Planetary concrete mixer

A concrete mixer, planetary technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems affecting the workability, strength and durability of concrete, cement particles are not uniformly dispersed, blades Complex structure and other problems, to achieve the effects of easy popularization, enhanced relative mobility, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

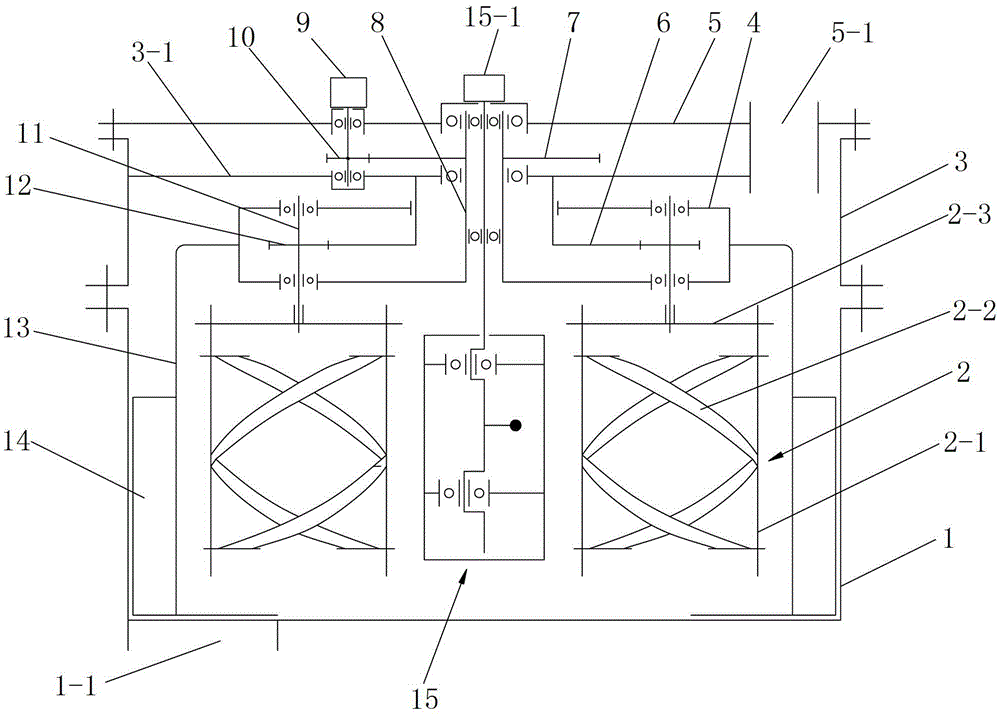

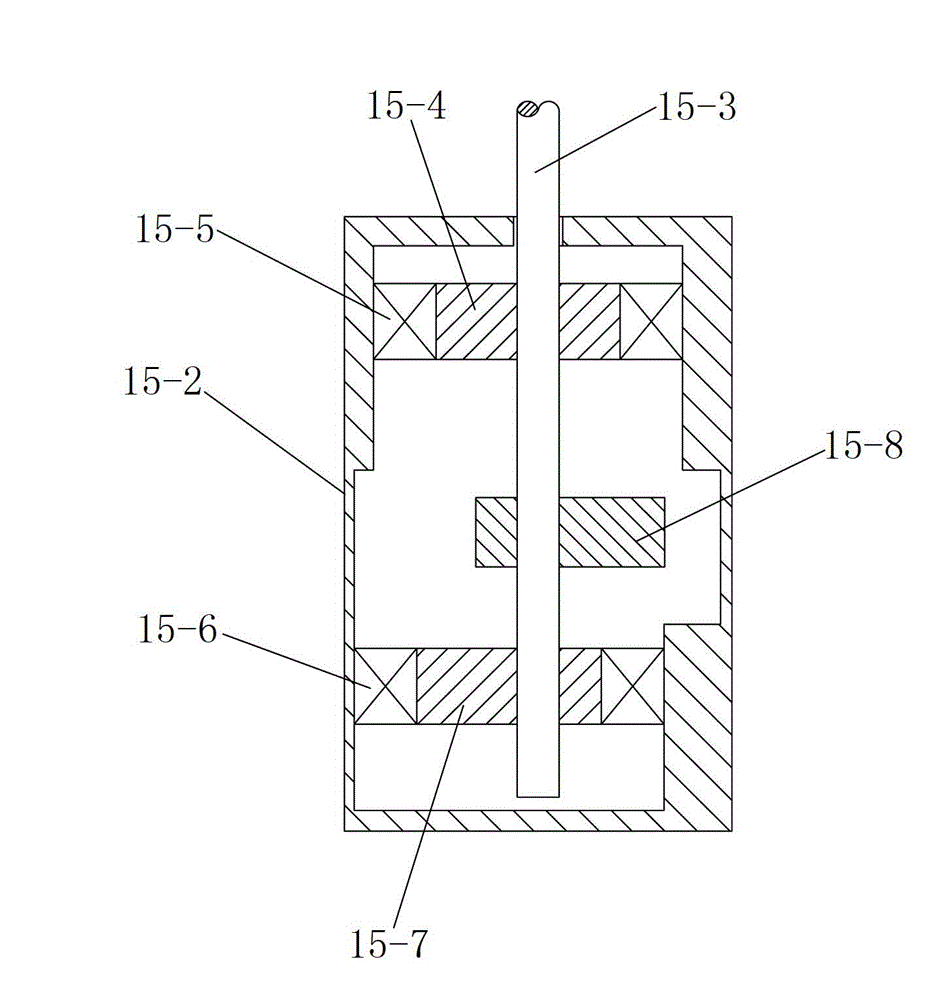

[0032] like figure 1 A planetary concrete mixer shown includes a lower cylinder 1 and a plurality of ribbon stirring devices 2 arranged inside the lower cylinder 1. The upper part of the lower cylinder 1 is connected with a middle A cylinder 3, a planetary gear mechanism is arranged in the middle cylinder 3; a cover plate 5 is arranged on the upper end of the middle cylinder 3, and a stirring drive device 9 is arranged on the cover plate 5, and the stirring drive device 9 The power output shaft passes through the cover plate 5 and extends into the middle cylinder 3, and a pinion 10 is installed at the position extending into the middle cylinder 3; the middle part of the cover plate 5 is rotatably connected with a vertically arranged stirring input shaft 8. The lower end of the stirring input shaft 8 extends into the middle cylinder 3, the large gear 7 meshing with the pinion 10 is installed on the stirring input shaft 8, and the cover plate 5 is provided with a The feed port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com