Narrow-linewidth metal type low-voltage pressure-sensitive device and preparation method for electrofluid printing

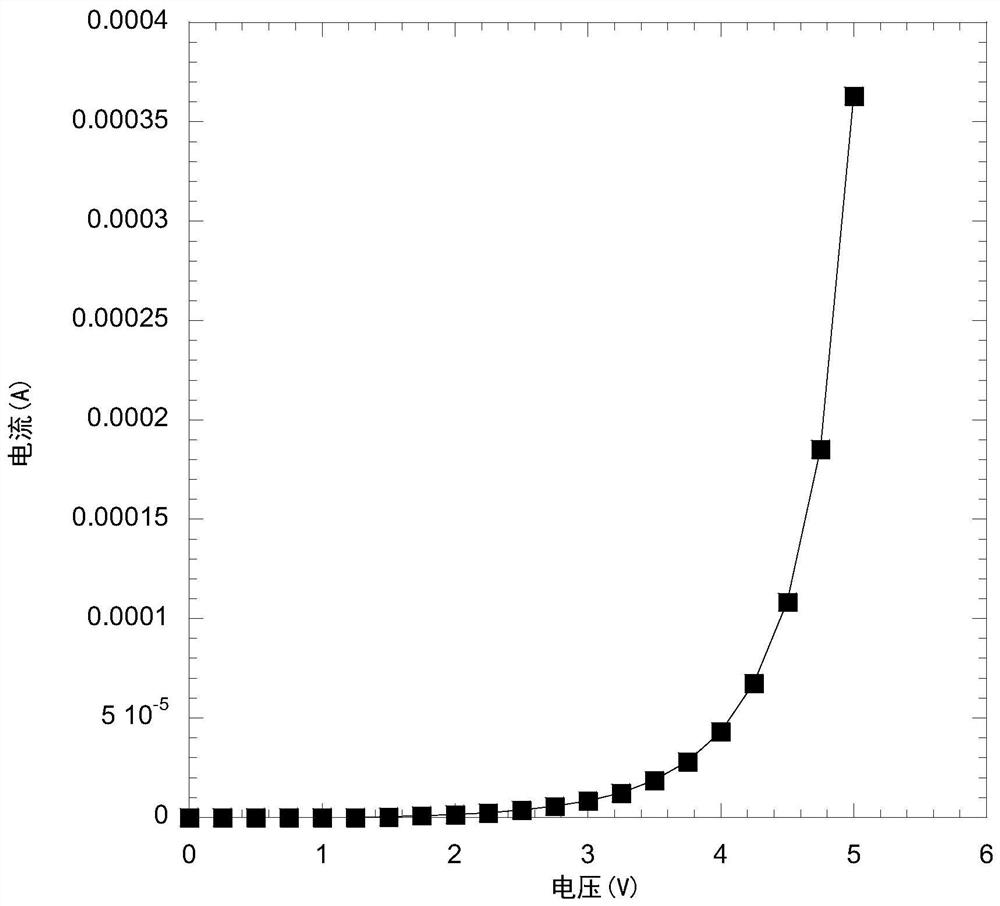

A metal type, narrow line width technology, applied in varistors, resistance manufacturing, circuits, etc., can solve the problems of destroying nano-powder agglomeration, electrical performance is difficult to guarantee, etc., to achieve good microscopic uniformity, small leakage current, non-toxic The effect of large linear coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, a nano-silver varistor based on electrofluid printing is provided, and the preparation method is as follows:

[0037] (1) Substrate cleaning: Put the substrate into an ultrasonic cleaner, and use recovered isopropanol, recovered tetrahydrofuran, alkaline cleaning solution, deionized water, and isopropanol to vibrate ultrasonically for 10 minutes, respectively.

[0038] (2) Substrate drying: put the cleaned n-type silicon plate into an oven, and dry it at 70°C.

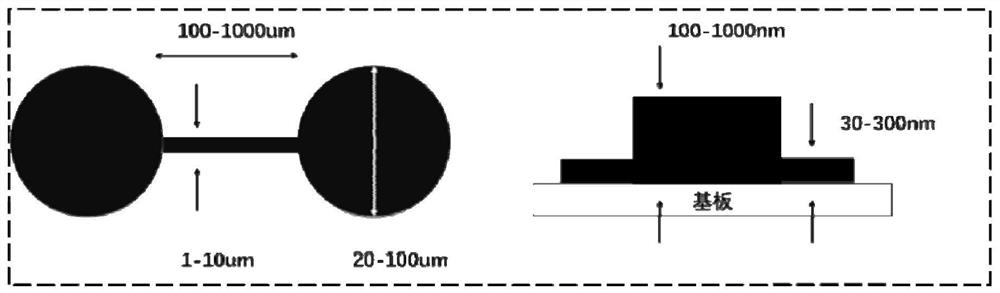

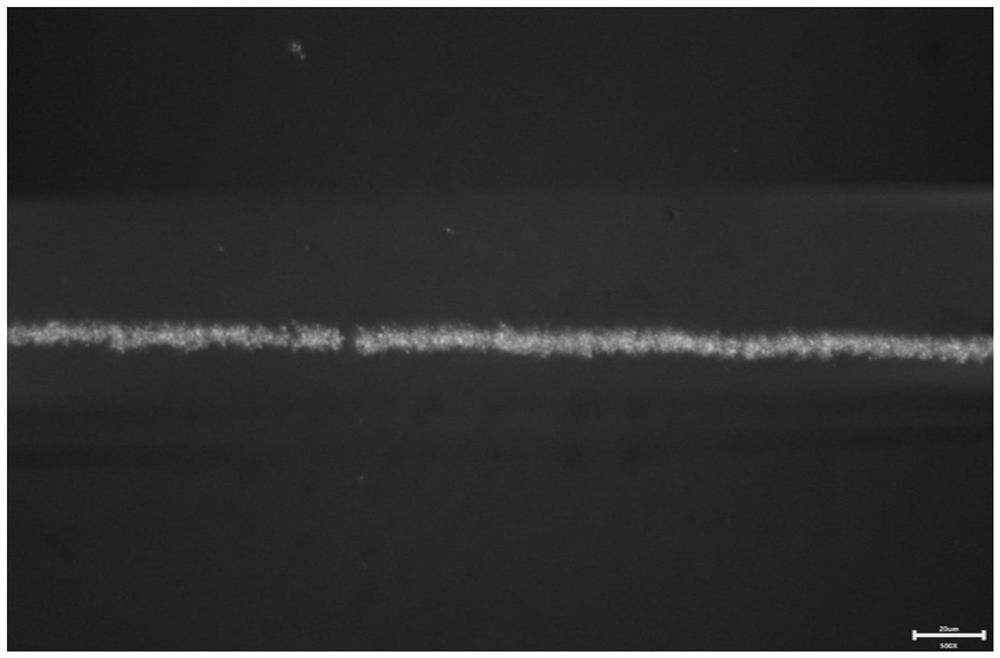

[0039] (3) Printing nano-silver varistors with narrow line width: use electrofluidic printer SIJ-S150 to electrofluidically print nano-silver varistors with nanosilver sol; electrofluidic printing parameters: voltage 700V, voltage waveform is triangular wave, voltage frequency 1000Hz, moving speed 5mm / s. Such as figure 1 As shown, the main line is 100um in length, 2um in width, and 100nm in height. The minor part is 20um in diameter and 100nm high.

[0040](4) Curing: Put the printed piez...

Embodiment 2

[0042] The difference from Example 1 is that the curing temperature is 300°C.

Embodiment 3

[0044] The difference from Example 1 is that the curing temperature is 450°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com