Preparation method of emulsified asphalt cold recycled mixture

A technology of cold recycled mixture and emulsified asphalt, which is applied in the field of preparation of emulsified asphalt cold recycled mixture, to achieve enhanced adhesion, high and low temperature performance, improved freeze-thaw damage resistance, and improved microscopic uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The embodiment of the present application provides a method for preparing emulsified asphalt cold recycled mixture, comprising the following steps:

[0024] S1. Add water to the fine RAP material, vibrate and mix to obtain the first premixed material;

[0025] S2. Add water after mixing the coarse RAP material and the aggregate, and obtain the second premixed material after mixing;

[0026] S3. Add the second premix to the first premix, then add emulsified asphalt, vibrate and mix evenly, then add mineral powder and cement and continue stirring to obtain emulsified asphalt cold recycled mixture;

[0027] Wherein, the particle size of the coarse RAP material is 15-25 mm, and the particle size of the fine RAP material is 0.01-15 mm.

[0028] It should be noted that, in the examples of the present application, the fine RAP material and water were vibrated and mixed to obtain the first premix, and the second premix was obtained after mixing the coarse RAP material, aggrega...

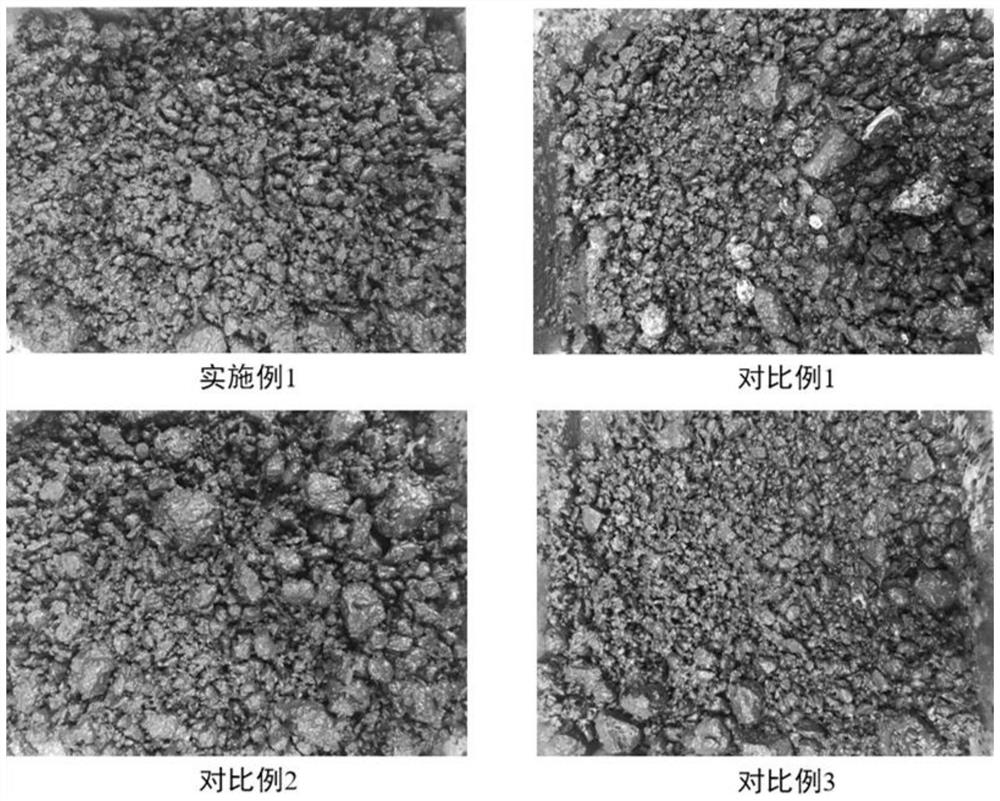

Embodiment 1

[0037] The embodiment of the present application provides a method for preparing emulsified asphalt cold recycled mixture, comprising the following steps:

[0038] S1. In parts by weight, add 65 parts of fine RAP material and 4 parts of water to the vibration stirring equipment, and vibrate and mix for 1 min at a rotation speed of 55 r / min and a vibration intensity of 4 to obtain the first premixed material;

[0039] S2. In parts by weight, add 2 parts of emulsifier to 65 parts of asphalt and stir to obtain emulsified asphalt;

[0040] S3. In parts by weight, mix 15 parts of rough RAP material and 15 parts of limestone, add 1 part of water, and stir evenly to obtain the second premixed material;

[0041] S4. Add the second premix in S3 and the first premix in S1 to Detong DT60ZBW twin-shaft vibrating mixer, then add 4 parts of emulsified asphalt, at a speed of 55r / min and a vibration intensity of 4 Vibrate and mix for 1 minute, then add 4 parts of mineral powder and 1 part of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com