Sintering additive composition, dielectric ceramic composition, and their applications

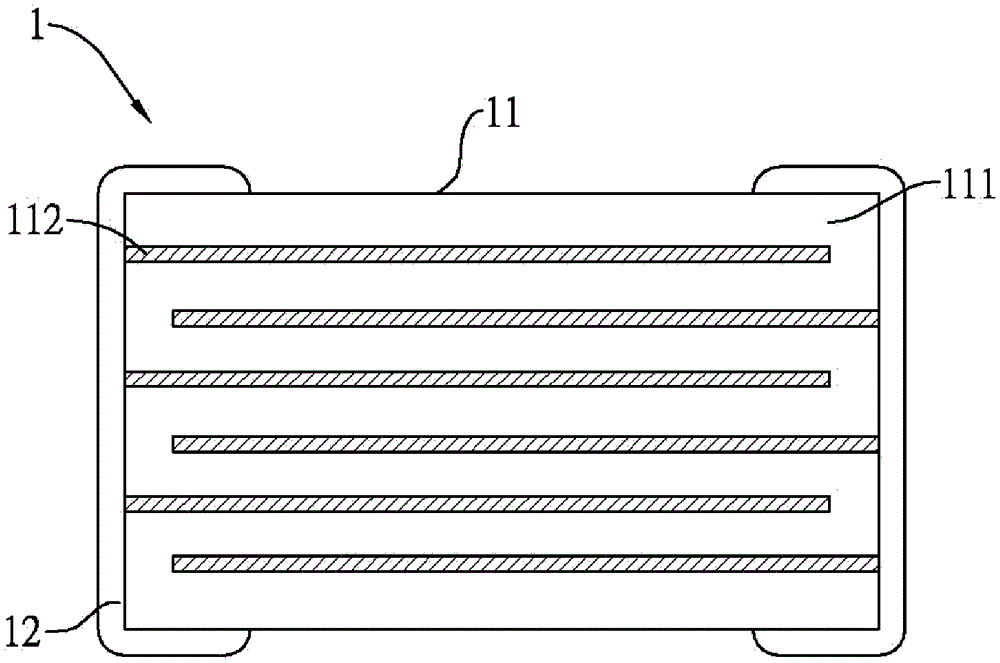

A technology for dielectric ceramics and compositions is applied in the field of multilayer ceramic capacitors and sintering additive compositions, which can solve the problems of reducing the effective electrode area size and decreasing the reliability of multilayer ceramic capacitors, so as to improve microscopic uniformity and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] "Preparation of sinter additive composition"

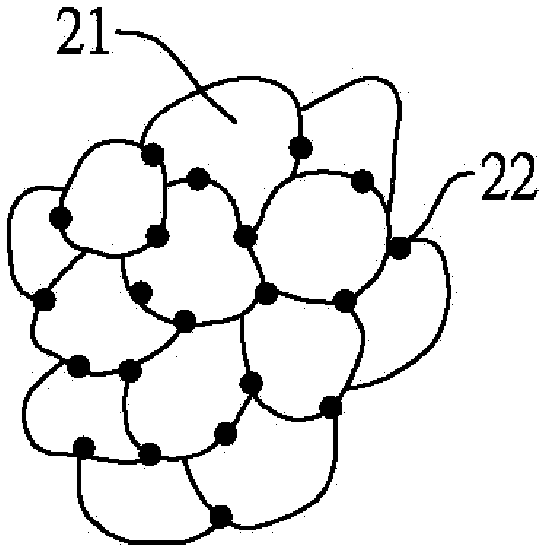

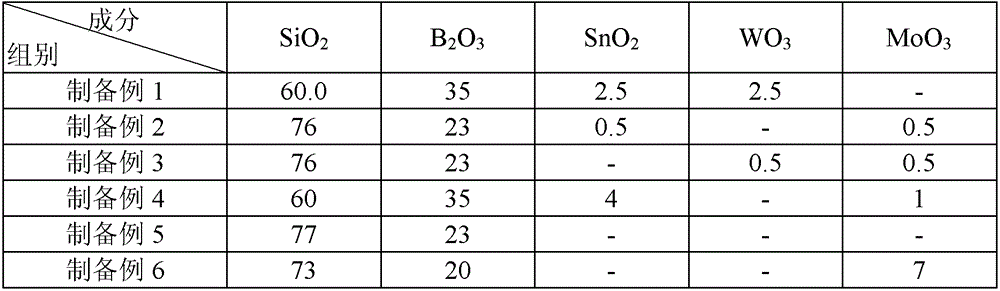

[0038] Silicon dioxide (SiO 2 ), boron trioxide (B 2 o 3 ) and tin dioxide (SnO 2 ), tungsten trioxide (WO 3 ) and molybdenum trioxide (MoO 3 ) is the modified component uniformly mixed into powder, placed in a high temperature environment for heat treatment, and ground and pulverized by a ball mill to form spherical particles with a particle diameter of about 50 to 100 nm, which is used as the sintering additive composition of the present invention. Wherein, the ingredients and content (mole) added in each preparation example are shown in Table 1.

[0039] Table 1: Components and contents of sintering additive compositions in each preparation example

[0040]

[0041] In Preparation Example 1 to Preparation Example 4, the overall sintering composition is 100 moles, the content of silicon dioxide is between 60 moles and 85 moles, and the content of diboron trioxide is between 10 moles and 35 moles. between, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com