Nano-ZnO varistor composite powder material and preparation method thereof

A nano-zinc oxide and composite powder technology is applied in the field of varistor manufacturing, which can solve the problems that the electrical properties of varistors cannot be greatly improved, and the uniformity of additive doping cannot be continuously improved, and the chemical composition can be achieved. Accurate control, uniform distribution of modified oxides, and the effect of increasing the density of grains and grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

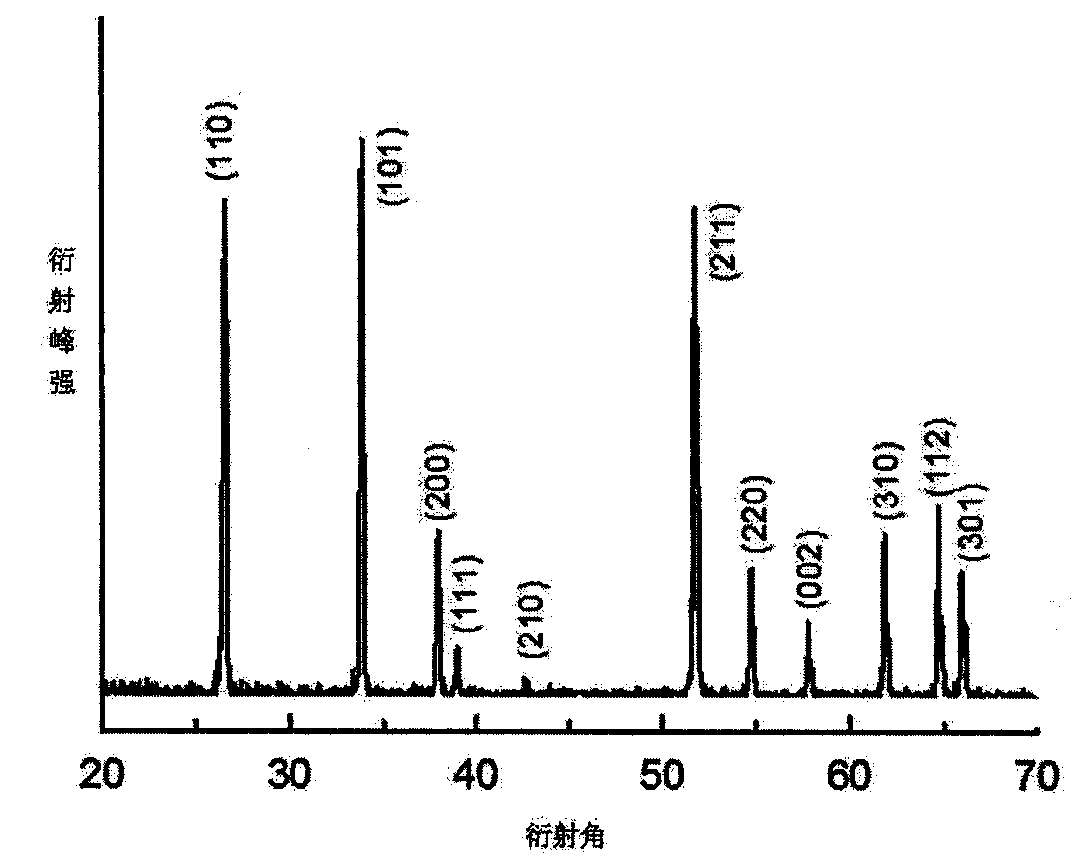

Image

Examples

Embodiment 1

[0022] In a beaker, mix zinc chloride 99mol%, dicobalt trichloride 0.4mol% powder, bismuth trichloride 0.2mol% powder, antimony trichloride 0.2mol% powder, yttrium chloride hexahydrate 0.2mol% powder , add 300mL of dilute hydrochloric acid, place in a constant temperature water bath environment at a temperature of 40°C, and stir until completely dissolved into a transparent solution;

[0023] Place the obtained transparent solution in a constant temperature water bath environment with a temperature of 40°C, use ammonia water with a volume fraction of 25% as a precipitant, and add it dropwise to the transparent solution at a constant speed, adjust the pH of the system to 8, continue stirring until the precipitation is complete, and age Filter after overnight to obtain the filtrate;

[0024] Wash the obtained filtrate, first wash with absolute ethanol with a volume fraction of 20% until the filtrate is neutral, and then wash with absolute ethanol until no chloride ions are detec...

Embodiment 2

[0028] In a beaker, put zinc chloride 89.6mol%, dicobalt trichloride 2.8mol% powder, bismuth trichloride 5.7mol% powder, antimony trichloride 0.95mol% powder, yttrium chloride hexahydrate 0.95mol% powder Mix, add 300mL dilute hydrochloric acid, place in a constant temperature water bath environment at a temperature of 50°C, and stir until completely dissolved into a transparent solution;

[0029] Place the obtained transparent solution in a constant temperature water bath environment with a temperature of 40°C, use ammonia water with a volume fraction of 25% as a precipitant, and add it dropwise to the transparent solution at a constant speed, adjust the system pH to 8, continue stirring until the precipitation is complete, and age overnight Post-filtering to obtain the filtrate;

[0030] Wash the filtrate, first wash with 20% absolute ethanol by volume fraction until the filtrate is neutral, and then wash with absolute ethanol until no chloride ions are detected in the filtra...

Embodiment 3

[0034] In a beaker, mix zinc chloride 98mol%, dicobalt trichloride 1mol% powder, bismuth trichloride 0.5mol% powder, antimony trichloride 0.25mol% powder, yttrium chloride hexahydrate 0.25mol% powder, Add 300mL of dilute hydrochloric acid, place in a constant temperature water bath environment at a temperature of 60°C, and stir until completely dissolved into a transparent solution;

[0035] Place the obtained transparent solution in a constant temperature water bath environment with a temperature of 40°C, use ammonia water with a volume fraction of 25% as a precipitant, and add it dropwise to the transparent solution at a constant speed, adjust the system pH to 8, continue stirring until the precipitation is complete, and age overnight Post-filtering to obtain the filtrate;

[0036] Wash the filtrate, first wash with 20% absolute ethanol by volume fraction until the filtrate is neutral, and then wash with absolute ethanol until no chloride ions are detected in the filtrate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com