Aluminum iron alloy with ultra-low carbon, ultra-low titanium and high silicon contents for deoxidizing aluminum silicon killed steel and manufacturing method of aluminum iron alloy

A silicon-killed steel and high-silicon-aluminum technology is applied in the field of smelting to achieve the effects of improving the utilization rate, avoiding oxidative burning loss, and improving the deoxidation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

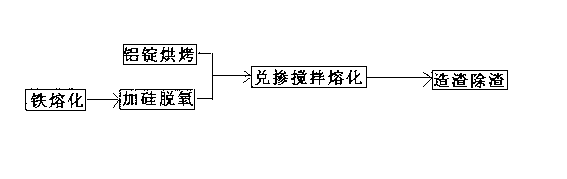

[0029] Embodiment 1, as shown in the figure:

[0030] The process conditions adopt a 2t intermediate frequency coreless induction heating furnace with a power of 500kw and a standard capacity of 1500kg; one 50kw natural gas heating mantle; one 1.5t pre-baked ladle.

[0031] (1) Ingredients:

[0032]259kg steel scrap (C: 0.15%, P: 0.035%, S: 0.022%, Cu: 0.031%, Ti: 0.0050%, manganese: 0.4%, nitrogen: 0.03%)

[0033] 524㎏ Metal silicon (Si: 99.3%, C: 0.01%, P: 0.010%, S: 0.010%, Ti: 0.0015%)

[0034] 259kg aluminum ingot (Al: 99.7%)

[0035] (2) Melting:

[0036] 1) Add 259㎏ aluminum ingot into the ladle heated by natural gas, and raise the temperature to 150℃.

[0037] 2) Add steel scrap to an intermediate frequency furnace with vent bricks at the bottom and melt it. After melting, the upper covering slag CaO: 16kg, Al2O3: 3.6kg, SiO2: 1.5kg, CaF2: 8.4kg, open the argon valve at the bottom, and blow into the furnace Argon, and oxygen is blown into the furnace from the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com