Light decorative plate material with high doping quantity of fly ash

A decorative board, fly ash technology, applied in building materials, sustainable waste treatment, solid waste management, etc., to achieve optimal performance, good social and economic benefits, and increased flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

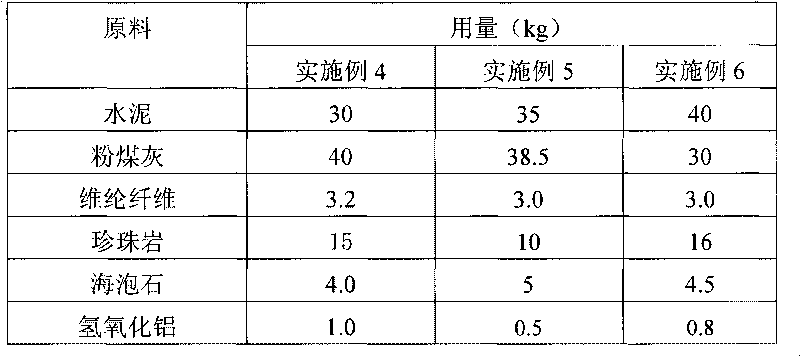

Examples

Embodiment 1

[0028] The following method is used to prepare an economical lightweight decorative board with high fly ash content, and the specific method includes the following steps:

[0029] (1) Weigh 6.75kg of vinylon fiber, 2.25kg of pulp, and 10.1kg of fibrous sepiolite, pour them into the loosening machine for 10 minutes, put them into the beater, and then add 42.5# ordinary Portland cement 76.5 kg, 1.3kg of aluminum hydroxide, 90kg of fly ash, 11.3kg of silica fume, 25kg of perlite fine powder with a particle size less than 0.15mm, 1.8kg of 10mm chopped glass fiber and water, and stir for 15 minutes to form a slurry. The concentration is controlled at 8-15wt% (percentage of dry material / (dry material+water)).

[0030] (2) The slurry is added into the net box for extraction, and three vacuum pumps are used for dehydration; the slurry is formed into a slab by the extraction forming machine.

[0031] During the copying operation, an anionic polyacrylamide solution with a molecular wei...

Embodiment 2

[0039] The following method is used to prepare an economical lightweight decorative board with high fly ash content, and the specific method includes the following steps:

[0040] (1) Weigh 6.75kg of vinylon fiber, 2.25kg of pulp, and 10.1kg of fibrous sepiolite, pour them into the loosening machine for 10 minutes, put them into the beater, and then add 42.5# ordinary Portland cement 72.9 kg, 1.3kg of aluminum hydroxide, 90kg of fly ash, 11.3kg of silica fume, 28.6kg of perlite fine powder with a particle size less than 0.15mm, 1.8kg of 10mm chopped glass fiber and water, and stirred for 15 minutes to form a slurry. The slurry concentration is controlled at 8-15 wt %; an anionic polyacrylamide solution (diluted to 0.2%) with a molecular weight of 8 million is added to the return water at 0.005-0.01% of the cement weight.

[0041] (2) Three vacuum pumps are used for dehydration during the copying process.

[0042] (3) The slurry is formed into blanks by taking the molding machin...

Embodiment 3

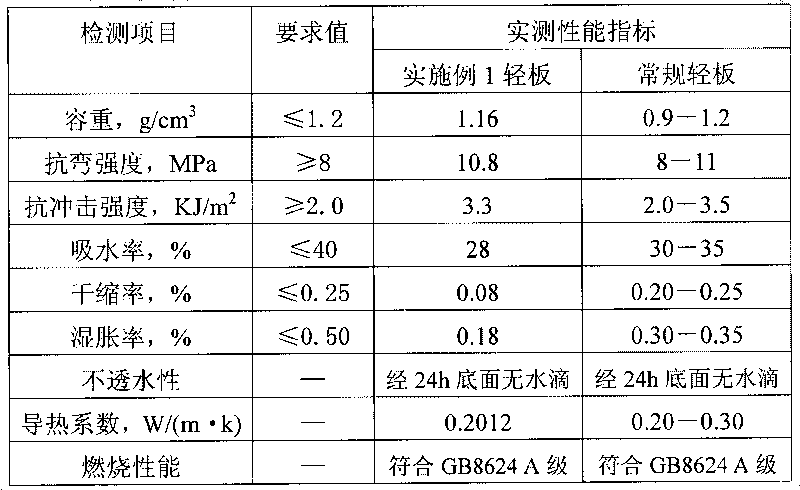

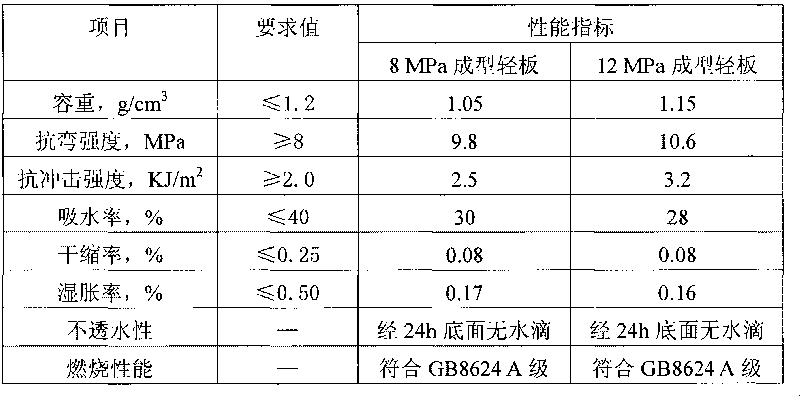

[0049] Using the same ratio of raw materials as in Example 1, wherein Portland cement is marked 52.5#, the same method as in Example 1 is used to prepare and detect a light board with high fly ash content without spraying paint. The test results are shown in Table 3.

[0050] Table 3 shows the physical and mechanical properties of the lightweight board with a fly ash content of 40%.

[0051] project

[0052] project

[0053] The test results show that increasing the grade of cement will increase the flexural strength and impact strength of the light board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Shock | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com