Patents

Literature

322results about How to "Reduce floating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

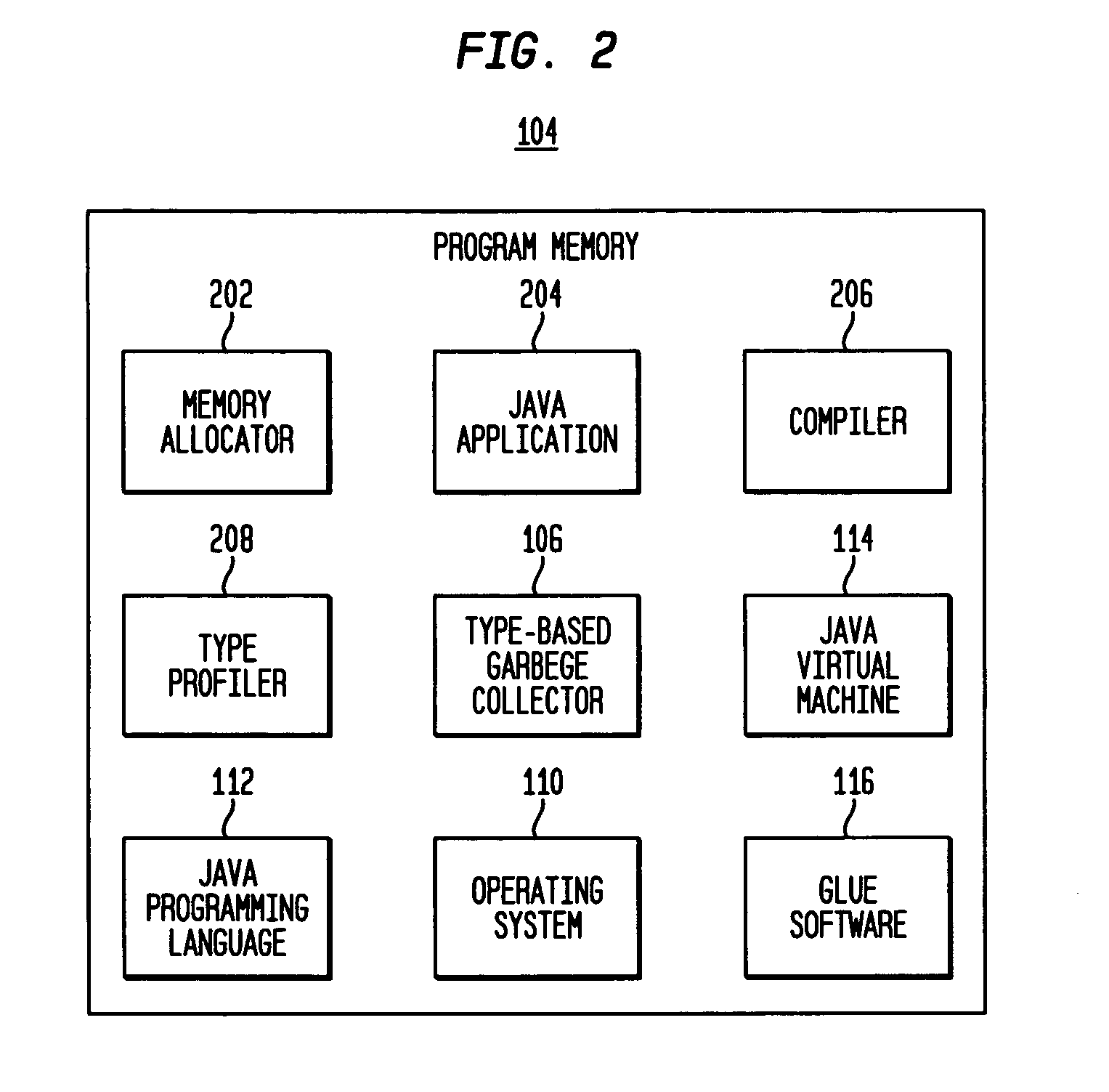

Generational real-time garbage collection

InactiveUS20060294165A1Improved real-time garbage collectionImprove utilizationSpecial data processing applicationsMemory systemsTime rangeRefuse collection

Disclosed are a partial heap garbage collector, and a partial heap garbage collection method, that during collection checks the time remaining (or equivalently the time taken so far, or the work done so far) to complete the partial heap collection. In a preferred embodiment, the partial heap collection is guaranteed to complete within a fixed time interval. For example, this guarantee may be obtained by applying a worst-case execution time (WCET) and sizing a nursery so that complete evacuation of the nursery can always be achieved on time. As an alternative, a technique, referred to as syncopation, may be used to allow generational collection to be used despite variance in program behavior over the short time scales in which a nursery can be collected. Syncopation may be accomplished via allocation control or via collection control.

Owner:IBM CORP

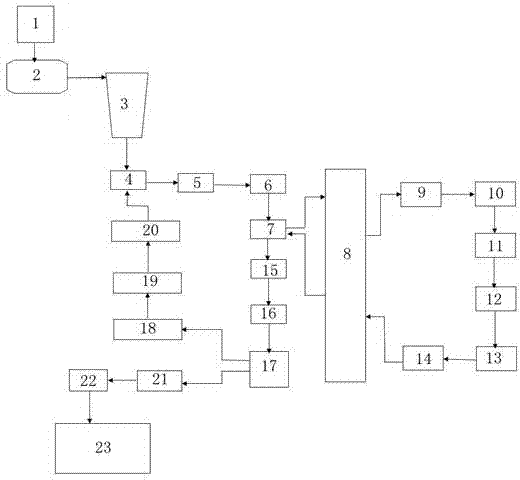

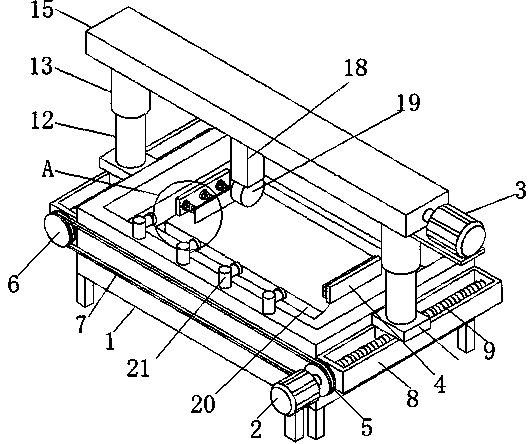

Full-automatic composite self-insulation building block production method

InactiveCN103612318AIncrease profitImprove thermal insulation performanceMixing operation control apparatusCeramic shaping plantsSocial benefitsFoaming agent

The invention discloses a full-automatic composite self-insulation building block production method. The full-automatic composite self-insulation building block production method includes distributing, building block forming, maintenance, supporting plate returning and product conveying. Distributing includes shell material distribution and thermal insulation material distribution. Shell materials are made of 15% of cement, 50% of coal cinders, 18% of sand, 10% of rubble and 7% of water. Thermal insulation materials are made of, by mass, 54% of PO42.5 cement, 10% of fly ash, 0.5% of foam stabilizer and fortifiers, 31.5% of water and 4% of foaming agents. The stirred raw materials are conveyed into a forming machine (4) so that forming can be carried out; a formed building block shell is conveyed into a maintenance kiln (8) to be maintained four hours; filling cores are poured, and the building block shell is conveyed into the maintenance kiln again to be maintained five to eight hours; maintained building blocks are piled, packaged and stacked. All the steps of the production method are coordinated, automatic control is achieved, and production efficiency is improved; the full-automatic composite self-insulation building block production method has good ecological benefit and social benefit.

Owner:连太吉 +3

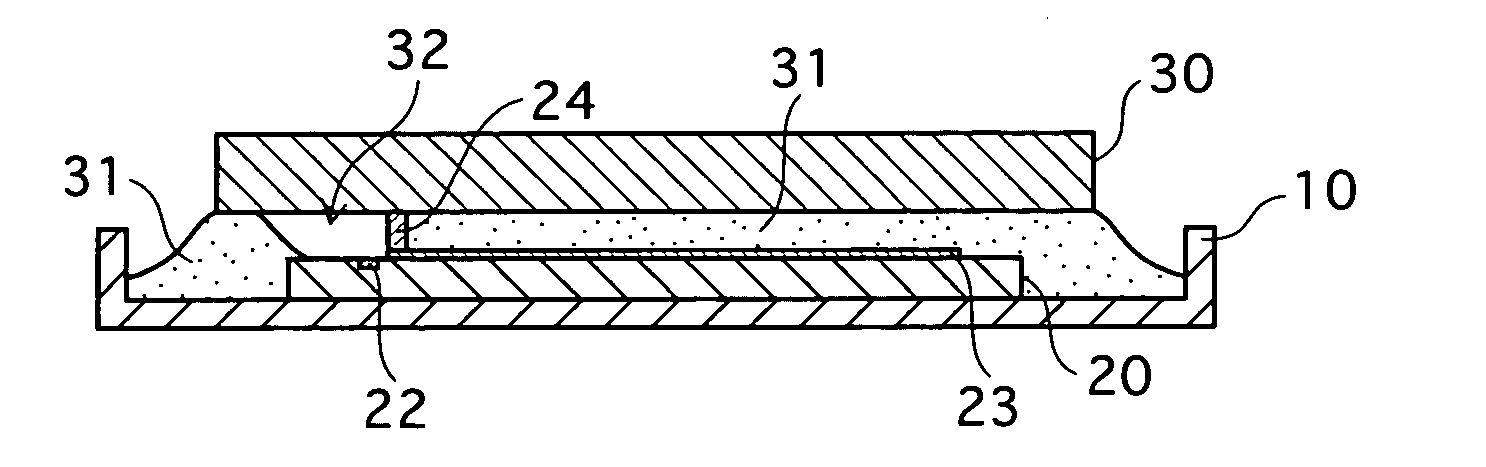

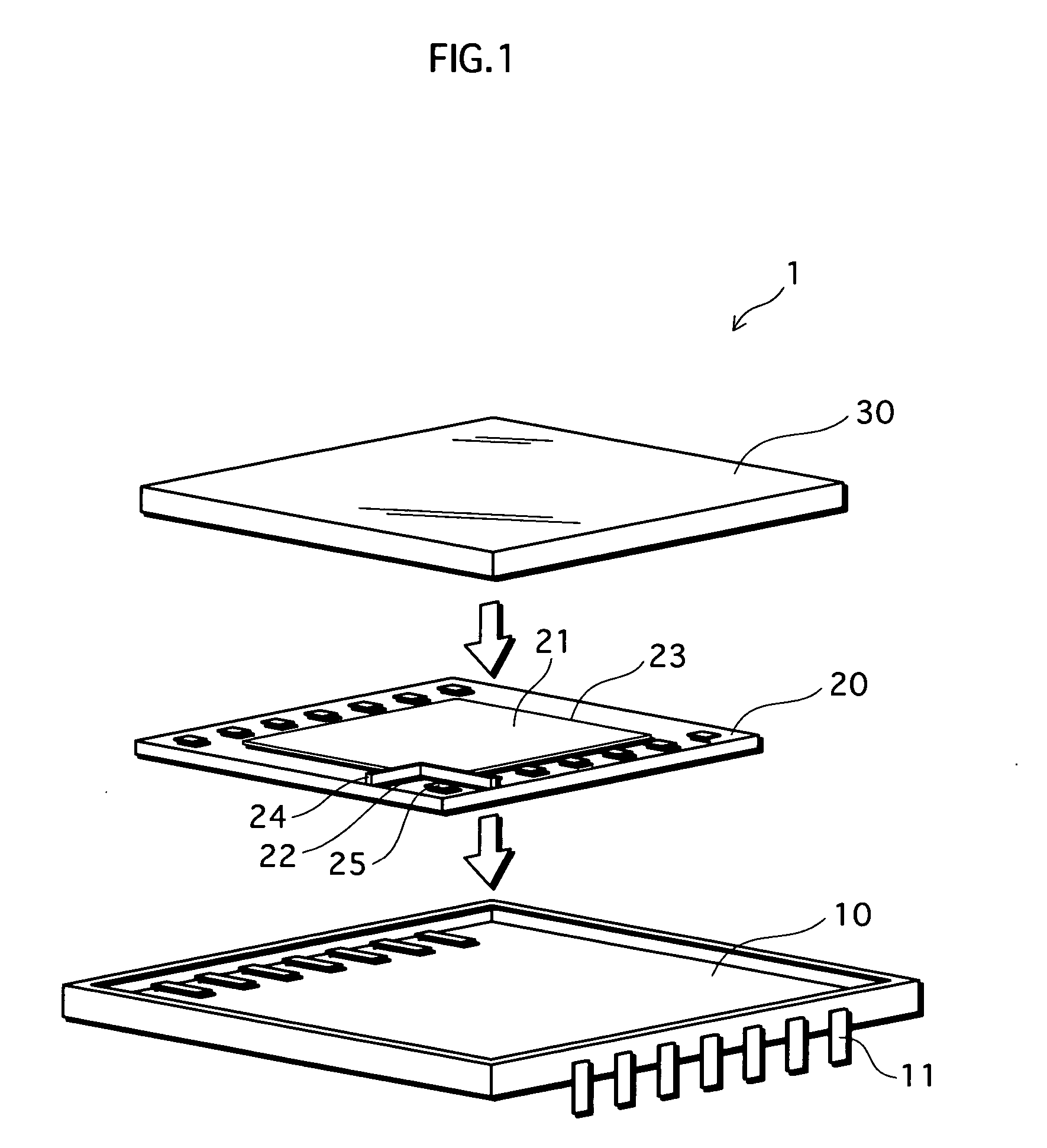

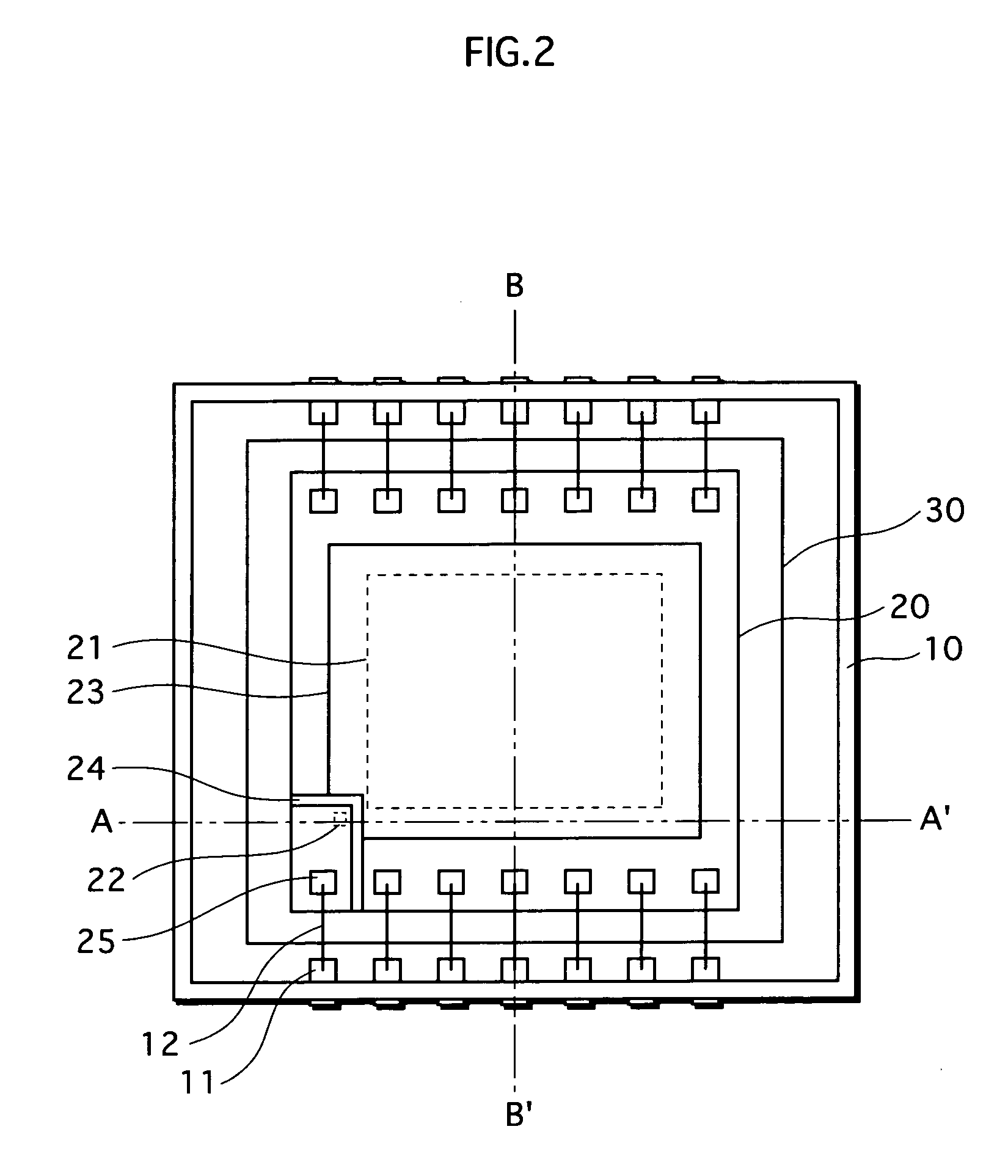

Manufacturing method for a solid-state imaging apparatus, and the solid-state imaging apparatus

InactiveUS20070200944A1Effective preventionAvoid stickingTelevision system detailsColor signal processing circuitsFloating diffusionSemiconductor

A light receiving region 21 and a floating diffusion region 22 are formed apart from each other in a semiconductor substrate 20 (S11), translucent adhesive 31 is applied to an area corresponding to the light receiving region 21 on the semiconductor substrate 20 (S22), and a translucent plate 30 is attached to the semiconductor substrate 20 on which the translucent adhesive 31 has been applied (S23). In this semiconductor manufacturing process, before the translucent adhesive 31 is applied, a dam member 24 is formed on the semiconductor substrate 20 so as to prevent the translucent adhesive 31 from flowing into an area corresponding to the floating diffusion region 22 on the semiconductor substrate 20 (S18).

Owner:PANASONIC CORP

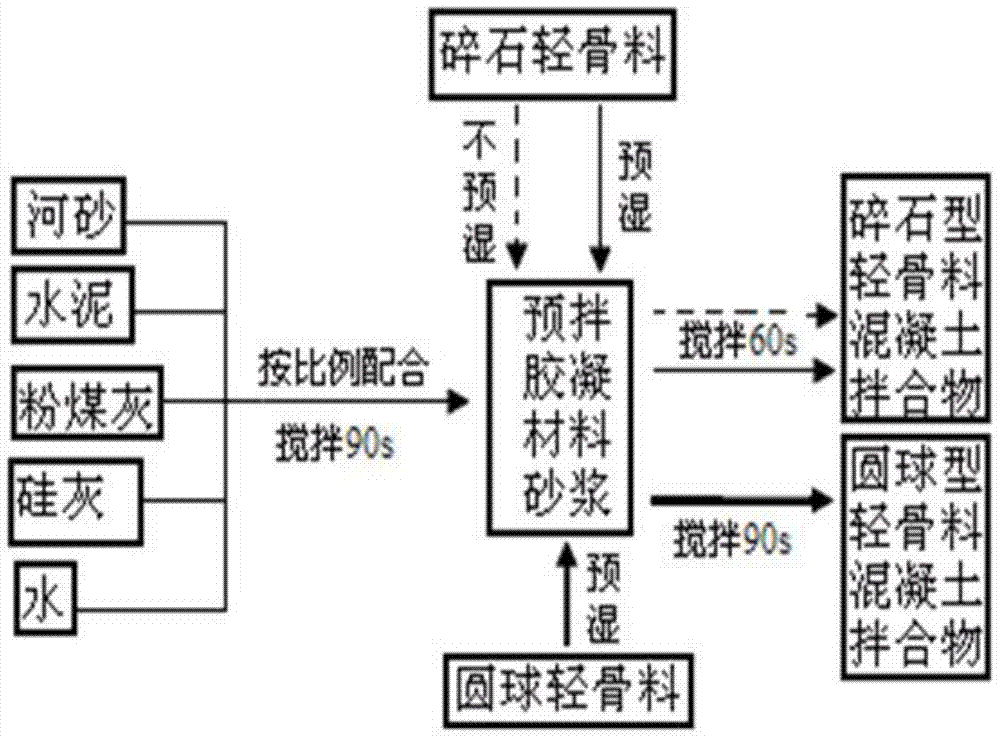

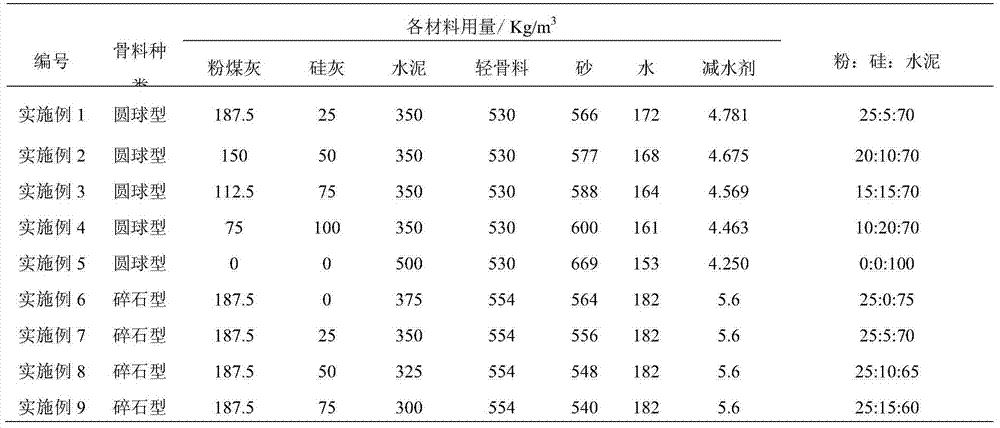

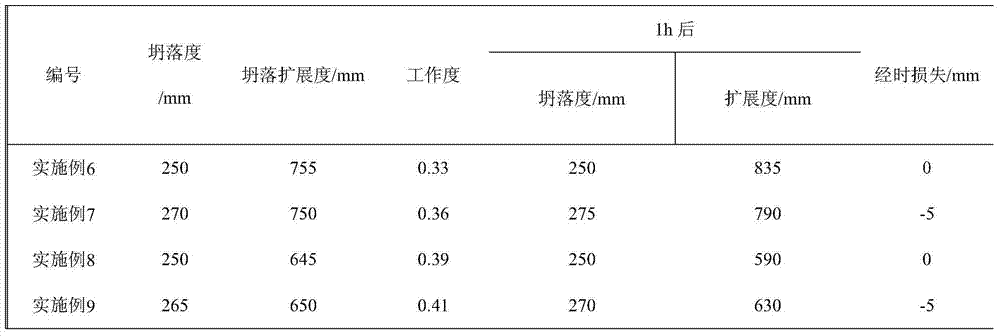

High-performance light-weight aggregate concrete and preparation method thereof

InactiveCN103613334AReduce floatingImprove work performanceSolid waste managementCompressive strengthUltimate tensile strength

The invention discloses high-performance light-weight aggregate concrete and a preparation method thereof. When aggregate is rubble type light-weight aggregate, the concrete contains the following components in parts by weight: 187.5 parts of coal ash, 0-75 parts of silica ash, 300-375 parts of cement, 554 parts of light-weight aggregate, 540-564 parts of sand, 182 parts of water and 5.6 parts of a water reducing agent; when the aggregate is spherical light-weight aggregate, the concrete contains the following components in parts by weight: 0-187.5 parts of coal ash, 0-100 parts of silica ash, 530 parts of light-weight aggregate, 566-669 parts of sand, 153-172 parts of water and 4.25-4.781 parts of a water reducing agent. The slump loss in 1 hour of the prepared high-fluidity light-weight aggregate is smaller than 15 mm, no light-weight aggregate floats upwards, and the compressive strength is higher than 65.0 MPa.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

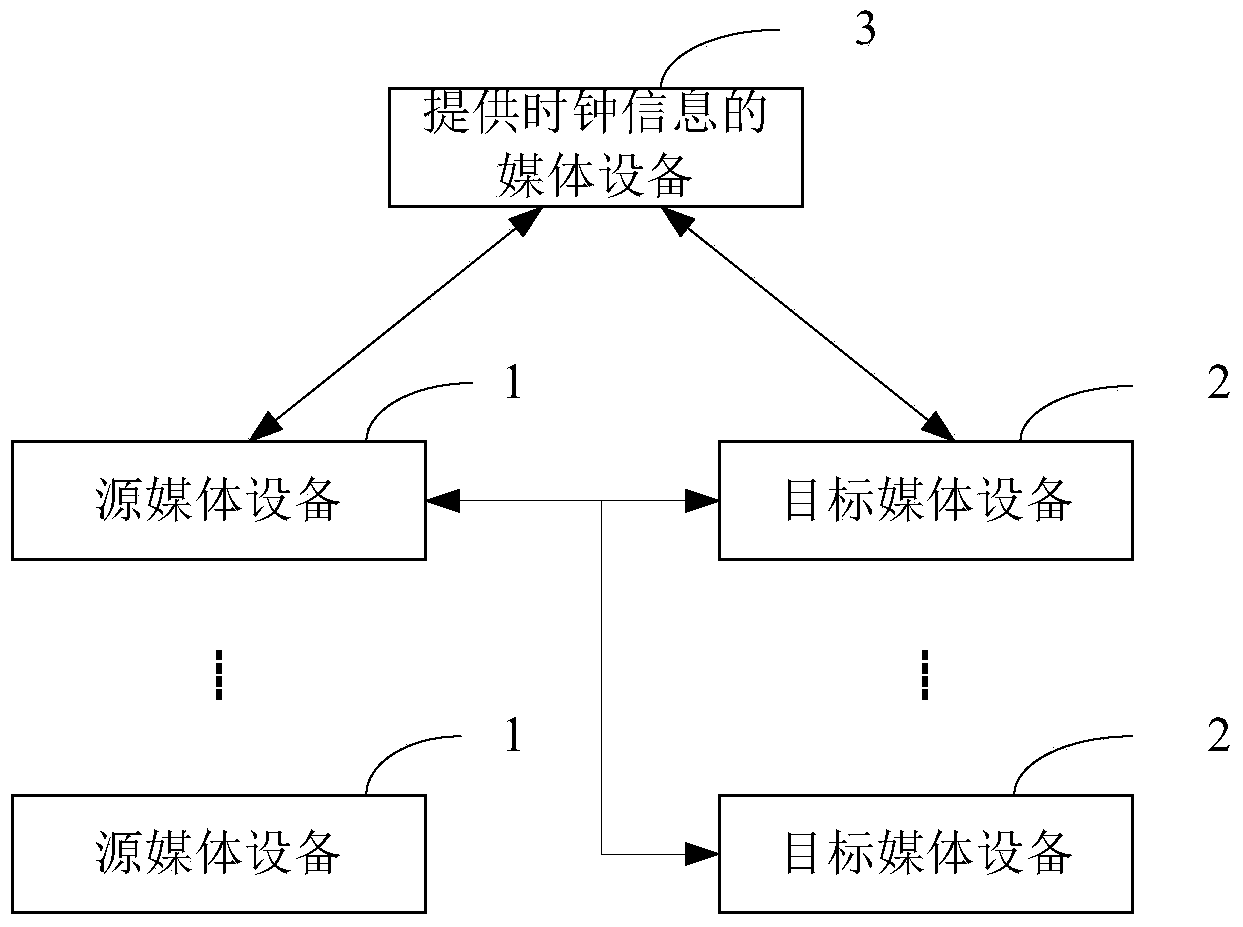

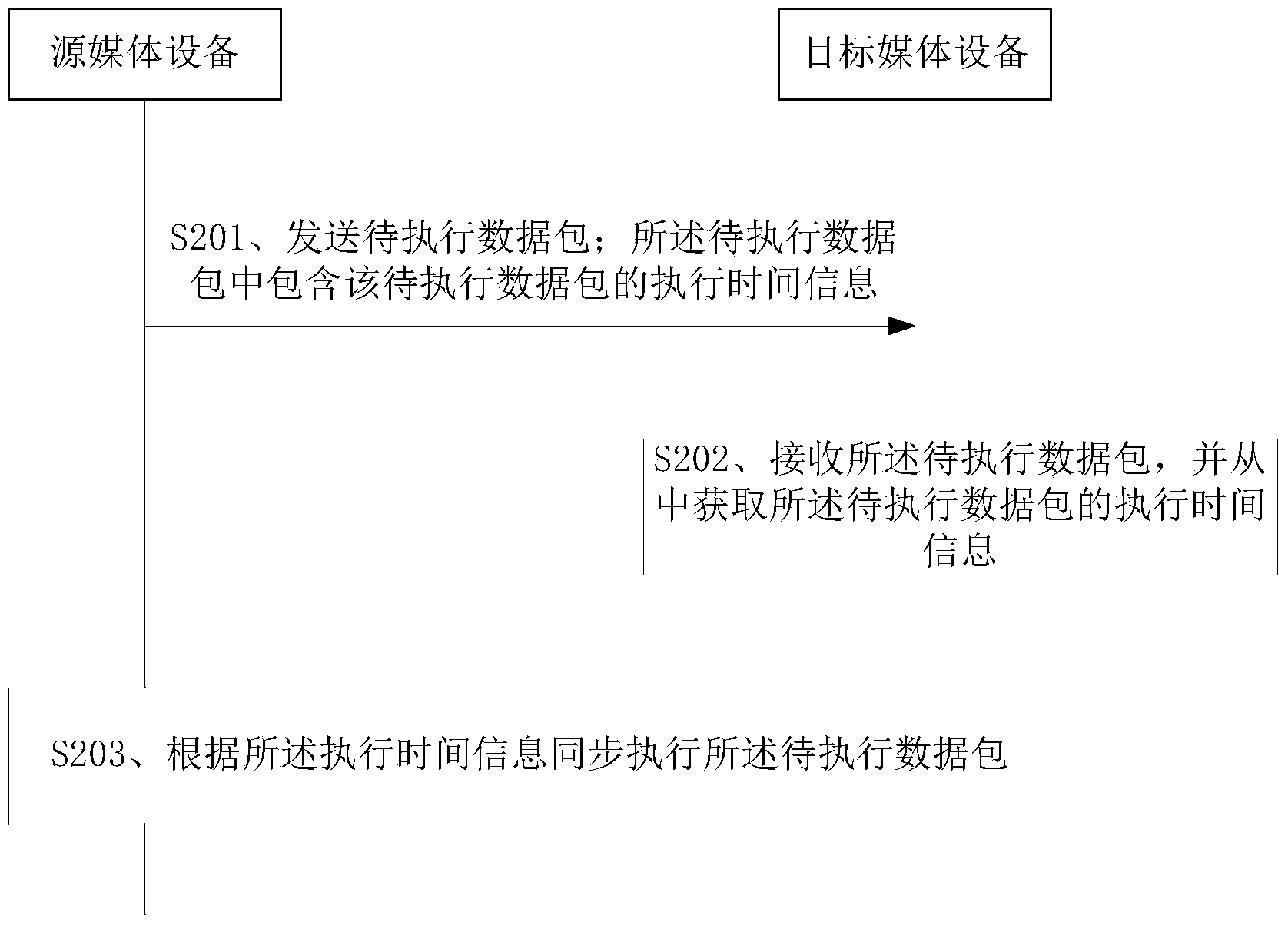

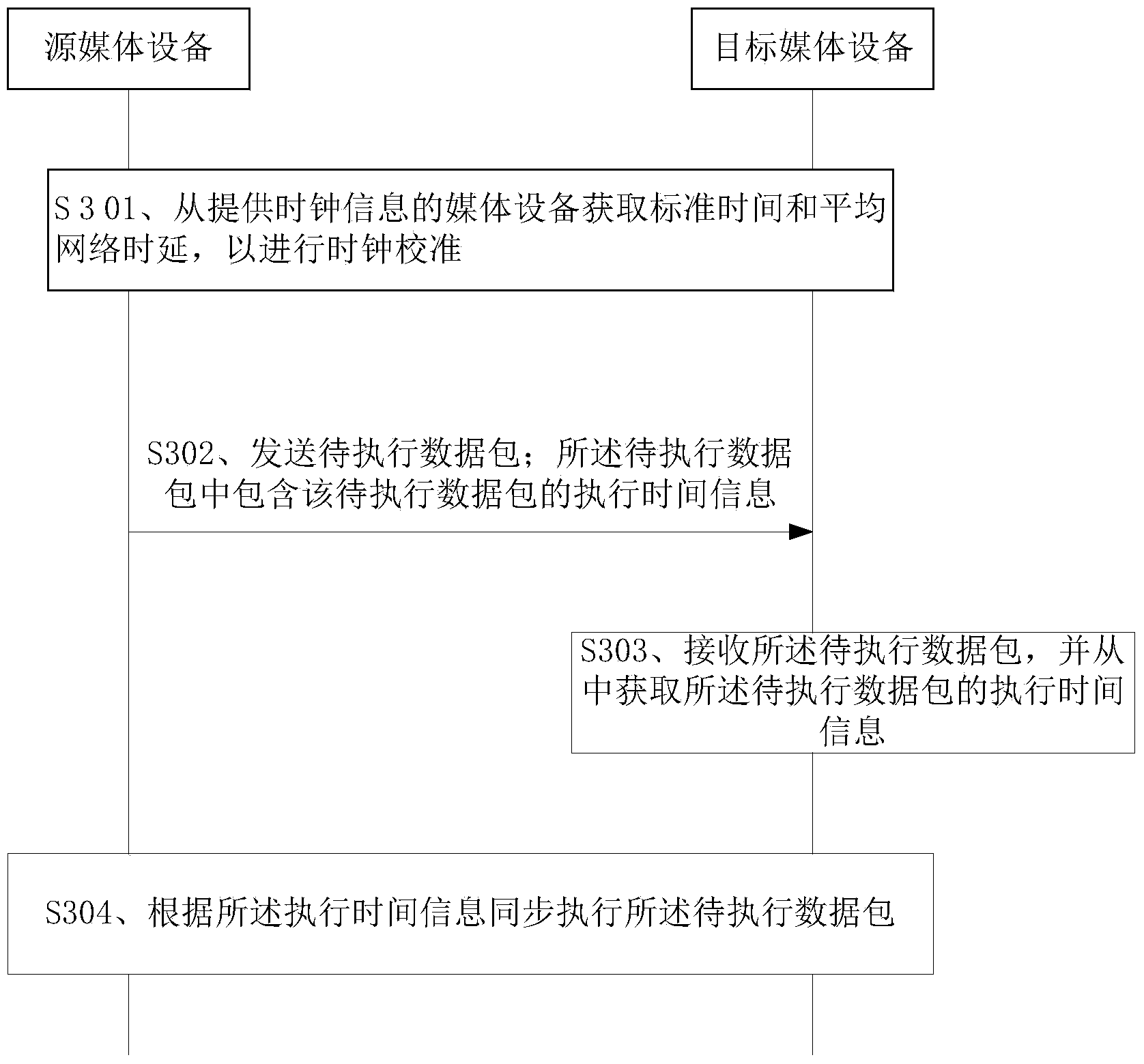

Multimedia device synchronous operation method and system

ActiveCN104079957AReduce loadShorten the timeSelective content distributionNetwork packetMultimedia device

The invention is applicable to the technical field of media devices, and provides a multimedia device synchronous operation method and system. The method is applied to a media system which is composed of at least one source media device and at least one target media device. The method includes the steps that the source media device sends a data packet to be executed to the target media device, wherein the data packet to be executed includes execution time information of the data packet to be executed; the target media device receives the data packet to be executed so as to obtain the execution time information of the data packet to be executed; the source media device and the target media device synchronously execute the data packet to be executed according to the execution time information. By means of the method and system, floating of network loads and delayed time which are caused when the media devices exceedingly transmit the specific synchronous data packet during time synchronization can be effectively relieved, and therefore accuracy is enhanced when the media devices synchronously play media data or execute an operation instruction.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

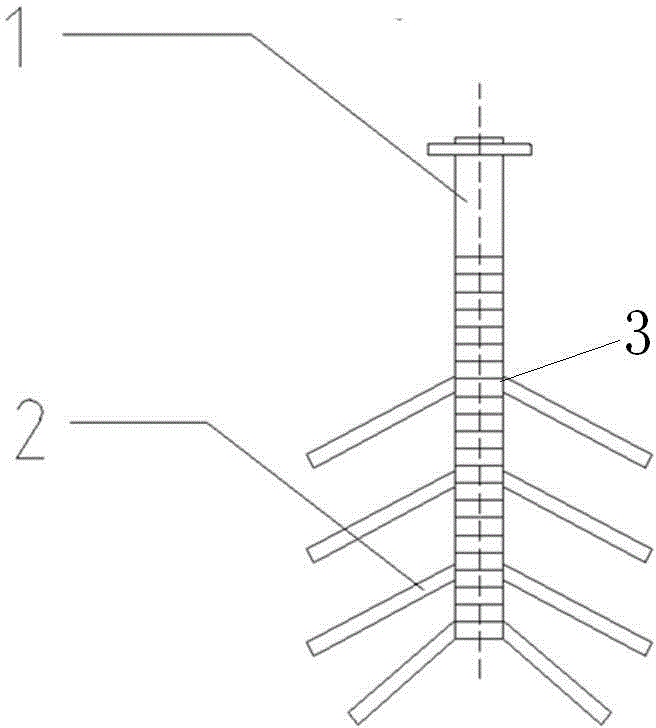

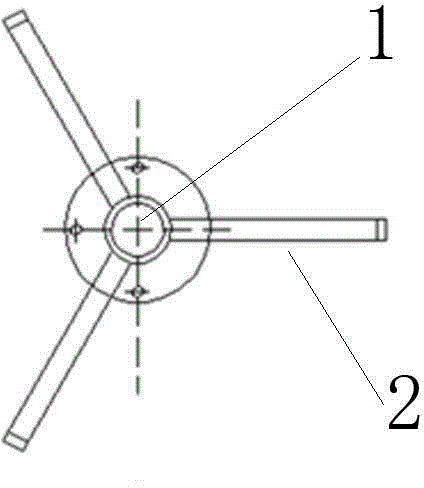

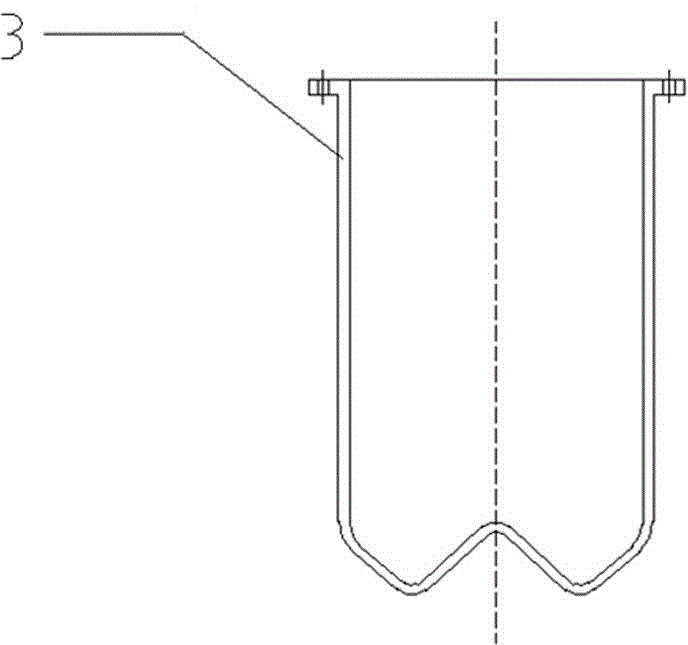

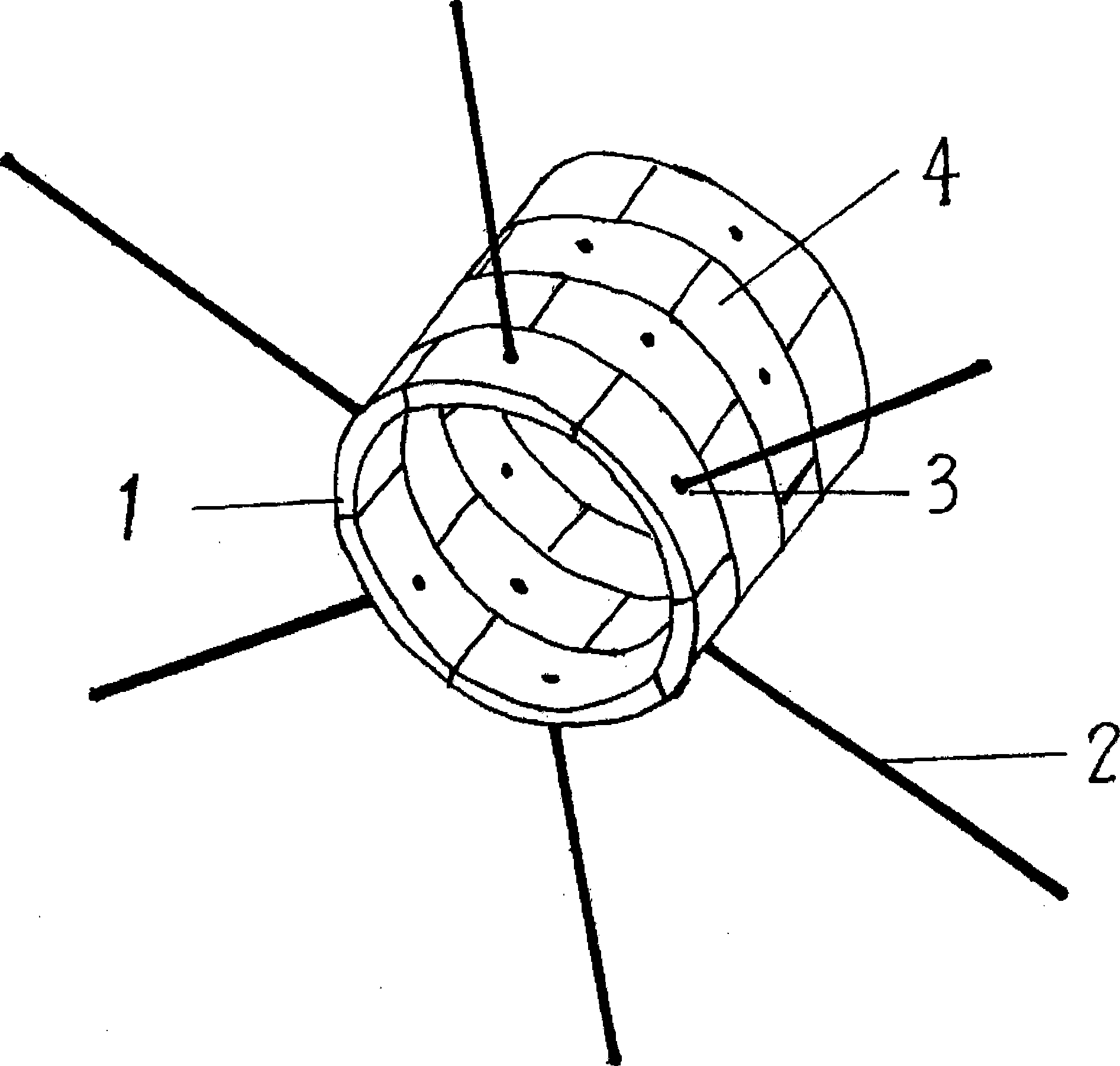

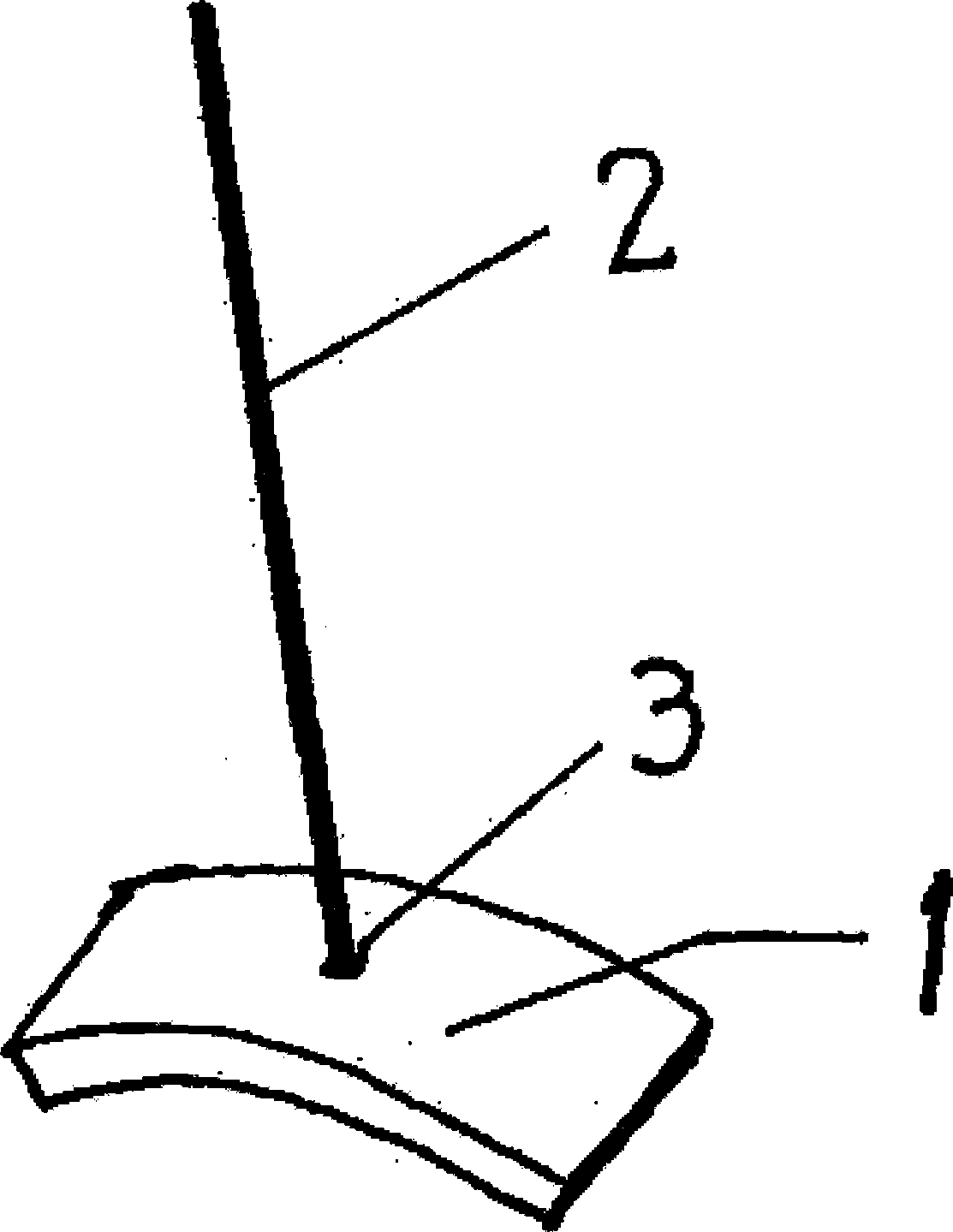

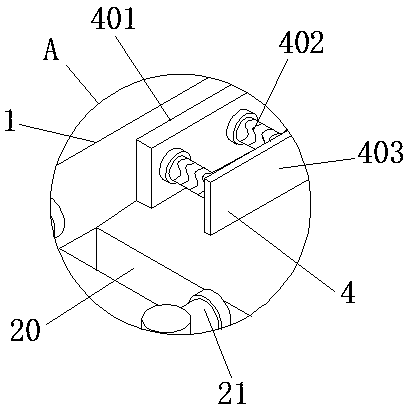

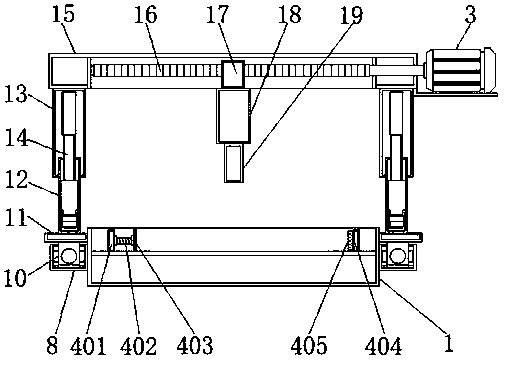

Tackifying and foaming stirring device for preparing foamed aluminum

ActiveCN104607079ASuppression of floatingStir wellRotary stirring mixersMixer accessoriesPolymer scienceAluminum can

The invention discloses a tackifying and foaming stirring device for preparing foamed aluminum, relates to a stirring device, and solves the problem that the high-quality foamed aluminum cannot be prepared by adopting the existing forming device. The tackifying and foaming stirring device for preparing the foamed aluminum comprises a cylindrical stirring furnace body, wherein a heating device is fixed outside the furnace body, a stirring paddle is arranged inside the furnace body, and the stirring paddle is installed on a furnace cover; the stirring paddle is in a four-layer folded-blade paddle form, four layers of paddle blades are arranged on a central shaft of the stirring paddle, each layer is provided with three paddle blades, the paddle blades at each layer are arranged to stagger each other for 120 degrees, a dip angle of the paddle blades at the lowermost layer is smaller than that of the paddle blades at the upper three layers, and the upper part of the central shaft is fixed on the furnace cover through a fixing disc and the central shaft driven by a motor to rotate. The tackifying and foaming stirring device is simple in structure, ingenious in design, capable of uniformly and rapidly stirring metal liquid by virtue of the four-layer paddle blades and good in foaming effect.

Owner:广东磐龙交通环境设施工程有限公司

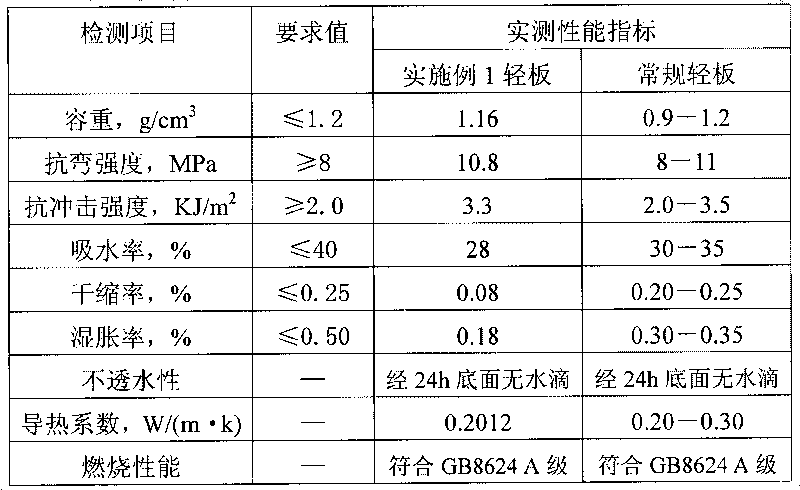

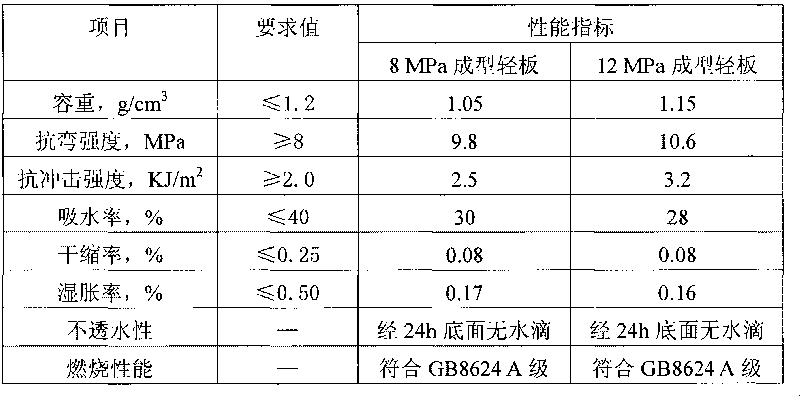

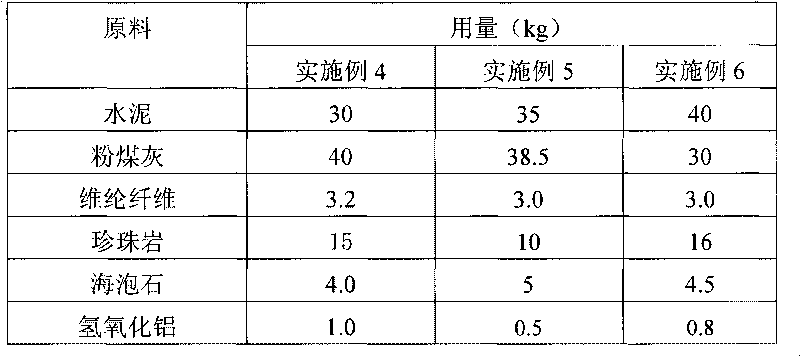

Light decorative plate material with high doping quantity of fly ash

ActiveCN101736852AImprove performanceImprove flexural strengthConstruction materialSolid waste managementPerliteAsbestos

The invention relates to a decorative plate material with high doping quantity of fly ash and a production method thereof, which belong to the field of construction materials. The decorative plate material comprises cement, fly ash, polyvinylformal fibre, perlite, meerschaum, pulp, micro silicon powder, glass fibre and polyacrylamide. A right amount of micro silicon powder is added into a formula, the floating of a light material in the wet process can be reduced, the use quantity of the fly ash in the decorative plate material is also enhanced greatly, and the highest doping quantity can reach 40%. The wet process of the conventional asbestos-free cement flat plate is properly improved, and the maintained decorative plate material has the advantages of economy, applicability, flame retardant, light weight, small contraction, environmental protection, heat insulation, moisture prevention and good durability after being sprayed with paint.

Owner:CHINA BUILDING MATERIALS ACAD

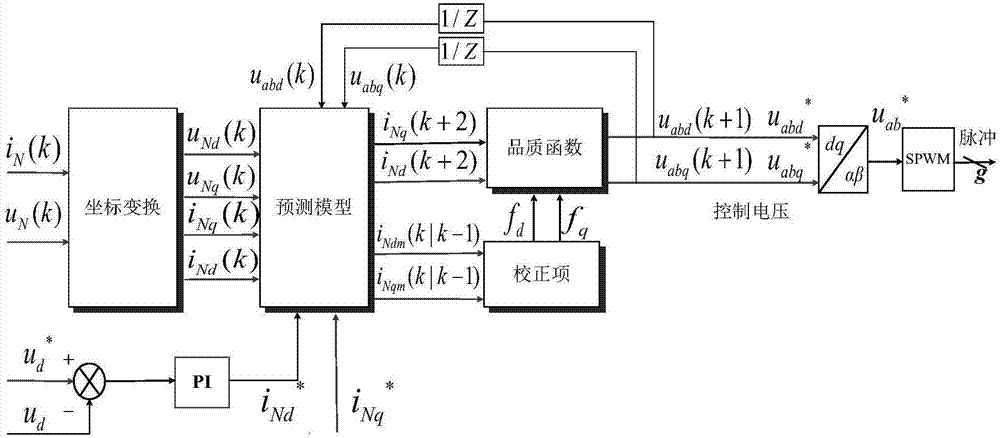

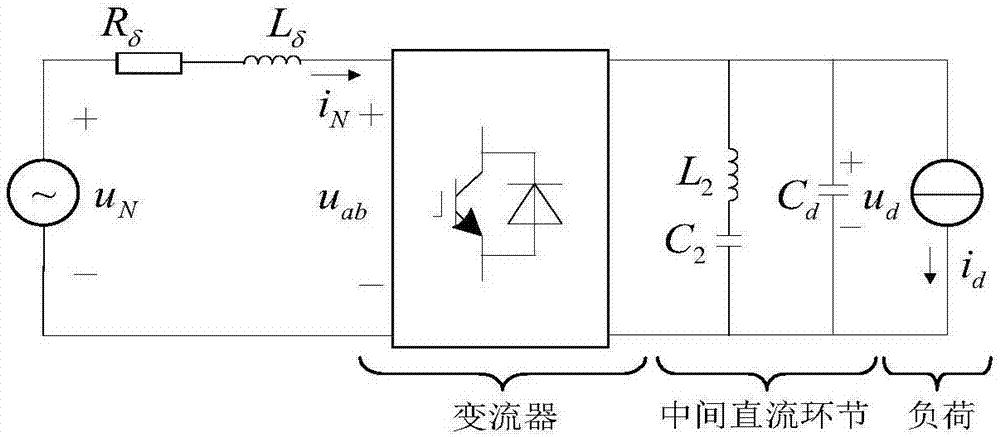

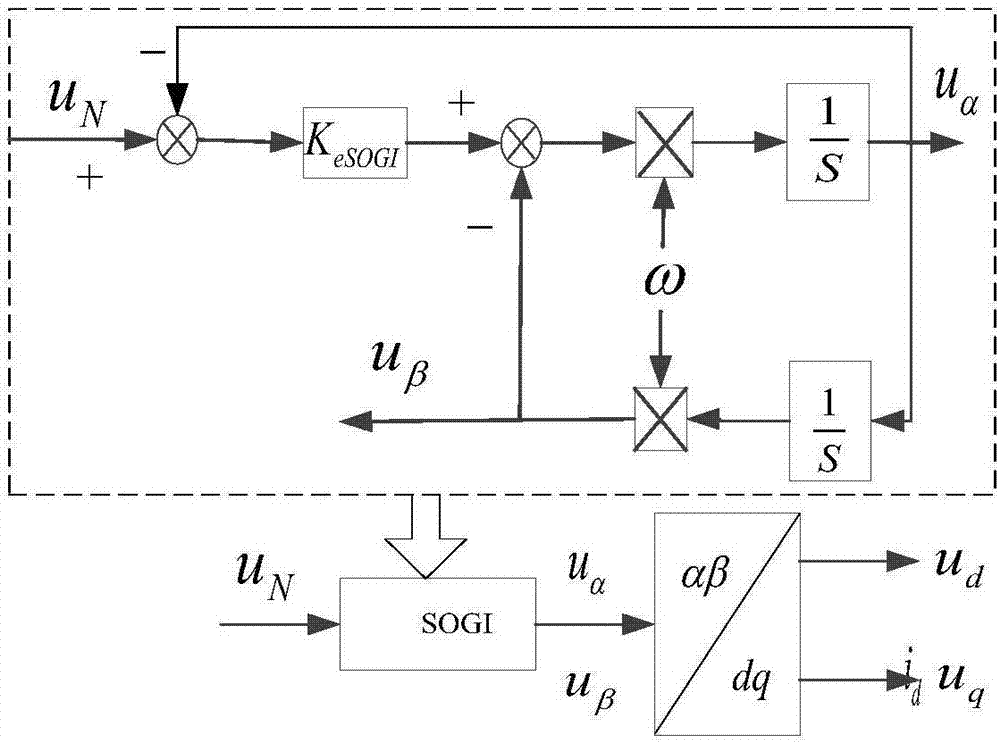

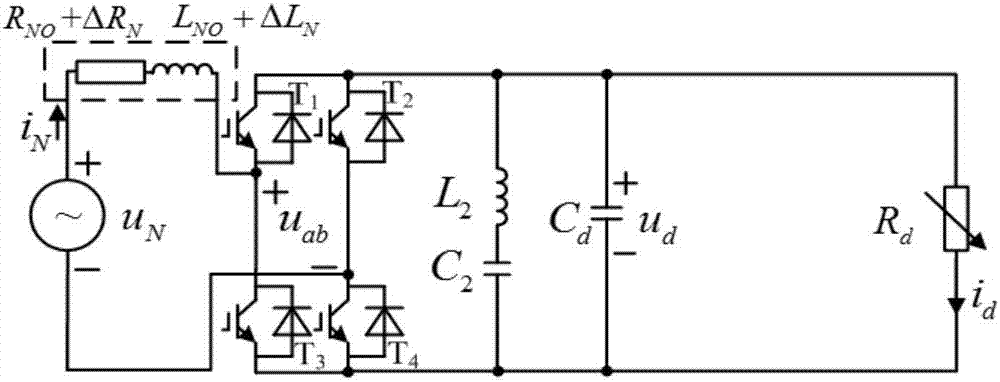

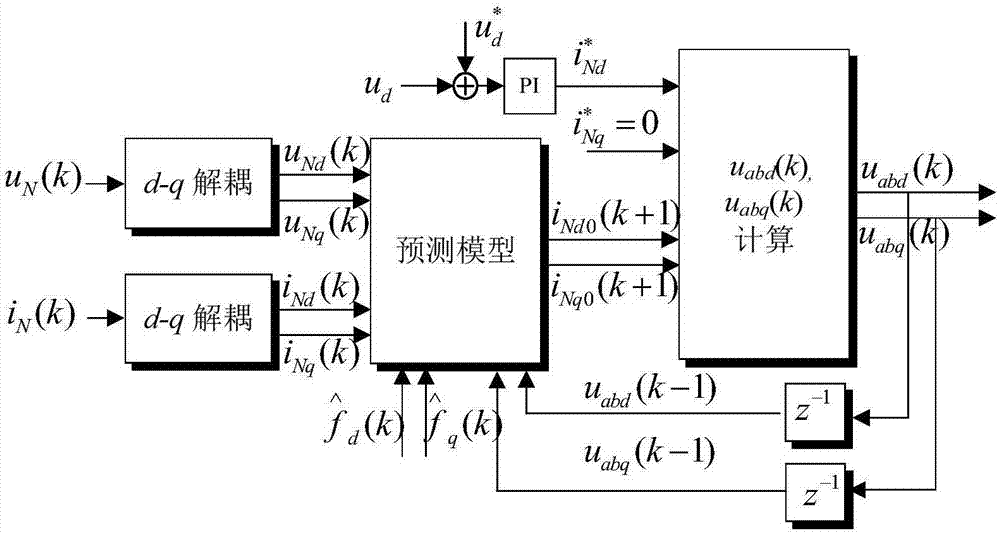

Method for suppressing low-frequency oscillation of high-speed rail based on model predictive current control

InactiveCN107154634AImprove anti-interference abilityImprove stabilityAc-dc conversion without reversalPower oscillations reduction/preventionIntegratorTotal harmonic distortion

The invention discloses a method for suppressing low-frequency oscillation of high-speed rail based on model predictive current control, comprising the following steps: constructing an Electric Multiple Units network side rectifier AC-side voltage and current dynamic characteristic relation; getting a current prediction model under a d-q two-phase rotating coordinate system through decoupling by a second-order generalized integrator; making compensation for control calculation delay through a two-step prediction method; calculating the partial derivative with respect to voltage variation for a quality function, and getting a voltage variation value minimizing the quality function; and carrying out SPWM modulation on the control voltage to get a control pulse. The fast dynamic response characteristic and the harmonic suppression effect of control are improved. Moreover, the total harmonic distortion is low, the current distortion is low, the DC voltage overshoot is small, and the dynamic response is fast. The electrical low-frequency oscillation problem of the traction network EMU can be suppressed. When the external parameters of the system change in a small range, the train network system does not oscillate compared with the transient DC oscillation mode and the oscillation peak.

Owner:SOUTHWEST JIAOTONG UNIV

Shield tunnel segment lining-anchor rod structure system

InactiveCN101392654AEnhanced longitudinal deformation resistanceReduce sinkingUnderground chambersTunnel liningEngineeringShield tunnelling

The invention discloses a shield tunnel segment lining-anchor rod structural system. Anchor rods are driven around a shield tunnel segment lining, and the effective connection between the anchor rods and the segment lining is established through steel bolts. The shield tunnel segment lining-anchor rod structural system introduces the anchorage function of the anchor rods into a shield tunnel segment lining structure, which can reduce the settlement or the floatation of tunnels, lighten the influence of recessive characters of surrounding soil bodies, strengthen the rigidity of adverse positions such as corners of the tunnels, stratum catastrophe positions and so on, and improve the whole and local stability of tunnel structures.

Owner:SHANGHAI UNIV

Thin film magnetic head and manufacturing method thereof

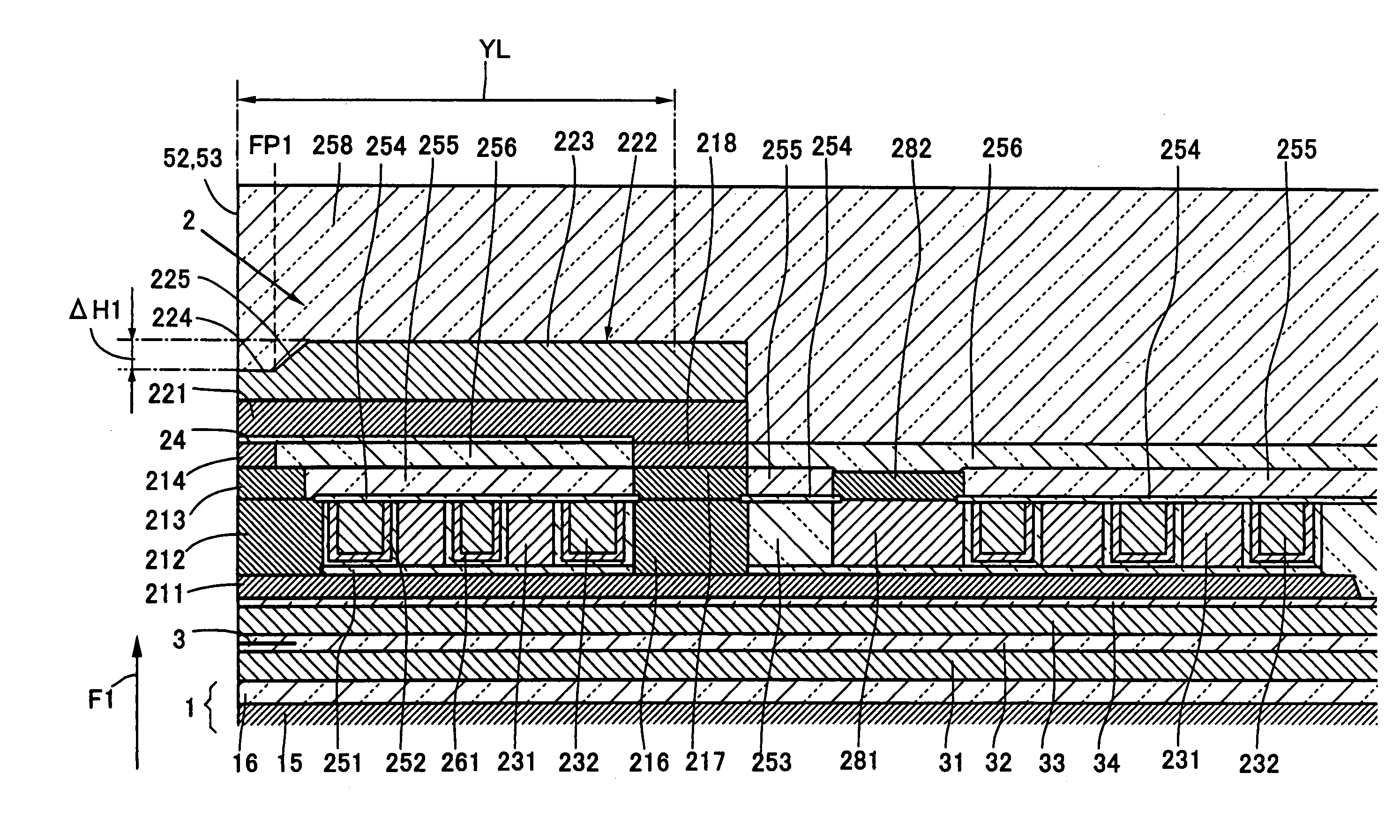

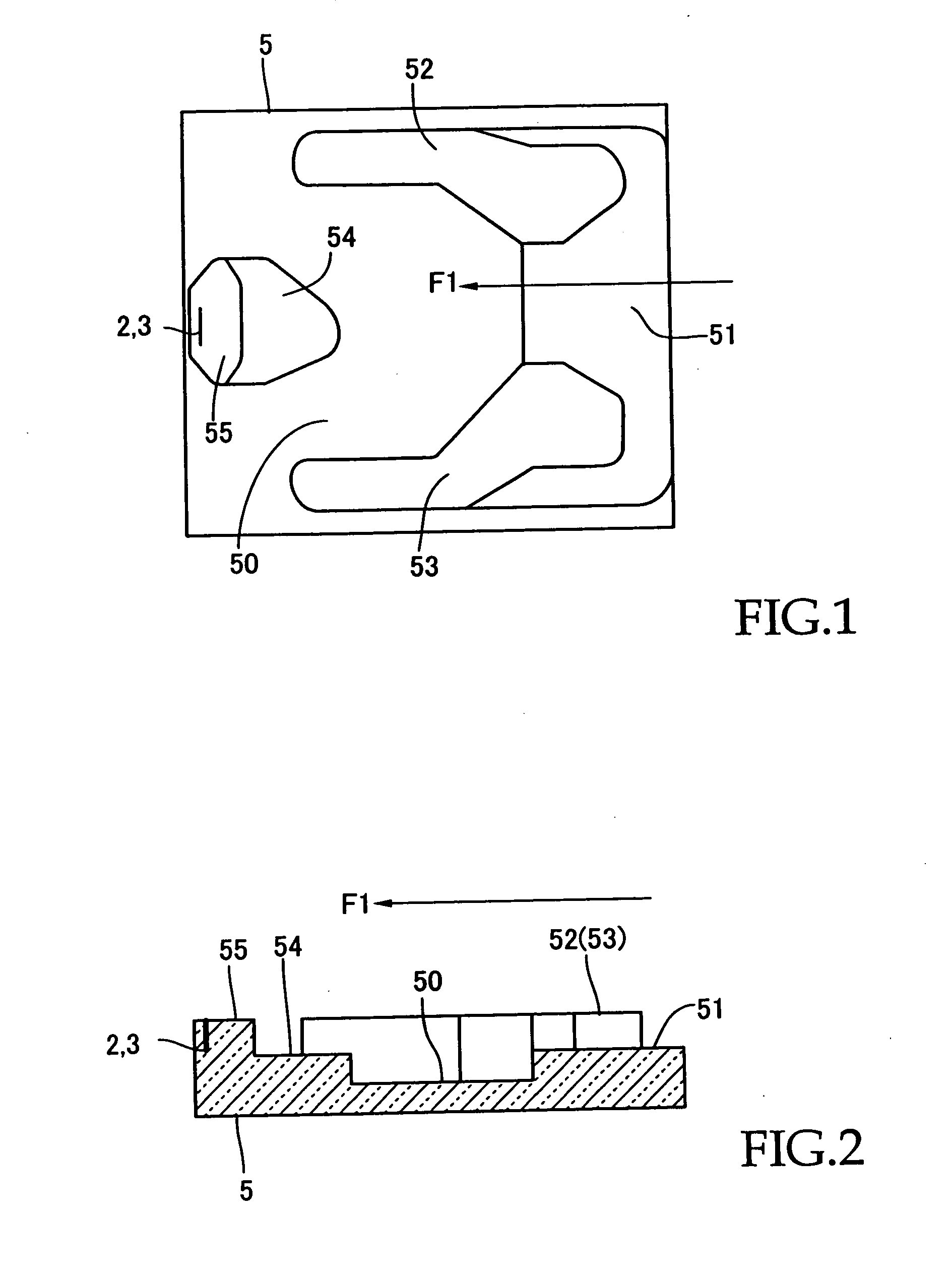

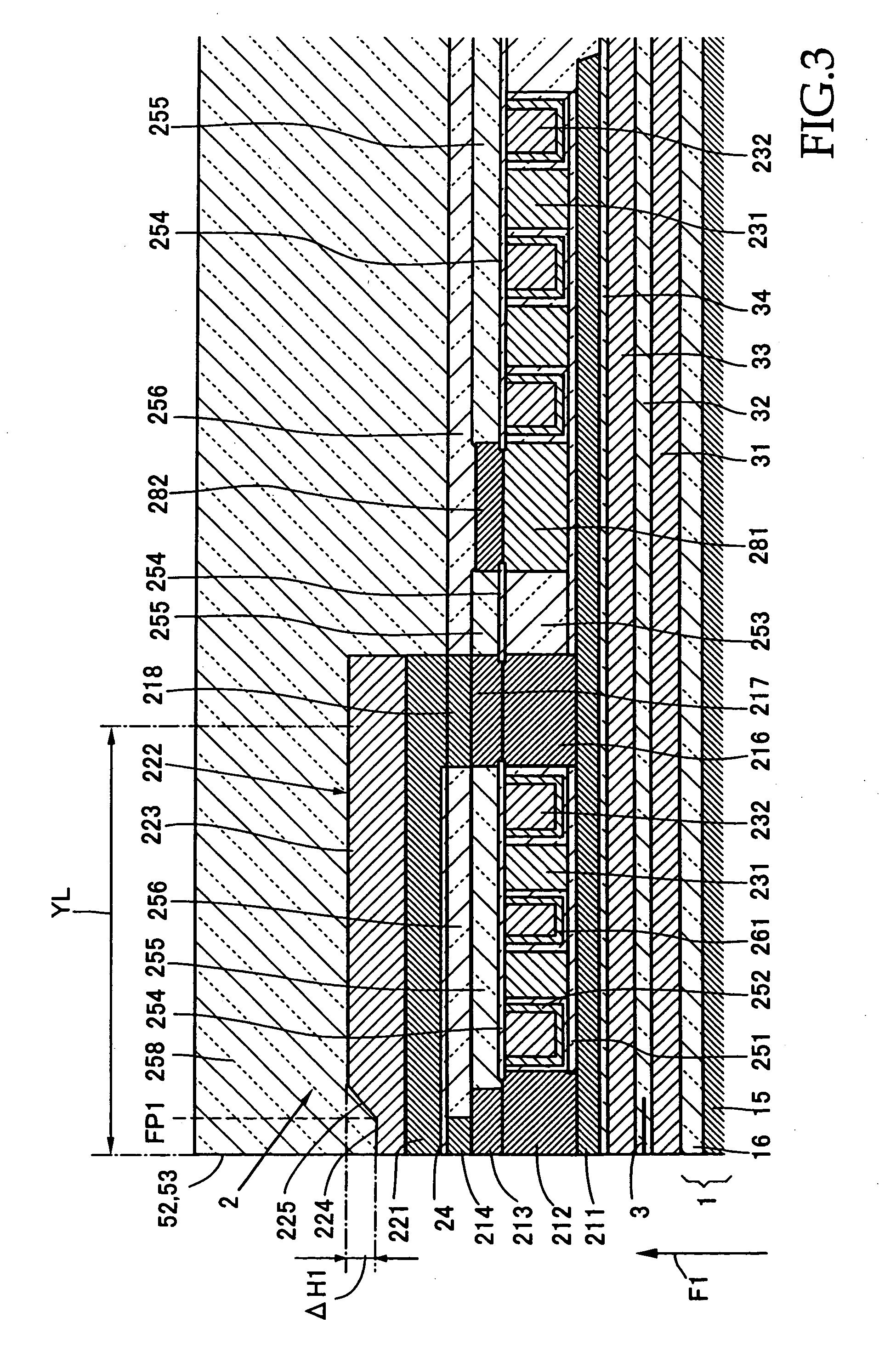

ActiveUS20050128639A1Maximize sectional areaLower coil resistanceConstruction of head windingsRecord information storageEngineeringHelix

The invention is directed to improvement of a write element of a thin film magnetic head. In said write element, a first coil and a second coil are provided on a first insulating film formed on one surface of a first magnetic film and surround in a spiral form a back gap portion. A second yoke portion in the upper position comprises a wide portion, a narrow portion and a sloping flare portion. The wide portion has a flat surface and is connected to the first magnetic film by a back gap portion at the rear of the medium-facing surface. The narrow portion forms the second pole portion and the surface of the narrow portion being at a lower position than the surface of the wide portion. The sloping flare portion extends from the narrow portion to the wide portion, gradually increasing in width and its surface sloping upward away from the surface of the narrow portion to the surface of the wide portion.

Owner:HEADWAY TECH INC +1

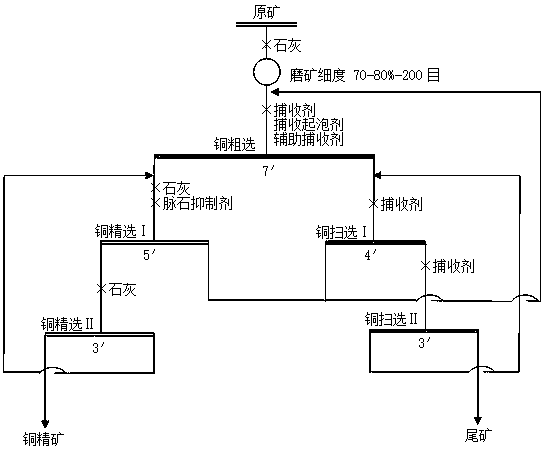

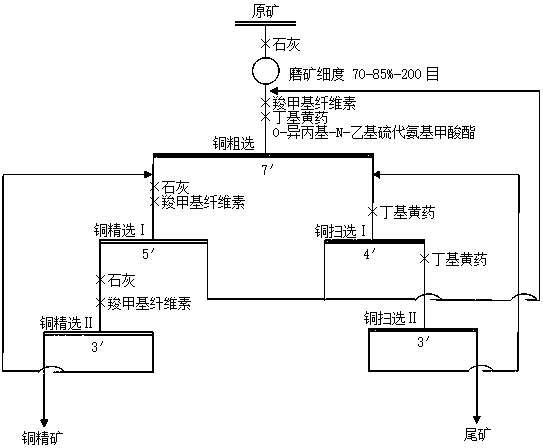

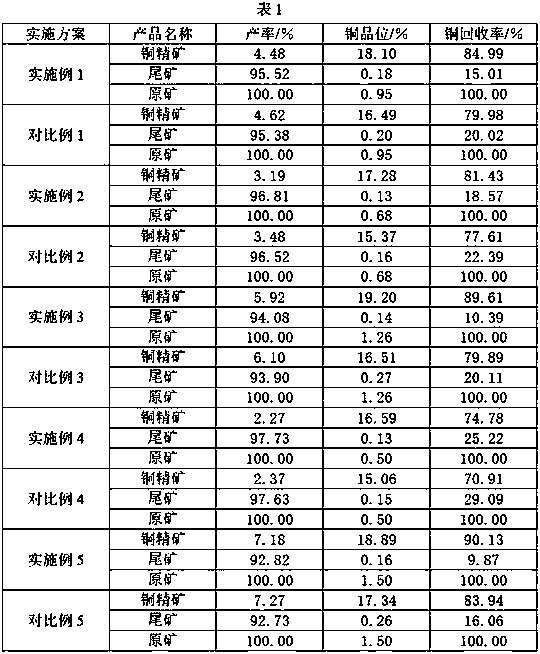

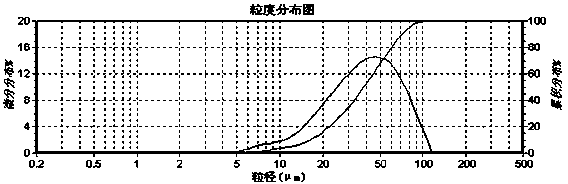

Gangue inhibitor and beneficiation method of copper sulfide ore containing easily floated gangue minerals

The invention discloses a gangue inhibitor and a beneficiation method of copper sulphide ore containing easily floated gangue minerals, belongs to the technical field of flotation, and solves the problem that gangue minerals have very adverse effects on flotation of copper sulphide ore. The gangue inhibitor comprises sodium polyacrylate, carboxymethyl cellulose, Arabic gum, sodium silicate, sodiumtripolyphosphate, anhydrous sodium sulfite, sodium lignosulfonate and anhydrous zinc sulfate. The method comprises the following steps: adding lime for ore grinding, and adding water for size mixing;sequentially adding a collecting foaming agent, an auxiliary collecting agent and a collecting agent into obtained ore pulp for roughing; adding a collecting agent into obtained roughing tailings, and scavenging for the first time; adding a collecting agent into the scavenging tailings, and carrying out secondary scavenging; sequentially adding pH regulator lime and the gangue inhibitor into an obtained roughing concentrate, and carrying out primary concentration; and adding pH regulator lime into an obtained primary concentration concentrate for secondary concentration. The gangue inhibitoris capable of reducing the floatability of gangue minerals greatly; the method is capable of improving the copper grade and the copper recovery rate of rough concentrate.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for preparing anti-freezing flame-retardant sheath

InactiveCN101649090AIncrease elasticitySmall permanent deformationInsulated cablesInsulated conductorsAnti freezingPolymer science

The invention relates to a process method for a sheath of a power transmission and transformation wire, in particular to a method for preparing an anti-freezing flame-retardant sheath. The method is characterized in that the anti-freezing flame-retardant sheath is prepared from the following raw materials in percentage by weight: 50 portions of base material, 1 portion of vulcanizing agent, 40 portions of strengthened plasticizer, 2 portions of antiager, 2 portions of damp-proof and moisture-proof separant and 5 portions of flame retardant. The anti-freezing flame-retardant sheath is preparedfrom novel high molecular materials, can protect power transmission and transformation wires, and can achieve the anti-freezing and flame-retardant effect.

Owner:陈志海

Low-water-absorption foamed concrete and preparation method thereof

InactiveCN104150951AShort initial setting timeReduced open porosityCeramicwareFoam concreteAluminate

The invention relates to a low-water-absorption foamed concrete and a preparation method thereof. The low-water-absorption foamed concrete is prepared from ordinary Portland cement, sulphoaluminate cement, raw material soil, water, a thickening agent, a water-reducing agent, a foam-stabilizing agent, an accelerator and a foaming agent. Through addition of the sulphoaluminate cement and the accelerator which can accelerate coagulation of the ordinary Portland cement, break of bubbles during an initial setting time is reduced and an opening porosity and water absorption of the foamed concrete are reduced. Through addition of the thickening agent, thickness of the foamed concrete can be adjusted and upward-floating of the bubbles is reduced so that the bubble is distributed uniformly. The foamed concrete is low in water absorption, is uniform in volume weight, is stable in compressive strength and has a better thermal-insulation and temperature-preserving performance, a better mechanical performance and a better freeze-thaw-destroy resistant performance.

Owner:WUHAN UNIV OF TECH

Special anticorrosive powder coating for high-decorativeness pure polyester aluminum section and preparation method of powder coating

ActiveCN104263211AGood weather resistanceImprove performanceAnti-corrosive paintsPowdery paintsMelt extrusionIsocyanuric acid

The invention discloses a special anticorrosive powder coating for a high-decorativeness pure polyester aluminum section and a preparation method of the powder coating. The powder coating comprises the following raw materials: carboxyl-terminated polyester resin, triglycidyl isocyanurate, titanium dioxide, ultrafine barium sulfate, a charging additive, a dry flow additive, benzoin, a leveling agent and a brightening agent. The preparation method mainly comprises the following steps: firstly, uniformly premixing the raw materials; secondly, performing melt extrusion; finally, performing crushing and ultrafine grinding. The powder coating prepared by the method is strong in adaptability to different thickness of coatings, and has relatively good leveling effects on thick coating (not less than 120 microns) and thin coating (not more than 60 microns); especially, the phenomena of melt falling and non-uniform thickness of powder applied to a workpiece due to influence of gravity on the powder product sprayed by vertical spraying equipment at the construction site in baking and curing processes are greatly reduced, and a paint film is excellent in appearance and free of particle phenomenon during thin coating.

Owner:西北永新涂料有限公司

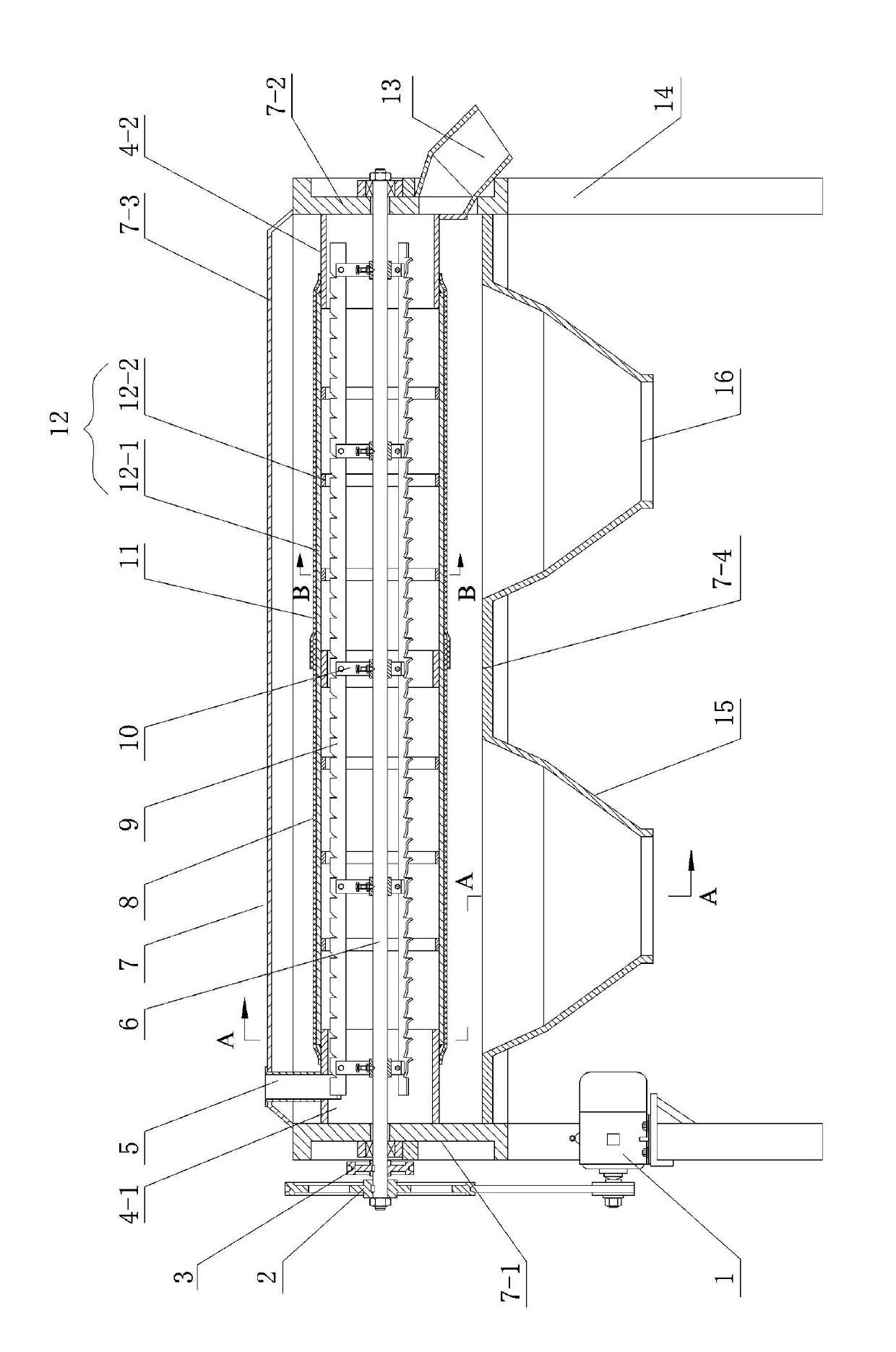

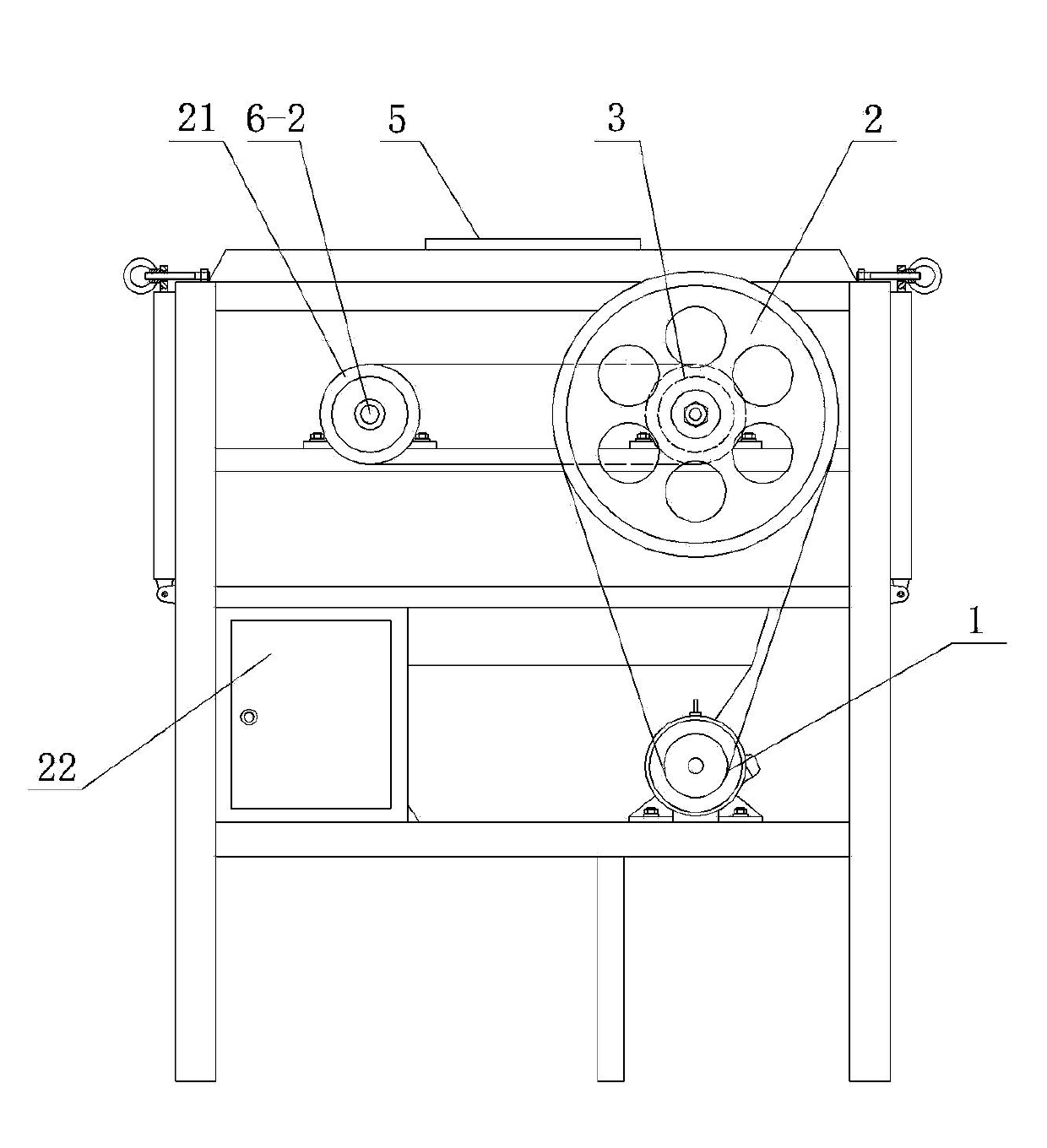

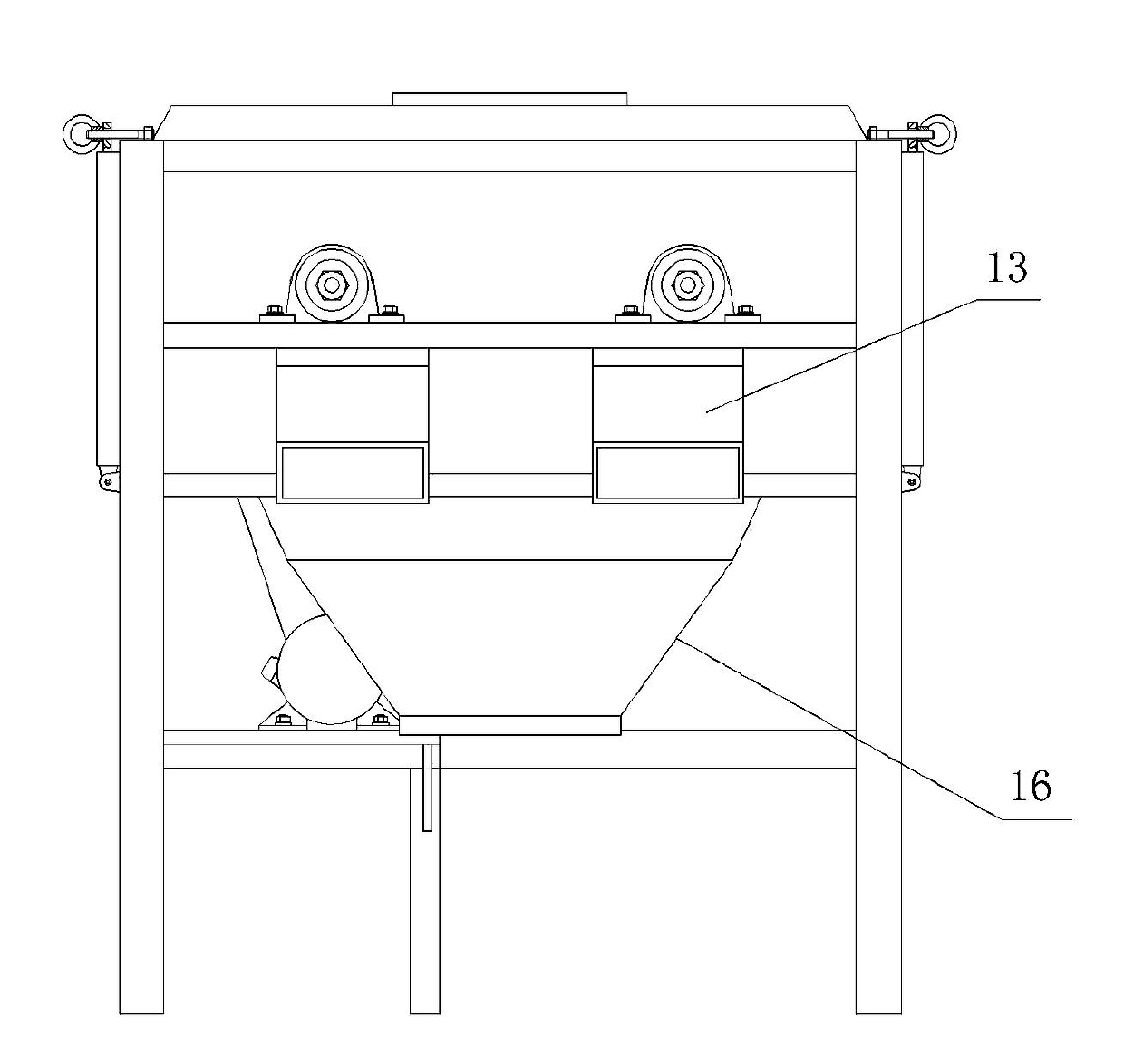

Plant fiber sizing screen powder machine

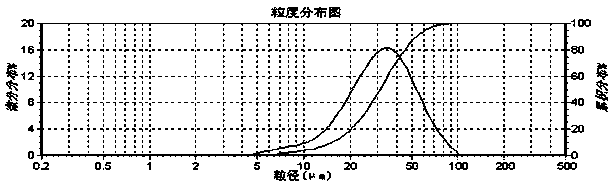

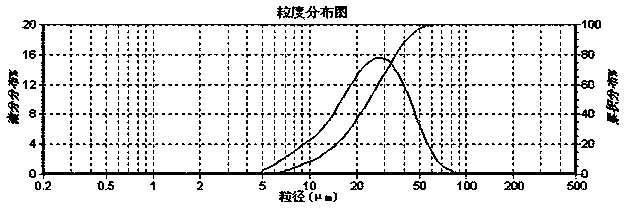

InactiveCN102652941ALiquidityGood fractionation effectSievingGas current separationMechanical engineeringPlant fibre

The invention discloses a plant fiber sizing screen powder machine, and belongs to the technical field of sifting machines. The plant fiber sizing screen powder machine comprises a rack and a machine shell, wherein the machine shell is formed by a front standing plate, a rear standing plate, a top shell and a bottom plate, and the machine shell is provided with a screen door; a screen drum is fixed between the front standing plate and the rear standing plate, the screen drum comprises front and rear end drums, a screen mesh frame and a screen mesh, the screen mesh comprises a first order screen mesh and a second order screen mesh, and the screen holes of the second order screen mesh are greater than that of the first order screen mesh; and the screen drum is internally provided with a pneumatic conveying device, the upper part of the machine shell is provided with a feeding bin, the lower part of the machine shell is provided with a first order discharge hopper and a second order discharge hopper, and the rear part of the machine shell is provided with a rear discharge port. The plant fiber sizing screen powder machine provided by the invention is used for screening plant fiber power, the structure that a screen drum is fixed and screen mesh is sectionalized is adopted, and the pneumatic conveying device is utilized to deliver powder; and the screening thing uniformly passes in a screening process, the liquidity is strong, the fractionation effect is good, and the output and the quality of the products are notably improved.

Owner:XUZHOU FUYANG ENERGY TECH

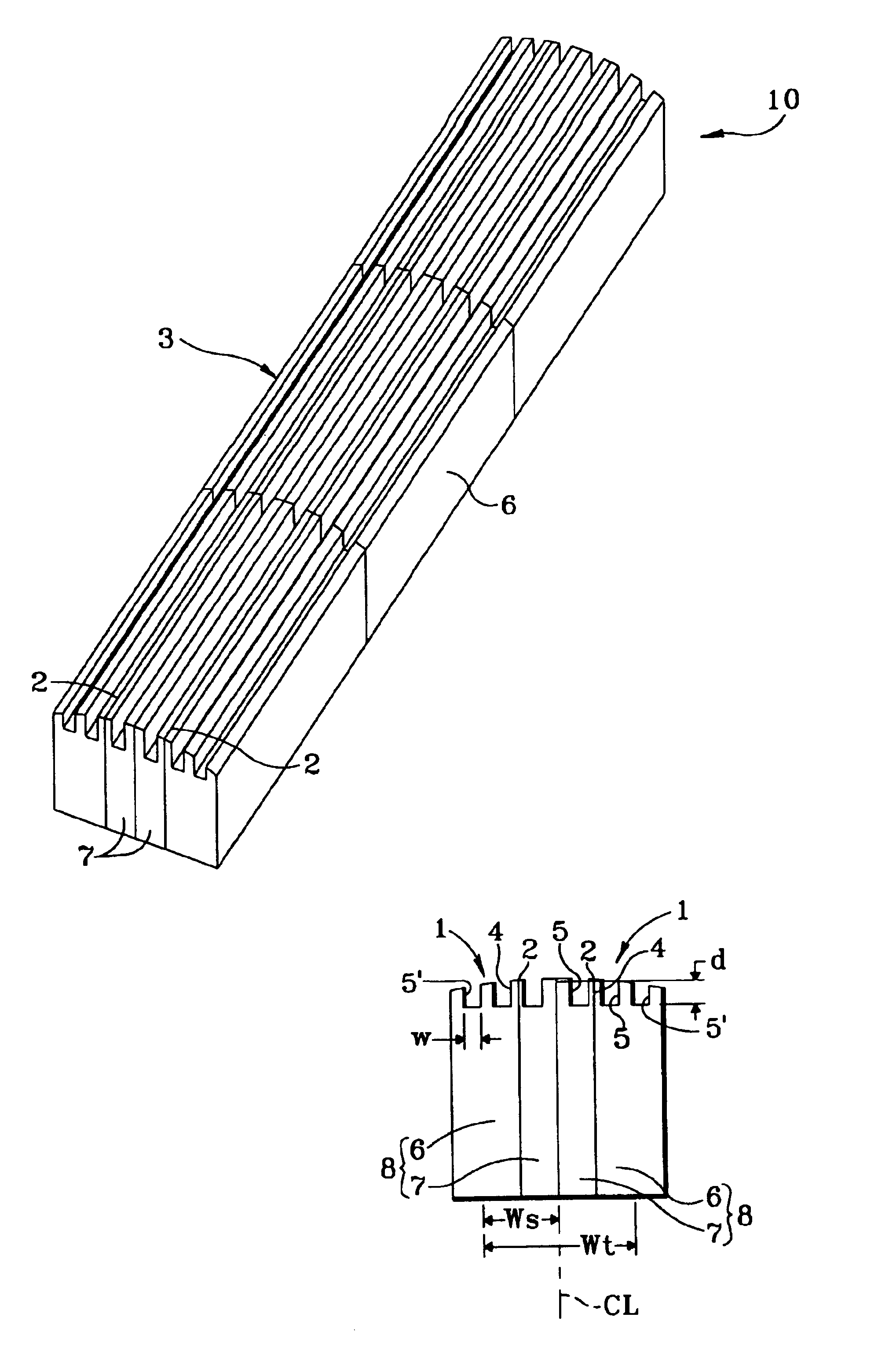

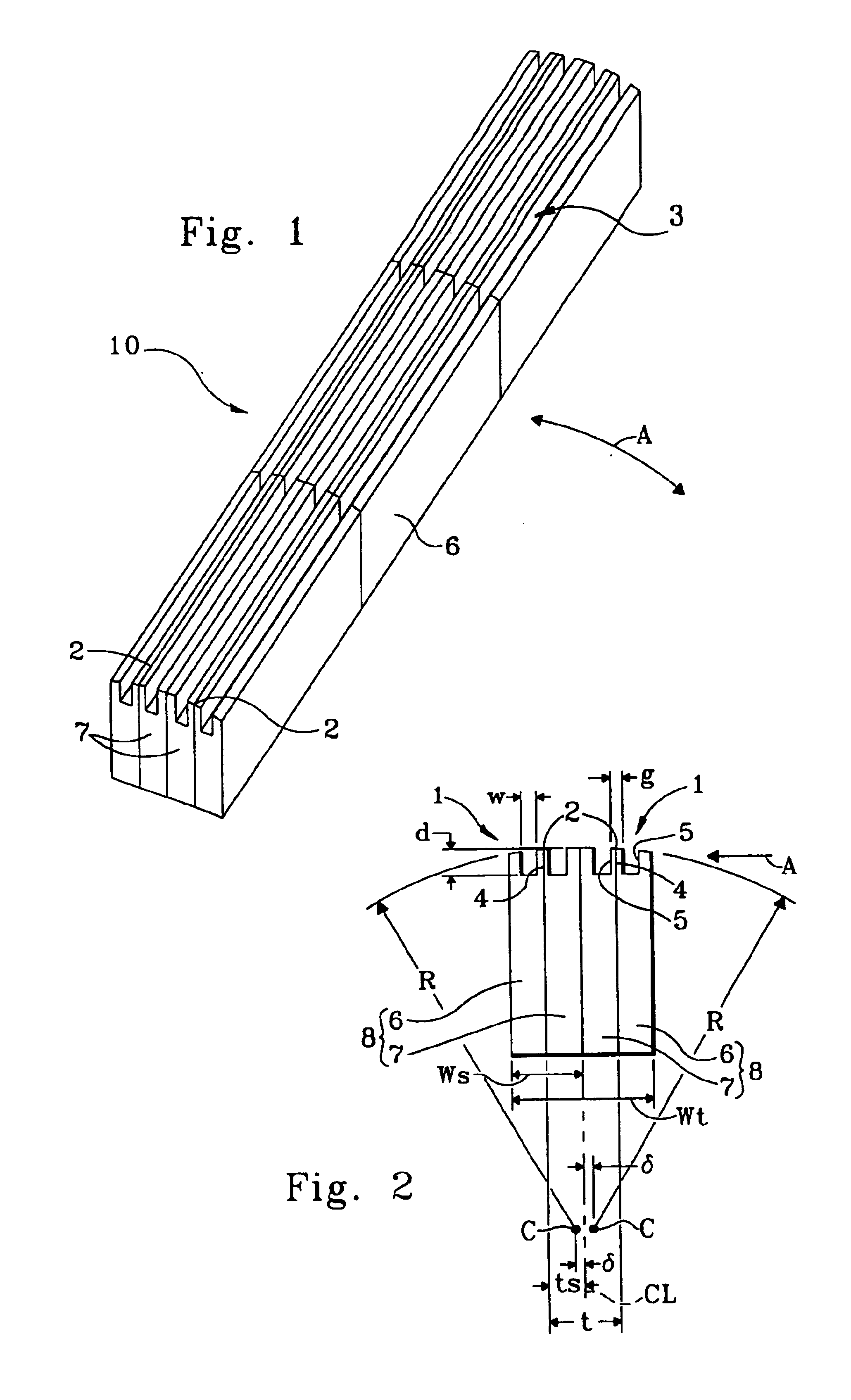

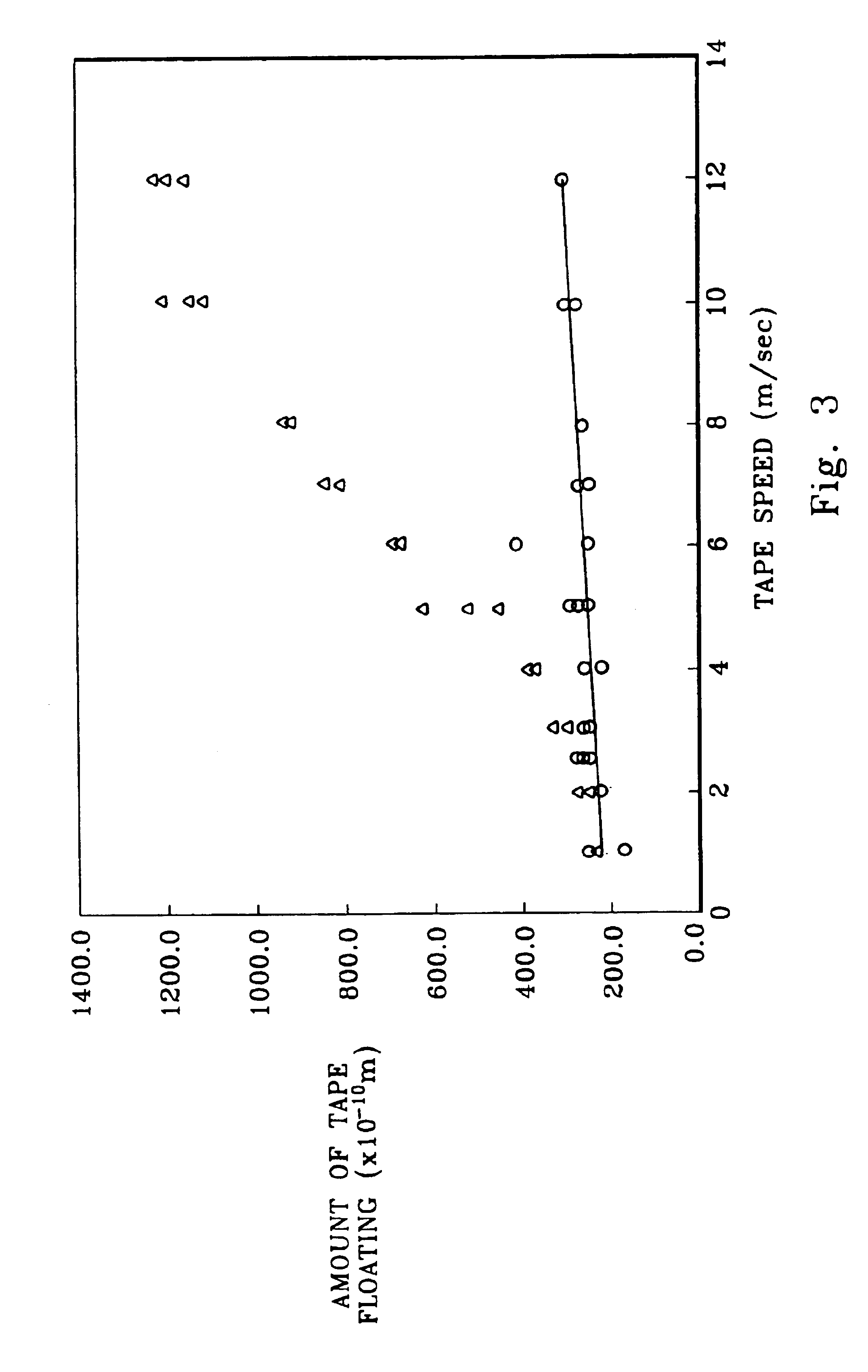

Read/write head for a magnetic tape device having grooves for reducing tape floating

InactiveUS6927937B2Reduce floatReduce floatingManufacture head surfaceManufacturing heads with multiple gapsEngineeringMagnetic tape

A read / write head for a magnetic tape includes an elongated chip assembly and a tape running surface formed in the longitudinal direction of the chip assembly. A pair of substantially spaced parallel read / write gap lines for supporting read / write elements extend longitudinally along the tape running surface of the chip assembly. Also, at least one groove is formed on the tape running surface on both sides of each of the read / write gap lines and extends substantially parallel to the read / write gap lines.

Owner:FUJITSU LTD

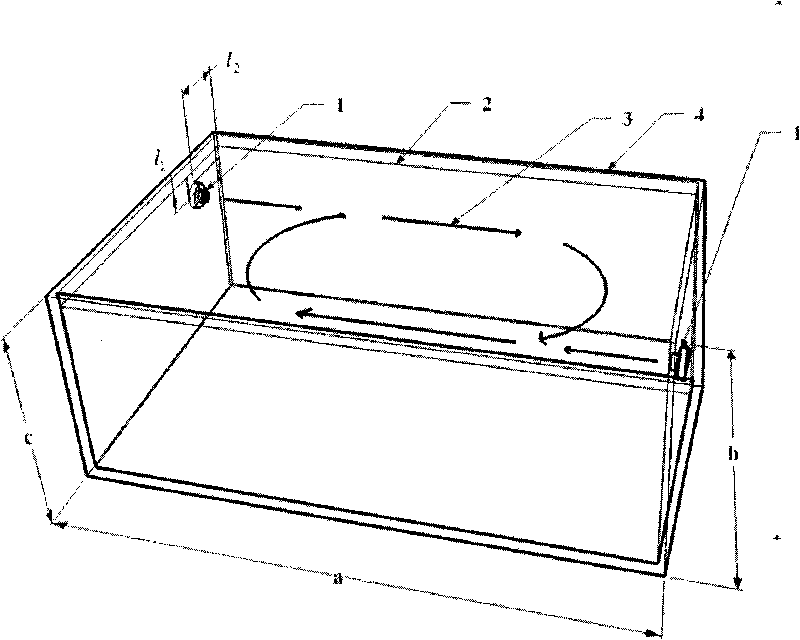

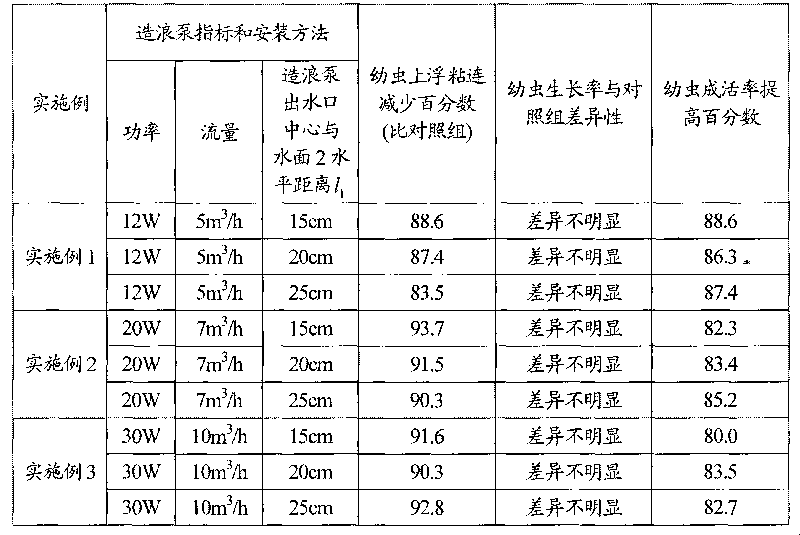

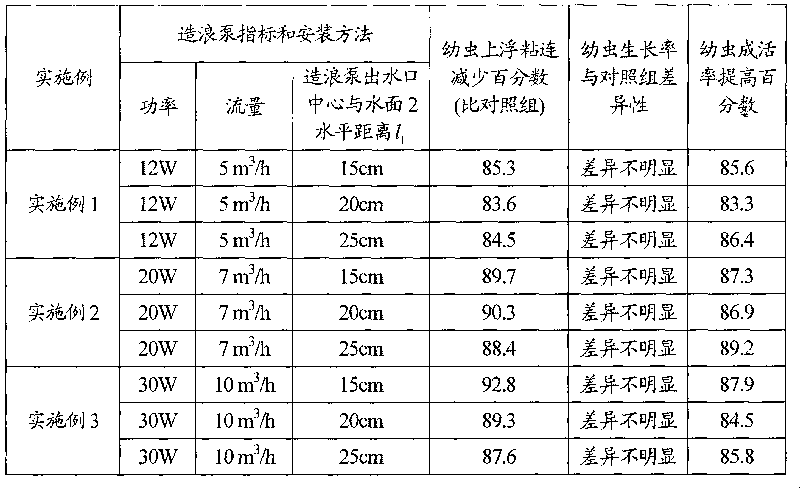

Method for preventing pinna pectinata larvae from floating upwards and adhering

ActiveCN101720704AGood waterproof performanceHigh dielectric strengthClimate change adaptationPisciculture and aquariaAdverse effectOffspring

The invention relates to aquaculture bivalve offspring seed production, in particular to a method for preventing pinna pectinata larvae from floating upwards and adhering. Two wave-making pumps are arranged in a diagonal shape on the pond wall of a culture pond in a width direction; waves and water flows which are generated by the wave-making pumps are used for dispersing the pinna pectinata larvae so that the pinna pectinata larvae are uniformly distributed in the culture pond, thus the pinna pectinata larvae are prevented from floating upwards and adhering; 24 hours after pinna pectinata fertilized ovums are incubated into D-shaped larvae, when the D-shaped larvae float upwards and are adhered, the wave-making pumps are installed; the proper power of the wave-making pumps is 12-30 W, the proper flow rate is 5-10 m3 / h, the proper distance horizontally kept between the water outlet centers of the wave-making pumps and a water surface is 15-25 cm, and the proper distance between the water outlet centers of the wave-making pumps and the adjacent pond wall of the culture pond is 20-40 cm. The invention can reduce upward floating and adhesion ratio matched groups of the pinna pectinata larvae more than 80 percent, enhance the survival rate by 80 percent without obvious adverse effect on the growth of the larvae and achieve the culture density of the larvae by 4-5 / ml, thereby effectively enhancing the survival rate and the culture efficiency of the pinna pectinata larvae.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Method of optimizing and returning to field of straw of cold region rice field

InactiveCN107484454ASolve floatingOvercoming the problem of easy hardeningSoil-working methodsEnvironment effectEcological safety

The invention discloses a method of optimizing and returning to field of straw of a cold region rice field, and relates to the field of returning to fields of straw of the rice fields. The method aims to solve the technical problems that according to a traditional method of returning to a field of straw, the effect of returning to the field is poor, during a process of returning to the field of the straw, the labor input of a farmer is increased, and the rice transplanting quality is affected. The method comprises the steps of (1) harvesting, wherein the straw is evenly dispersed in the field during harvesting; (2) land preparation and stubble burying, (3) irrigation for field steeping, stubble burying and land leveling and (4) rice transplanting and fertilizer application. Through the method, not only can returning to the field of the straw be achieved in the cold region rice field to achieve a purpose of land fertility betterment, but also negative environment effects caused by mass burning of the straw are alleviated, and fertilizer saving, the high yield, the high quality, the high efficiency and the ecological safety of the rice field are achieved; the method is used for returning to the field of the straw in a cold region.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Environmentally-friendly textile machine with functions of shock absorption and cotton flock absorption

PendingCN107575718AImprove practicalityAvoid excessive vibrationNon-rotating vibration suppressionDirt cleaningWater diversionWater pipe

The invention discloses an environmentally-friendly textile machine with functions of shock absorption and cotton flock absorption. The environmentally-friendly textile machine with the functions of shock absorption and cotton flock absorption comprises a hydraulic expansion link, an exhaust fan, a booster pump, a shock absorption device, a baseplate and a base, wherein the hydraulic expansion link is used for adjusting the height of the baseplate and further realizes the adjustment of the height of a textile machine body, thereby meeting the using requirements of operators with different height; the exhaust fan is used for causing cotton flocks generated in the working process of the textile machine body to enter a pipeline through an absorption cover and further enter a cotton flock collecting tank, thereby avoiding the problem that the cotton flocks generated in the working process of the textile machine body float in the air to cause pollution and affect the physical health of bodies of operators in the workshops; the booster pump is used for causing water in a water storage tank to pass through a water diversion pipe and then be sprayed from an atomizing spray head so as to humidify the cotton flocks floating in the air in the workshops, thereby causing the cotton flocks floating in the air in the workshops to fall on the ground under the action of gravity.

Owner:长兴宝诺纺织科技有限公司

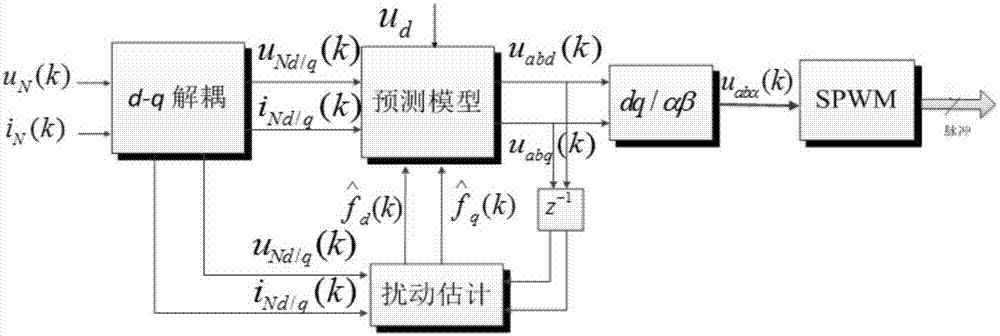

Disturbance-estimation-based model prediction control high-speed railway low frequency oscillation inhibition method

InactiveCN107294372AImprove anti-interference abilityImprove robustnessAc-dc conversionParameter errorState-space representation

The invention discloses a disturbance-estimation-based model prediction control high-speed railway low frequency oscillation inhibition method. The disturbance-estimation-based model prediction control high-speed railway low frequency oscillation inhibition method includes the following steps: A, constructing a D-series high-speed train network side rectifier dynamic characteristic equation considering the parameter error quantity under a d-q rotating coordinate system; B, defining the disturbance quantity, and according to the dynamic characteristic equation, obtaining a D-series high-speed train network side rectifier current prediction model considering the disturbance quantity under the d-q rotating coordinate system; C, taking the current and the disturbance quantity as state variables, obtaining a state space model of a disturbance estimator, and constructing the disturbance estimator; D, substituting a estimated value of the disturbance quantity into the current prediction model in the step B to obtain a current prediction value, and substituting the obtained current prediction value into a cost function to obtain the next sampling period control voltage; and E, obtaining an alpha-beta coordinate system component by performing coordinate transformation on the control voltage, and outputting the control pulse through sine pulse width modulation to complete high-speed railway low frequency oscillation inhibition. The disturbance-estimation-based model prediction control high-speed railway low frequency oscillation inhibition method can improve the anti-interference capability and the robustness performance of the control system, can minimum floating of the voltage variance in the period, and is not sensitive to change of parameters.

Owner:SOUTHWEST JIAOTONG UNIV

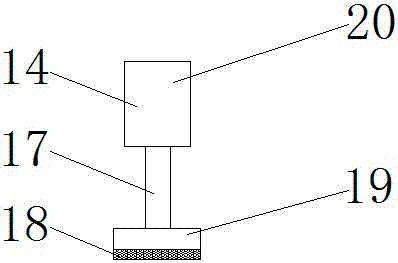

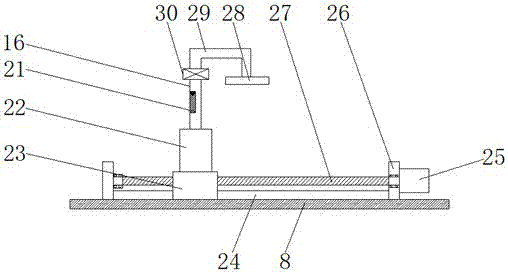

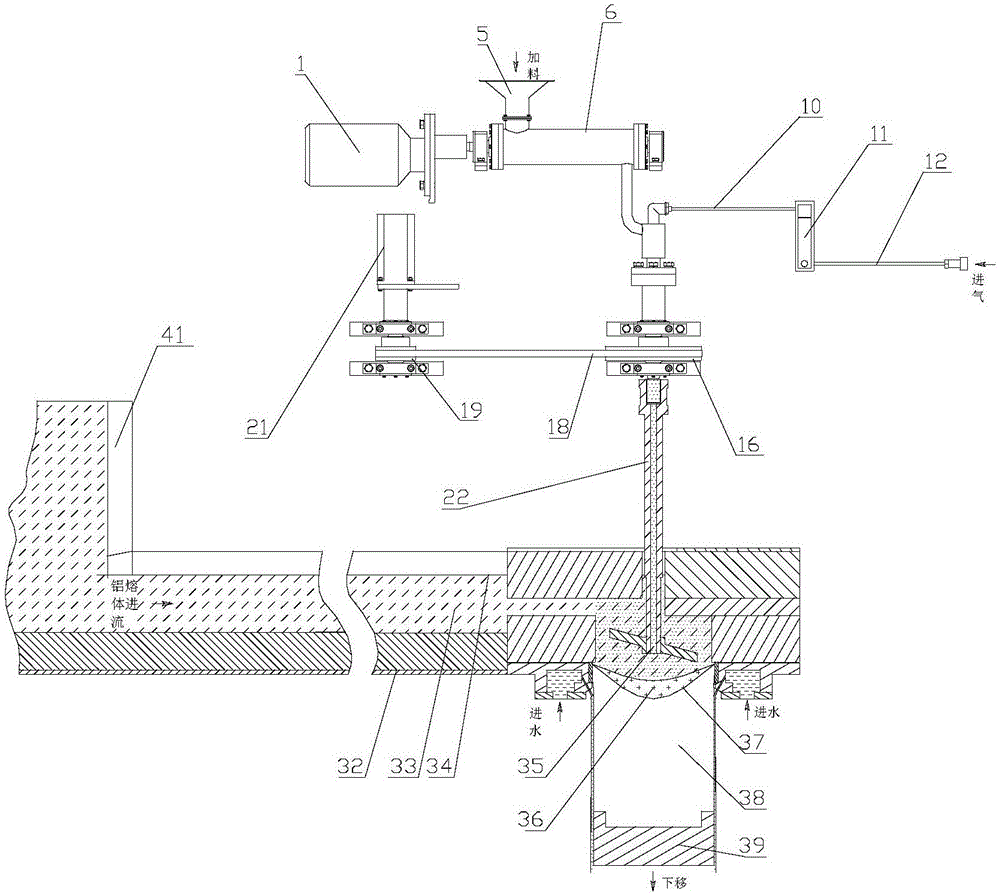

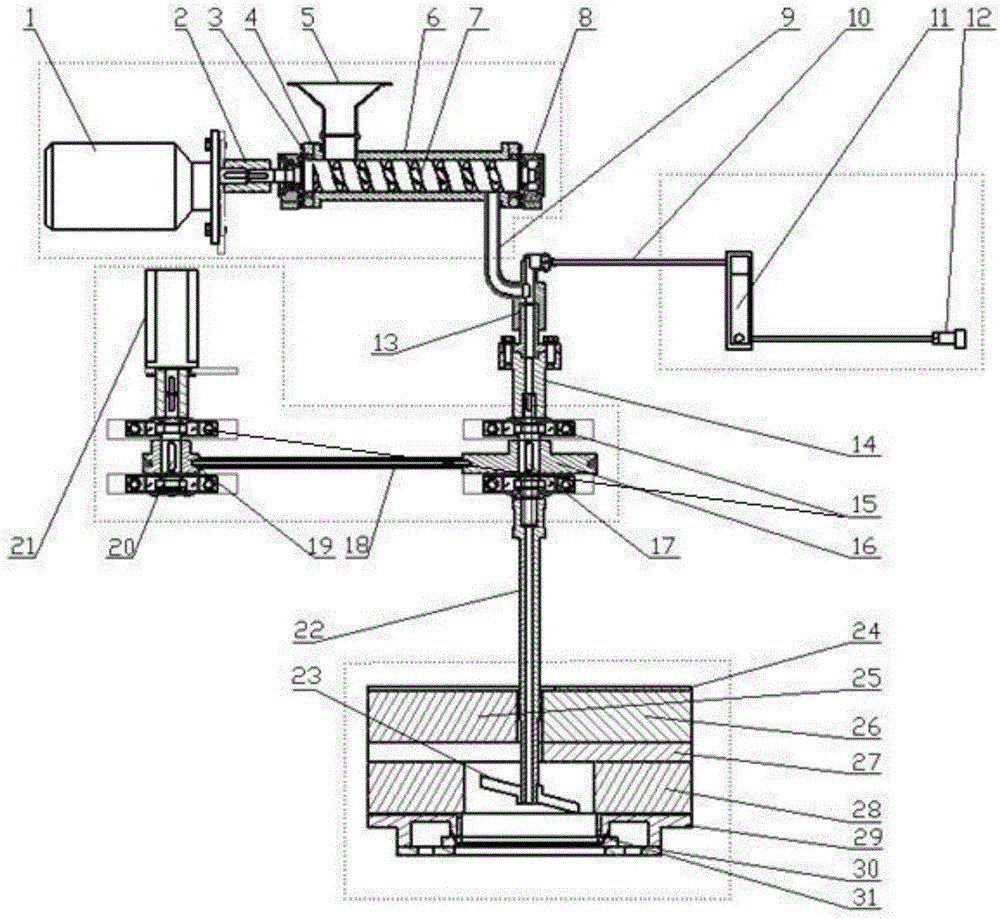

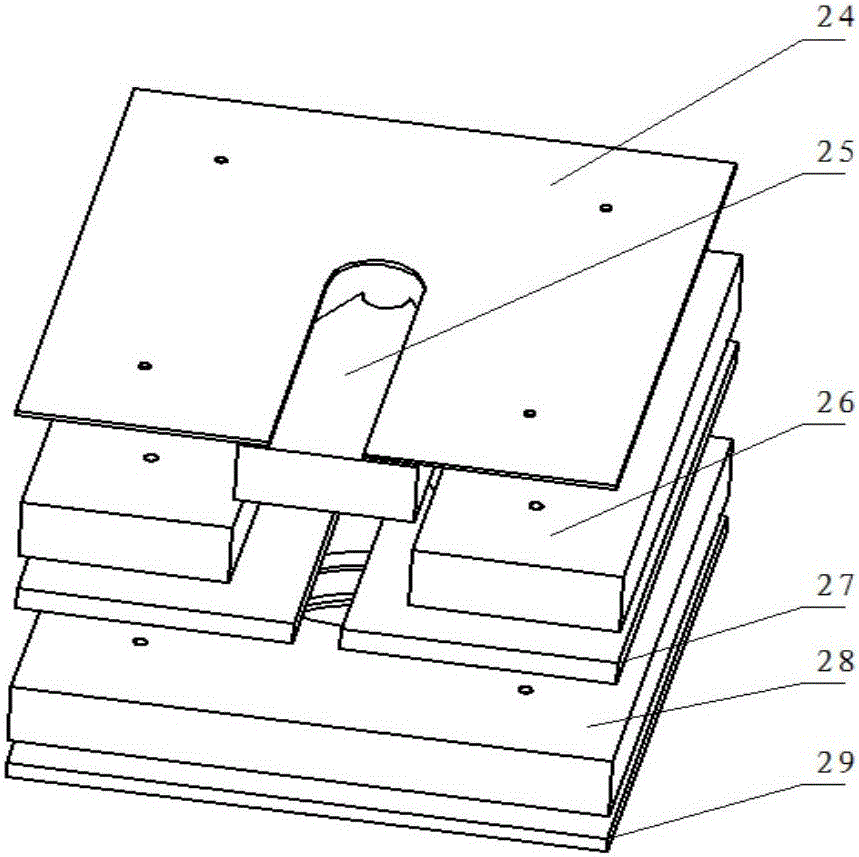

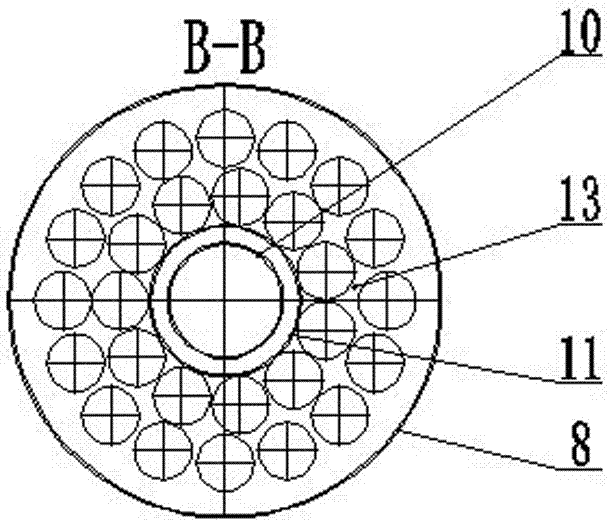

Semi-continuous casting device for preparation of aluminum matrix composites

The invention discloses a semi-continuous casting device for preparation of aluminum matrix composites. The semi-continuous casting device for preparation of the aluminum matrix composites comprises a smelting holding furnace, a charging device, an air supply device, a rotation driving device, a connecting mechanism, a stirring device, a crystallizer, a heat preservation device and a runner. The smelting holding furnace communicates with the runner. The runner communicates with the heat preservation device. The heat preservation device communicates with the crystallizer. The stirring device is mounted in the heat preservation device. The charging device and the air supply device communicate with the stirring device through the connecting mechanism. The rotating driving device is connected with the stirring device and drives the stirring device to rotate. According to the semi-continuous casting device for preparation of the aluminum matrix composites, in the semi-continuous casting process, a stirring rod is arranged near the solidification front of aluminum alloy melt, reinforcement powder is continuously added to the position near the solidification front in a quantitative mode, highs-speed stirring is conducted through the stirring rod, and an aluminum matrix composite cast ingot is obtained along with downward movement of a dummy ingot; and the probability of floating of reinforcement in the melt can be greatly lowered, defects such as oxide films are reduced, and meanwhile, the semi-continuous casting device is suitable for industrial continuous production.

Owner:苏州有色金属研究院有限公司

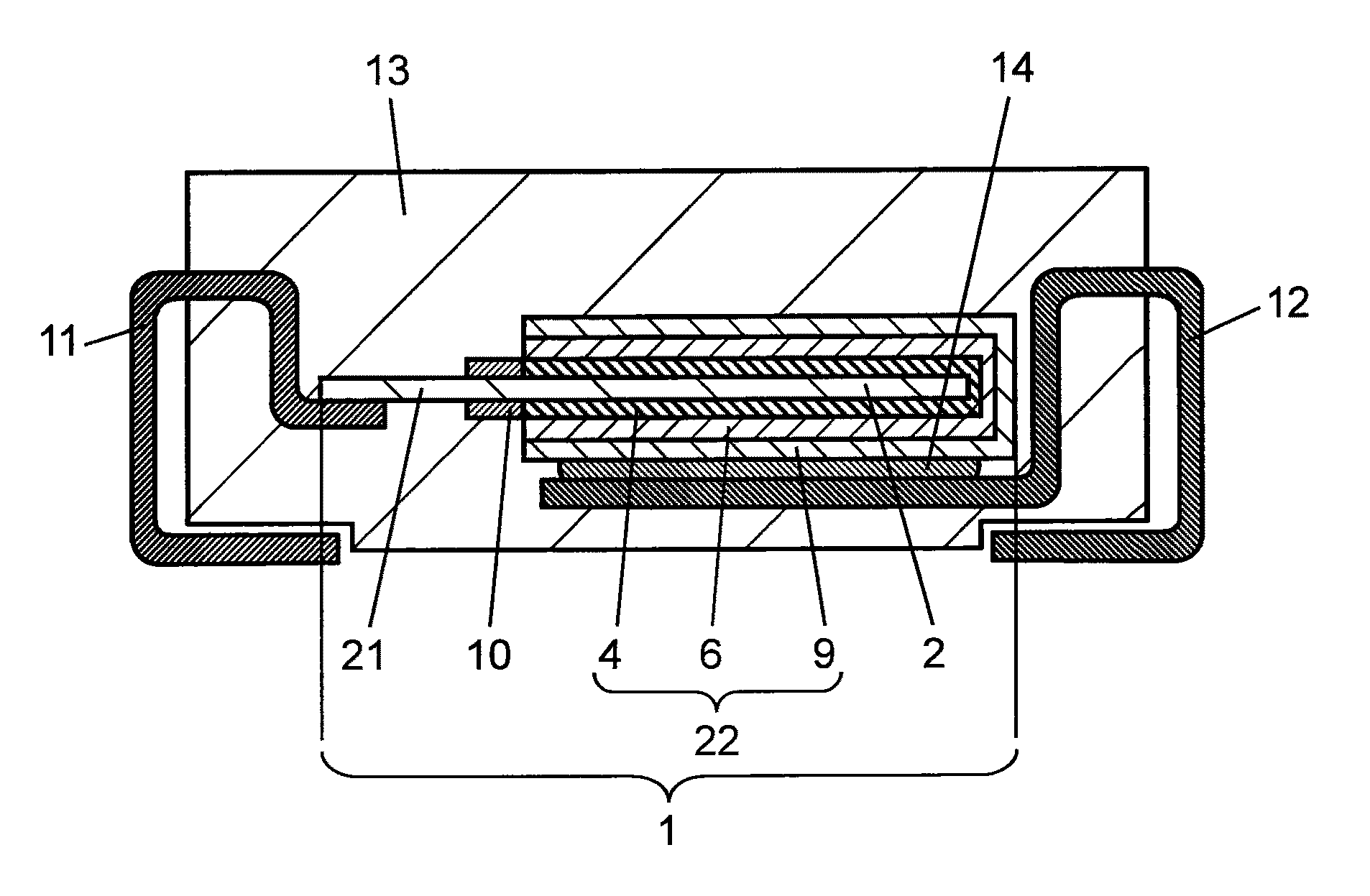

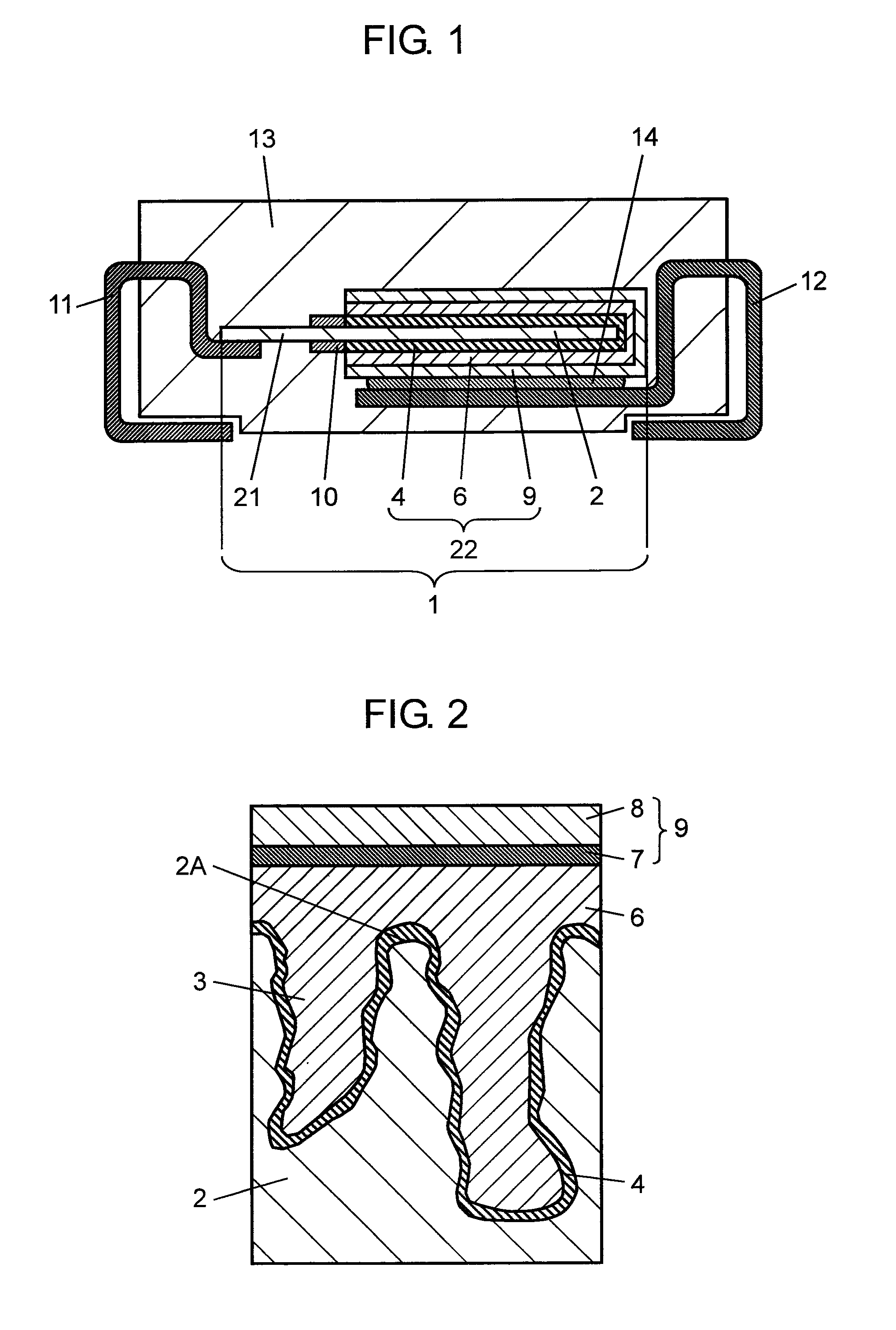

Method for manufacturing solid electrolytic capacitor

InactiveUS7988743B2Increase productionReduce floatingSolid electrolytic capacitorsCapacitor electrolytes/absorbentsElectrolysisConductive polymer

Disclosed is a method for manufacturing a solid electrolytic capacitor in which a capacitor element has conductive polymer solid electrolyte on a dielectric oxide film layer. The method includes the following processes: forming a manganese oxide layer on the dielectric oxide film layer; and chemically polymerizing a reaction solution containing a monomer, aromatic sulfonic acid, and a solvent using the manganese oxide layer as an oxidizing agent. Here, polyhydric alcohol capable of being coordinated to manganese ions released from the manganese oxide layer is made to coexist with the chemical polymerization reaction.

Owner:PANASONIC CORP

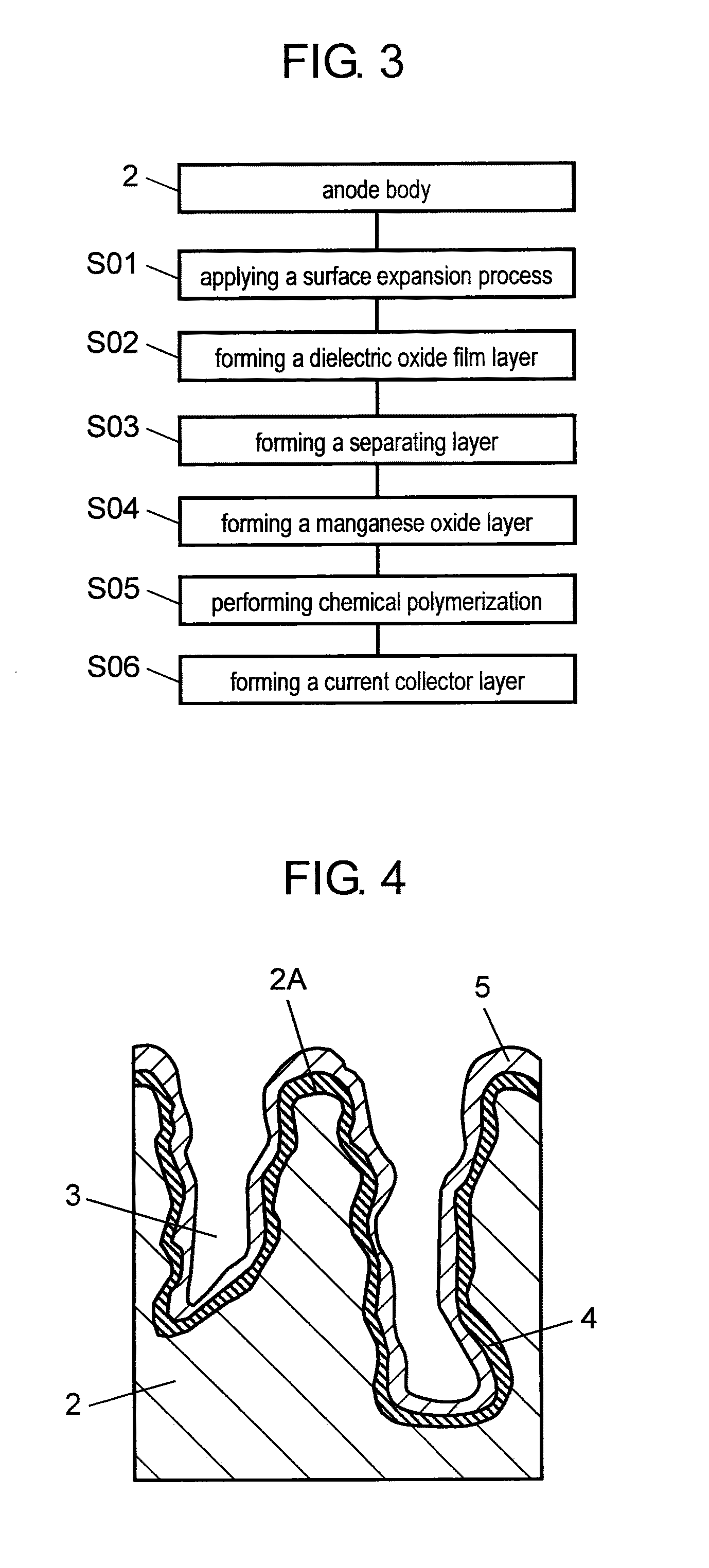

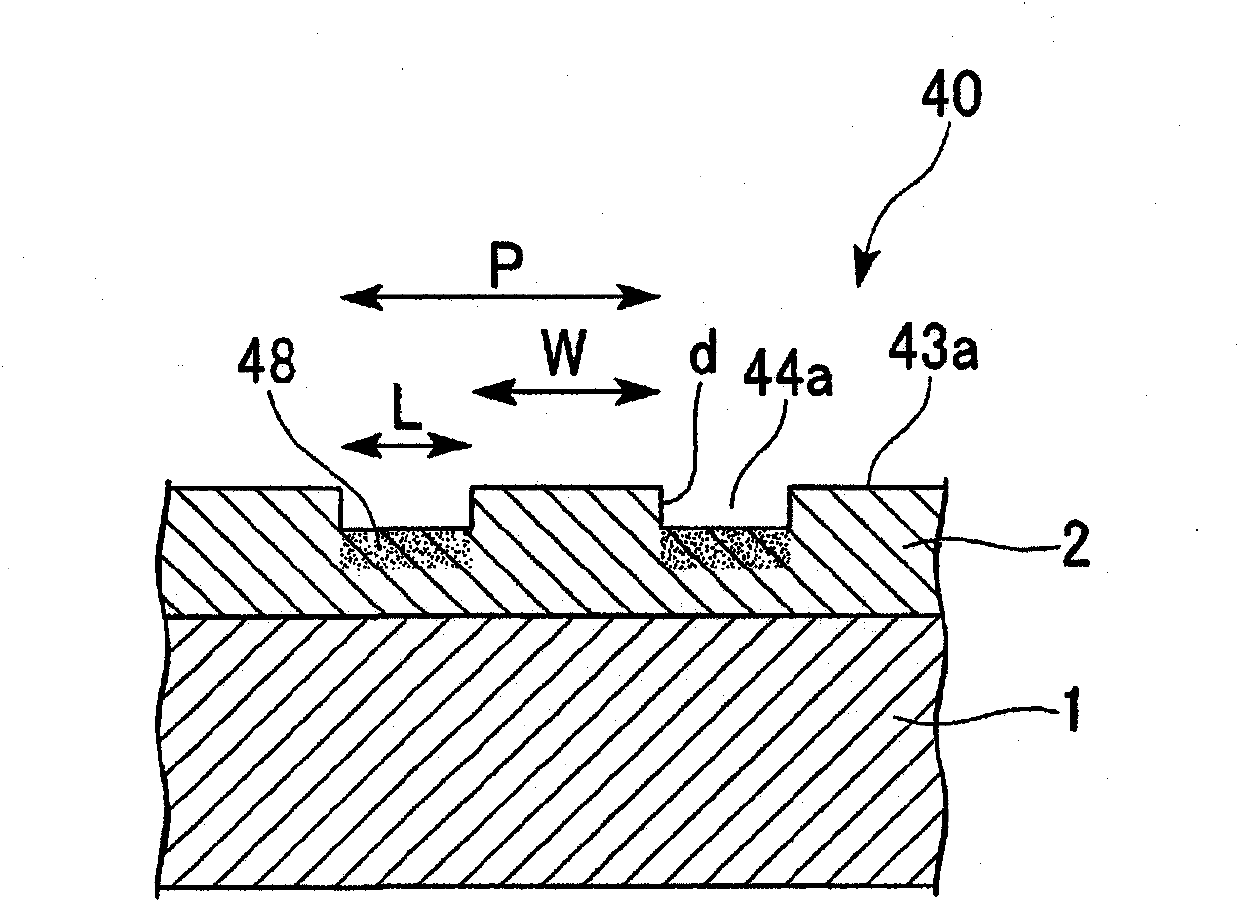

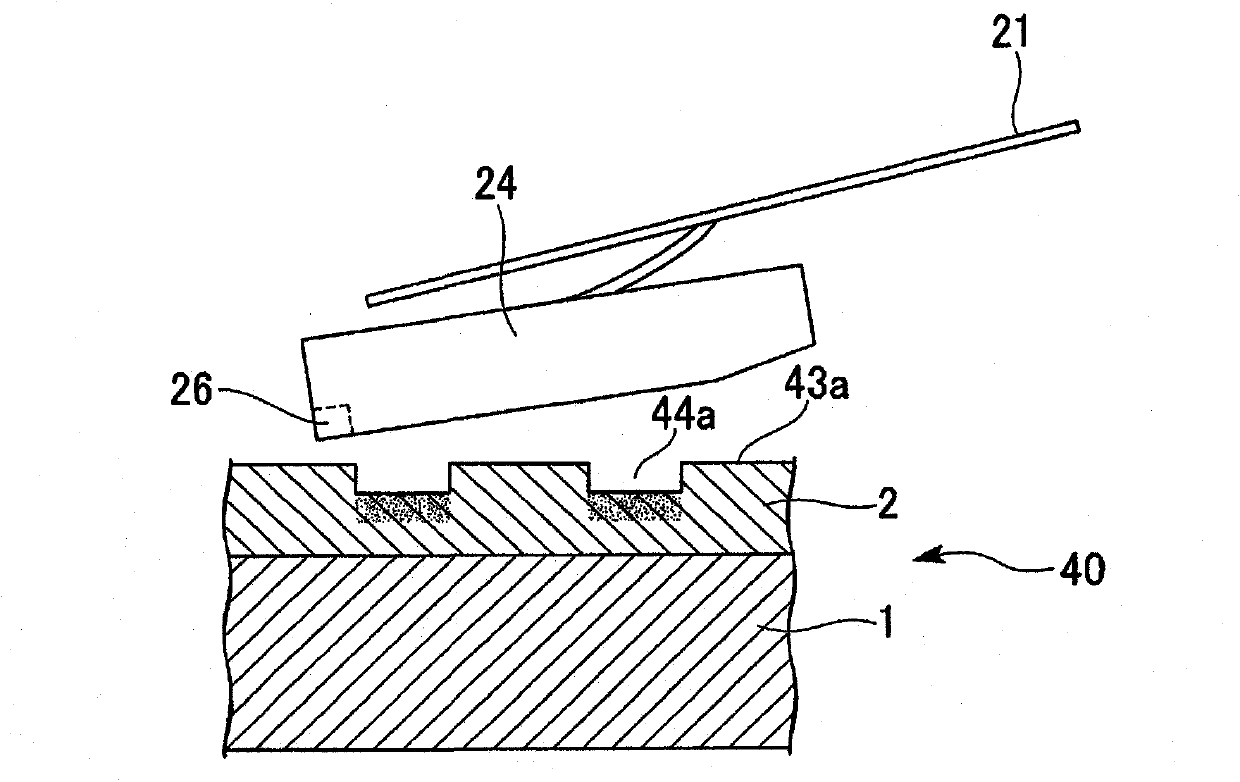

Magnetic recording medium, magnetic recording/reproducing device and method for manufacturing magnetic recording medium

InactiveCN102016987AImprove stabilityAvoid contactDisposition/mounting of recording headsNanoinformaticsIn planeData graph

Provided is a magnetic recording medium which can be manufactured at high manufacturing efficiency, has protruding sections which are composed of a magnetic layer and can be separated by a recessed separating region, and provides excellent stable floating characteristics of a magnetic head. In a magnetic recording medium (40), at least on one surface of a disc-like substrate, an annular magnetic recording region (A), and a landing region (B) arranged along an edge section of the magnetic recording region (A) are arranged. The magnetic recording region (A) is provided with a data region (41) having a data pattern (45) composed of protruding sections (43a) composed of a magnetic layer, and a recessed separating regions (44a) formed at the periphery of the protruding sections (43a); and a servo information region (42) provided with a servo pattern (46), which is composed of protruding sections (43b, 43c) and an isolating region (44b) and has a shape different from that of the data pattern (45) in plane view. At least on a part of the landing region (B), an uneven pattern (47) having a protruding section (43d) which has the same shape as that of the protruding section (43a) of the data pattern (45) is arranged.

Owner:SHOWA DENKO KK

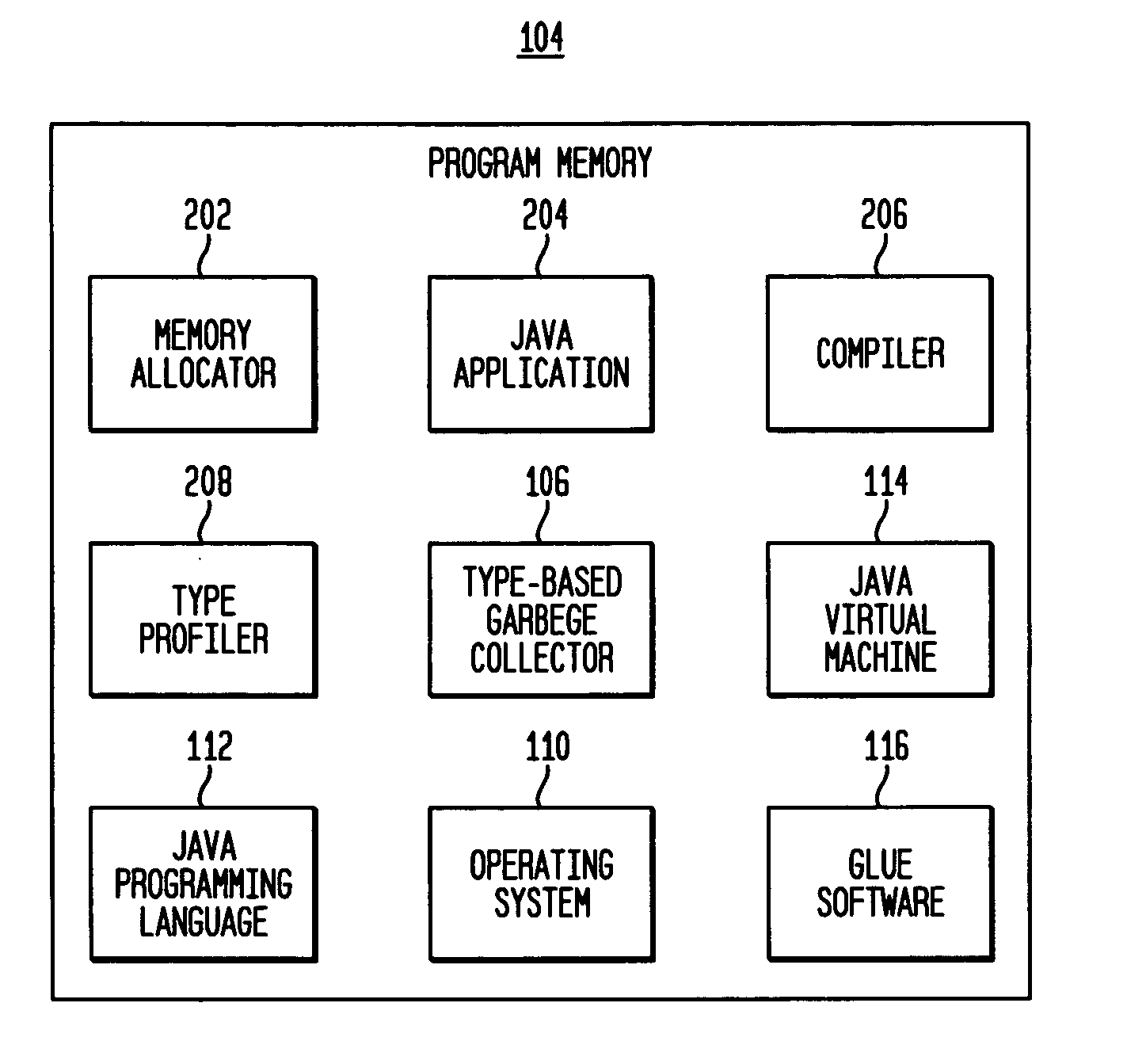

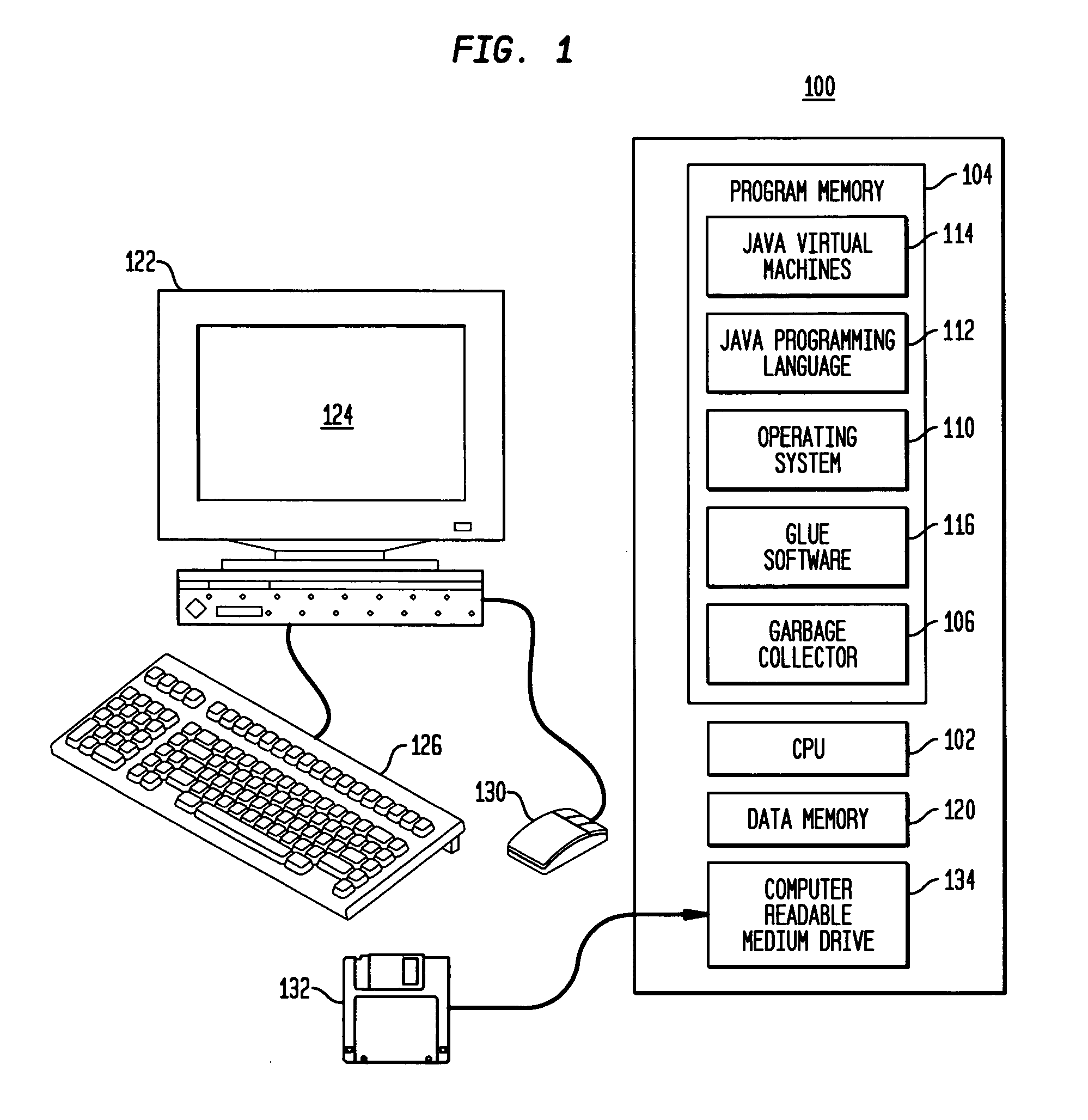

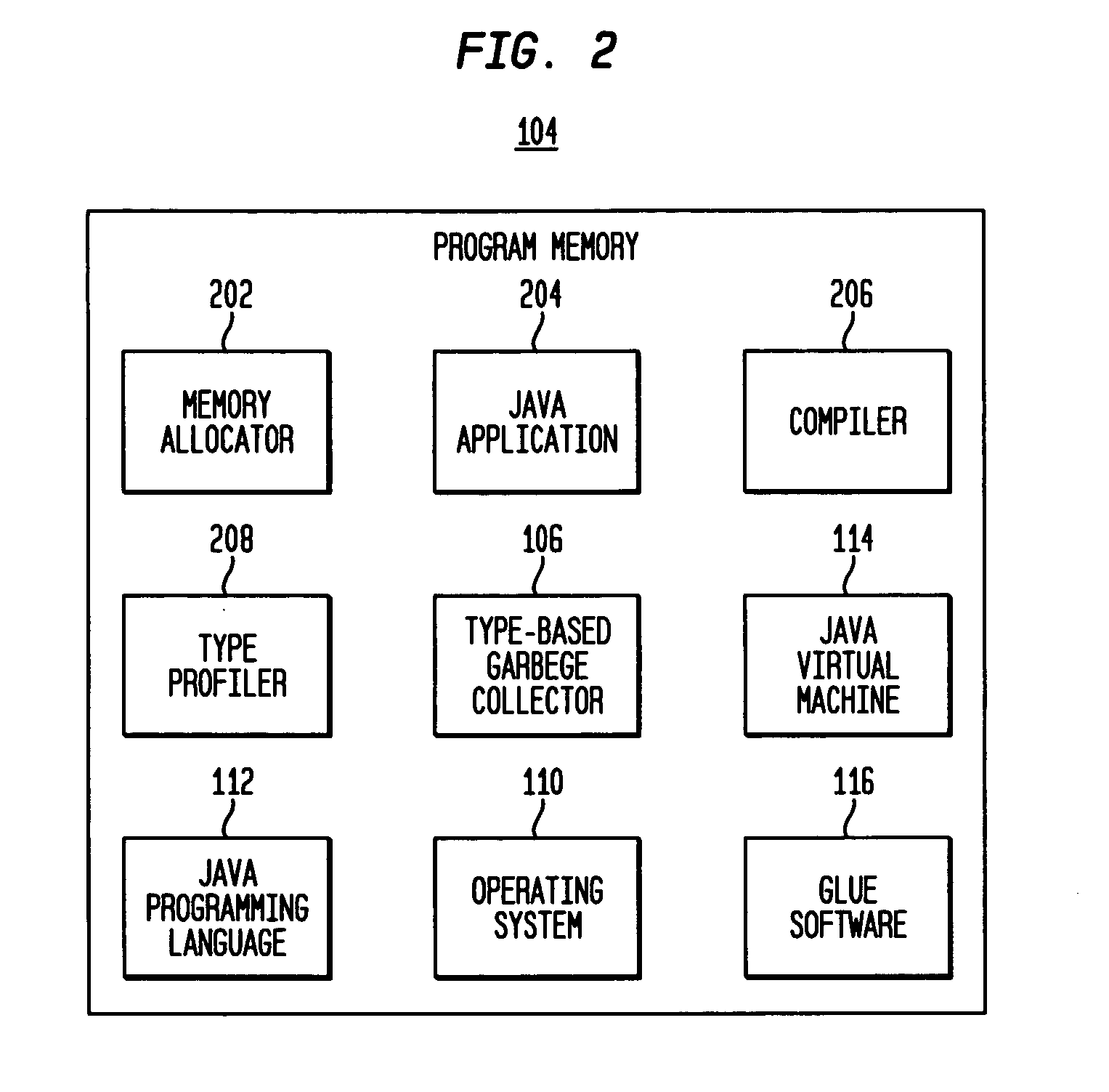

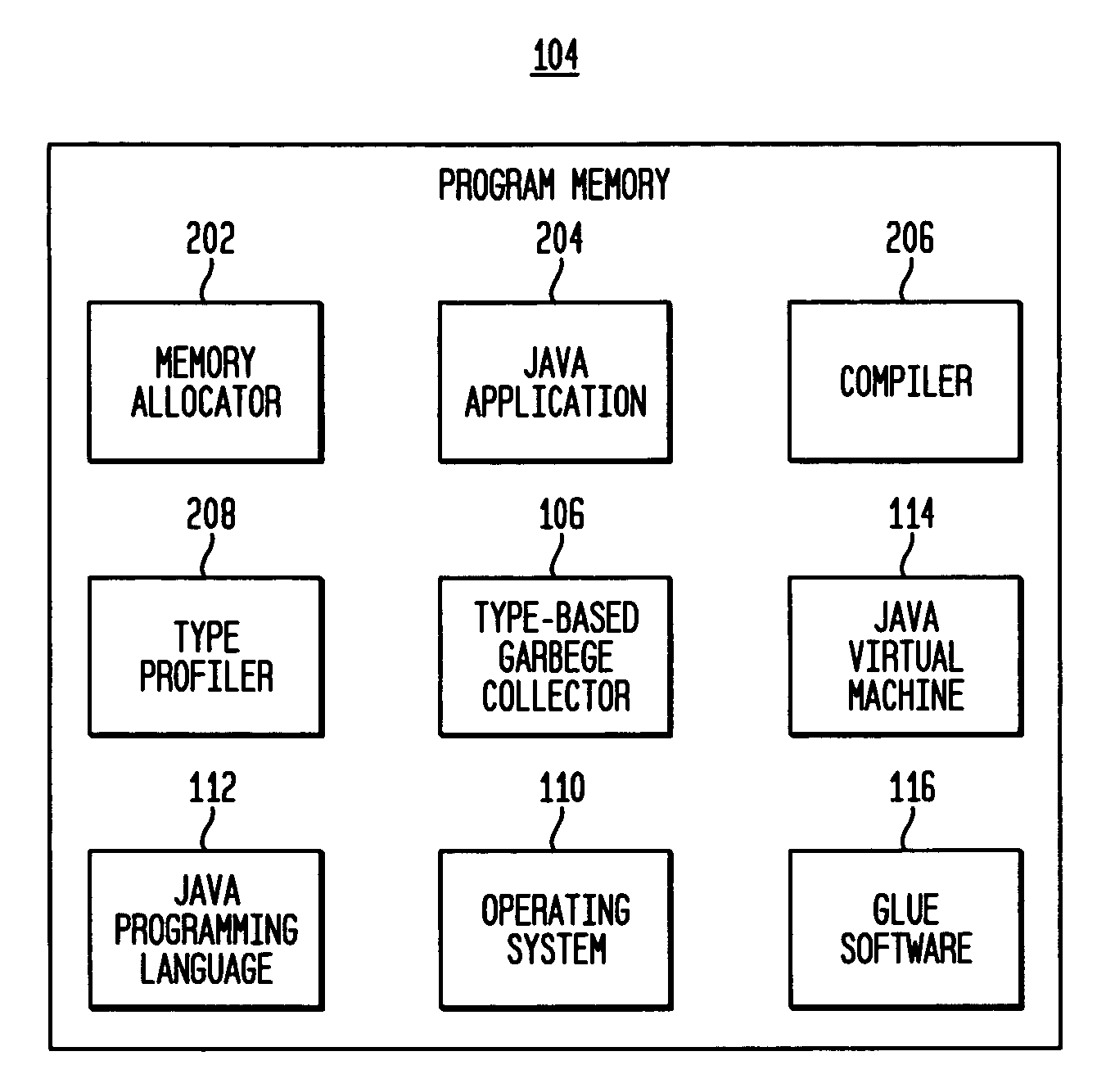

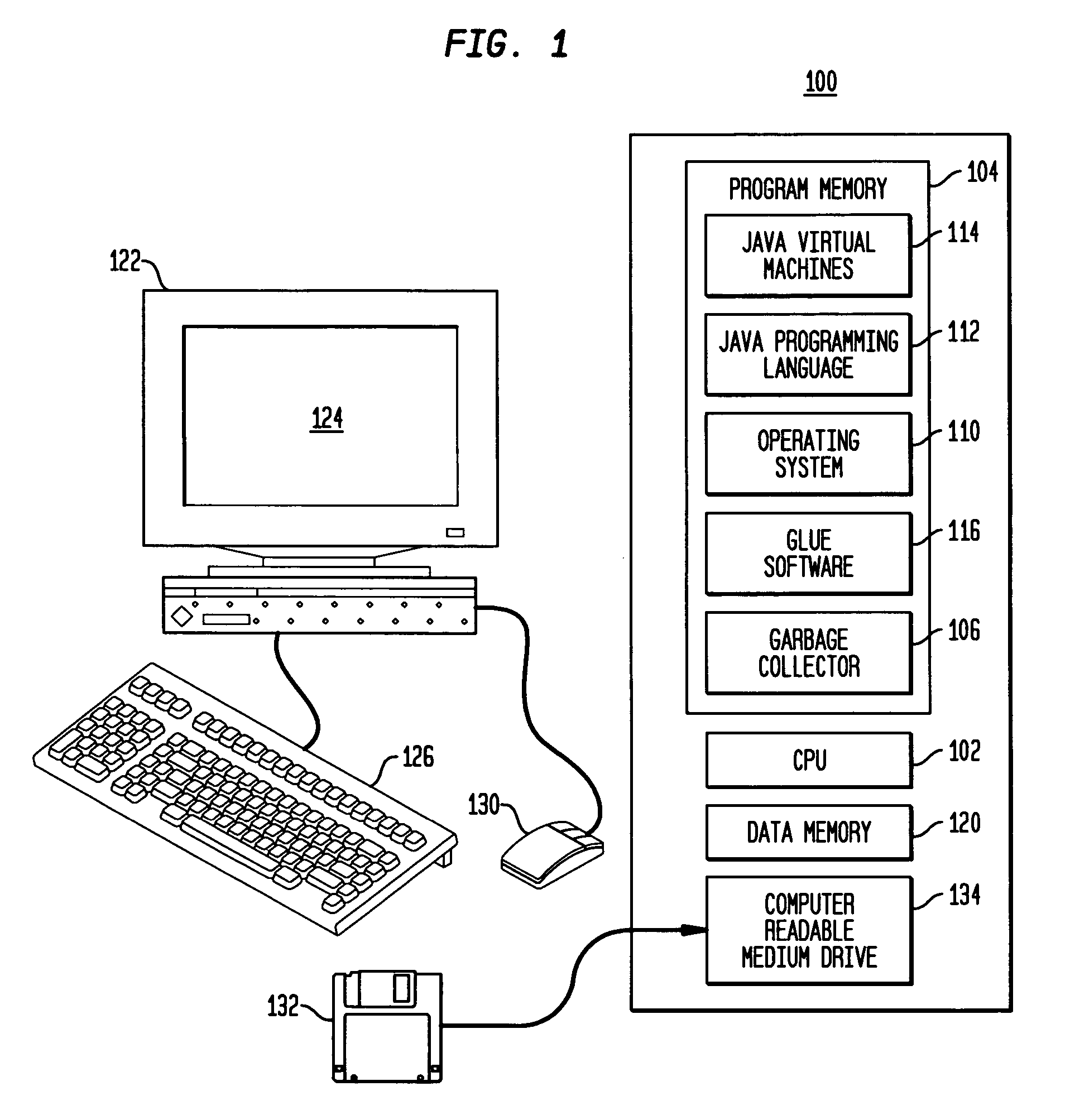

Generational real-time garbage collection

InactiveUS7548940B2Improve utilizationImprove throughputSpecial data processing applicationsMemory systemsRefuse collectionLitter

Disclosed are a partial heap garbage collector, and a partial heap garbage collection method, that during collection checks the time remaining (or equivalently the time taken so far, or the work done so far) to complete the partial heap collection. In a preferred embodiment, the partial heap collection is guaranteed to complete within a fixed time interval. For example, this guarantee may be obtained by applying a worst-case execution time (WCET) and sizing a nursery so that complete evacuation of the nursery can always be achieved on time. As an alternative, a technique, referred to as syncopation, may be used to allow generational collection to be used despite variance in program behavior over the short time scales in which a nursery can be collected. Syncopation may be accomplished via allocation control or via collection control.

Owner:INT BUSINESS MASCH CORP

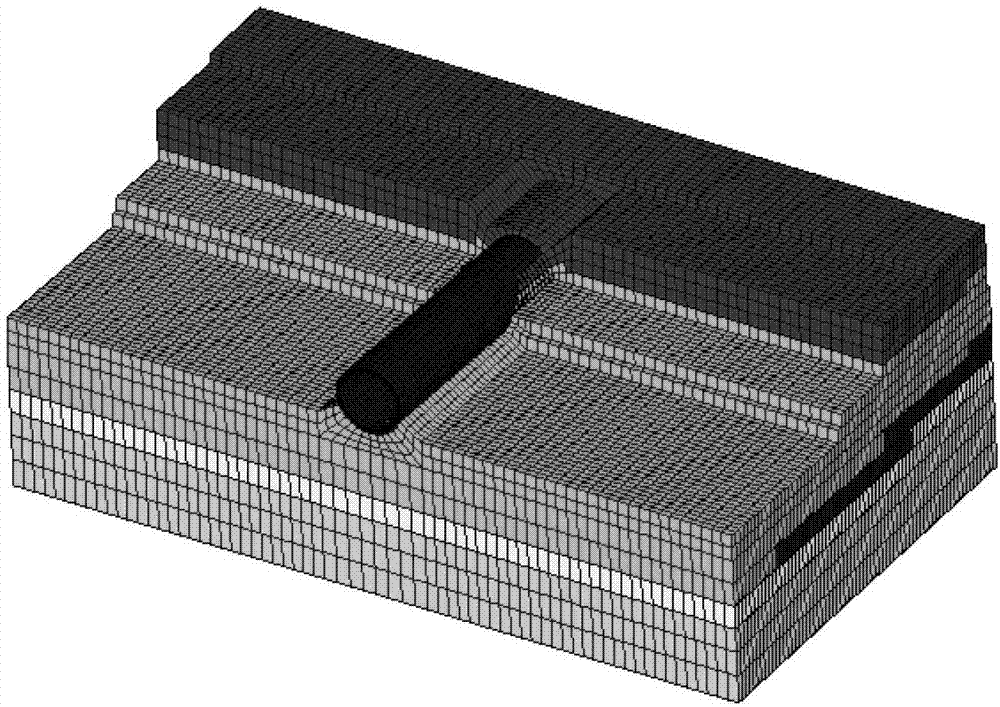

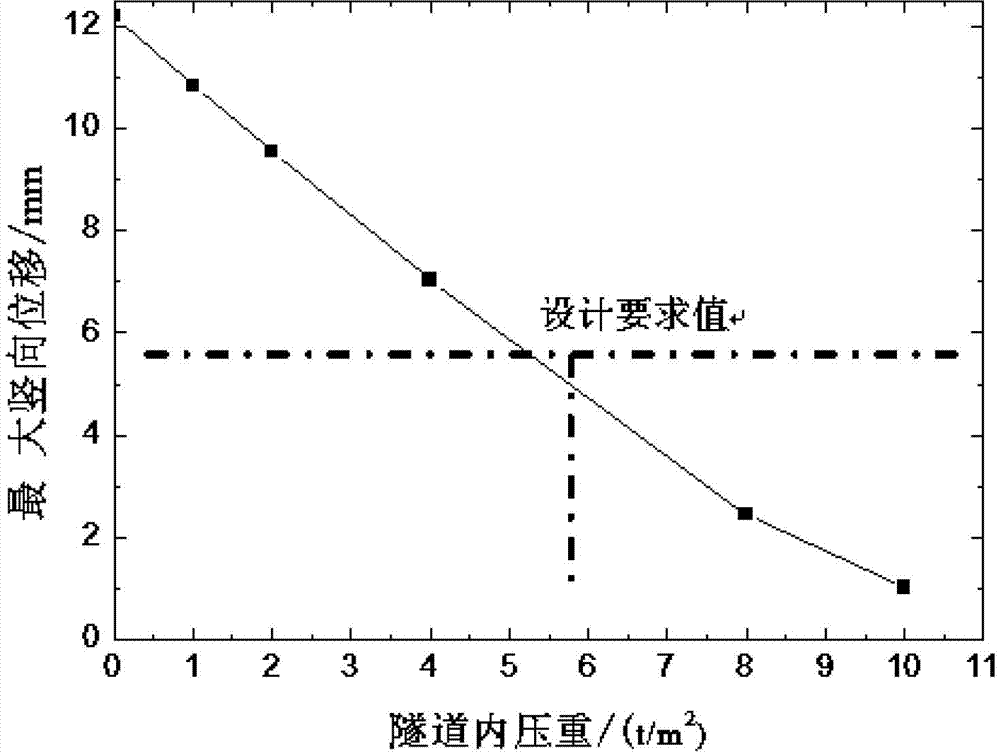

Anti-floating ballasting method for shield tunnel under negative earthing condition

ActiveCN103244134AReduce floatingThe anti-floating method is simple and practicalTunnelsFinite element methodEngineering

The invention provides an anti-floating ballasting method for a shield tunnel under negative earthing condition. The method includes the steps of firstly, calculating according to borne load and formation condition of a tunnel segment in actual construction by the finite element method to obtain magnitude of ballasting load, with lead blocks as weights for ballasting; secondly, designing the shape of the lead blocks; and thirdly, setting the positions of the lead blocks, namely setting the lead blocks at the anti-floating-required part of the bottom of the tunnel. According to the method, the lead weights are disposed at the anti-floating-required part of the bottom of the tunnel so that the tunnel segment can bear extra weight of the lead weights and floating quantity of the tunnel segment is reduced; the method is simple and practical, and by the method, floating quantity of the tunnel is reduced greatly; and the method is applicable to anti-floating application in shield tunnel construction.

Owner:SHANGHAI JIAO TONG UNIV

Polystyrene foam grain light-weight aggregate and preparation method thereof

The invention discloses a polystyrene foam grain light-weight aggregate and a preparation method thereof. The polystyrene foam grain light-weight aggregate is prepared from the following raw materials: polystyrene foam grains, E44 epoxy resin, T31, dibutyl ester and acetone. The preparation method comprises the following steps: weighing polystyrene foam grains, E44 epoxy resin, T31, acetone and dibutyl ester according to the mass ratio of 1: (2.5-3): (2-3): (0.25-0.3): (0.25-0.3) for later use; sequentially adding T31, acetone and dibutyl ester into E44 epoxy resin to prepare an epoxy resin adhesive; then pouring the prepared epoxy resin adhesive into the polystyrene foam grains, and uniformly stirring to obtain the polystyrene foam grain light-weight aggregate. The prepared polystyrene foam grain light-weight aggregate has the characteristic of light weight, overcomes the shortcoming that the surface cohesive force between the polystyrene foam grains and a binding material is relatively poor, is extremely low in water absorption and relatively good in service durability, and facilitates reclamation and utilization of waste polystyrene foam.

Owner:SHIHEZI UNIVERSITY

Hardware accessory polishing device

InactiveCN111015487AAchieve forward and backward movementAchieve left and right movementGrinding carriagesPolishing machinesPolishingElectric machinery

The invention discloses a hardware accessory polishing device and relates to the technical field of hardware accessory processing equipment. The hardware accessory polishing device comprises a worktable, wherein first connecting seats are connected to two side of the worktable, a first motor is mounted on one side of one first connecting seat, the output end of the first motor is connected to a first belt wheel, and one end of the first belt wheel is connected to a first lead screw. By arranging the first motor, a second motor, an electric push rod, the first connecting seats, a second connecting seat, a first slide block and a second slide block, the first motor drives the first slide block to move on the first lead screw in the first connecting seat, so that a polishing wheel moves frontand back; the second motor drives the second slide block to move on the second lead screw in the second connecting seat, so that the polishing wheel moves left and right; the electric push rod stretches , so that the polishing wheel moves up and down to polish a workpiece all around, and therefore, the operating labor force of staff is reduced and the production efficiency of the device is improved.

Owner:徐罗斌

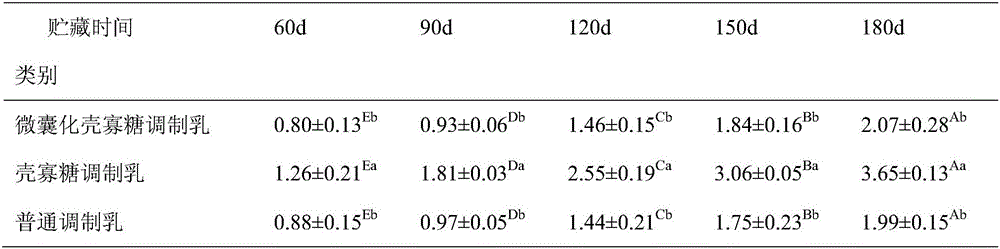

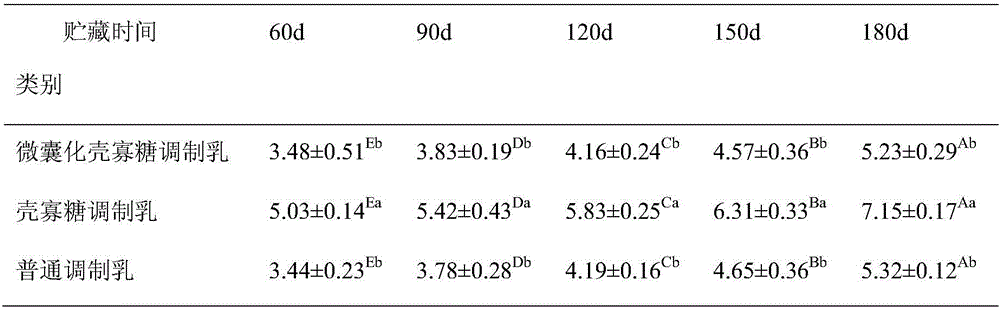

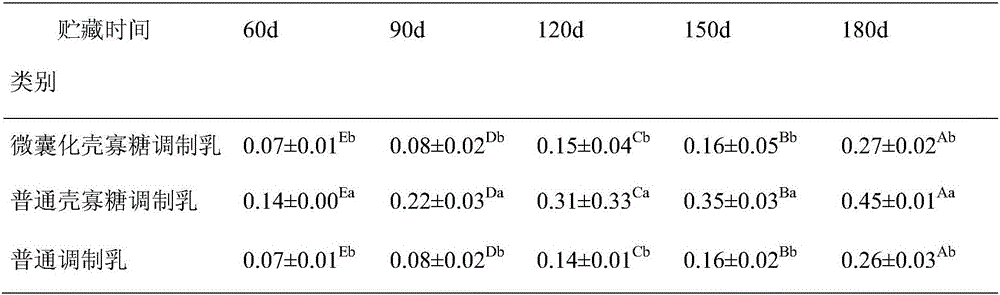

Microencapsulated chitosan-oligosaccharide, and preparing method and applications thereof

ActiveCN105831784AImprove application stabilityGuaranteed uniformityMilk preparationMilk preservationHigh pressureOligosaccharide

The invention discloses microencapsulated chitosan-oligosaccharide, and a preparing method and applications thereof, belonging to the technical field of food processing. A wall material of the microencapsulated chitosan-oligosaccharide is composed of protein and polysaccharide, the core material is chitosan-oligosaccharide the molecular weight of which is less than 5000 Da, and the mass ratio of the wall material to the core material is (2:1)-(10:1). The microencapsulated chitosan-oligosaccharide is prepared by separately dissolving the core material and the wall material, mixing to obtain a mixed solution, pretreating the mixed solution through a high-speed dispersing machine, homogenizing through a high-pressure microjet nanometer homogenizer, and performing spray-drying. The microencapsulated chitosan-oligosaccharide prepared by the method covers up amino characteristics, charge performance and color of the chitosan-oligosaccharide, and broadens the application range of the chitosan-oligosaccharide in the food industry on the basis of ensuring functions of the chitosan-oligosaccharide itself.

Owner:CHINA AGRI UNIV

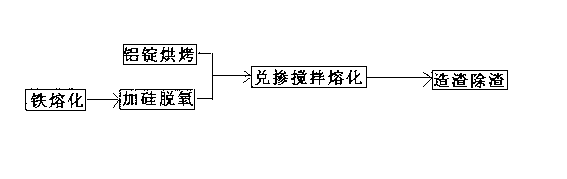

Aluminum iron alloy with ultra-low carbon, ultra-low titanium and high silicon contents for deoxidizing aluminum silicon killed steel and manufacturing method of aluminum iron alloy

The invention belongs to the technical field of metallurgy and particularly relates to an aluminum iron alloy with ultra-low carbon, ultra-low titanium and high silicon contents for deoxidizing aluminum silicon killed steel and a manufacturing method of the aluminum iron alloy. The alloy contains aluminum, iron, silicon and impurities, and is characterized in that the alloy comprises the following components by weight percentage: 20%-30% of aluminum, 45%-55% of silicon, 22%-28% of iron and the balance of impurities. The impurities comprise the components by weight percentage: less than 0.008% of carbon, less than 0.02% of phosphorus, less than 0.02% of sulfur, less than 0.05% of copper, less than 0.005% of titanium, less than 1.0% of manganese and less than 0.05% of nitrogen. The manufacturing method comprises the steps of burdening, melting and casting. The alloy has the advantages of ultra-low titanium content, ultra-low carbon content, low impurity content and the like, and particularly meets the requirement of the aluminum iron killed steel on the ultra-low titanium and ultra-low carbon contents of a deoxidier.

Owner:江苏江南铁合金有限公司

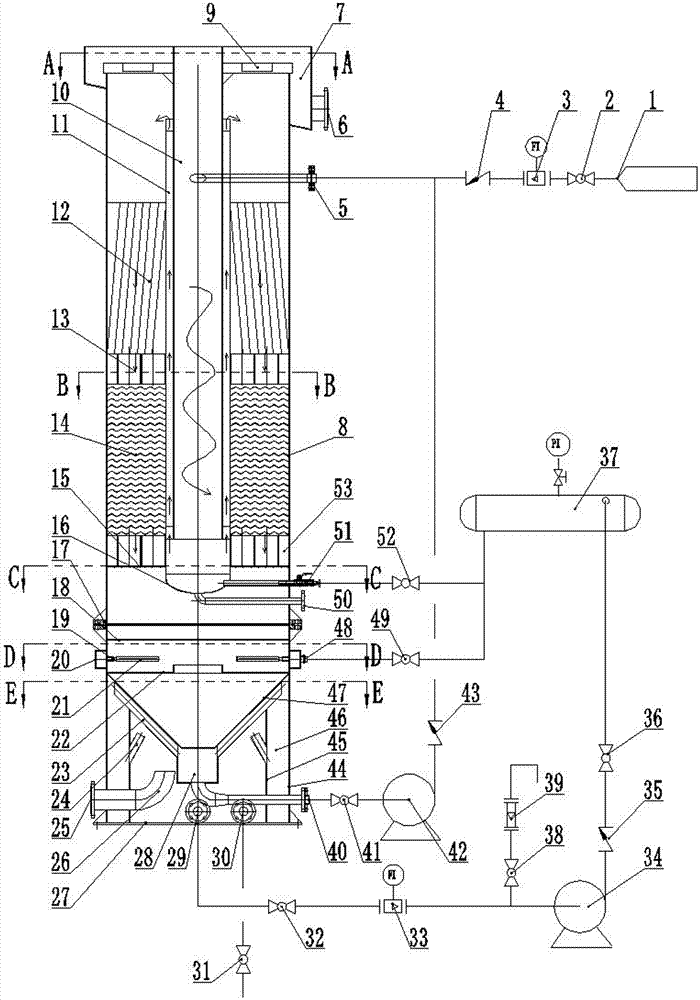

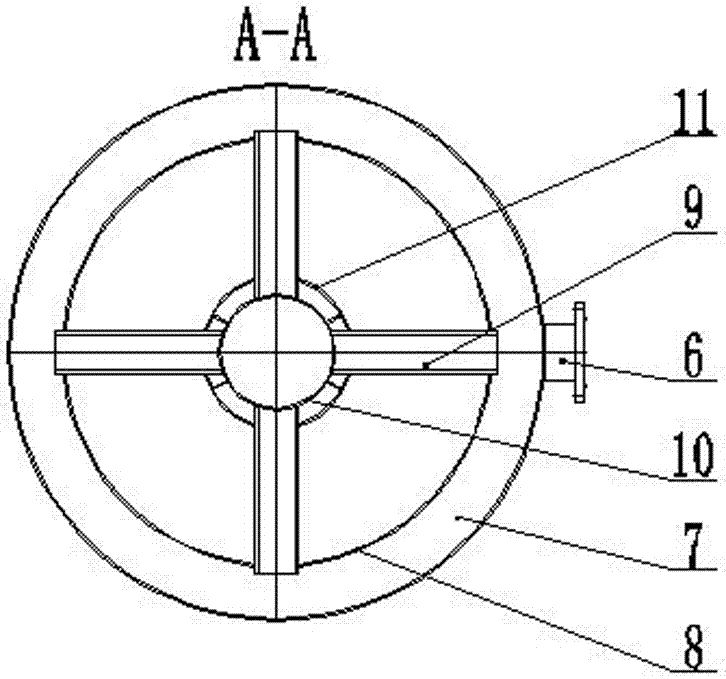

Swirling aggregation air flotation degreasing column

PendingCN107162239AReduce floatingShorten the timeWaste water treatment from quariesWater/sewage treatment by centrifugal separationSludgeSuspended matter

The invention relates to a swirling aggregation air flotation degreasing column, which comprises a lower air flotation column, an upper air flotation column and a swirling dissolved air tank, wherein a swirling air flotation oil collection tank, a floating residue discharging port, a swirling air flotation column outer cylinder, a center swirling air flotation column, a water distribution pore plate, a support pipe, an egg tray shaped disk sheet aggregation filler, a support pipe and an aggregation inclination plate filler are arranged in the upper air flotation column, the swirling air flotation column outer cylinder is connected to the swirling dissolved air tank, a baffle, a dissolved air release device, a separation plate, a sludge collection cone cylinder, a water purification area, a water outlet, a dissolved air water outlet and a venting port are arranged in the lower air flotation column, the dissolved air release device is communicated to the swirling dissolved air tank, the bottom portion of the sludge collection cone cylinder is provided with a precipitation cylinder, the bottom portion of the precipitation cylinder is communicated to the water inlet of the center swirling air flotation column, the precipitation cylinder is communicated to the water purification area, the water purification area is communicated to the lower air flotation column, and the dissolved air water outlet is connected to the swirling dissolved air tank. According to the present invention, the swirling aggregation air flotation degreasing column has advantages of simple structure, high degreasing efficiency, high suspended solid removal efficiency, fine and uniformly-dispersed air bubbles, and the like.

Owner:ZHEJIANG JINLONG AUTOMATIC CONTROL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com