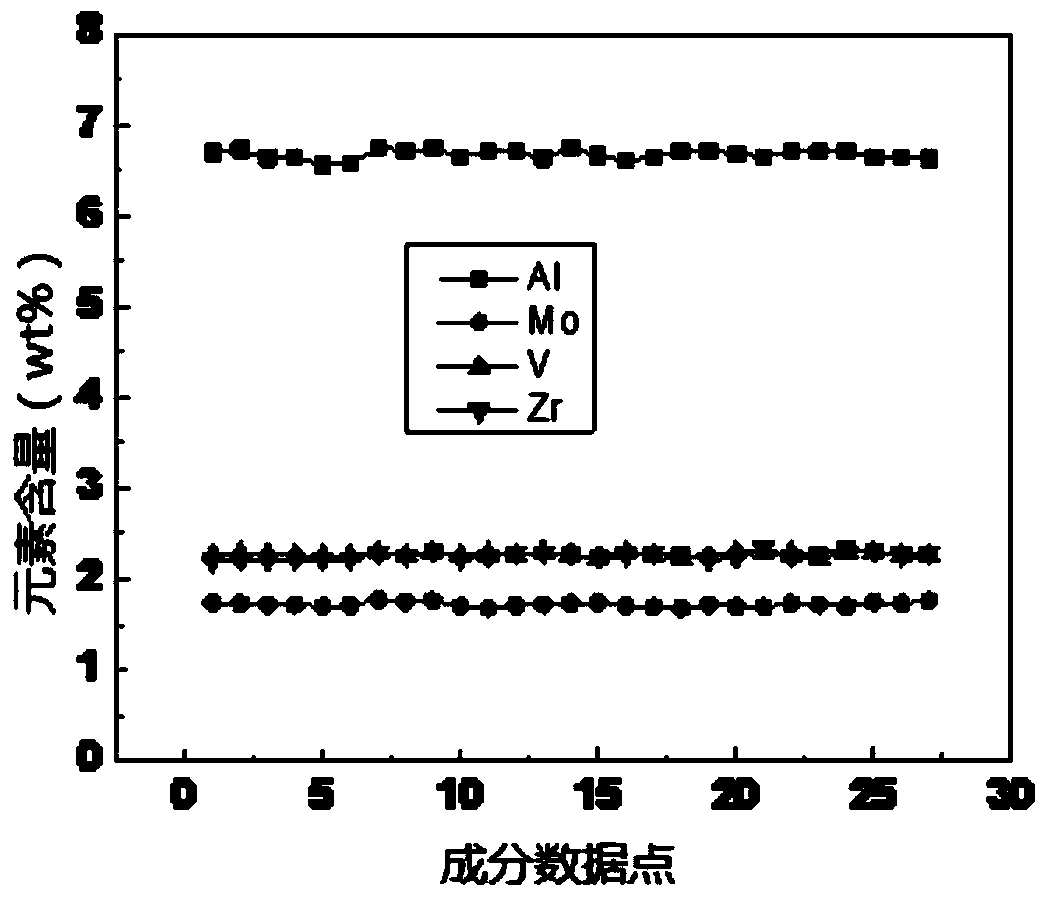

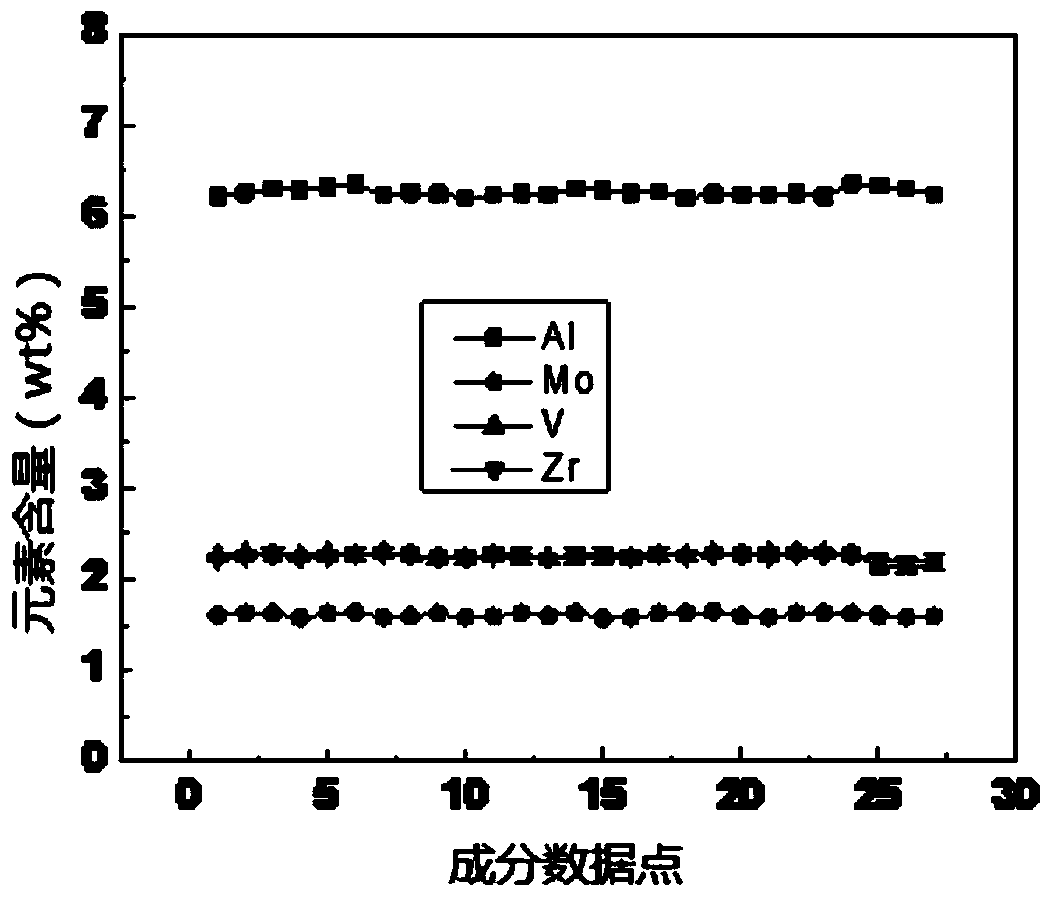

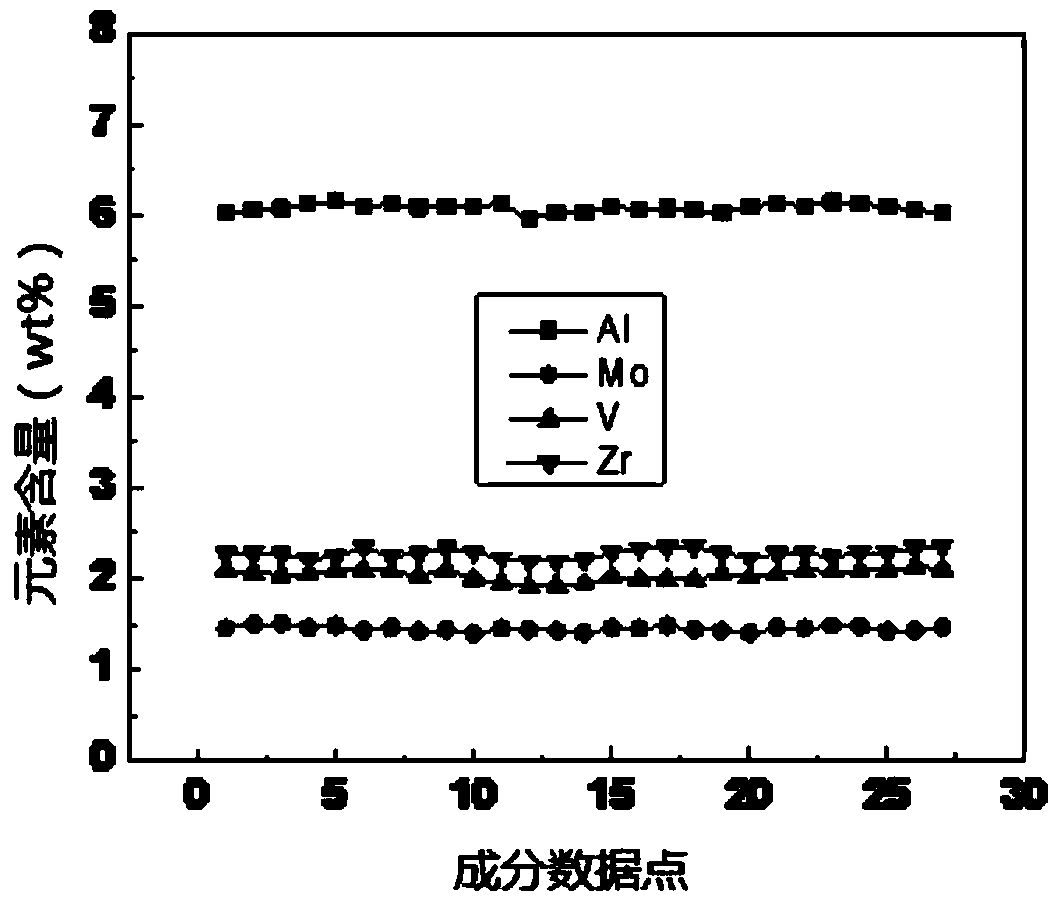

Near-alpha titanium alloy with high dynamic performance and preparation method of near-alpha titanium alloy

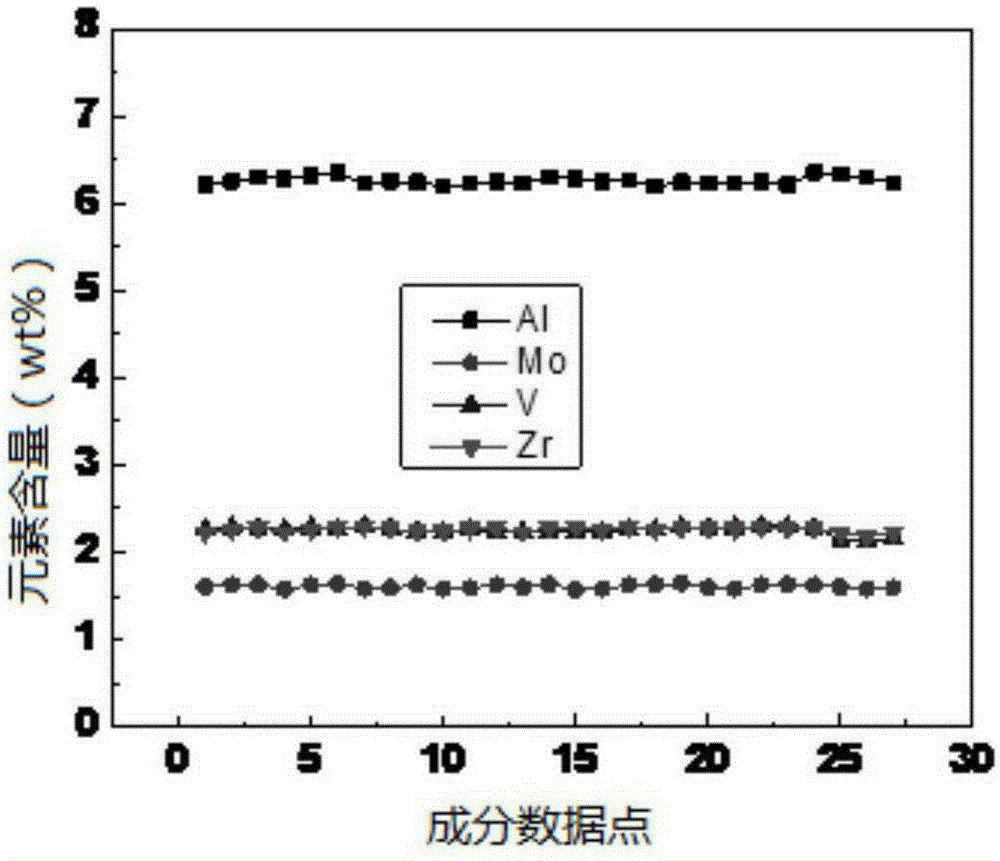

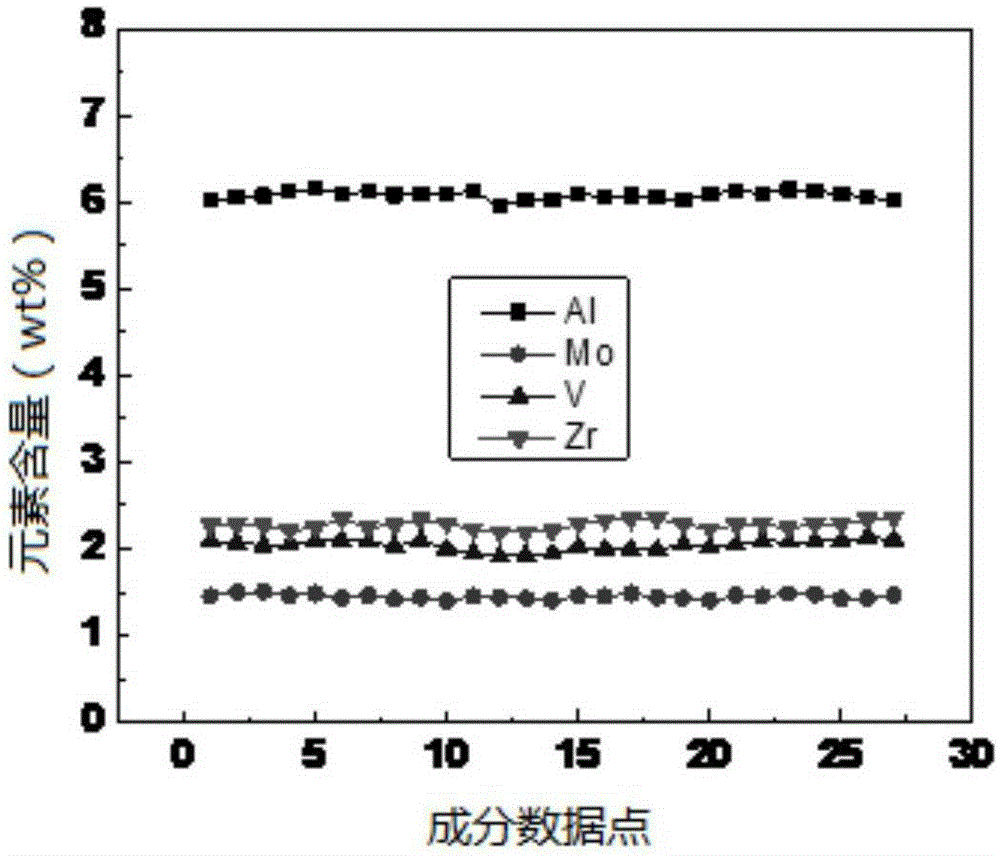

The invention discloses a near-alpha titanium alloy with high dynamic performance. The near-alpha titanium alloy is composed of, by mass percent, 5.0%-6.8% of Al, 1.5%-2.4% of Zr, 1.0%-1.9% of Mo, 1.5%-2.5% of V, 0.05%-0.30% of Fe, 0.05%-0.14% of O, and the balance Ti. The sum of the mass percents of the components is 100%. The invention further discloses a preparation method of the titanium alloy. The as-cast structure of a large cast ingot is refined and the microcosmic uniformity of cast ingot components is improved through a purification and high-homogeneity smelting method; and meanwhile, as the content of Al and the content of O are controlled, it is guaranteed that the WSTi6211F titanium alloy has enough strength, the plasticity and the toughness of the WSTi6211F titanium alloy are greatly improved, and the purpose of improving the dynamic performance of the titanium alloy is achieved in combination with a high-temperature homogenizing treatment and cyclic forging process.

Owner:西部超导材料科技股份有限公司

Silicon nitride nano-wire enhanced porous silicon nitride composite material and preparation method thereof

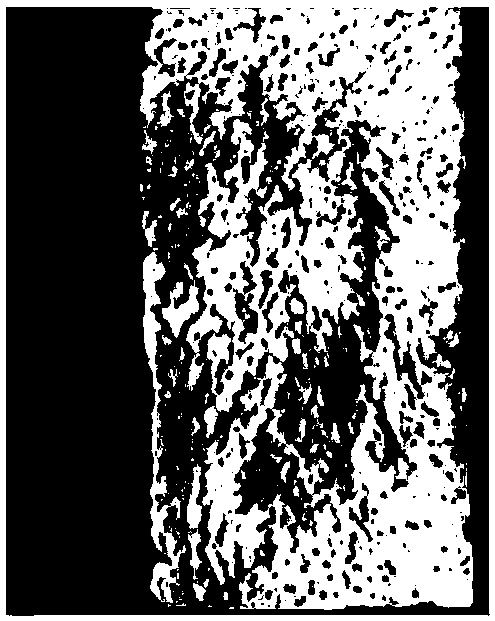

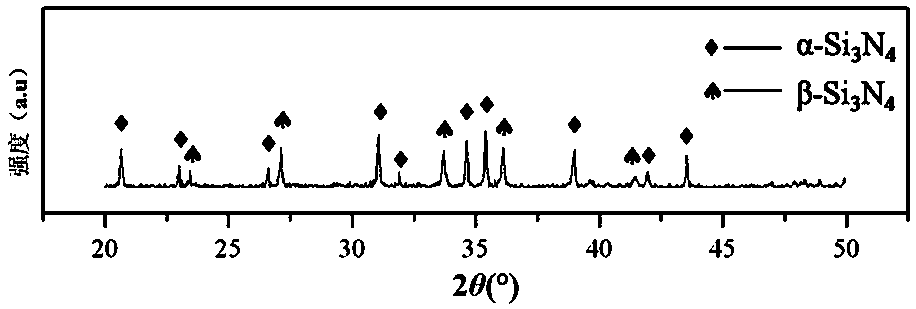

The invention discloses a silicon nitride nano-wire enhanced porous silicon nitride composite material and a preparation method thereof. The preparation method includes the steps: (1) mixing polymer monomers, cross-linking agents, dispersing agents, pore-forming agents and deionized water, mixing silicon nitride ceramic powder, silicon monoxide, nano-wire catalysts, sintering additives and mixed solution, and then performing ball-milling in advance; (2) adjusting a pH (potential of hydrogen) value of obtained premixed slurry to 9.5-11.5, performing ball milling and vacuum degassing, and mixingthe slurry and initiating agents; (3) performing injection molding by the aid of obtained injection molding slurry, and performing demolding, drying and rubber discharging; (4) sintering silicon nitride ceramic blanks in a protective atmosphere to obtain the composite material. The method has the advantages that the positions and the quantity of the nano-wires can be controlled, complicated shapes and molding of large components can be adapted, devices are simple, a process is safe and controllable and the like. Correspondingly, the prepared composite material is high in fracture toughness.

Owner:NAT UNIV OF DEFENSE TECH

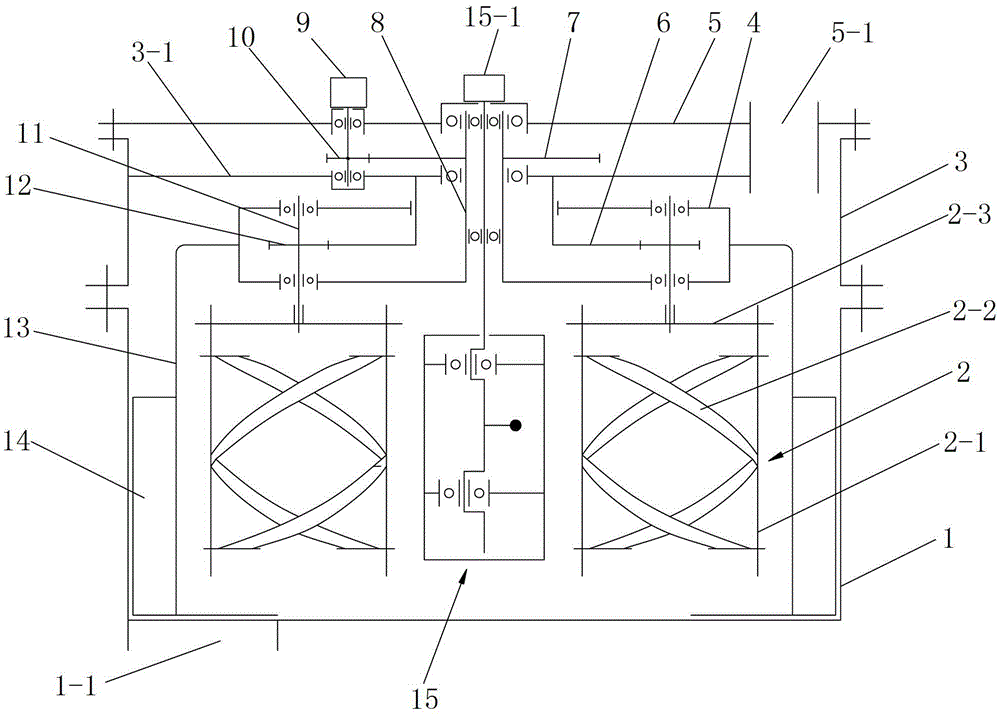

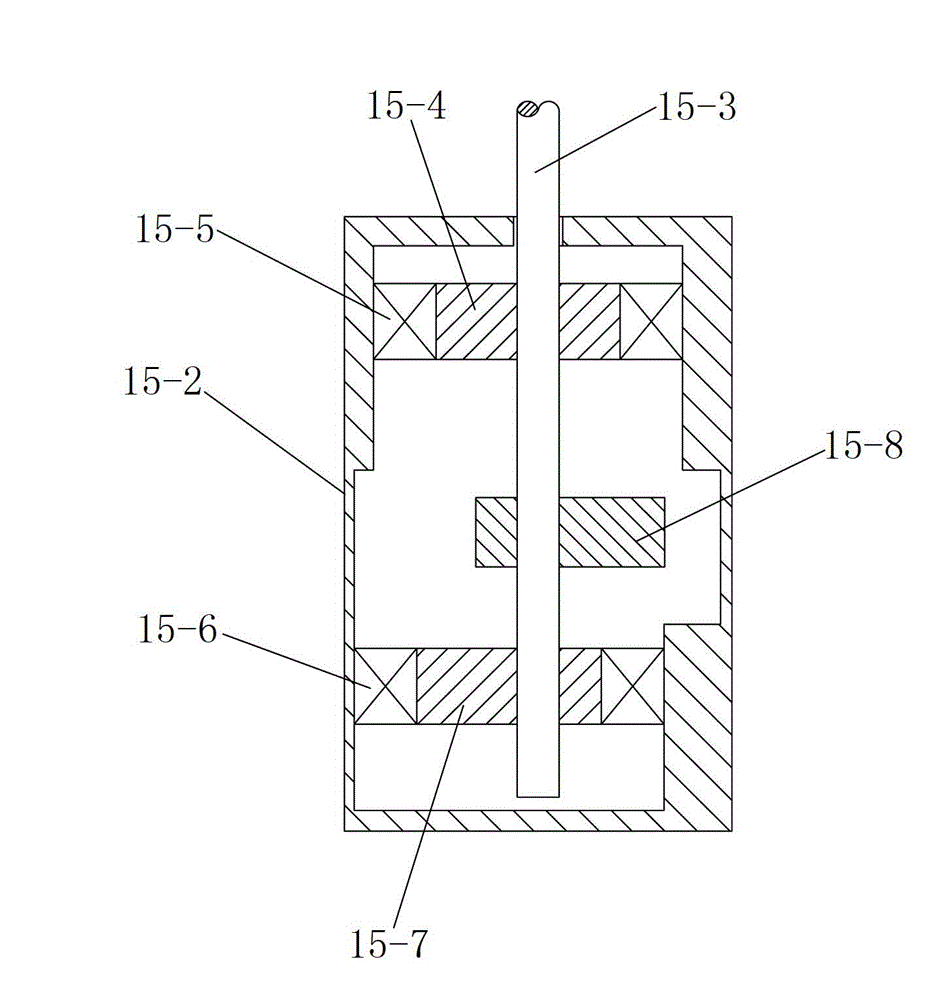

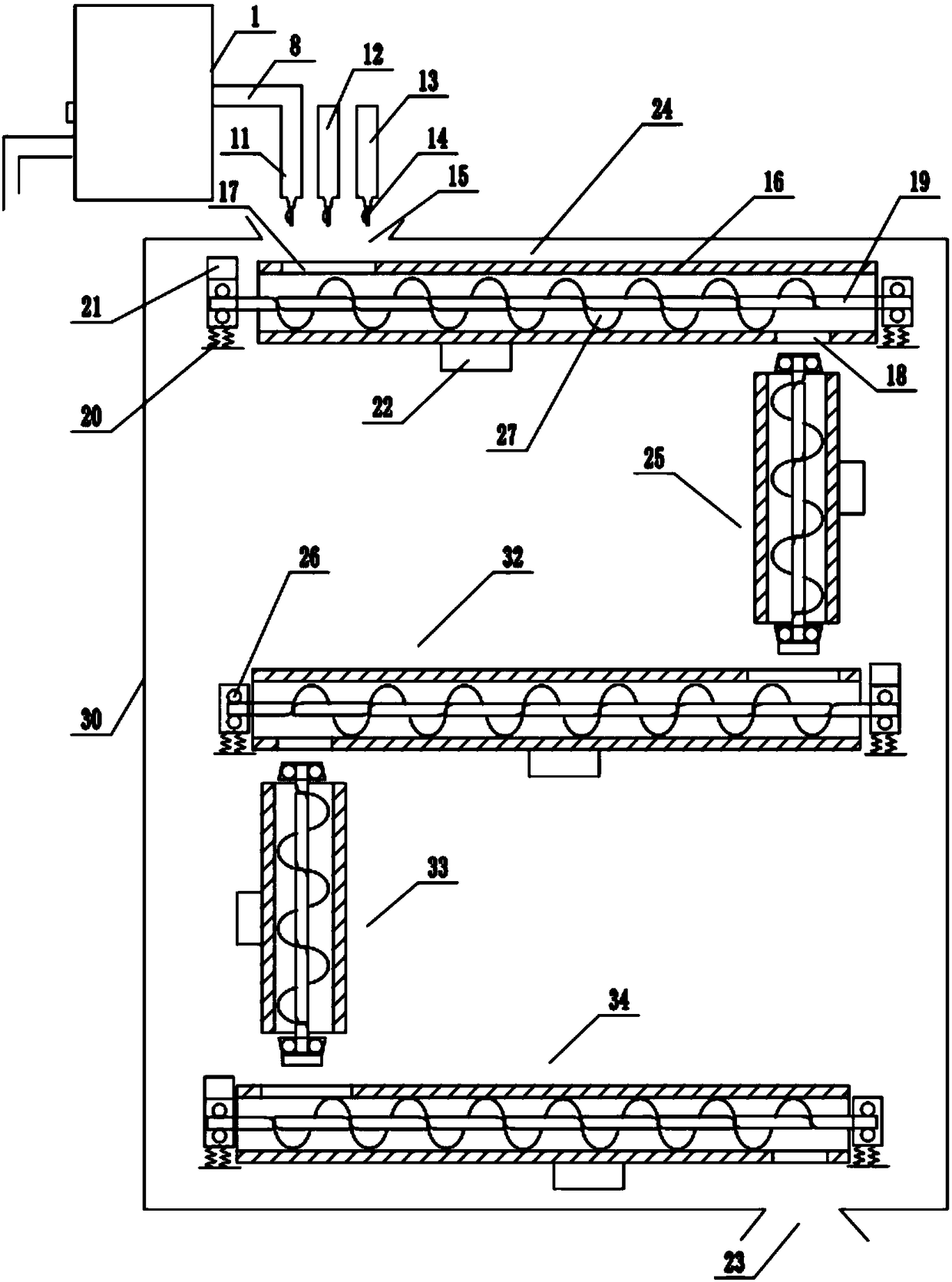

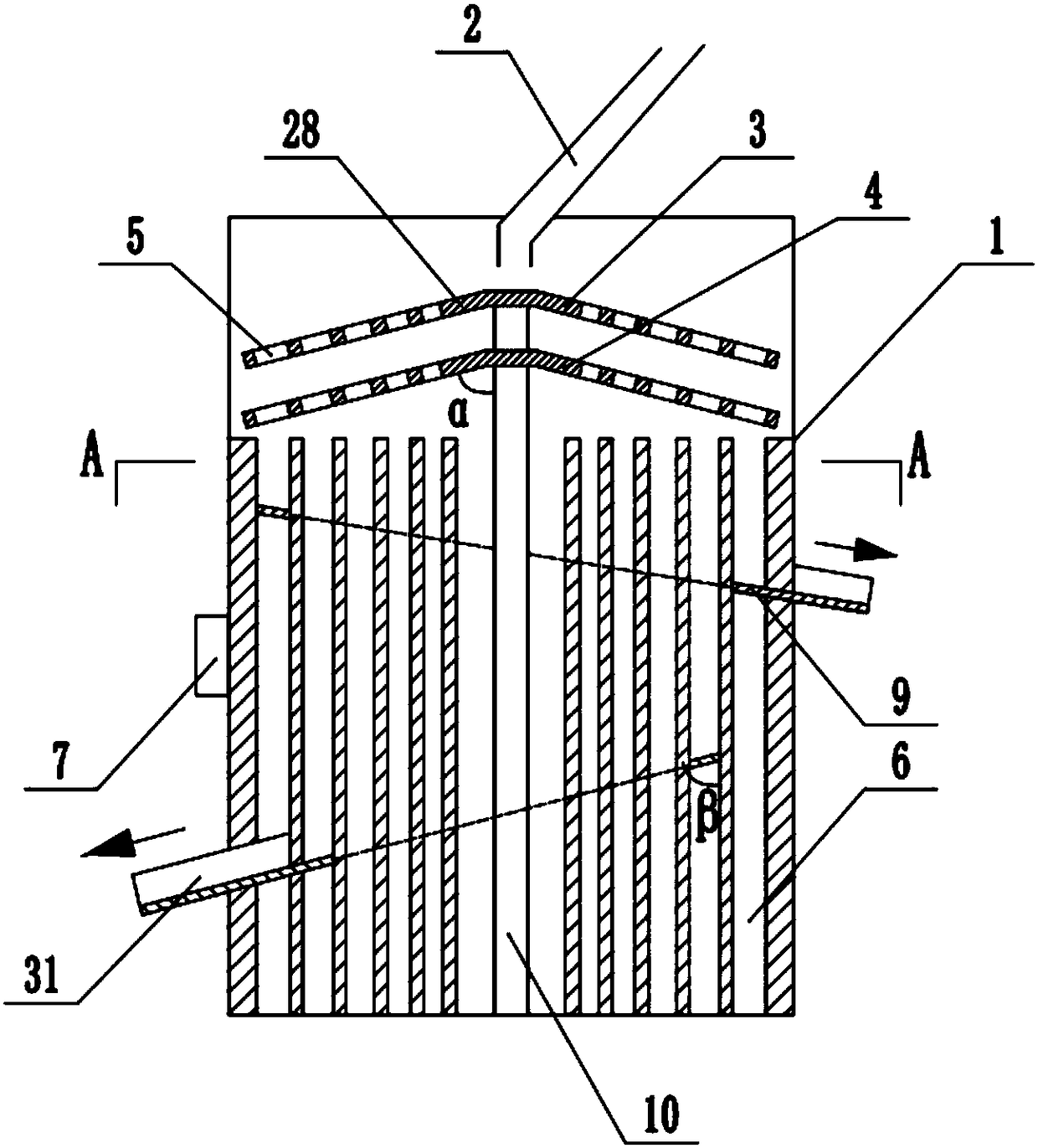

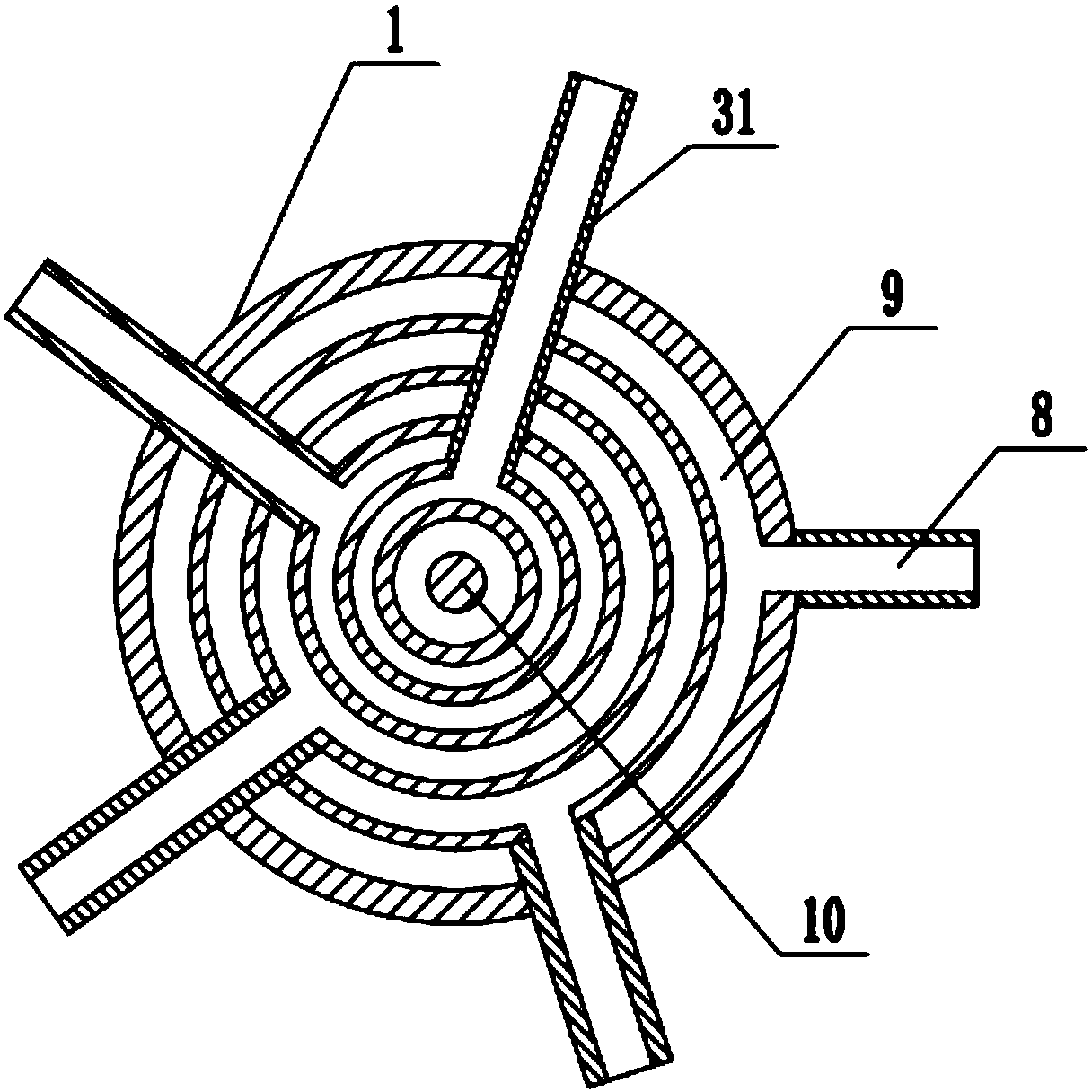

Planetary concrete mixer

InactiveCN102975287ASimple structureNovel and reasonable designCement mixing apparatusGear wheelEpicyclic gearing

The invention discloses a planetary concrete mixer, which comprises a lower barrel body and a plurality of helical ribbon mixing devices, wherein a middle barrel body is connected to the upper part of the lower barrel body; a planetary gear mechanism is arranged in the middle barrel body; a cover plate is arranged at the upper end of the middle barrel body; a mixing drive device is arranged on the cover plate; a mixing input shaft is rotationally connected in the middle of the cover plate; the planetary gear mechanism comprises planetary racks, sun wheels and a plurality of planetary wheels; the planetary racks are connected to the lower end of the mixing input shaft; the sun wheels are sleeved on the mixing input shaft; the upper ends of the sun wheels are connected with the middle barrel body; planetary wheel shafts are arranged on the planetary racks; the planetary wheels are mounted on the planetary wheel shafts; each helical ribbon mixing device comprises two mixing arms; mixing helical ribbons are connected on the inner side surfaces of the two mixing arms; the upper parts of the two mixing arms are connected through a connecting plate; the lower ends of the planetary wheel shafts are connected with the connecting plates; and a vibration mechanism is arranged in the lower barrel body. According to the planetary concrete mixer, the microcosmic uniformity of concrete can be effectively improved.

Owner:CHANGAN UNIV

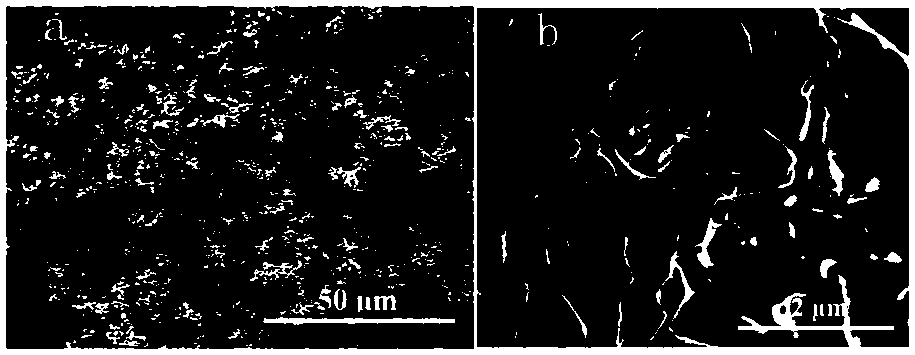

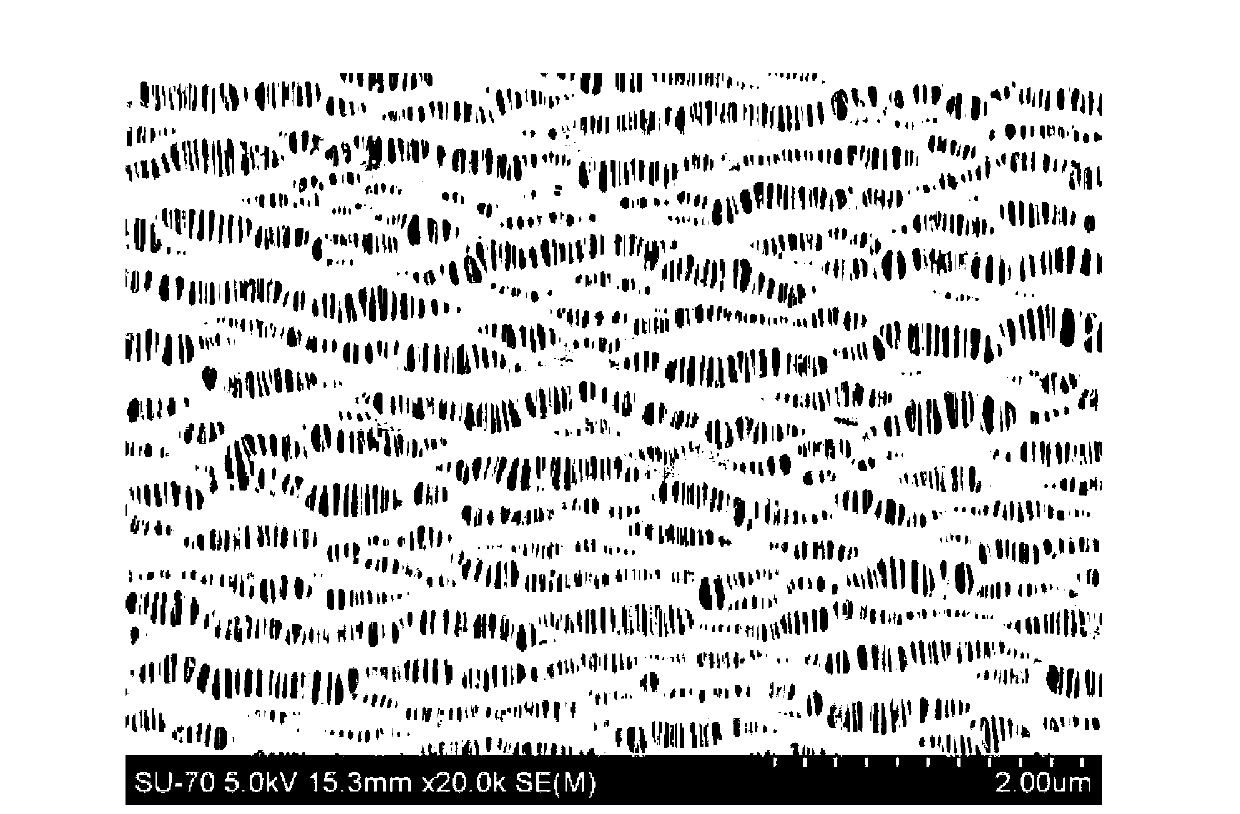

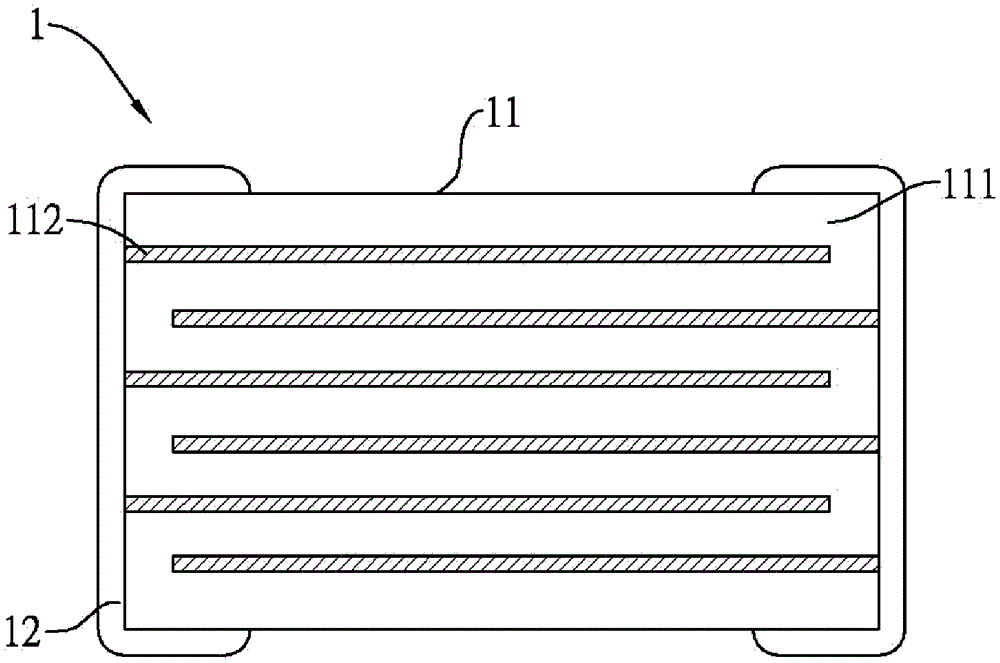

Polypropylene microporous membrane and preparation method thereof

The invention discloses a polypropylene microporous membrane and a preparation method and an application thereof. The polypropylene microporous membrane provided by the invention is composed of, by weight, 80-90% of a first component and 10-20% of a second component. The first component is polypropylene with weight average molecular weight of 2*10<5>-5*10<5>. The second component is polypropylene with weight average molecular weight of 5*10<4>-1*10<5>. According to the invention, the polypropylene microporous membrane is prepared from a mixed raw material of high-molecular-weight polypropylene and low-molecular-weight polypropylene, such that the micro-pore size and distribution of the polypropylene microporous membrane are uniform. Also, microporous membrane performances such as transverse and longitudinal tensile strength, puncture strength, porosity and thermal shrinkage reach good homogeneity. The polypropylene microporous membrane provided by the invention can satisfy applications with high requirements on microporous membrane pore-forming uniformity, and is especially suitable to be used in the field of battery separator.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

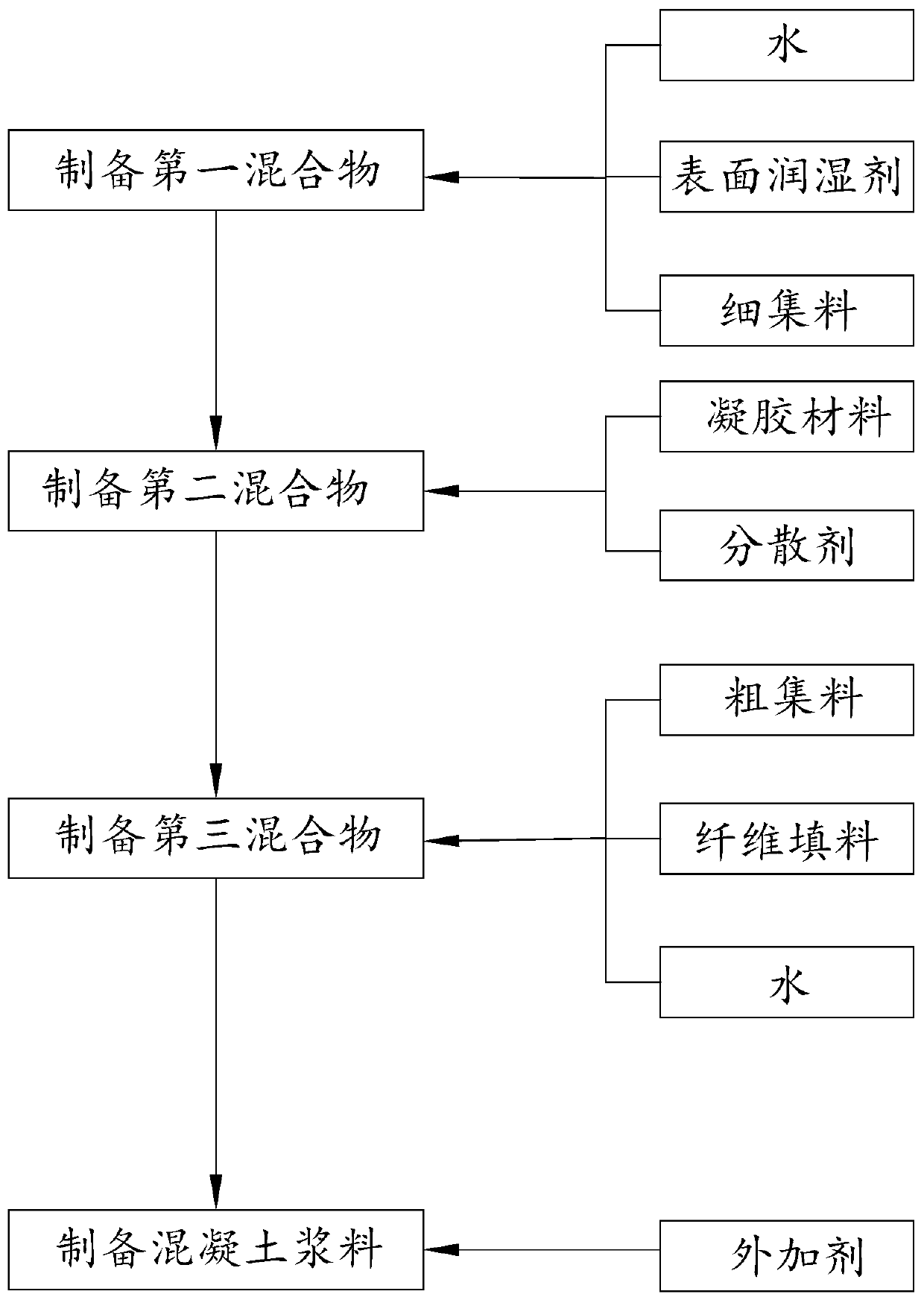

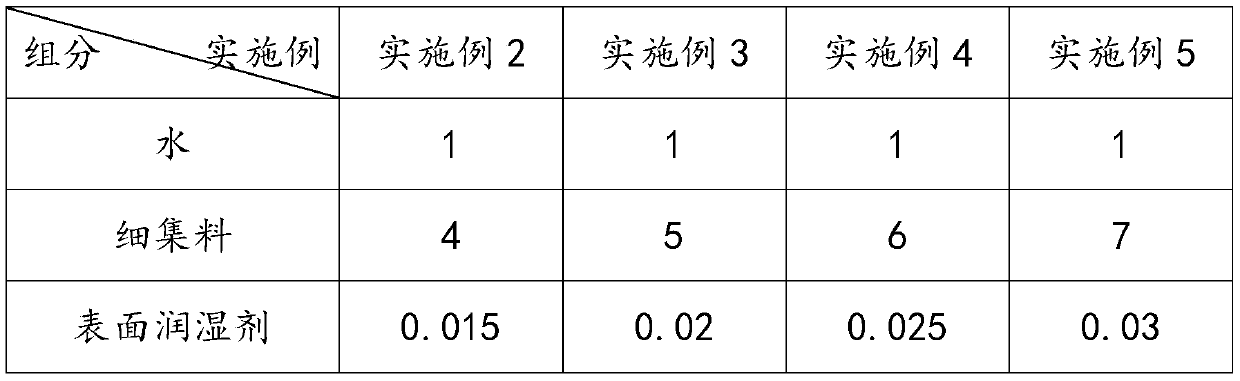

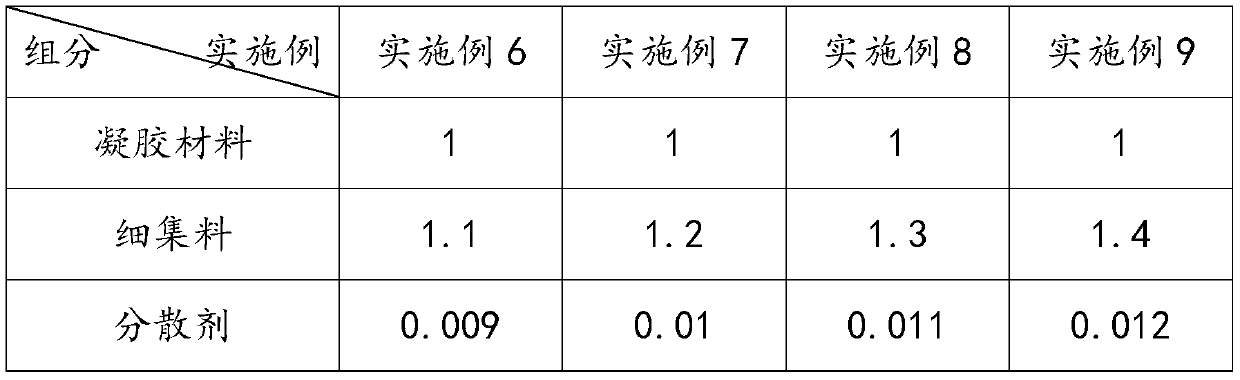

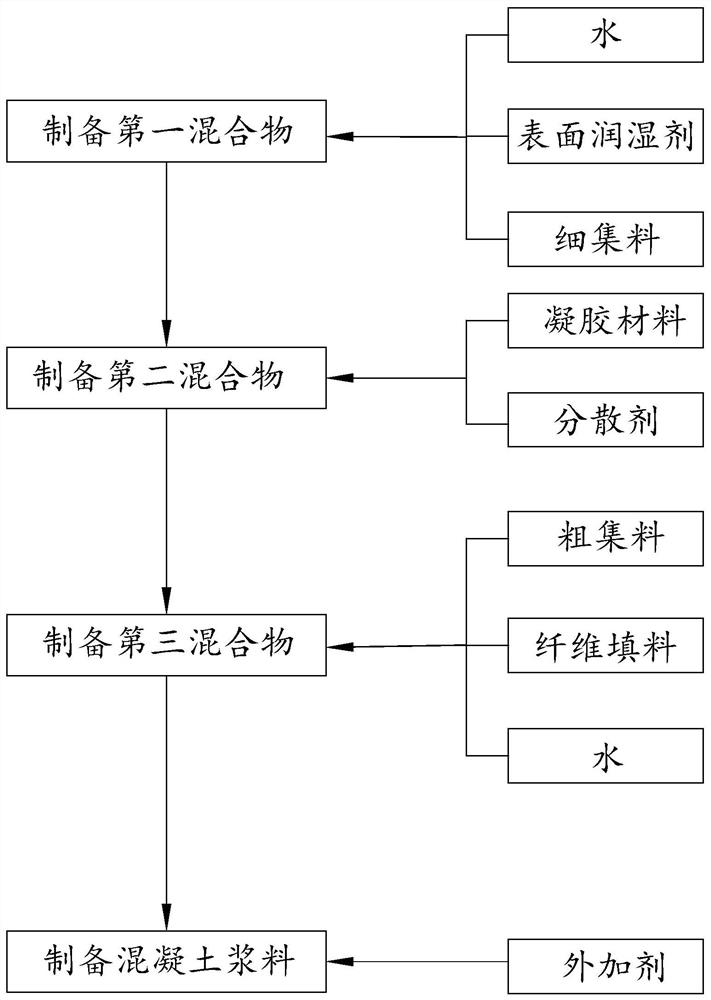

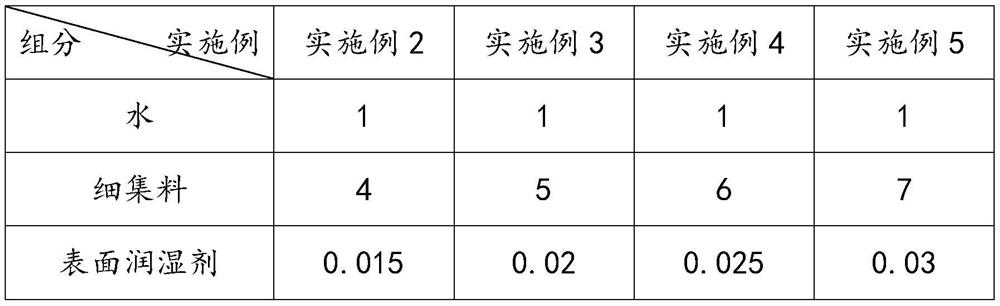

Concrete preparation process

The invention relates to a concrete preparation process, which comprises the following process steps: s1, uniformly stirring water and a surface wetting agent, adding a fine aggregate, and uniformly stirring to obtain a first mixture; wherein the weight ratio of water, fine aggregate and surface wetting agent is 1: (3-7): (0.01-0.03); s2, adding a gel material and a dispersant into the first mixture, and uniformly stirring to obtain a second mixture; wherein the weight ratio of gel material, fine aggregate and dispersant is 1: (1-1.4): (0.008-0.012); s3, adding a coarse aggregate, a fiber filler and water into the second mixture, and uniformly stirring to obtain a third mixture; wherein the weight ratio of fine aggregate, coarse aggregate, fiber filler and water is 1: (2-2.4): (0.06-0.1):(0.08-0.12); and s4, adding an additive into the third mixture and uniformly stirring to prepare concrete slurry; wherein the weight ratio of additive to fine aggregate is (0.02-0.03): 1. The workability and working performance of the mixed soil are improved by reasonably setting the feeding sequence of concrete raw materials.

Owner:四川信敏绿色新建筑材料科技有限公司

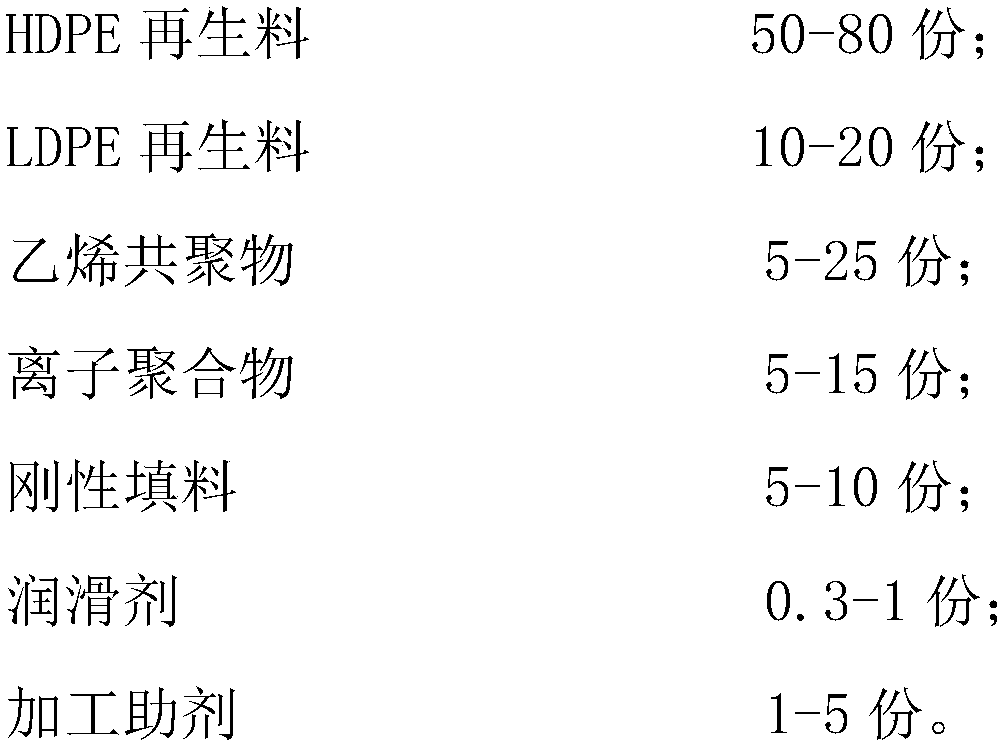

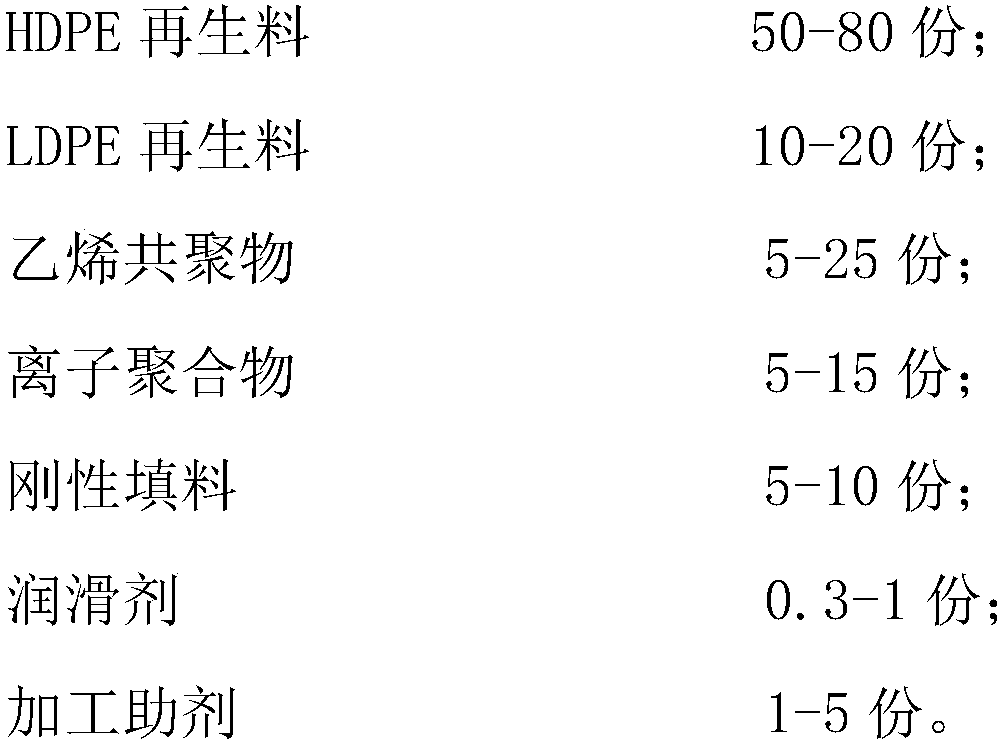

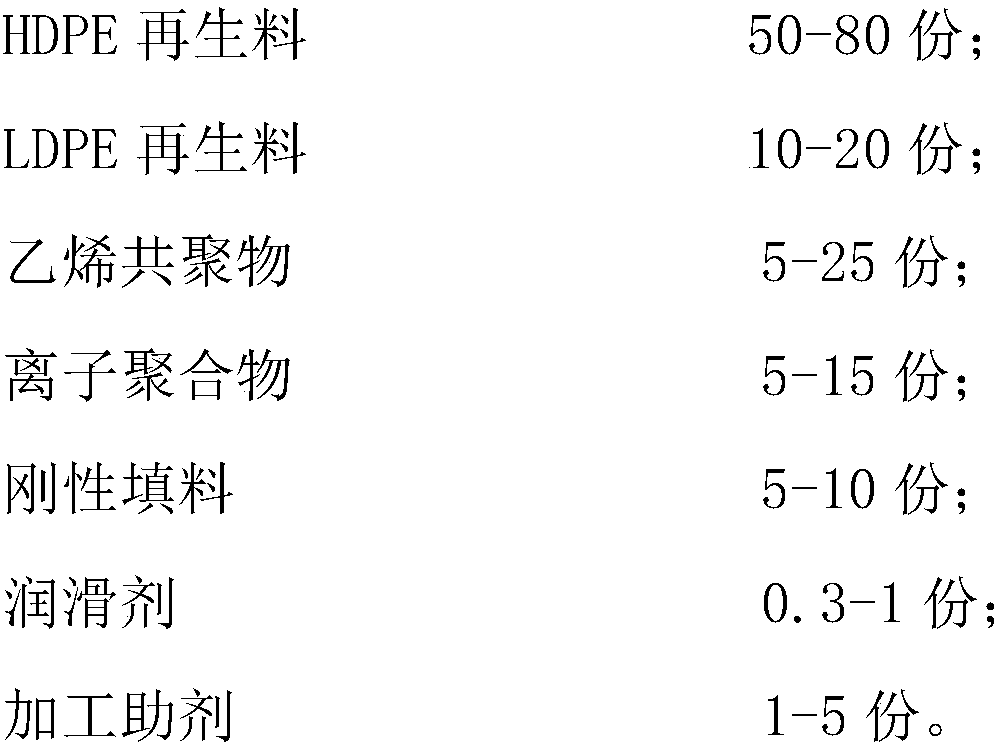

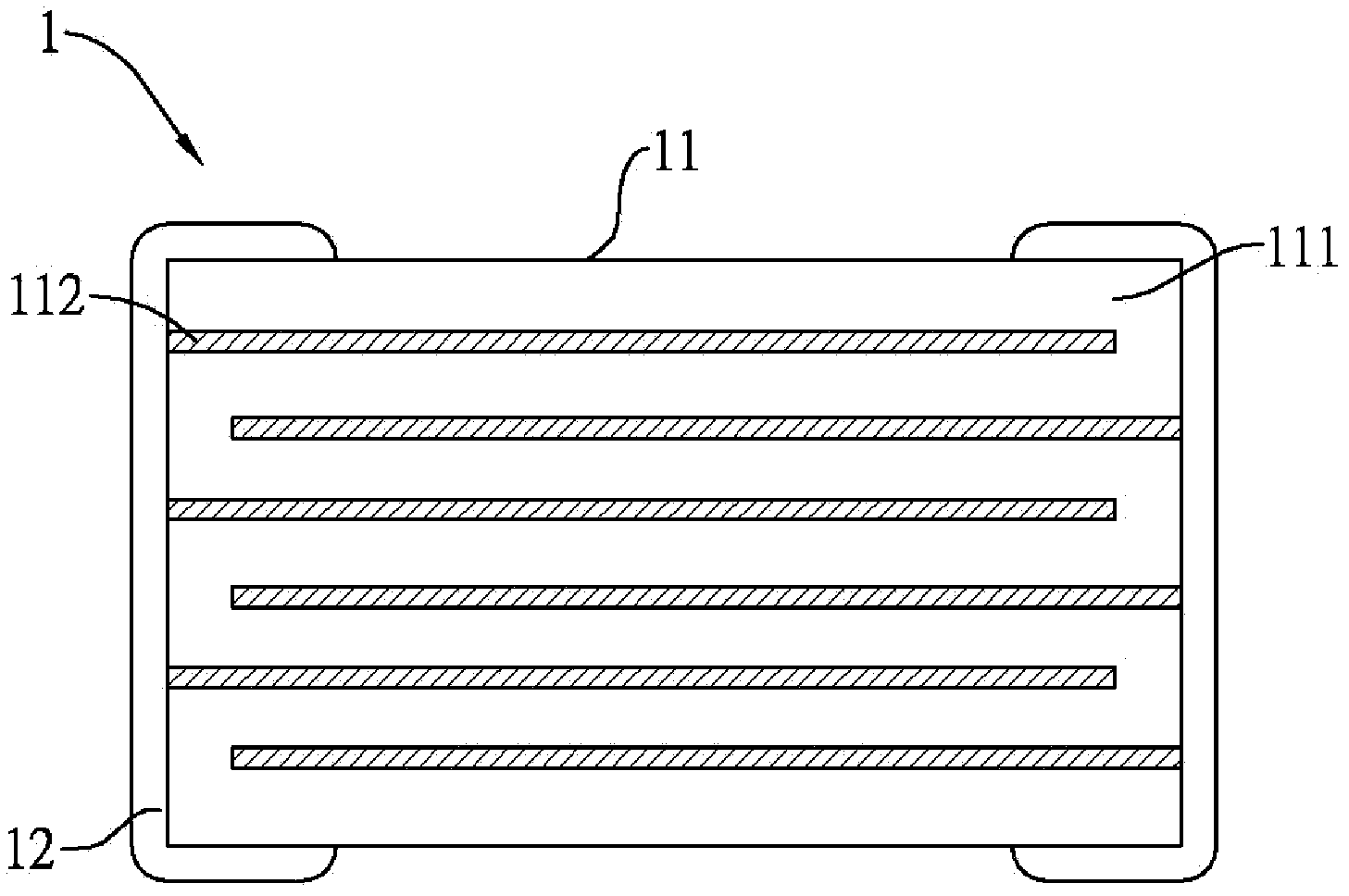

Modified recyclable recycled high-impact-resistant PE (Polyethylene) applied tofor plastic tray and preparation method thereof

The invention is suitable for the technical field of resource recycling, and provides a modified recyclable recycled high-impact-resistant PE (Polyethylene) and a preparation method thereof. The modified recyclable recycled high-impact-resistant PE is characterized in that: PE waste plastic is prepared by adopting multipathobtained by recycling through multiple ways, wherein the total proportion of the recyclable recycled plastic and the stuffing is 90 percent or more, ethylene copolymer and ionic polymer are added, and rigid inorganic particles are added, so that a material is enhanced, meanwhile, the toughness and abrasion resistance of the material can be improved greatly; the impaction resistance of the prepared modified recyclable recycled particles is increased by 1 to 2 times compared withhigher than the conventional recyclable particles; moreover, the inorganic stuffing can be added, thereby improving the rigidity of the material is improved, meanwhile, the material is taken asthe stuffing, so thatand reducing the cost of the material is lowered; the plastic tray has the advantages of low preparation cost and high plastic tray performance.

Owner:GEM WUHAN URBAN MINE RECYCLING IND PARK DEV +1

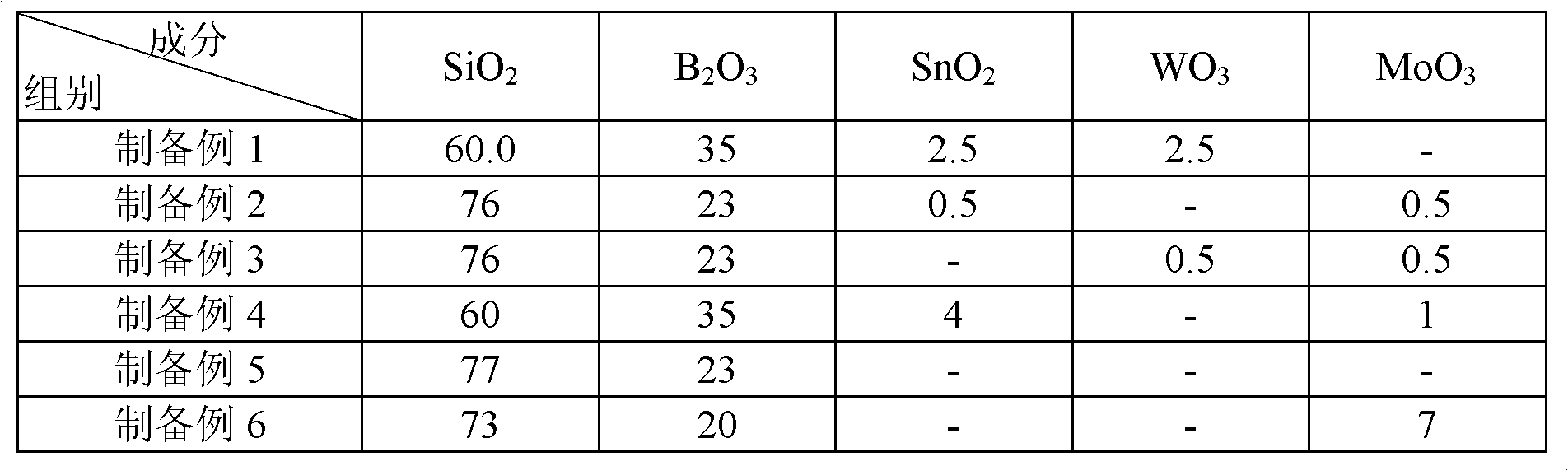

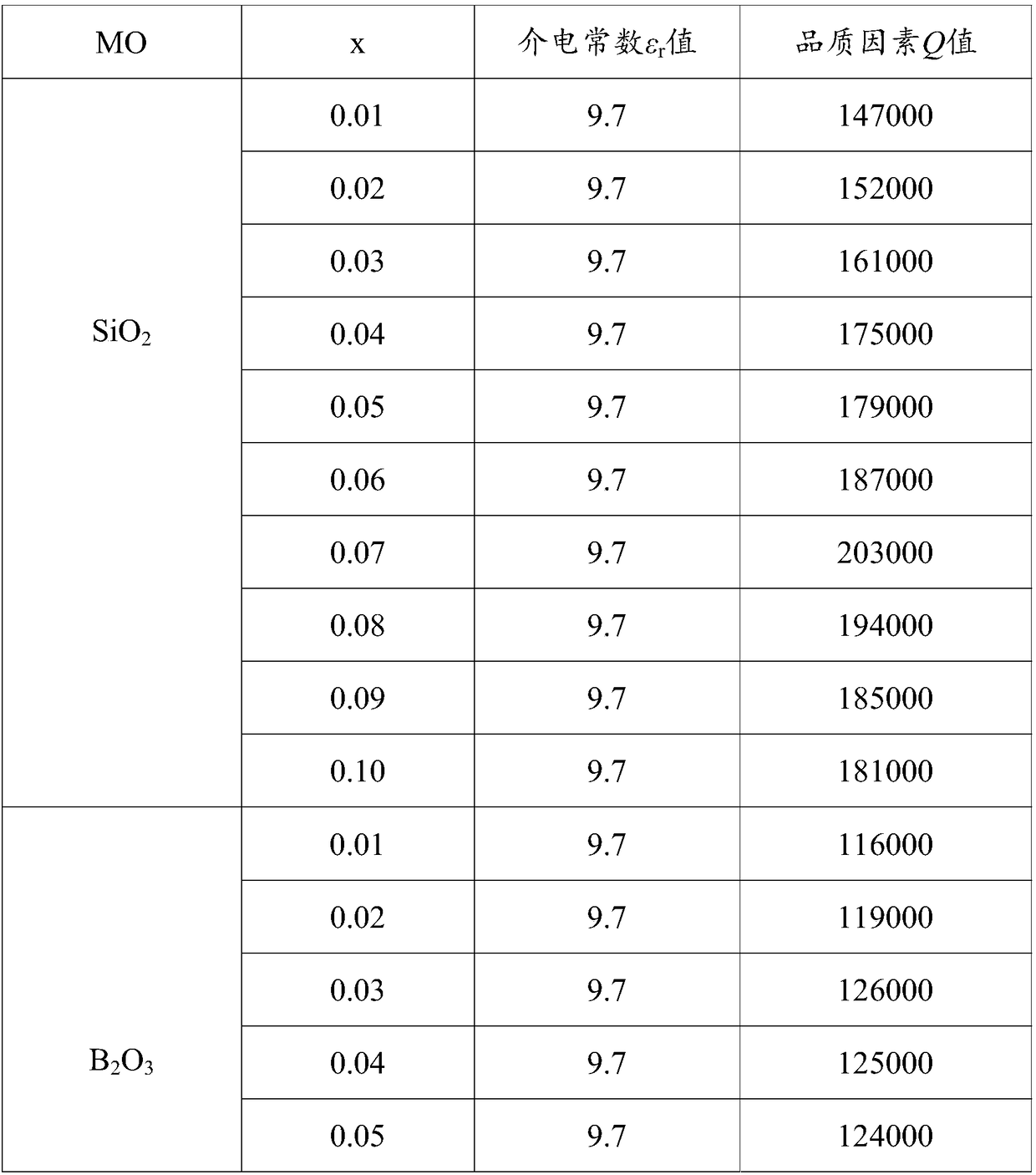

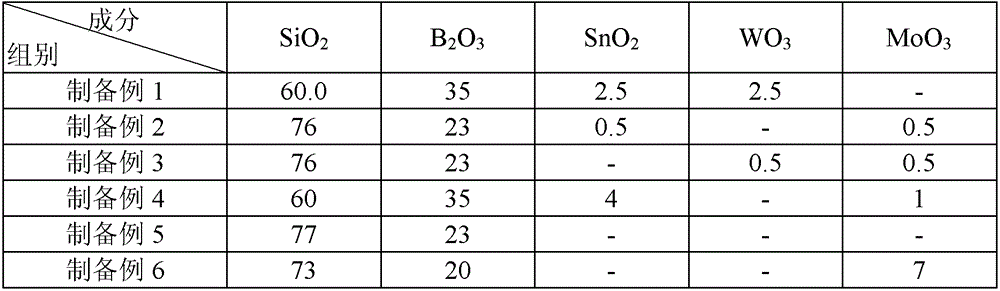

Sintering additive composition and dielectric ceramic composition, and applications thereof

ActiveCN103073305AHigh mechanical strengthImprove the immunityFixed capacitor dielectricTin dioxideCeramic capacitor

The invention relates to a sintering additive composition comprising silica, boron trioxide, and at least two modification components selected from the group comprising tungsten trioxide, molybdenum trioxide and tin dioxide. Calculated according to a total amount of the sintering additive composition as 100mol, the content of silica is 60-85mol, the content of boron trioxide is 10-35mol, and the content of the at least two modification components is 0.1-5mol. Also, the invention relates to a dielectric ceramic composition comprising the sintering additive composition. The invention also relates to a laminated ceramic capacitor comprising the dielectric ceramic composition. The composition has an excellent low-temperature sintering property, such that the reliability of the capacitor can be improved.

Owner:DONGGUAN HUAKE ELECTRONICS

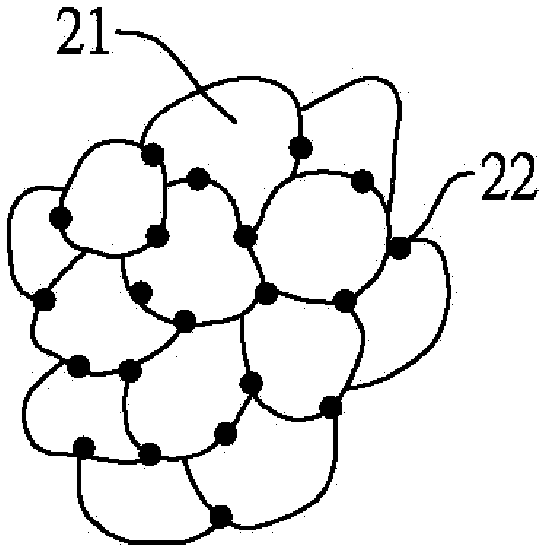

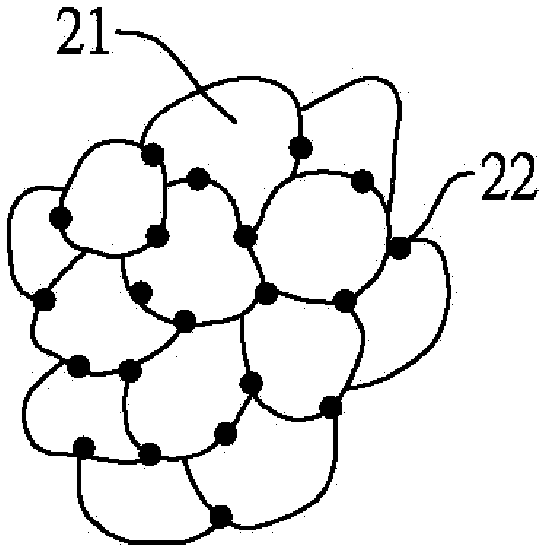

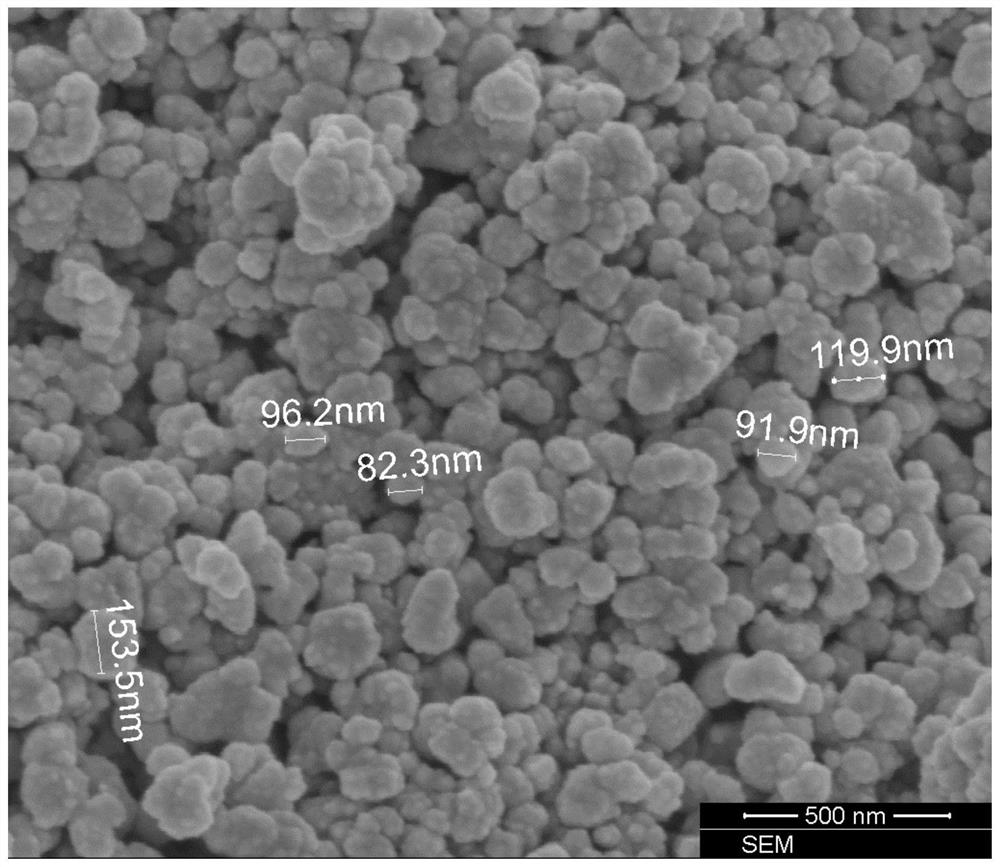

Nano-ZnO varistor composite powder material and preparation method thereof

InactiveCN104193320AImprove stabilityRaise the potential gradientAqueous solutionParticle-size distribution

The invention relates to a nano-ZnO varistor composite powder material and a preparation method thereof. The material is composed of ZnO, Co2O3, Bi2O3, Sb2O3 and Y2O3. The preparation method adopts a chemical coprecipitation method and particularly comprises the following steps: adding ZnO, Bi2O3, Co2O3, Sb2O3 and Y2O3 in dilute hydrochloric acid serving as a solvent, dissolving to form a transparent solution in a constant-temperature water bath environment; dropwise adding an ammonia solution serving as a precipitant into the transparent solution at a constant speed; and precipitating, filtrating, washing, drying, grinding and calcinating, thus obtaining the nano-ZnO varistor composite powder material. The preparation of nano-ZnO composite powder with excellent performances is a key of manufacture of a high-performance varistor. The ZnO composite powder prepared by using the method disclosed by the invention has the advantages of small particle size, uniform modified oxide distribution and narrow particle size distribution; and the preparation method disclosed by the invention is simple, and precisely controllable in component, and products have the characteristics of good morphology consistency, excellent electrical properties and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Preparation process for foam magnesium plastic composite material

The invention is a foam Mg plastic composite preparing method, including techniques of preparing foam Mg backing material and protecting surface, and its characteristic: firstly making foam Mg material into a 3D-connection prefab at hole diameter of 1-5mm, placing the prefab in a mould to preserve heat at 150-350deg.C, vacuumizing, and injecting and filling to make it at once. It has metallic mechanical property, and plastic manufacturability, functionality and artistry. It can be designed and made into various formal patterns. Its surface plastic layer makes it have excellent manufacturability and corrosion resistance. It is an ideal material on many occasions.

Owner:NANCHANG AERONAUTICAL ENG INST

Wide-temperature sulfur-tolerance shift catalyst and preparation method therefor

ActiveCN104971731AHigh low temperature activityLarge specific surface areaHydrogenMetal/metal-oxides/metal-hydroxide catalystsSulfurActive component

The invention provides a wide-temperature sulfur-tolerance shift catalyst and a preparation method therefor. The shift catalyst comprises a carrier and an active component, wherein the carrier is a roasted product of hydrotalcite, and the active component is cobalt and molybdenum. According to the wide-temperature sulfur-tolerance shift catalyst and the preparation method therefor, disclosed by the invention, the roasted product of magnesium aluminum hydrotalcite is used as the carrier for preparing the shift catalyst for the first time, so that the prepared shift catalyst has high hydrability resistance, high heat stability, and large specific surface area; compared with the shift catalyst in the prior art, the shift catalyst disclosed by the invention has better catalytic activity; even under the circumstance of low load amount of the active component, the shift catalyst disclosed by the invention is still high in catalytic activity for a water-gas shift reaction, and the conversion rate of CO can reach 87.62%.

Owner:FUZHOU UNIV

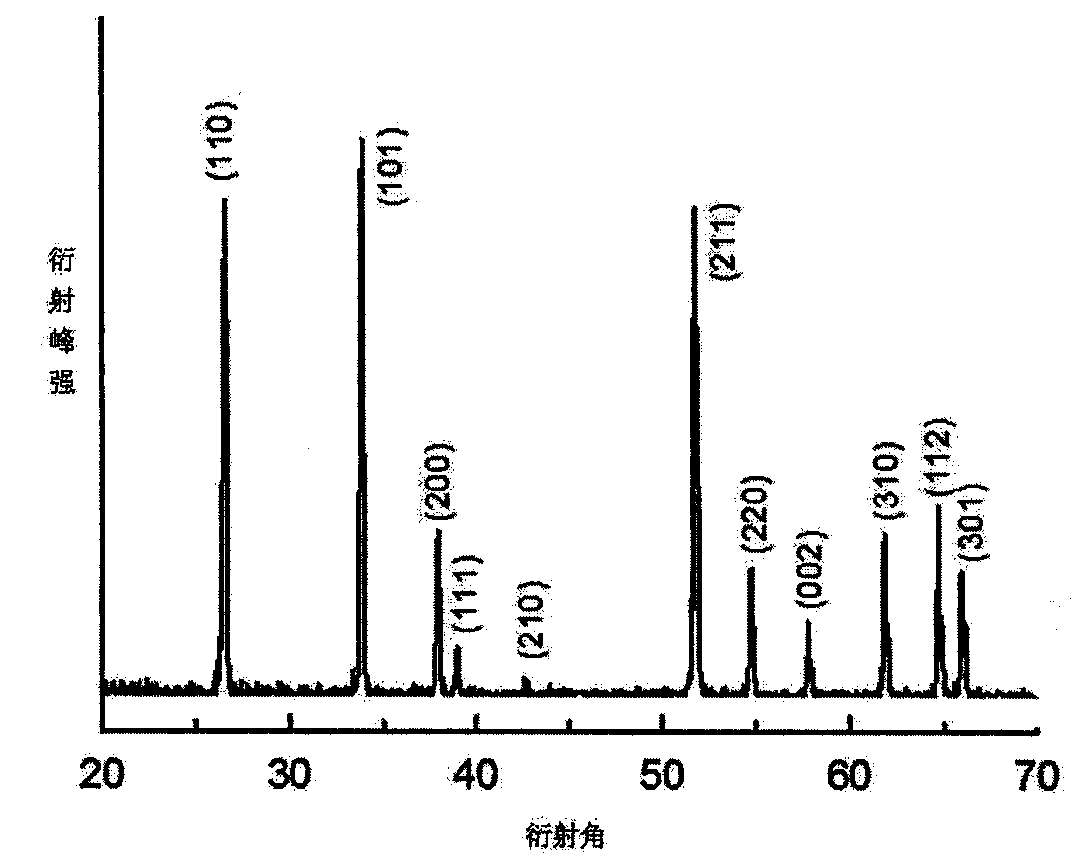

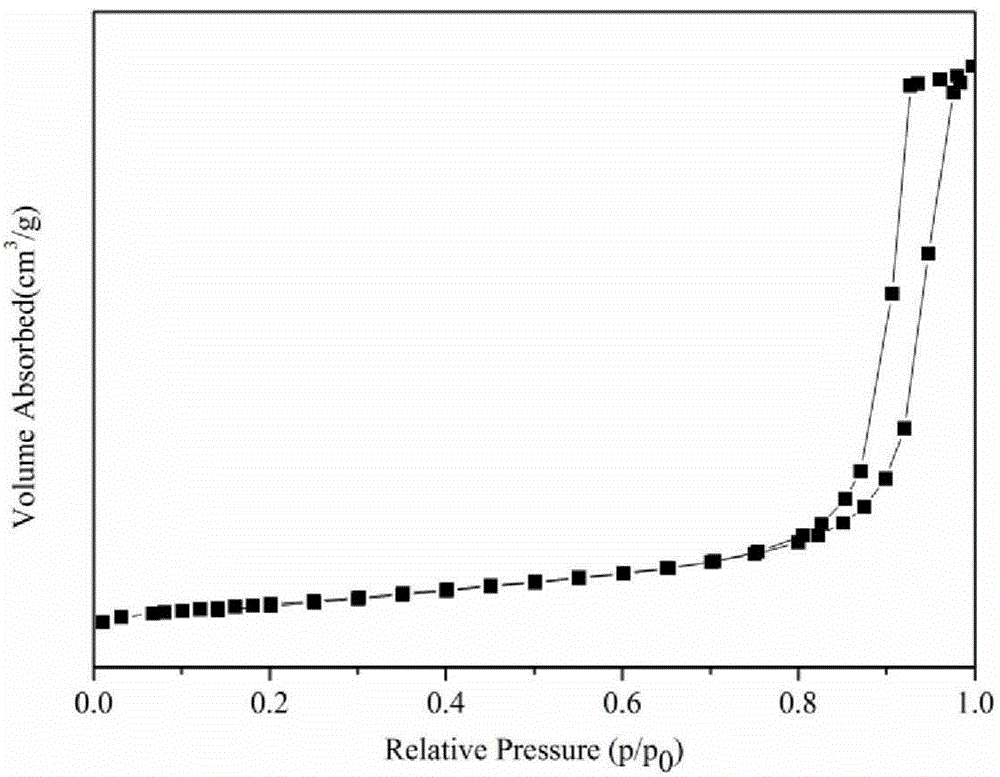

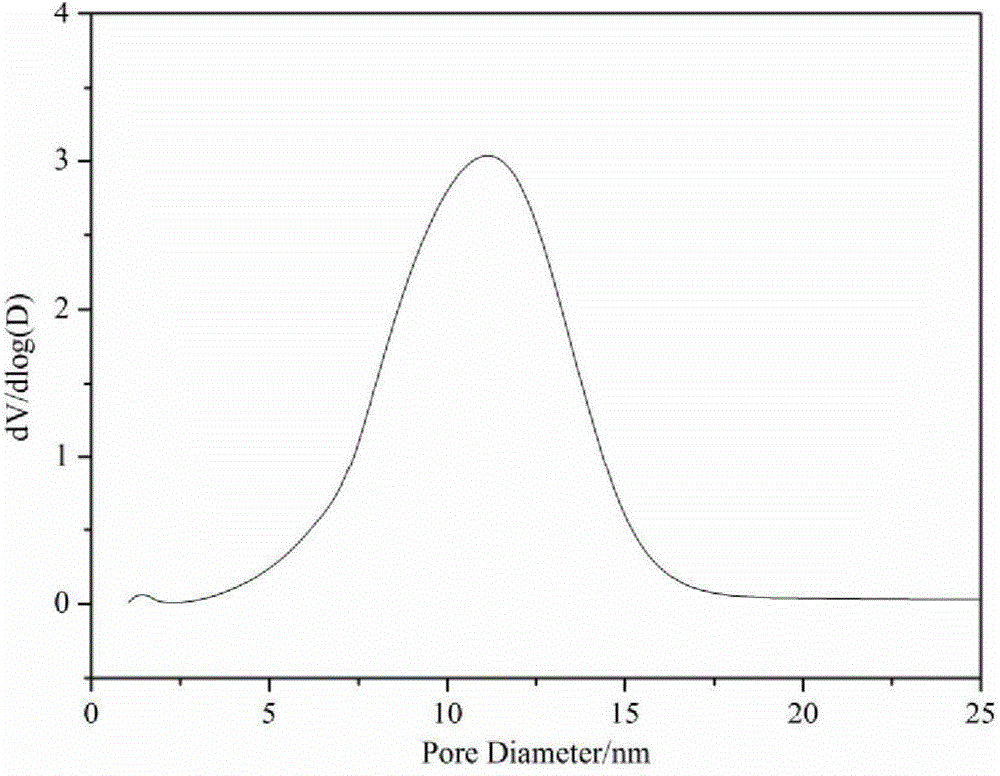

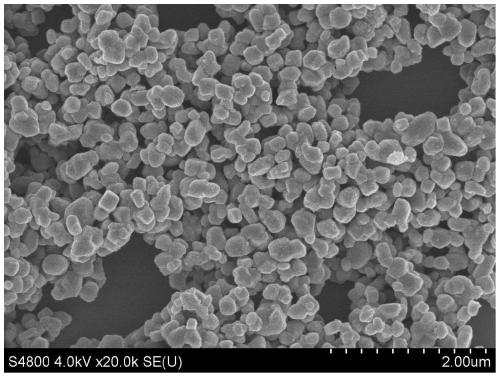

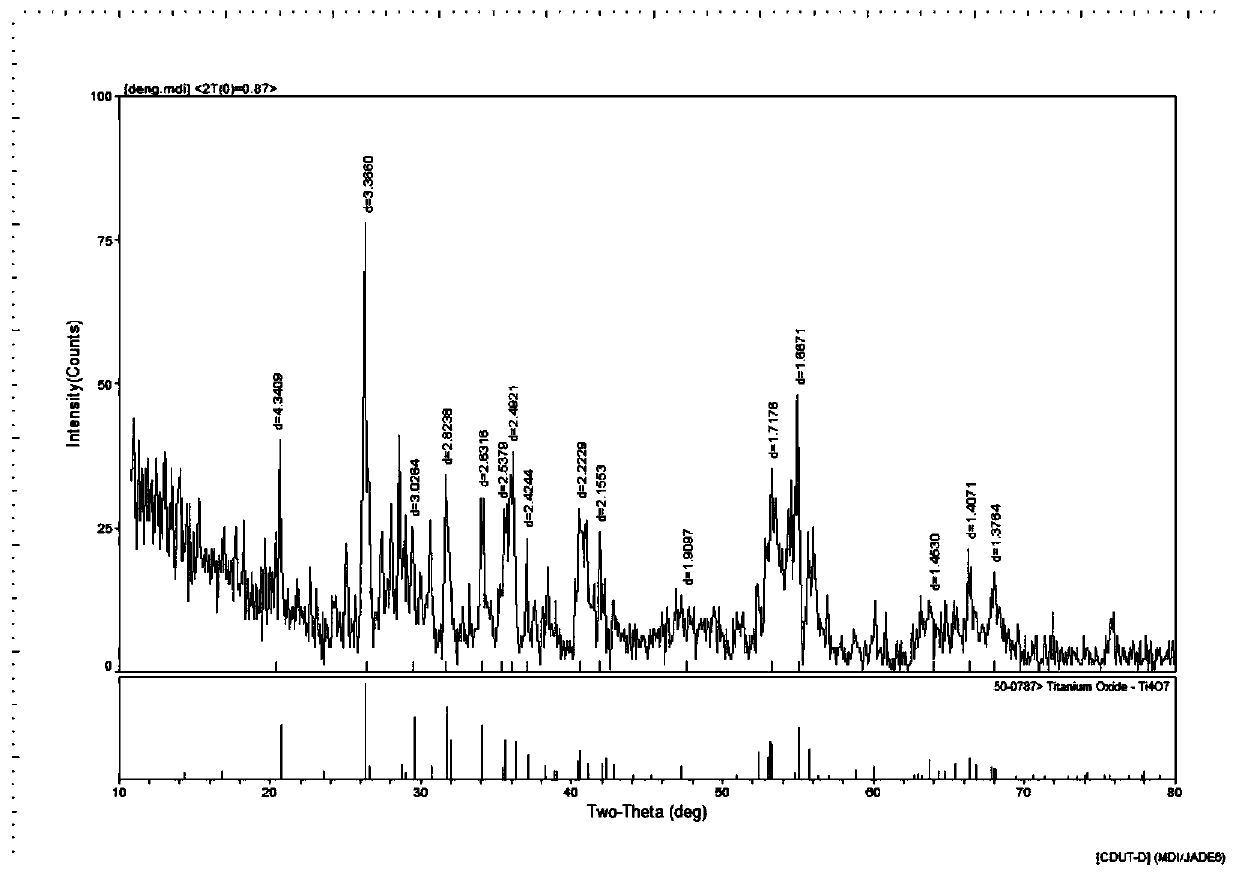

Method for preparing titanium oxide through reducing titanium-containing complexes at normal temperature

ActiveCN109879311ALow costMass productionTitanium oxides/hydroxidesTitanium oxideTitanium tetrachloride

The invention discloses a method for preparing titanium oxide through reducing titanium-containing complexes at normal temperature. The method is characterized in that reduction reaction occurs in a normal temperature liquid phase; the potential safety hazards due to mixing of reducing agents and air are eliminated; the reduction is performed in the liquid phase, the microscopic uniformity is high; the firing temperature is low; the time is short. The method has the following principle and steps that titanium sulfate or titanium tetrachloride and ammonium hydroxide or sodium hydroxide take a reaction to obtain titanic acid; the titanic acid reacts with oxalic acid or citric acid to form an oxalate oxytitanate complex-ion or oxytitanate citrate complex-ion solution; next, reaction is performed with zinc powder; the complex ions are reduced into low-valent titanium complex ions; the pH value of the solution is regulated to 12 by ammonium hydroxide; precipitates of dark brown color to dark violet color are generated; washing is performed for 3 to 5 times by 3 to 5 times of deionized water; the zin is washed away in an ion ZnO2<2-> form to obtain pure titanium hydroxide precipitates; oxalic acid is added until the pH is 0.5 to 1.5; drying is performed to 2 to 5 hours at 120 to 180 DEG C; the temperature is raised from room temperature to 820 to 950 DEG C by a muffle furnace; roasting is performed for 2 to 6 hours; titanium oxide spherical powder with the Ti4O7 content being 90 percent or higher is obtained.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

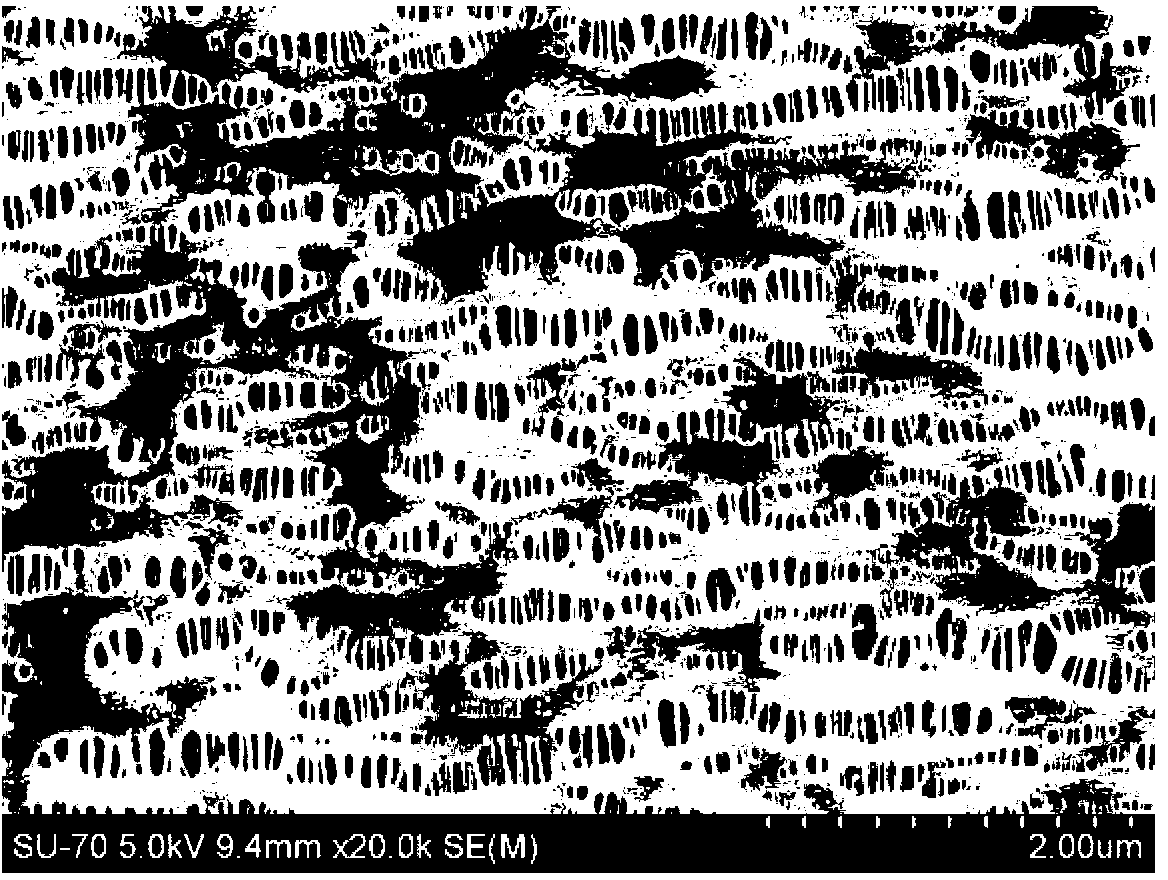

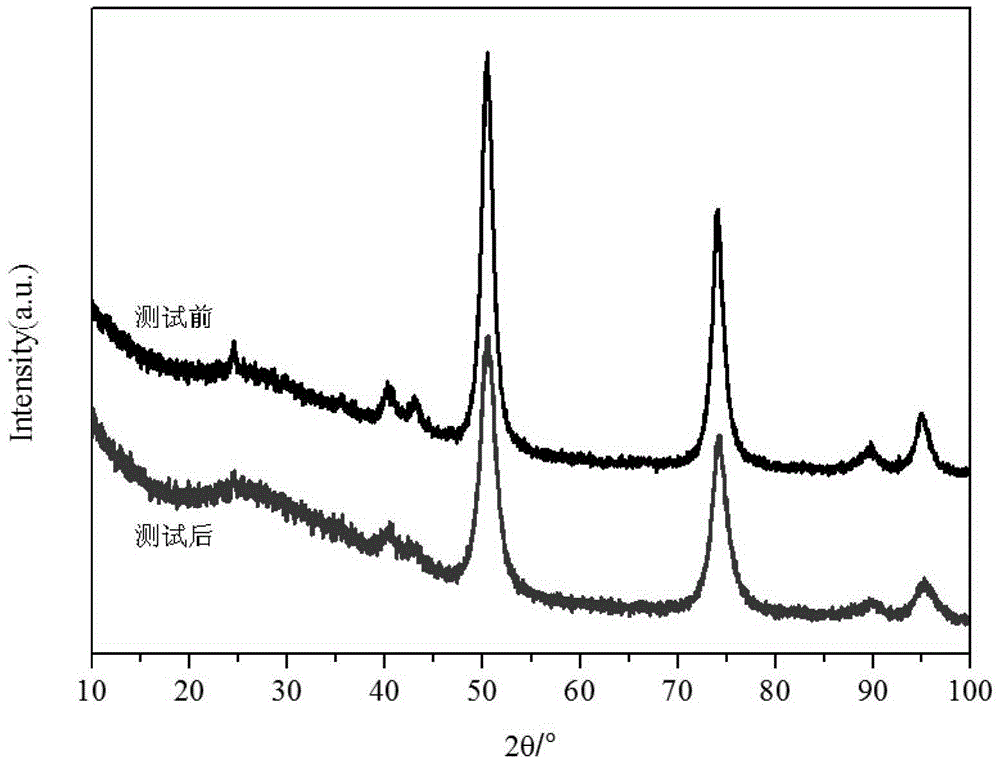

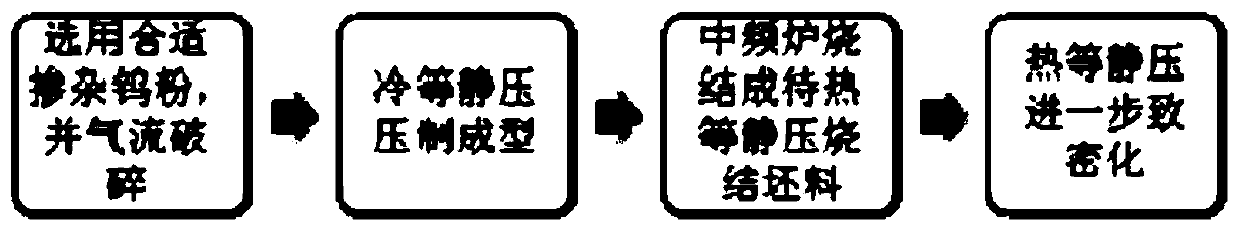

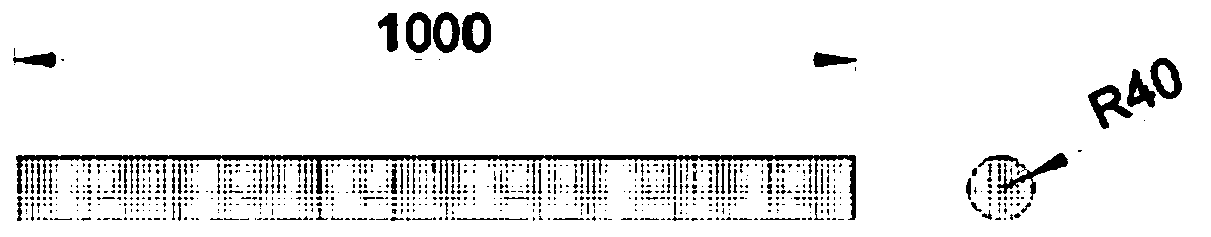

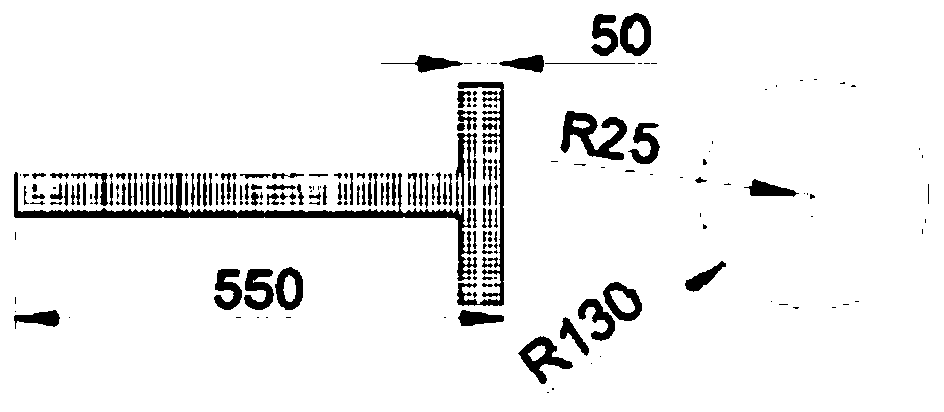

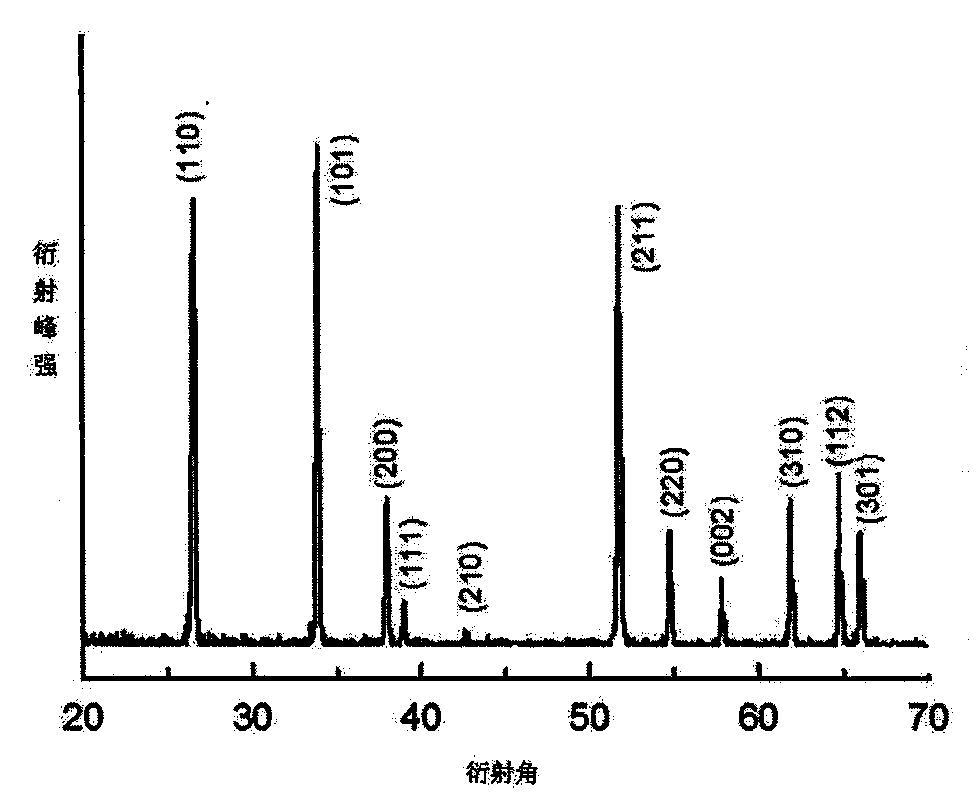

Preparation method of high-density rare earth tungsten electrode

ActiveCN110788318AImprove micro-uniformityHigh bulk densityElectric discharge tubesTransportation and packagingHigh volume manufacturingHot isostatic pressing

The invention discloses a preparation method of a high-density rare earth tungsten electrode. The method comprises the following steps of pretreatment, selecting raw material powder meeting requirements, and carrying out crushing treatment; pressing and forming, carrying out press forming treatment on the powder obtained in the pretreatment step to obtain a pressed blank; sintering, carrying out sintering treatment on the pressed blank to obtain a sintered blank; and hot isostatic pressing, carrying out hot isostatic pressing treatment on the sintered blank to obtain the high-density rare earth tungsten electrode. The preparation method has the advantages that the steps are well matched, the overall synergistic effect is obvious, the operation steps are simple and feasible, large-batch production is facilitated, the density of the prepared rare earth tungsten electrode product reaches 99.5% or above, the purity is high, the internal tissue structure is uniform, the grain size is fine,the strength is high, and the preparation method is suitable for mass production.

Owner:BAOJI JING LONG TUNGSTEN & MOLYBDENUM CO LTD +2

Stannic oxide pressure sensitive resistor composite powder material and preparation method thereof

The invention relates to a stannic oxide pressure sensitive resistor composite powder material with excellent properties, and a preparation method thereof. The powder material is prepared from SnO2, Co2O3, Bi2O3, Pr2O3 and Y2O3. The preparation method comprises the following steps: by adopting a chemical coprecipitation method and by taking absolute ethyl alcohol as an organic solvent and polyethylene glycol as a dispersing agent, adding stannic chloride, tribismuth chloride, tricobalt chloride, praseodymium nitrate and yttrium nitrate, dissolving the components into a transparent solution in a constant temperatue water bath environment, dropwise adding an ammonia water solution used as a precipitator into the transparent solution at a uniform speed, precipitating, filtering, washing, drying, grinding and calcining, thereby obtaining the stannic oxide pressure sensitive resistor composite powder material. The stannic oxide composite powder with excellent properties is essential to manufacturing of high-performance pressure sensitive resistors. The stannic oxide composite powder prepared by using the method disclosed by the invention has the advantages of small particle size, uniform modified oxide distribution and narrow particle size distribution. The stannic oxide pressure sensitive resistor composite powder material disclosed by the invention is simple in preparation method, precise and controllable in component, relatively good in product morphology consistence and excellent in electric property.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

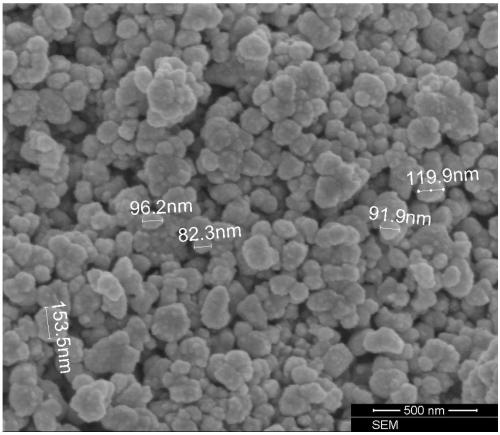

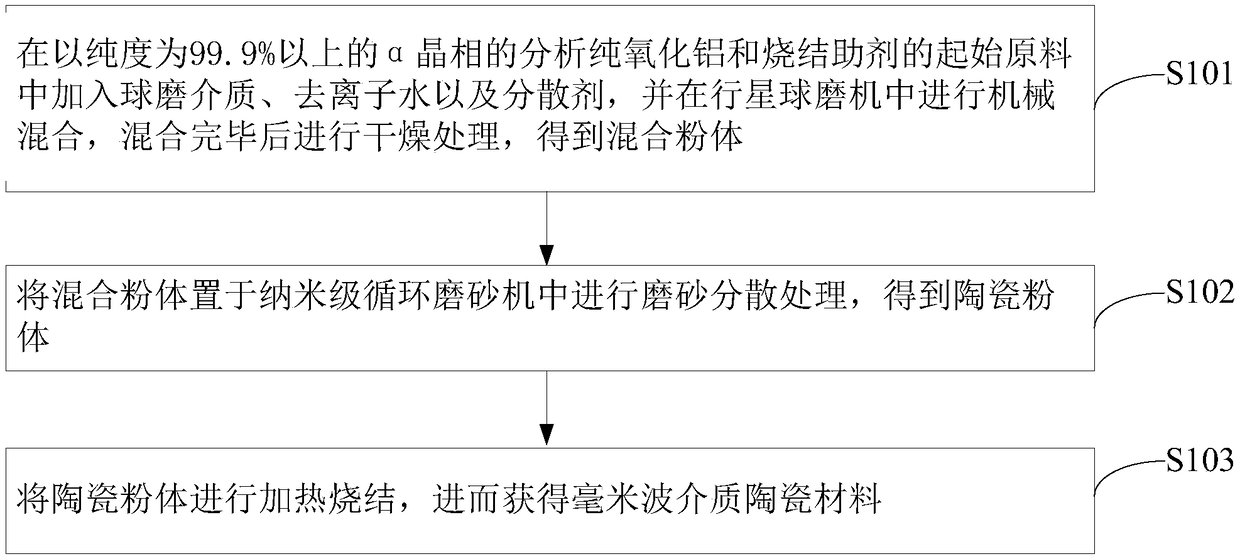

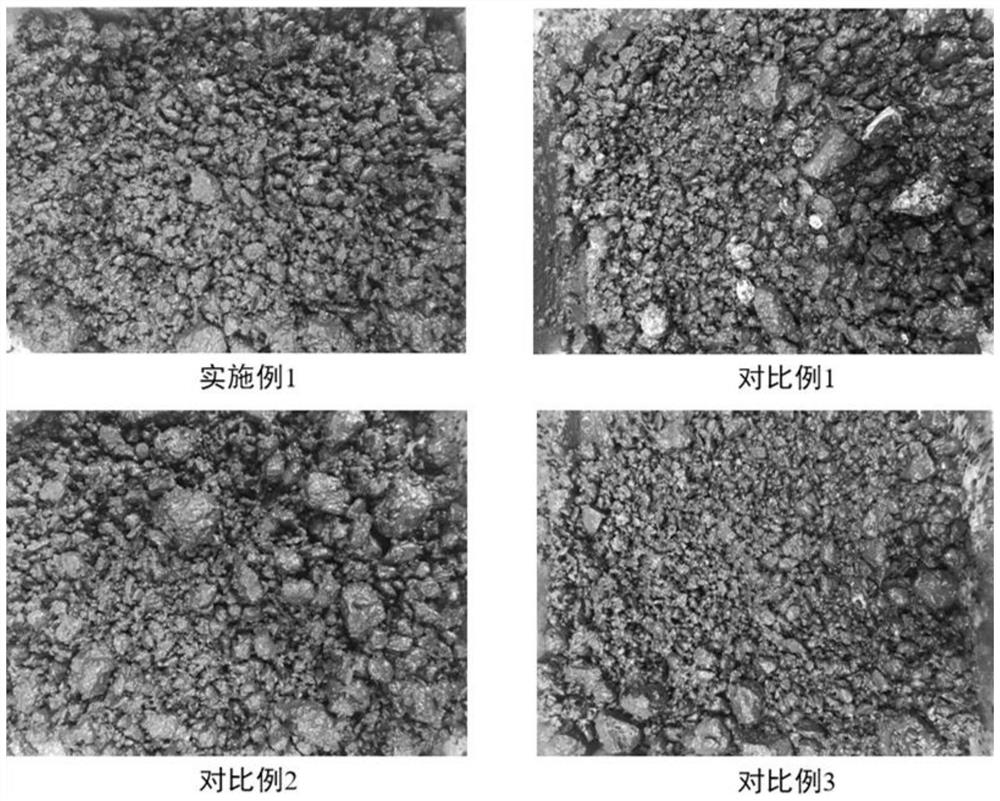

A dielectric ceramic material and a preparation method thereof

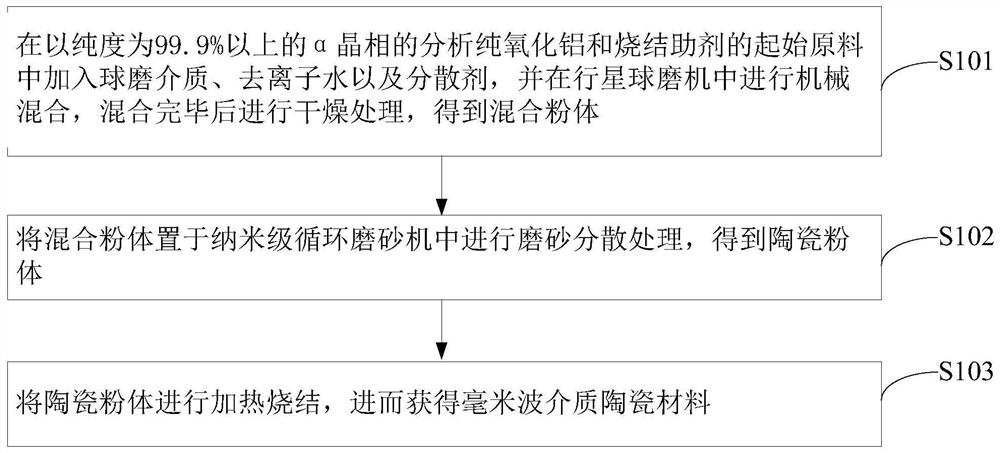

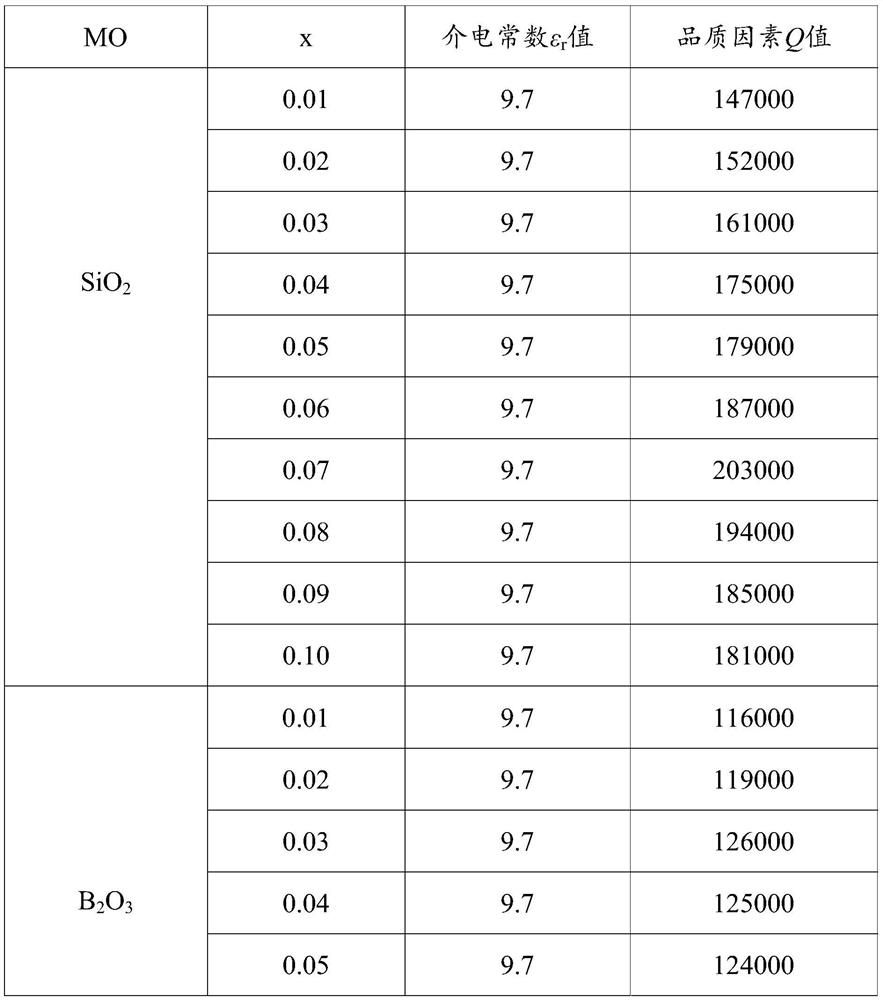

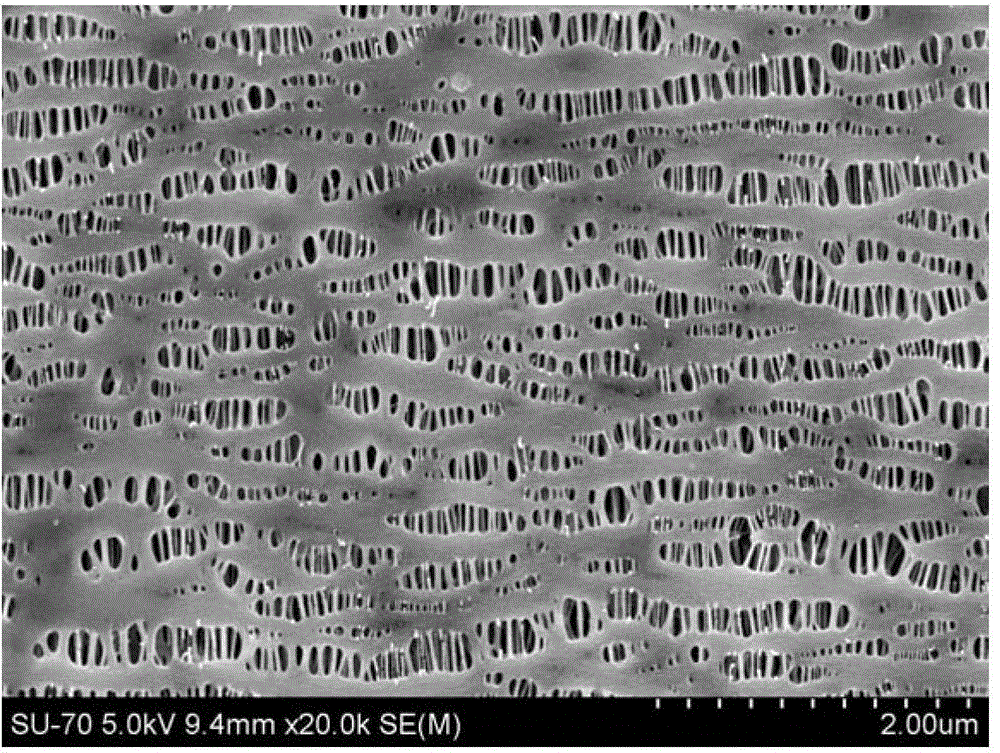

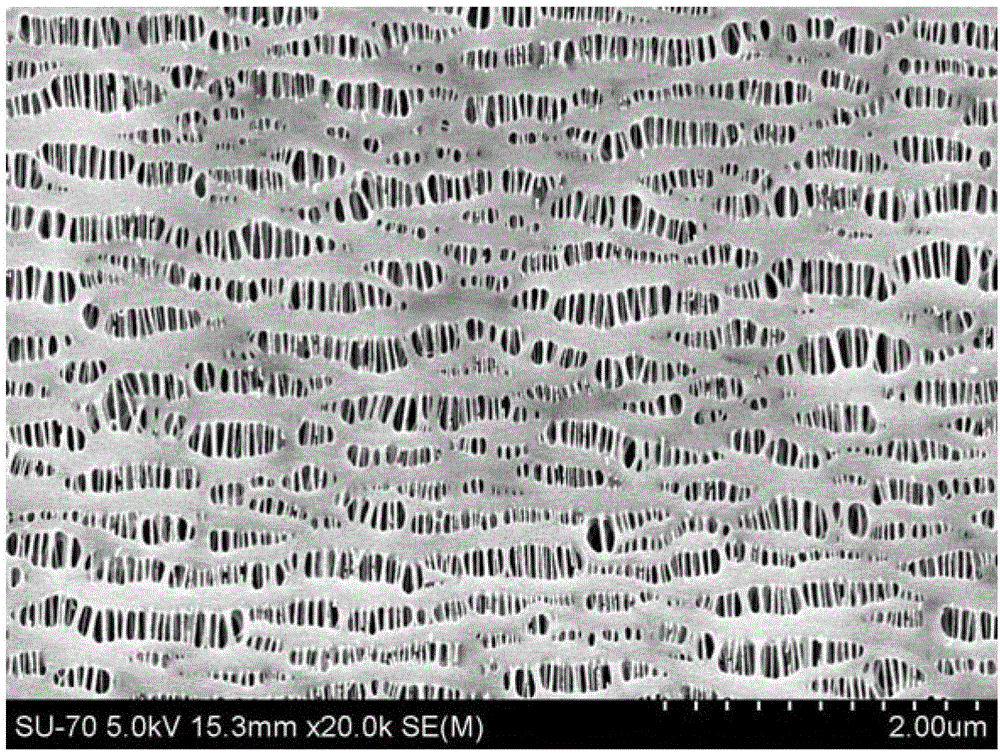

A dielectric ceramic material and a preparation method thereof, wherein a ball milling medium, a deionized water and a dispersing agent are added to a starting material of an analytically pure alpha-alumina and a sintering aid having a purity of 99.9% or more, and are mixed in a planetary ball mill. Mechanical mixing and drying are carried out to obtain a mixed powder, wherein the mass ratio of the starting material, the ball milling medium and the deionized water is 1:4:1.1 to 1.3, the ball milling time is 4 hours, and the diameter of the ball milling medium is 2-3mm; the mass percentage of the dispersing agent in the dielectric ceramic material is from three thousandths to six thousandths; the mixed powder is placed in a nano-scale circulating sander for sanding and dispersing treatmentto obtain the ceramic powder; the ceramic powder is subjected to heat sintering to further obtain the dielectric ceramic material.

Owner:ANHUI TATFOOK TECH CO LTD

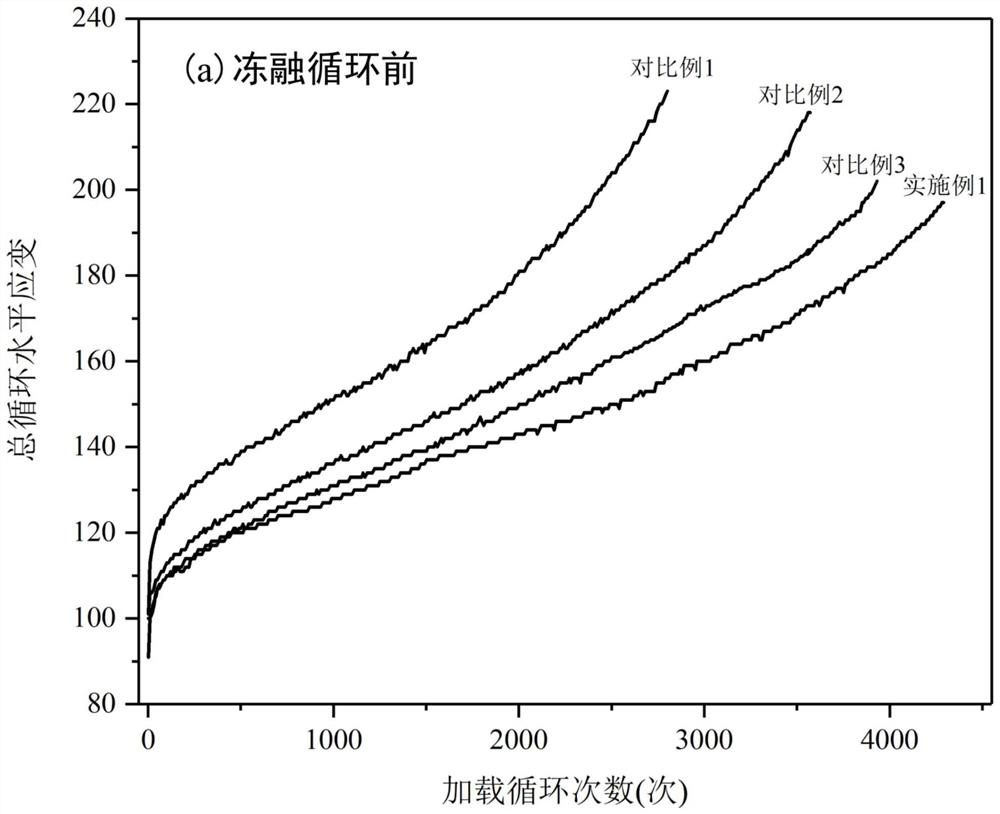

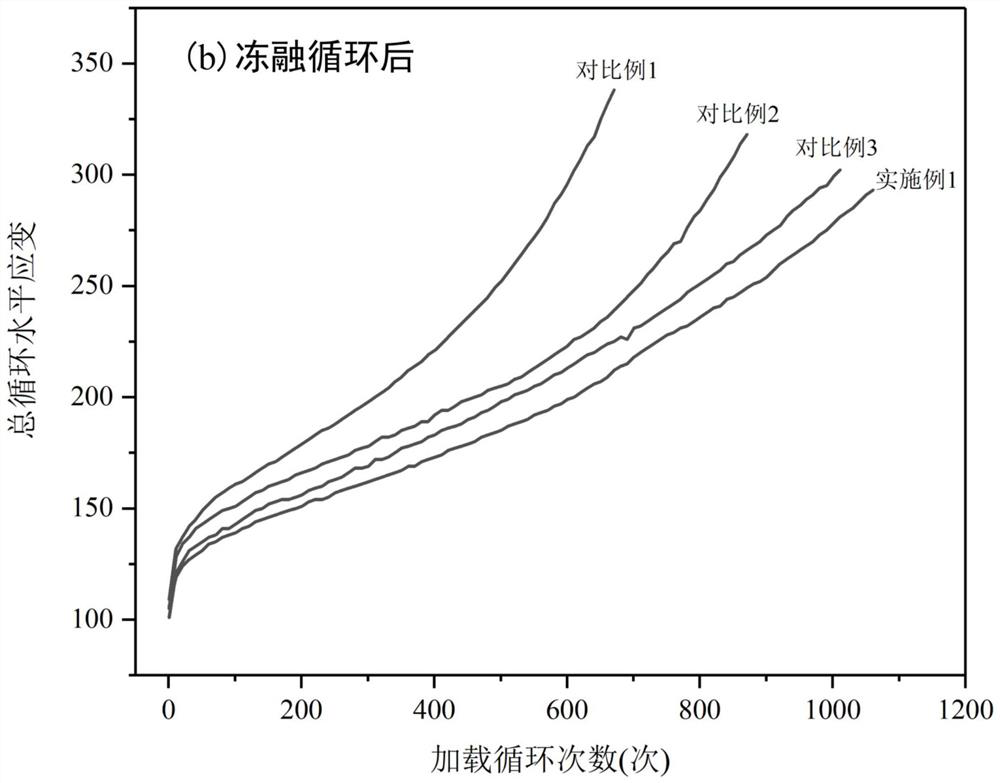

Preparation method of emulsified asphalt cold recycled mixture

InactiveCN113563031AImprove low temperature performanceImprove micro-uniformityBitumen emulsionPitch

The invention provides a preparation method of an emulsified asphalt cold-recycled mixture, which comprises the following steps: adding water into a fine RAP material, vibrating and mixing to obtain a first premixed material; mixing a coarse RAP material with aggregate, adding water, and stirring to obtain a second premixed material; and adding the second premixed material into the first premixed material, then adding emulsified asphalt, vibrating and uniformly mixing, then adding mineral powder and cement, and continuously stirring to obtain an emulsified asphalt cold-recycled mixture, wherein the particle size of the coarse RAP material is 15-25 mm, and the particle size of the fine RAP material is 0.01-15 mm. According to the method disclosed by the invention, the aggregate is more uniformly and fully wrapped by the emulsified asphalt, so that the generation of gray materials is basically eliminated, the adhesion between the emulsified asphalt and the aggregate is enhanced, and the microscopic uniformity of the mixture is improved, thereby effectively improving the high and low temperature performance and freeze-thaw damage resistance of the cold recycled asphalt mixture.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Corrosion-resistant zirconium alloy

InactiveCN110904359AImprove corrosion resistanceImprove mechanical propertiesRare-earth elementLithium hydroxide

The invention provides a corrosion-resistant zirconium alloy. The corrosion-resistant zirconium alloy comprises the following components in percentage by weight: 2.4%-4.5% of Nb, 0.5%-2.1% of Sn, 0.5%-1.3% of Cr, 0.01%-0.1% of Fe, 0.02%-0.1% of Ce, 0.03%-0.1% of Y and the balance of Zr. Nb is added into the corrosion-resistant zirconium alloy disclosed by the invention, Nb serves as a corrosion-resistant element, a passivation film containing Nb2O5 can be generated on the surface of the alloy in the environment containing a corrosion medium, the chemical property of Nb2O5 is stable, the microcosmic uniformity of the passivation film can be effectively improved, and ions in the corrosion medium are prevented from further corroding the interior of the alloy; rare earth elements are added into the corrosion-resistant zirconium alloy, so that the corrosion resistance of the zirconium alloy in a lithium hydroxide solution can be remarkably improved, and the good mechanical property of the corrosion-resistant zirconium alloy is also ensured.

Owner:FOSHAN UNIVERSITY

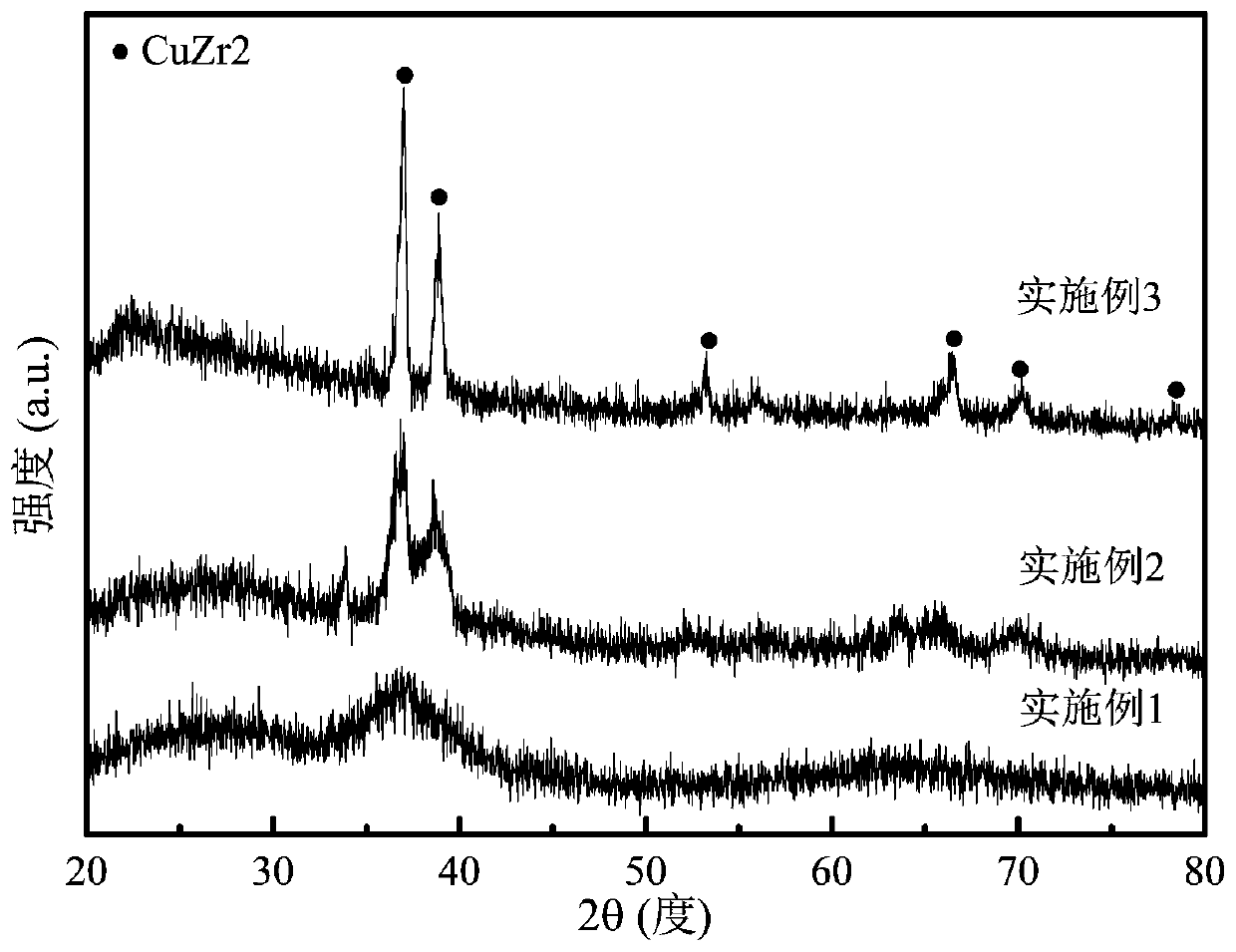

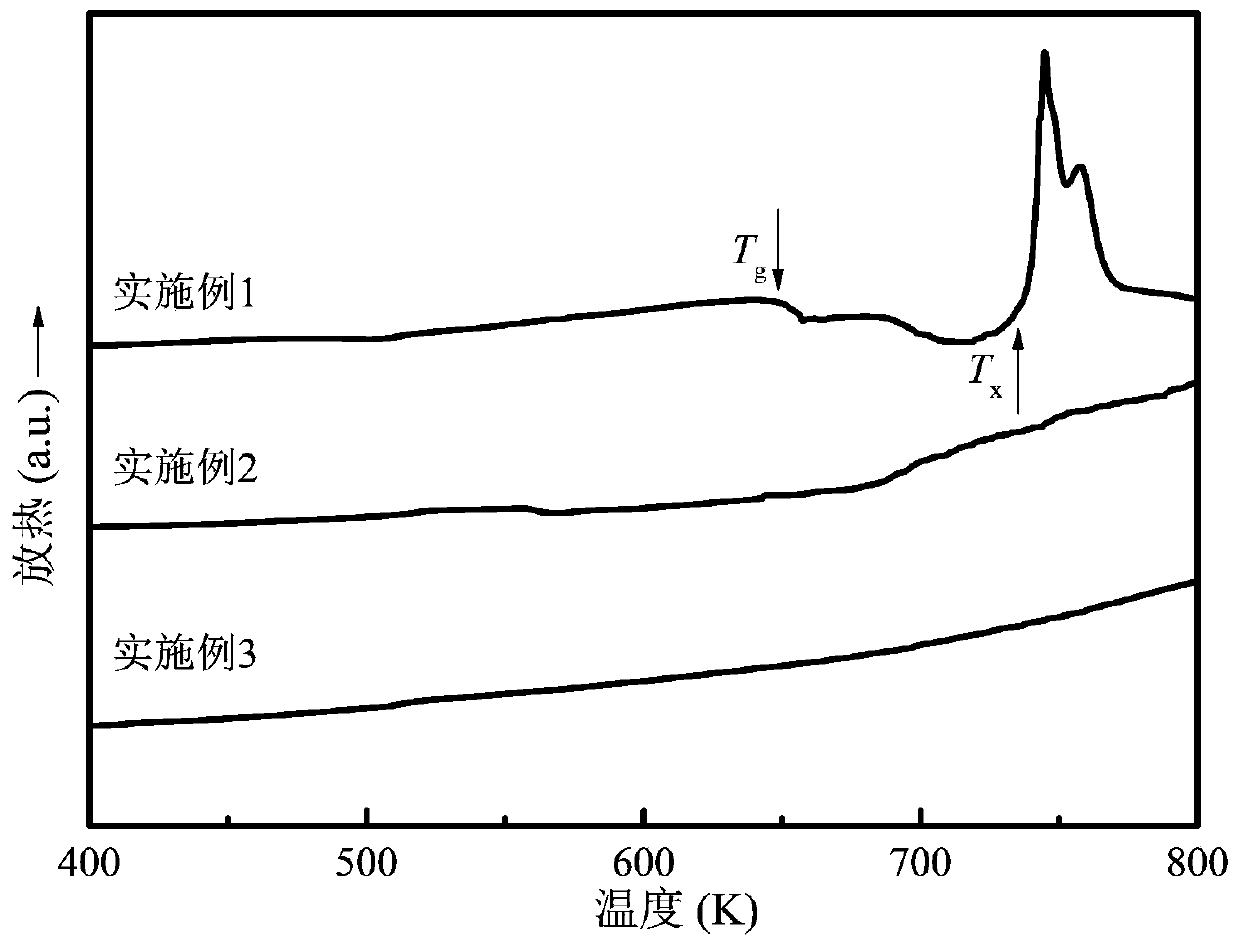

Novel corrosion-resistant zirconium-based alloy and preparation method thereof

The invention relates to a novel corrosion-resistant zirconium-based alloy and a preparation method thereof. The composition of the alloy is Zr60Cu(25-a)Al10Fe5Nba, and the atomic percentage a of theelemental composition is equal to 1-12; and in the preparation process, a rod-shaped bulk alloy with the diameter being 2 mm-4 mm is prepared through vacuum melting and copper die casting technologies, a microstructure of the bulk alloy can have an amorphous phase so as to improve the strength compared with a traditional zirconium alloy, a crystal phase exists to improve the plasticity of the amorphous alloy, and the crystal phase is single so that influences of more uncertain factors on the performance can be avoided. According to the novel corrosion-resistant zirconium-based alloy and the preparation method, the Nb content is added, the corrosion resistance of the alloy is improved, and meanwhile use of the highly toxic Be element in an existing Zr alloy is avoided.

Owner:HEBEI UNIV OF TECH

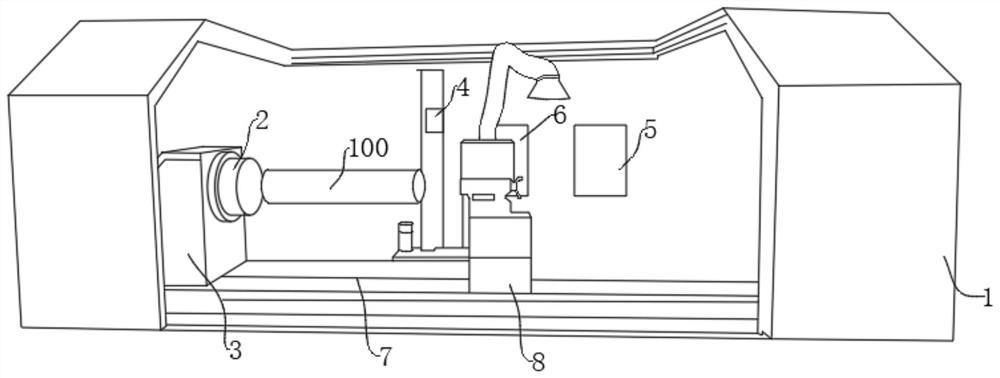

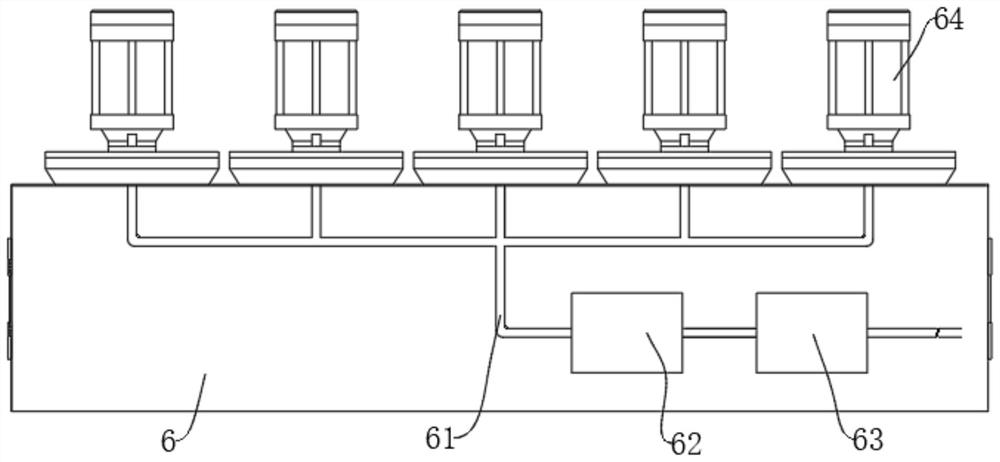

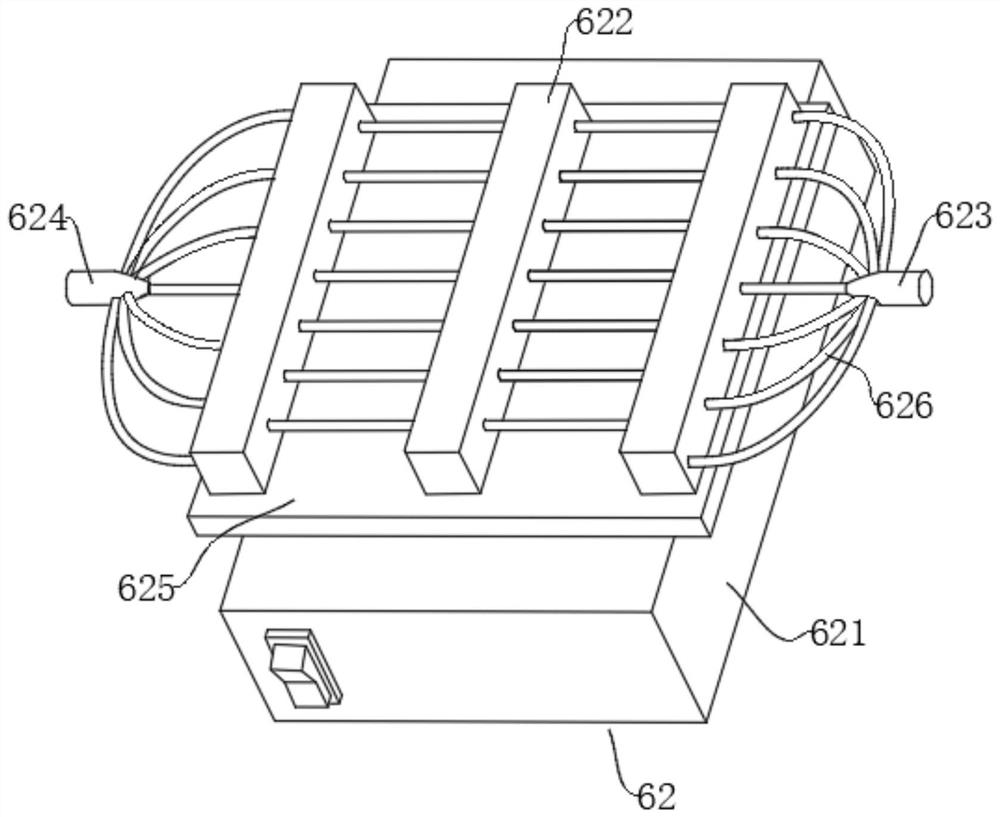

Special machine tool equipment for laser cladding of high-entropy alloy

PendingCN114438491AImprove macro uniformityImprove micro-uniformityTransportation and packagingMetal-working apparatusPhysicsHigh entropy alloys

The invention discloses special machine tool equipment for laser cladding of high-entropy alloy, and relates to special equipment for laser cladding of high-entropy alloy, which comprises a special machine tool body for laser cladding of high-entropy alloy, a chuck for clamping a workpiece is arranged on the special machine tool body for laser cladding of high-entropy alloy, and the chuck is driven by a servo motor arranged in a servo motor box. An electric tailstock used for being matched with clamping and rotating of a workpiece, a sliding rail used for installing a cladding head, a laser device and a powder mixing system are arranged on the special machine tool body for laser cladding of the high-entropy alloy. The machine tool head servo motor can drive the workpiece to rotate at a high speed so as to ensure that the molten pool can move at a high speed in the laser cladding process, so that the high-speed rotation of the workpiece enables the cooling speed of the molten pool to be further increased, diffusion of elements and segregation of the elements can be effectively reduced, the grain size can be effectively reduced, and the mechanical and corrosion-resistant performance of a coating can be improved.

Owner:安徽铭谷激光智能装备科技有限公司

A kind of thermal deformation rare earth permanent magnet material and preparation method thereof

ActiveCN106548844BDiffuse fullyImprove micro-uniformityInductances/transformers/magnets manufactureMagnetic materialsThermal deformationDehydrogenation

The invention relates to a preparation method of a thermal deformation rare-earth permanent magnet material. The method comprises the following steps of (1) providing main magnetic powder and low-melting-point alloy powder separately, wherein a chemical formula of the main magnetic powder is Re<x>Fe<100-x-y-z>M<y>B<z> according to the mass percent, the chemical formula of the low-melting-point alloy powder is ReCu<100-a>, Re is one or more of Nd, Pr, Dy, Tb, La and Ce and a is smaller than or equal to 90 and greater than or equal to 60; (2) mixing the main magnetic powder with the low-melting-point alloy powder evenly to obtain mixed magnetic powder, wherein the mass ratio of the low-melting-point alloy powder in the mixed magnetic powder is greater than 0 and smaller than or equal to 10%; (3) carrying out hydrogenation-disproportionation-dehydrogenation-recombination treatment on the mixed magnetic powder and diffusing a low-melting-point alloy in the treatment process to obtain HDDR magnetic powder; and (4) sequentially carrying out hot-press molding and deformation molding on the HDDR magnetic powder to obtain the thermal deformation rare-earth permanent magnet material. The invention further provides the thermal deformation rare-earth permanent magnet material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

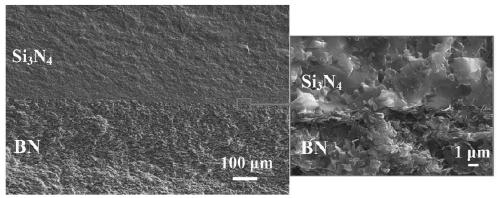

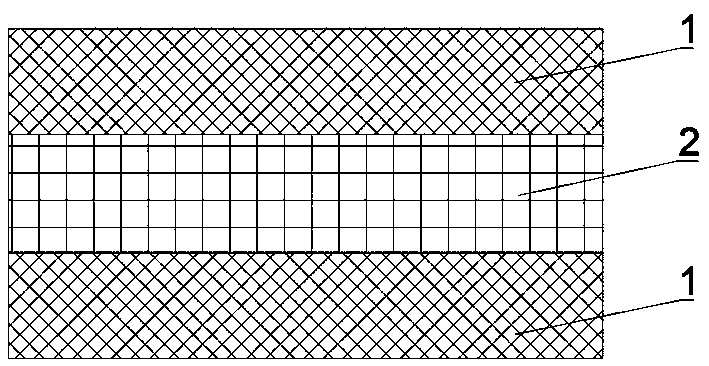

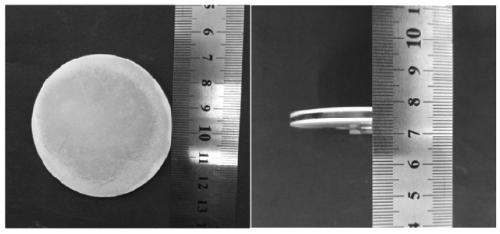

Boron nitride-silicon nitride sandwich wide-frequency wave-transmitting material and preparation method thereof

ActiveCN109231996AAdjustable microstructureAchieve densificationCeramicwarePowder mixtureFrequency wave

The invention discloses a preparation method for a boron nitride-silicon nitride sandwich wide-frequency wave-transmitting material. The preparation method comprises the following steps: taking silicon nitride ceramic powder as a raw material, adopting a gel injection-moulding method to prepare a porous silicon nitride blank; spreading a boron nitride powder mixture on upper and lower surfaces ofthe porous silicon nitride blank, and sintering through a discharge plasma sintering process to obtain sandwich ceramic; performing decarbonizing treatment on the sandwich ceramic to obtain the boronnitride-silicon nitride sandwich wide-frequency wave-transmitting material. The boron nitride-silicon nitride sandwich wide-frequency wave-transmitting material prepared by the preparation method is not liable to crack, good in interlayer combination, and adjustable in microstructure, and can be applied to wave-transmitting parts such as a high-temperature wide-frequency antenna cover.

Owner:NAT UNIV OF DEFENSE TECH

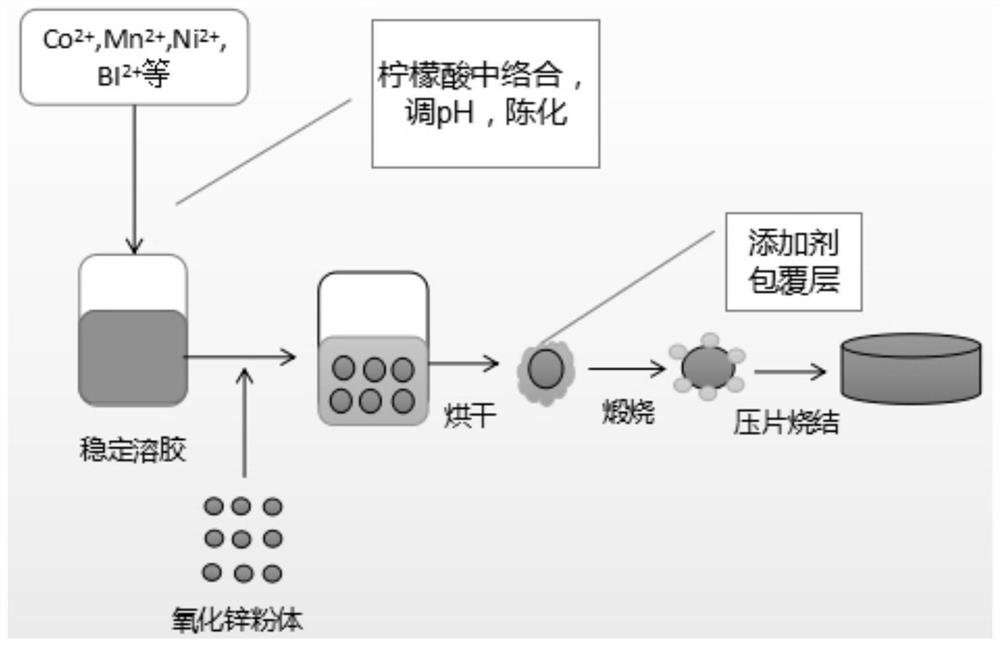

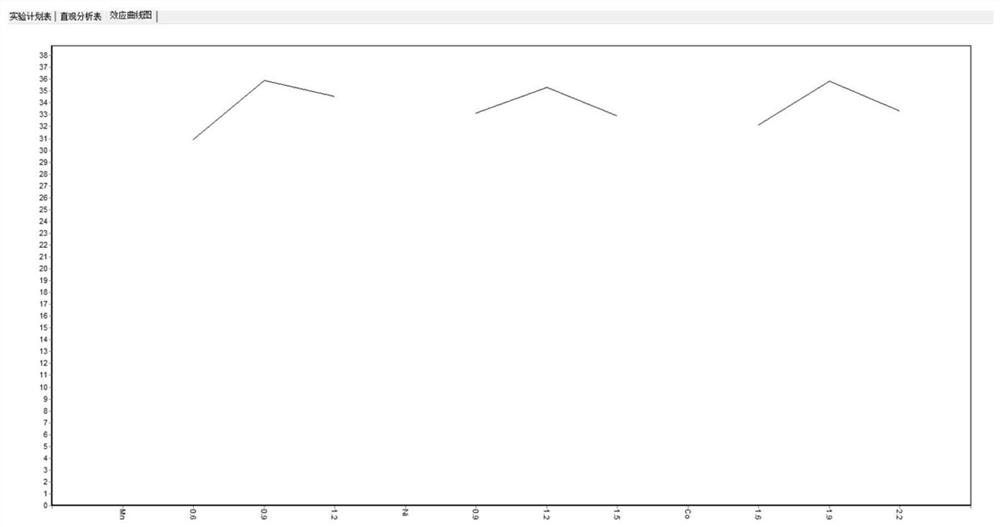

Method for preparing high-voltage gradient zinc oxide piezo-resistance by doping and coating method

InactiveCN112851332AImprove performanceTo achieve a stable distributionVaristor coresMaterials scienceVaristor

The invention relates to the technical field ofpiezo-resistance materials, in particular to a method for preparing a high-voltage gradient zinc oxide piezo-resistance by a doping and coating method, which comprises the following steps of: S1, using additives manganese carbonate, bismuth oxide, nickel hydroxide and cobalt nitrate hexahydrate to prepare sol by a liquid phase method; S2, performing water bath on the sol prepared in the step S1 to form wet sol; S3, adding ZnO into the wet sol prepared in the step S2, continuously conducting stirring in a stirrer, and carrying out water bath for 15 hours; S4, drying the coated ZnO, and calcining the ZnO to obtain ZnO powder uniformly coated with the additives; and S5, adopting an electronic ceramic preparation process, and sequentially carrying out granulation, tabletting, sintering, silver coating and silver firing on the powder prepared in the step S4 to prepare the zinc oxide piezo-resistance. The microcosmic uniformity of the additives at the grain boundary can be better, the effect of stable distribution of the additives in the grain boundary is achieved, and then the performance of the piezoresistor is improved.

Owner:XIDIAN UNIV

Sintering additive composition, dielectric ceramic composition, and their applications

ActiveCN103073305BHigh mechanical strengthImprove the immunityFixed capacitor dielectricTin dioxideCeramic capacitor

The invention relates to a sintering additive composition comprising silica, boron trioxide, and at least two modification components selected from the group comprising tungsten trioxide, molybdenum trioxide and tin dioxide. Calculated according to a total amount of the sintering additive composition as 100mol, the content of silica is 60-85mol, the content of boron trioxide is 10-35mol, and the content of the at least two modification components is 0.1-5mol. Also, the invention relates to a dielectric ceramic composition comprising the sintering additive composition. The invention also relates to a laminated ceramic capacitor comprising the dielectric ceramic composition. The composition has an excellent low-temperature sintering property, such that the reliability of the capacitor can be improved.

Owner:DONGGUAN HUAKE ELECTRONICS

A composite vibrating mixer capable of classifying raw materials

ActiveCN107379246BIncrease the number of collisionsImprove macro uniformityCement mixing apparatusSold ingredients supply apparatusRotary stageEngineering

A composite vibrating mixer capable of grading raw materials, including a grading part and a stirring part, the grading part includes a rotary table and a rotating shaft, a leak hole is provided on the rotary table, a grading ring cylinder is provided at the bottom of the rotary table, and the agitating part includes a horizontal strand The dragon and the vertical auger, the auger is equipped with a vibrator, the invention classifies the stone according to the different volumes of the stone, and mixes different amounts of cement and water after classification to achieve the best ratio formula. When stirring, the side moves forward It vibrates and stirs while transporting, and the stirring effect is good. In a word, the present invention has simple structure and high stirring efficiency, and is suitable for industrial production.

Owner:HEBEI ROAD & BRIDGE GROUP

A kind of dielectric ceramic material and preparation method thereof

A dielectric ceramic material and its preparation method, adding ball milling media, deionized water and dispersant to the starting raw materials of analytically pure α-alumina with a purity of more than 99.9% and sintering aids, and mechanically performing the process in a planetary ball mill Mix and dry to obtain a mixed powder, wherein the mass ratio of the starting material, ball milling medium and deionized water is 1:4:1.1 to 1.3, the ball milling time is 4 hours, the diameter of the ball milling medium is 2 to 3 mm, and the dispersant The mass percentage content in the dielectric ceramic material is 3 / 1000 to 6 / 1000; the mixed powder is placed in a nano-scale circulating sander for grinding and dispersing treatment to obtain a ceramic powder; the ceramic powder is heated and sintered, Then a dielectric ceramic material is obtained.

Owner:ANHUI TATFOOK TECH CO LTD

Polypropylene microporous membrane and preparation method thereof

The invention discloses a polypropylene microporous membrane and a preparation method and an application thereof. The polypropylene microporous membrane provided by the invention is composed of, by weight, 80-90% of a first component and 10-20% of a second component. The first component is polypropylene with weight average molecular weight of 2*10<5>-5*10<5>. The second component is polypropylene with weight average molecular weight of 5*10<4>-1*10<5>. According to the invention, the polypropylene microporous membrane is prepared from a mixed raw material of high-molecular-weight polypropylene and low-molecular-weight polypropylene, such that the micro-pore size and distribution of the polypropylene microporous membrane are uniform. Also, microporous membrane performances such as transverse and longitudinal tensile strength, puncture strength, porosity and thermal shrinkage reach good homogeneity. The polypropylene microporous membrane provided by the invention can satisfy applications with high requirements on microporous membrane pore-forming uniformity, and is especially suitable to be used in the field of battery separator.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

A concrete preparation process

The invention relates to a concrete preparation process, which includes the following process steps: S1: After stirring water and a surface wetting agent evenly, putting fine aggregate into it, and after stirring evenly, a first mixture is prepared; water, fine aggregate and The weight ratio of the surface wetting agent is 1: (3‑7): (0.01‑0.03); S2: add the gel material and dispersant to the first mixture, and stir evenly to prepare the second mixture; gel The weight ratio of material, fine aggregate and dispersant is 1: (1‑1.4): (0.008‑0.012); S3: add coarse aggregate, fiber filler and water into the second mixture, and stir well to obtain The third mixture; the weight ratio of fine aggregate, coarse aggregate, fibrous filler and water is 1: (2‑2.4): (0.06‑0.1): (0.08‑0.12); S4: add additives in the third mixture After stirring evenly, the concrete slurry is prepared; the weight ratio of admixture to fine aggregate is (0.02‑0.03):1. The workability and workability of the mixed soil are improved by rationally setting the feeding sequence of the concrete raw materials.

Owner:山西住工建筑科技有限公司

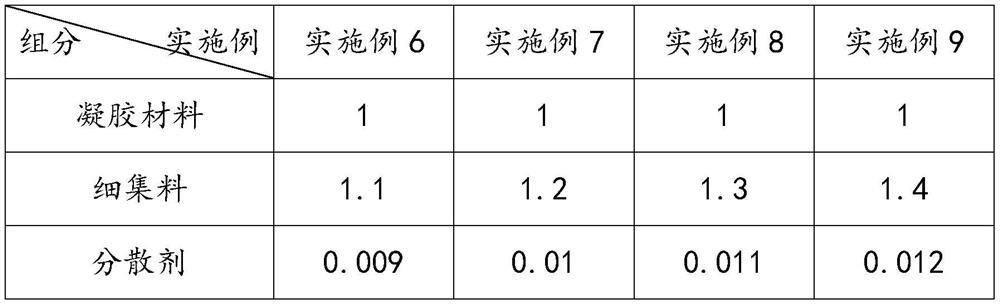

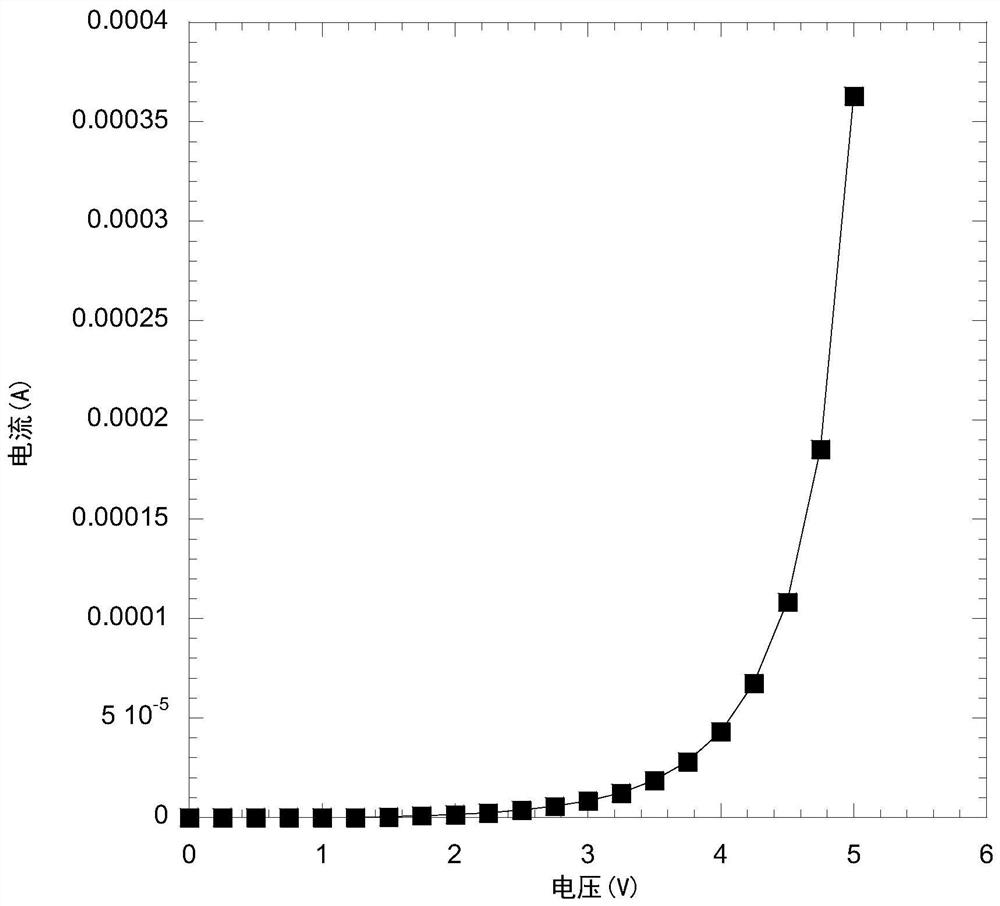

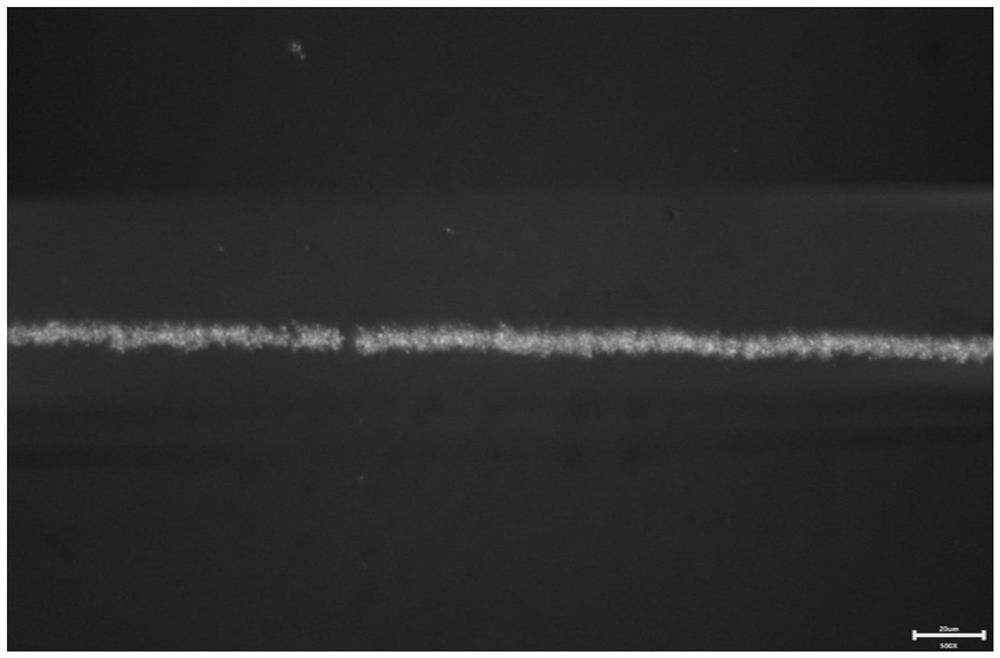

Narrow-linewidth metal type low-voltage pressure-sensitive device and preparation method for electrofluid printing

ActiveCN113223791ASimple processLower sintering temperatureResistor manufactureVaristorsCellulosePyrrolidinones

The invention discloses a narrow-linewidth metal type low-voltage pressure-sensitive device and a preparation method for electrofluid printing. The pressure-sensitive device comprises the components of nano-silver particles, ethyl cellulose and polyvinylpyrrolidone. The pressure-sensitive device comprises a main body part and two external contacts, wherein the external contacts are located at two ends of the main body part. The preparation method comprises the following steps of cleaning and drying a substrate, then printing nano-silver sol on the substrate by adopting electrofluid printing to form a pressure-sensitive device, and annealing and curing the printed pressure-sensitive device to obtain the narrow-linewidth metal type low-voltage pressure-sensitive device. The piezo-resistance of the pressure-sensitive device is stable, the nonlinear coefficient is relatively large, the leakage current is small, and the microscopic uniformity is relatively good; and the process is simple, and the sintering temperature is low.

Owner:SOUTH CHINA UNIV OF TECH

A kind of near α-type titanium alloy with high dynamic performance and preparation method thereof

The invention discloses a near-alpha titanium alloy with high dynamic performance. The near-alpha titanium alloy is composed of, by mass percent, 5.0%-6.8% of Al, 1.5%-2.4% of Zr, 1.0%-1.9% of Mo, 1.5%-2.5% of V, 0.05%-0.30% of Fe, 0.05%-0.14% of O, and the balance Ti. The sum of the mass percents of the components is 100%. The invention further discloses a preparation method of the titanium alloy. The as-cast structure of a large cast ingot is refined and the microcosmic uniformity of cast ingot components is improved through a purification and high-homogeneity smelting method; and meanwhile, as the content of Al and the content of O are controlled, it is guaranteed that the WSTi6211F titanium alloy has enough strength, the plasticity and the toughness of the WSTi6211F titanium alloy are greatly improved, and the purpose of improving the dynamic performance of the titanium alloy is achieved in combination with a high-temperature homogenizing treatment and cyclic forging process.

Owner:西部超导材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com