Titanium alloy and machining method thereof

A titanium alloy, the obtained technology, applied in the field of titanium alloy, can solve the problems of high price and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

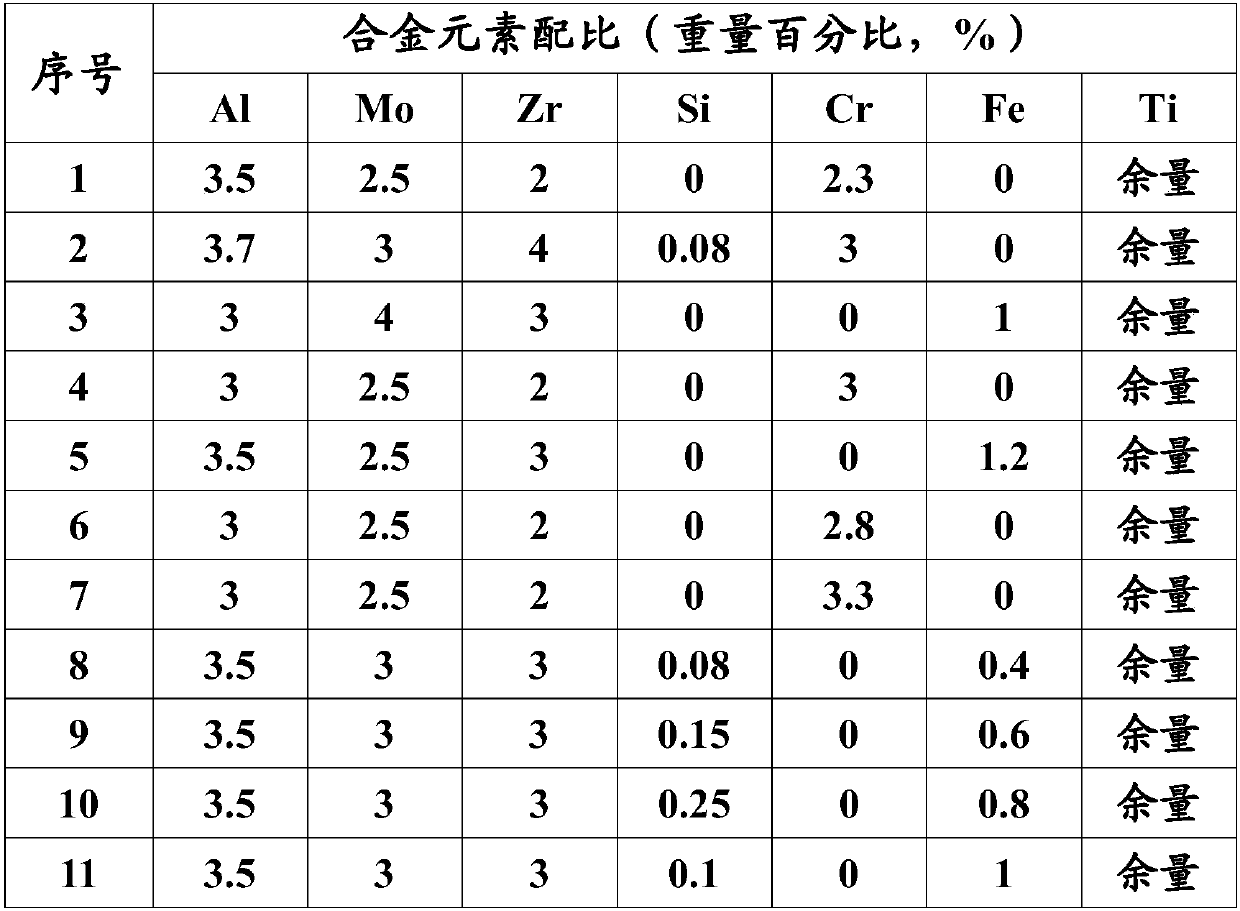

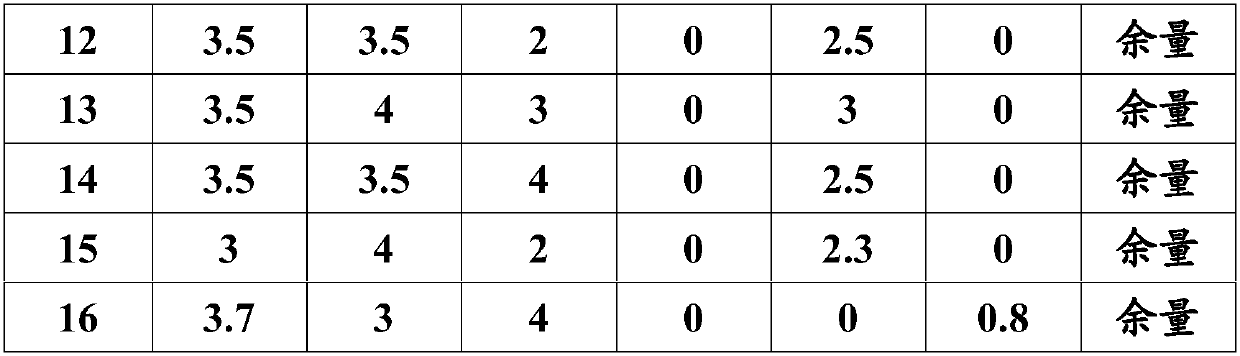

Examples

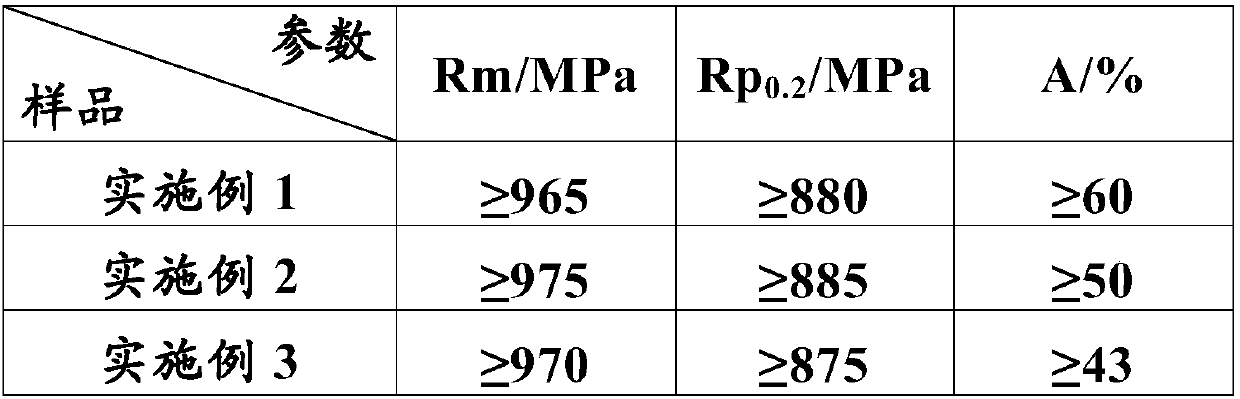

Embodiment 1

[0113] Obtain a titanium alloy ingot with a nominal composition of Ti-3.5Al-2.5Mo-2Zr-2.3Cr (weight percent, %), open billet forging at 1150°C, and obtain a rod-shaped titanium alloy billet to be processed, Φ160mm, the titanium alloy T β It is 900-915°C.

[0114] 1) Heating the titanium alloy blank to be processed to T β +60°C, keep warm for 100min, then forge, first pier rough deformation 50%, and then elongate deformation 50%, after forging, quickly put into water with a temperature of 15°C to 25°C to cool;

[0115] 2) step 1) gained titanium alloy is heated to T β -30°C, keep warm for 100min, then forge, first pier rough deformation by 50%, and then elongate by 50%, after forging, quickly put into water at a temperature of 15°C to 25°C to cool;

[0116] 3) step 2) gained titanium alloy is heated to T β +20°C, keep warm for 80 minutes, then forge, first pier rough deformation by 50%, then elongate and deform by 50%, after forging, quickly put it into water at a temperatu...

Embodiment 2

[0121] Obtain a titanium alloy ingot with a nominal composition of Ti-3.7Al-3Mo-4Zr-3Cr-0.08Si (weight percent, %), open billet forging at 1150°C, and obtain a rod-shaped titanium alloy billet to be processed, Φ160mm, the titanium alloy the T β It is 895~910℃.

[0122] 1) Heating the titanium alloy blank to be processed to T β+55°C, keep warm for 100min, then forge, first pier rough deformation by 40%, then elongate and deform by 40%, after forging, quickly put into water with a temperature of 15°C to 25°C to cool;

[0123] 2) step 1) gained titanium alloy is heated to T β -35°C, keep warm for 100min, then forge, first pier rough deformation by 40%, then elongate and deform by 40%, after forging, quickly put into water with a temperature of 15°C to 25°C to cool;

[0124] 3) step 2) gained titanium alloy is heated to T β +15°C, keep warm for 80 minutes, then forge, first pier rough deformation by 40%, then elongate and deform by 40%, after forging, quickly put it into water...

Embodiment 3

[0129] Obtain a titanium alloy ingot with a nominal composition of Ti-3Al-4Mo-3Zr-1Fe (weight percent, %), open billet forging at 1150°C, and obtain a rod-shaped titanium alloy billet to be processed, Φ160mm, the T of the titanium alloy β It is 905-920°C.

[0130] 1) Heating the titanium alloy blank to be processed to T β +65°C, keep warm for 100min, then forge, first pier rough deformation by 50%, and then elongate by 50%, after forging, quickly put into water with a temperature of 15°C to 25°C to cool;

[0131] 2) step 1) gained titanium alloy is heated to T β -25°C, keep warm for 100min, then forge, first pier rough deformation by 50%, and then elongate by 50%, after forging, quickly put into water at a temperature of 15°C to 25°C to cool;

[0132] 3) step 2) gained titanium alloy is heated to T β +25°C, keep warm for 80 minutes, then forge, first pier rough deformation 50%, then elongate deformation 50%, after forging, quickly put into water with a temperature of 15°C t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com