Patents

Literature

40results about How to "Solve broken problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

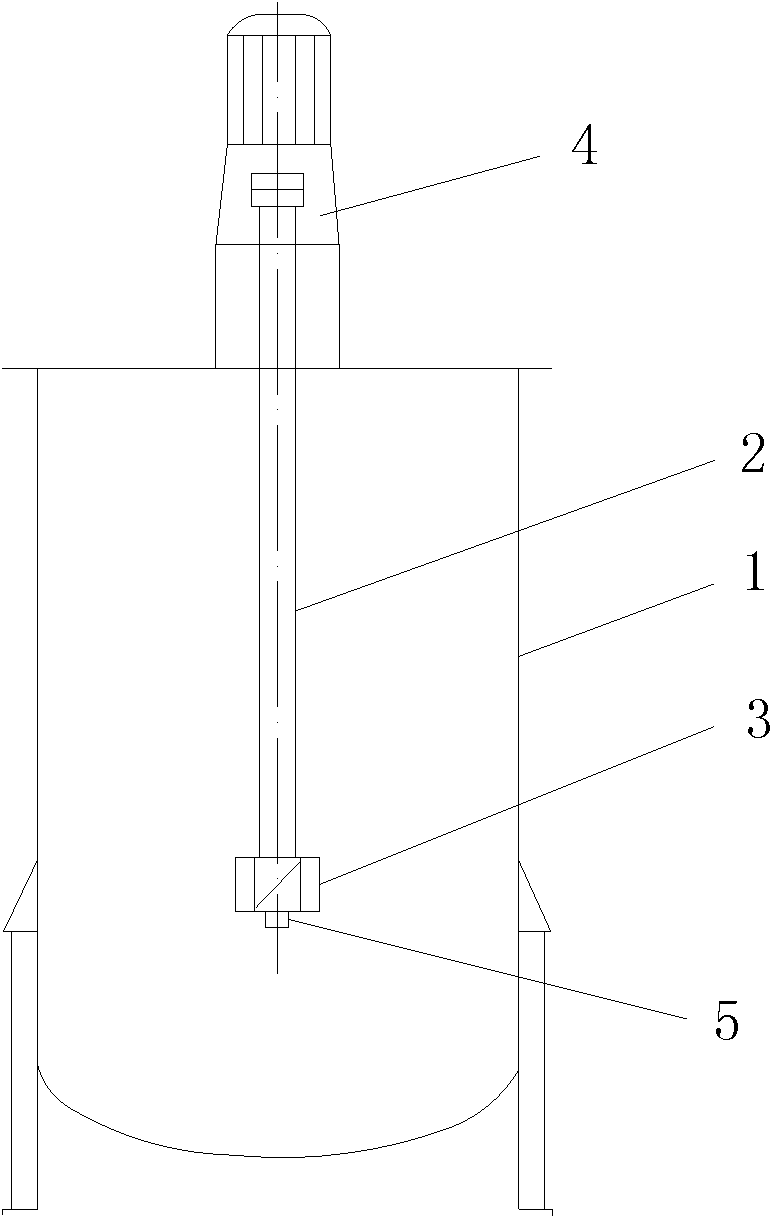

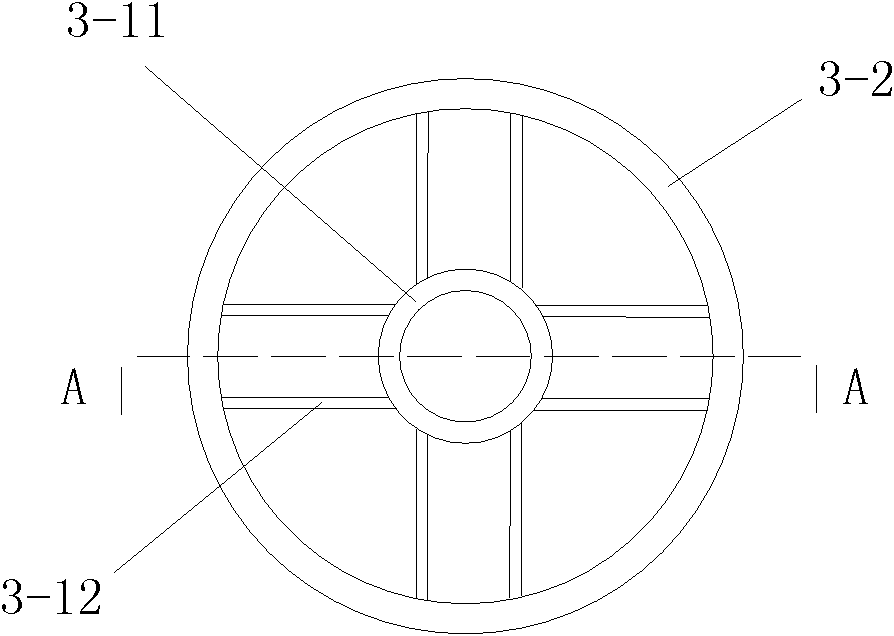

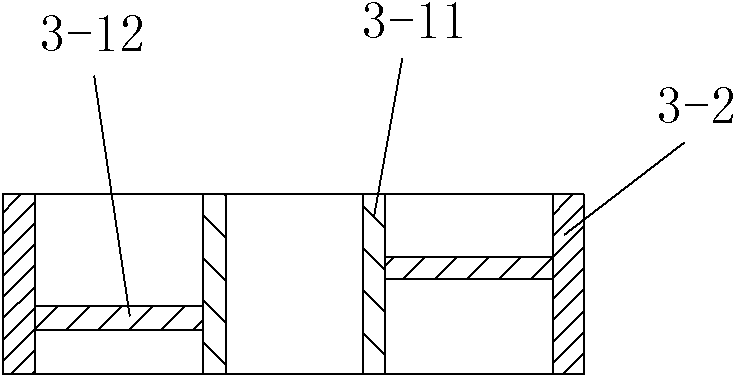

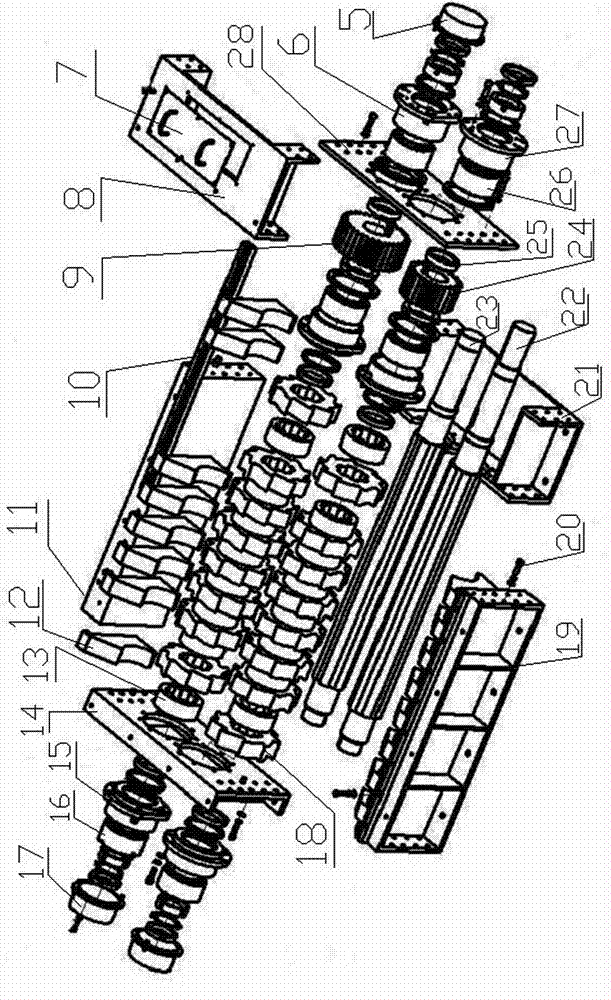

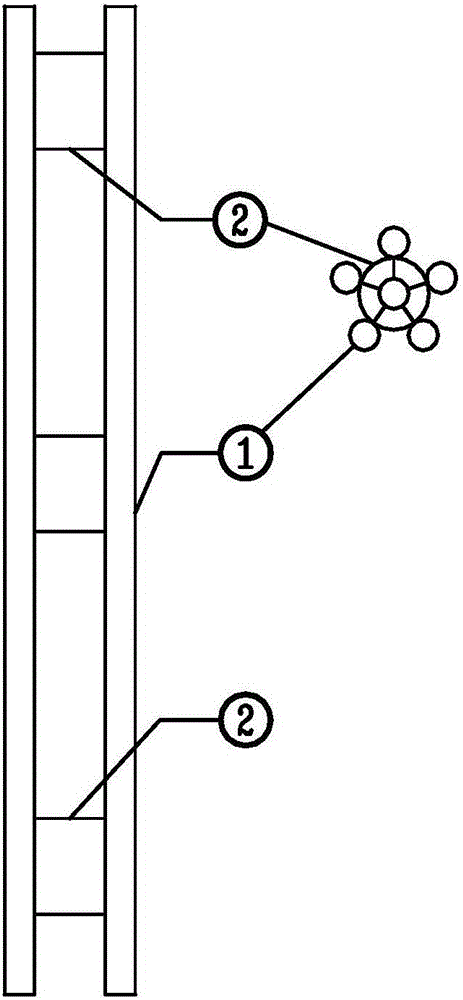

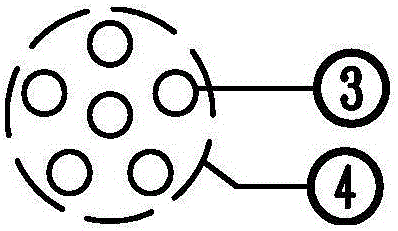

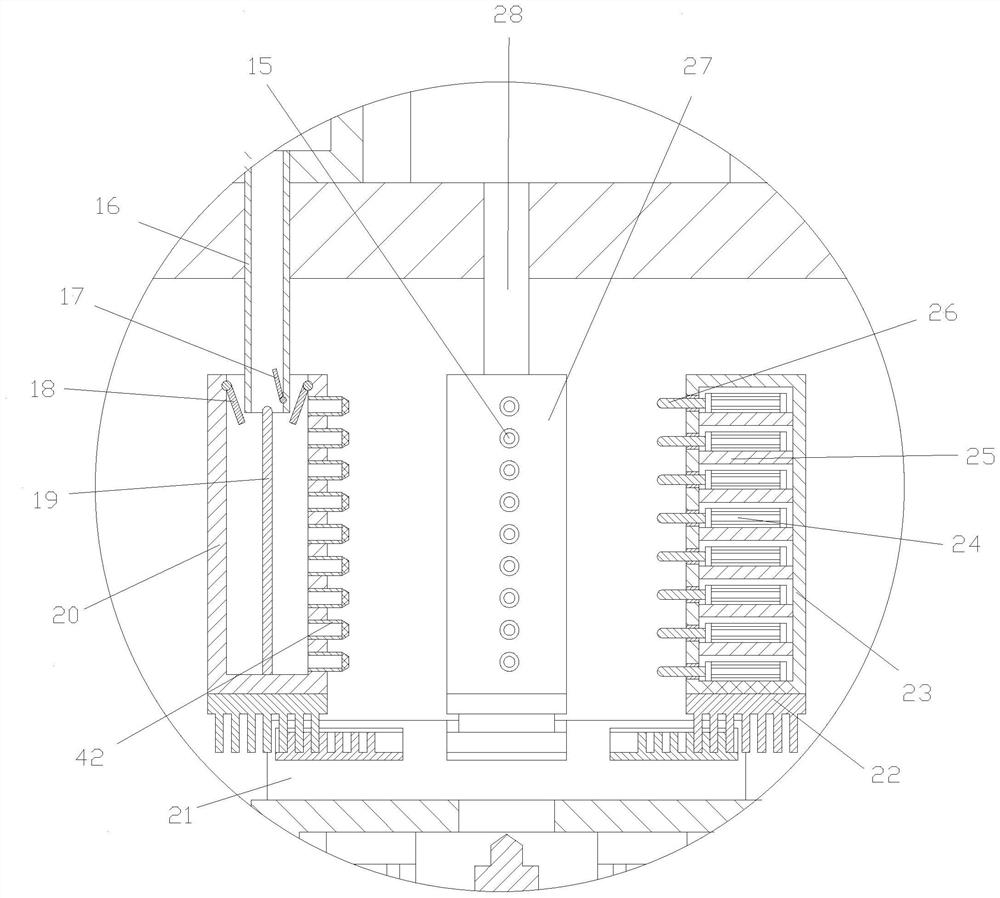

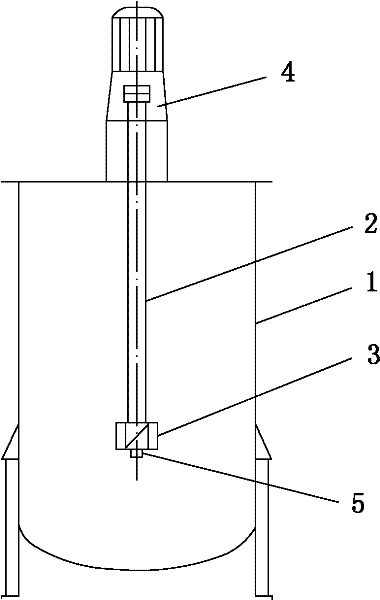

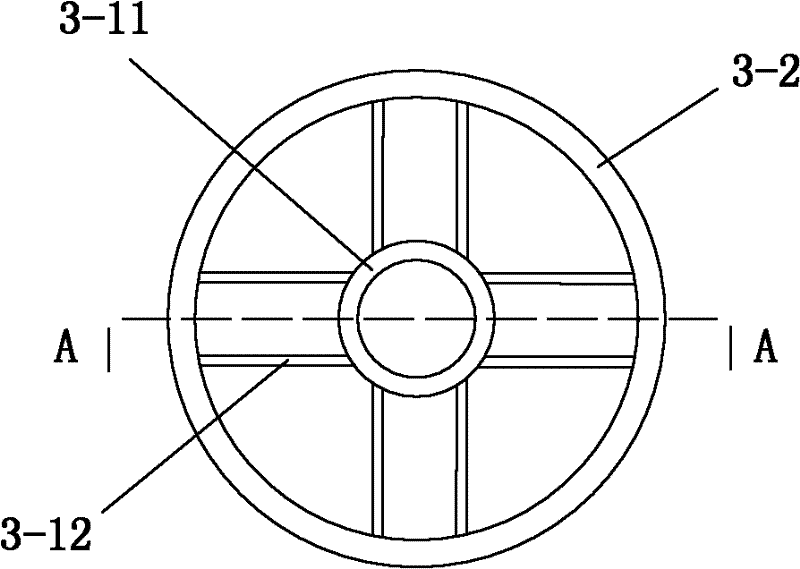

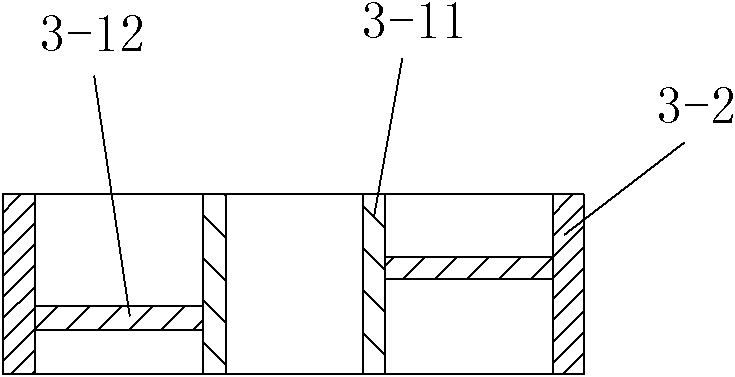

Single-shaft mortar and high-viscosity fluid stirrer for axial turbulent flow pattern multi-wire cutting machine

InactiveCN102059068AReasonable structural designEasy to manufacture and installRotary stirring mixersTransportation and packagingFlow diversionWire cutting

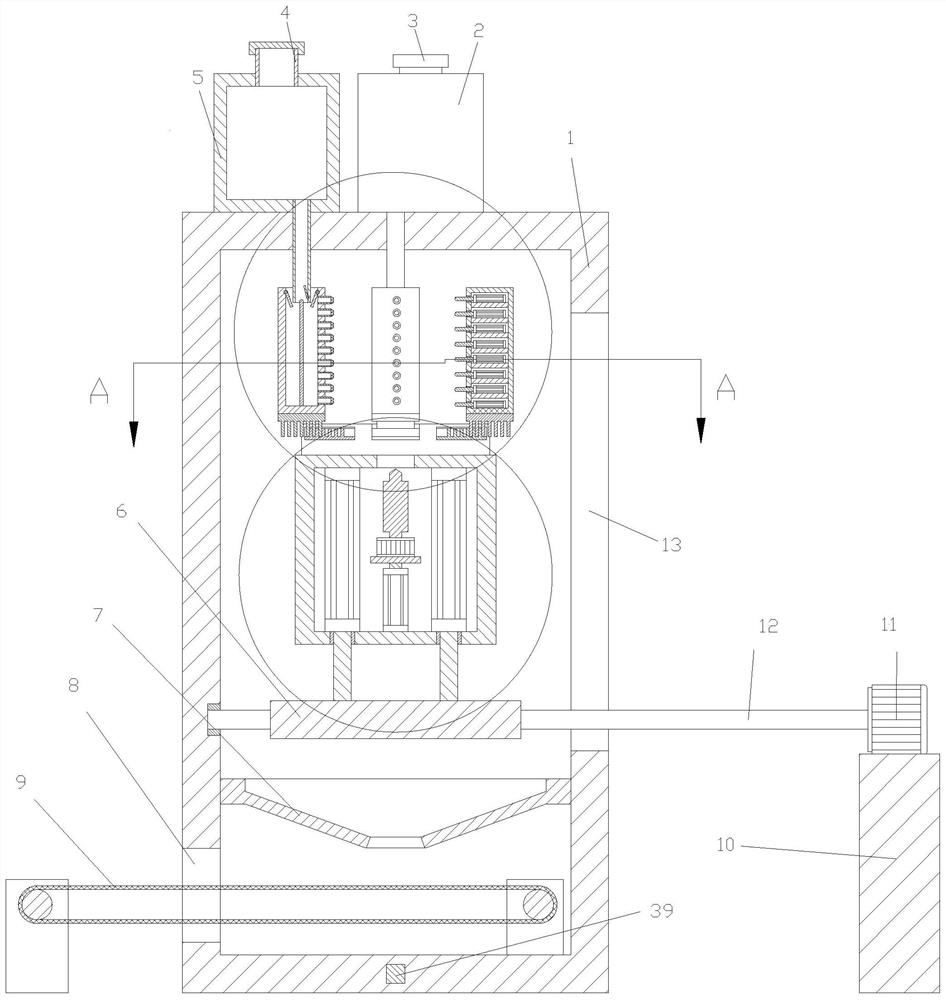

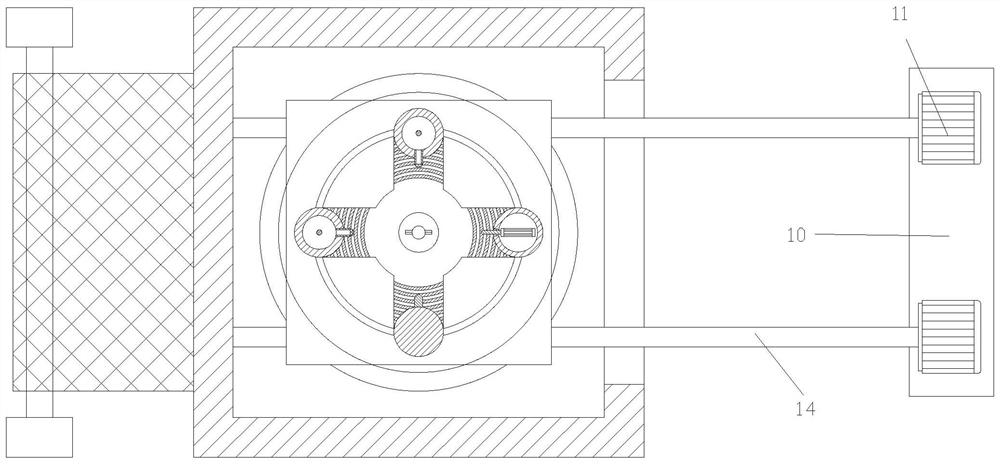

The invention discloses a single-shaft mortar and high-viscosity fluid stirrer for an axial turbulent flow pattern multi-wire cutting machine, comprising a stirring shaft, a stirring assembly and a driving mechanism, wherein the stirring assembly comprises impellers and short flow diversion tubes, the impellers are used for driving a material to move up or down in an axial and spiral mode along the inner wall of a pot body of a stirring pot, the short flow diversion tubes are used for restricting the material flow direction to an axial movement along the axis of the stirring shaft when the material moves up or down in the axial and spiral mode, the impellers and the short flow division tubes are assembled into the stirring assembly which drives the material needed to be mixed and stirred to do an axial turbulent flow motion during stirring, the impellers are coaxially installed at the bottom end of the stirring shaft, the short flow division tubes are coaxially and fixedly sleeved at the outer sides of the impellers, and the stirring speed of the stirring shaft is 600-1500rmp. The single-shaft mortar and high-viscosity fluid stirrer has the advantages of simplicity in structure, high stirring capacity, small shearing force, high dispersing power and high effect, and can be used for solving the problem that silicon carbide is broken due to the shearing force during the high-speed stirring of various traditional stirrers. Moreover, a stuck phenomenon is difficult to generate.

Owner:XIAN HUAJING ELECTRONICS TECH

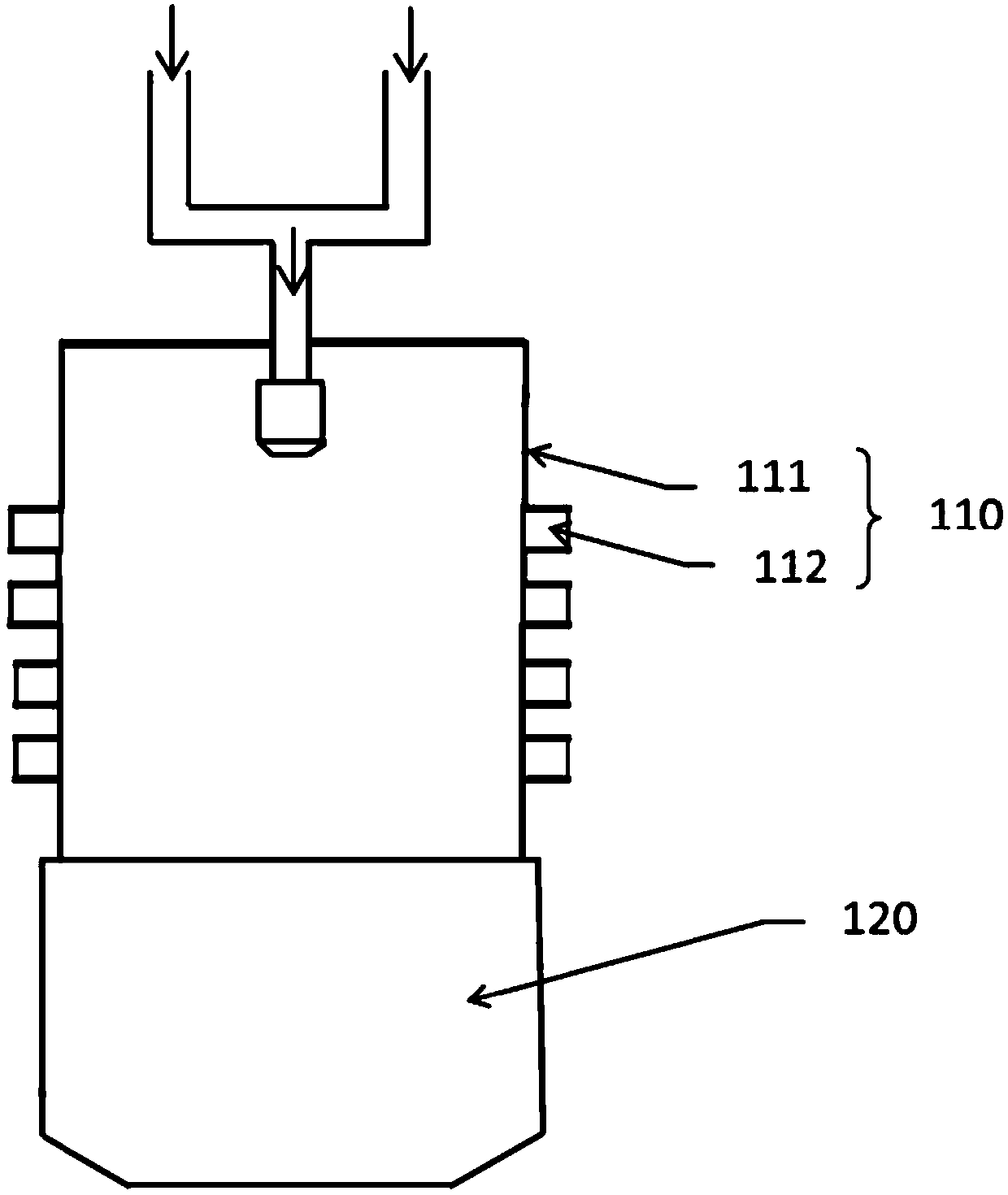

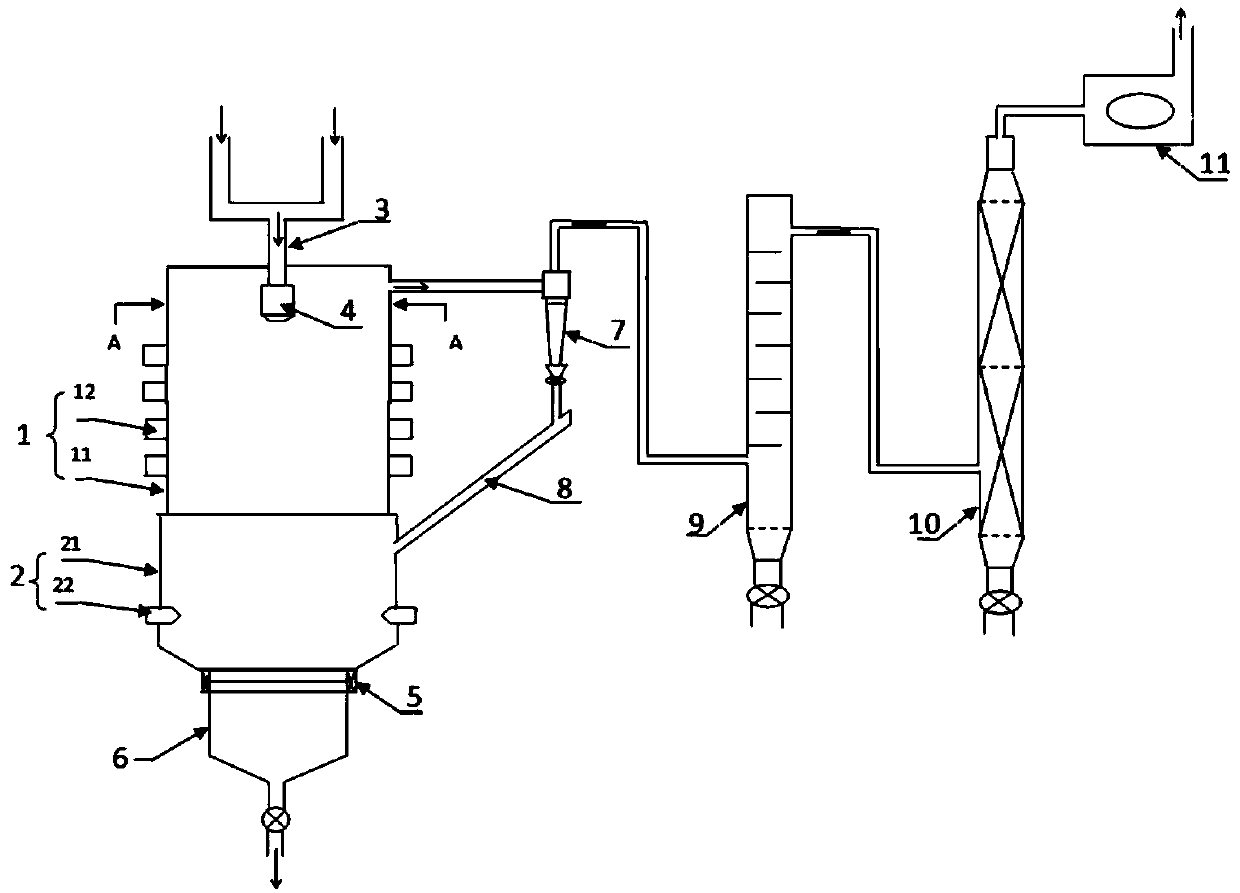

Spray pyrolysis device with microwave heating and method for preparing ternary precursor thereof

ActiveCN109647310AImprove heating efficiencyFast heatingCell electrodesSecondary cellsLow chlorideSpray pyrolysis

The invention provides a spray pyrolysis device with microwave heating and a method for preparing a ternary precursor thereof. The spray pyrolysis device comprises a microwave heating unit and a sintering unit from top to bottom; wherein the cavity of the microwave heating unit is provided with at least one set of microwave generator module. The method comprises the following steps: spraying ionized water into the spray pyrolysis device through an atomizing device, sequentially starting microwave generators of an evaporation zone, a drying zone and a thermal decomposition zone, switching the deionized water to a ternary precursor mixed solution after the temperature of the midpoint in the horizontal direction of each zone reaches a set value, and carrying out spray pyrolysis to obtain theternary precursor powder. By microwave heating for the evaporation zone, the drying zone and the thermal decomposition zone of the spray pyrolysis device, the problems of hollowing and breaking of secondary particles of the precursor prepared by spray pyrolysis are fundamentally solved, and favorable conditions are created for the preparation of the ternary precursor having high tap density, smallspecific surface area and low chloride content.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

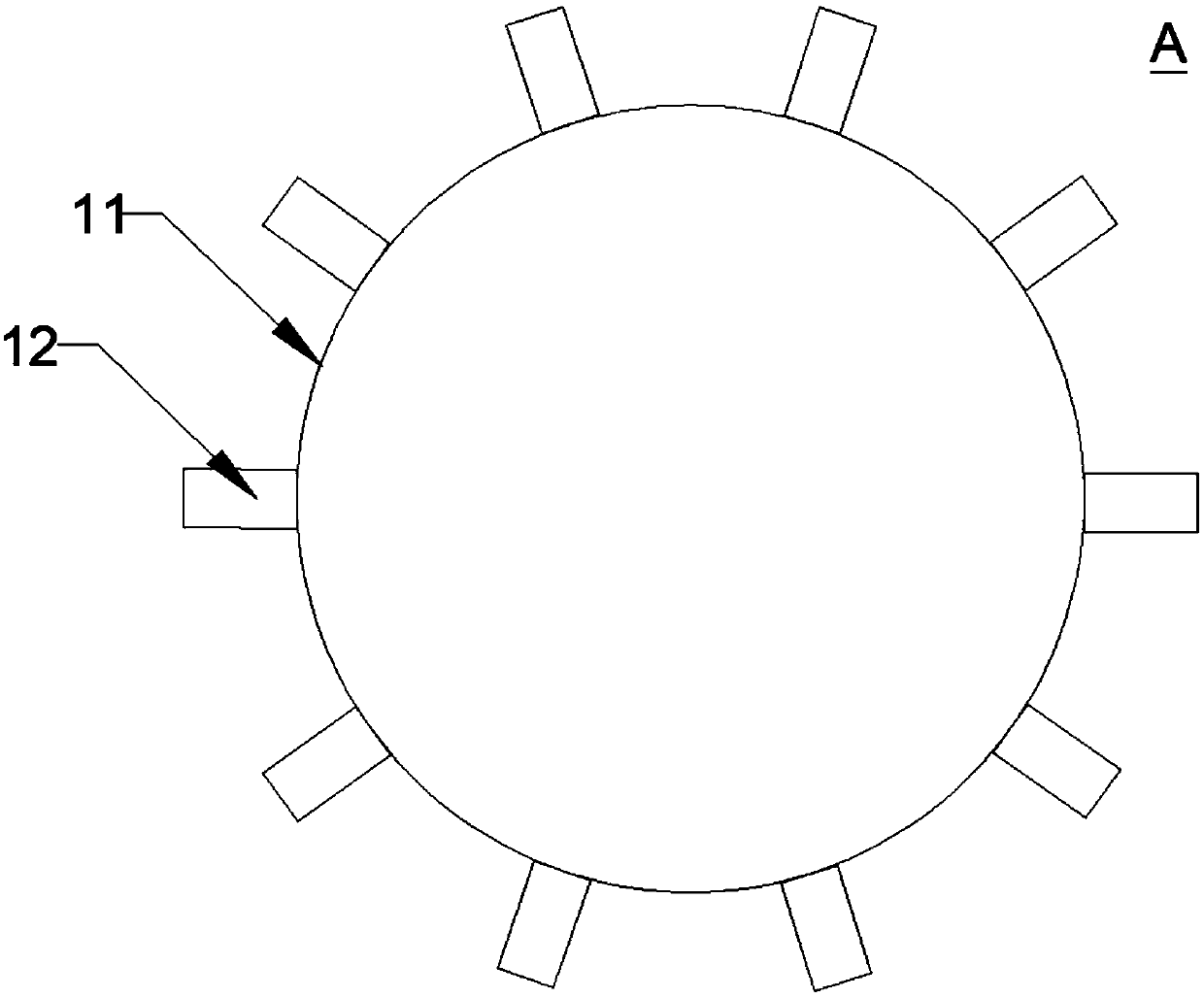

Garbage pulverizer

InactiveCN104722551AHigh shear forceEfficient crushingSolid waste disposalFurniture waste recoverySheet steelDrive shaft

The invention discloses a garbage pulverizer which comprises a pulverizer main-body, a driving mechanism, a feed hopper and a support, wherein the pulverizer main-body comprises a main shaft, a driven shaft, several blades and a pad. Through powerful shear force generated between the blade and the pad and between the blades by torque generated by the main shaft and the driven shaft, garbage is crushed. By the above design, the garbage pulverizer has advantages of scientific and reasonable design and large shear force of the blades. By the use of the garbage pulverizer, hard objects such as massive wood, steel bars, sheet steel and the like in garbage can be crushed, and the crushing difficulty of soft or high-toughness objects such as ropes, plastic bags and the like also can be effectively solved. The garbage pulverizer has long service life, and operating maintenance costs are low.

Owner:HUANCHUANG XIAMEN TECH

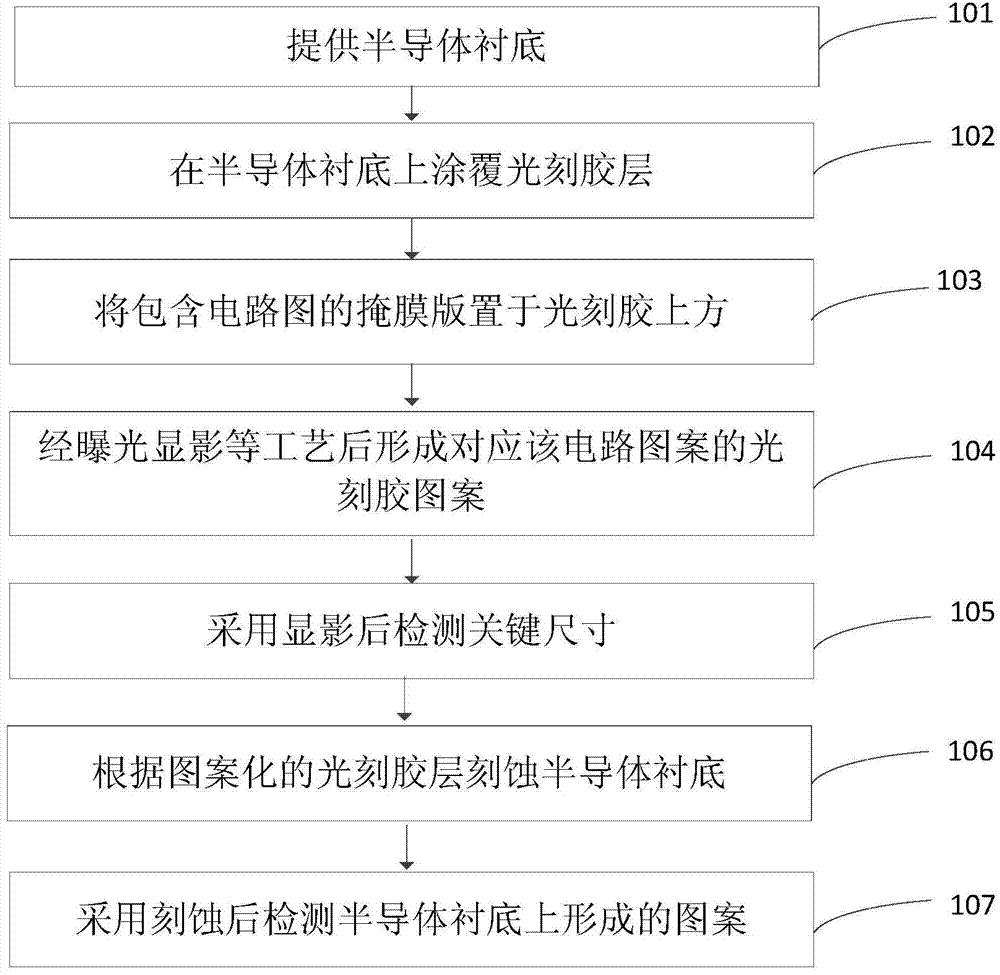

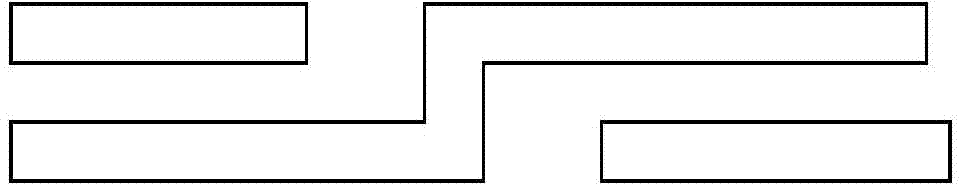

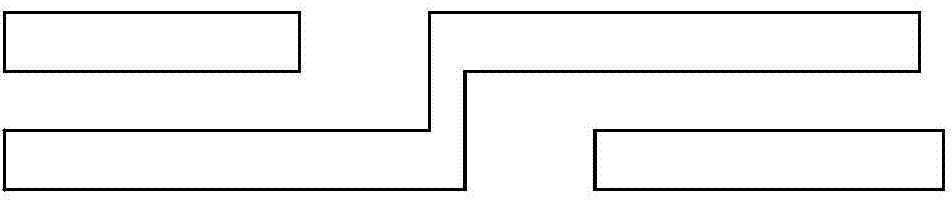

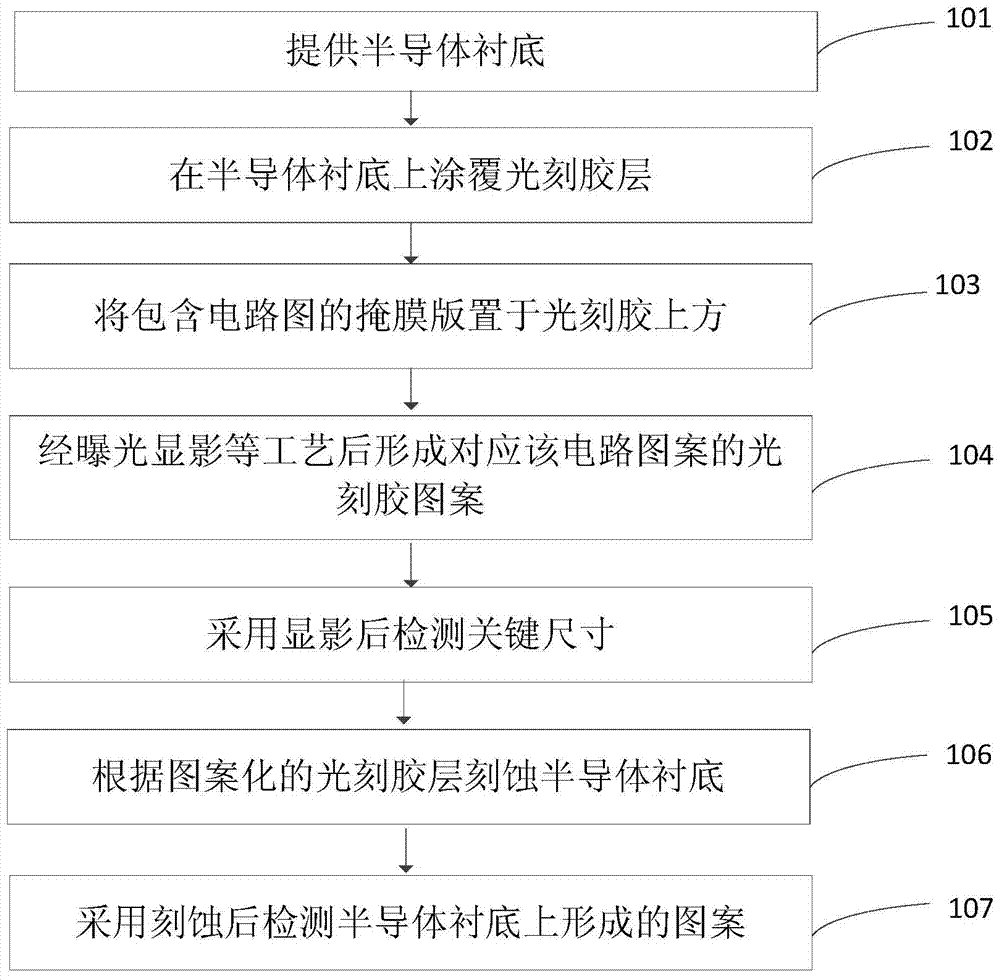

Semiconductor device production method

ActiveCN104517802AImprove reliabilityIncrease productivityPhotomechanical apparatusSemiconductor/solid-state device manufacturingSemiconductorSilicon

The invention discloses a semiconductor device production method. The semiconductor device production method includes: providing a design mask comprising multiple designed main line patterns; lengthening the designed main line patterns or adding auxiliary virtual strip patterns to end points of the designed main line patterns to further obtain a revised deign mask; producing a photoetching mask according to the revised design mask; using the photoetching mask for performing photoetching and etching on a chip; finally, using a cutting mask to cut off unnecessary auxiliary lines according to design requirements. According to the semiconductor device production method, the problem that the lines are easy to break during micropattern processing of a silicon semiconductor substrate is solved, the patterns on the mask are ensured to be completely transferred to the silicon semiconductor substrate, and further reliability and production efficiency of the produced semiconductor device structure are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Golden rod natural dyestuff, preparation method and use thereof

InactiveCN101054475ANo pollution in the processNon-toxicNatural dyesDyeing processCentrifugationDistilled water

The invention relates to a Solidago canadensis natural dye and its producing method and application. The invention comprises following steps: selecting Solidago canadensis, adding distilled water solution after smashing, boiling, filtering after cooling, getting the dye liquid; depressed concentrating extracted dye liquid, producing dye concentration liquid; dissolving the dye concentration liquid under the ultrasonic shock; spray drying the dye concentration liquid by high speed centrifugation, obtaining the yellow natural dye powder. The Solidago canadensis natural dye can be used for printing and dyeing of fabric. The invention has a simple production method without pollution. The prepared dye is natural, elegant, nonhazardous and can be applied in textile industry. The invention uses modern means based on the traditional art to improve the extraction art and facilitate the storage and transportation.

Owner:上海多普富生物技术有限公司

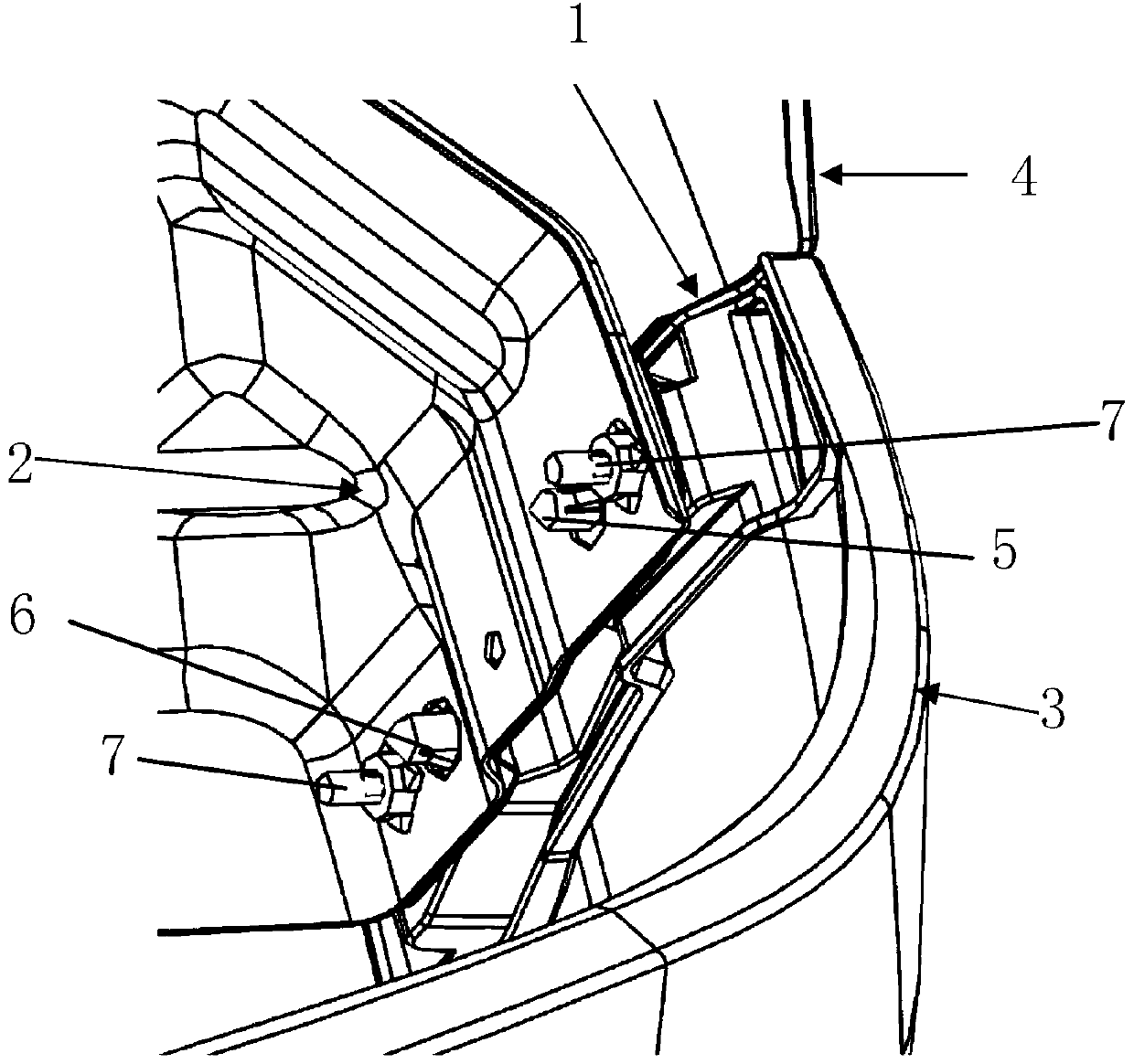

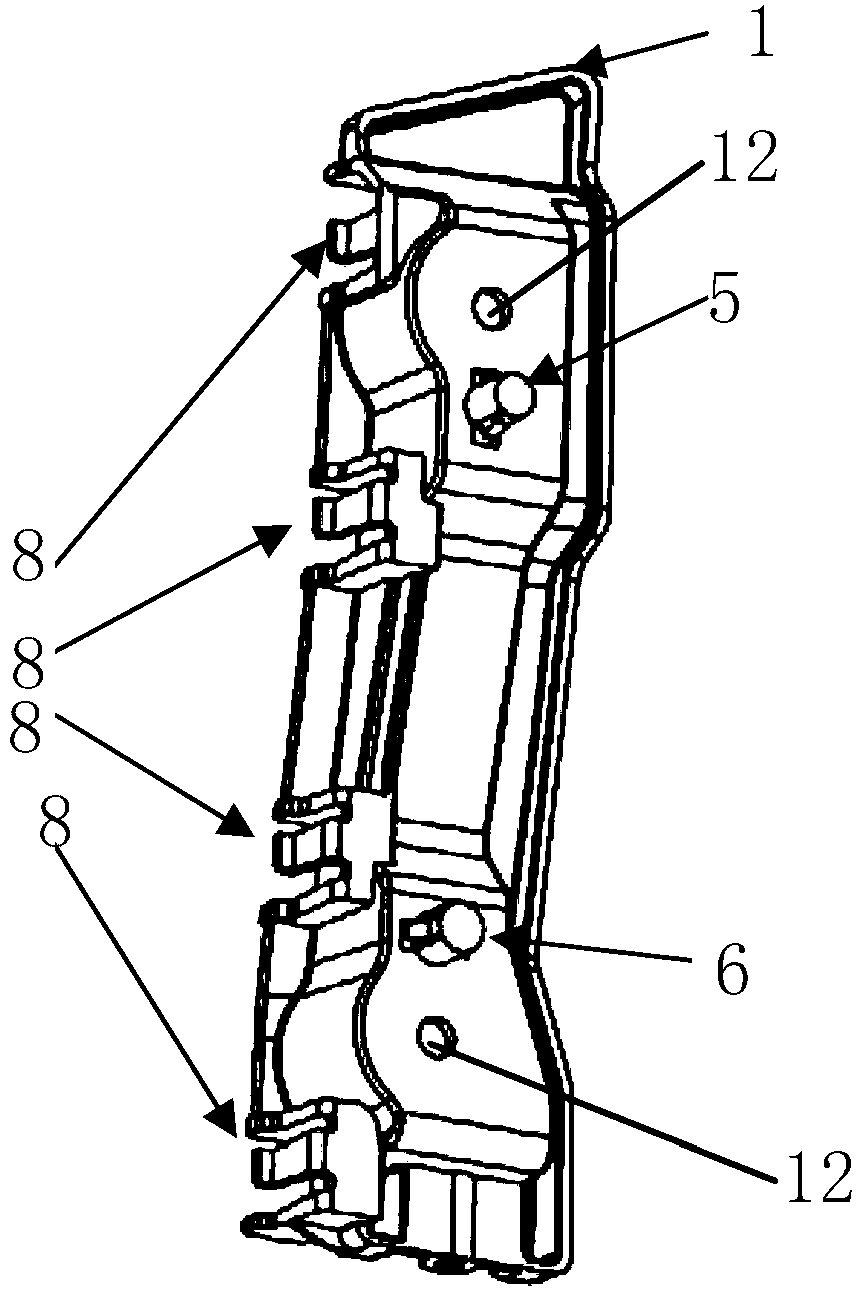

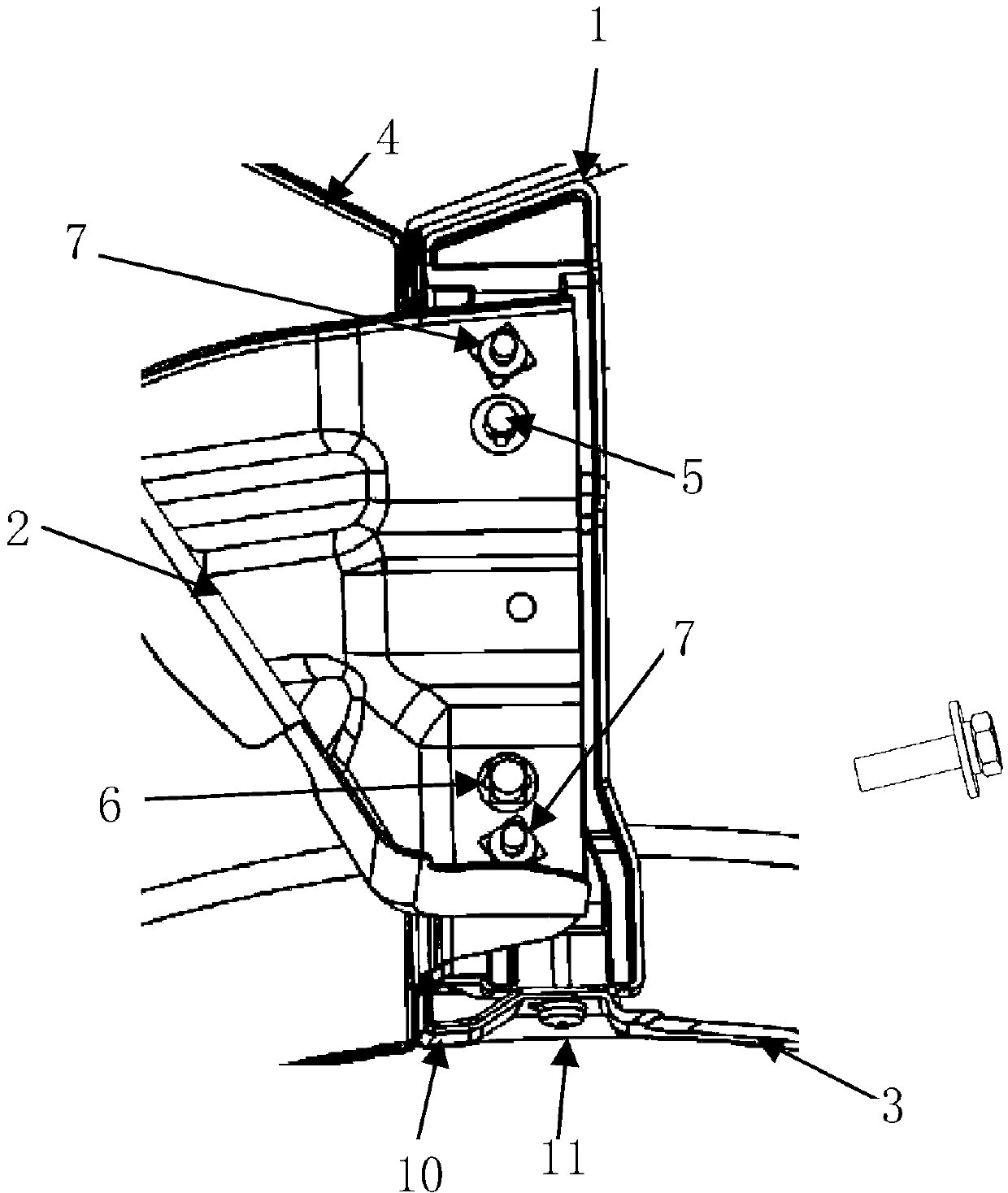

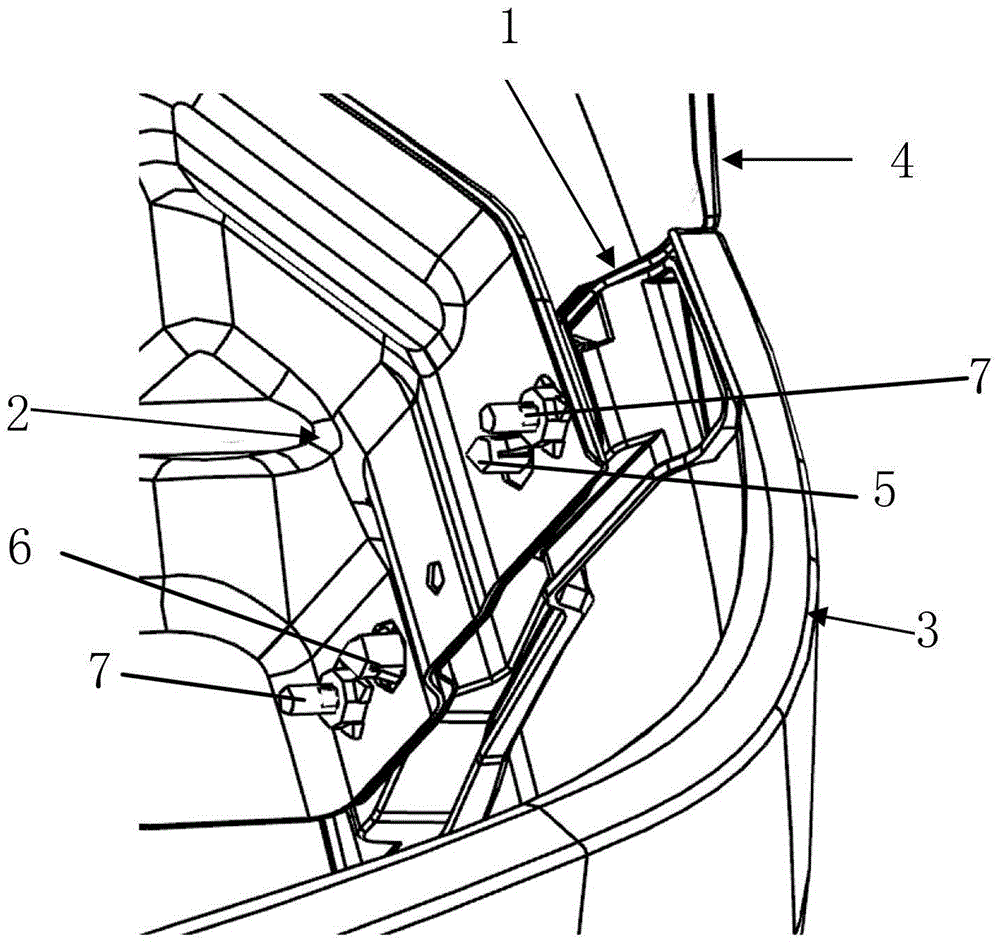

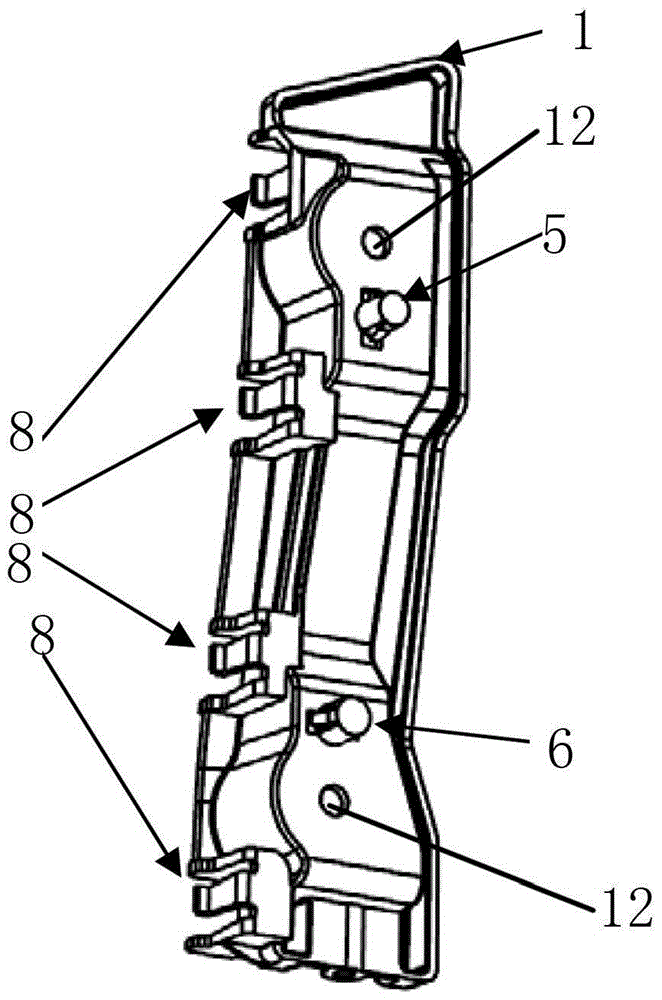

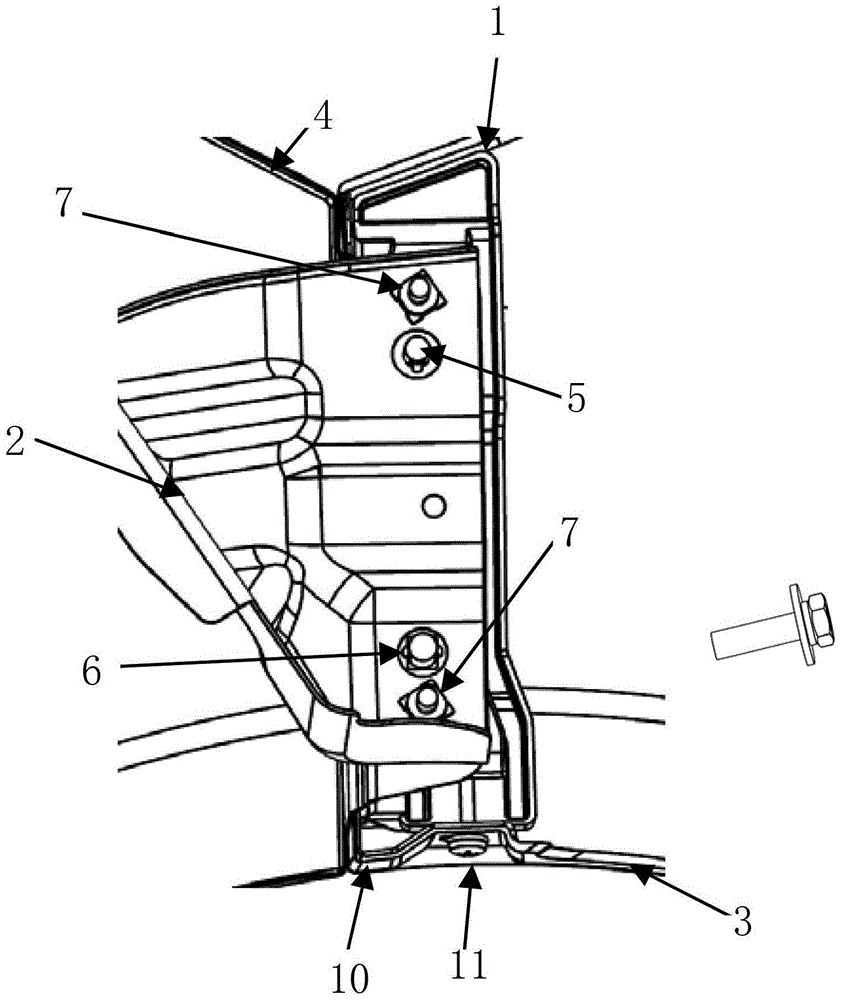

Automotive front bumper mounting bracket

The invention discloses an automotive front bumper mounting bracket comprising a bracket body. The bracket body is connected with a wheel fender, an automotive frame and a front bumper respectively. The upper portion of the bracket body and the lower portion of the bracket body are provided with a first positioning pin and a second positioning pin which are connected with the wheel fender in a clamping manner. The automotive frame and the wheel fender are fixed through bolts. The automotive frame and the front bumper are fixed in a clamping manner. One side of the bracket body is provided with at least two clamp claws extending downwards, and clamp claw fasteners are arranged on the front bumper. The clamp claws are connected with the clamp claw fasteners in a clamping manner. The bracket body is made of plastic material. The automotive front bumper mounting bracket is simple in structure, low in cost, high in mounting efficiency, ergonomic, light in weight and environment-friendly; parts strength is increased; and the problems that limited flange shape of the front bumper influences demoulding, a gap between the wheel fender and the front bumper is uneven, segment difference is difficult to control and matching accuracy of parts is low are solved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

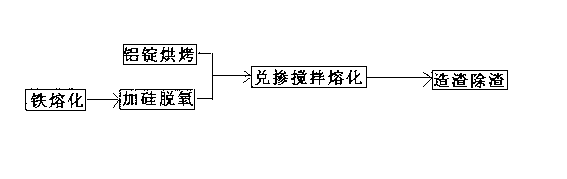

Aluminum iron alloy with ultra-low carbon, ultra-low titanium and high silicon contents for deoxidizing aluminum silicon killed steel and manufacturing method of aluminum iron alloy

The invention belongs to the technical field of metallurgy and particularly relates to an aluminum iron alloy with ultra-low carbon, ultra-low titanium and high silicon contents for deoxidizing aluminum silicon killed steel and a manufacturing method of the aluminum iron alloy. The alloy contains aluminum, iron, silicon and impurities, and is characterized in that the alloy comprises the following components by weight percentage: 20%-30% of aluminum, 45%-55% of silicon, 22%-28% of iron and the balance of impurities. The impurities comprise the components by weight percentage: less than 0.008% of carbon, less than 0.02% of phosphorus, less than 0.02% of sulfur, less than 0.05% of copper, less than 0.005% of titanium, less than 1.0% of manganese and less than 0.05% of nitrogen. The manufacturing method comprises the steps of burdening, melting and casting. The alloy has the advantages of ultra-low titanium content, ultra-low carbon content, low impurity content and the like, and particularly meets the requirement of the aluminum iron killed steel on the ultra-low titanium and ultra-low carbon contents of a deoxidier.

Owner:江苏江南铁合金有限公司

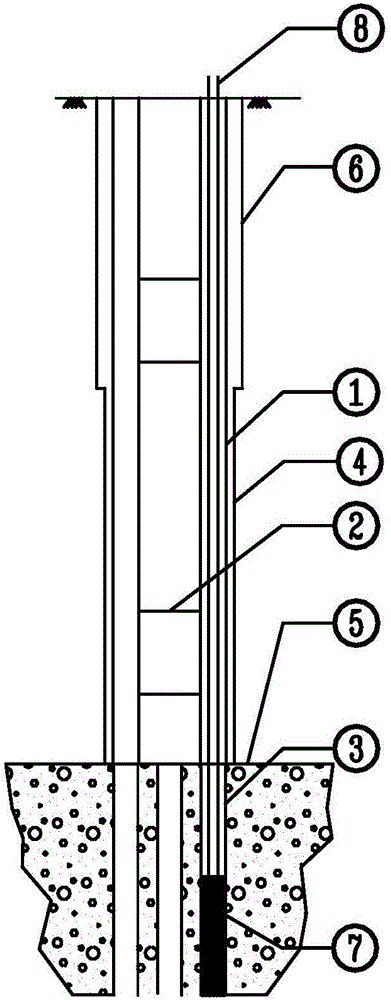

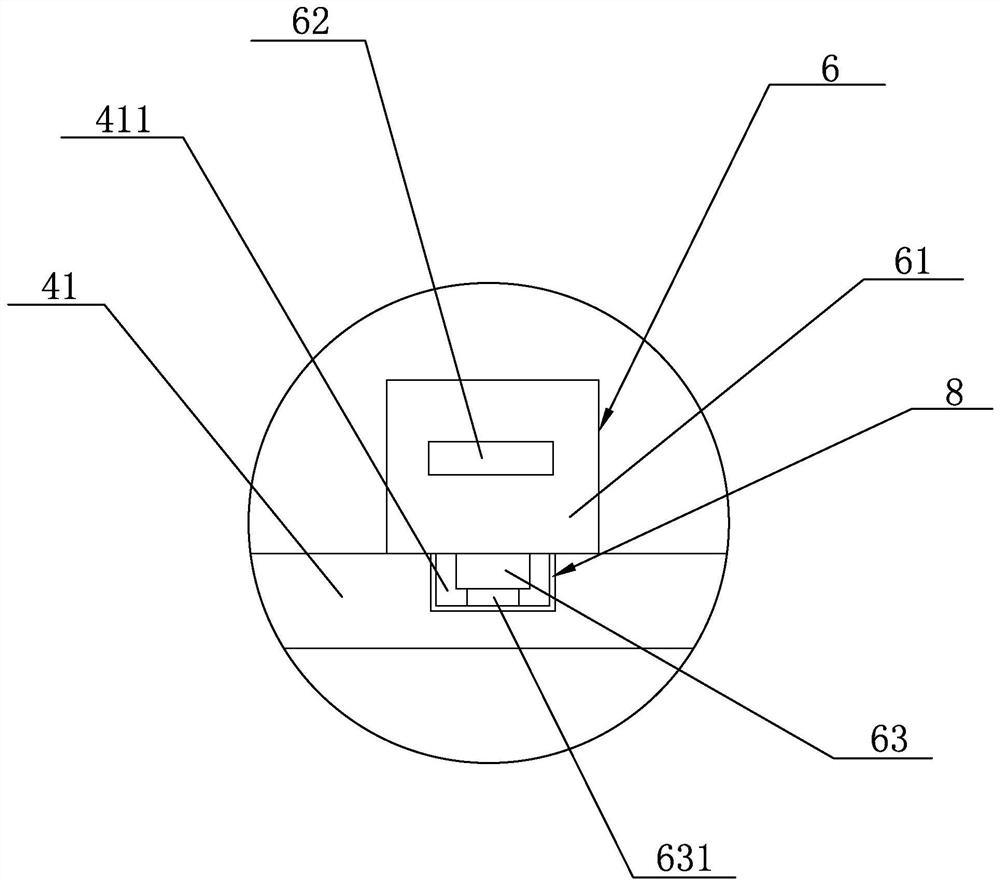

Tool and method for smashing hard rock in large-diameter pile hole

InactiveCN105804079ASolve broken problemsAchieve the effect of forming piles and holesBulkheads/pilesHoneycombRetaining wall

The invention discloses a tool and method for smashing hard rock in a large-diameter pile hole. Under the condition that hard rock exists in the pile hole in the pile forming process, low-cost rapid construction can be achieved. Guiding pipes are aligned and welded to an internal supporting frame of a guiding pipe bent frame, and the guiding pipes are aligned in parallel; the guiding pipe bent frame can be annular or square, and the guiding pipes are fixed on the guiding pipe bent frame and evenly distributed; a drilling rock stratum at the top of the drilled hole is completely removed through a pile hole forming drill jig, a pile hole retaining wall is downwards placed into a top hole collapse section, a bottom pile hole wall is kept stable, and the welded guiding pipe bent frame is downwards placed in, regulated to a vertical state and stably welded to the pile hole retaining wall 6; and a down-the-hole hammer is used for forming holes to designed depths along the guiding pipes, rock is smashed in a honeycomb shape, and then a pile is quickly formed through a conventional pile forming process. Compared with dedicated special equipment such as a large-caliber down-the-hole hammer and a high-power drill jig, the manufacturing cost is lowered by at least 50%, and the speed is increased by 3-4 times.

Owner:DALIAN JIUDING XIANGRUI SPECIAL ENG TECH RES INST CO LTD

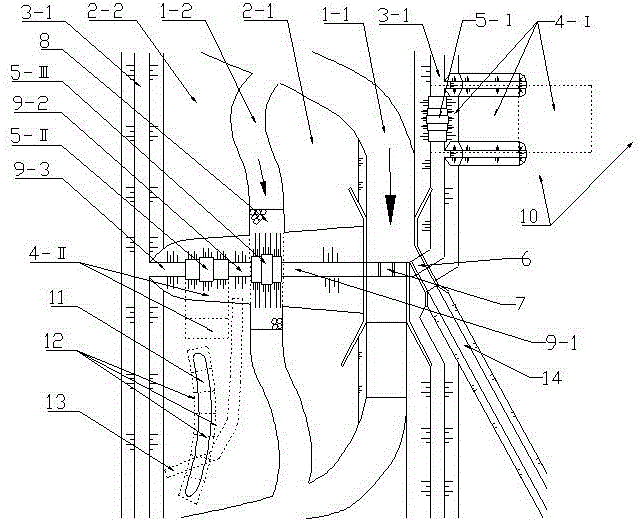

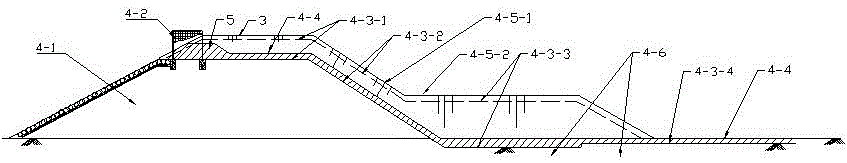

Multi-stage self-collapsing closed headwork

ActiveCN105696514ASubversiveChange design conceptHydraulic engineering apparatusSynthetic materialsStructure of the Earth

The invention discloses a multi-stage self-collapsing closed headwork and belongs to the technical field of hydro project headworks. The multi-stage self-collapsing closed headwork can resist flood exceeding the designed level, is simple in structure, convenient to implement and low in construction cost and does not occupy space permanently. The problem that headworks are damaged by flood exceeding the designed level is solved through the disaster prevention and mitigation design theory of the multi-stage self-collapsing closed headwork. The structure of the multi-stage self-collapsing closed headwork comprises a flood discharge bottomland (2-2), an earthy embankment (3), a geotechnical synthetic material armour earthy flood diversion dyke (4), a geotechnical synthetic material protecting multi-stage self-collapsing earth embankment (5), an intake gate (6), a barrage gate (7), a rockfill dam (8), an earthy barrage (9), flood diversion farmlands (10), a gulch (11), rope system non-woven fabric grid bands (12) and a rope system non-woven fabric bottomland locking penetrating band (13). The structure is suitable for closed headworks with the bottomland, headworks with rockfill dams, open headwork bottomland treatment and headworks with flood exceeding the designed level outside the embankment farmland for flood diversion.

Owner:HEILONGJIANG UNIV +1

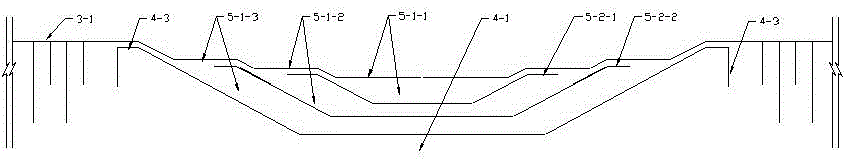

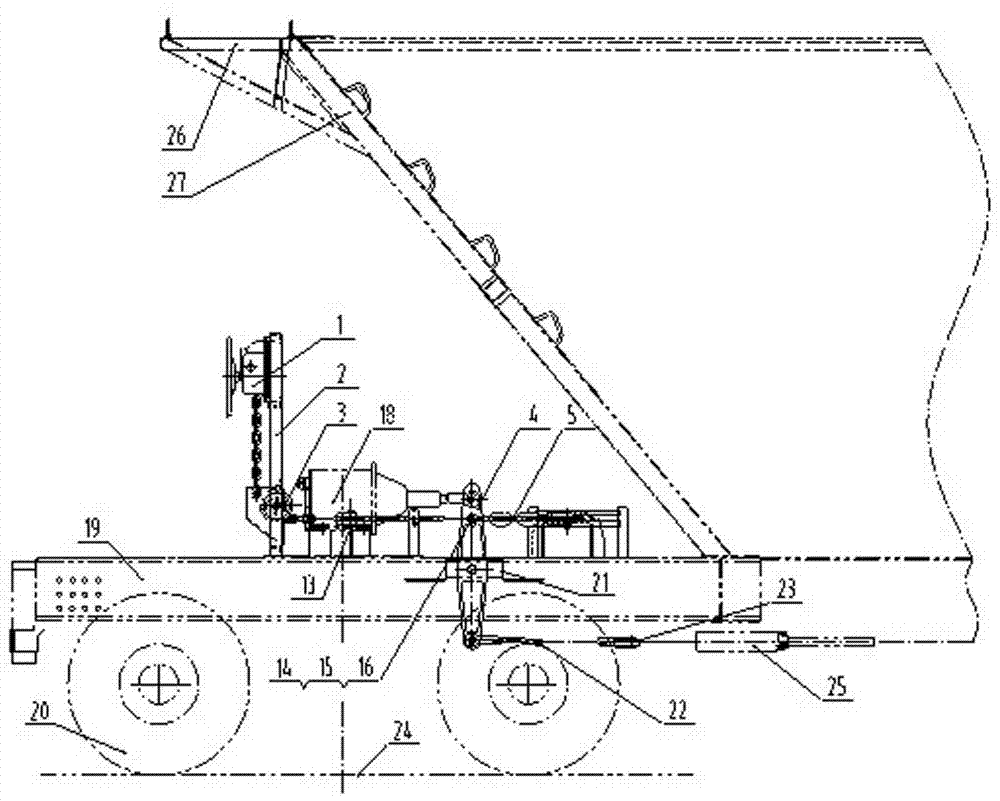

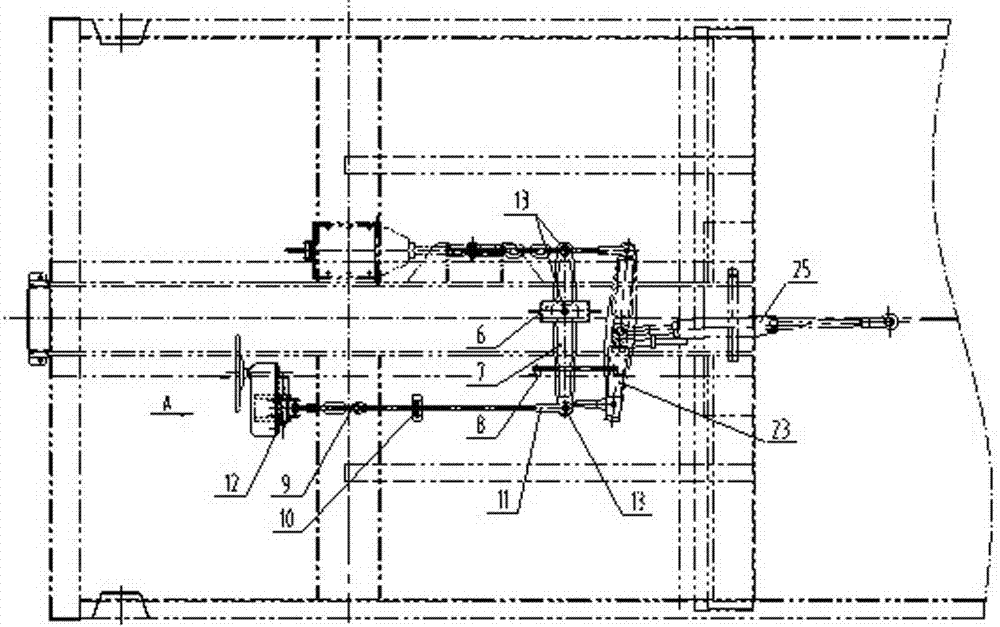

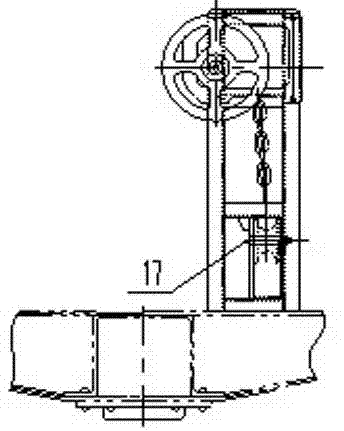

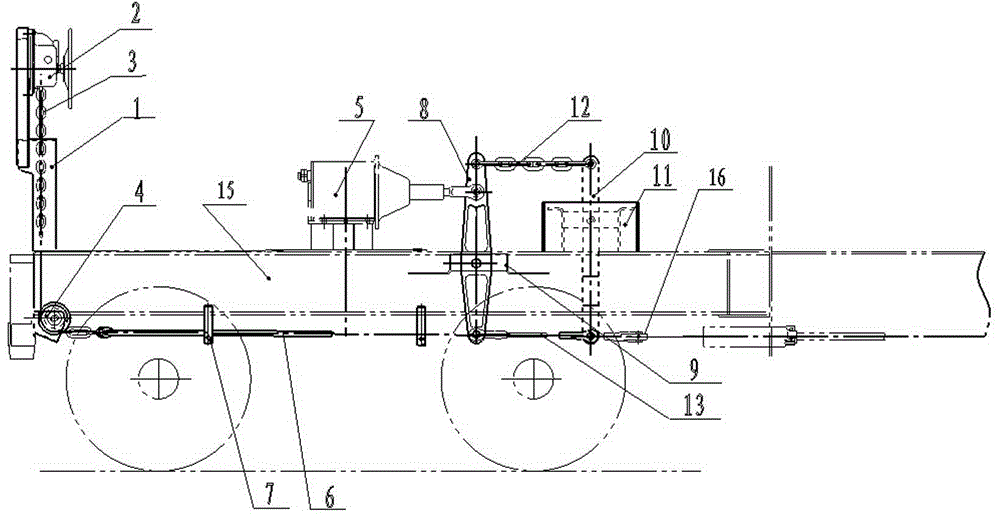

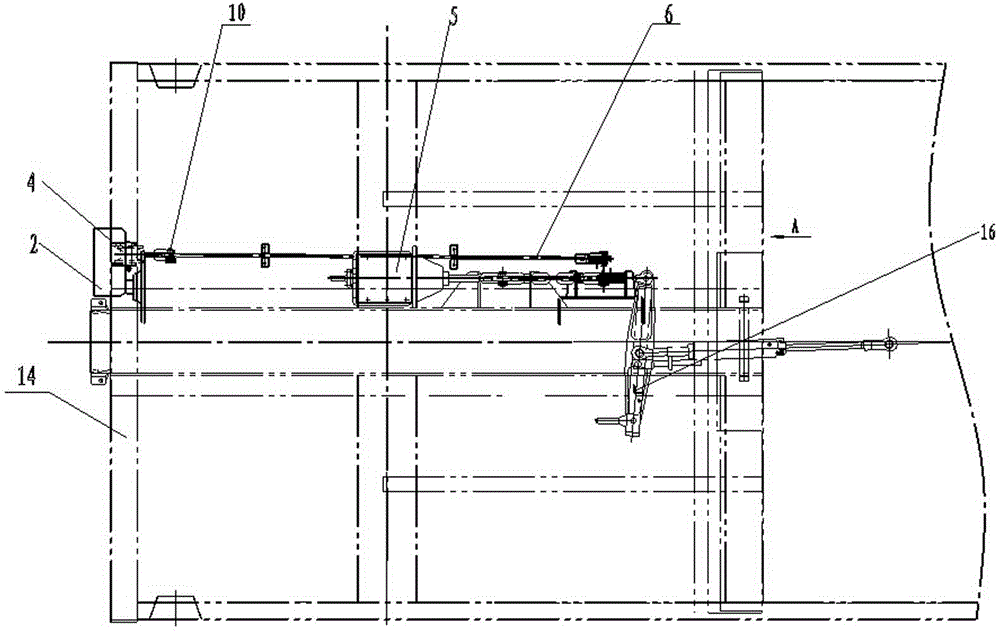

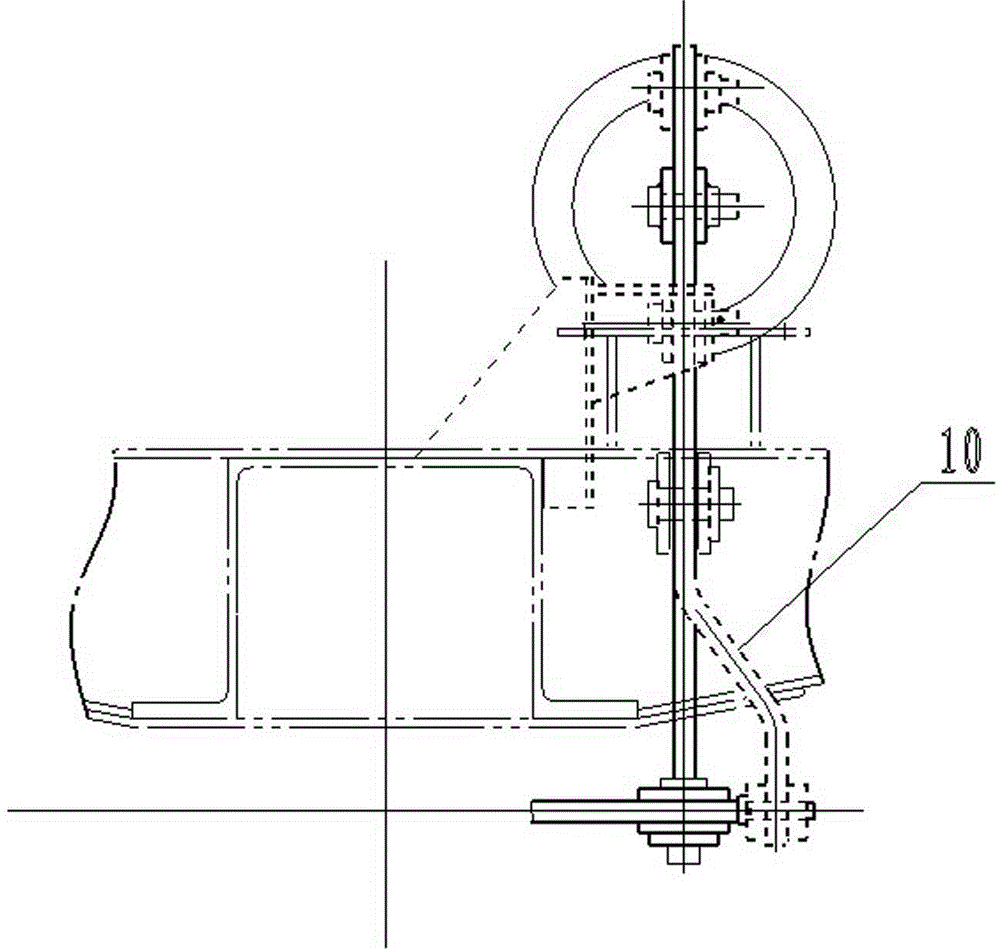

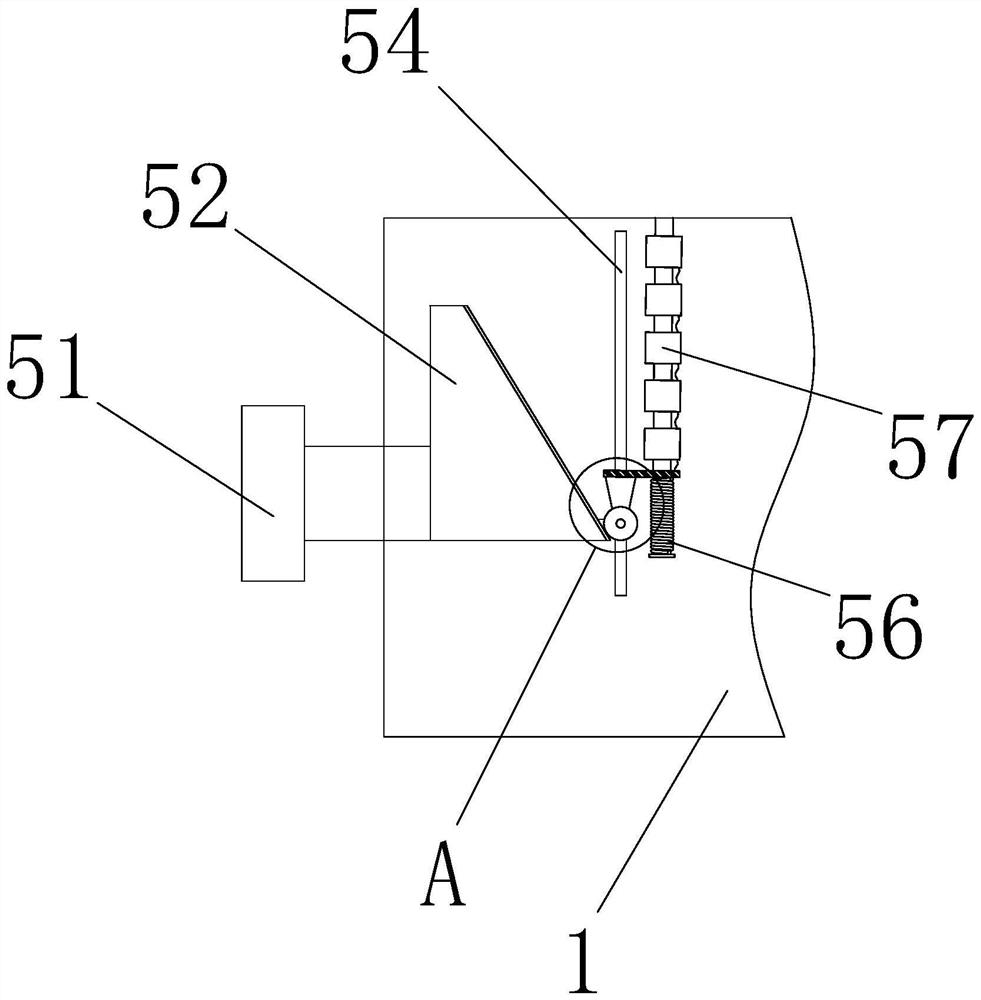

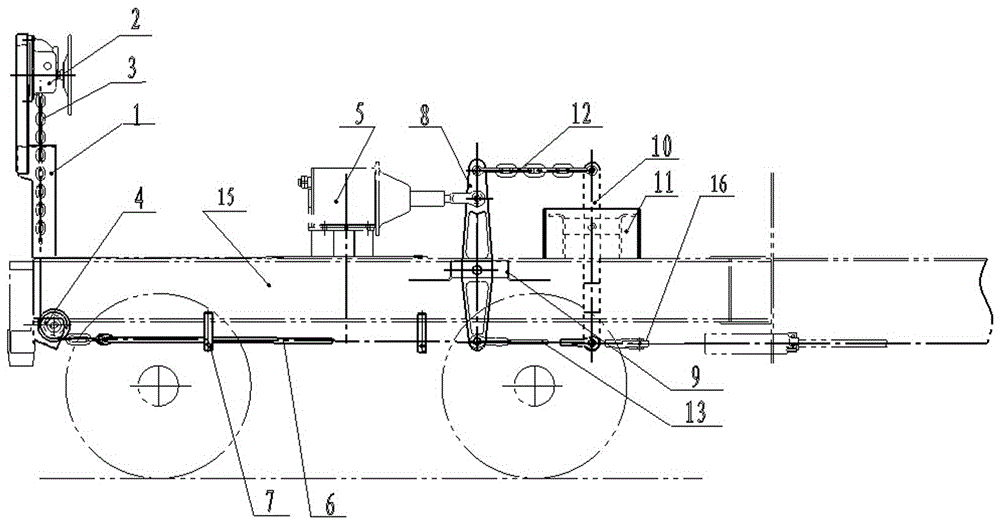

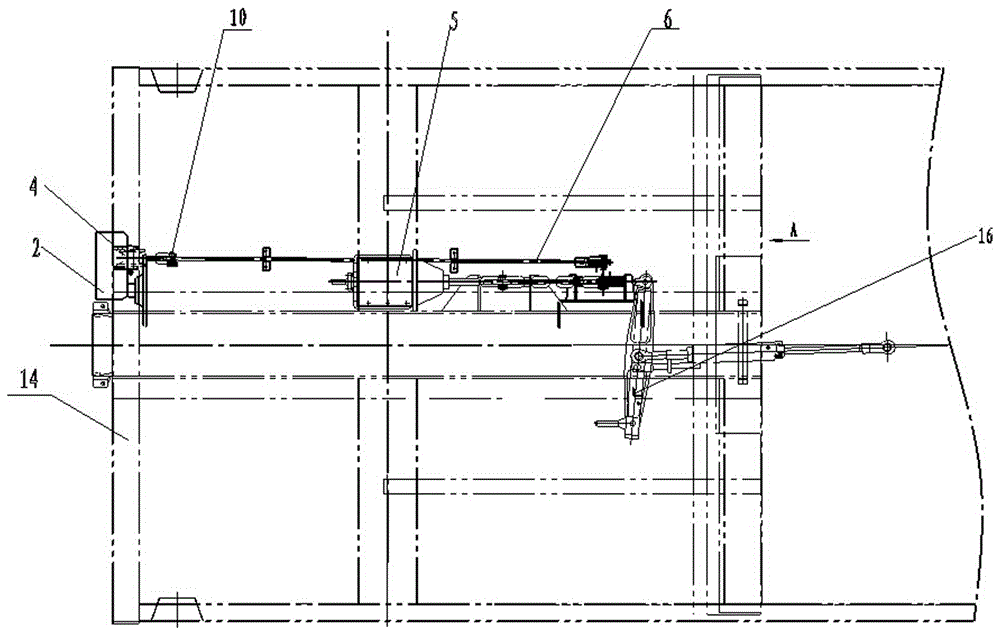

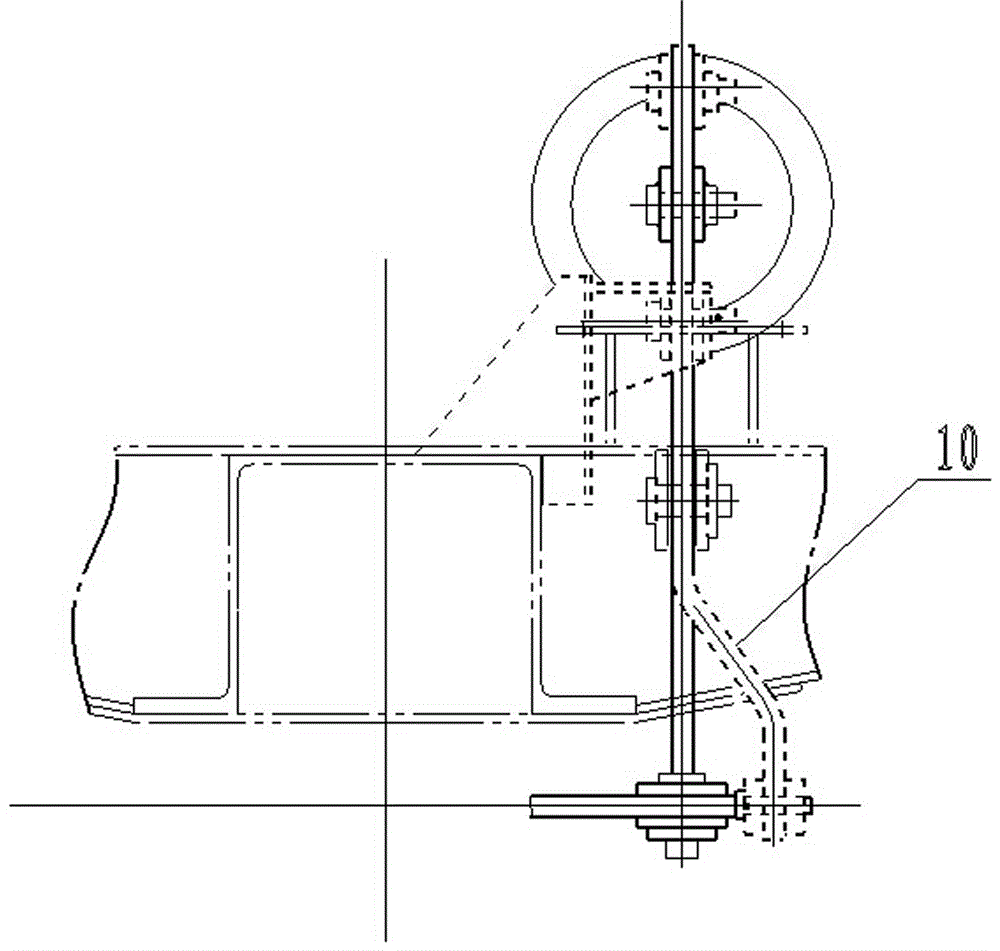

Hand braking device mounted on chassis of railway hopper wagon

The invention belongs to the technical field of a railway wagon and specifically relates to a hand braking device mounted on a chassis of a railway hopper wagon. The problems of the present hand braking device of the railway hopper wagon are solved. The hand braking device comprises a hand brake, a hand brake bracket, a fixed pulley, a chain assembly, a vertical lever assembly, a hand braking shifter lever fulcrum base, a hand braking shifter lever, a hand braking shifter lever supporting frame, a hand brake chain assembly, a hand brake pull rod guiding frame and a hand brake pull rod. The hand braking device is arranged on a floor of the chassis assembly of the hopper wagon; under the condition of no influence on the function of the hand braking device, the possibility of pulling out the supporting frame by a current hand brake pull rod reinforcing rid of the hopper wagon and the problem of influence on the traffic safety caused by the breaking of the hand brake pull rod are thoroughly eliminated; the demand on the traffic safety of the railway wagon is met.

Owner:CRRC TAIYUAN CO LTD

Railroad hopper car hand braking device

ActiveCN104590312AMeet the requirements of driving safetyEliminate the problem of fracture affecting driving safetyRail brake actuationBrakeControl theory

The invention relates to the technical field of a railroad freight car braking, in particular to a railroad hopper car hand braking device which solves a plurality of problems existing in actual application of an existing railroad hopper car. The railroad hopper car hand braking device comprises a hand brake support, a hand brake, a hand brake chain, a fixed pulley, a supporting base, a brake cylinder and a push rod, and further comprises a hand brake pull rod, a hand brake pull rod guide frame, a vertical lever, a vertical lever supporting point base, a switching lever, a switching lever supporting point base, a horizontal transmission chain and a switching pull rod. The hand brake support, the fixed pulley and the supporting base are fixed to an end beam, the hand brake pull rod guide frame and the brake pull rod are installed on the lower portion of a bottom frame, the vertical lever is vertically hinged to the bottom frame, and the lower end of the switching lever extends to the position below the bottom frame. The railroad hopper car hand braking device is arranged below the end beam and the bottom frame, completely eliminates the probability that a supporting frame is pulled out through an existing hopper car hand brake pull rod reinforcing rib and the problem that a hand brake pull rod breaks and influences running safety, and meets the requirement for running safety of the railroad hopper car.

Owner:CRRC TAIYUAN CO LTD

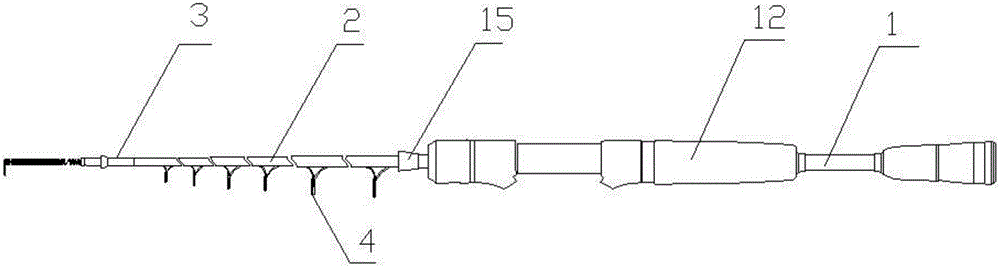

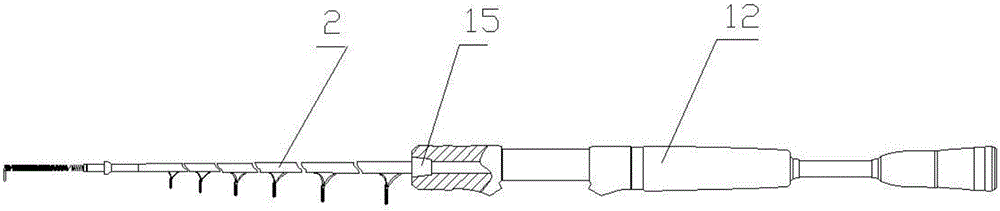

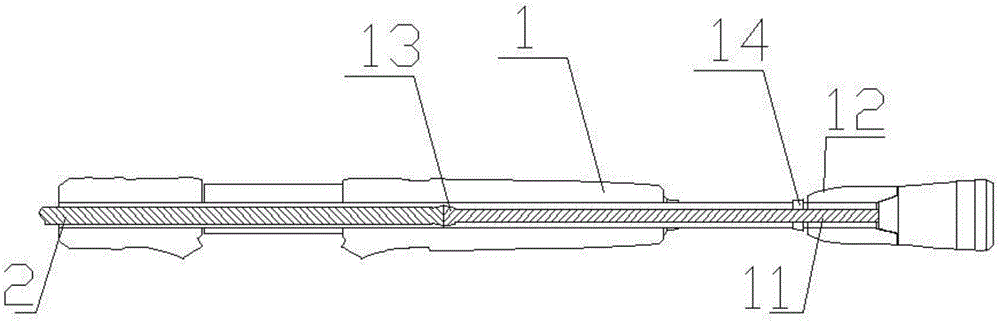

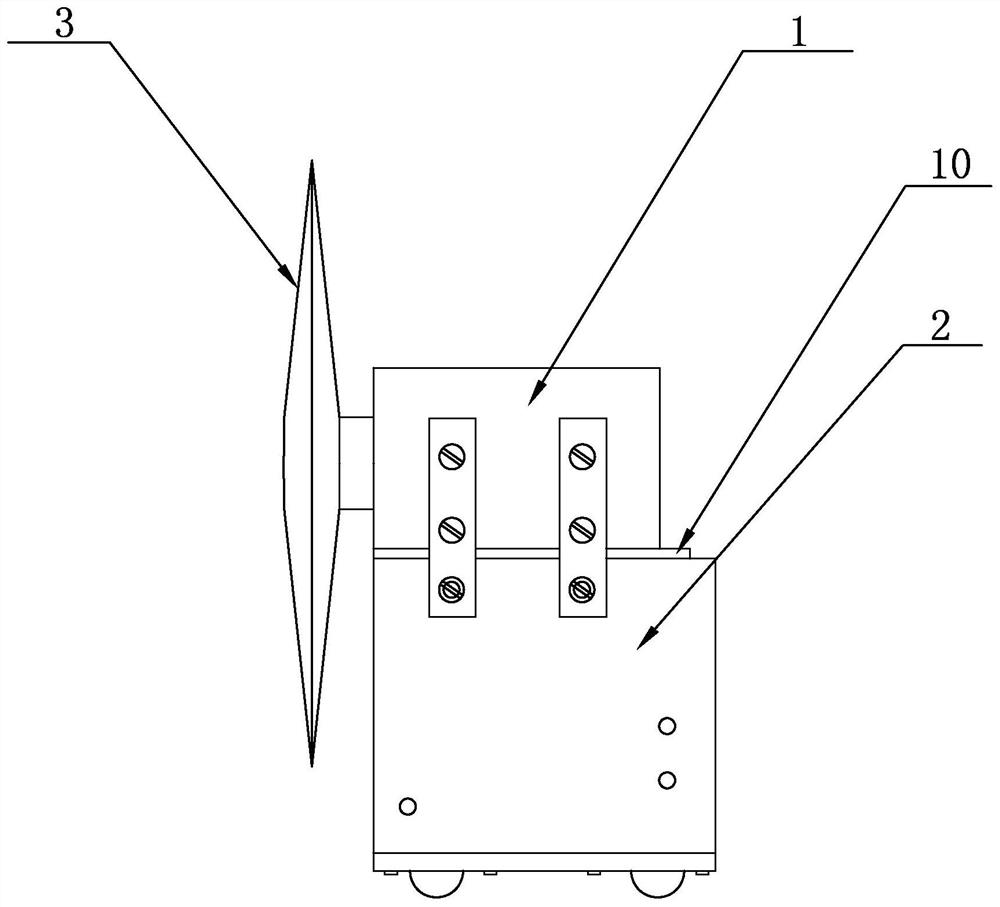

Raft fishing rod

PendingCN106665516ASolve the broken problemThe problem of broken point is not easy to happenRodsEngineeringFishing

The invention discloses a raft fishing rod, comprising a handheld segment, a rod body and a tip; the handheld segment, the rod body and the tip are connected in sequence, the tip incudes a connection portion and a diverting portion, the connection portion is connected to the tail end of the rod body, the diverting portion is hinged to the connection portion, the connection portion is also provided with a flexible marking portion, elastic coefficient of the marking portion decreases gradually along the extension direction of the rod body. The application discloses the raft fishing rod that is high in strength and high in sensitivity; the tip is rarely broken, and it is convenient for an angler to observe the state of the tip visually.

Owner:夏金利 +1

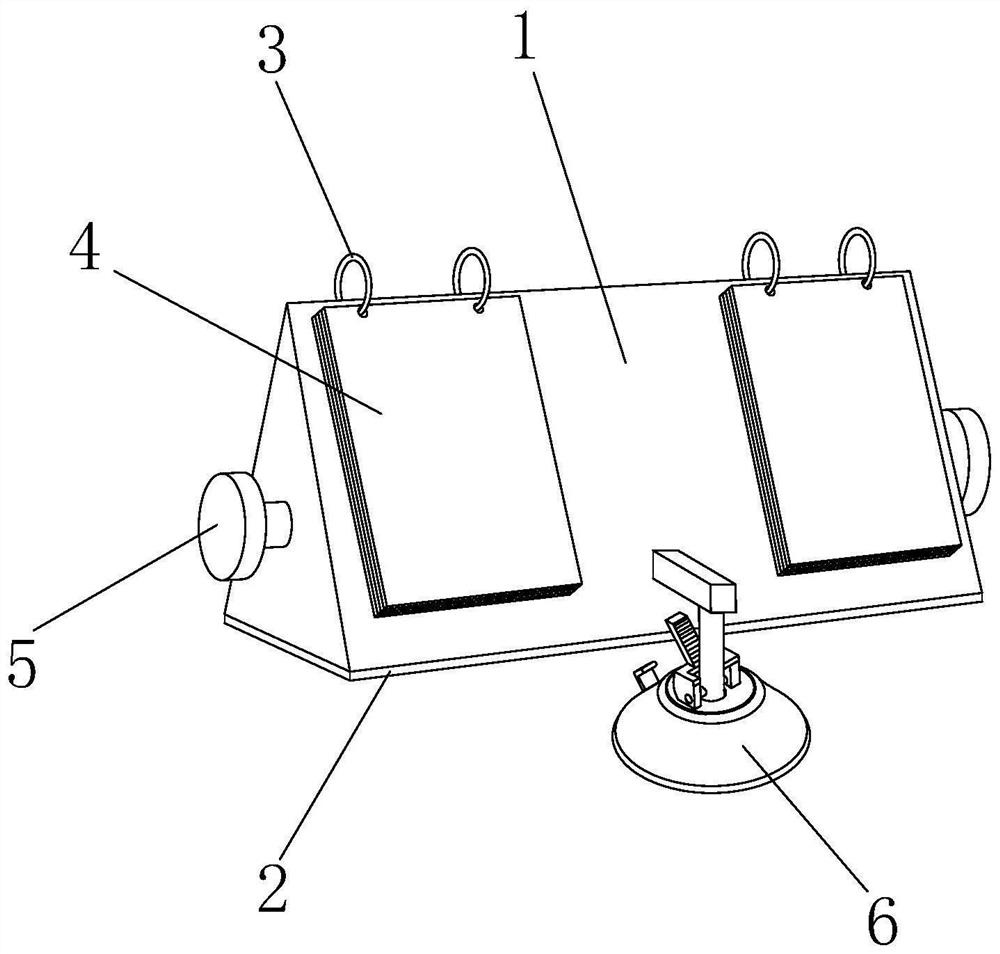

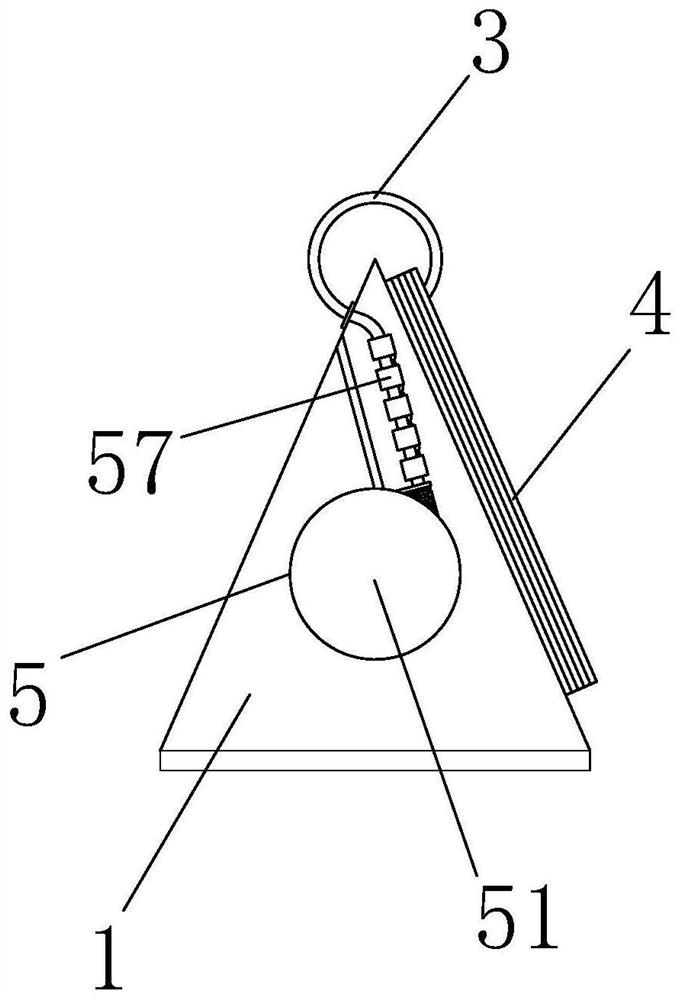

Multifunctional counting device for physical exercise

InactiveCN111729285ASolve the broken problemSolve the errorSport apparatusPhysical medicine and rehabilitationEngineering

The invention discloses a multifunctional counting device for physical exercise. The device comprises a supporting block, a bottom pad, a ring body, a counting plate, a reset mechanism and a reinforcing device. According to the invention, through the arrangement of the reset mechanism, after use, a pressing block can be pressed to drive an inclined block to move rightwards when resetting is needed, and a sliding block continuously moves upwards in a sliding groove; therefore, a plurality of push blocks slide along a ring body to reset the counting plate. The problem that an existing counting device needs to be reset after being used and is inconvenient and a counting plate is easy to break is solved. By arranging the reinforcing device, the pressing block can be used for rotating downwardsthrough a rotating shaft and being buckled into a clamping hook to be fixed after the counting plate is placed, so that air at the bottom of a suction cup is extruded out to adsorb a table top, the fixity is improved, and the problem that recorded data are wrong due to the fact that the counting device is prone to collision and falling off by external factors is solved.

Owner:泉州建驰体育器材设计有限公司

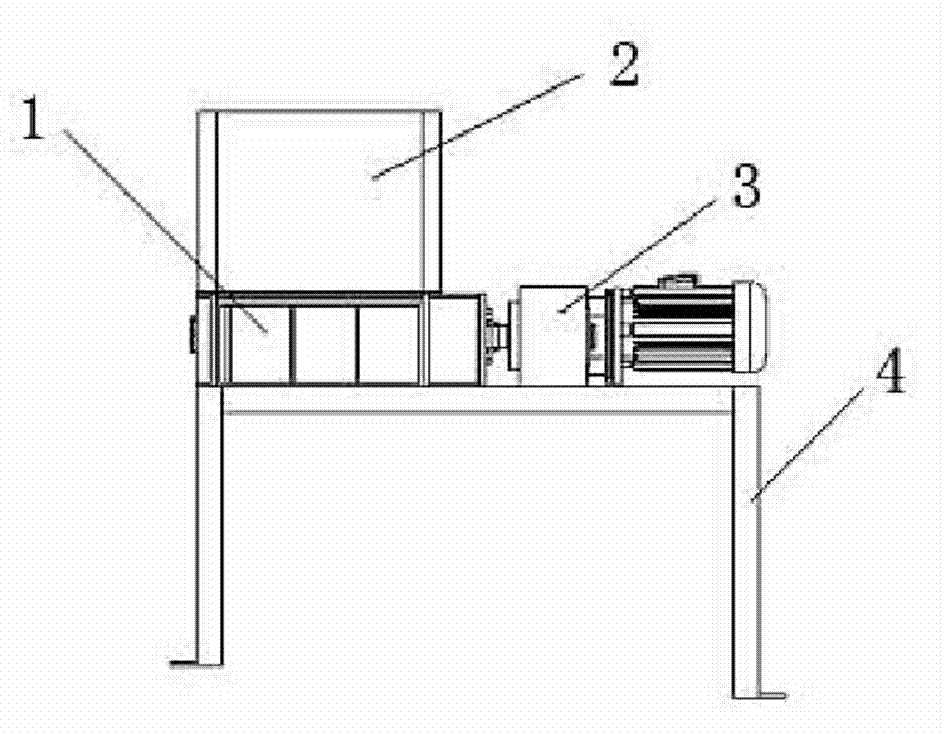

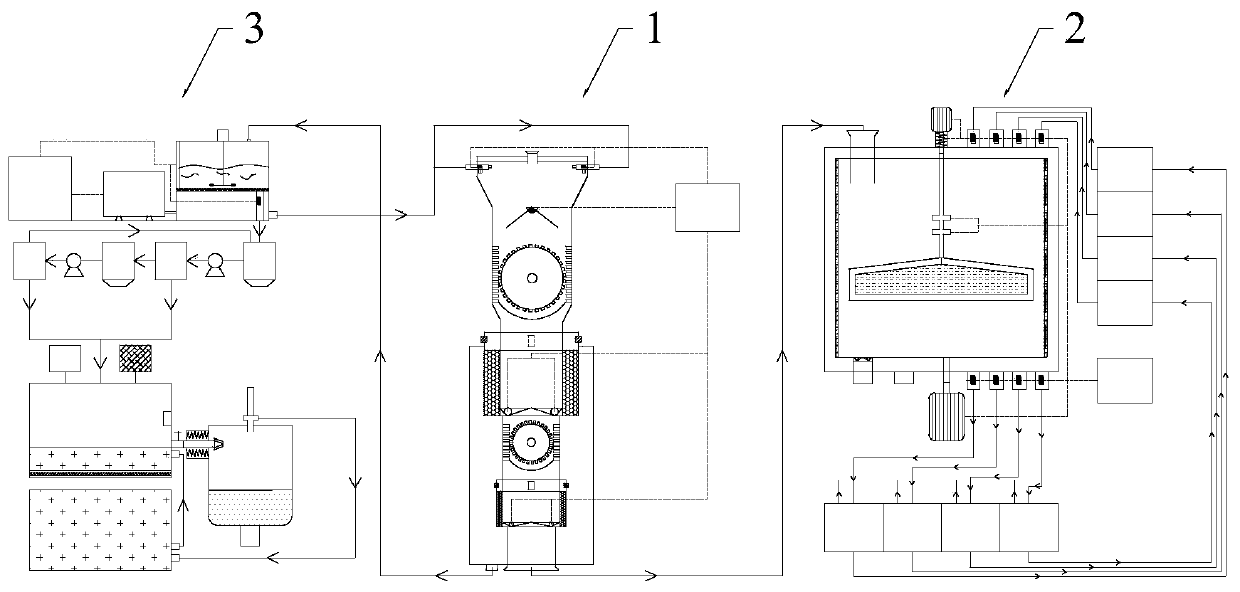

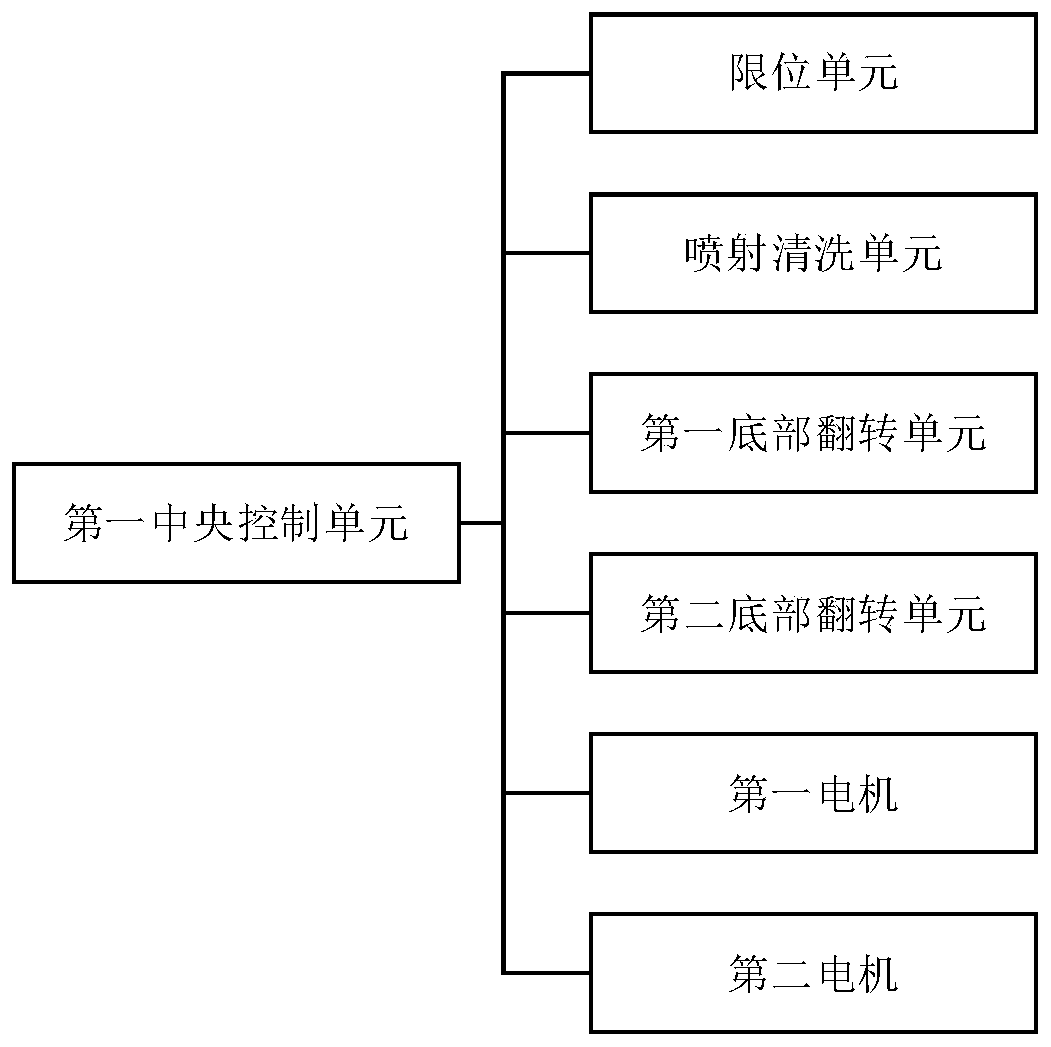

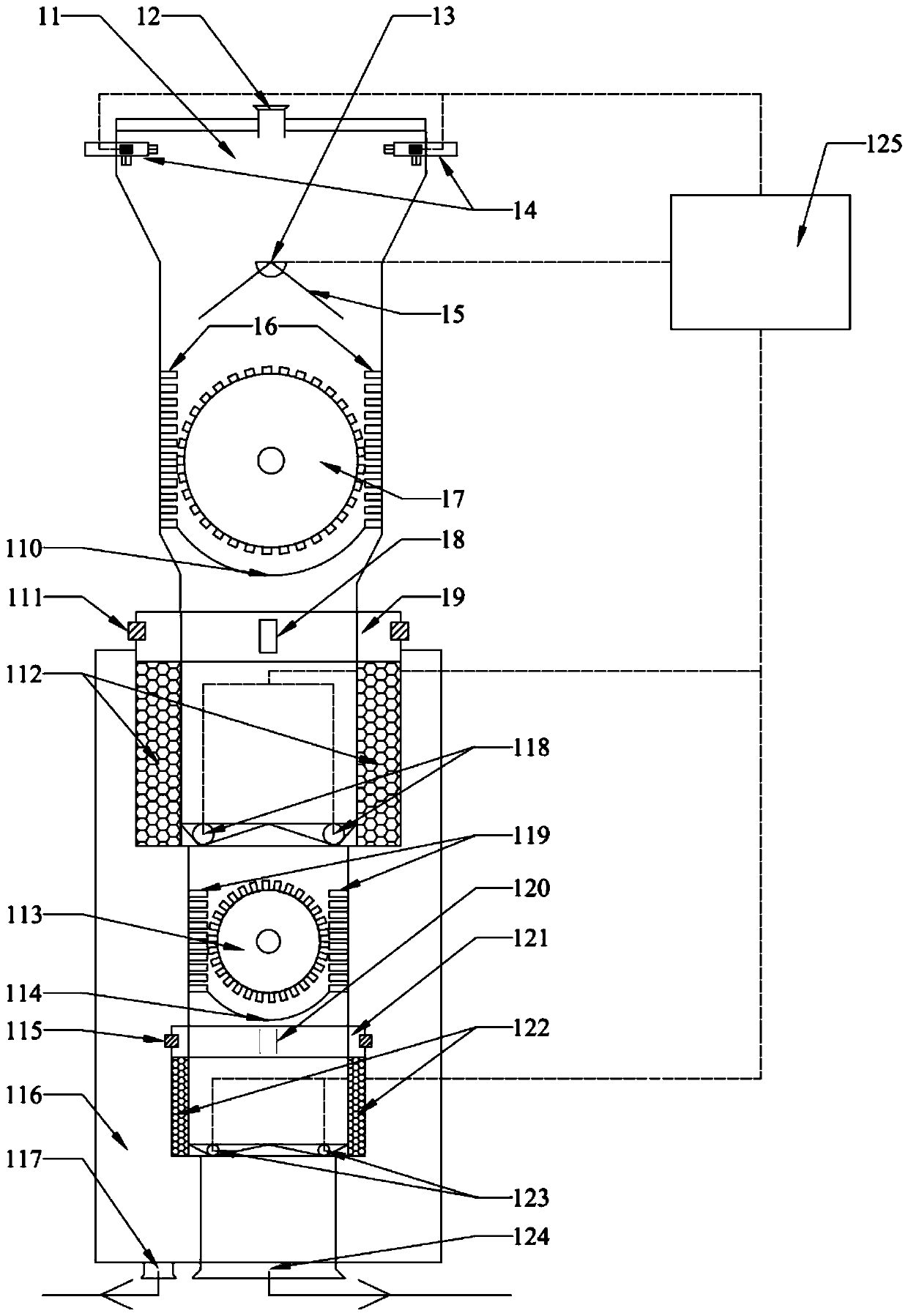

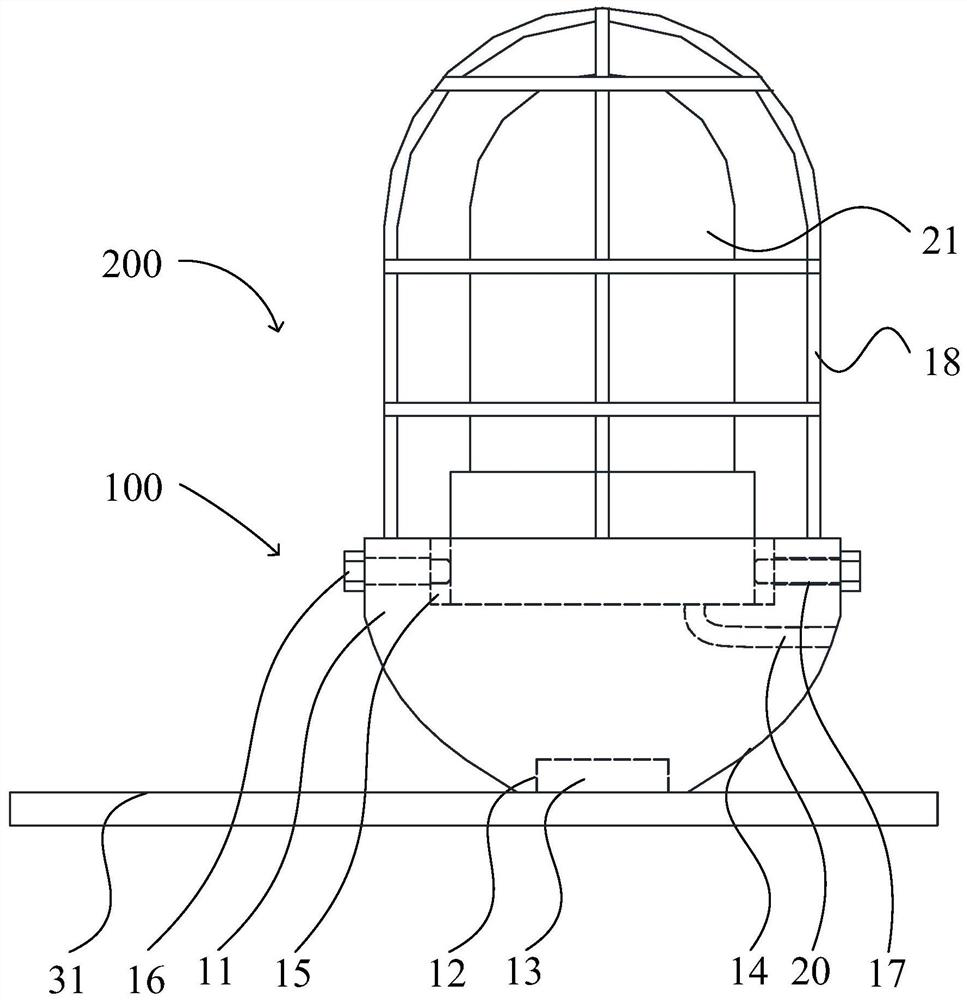

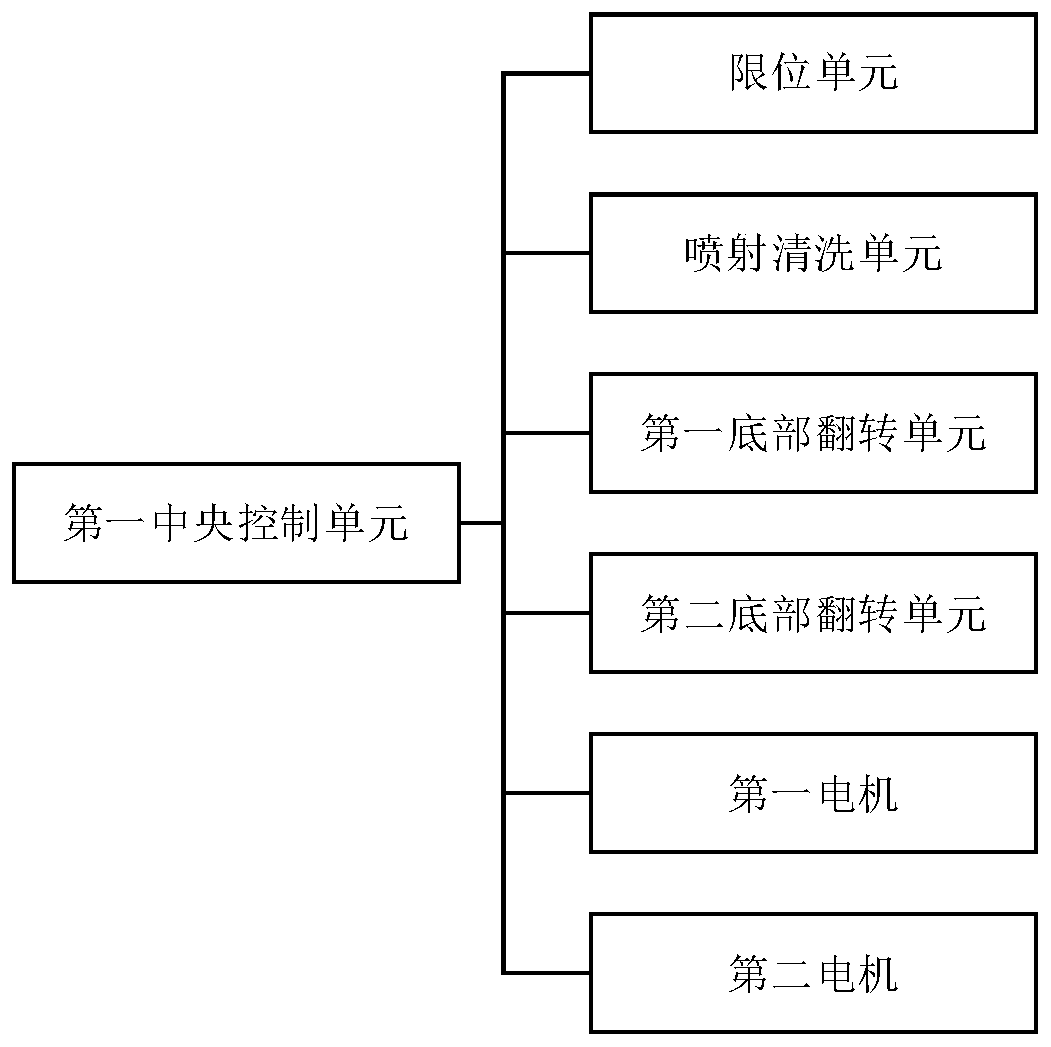

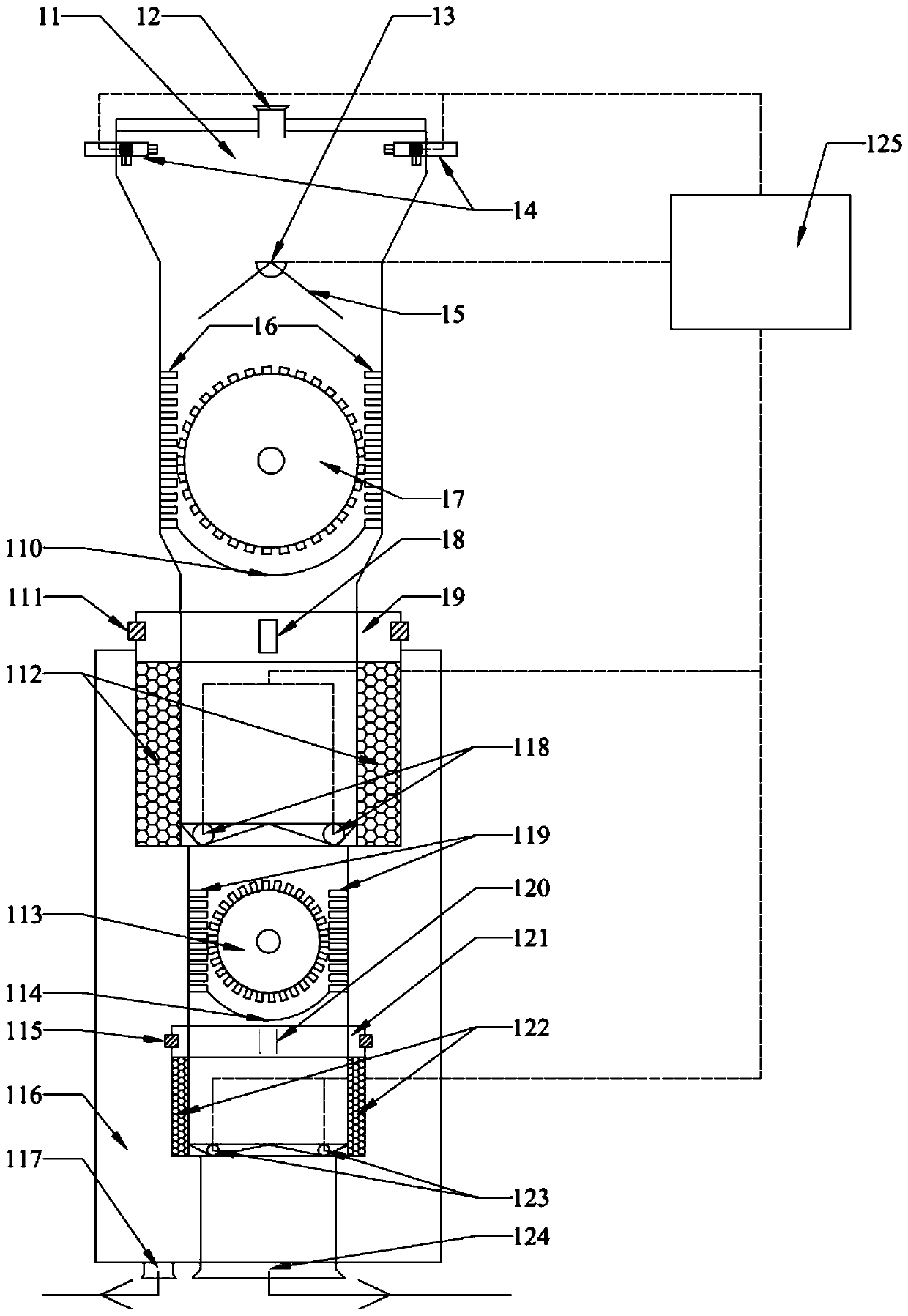

Carapace pretreatment device and equipment for recycling crustacean solid wastes

InactiveCN109701990ASolve broken problemsReduce system failure rateSolid waste disposalEngineeringAutomation

Owner:HUAZHONG UNIV OF SCI & TECH

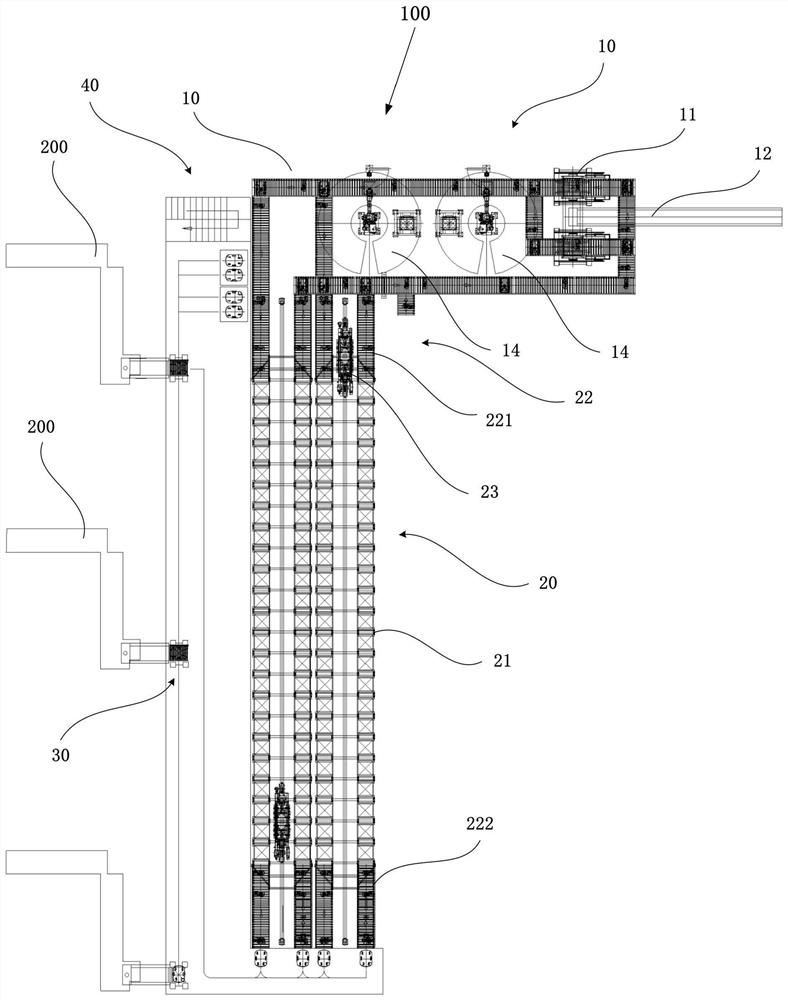

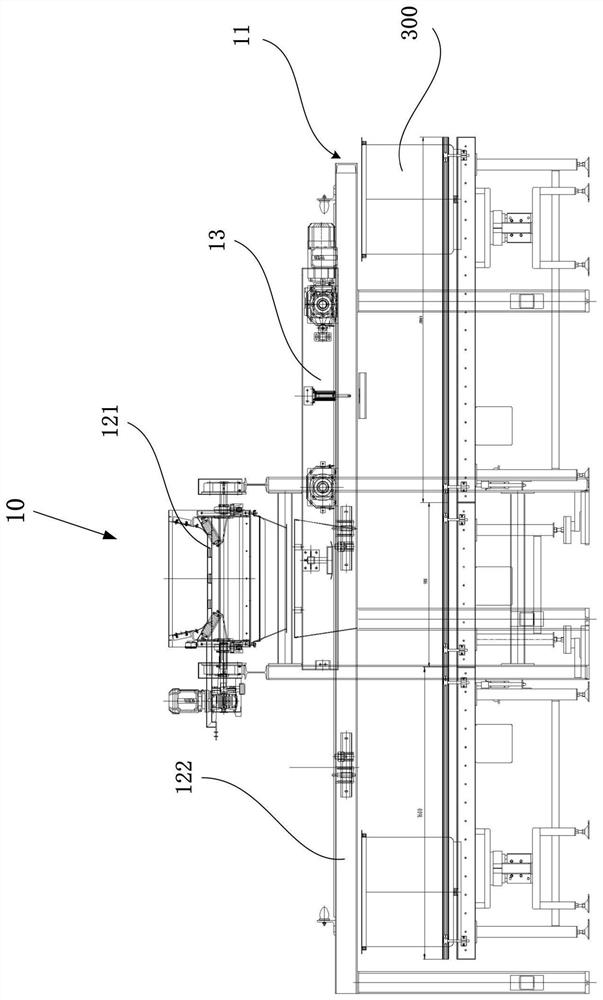

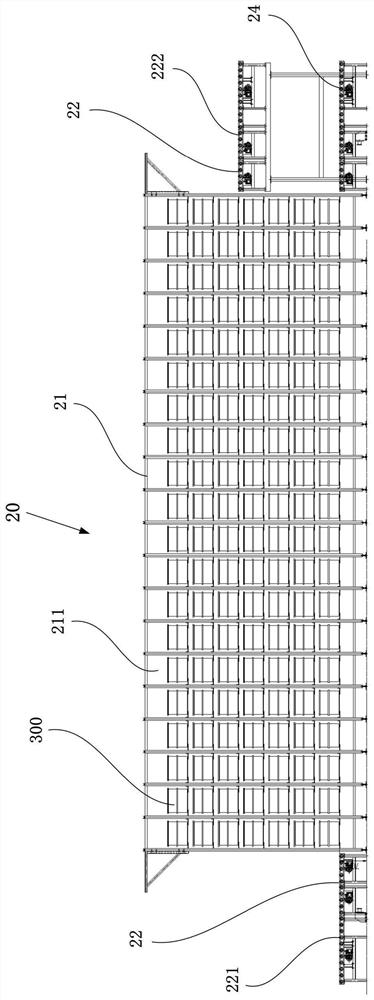

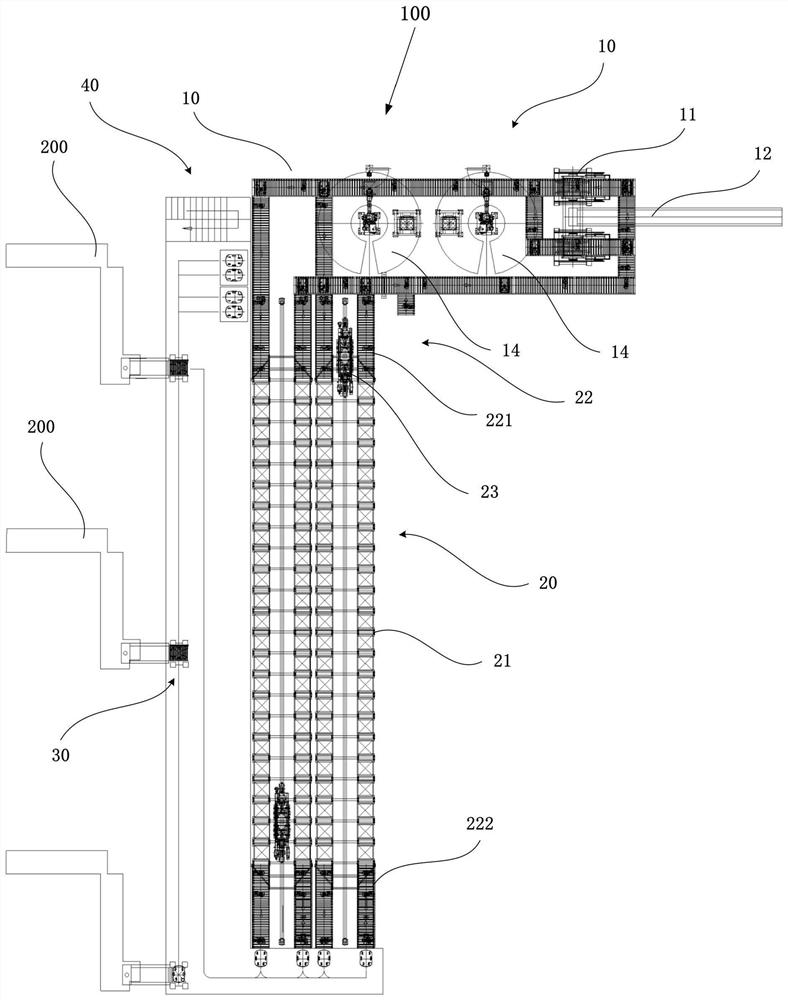

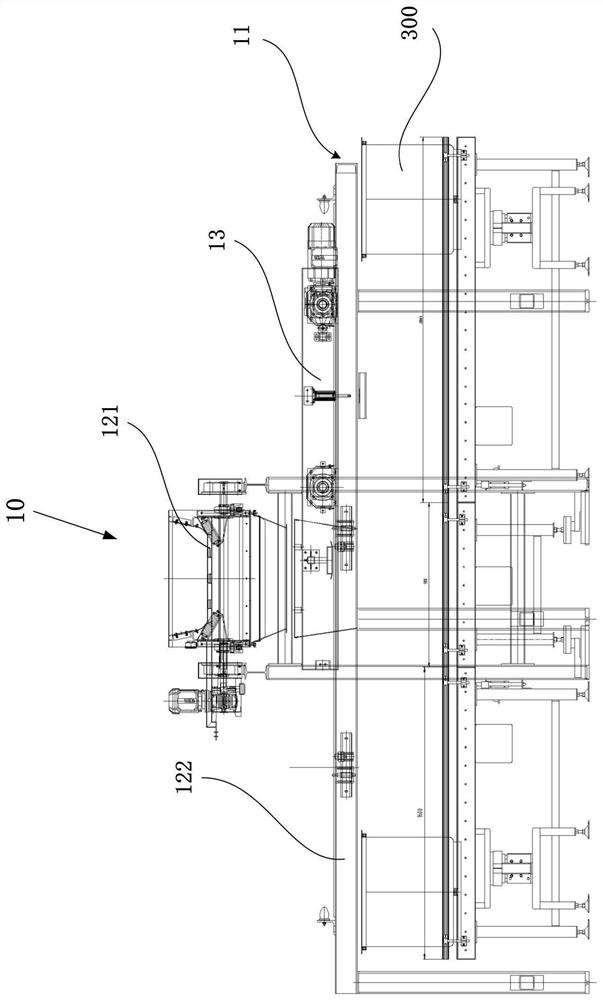

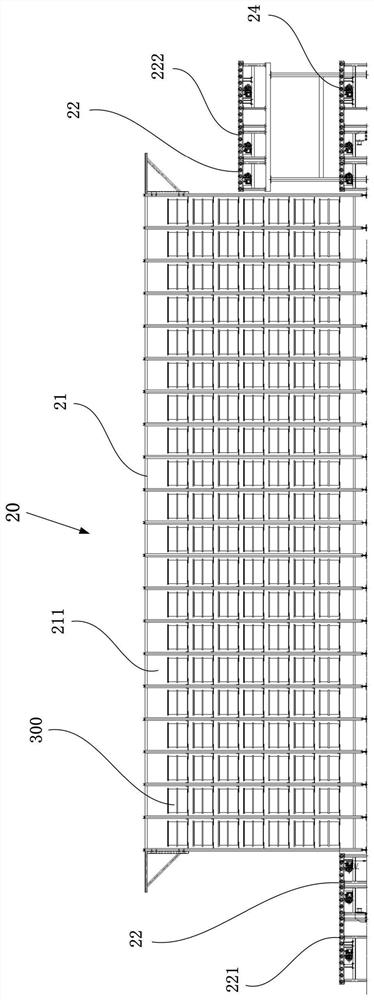

Automatic tobacco shred feeding system

ActiveCN111838751AFine managementProductive profitCigarette manufactureArticle unpackingAgricultural scienceAgricultural engineering

The invention provides an automatic tobacco shred feeding system. The automatic tobacco shred feeding system comprises a boxing unit, a storage unit, a tobacco shred feeding unit and a transferring unit. The boxing unit is connected with a tobacco shred making machine and is used for automatically boxing tobacco shreds output by the tobacco shred making machine into empty tobacco shred boxes. Thestorage unit is used for storing the full tobacco shred boxes output after boxing of the boxing unit is completed; the tobacco shred feeding unit is connected with a cigarette making machine and is used for feeding tobacco shreds in the full tobacco shred boxes into the cigarette making machine. The transfer unit is used for realizing cyclic transfer of the empty tobacco shred boxes and full tobacco shred boxes among the boxing unit, the storage unit and the tobacco shred feeding unit. Therefore, the tobacco shreds are transferred and fed between the tobacco shred making machine and the cigarette making machine, the exposure time of the tobacco shreds in a production environment is shortened to solve the problem that the moisture of the tobacco shreds is unstable, the impact of external force on tobacco raw materials is reduced, the tobacco shred breaking problem is solved, the requirement for automatic transfer from tobacco shred making to cigarette making is met, and the labor intensity is reduced. And fine management and flexible production of the tobaccos are better facilitated.

Owner:HUBEI CHINA TOBACCO IND

Method for preparing master alloy by crushing through using water quenching method

The invention discloses a method for preparing a master alloy by crushing through using a water quenching method. The method comprises the following steps of: selecting a single crystal furnace, placing a quartz crucible into the single crystal furnace, closing the furnace to exhaust the furnace, electrifying the single crystal furnace for heating, placing a basket containing a master alloy silicon briquette into the furnace when the inner wall temperature of the quartz crucible reaches 750-800 DEG C, placing 25-30kg of 20mm-thick boron-containing silicon briquette into the quenching basket, lifting the basket into the furnace, and placing the basket in the quartz crucible with the basket bottom approaching to the bottom of the quartz crucible, wherein the temperature of the boron-containing silicon briquette approaches to 650 DEG C after heating for half of a hour; and rapidly lifting the quenching basket, turning on an auxiliary furnace chamber of the single crystal pulling furnace, sending the basket down, lifting the basket to separate the basket from a hook when the upper edge of the basket descends to leave the drum of the auxiliary furnace chamber, directly and rapidly sinking the basket into a cold rinse bank, and simultaneously heating another quenching basket containing the boron-containing silicon briquette in the single crystal furnace. The problem of difficult crushing is solved and the method has the characteristics that the raw material is saved, the cost is reduced, and the labor intensity is reduced.

Owner:JIANGXI SORNID HI TECH

Updating method for indoor pipeline

InactiveCN104595578ASolve the broken problemAvoid disputesPipe laying and repairComputer scienceBuilding construction

Owner:天津穿越工程技术有限公司

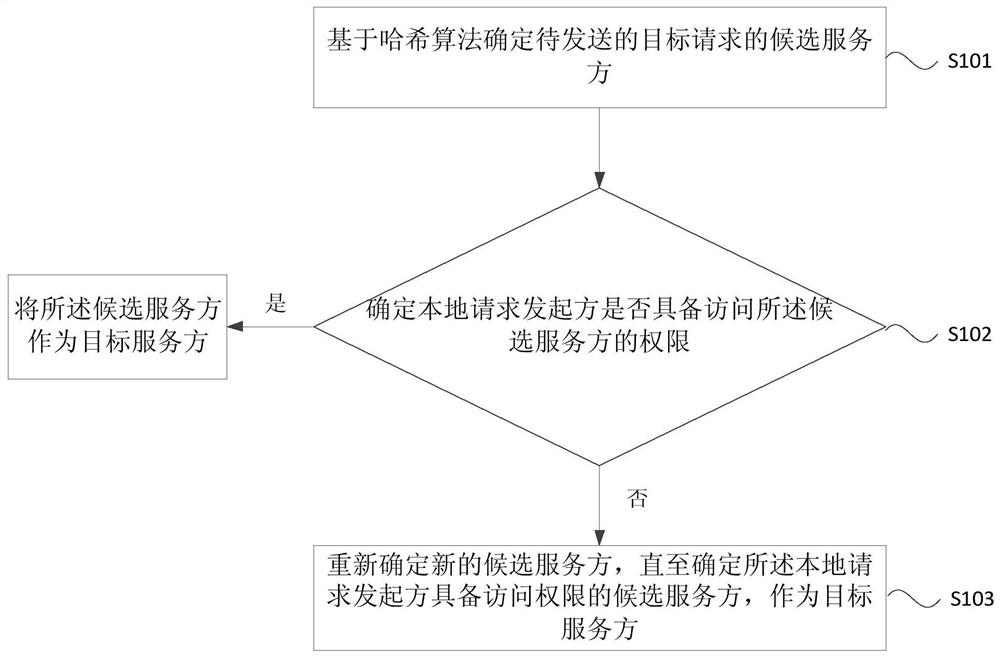

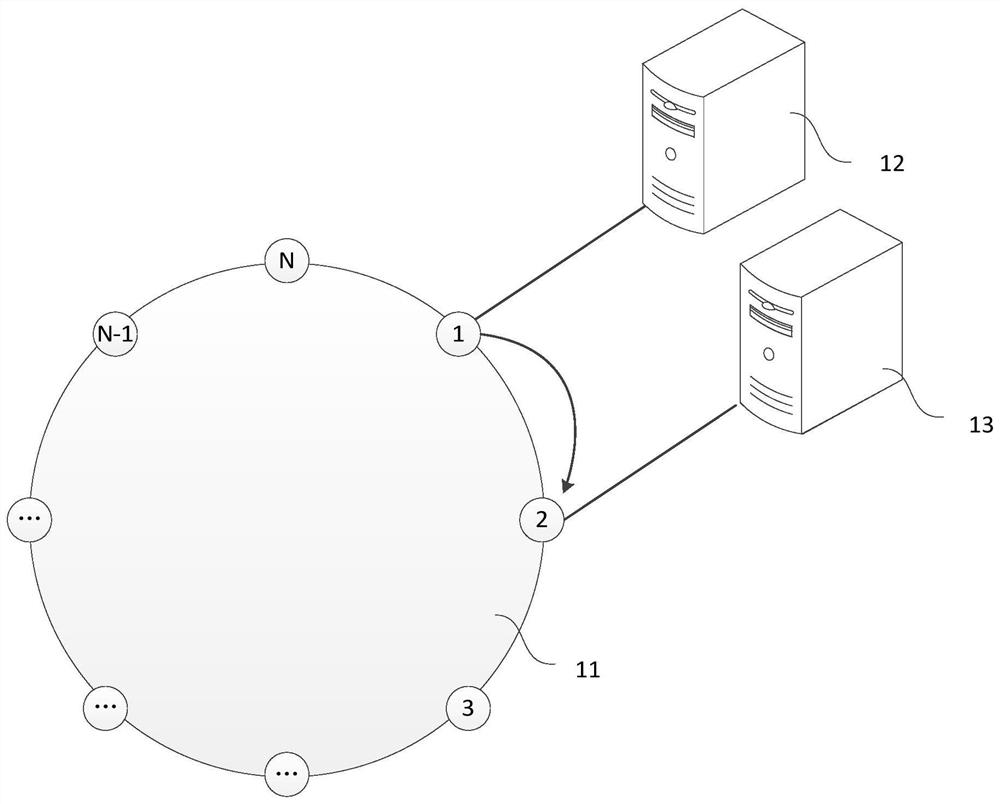

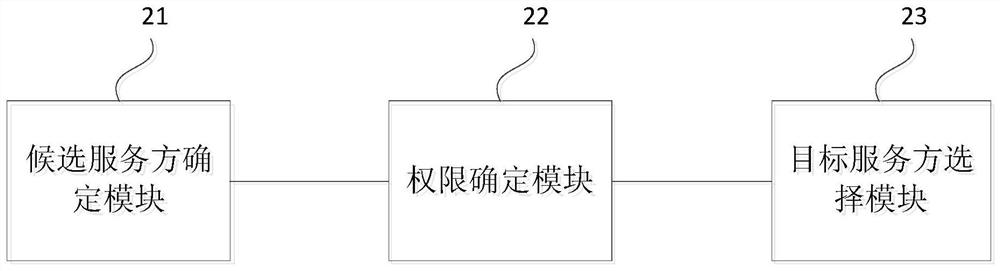

Load balancing method, apparatus, device and storage medium

ActiveCN109408241BSolve broken problemsThe access speed will not exceedResource allocationEngineeringNetwork communication

The embodiment of the invention discloses a load balancing method, device, equipment and storage medium, and relates to the field of network communication. The method includes: determining the candidate server of the target request to be sent based on a hash algorithm; determining whether the local request initiator has the authority to access the candidate server; A target server is selected from the server, and the target request is sent to the target server. The embodiment of the present invention ensures that the access speed of the requester will not exceed the maximum carrying capacity of the server by configuring the access authority of the server for the request initiator.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

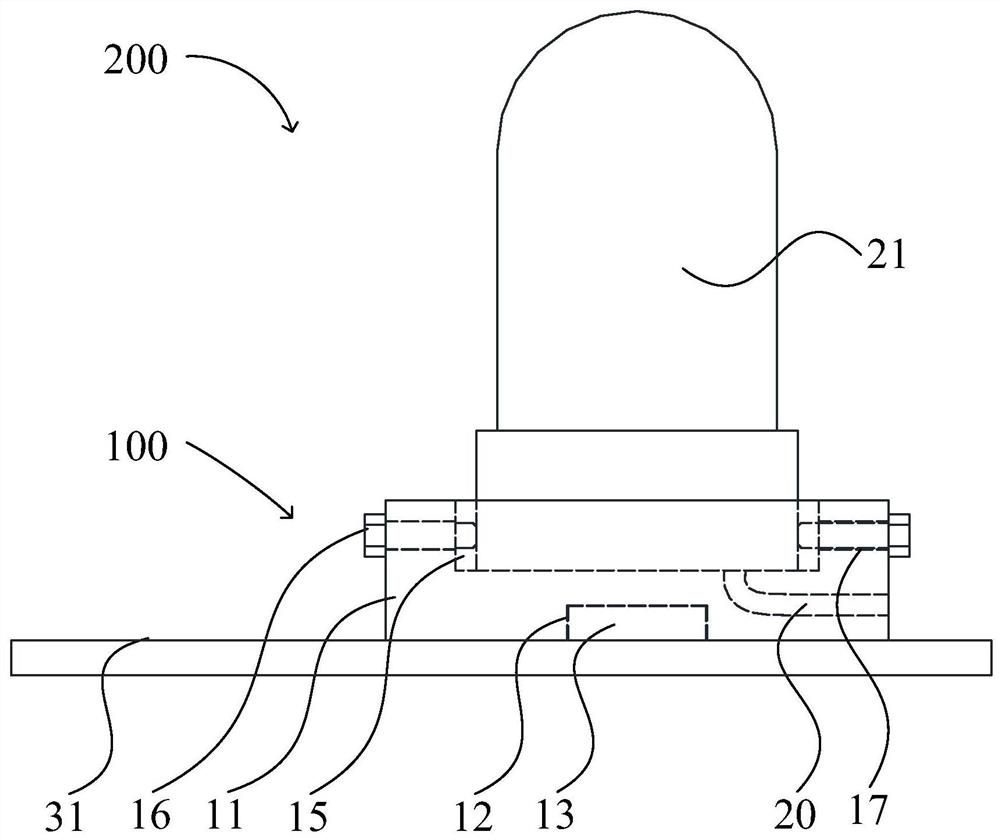

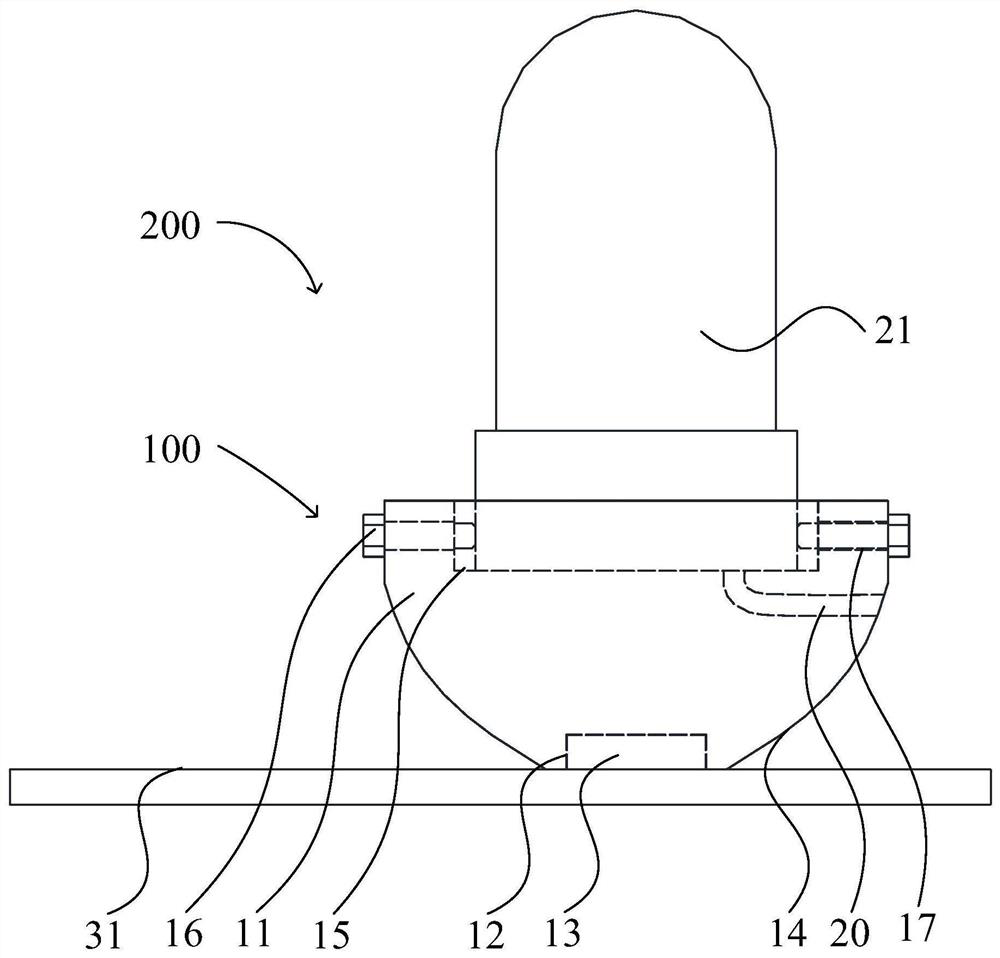

Fixing device, alarm device and overhead vehicle

InactiveCN111649216AAvoid damageSimplified installation stepsSafety devices for lifting equipmentsMachine supportsStructural engineeringMechanical engineering

The invention discloses a fixing device, an alarm device and an overhead vehicle. The fixing device is used to mount an alarm, the fixing device includes a fixing body and a magnetic part, an accommodating groove is formed in the lower side surface of the fixing body, the accommodating groove is used to accommodate the magnetic part, and the magnetic part is used to absorb the fixing body to a mounting surface of the alarm. According to the fixing device, the alarm device and the overhead vehicle, the alarm is arranged on the fixing body, the fixing body is absorbed on the mounting surface bymaking use of the magnetic part arranged in the accommodating groove, the magnetic part breaks away from the mounting surface under the external force action when the alarm is touched so that the alarm is avoided to be damaged, the magnetic part can be absorbed on the mounting surface when the fixing device is lifted again merely, and mounting steps of the alarm are simplified. The fixing device is simple in structure, and the problem that the alarm is damaged is efficiently solved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

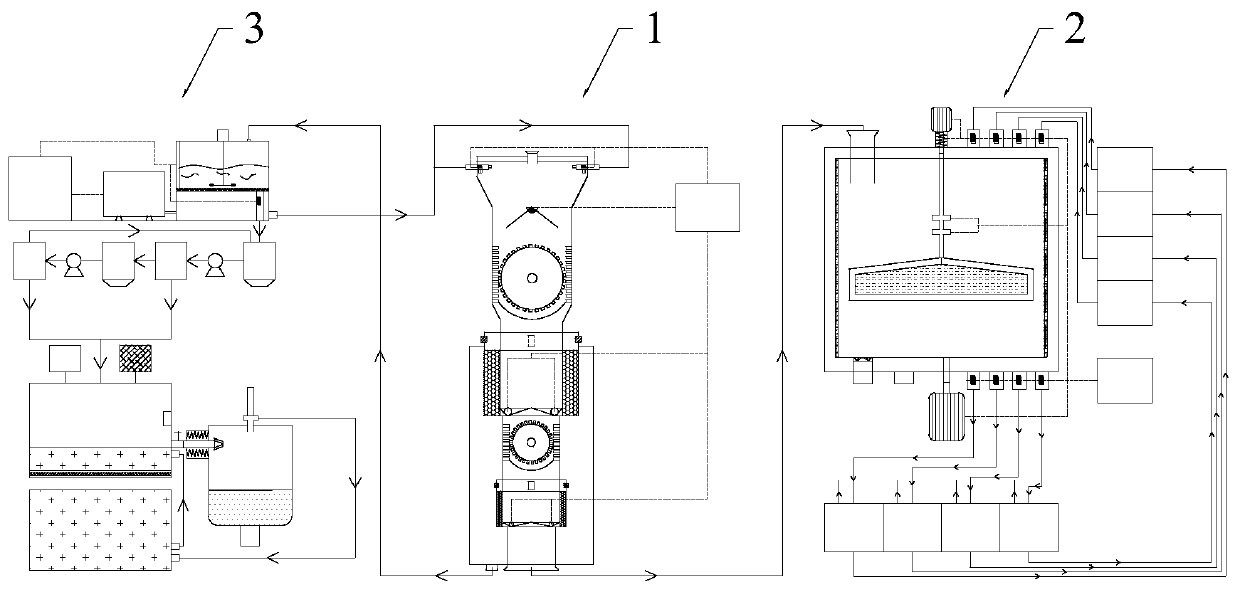

Crustacean solid waste recycling system and method

ActiveCN109796542AEfficient recyclingHighly integratedSolid waste disposalPeptide preparation methodsPre treatmentEngineering

The invention belongs to the related technical field of crustacean solid waste recycling, and discloses a crustacean solid waste recycling system and method. The system comprises a carapace pretreatment subsystem, a chitosan extraction subsystem and a protein extraction subsystem, wherein the chitosan extraction subsystem and the protein extraction subsystem are connected to the carapace pretreatment subsystem separately; the carapace pretreatment subsystem is used for performing two-stage smashing and solid-liquid separation on crustacean solid waste raw materials, thereby pretreating the crustacean solid waste raw materials into a solid substance and a liquid substance in a flowing state, and the solid substance and the liquid substance enter the chitosan extraction subsystem and the protein extraction subsystem; the chitosan extraction subsystem is used for treating the solid substance to obtain a chitosan product; the protein extraction subsystem is used for treating the liquid substance to obtain a protein product. The crustacean solid waste recycling system and method have the advantages that the extraction efficiency is higher, the operation is simple, and the production cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

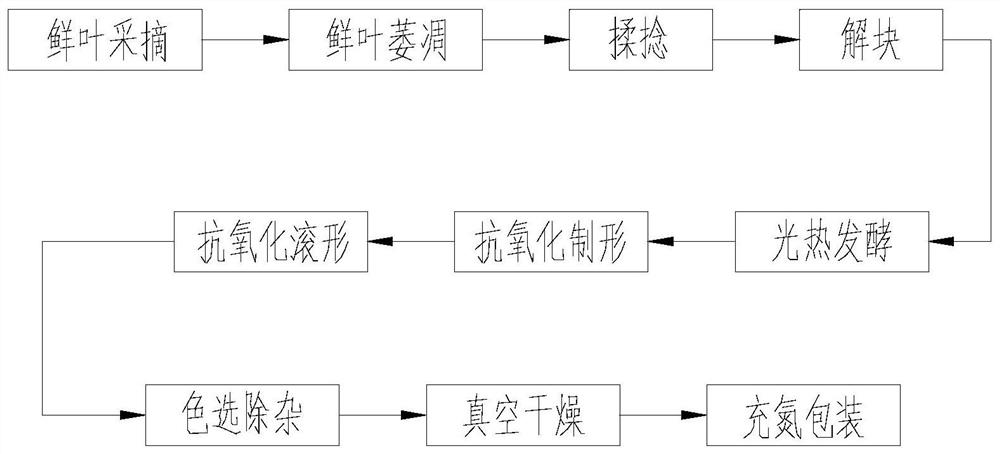

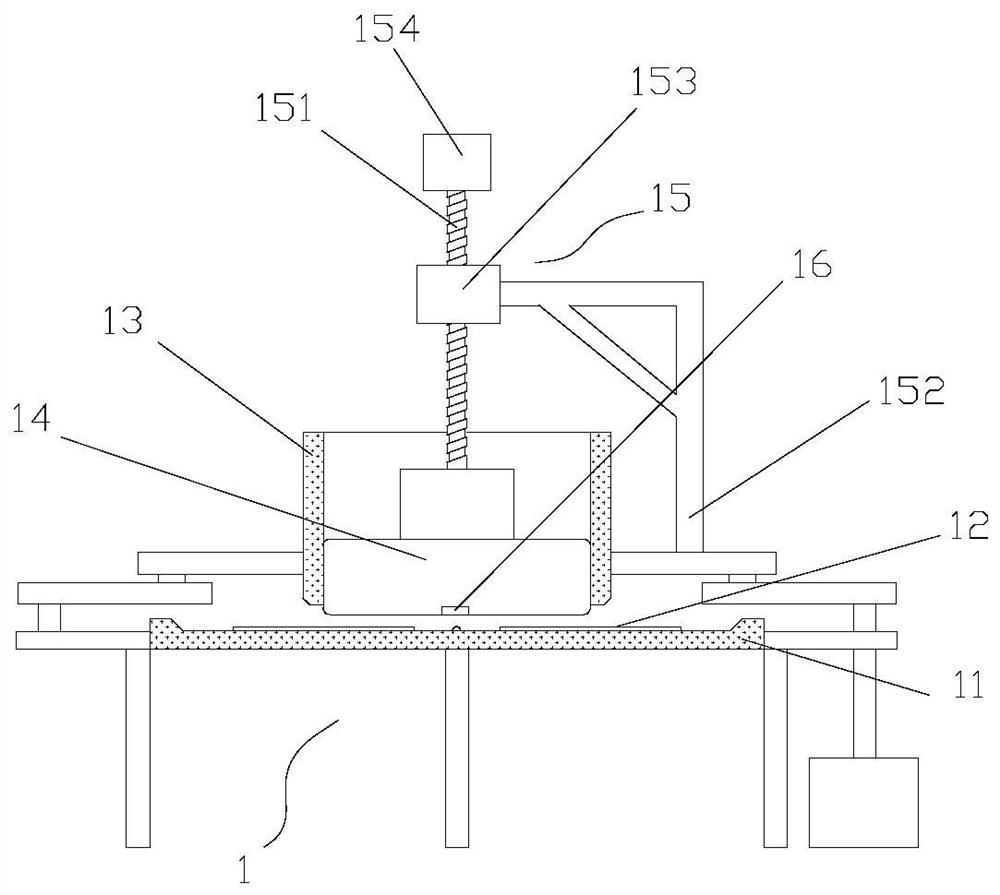

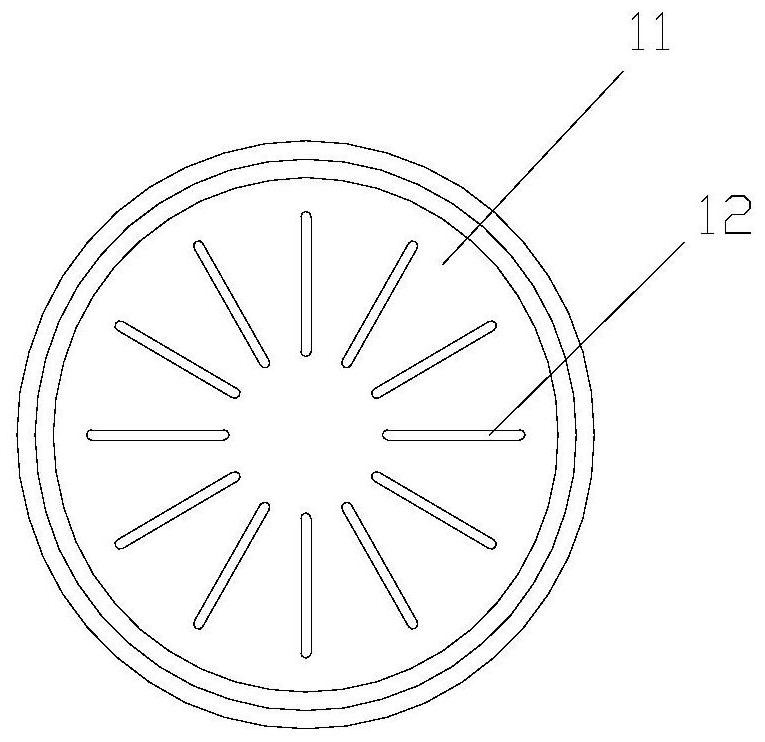

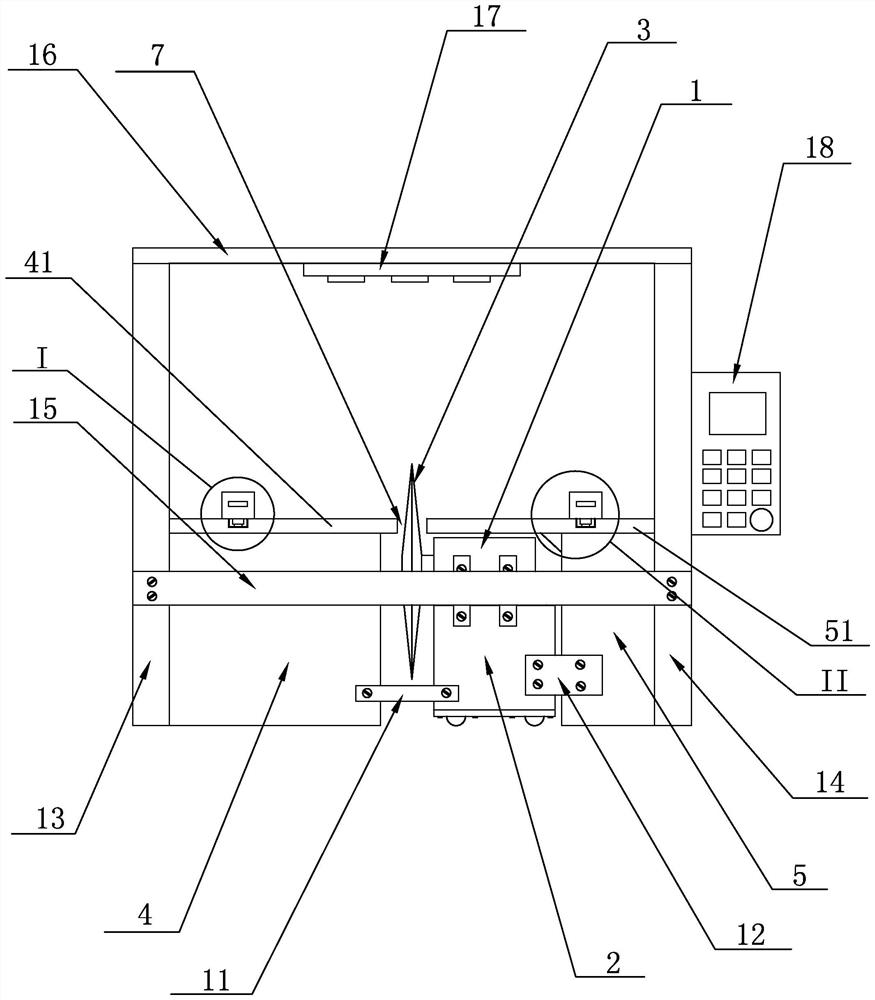

Small-pot Jinjunmei black tea making method

PendingCN113412867AFavorable redness reactionReduce breakage ratePre-extraction tea treatmentFood preservationBiotechnologySuperoxide dismutases

The invention discloses a small-pot Jinjunmei black tea making method which comprises the working procedures of fresh leaf picking, fresh leaf withering, rolling, deblocking, photo-thermal fermentation, antioxidant shaping, antioxidant rolling, color sorting and impurity removal, vacuum drying, nitrogen-filled packaging and the like. Withering is performed by adopting three different withering modes, meanwhile, near-infrared illumination treatment is carried out in the fermentation process, superoxide dismutase is added in the shaping and rolling processes to prevent the tea leaves from being oxidized, and then the vacuum drying technology is used for drying, so that the Jinjunmei black tea with superior quality is obtained, and the process method can be widely applied to the technical field of Jinjunmei black tea processing.

Owner:黄山小罐茶业有限公司

Splitting machine

InactiveCN113635369AEasy to assemble and disassembleReasonable structureMetal working apparatusElectric machinerySS - Stainless steel

The invention discloses a splitting machine. The splitting machine comprises a motor, a motor base and a cutting blade; a motor shaft of the motor is sleeved with the cutting blade; a left workbench is arranged at the left end of the cutting blade; a right workbench is arranged at the right end of the cutting blade; a left stainless steel panel is integrally arranged on the upper end face of the left workbench; at least one first guide sliding groove is formed in the left stainless steel panel; a first film roll positioning seat is arranged in the first guide sliding groove; the first film roll positioning seat slides back and forth along the first guide sliding groove; a right stainless steel panel is integrally arranged on the upper end face of the right workbench; a cutting blade moving gap is formed between the right stainless steel panel and the left stainless steel panel; and the cutting blade is located behind the cutting blade moving gap. According to the technical scheme, the structural design is reasonable, the structure is simple, the cutting size is accurate, the whole film roll can be directly cut, maintenance is easy, and practicability is good.

Owner:江苏宇狮薄膜科技有限公司

A railway funnel driver brake device

ActiveCN104590312BMeet the requirements of driving safetyEliminate the problem of fracture affecting driving safetyRail brake actuationBrakeControl theory

The invention relates to the technical field of a railroad freight car braking, in particular to a railroad hopper car hand braking device which solves a plurality of problems existing in actual application of an existing railroad hopper car. The railroad hopper car hand braking device comprises a hand brake support, a hand brake, a hand brake chain, a fixed pulley, a supporting base, a brake cylinder and a push rod, and further comprises a hand brake pull rod, a hand brake pull rod guide frame, a vertical lever, a vertical lever supporting point base, a switching lever, a switching lever supporting point base, a horizontal transmission chain and a switching pull rod. The hand brake support, the fixed pulley and the supporting base are fixed to an end beam, the hand brake pull rod guide frame and the brake pull rod are installed on the lower portion of a bottom frame, the vertical lever is vertically hinged to the bottom frame, and the lower end of the switching lever extends to the position below the bottom frame. The railroad hopper car hand braking device is arranged below the end beam and the bottom frame, completely eliminates the probability that a supporting frame is pulled out through an existing hopper car hand brake pull rod reinforcing rib and the problem that a hand brake pull rod breaks and influences running safety, and meets the requirement for running safety of the railroad hopper car.

Owner:CRRC TAIYUAN CO LTD

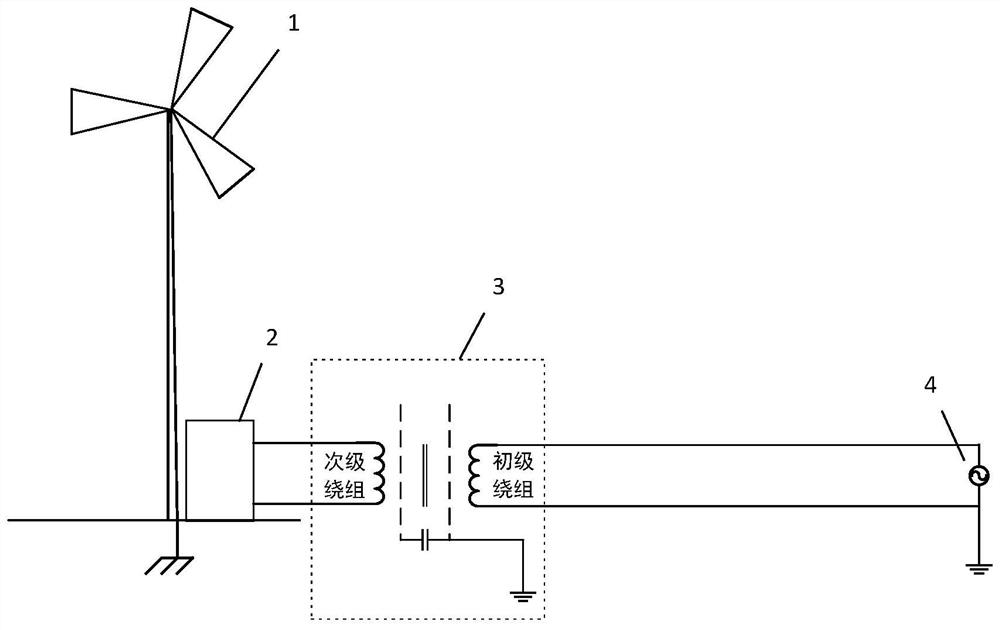

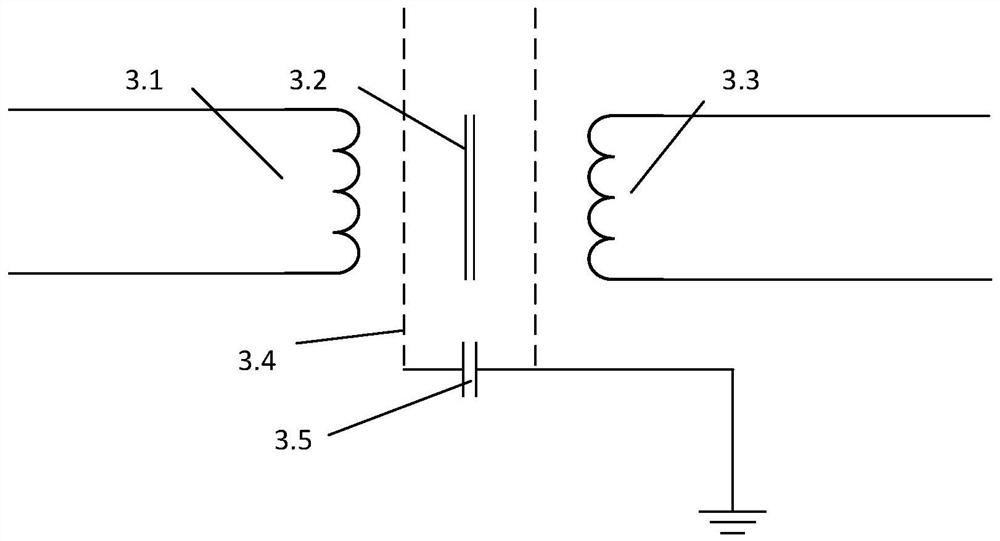

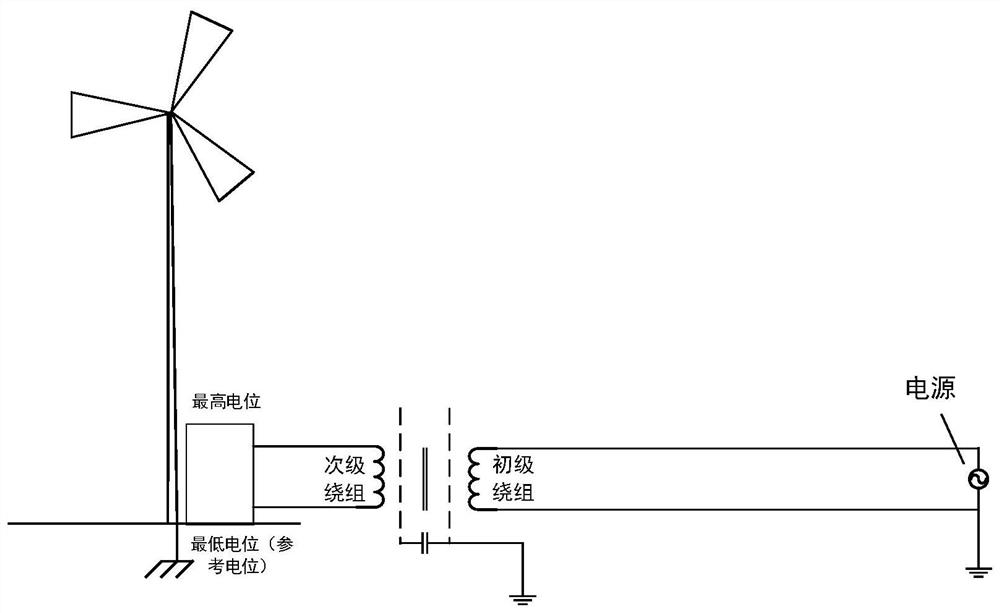

A method to prevent lightning counterattack of power distribution cabinet

ActiveCN111009885BSolve broken problemsImprove the protective effectMachines/enginesWind energy generationGrounding gridLightning strike

The invention discloses a method for preventing lightning counterattack of a power distribution cabinet, which belongs to the technical field of lightning protection of a power distribution cabinet. The method includes the following steps: setting an isolation transformer on the power supply line of the power distribution cabinet, There is a shielding layer between the primary winding and the primary winding; when the lightning strikes the fan, the ground potential of the lightning strike point rises, and the potential of the ground side of the power distribution cabinet below the fan rises with the rise of the ground potential; when the potential of the ground side of the power distribution cabinet rises , the high potential side of the power distribution cabinet rises synchronously; by setting the shielding layer to ground, and at the same time the power distribution cabinet is connected to the secondary winding, the voltage difference added to the equipment in the power distribution cabinet is always the power supply voltage, and the potential difference is constant, eliminating the ground grid Counterattack caused by high potential difference to avoid equipment damage. Through equipotential technology and reference potential floating technology, the potential reference point of the lightning strike point is the reference point of the power supply voltage, and the potential difference between the two ends of the equipment in the power distribution cabinet is constant, which solves the problem that the equipment in the cabinet is damaged due to lightning strikes.

Owner:GUANGXI UNIV +1

Tobacco automatic wire feeding system

ActiveCN111838751BEasy to manageIncrease production capacityCigarette manufactureArticle unpackingProcess engineeringMechanical engineering

The invention provides an automatic tobacco wire feeding system, comprising: a packing unit, a storage unit, a wire feeding unit and a transfer unit; In the box, the storage unit is used to store the cut tobacco solid boxes output by the box packing unit, the wire feeding unit is connected to the cigarette making machine, and is used to feed the shredded tobacco in the cut tobacco solid box to the cigarette making machine, and the transfer unit is used for Cartoning unit, storage unit and wire feeding unit realize the circular transfer of empty cut tobacco boxes and full cut tobacco boxes, so as to realize the transfer and feeding of cut tobacco between the shredding machine and the cigarette rolling machine, and reduce the exposure of cut tobacco in the production environment time to solve the problem of moisture instability in shredded tobacco, reduce the impact of external forces on tobacco raw materials, solve the problem of shredded tobacco, realize the need for automatic sequence transfer from shredded shreds to coiling, and reduce labor intensity; it is more conducive to the fine management of tobacco and flexible production.

Owner:HUBEI CHINA TOBACCO IND

A method of manufacturing a semiconductor device

ActiveCN104517802BImprove reliabilityIncrease productivityPhotomechanical apparatusSemiconductor/solid-state device manufacturingPower semiconductor deviceEtching

The invention discloses a method for manufacturing a semiconductor device, comprising: providing a design mask, the design mask including a plurality of design main line patterns; Add auxiliary virtual strip pattern at the endpoint of the line pattern, and then obtain the revised design mask; make a photolithography mask according to the modified design mask; use the photolithography mask to process the wafer Photolithography and etching; finally use a cutting mask to cut off unnecessary auxiliary lines according to design needs. According to the method for preparing a semiconductor device of the present invention, the problem that the lines generated during the micropatterning process of the silicon semiconductor substrate are easily broken is solved, so as to ensure that the pattern on the mask plate is completely transferred to the silicon semiconductor substrate, and then The reliability and production efficiency of the prepared semiconductor device structure are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

A high-hardness raw ore stripping type automatic crushing device and its application method

The invention discloses a high-hardness raw-ore stripping type automatic pulverizing device. The device comprises a first box body, a four-claw clamping disc and a clamping disc sliding block, a fueltank is fixedly installed on the top of the first box body, and the right side of the fuel tank is provided with a water tank which is fixedly installed on the top of the first box body. The device has the advantages that the structure is simple, the operation is simple and convenient, the current problem of high-hardness raw ore pulverizing is solved, rapid temperature reduction is conducted by spraying water mist after high-hardness raw ores are flamed and heated, so that the internal molecular structures of the high-hardness raw ores are changed through the principle that expansion is caused by heat and contraction is caused by cold to allow the raw ores to be stripped layer by layer to be easily pulverized, fuel and water can be automatically added, the whole operation is automated, manual operation is not needed, and therefore the efficiency is greatly improved.

Owner:阿巴嘎旗金地矿业有限责任公司

Single-shaft mortar and high-viscosity fluid stirrer for axial turbulent flow pattern multi-wire cutting machine

InactiveCN102059068BReasonable structural designEasy to processRotary stirring mixersTransportation and packagingImpellerWire cutting

The invention discloses a single-shaft mortar and high-viscosity fluid stirrer for an axial turbulent flow pattern multi-wire cutting machine, comprising a stirring shaft, a stirring assembly and a driving mechanism, wherein the stirring assembly comprises impellers and short flow diversion tubes, the impellers are used for driving a material to move up or down in an axial and spiral mode along the inner wall of a pot body of a stirring pot, the short flow diversion tubes are used for restricting the material flow direction to an axial movement along the axis of the stirring shaft when the material moves up or down in the axial and spiral mode, the impellers and the short flow division tubes are assembled into the stirring assembly which drives the material needed to be mixed and stirred to do an axial turbulent flow motion during stirring, the impellers are coaxially installed at the bottom end of the stirring shaft, the short flow division tubes are coaxially and fixedly sleeved at the outer sides of the impellers, and the stirring speed of the stirring shaft is 600-1500rmp. The single-shaft mortar and high-viscosity fluid stirrer has the advantages of simplicity in structure, high stirring capacity, small shearing force, high dispersing power and high effect, and can be used for solving the problem that silicon carbide is broken due to the shearing force during the high-speed stirring of various traditional stirrers. Moreover, a stuck phenomenon is difficult to generate.

Owner:XIAN HUAJING ELECTRONICS TECH

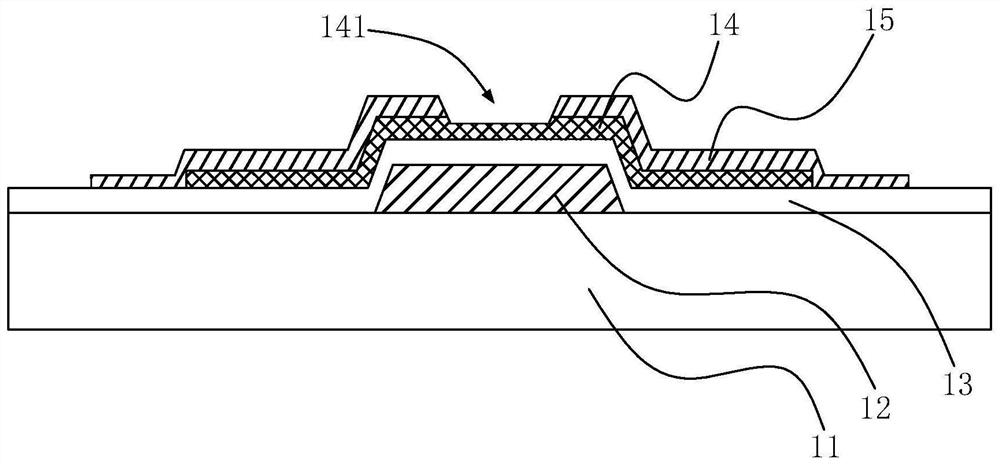

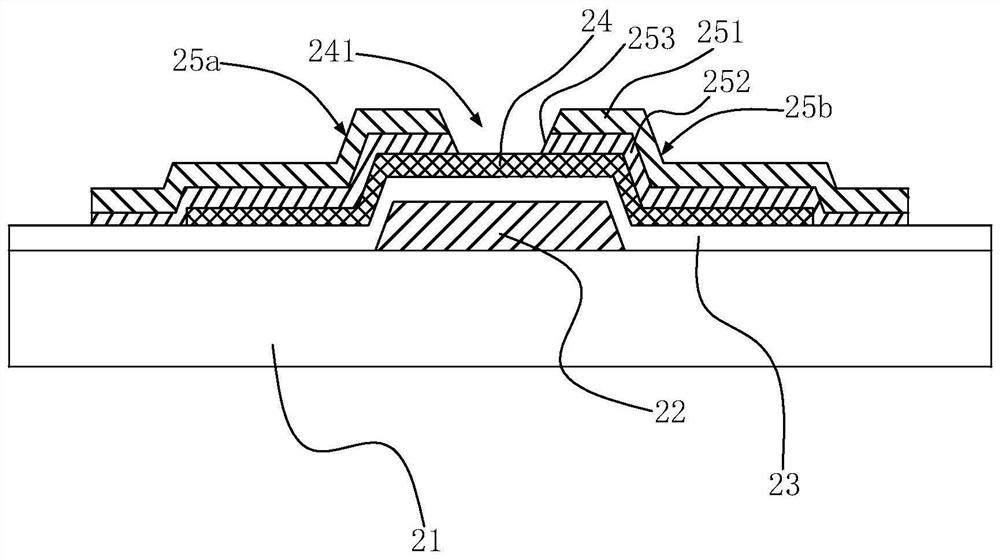

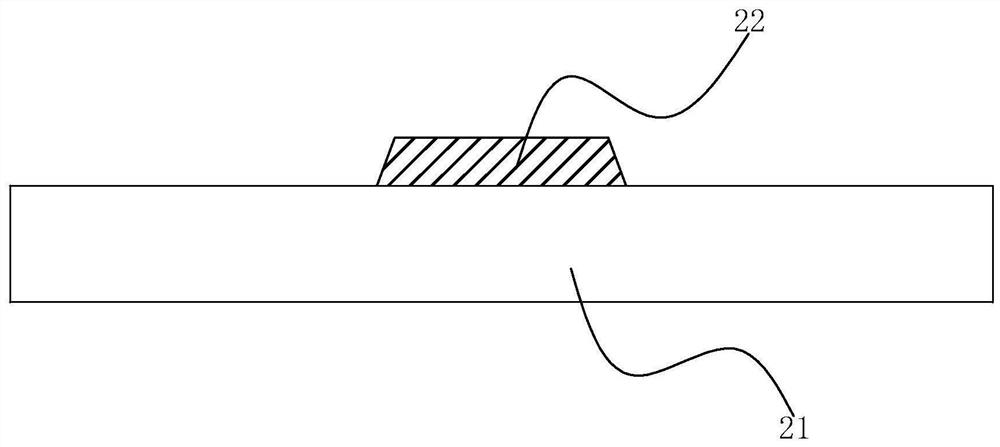

Thin film transistor and manufacturing method thereof

PendingCN112928027AImprove production yieldAvoid the case of etch fractureTransistorSemiconductor/solid-state device manufacturingEtchingThin membrane

The invention provides a thin film transistor and a manufacturing method thereof, and the method comprises the following steps: providing a substrate, and forming a gate electrode on the substrate; depositing a gate electrode insulating layer covering the gate electrode on the substrate; forming an oxide semiconductor layer on the gate electrode insulating layer; continuously depositing a second metal layer and a first metal layer on the oxide semiconductor layer; coating a photoresist on the first metal layer; carrying out first wet etching on the exposed first metal layer by adopting first etching liquid; performing second wet etching on the exposed second metal layer by using a second etching solution; and removing the photoresist. According to the thin film transistor and the manufacturing method thereof provided by the invention, the oxide semiconductor layer can be well protected from being etched by etching liquid, and the problem that the oxide semiconductor layer at the channel is etched off is solved.

Owner:KUSN INFOVISION OPTOELECTRONICS +1

Car front bumper mounting bracket

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com