Thermal deformation rare-earth permanent magnet material and preparation method thereof

A rare-earth permanent magnet and thermal deformation technology, which is applied in the direction of magnetic materials, inductors/transformers/magnets, and magnetic objects, can solve the problems of lack of rare-earth-rich grain boundary phases and difficulty in entering rare-earth-rich grain boundary phases, so as to promote The effect of formation and optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing a thermally deformed rare earth permanent magnet material, which comprises the following steps:

[0039] S1, providing main magnetic powder and low melting point alloy powder respectively, wherein the chemical formula of the main magnetic powder is Re by mass percentage x Fe 100-x-y-z m y B z , where Re is one or more of Nd, Pr, Dy, Tb, La, Ce, M is one or more of Al, Co, Cu, Ga, 20≤x≤40, 0≤y≤ 10, 0.7≤z≤1.5, the chemical formula of the low melting point alloy powder is Re in mass percentage a Cu 100-a , where Re is one or more of Nd, Pr, Dy, Tb, La, Ce, 60≤a≤90;

[0040] S2, uniformly mixing the main magnetic powder and the low melting point alloy powder to obtain a mixed magnetic powder, wherein the mass proportion of the low melting point alloy powder in the mixed magnetic powder is greater than 0 and less than or equal to 10%; and

[0041] S3, subjecting the mixed magnetic powder to hydrogenation-disproportionation-de...

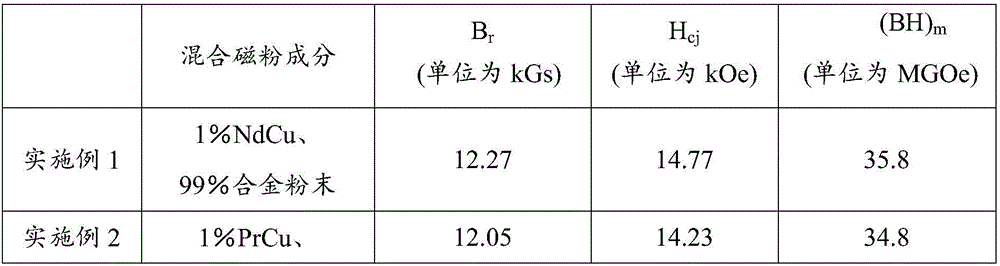

Embodiment 1 to Embodiment 3

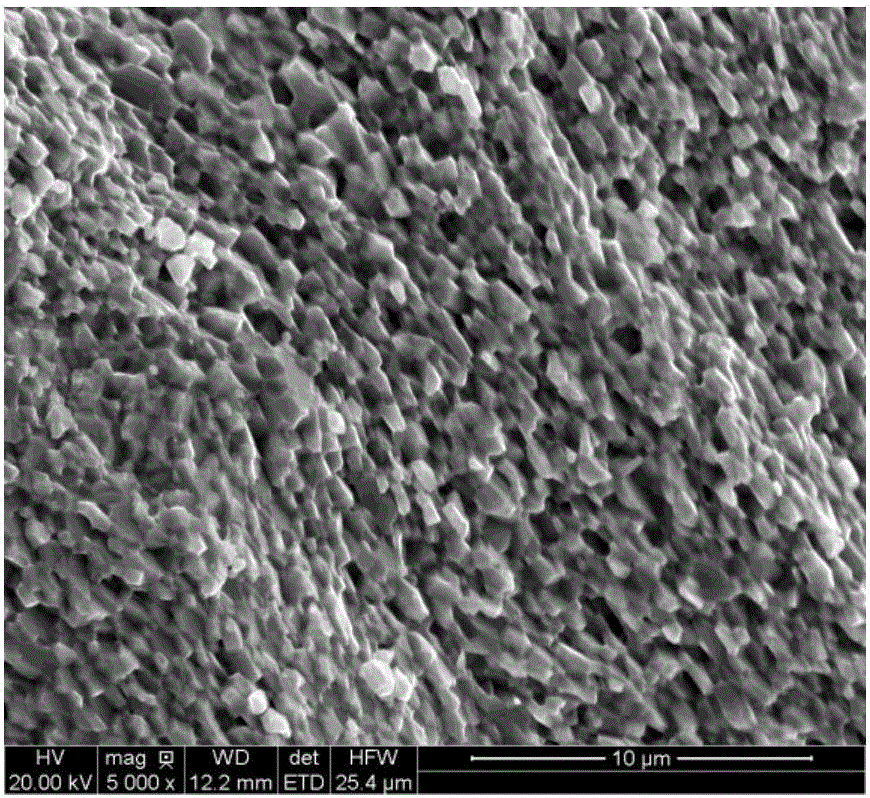

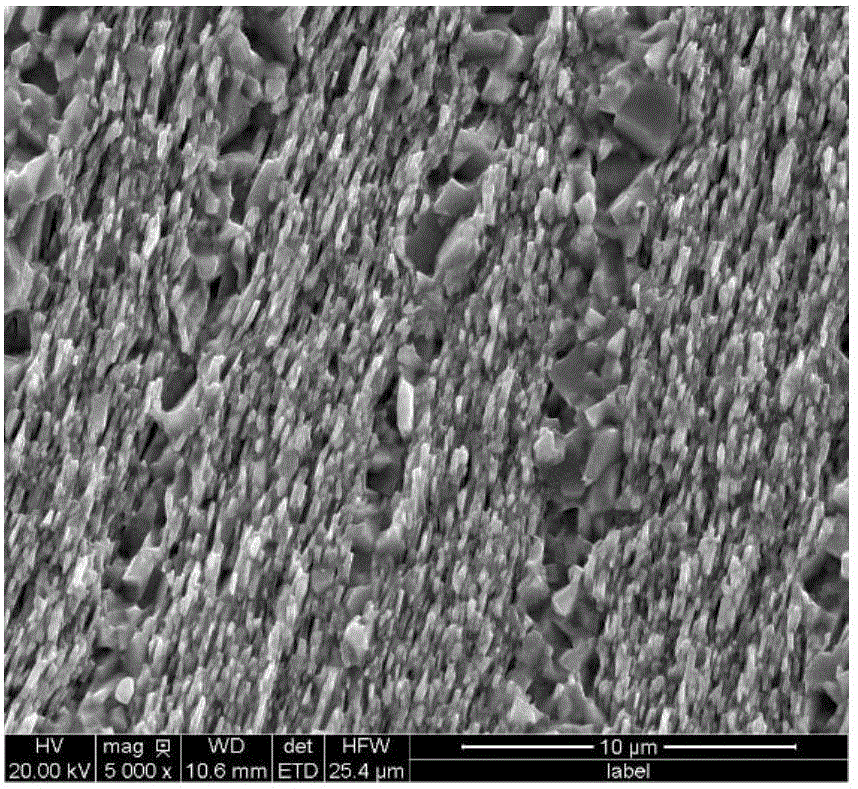

[0074] In composition Nd 30.3 PR 0.1 Ga 0.46 co 4.1 Fe bal. B 0.92 Add low-melting point alloy powders with a grain size of 100 microns to 350 microns to the rapidly solidified alloy magnetic powder with a grain size of 30 nanometers to 50 nanometers, and mix them evenly. The addition amount and type of the low-melting point alloy powder in Examples 1 to 3 are different, please refer to Table 1 for details.

[0075] Put the mixed magnetic powder into the rotary hydrogen heat treatment furnace, heat the magnetic powder to 840°C in the hydrogen atmosphere, and keep the hydrogen pressure in the cavity at 50kPa, so that the mixed powder can diffuse in the hydrogen atmosphere, so that the low-melting point alloy can fully diffuse, and at the same time A sufficient disproportionation reaction occurs. When the disproportionation reaction is complete, turn off the hydrogen controller and work together with the vacuum system to maintain a vacuum of 3kPa in the chamber. After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com