Modified recyclable recycled high-impact-resistant PE (Polyethylene) applied tofor plastic tray and preparation method thereof

A plastic pallet, high impact technology, applied in the field of modified recycled high impact PE and its preparation, can solve the problems of performance deviation of recycled plastic pallets, achieve good material shearing effect, reduce cost and improve rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

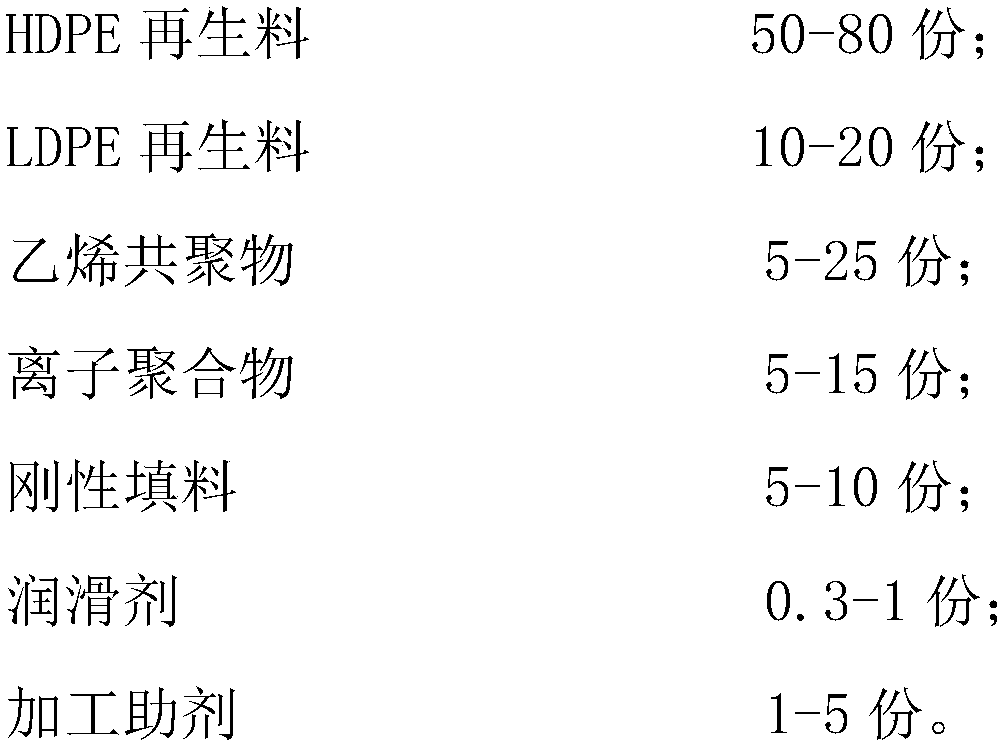

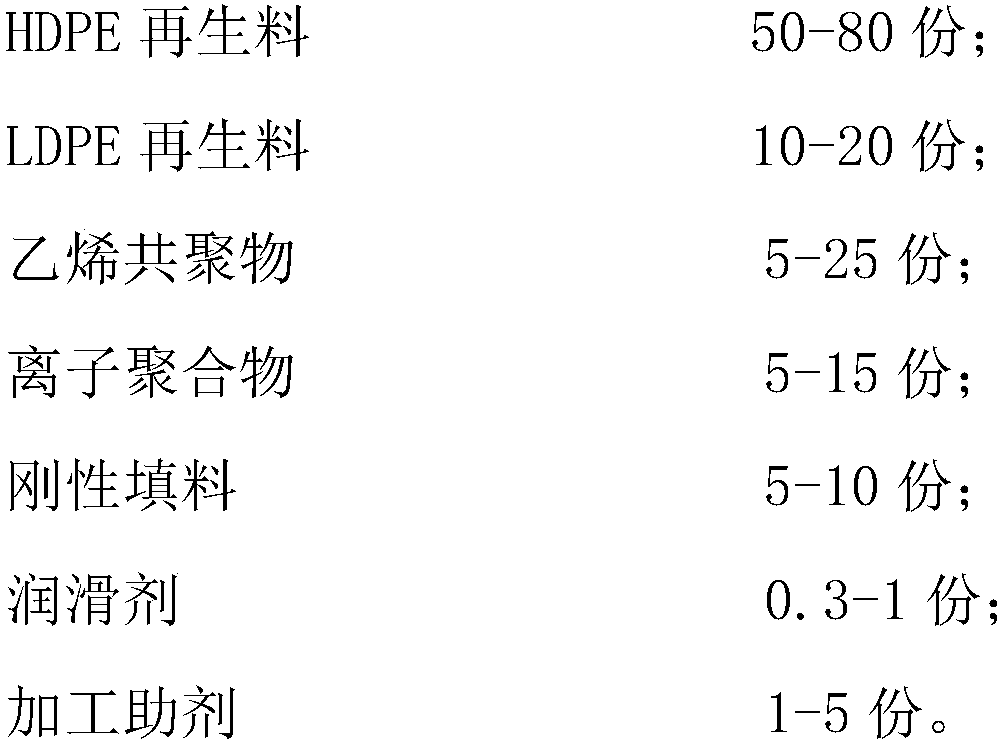

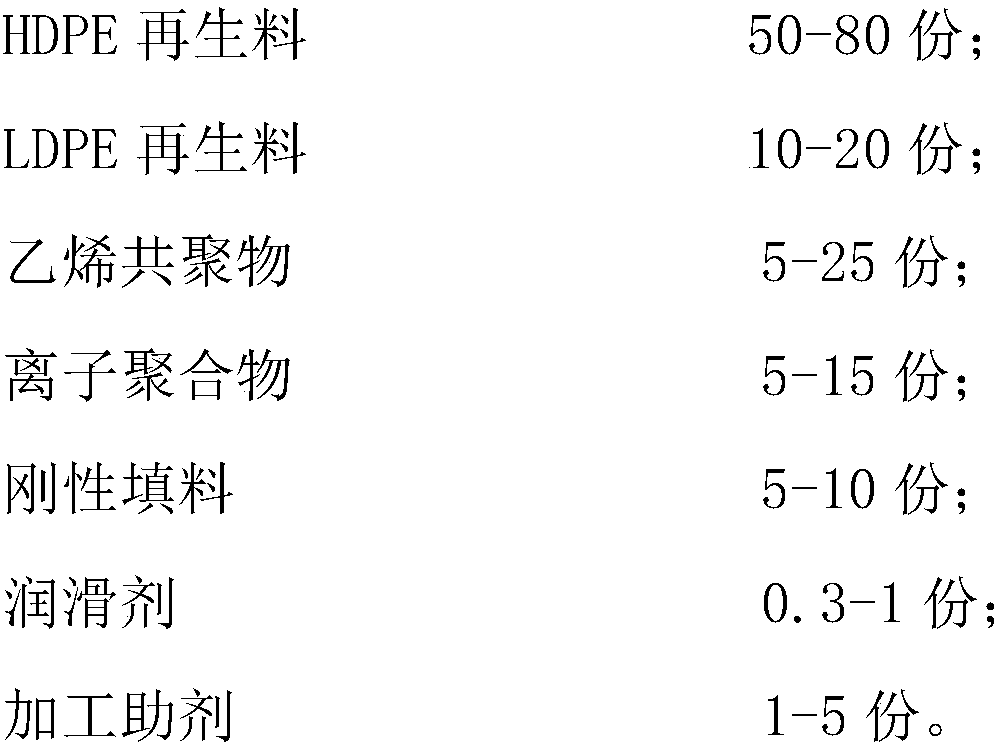

Method used

Image

Examples

Embodiment 1

[0045] Formula (raw material components by weight): 45 parts of recycled blue PE tray crushed material, 20 parts of recycled white PE small hollow bucket crushed material, 15 parts of recycled LDPE film granulation material, 10 parts of recycled white PE copolymer paint bucket crushed material parts, sarin resin 8 parts, talcum powder 8 parts, compound lubricant 0.5 parts, antioxidant 1010 0.3 parts, antioxidant 168 0.3 parts, blue mother 0.5 parts.

[0046] According to the above formula, mix the materials evenly with a high-speed mixer, and then extrude and granulate with a conical twin-screw extruder to prepare blue modified recycled PE particles. , three zones 165°C, confluent core 160°C, die one 140°C, die two 150°C; speed setting: feeding speed 12 rpm, extrusion speed 15 rpm, rotary cutting speed 44 rpm .

[0047] The prepared particles were injection-molded as specimens, and then tested.

[0048] Through the test of the standard sample, it can be found that the modifi...

Embodiment 2

[0050]Formula (raw material components by weight): 30 parts of recycled white PE fruit basket crushed material, 25 parts of recycled blue PE tray crushed material, 15 parts of recycled blue PE large hollow barrel crushed material, 10 parts of recycled LDPE film pelletizing material 20 parts, recycled blue EVA sheet broken material 20 parts, regenerated ionic polymer material 10 parts, calcium carbonate 5 parts, talcum powder 4 parts, compound lubricant 0.7 part, antioxidant 1010 0.3 part, antioxidant 168 0.3 part , blue mother 0.8 part.

[0051] According to the above formula, mix the materials evenly with a high-speed mixer, and then extrude and granulate with a conical twin-screw extruder to prepare blue modified recycled PE particles. , three zones 185°C, confluent core 180°C, die one 165°C, die two 160°C; speed setting: feeding speed 20 rpm, extrusion speed 18 rpm, rotary cutting speed 50 rpm .

[0052] The prepared particles were injection-molded as specimens, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com