Method for improving room-temperature tensile property of Ti-48Al-2Cr-2Nb alloy through adding of nano Y2O3

A tensile property, nanotechnology, applied in the field of improving the room temperature tensile properties of Ti-48Al-2Cr-2Nb alloys, can solve the problems of coarse alloy structure and segregation, and achieve room temperature plastic improvement, increase the number of dislocations, and improve room temperature resistance. The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

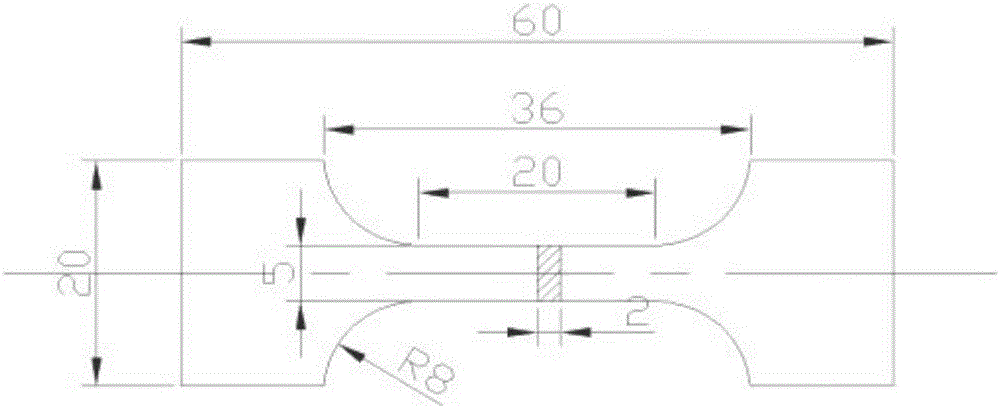

[0017] Specific implementation mode 1: In this implementation mode, a method by adding nano-Y 2 o 3 The method to improve the tensile properties of Ti-48Al-2Cr-2Nb alloy at room temperature is:

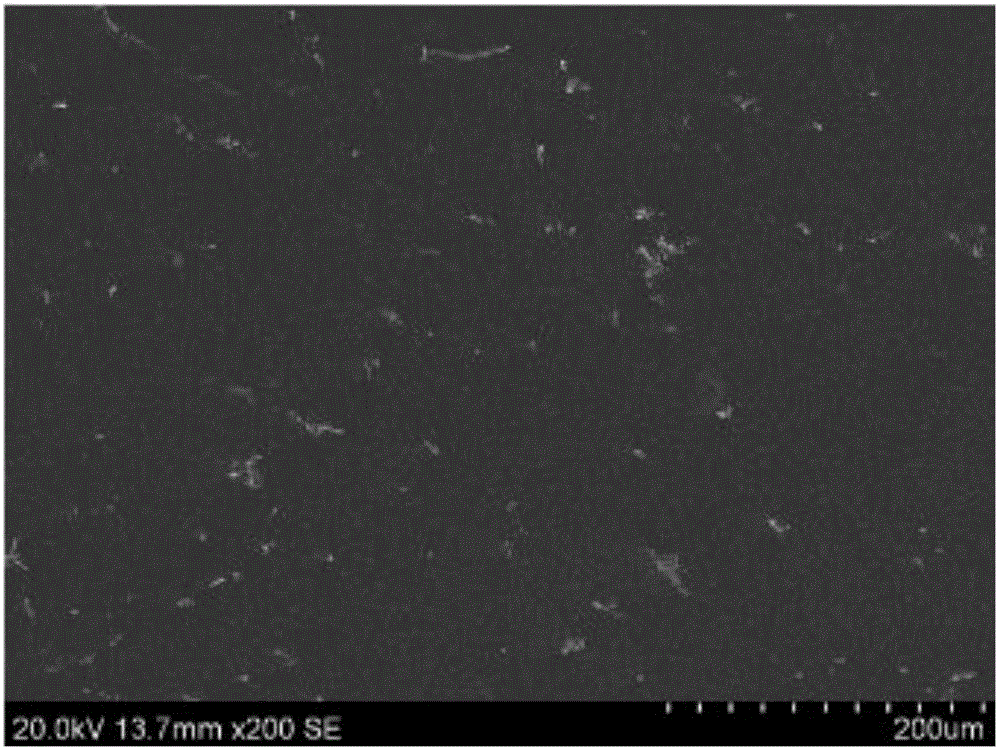

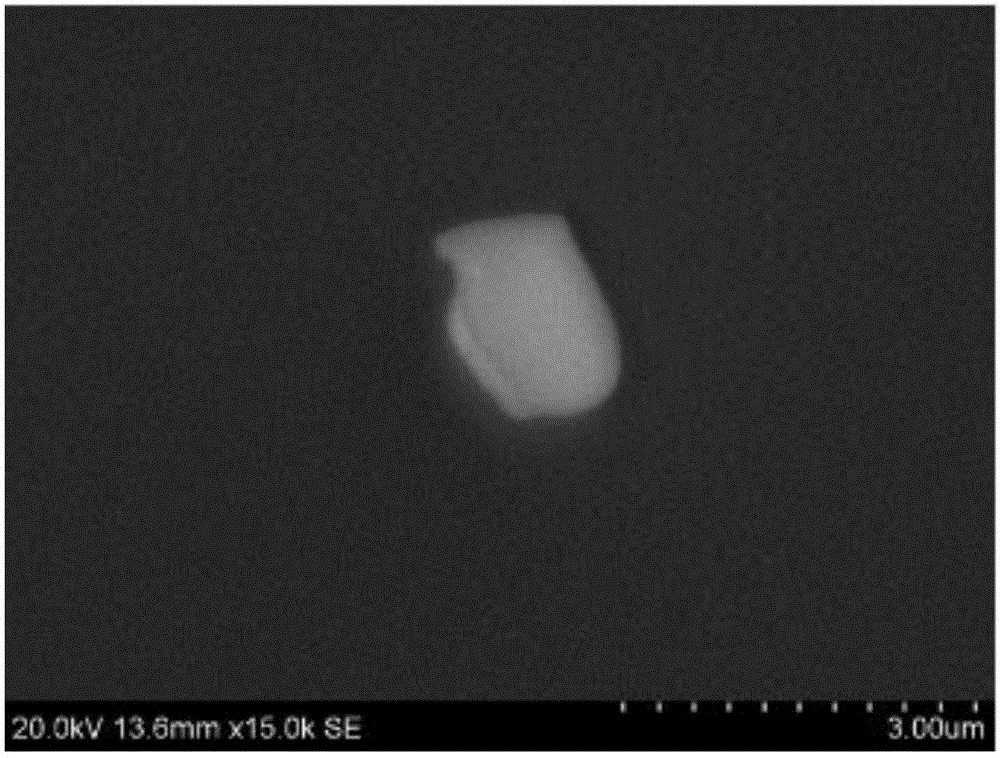

[0018] 2. First pump the air pressure in the furnace cavity of the water-cooled copper crucible induction shell melting furnace to 4Pa, then fill it with argon to 700-800Pa, and repeat the gas washing process twice; Alloys, pure titanium rods, pure aluminum ingots, pure Cr and nano Y with a diameter of 10-100nm and an atomic percentage of 0.025-0.1 2 o 3 Mix the particles evenly, put them into a water-cooled copper crucible induction shell melting furnace, turn on the circulating cooling water, and adjust the power to 20kw in an argon environment. After all the pure aluminum ingots are melted, increase the power to 40-50kw. After the pure titanium rod is melted, adjust the power to 80kw, keep it warm for 20 minutes, and then cast it to obtain nano-Y 2 o 3 Ti-48Al-2Cr-2Nb alloy, w...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that: the pure titanium rod in step 2 refers to a titanium rod with a titanium mass percentage of 99.9%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the pure aluminum ingot in step 2 refers to an aluminum ingot with an aluminum mass percentage of 99.9%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com