A dielectric ceramic material and a preparation method thereof

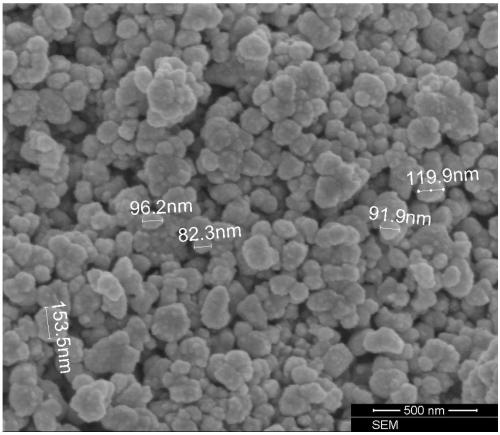

A technology for dielectric ceramics and ceramic powders, applied in the field of ceramic materials, can solve the problems of damaging the dielectric properties of alumina dielectric ceramic materials and reducing the Q value of the quality factor of alumina dielectric ceramics, achieving high density, high Q value, The effect of uniform grain distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

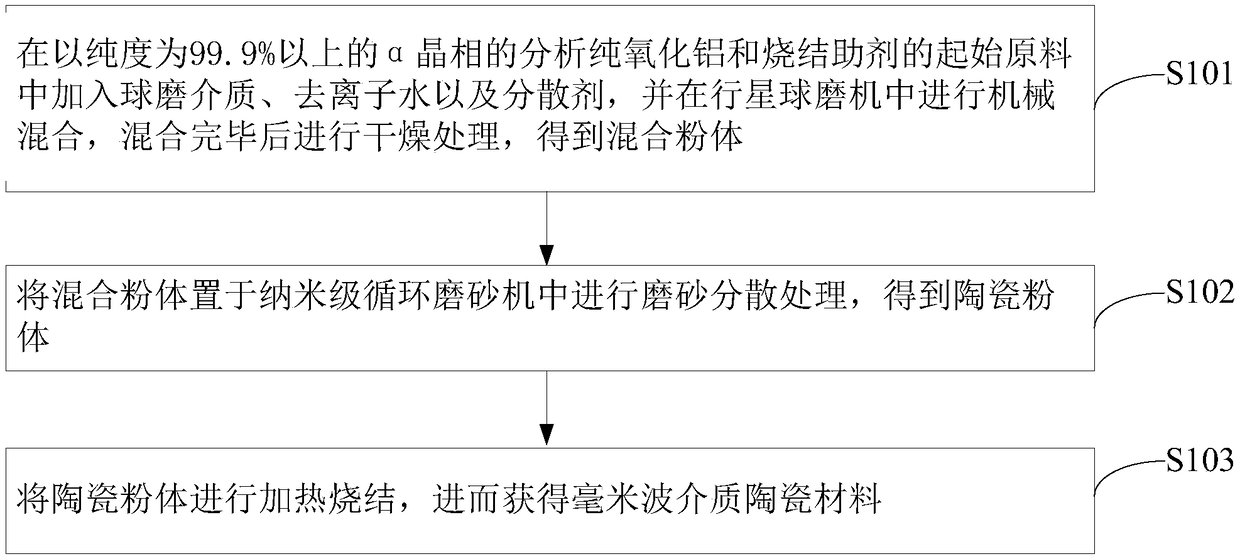

[0044] see figure 2 , figure 2 It is a schematic flow chart of an embodiment of the method for preparing a dielectric ceramic material of the present invention. The preparation method of the dielectric ceramic material of an embodiment provided by the present invention, the preparation method comprises:

[0045] Step S101, adding ball milling medium, deionized water and dispersant to the starting raw materials of analytically pure alumina with a purity of 99.9% or more in the α crystal phase and sintering aids, and mechanically mixing in a planetary ball mill, and the mixing is completed Afterwards, drying treatment is carried out to obtain a mixed powder.

[0046] The molecular formula is Al 2 o 3 —xMO, wherein, MO represents a sintering aid, and the sintering aid is selected from at least one of analytically pure boron oxide, analytically pure silicon dioxide, analytically pure magnesium oxide, and analytically pure zinc oxide, and the analytically pure alumina and the...

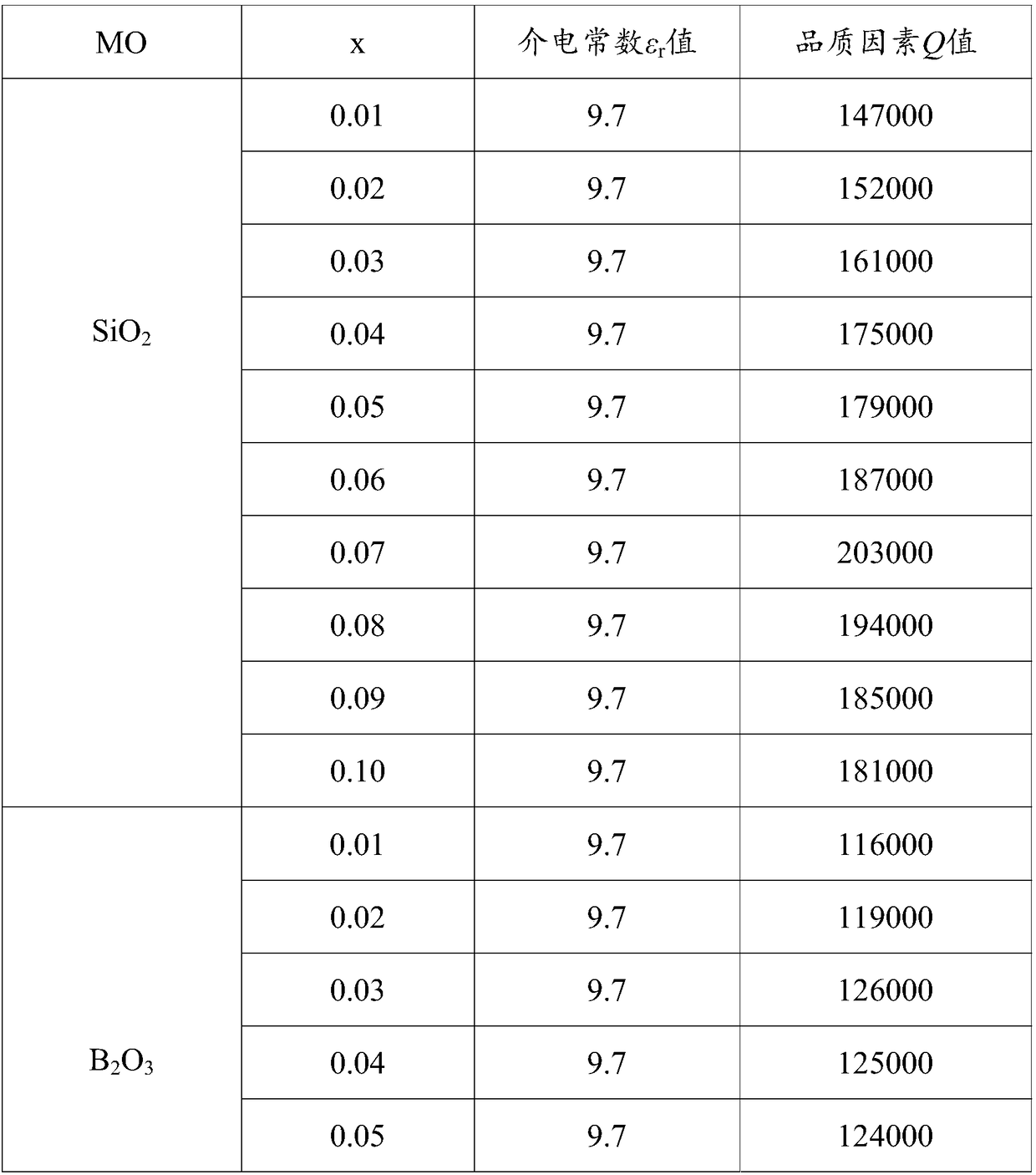

Embodiment 1

[0072] The starting materials in Example 1 are proportioned according to the molecular formula Al2O3—xMO, wherein MO represents one of B2O3, SiO2, MgO, and ZnO, and the molar ratio of analytically pure alumina to sintering aid is 1:x, where x is The value range is 0.01 to 0.1. The mixed material of analytically pure alumina with a purity of 99.9% alpha crystal phase and analytically pure boron oxide, analytically pure silicon dioxide, analytically pure magnesium oxide or analytically pure zinc oxide is used as a starting material, and is realized through the following process steps.

[0073] 1) Using a mixture of analytically pure alumina with a purity of 99.9% α crystal phase and analytically pure boron oxide, analytically pure silicon dioxide, analytically pure magnesium oxide or analytically pure zinc oxide as the starting material, the above starting material Weigh it according to a certain molar ratio and place it in a polyurethane ball mill jar, add a certain amount of z...

Embodiment 2

[0085] The starting raw material of embodiment 2 carries out proportioning according to molecular formula Al2O3—0.07{SiO2—(1-y)ZnO—yMgO}, wherein analytically pure alumina, analytically pure silicon dioxide, analytically pure zinc oxide and analytically pure magnesium oxide The molar ratio is 1:0.07:0.07(1-y):0.07y, wherein the range of y is 0-1. The mixed material of analytically pure alumina, analytically pure silicon dioxide, analytically pure magnesium oxide or / and analytically pure zinc oxide with a purity of 99.9% in alpha crystal phase is used as a starting material, and is realized through the following process steps.

[0086] 1) Using a mixture of analytically pure alumina, analytically pure silicon dioxide, analytically pure magnesium oxide or / and analytically pure zinc oxide with a purity of 99.9% of the α crystal phase as the starting material, the above-mentioned starting materials are mixed in a certain molar ratio Weigh it and place it in a polyurethane ball mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com