Novel corrosion-resistant zirconium-based alloy and preparation method thereof

A zirconium-based alloy and corrosion-resistant technology, which is applied in the field of new corrosion-resistant zirconium-based alloy and its preparation, can solve the problems of inability to adjust the performance characteristics of elements, restricting the application of alloys, and being highly toxic to the human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Press Zr 60 Cu 21 al 10 Fe 5 Nb 4 Component ratio Weigh pure zirconium, pure copper, pure aluminum, pure iron, pure niobium with a purity of 99.9%, put the raw materials into the electric arc melting furnace after weighing;

[0033] (2) Vacuumize the arc melting furnace to 5×10 -3 After the Pa is filled with argon, under the protective atmosphere, the raw materials prepared in step (1) except pure aluminum are heated to 2500 °C for 15 minutes in an electric arc melting furnace. After the melting is completed, the alloy ingot is turned over with a manipulator in the furnace, Repeat the melting 6 times to ensure that the components are evenly distributed;

[0034] (3) Mix the alloy ingot smelted in step (2) with pure aluminum and heat it to 1400°C for 15 minutes in an electric arc melting furnace. A good master alloy is broken and ultrasonically cleaned with distilled water and alcohol;

[0035] (4) The sample dried in (3) is packed into a quartz tube, and plac...

Embodiment 2

[0038] Other steps are with embodiment 1, difference is by Zr 60 Cu 17 al 10 Fe 5 Nb 8 Component ratio: Weigh pure zirconium, pure copper, pure aluminum, pure iron, and pure niobium with a purity of 99.9%.

Embodiment 3

[0040] Other steps are with embodiment 1, difference is by Zr 60 Cu 13 al 10 Fe 5 Nb 12 Component ratio: Weigh pure zirconium, pure copper, pure aluminum, pure iron, and pure niobium with a purity of 99.9%.

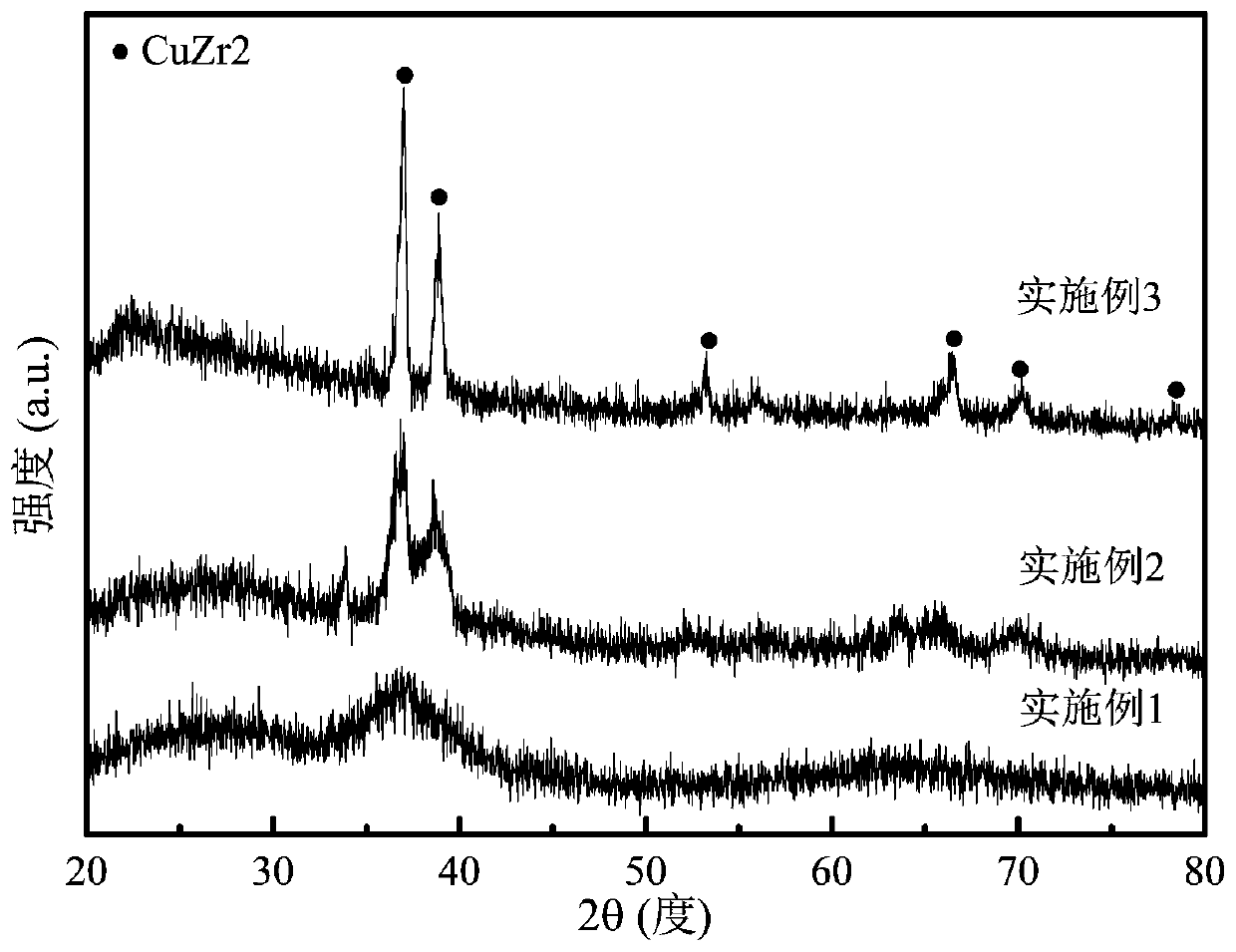

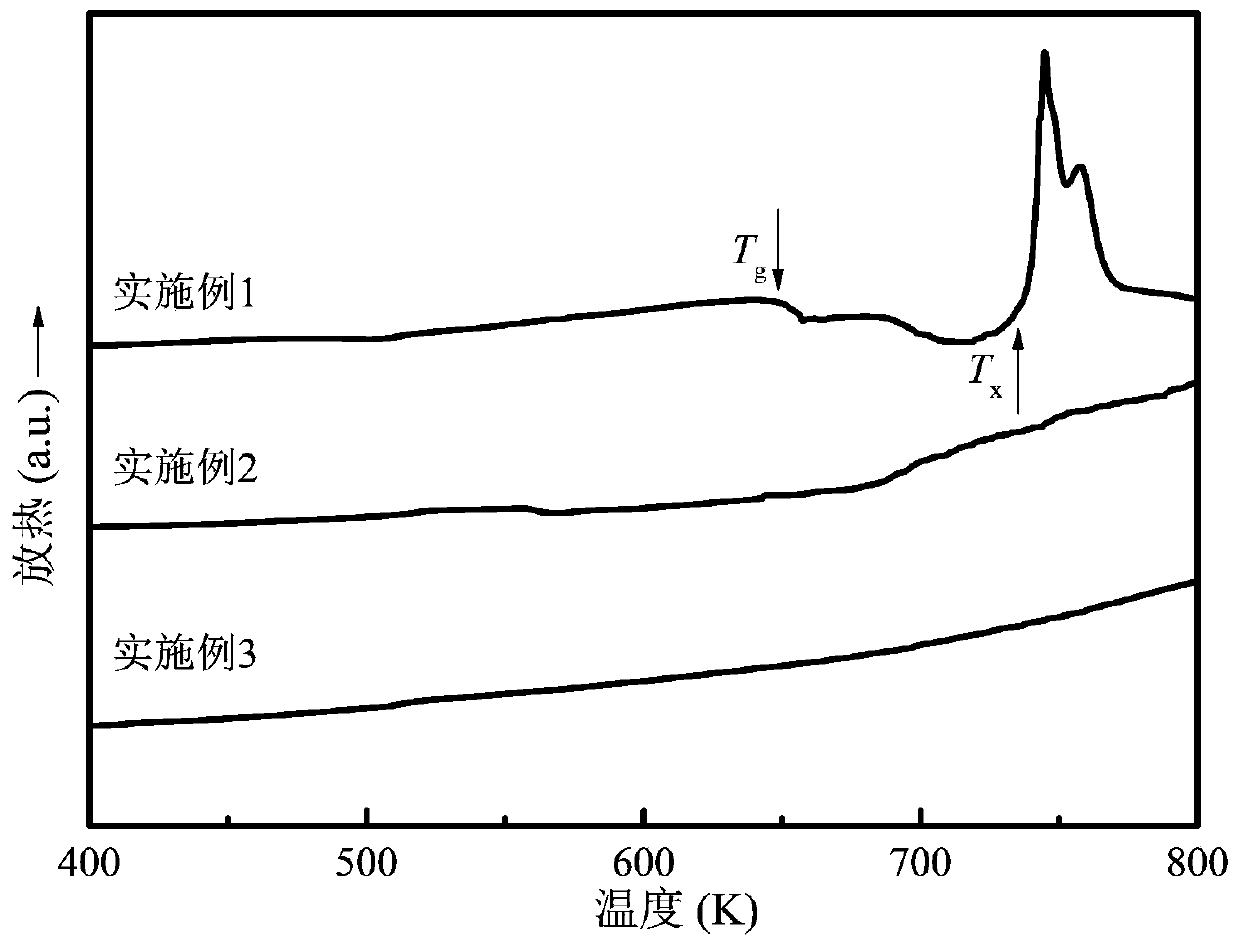

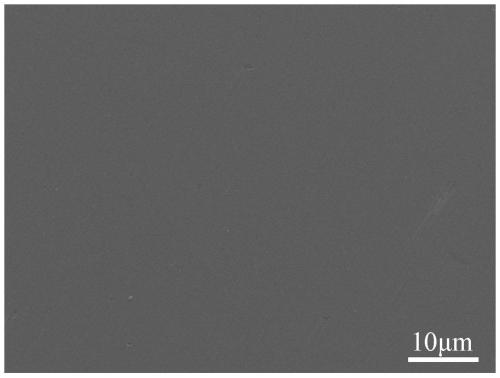

[0041] Through the above examples combined with the attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 It can be seen that sharp crystal peaks have occurred on the XRD spectrum of Example 2, indicating that a crystalline phase has occurred; the exothermic peaks on the DSC curves of Examples 1 and 2 indicate that crystallization exothermic phenomenon has occurred, which proves that the presence of an amorphous phase. Therefore in Zr 60 Cu 25 al 10 Fe 5 Zirconium-based alloys with completely amorphous structure, amorphous composite structure and completely crystalline structure can be prepared by adding different amounts of Nb elements in Zr, and the crystalline phase is dendritic, so the room temperature pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com