Patents

Literature

63results about How to "Automatically added" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Message processing method and message processing equipment

ActiveCN104754066ASelf-directed learningAutomatically addedData switching networksDomain nameIp address

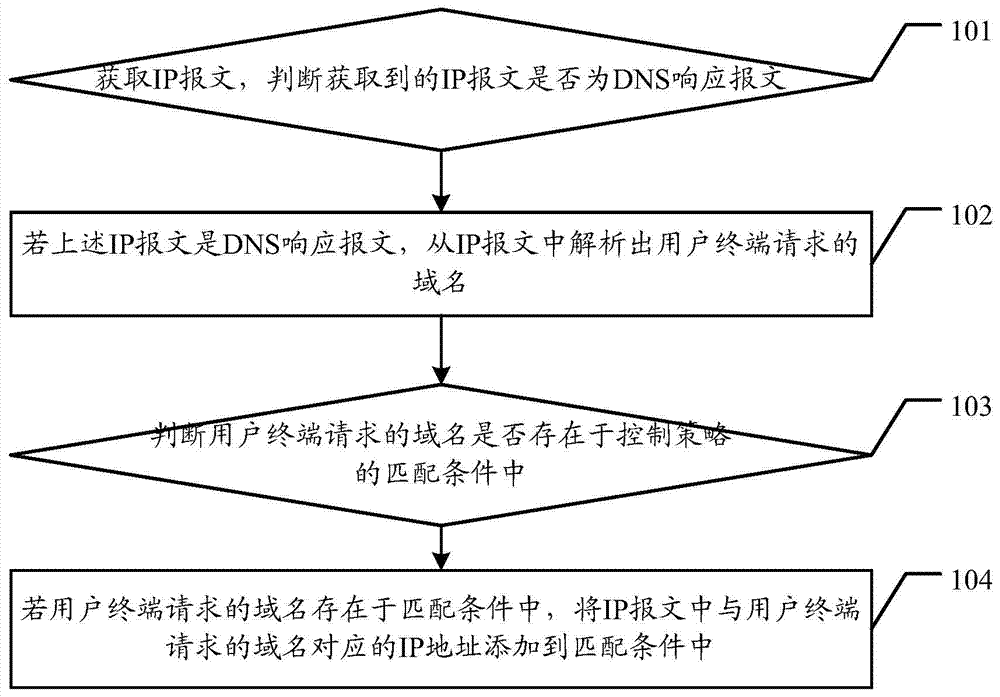

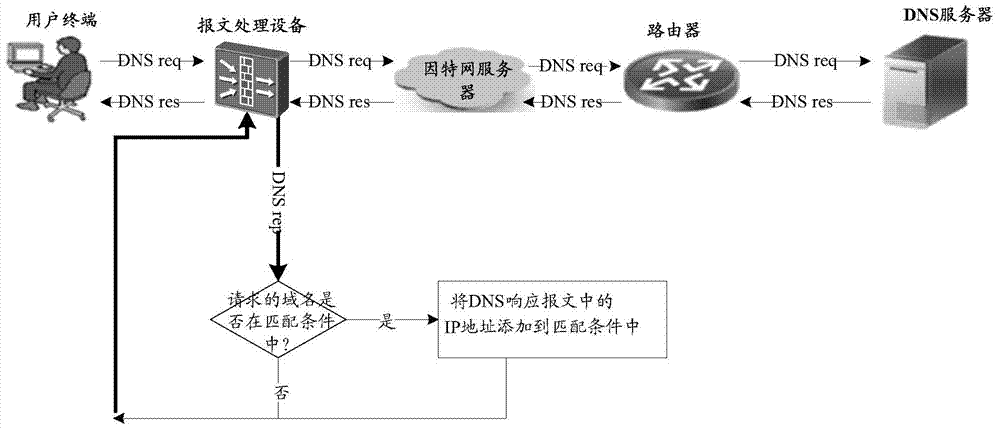

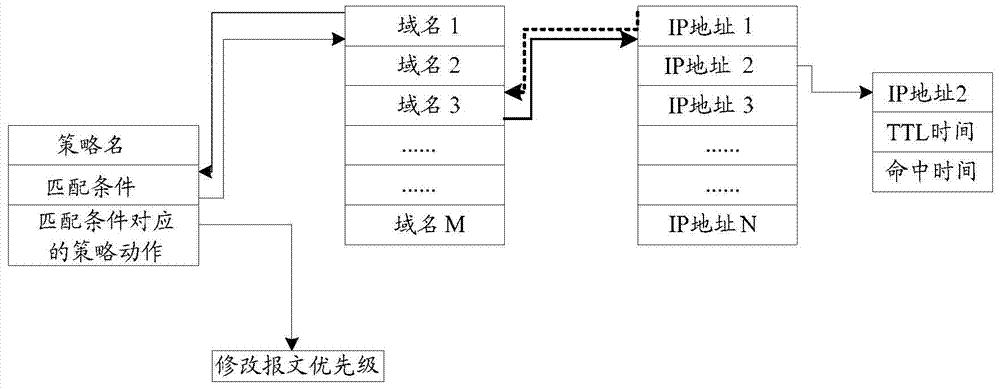

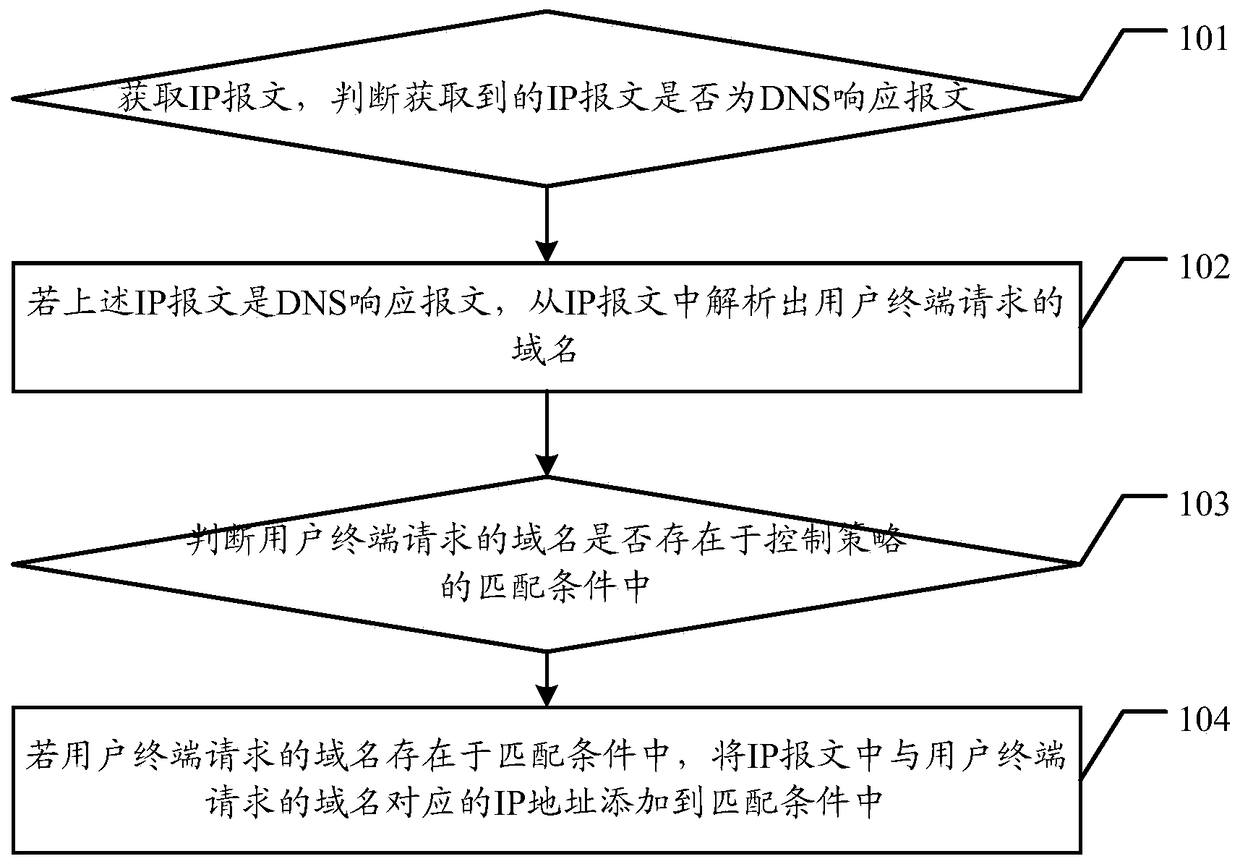

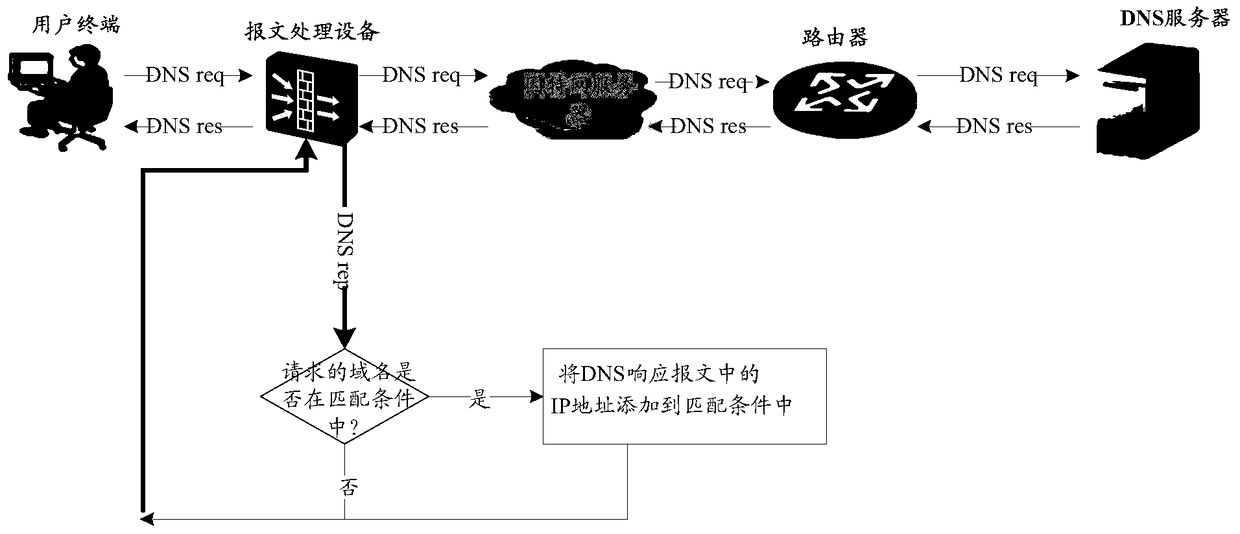

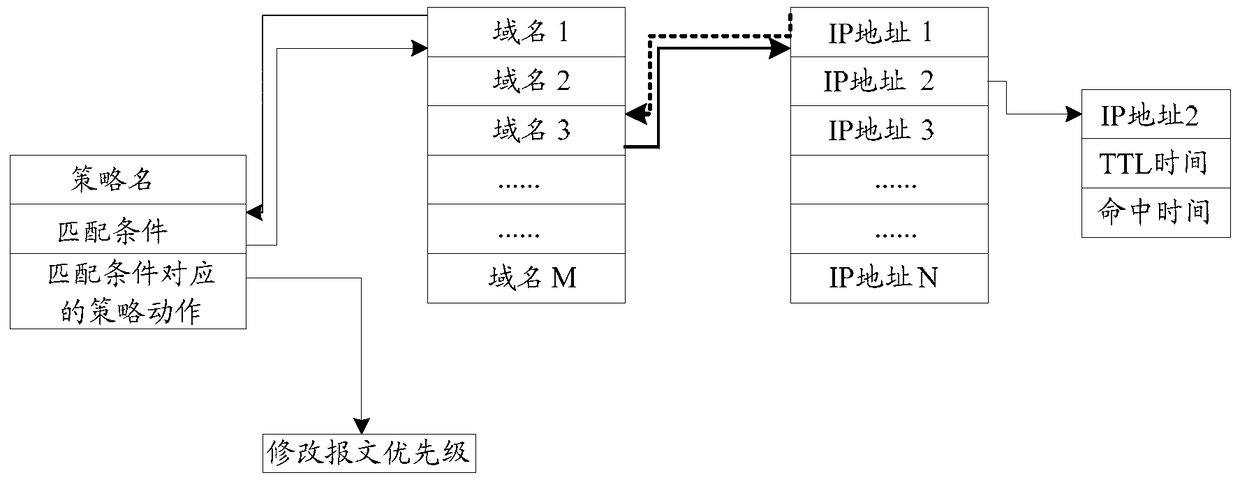

The application discloses a message processing method and message processing equipment, which are used for realizing autonomic learning of IP (Internet Protocol) addresses by a matching condition and are suitable for a plurality of scenes taking message features as a static parameter and a dynamic parameter. According to the embodiment of the invention, the method comprises the following steps: acquiring an IP message, and judging whether or not the acquired IP message is a domain name system (DNS) response message; if the IP message is the DNS response message, resolving a domain name requested by a user terminal from the IP message; judging whether or not the domain name requested by the user terminal exists in the matching condition of a control strategy, wherein the matching condition comprises a domain name needing to perform message control according to the strategy action of the control strategy; and if the domain name requested by the user terminal exists in the matching condition, adding an IP address corresponding to the domain name requested by the user terminal in the IP message into the matching condition in order that the matching condition further comprises the added IP address.

Owner:XFUSION DIGITAL TECH CO LTD

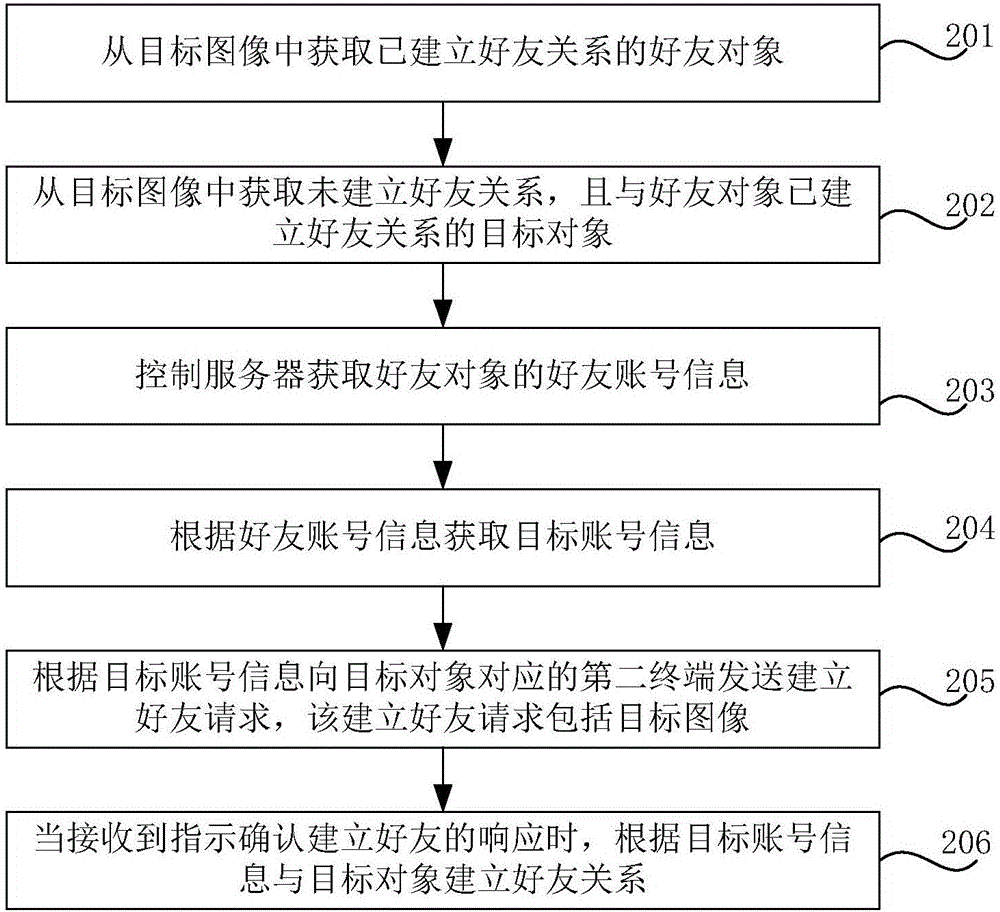

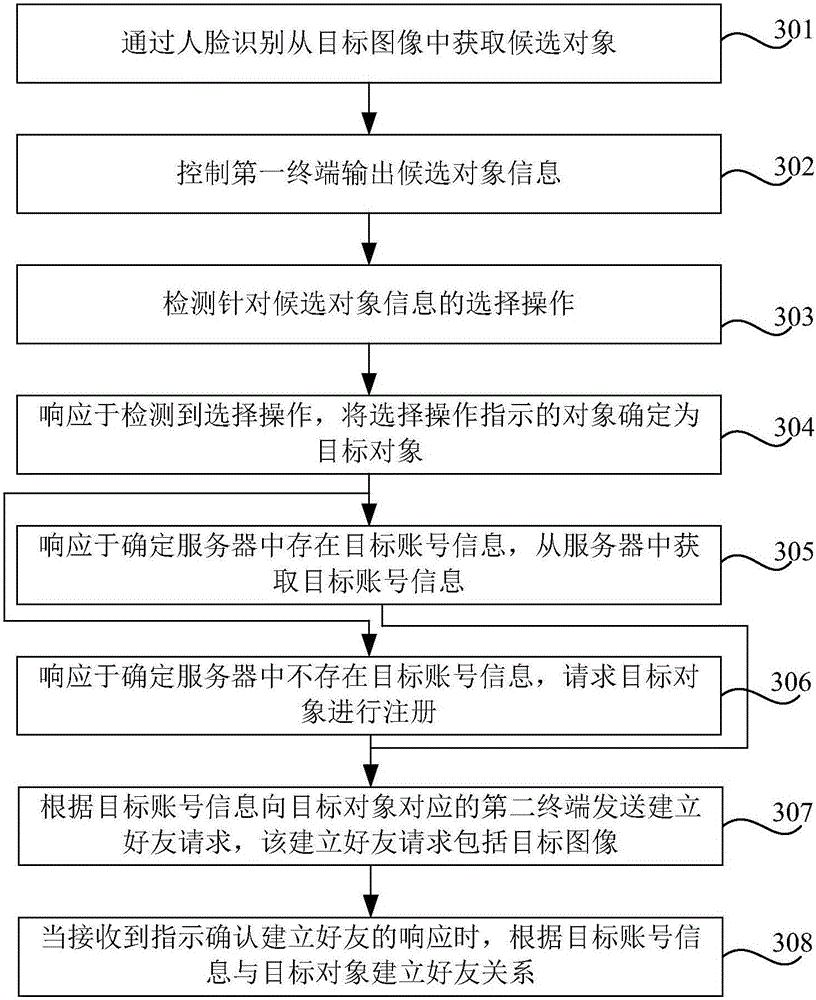

Method and device for adding friend

InactiveCN105847111AImprove user experienceExpand contact informationCharacter and pattern recognitionData switching networksEngineeringData science

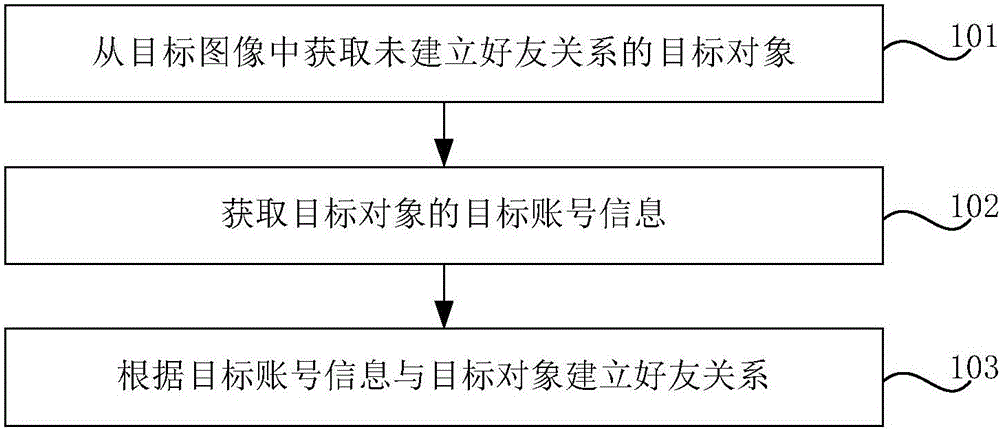

The invention discloses a method and device for adding a friend. The method comprises following steps of obtaining target objects from target images, wherein friend relationship is not established with the target objects; obtaining the target account information of the target objects; and establishing the friend relationship with the target objects according to the target account information. Through application of the embodiment of the method and the device, a server or a terminal can obtain the target account information of the target objects in the images transmitted / received by social network App users, wherein the friend relationship is not established with the target objects; and the friend relationship with the target objects is established according to the target account information. The mode of automatically matching the account information by the images and adding the friends is very convenient; the friends in the group images can be automatically added; the friends of the friends can be added as the friends conveniently and accurately; and the user experience is optimized.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

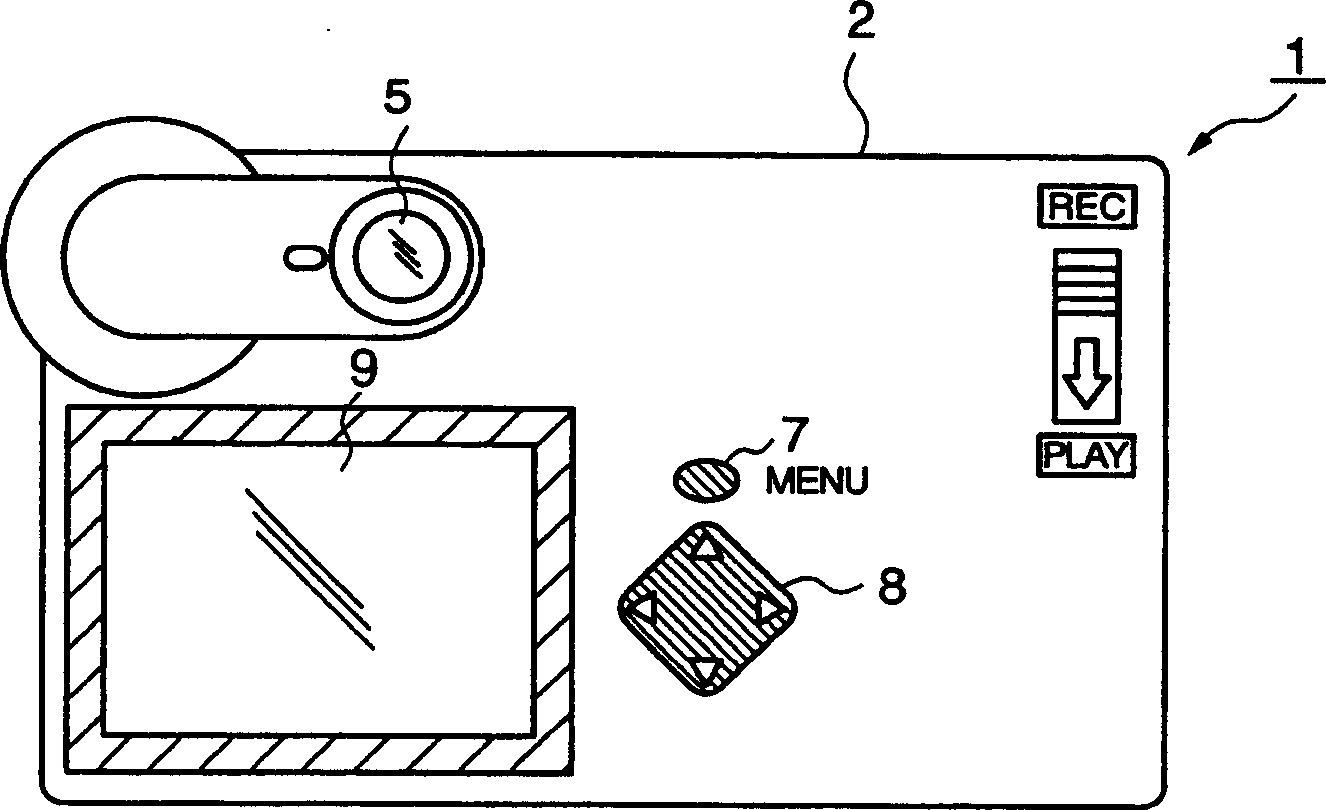

Portable electronic equipment and power supply control method

InactiveCN1536878AAutomatically addedTelevision system detailsVolume/mass flow measurementOperation modePerformed Imaging

A digital camera (1) is provided with a direction sensor (14) which senses a vertical or horizontal direction along a direction of rotation about a predetermined axis of the camera body. When the direction sensor (14) senses that the camera body is changed from a vertically laid state to a horizontally laid state or from a horizontally laid state to a vertical laid state in a power source off state with a predetermined operation mode being set, a control unit (30) switches on the power source. If no operation is made during a short time period after the power source is switched on, the control unit (30) switches off the power source. A user can quickly perform image capturing at a desired timing without having to perform the power source switching on operation, when taking out the digital camera (1) from where it has been put such as a pocket of the clothes.

Owner:CASIO COMPUTER CO LTD

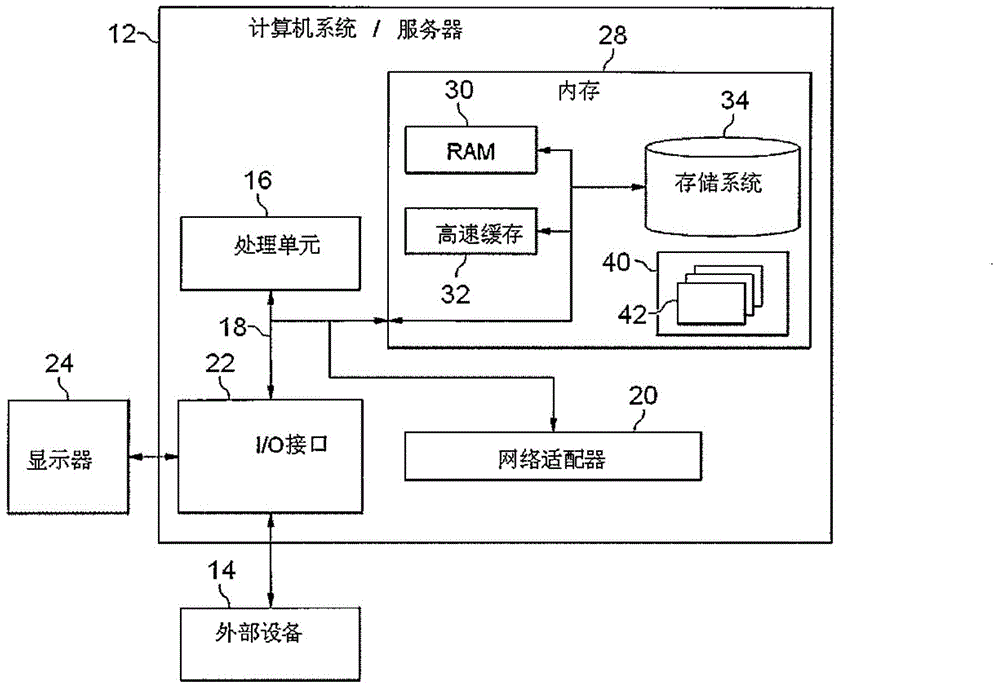

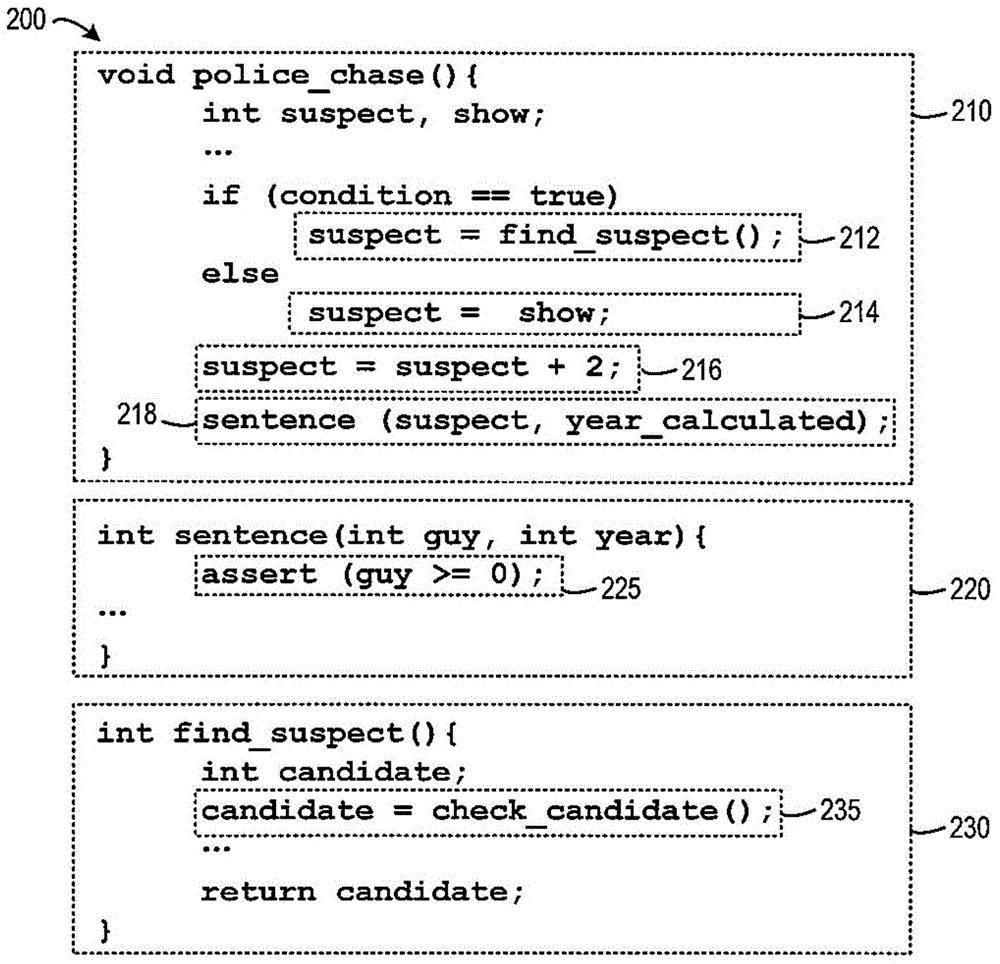

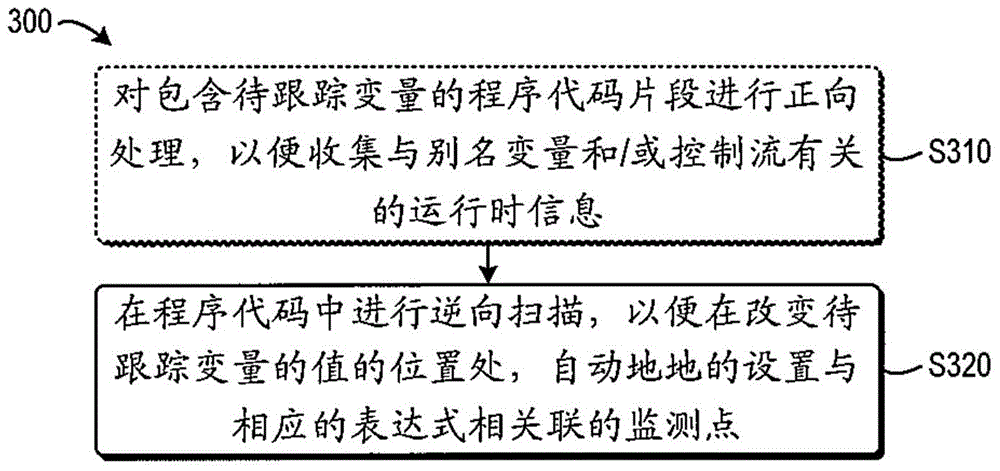

Method and system for variable tracking in program debugging

ActiveCN105701006AAutomatically addedSoftware testing/debuggingTheoretical computer scienceComputer science

The invention relates to a method and a system for variable tracking in program debugging. An embodiment discloses the method for variable tracking in program debugging. The method comprises the steps of determining a to-be-tracked first variable and a to-be-monitored first expression associated with the first variable; performing reverse scanning on a debugged program code to search for an assignment expression used for performing assignment on the first variable; and in response to the found assignment expression, setting a monitoring point associated with the first expression after an assignment statement with the assignment expression to check whether the first expression is satisfied or not. The corresponding system is further described.

Owner:IBM CORP

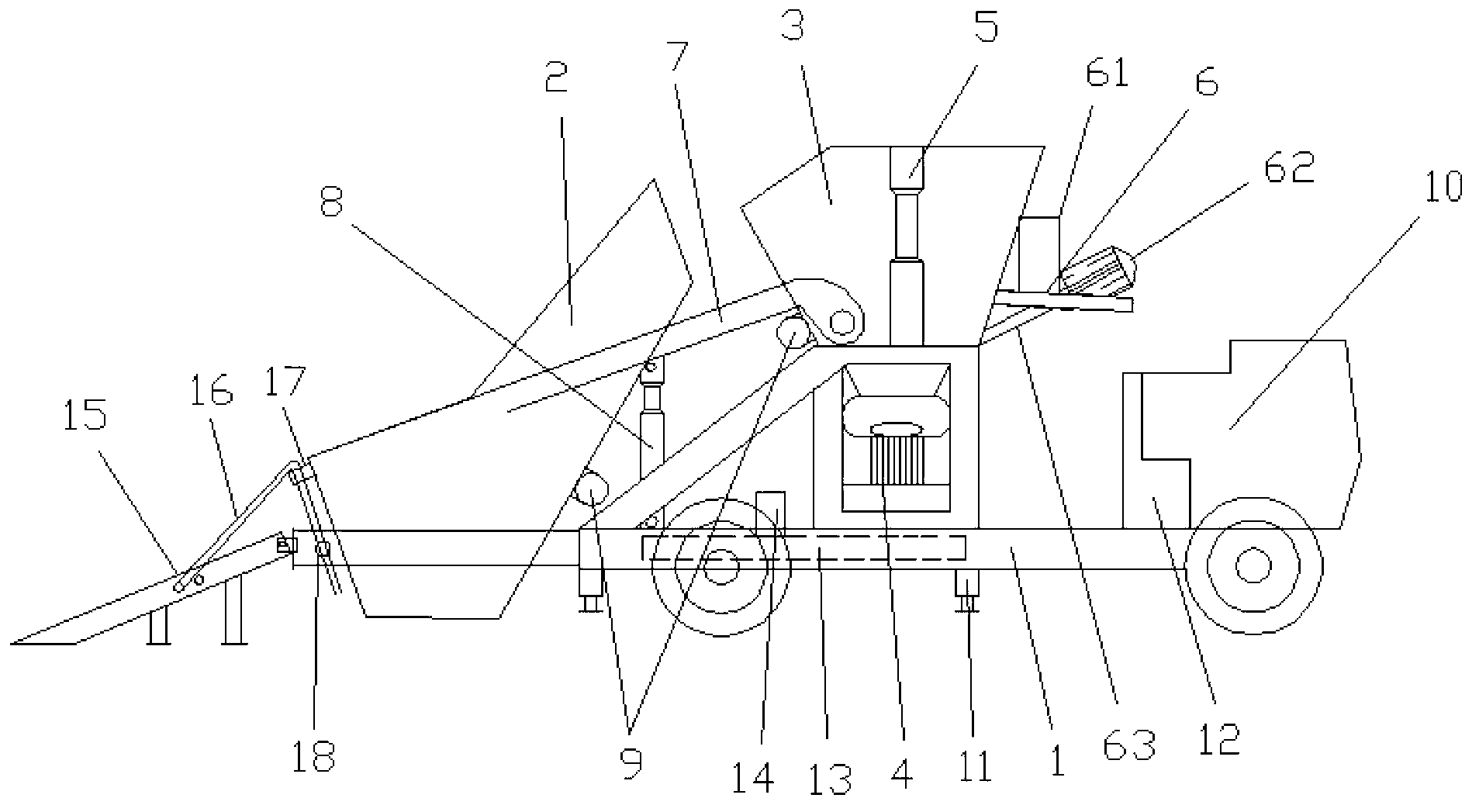

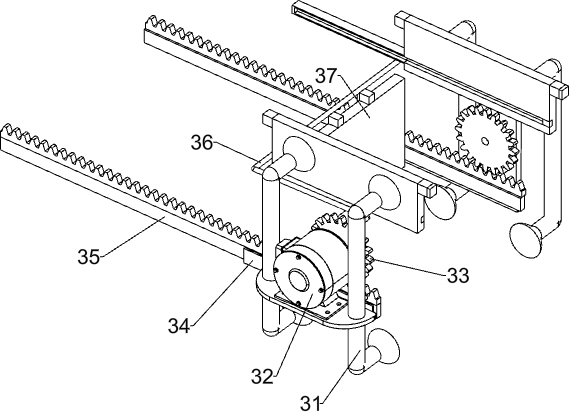

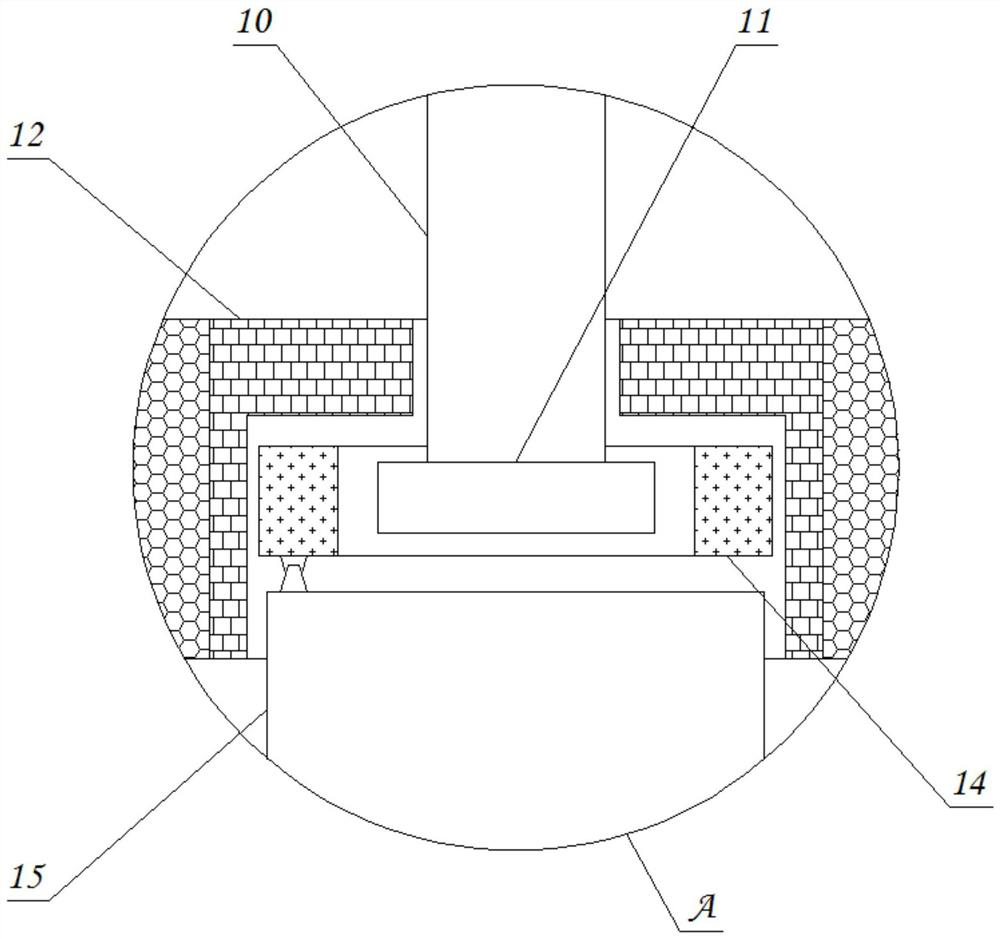

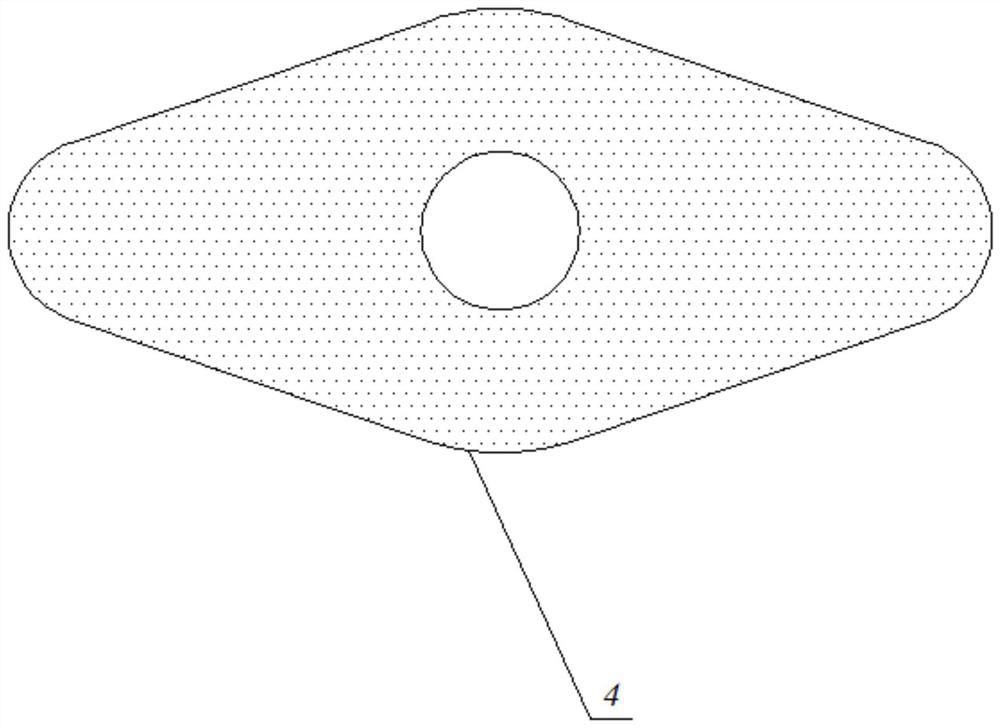

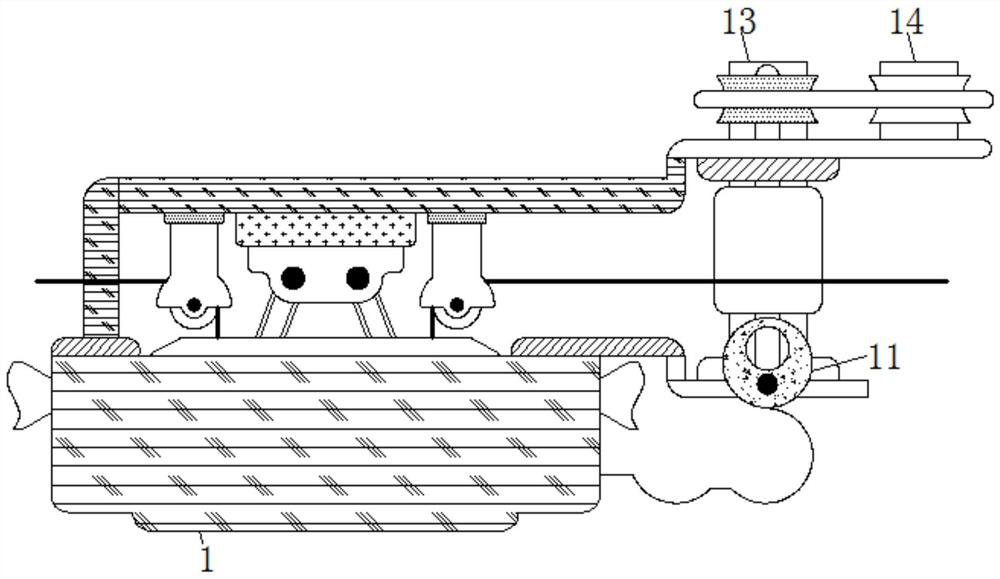

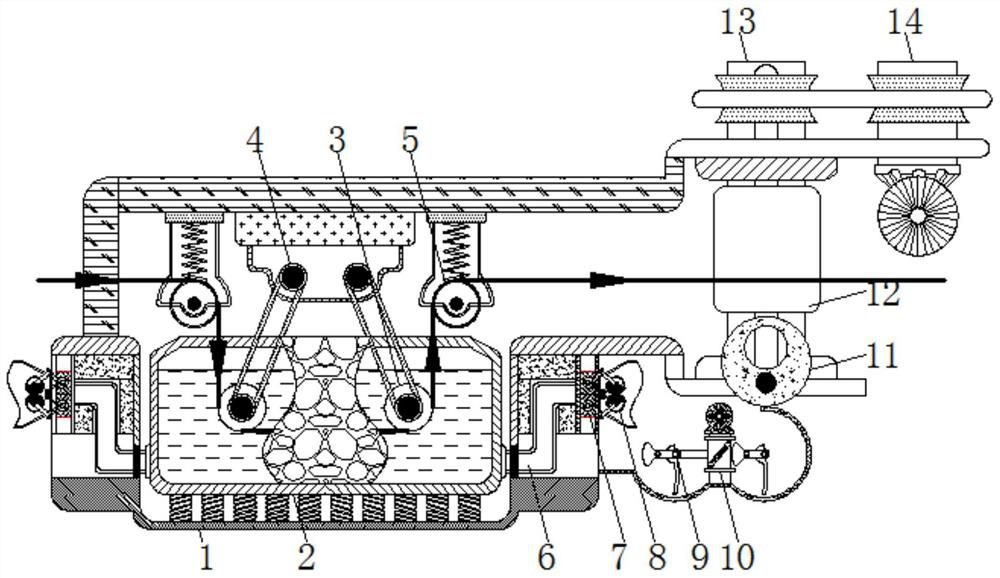

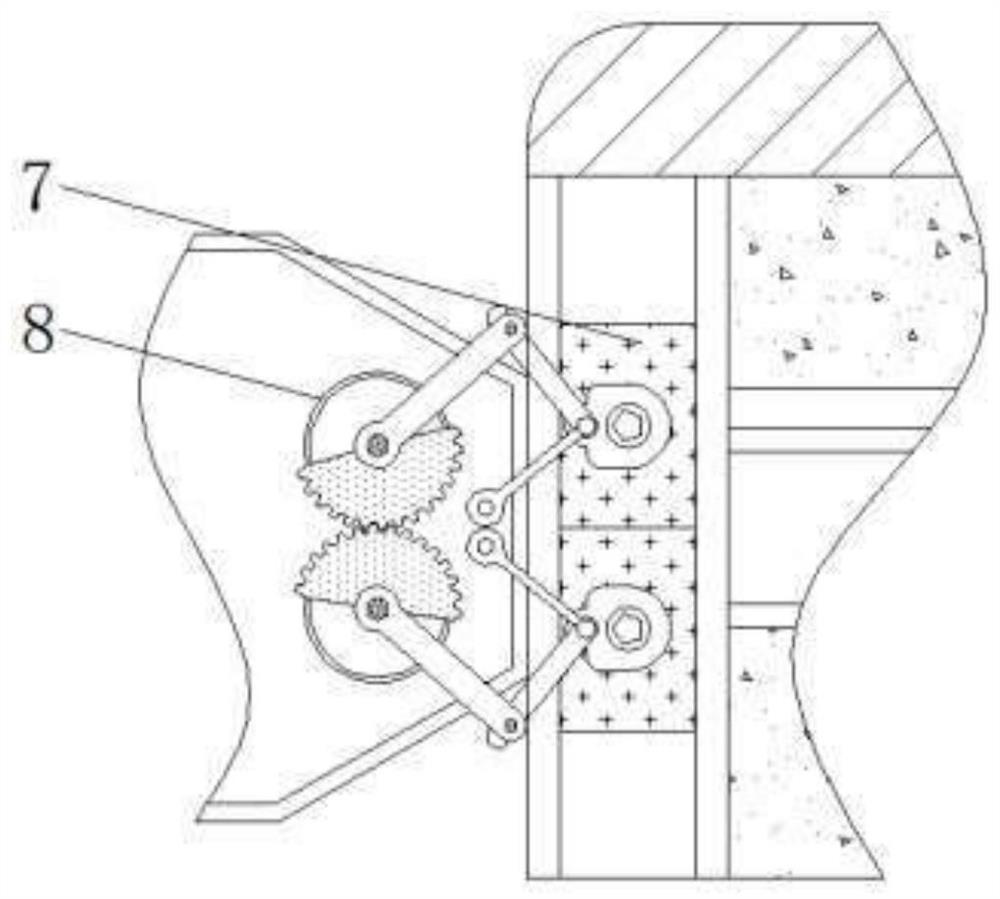

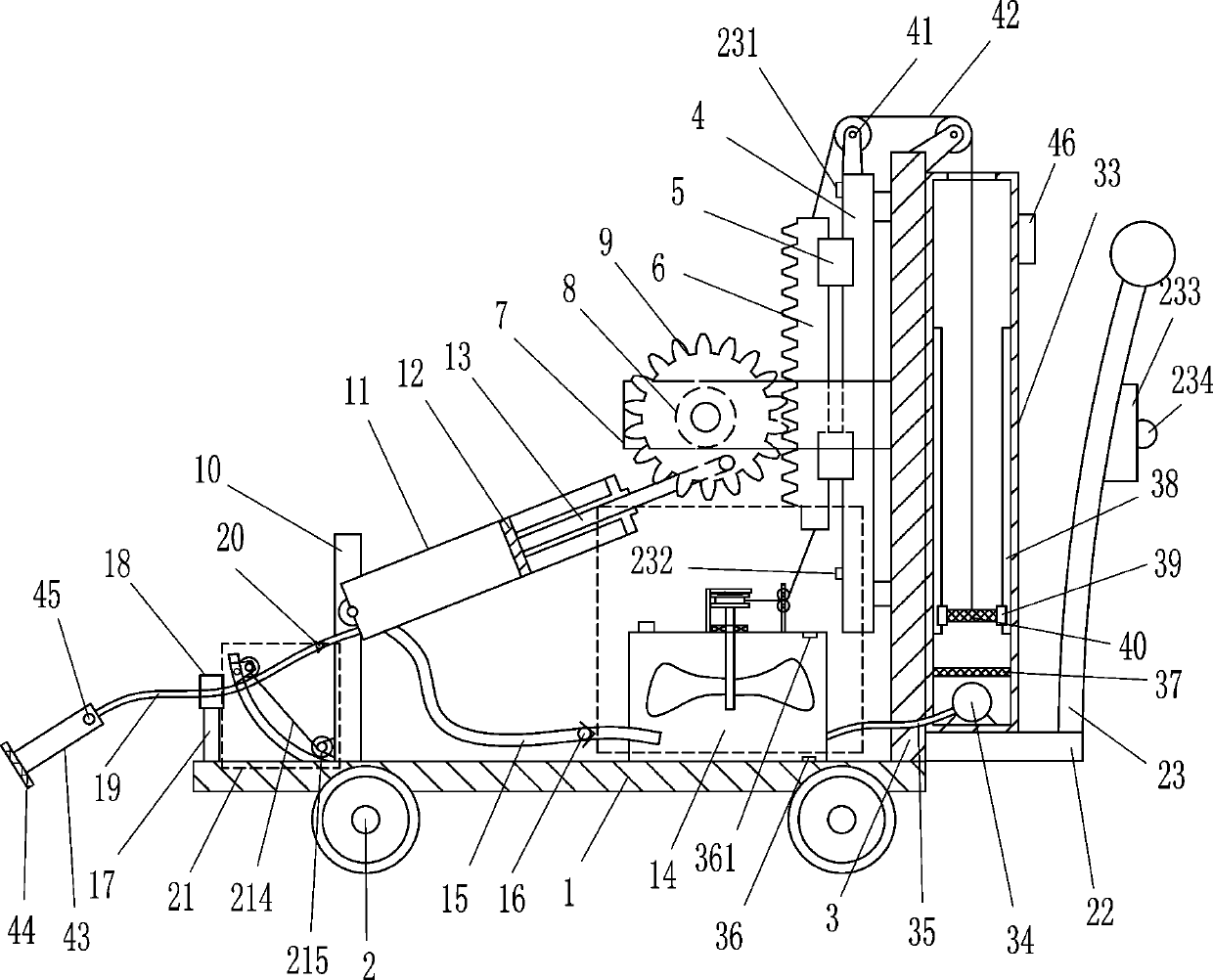

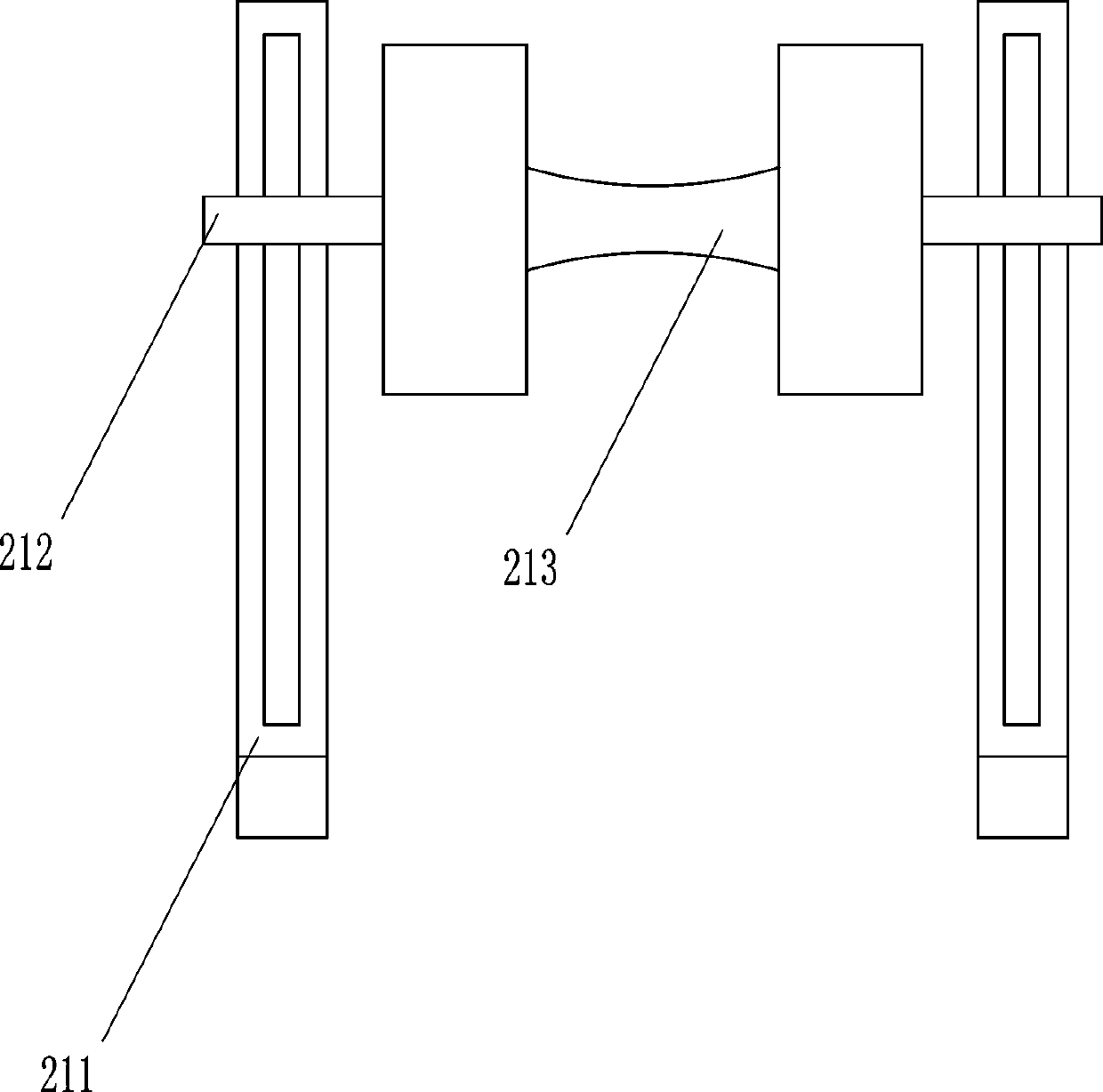

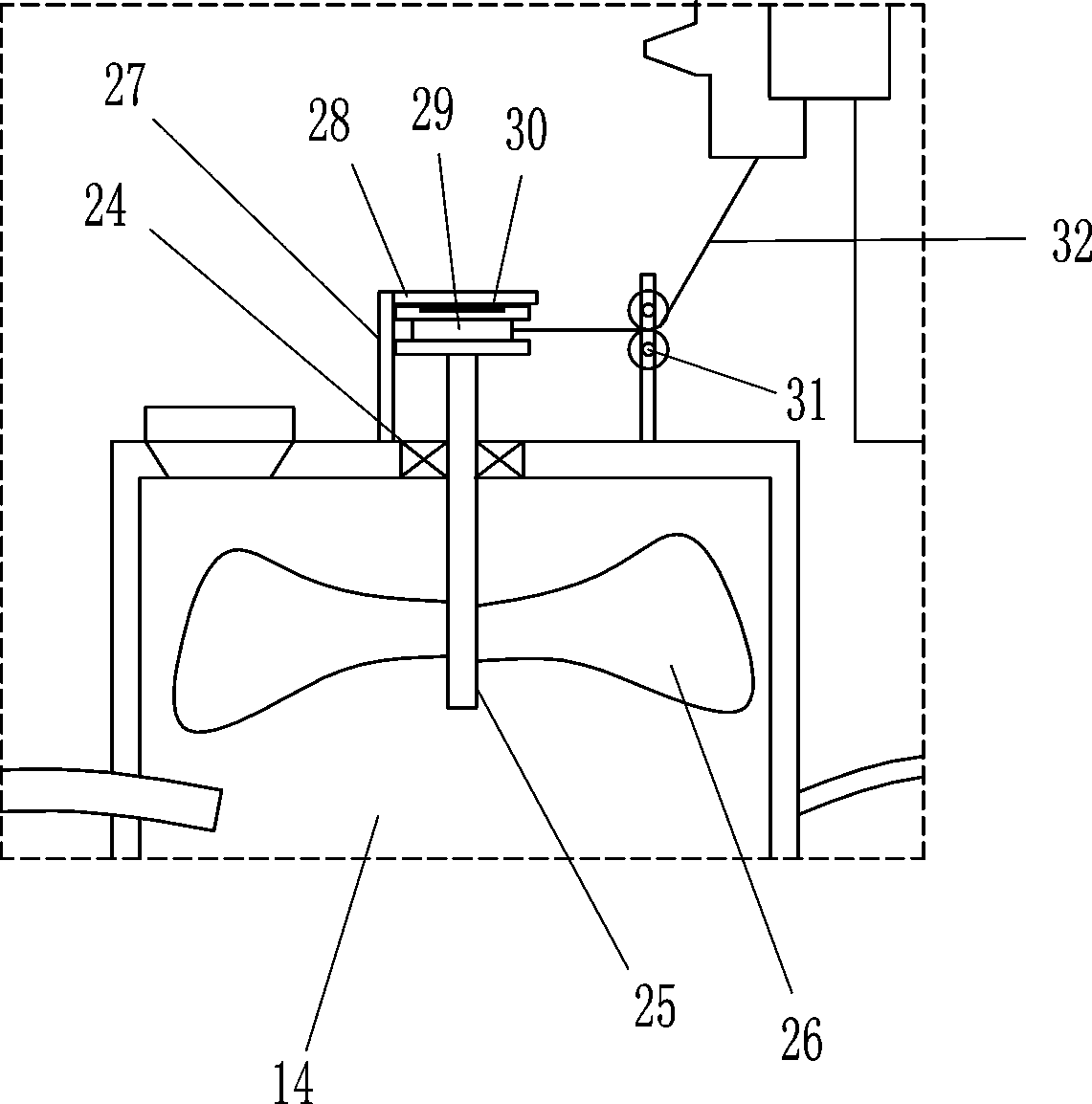

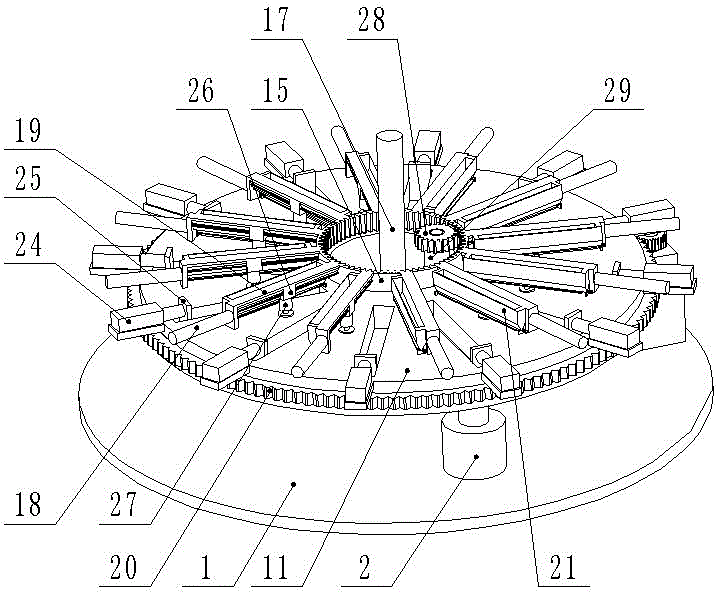

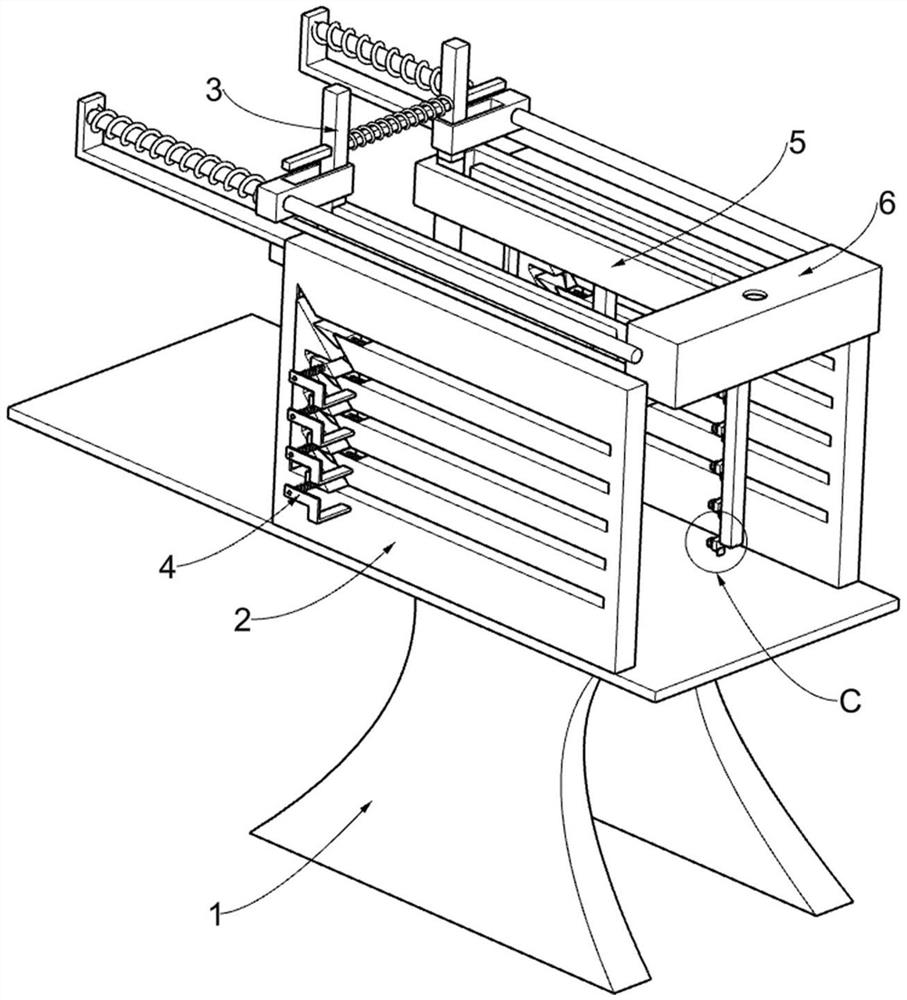

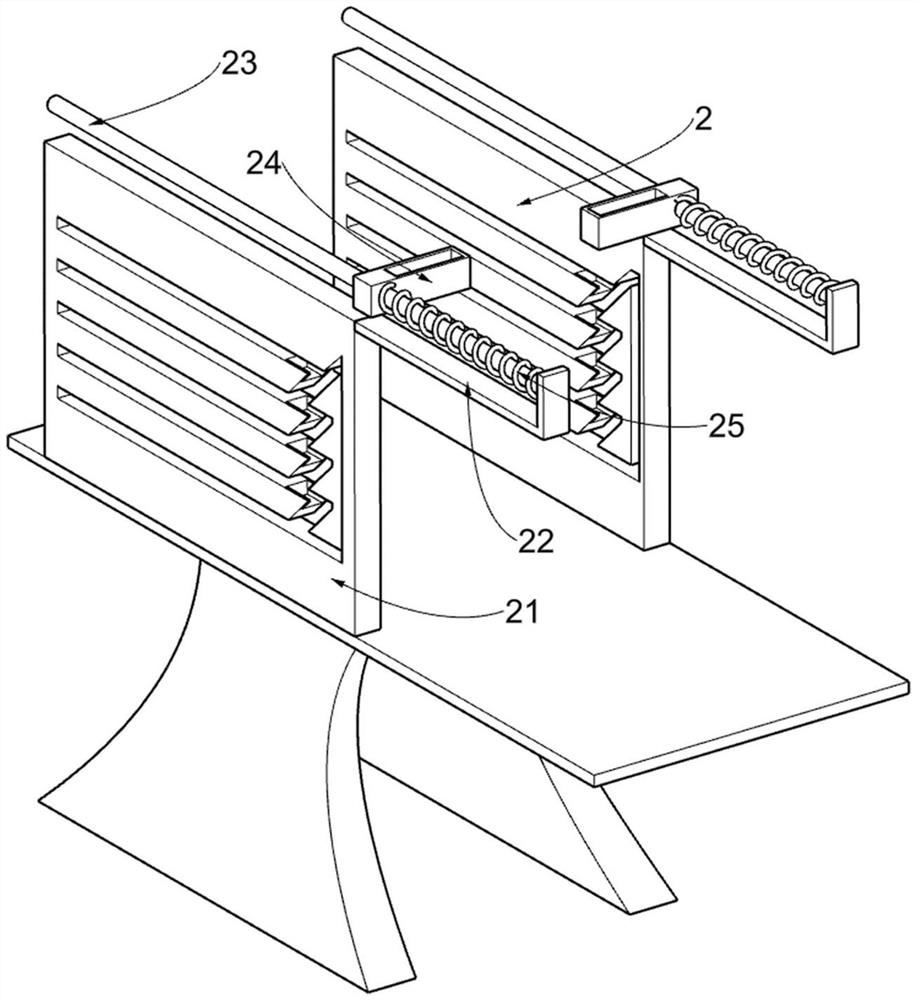

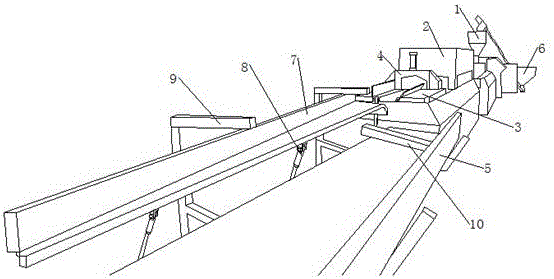

Automatic feeding type concrete spraying trolley

InactiveCN103255922AAutomatically addedReduce labor costsUnderground chambersBuilding material handlingHydraulic cylinderEngineering

The invention discloses an automatic feeding type concrete spraying trolley which comprises a trolley body, a storing bucket, a feeding bucket and a concrete spraying machine, wherein the feeding bucket is hinged to the trolley body, a first hydraulic cylinder is arranged between the feeding bucket and the trolley body, the cylinder body of the first hydraulic cylinder is hinged to the trolley body, a pushing rod of the first hydraulic cylinder is hinged to the feeding bucket, and an automatic flash setting admixture adding device is arranged on the feeding bucket. The automatic feeding type concrete spraying trolley has the advantages that due to the fact that materials and admixtures can be added automatically, labor cost is reduced and working efficiency is improved; the concrete spraying machine is integrated with the trolley, and therefore fast transportation can be achieved; when the first hydraulic cylinder ascends, the feeding bucket inclines backwards to pour remaining materials back into the storing bucket, and a larger operating space is provided for replacement and maintenance of the concrete spraying machine.

Owner:杨斌

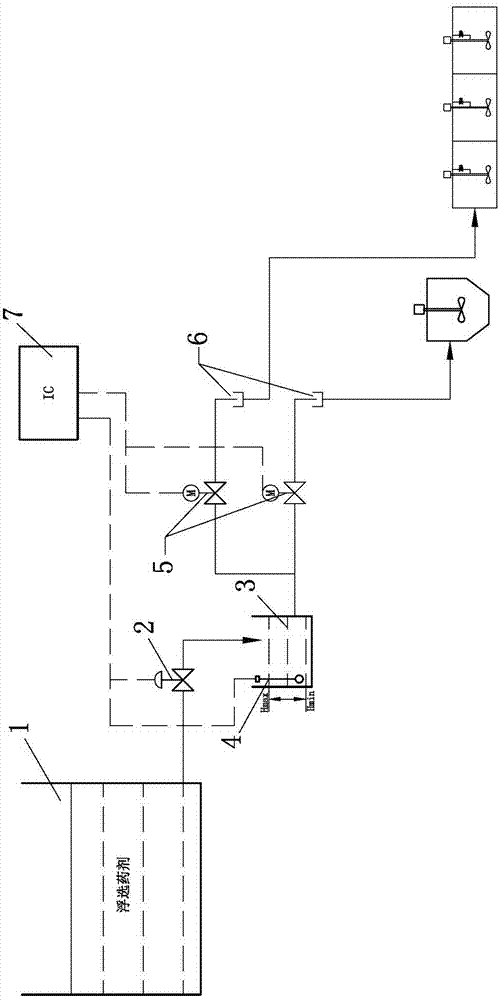

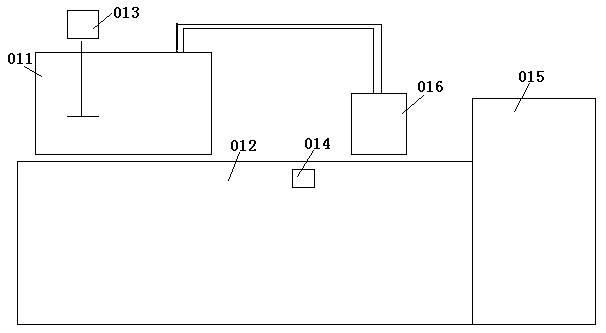

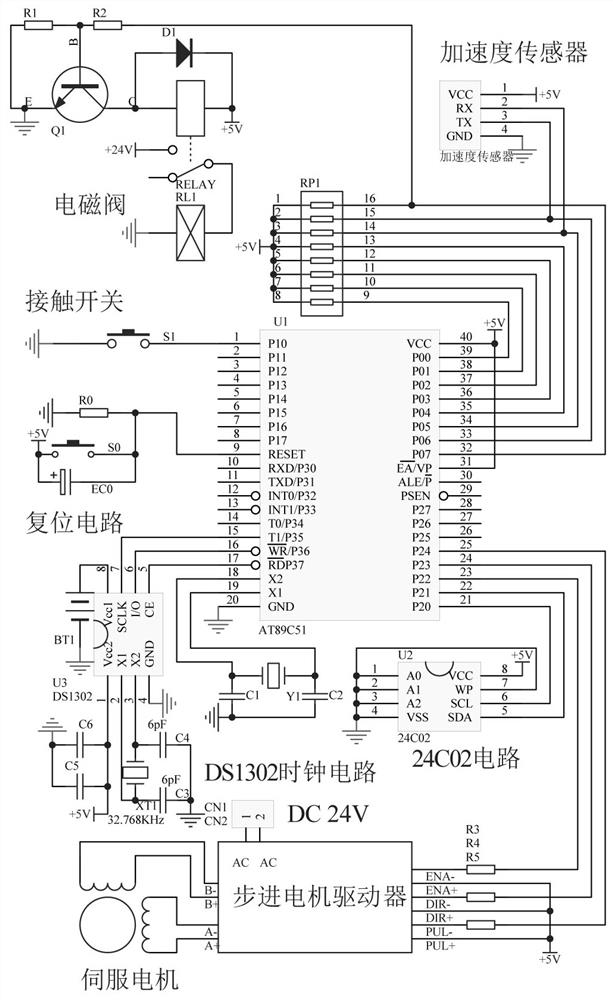

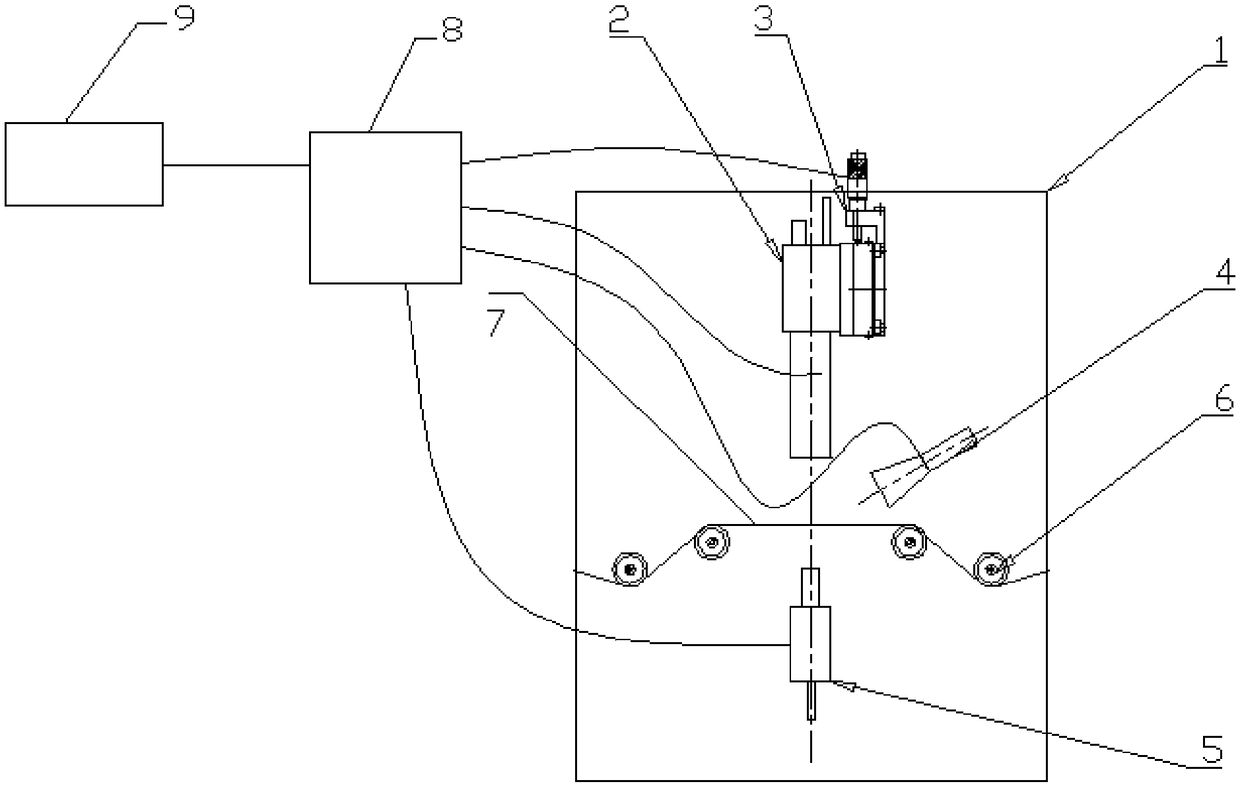

Intelligent flotation medicine quantitative adding system

InactiveCN105446401APrecise control of drug dosageLess dosageSimultaneous control of multiple variablesManual medicineBiomedical engineering

The invention provides an intelligent flotation medicine quantitative adding system. The system comprises a high-position medicine box, a solenoid valve, a low-position medicine box, a liquid level meter, an electric adjusting valve, a medicine buffer and an intelligent controller, wherein the high-position medicine box communicates with a pipeline to the low-position medicine box through the solenoid valve, the liquid level meter is arranged in the low-position medicine box for detecting high and low liquid level restrictions of floatation medicine, the bottom of the low-position medicine box communicates with the medicine buffer downstream through the electric adjusting valve and the pipeline, the medicine buffer communicates with a pulp pretreatment and flotation system through the pipeline, and the solenoid valve, the liquid level meter and the electric adjusting valve are connected with the intelligent controller through a wired mode. The intelligent flotation medicine quantitative adding system has the advantages of automatic real-time addition of the medicine in a flotation process, accurate dosage control and smaller medicine amount, at the same time, effectively solves the defects of poor accuracy, lagged reaction and the like of a conventional manual medicine adding mechanism, and guarantees qualified floatation product indexes.

Owner:TIANJIN MEITENG TECH CO LTD

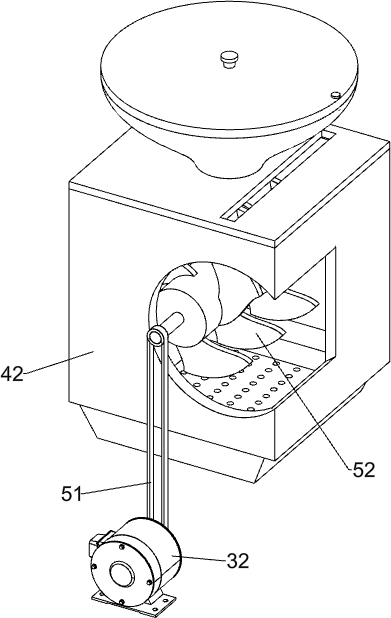

Municipal sludge dewatering and recycling device

InactiveCN112010524AAutomatically put downPrevent solidificationSludge treatmentProcess engineeringDewatered sludge

The invention relates to a recycling device, in particular to a municipal sludge dewatering and recycling device. According to the municipal sludge dewatering and recycling device, dewatered sludge can be conveniently taken out, and sludge can be automatically added for dewatering. The municipal sludge dewatering and recycling device comprises a bracket; a dewatering container which is arranged onthe bracket and is used for dewatering the sludge; an extrusion assembly which is arranged on the dehydration container and is used for dehydrating in an extrusion manner; and a discharging assemblywhich is mounted on the extrusion assembly and used for discharging the sludge in a sliding manner. With cooperation of the dewatering container and the extrusion assembly, sludge can be dewatered, meanwhile, dewatered sludge can be automatically discharged, the equipment is very convenient to use; with application of the discharging assembly, when the sludge is dewatered, falling of the sludge can be stopped, and after the sludge is dewatered, the sludge can be automatically discharged.

Owner:高超

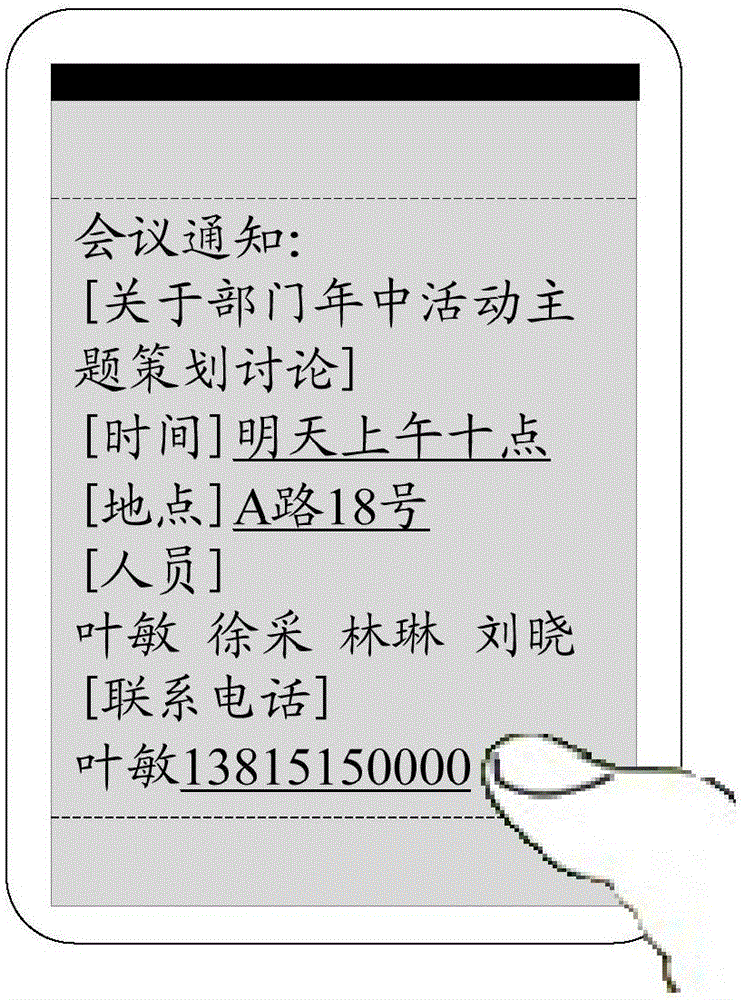

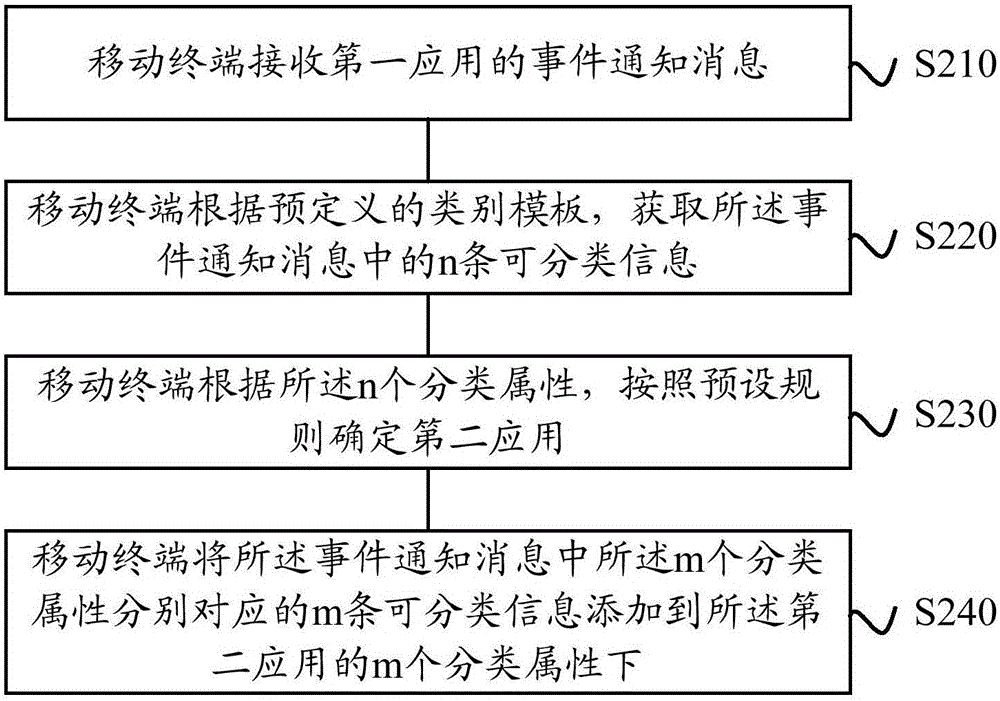

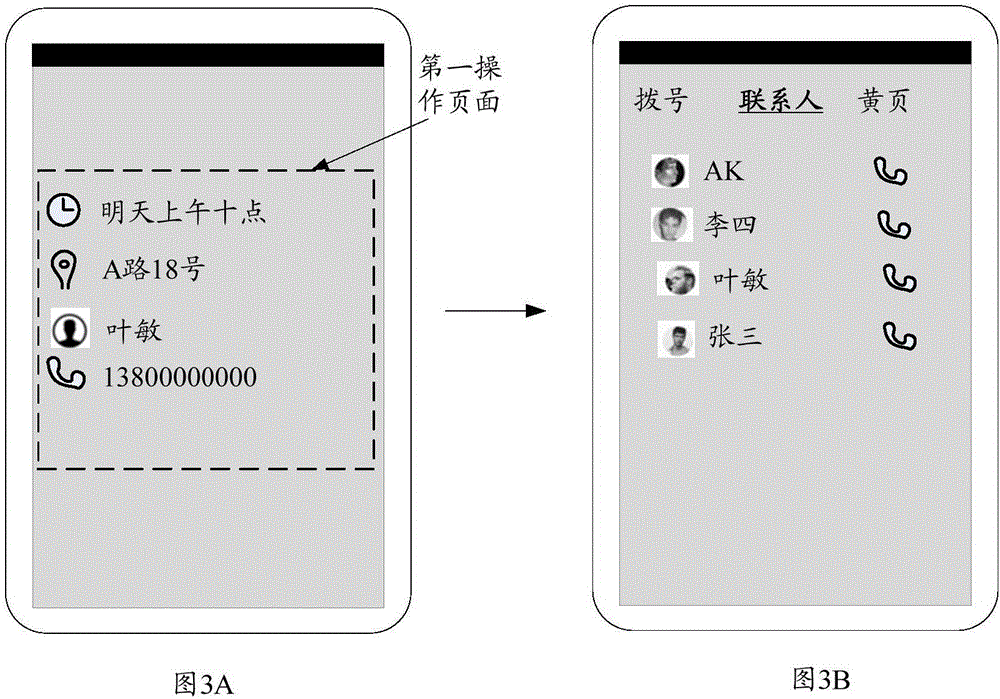

Mobile terminal and method for acquiring event information on mobile terminal

ActiveCN106686240AAutomatically addedImprove adding efficiencyInterprogram communicationServices signallingComputer terminalReal-time computing

Owner:HUAWEI MACHINERY

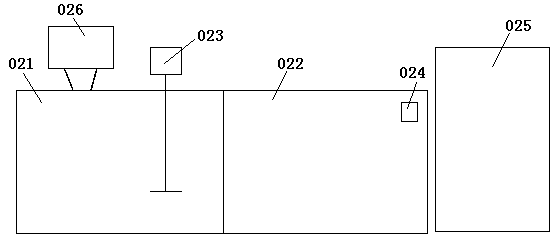

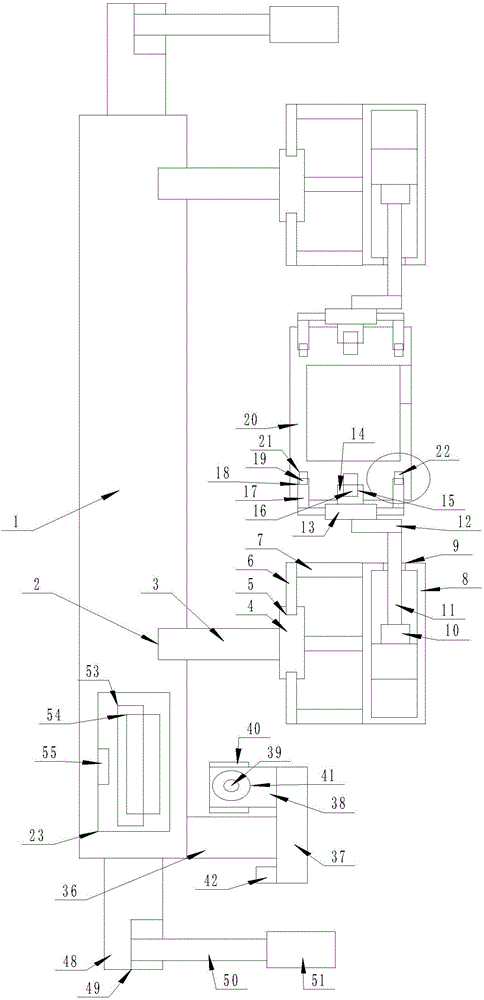

Coal preparation plant slime water intelligent dosing system and dosing method

PendingCN111470583AReduce lossDosage controlWater/sewage treatment by ion-exchangeProcess engineeringEnvironmental engineering

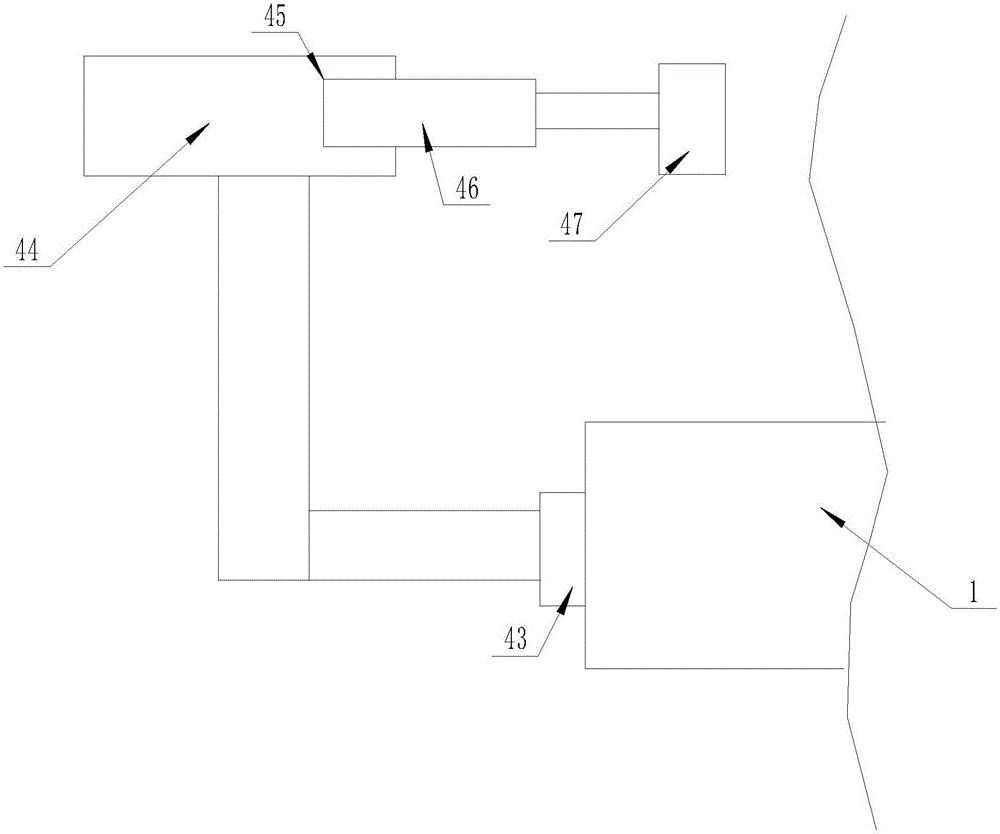

The invention relates to a coal preparation plant slime water intelligent dosing system and dosing method, and belongs to the technical field of coal washing. According to the system, one end of a No.1 slime water feeding pipeline is connected with a concentration tank, and the other end of the No.1 slime water feeding pipeline is connected with a protection box; one end of a first cation dosing pipeline is connected with cation dosing equipment, and the other end of the first cation dosing pipeline is connected with a protection box; one end of a first anion dosing pipeline is connected withanion dosing equipment, and the other end of the first anion dosing pipeline is connected with a first slime water feeding pipeline; one end of a second anion dosing pipeline is connected with the first anion dosing pipeline, and the other end of the second anion dosing pipeline is connected with the first slime water feeding pipeline; one end of a third anionic dosing pipeline is connected with the first anionic dosing pipeline, the other end of the third anionic dosing pipeline is connected with the concentration tank, one end of the second slime water feeding pipeline is connected with theanionic dosing equipment, and the other end of the second slime water feeding pipeline is connected with the cationic dosing equipment.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

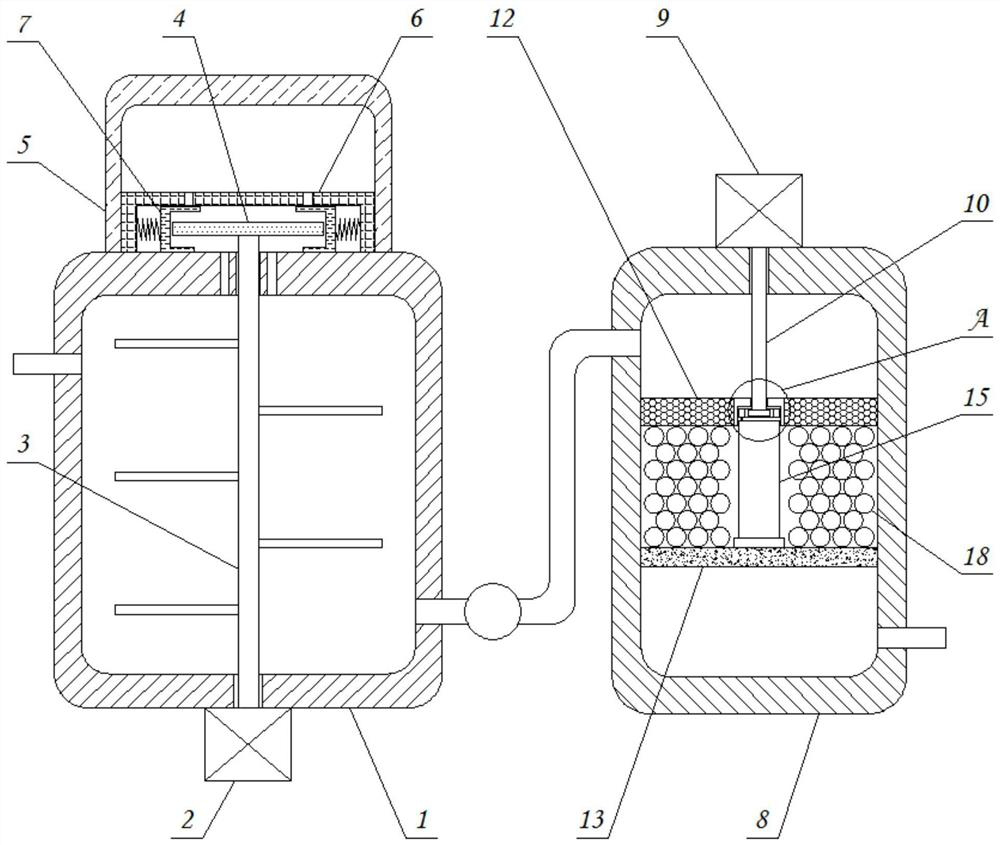

Efficient sewage treatment device capable of automatically adding chemicals

InactiveCN112158991AImprove processing efficiencyReduce workloadMultistage water/sewage treatmentWater/sewage treatment apparatusElectric machinerySewage treatment

The invention relates to the technical field of water treatment environmental protection equipment, and discloses an efficient sewage treatment device capable of automatically adding chemicals, wherien the efficient sewage treatment device comprises a stirring box, wherein the bottom of the stirring box is fixedly connected with a first motor, the top of the first motor is rotatably connected witha stirring rod, and the top of the stirring rod is fixedly connected with a cam; a medicine storage box is fixedly connected to the top of the stirring box, a medicine dispensing box is fixedly connected to the interior of the medicine storage box, two U-shaped plates are movably connected to the interior of the medicine dispensing box, an adsorption box is arranged on the right side of the stirring box, a second motor is fixedly connected to the top of the adsorption box, and a rotating shaft is rotatably connected to the bottom of the second motor. Through cooperation of a first motor, a stirring rod, a cam and two U-shaped plates, a medicament in the dispensing box falls into the stirring box through a medicament outlet hole, so that the effect that a proper amount of medicament in thedispensing box automatically enters the stirring box during stirring is achieved, manpower is saved, and the dosage of the added medicament is more accurate.

Owner:聂燕玲

Enameled wire lubricating liquid coating device with automatic lubricating liquid adding and uniform winding functions

InactiveCN112916303AAvoid breakingEven windingLiquid surface applicatorsCoatingsComposite materialManufacturing engineering

The invention relates to the technical field of enameled wires, and discloses an enameled wire lubricating liquid coating device with automatic lubricating liquid adding and uniform winding functions. Through cooperative use of liquid conveying pipes, baffles and first gears, in the process of coating the enameled wires with lubricating liquid, the lubricating liquid can be automatically added along with use of the lubricating liquid, and manual regular adding is not needed, so that more time and effort are saved; through cooperative use of a first limiting wheel, a second limiting wheel and third limiting wheels, in the lubricating liquid coating process, sufficient tension can be guaranteed, and buffering can be achieved through movement of the third limiting wheels when the enameled wires are pulled, so that the enameled wires are prevented from being broken; and through cooperative use of an eccentric wheel, a winding roller, a first rotating shaft and a second rotating shaft, the enameled wires coated with the lubricating liquid are automatically wound, and the winding roller moves up and down during winding, so that winding is more uniform, and knotting caused by mutual winding during winding is avoided.

Owner:嘉兴民创贸易有限公司

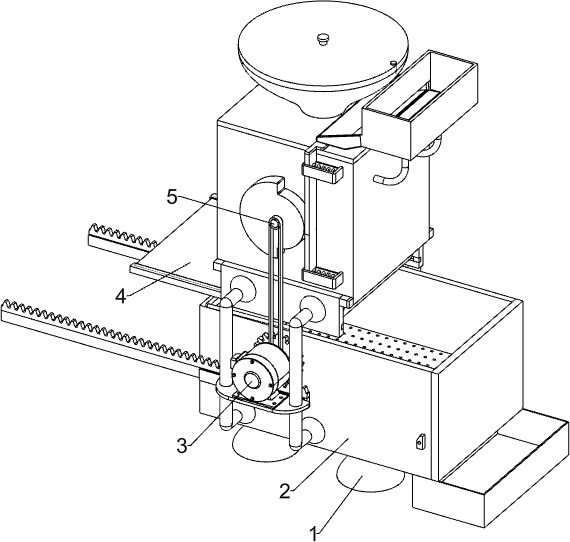

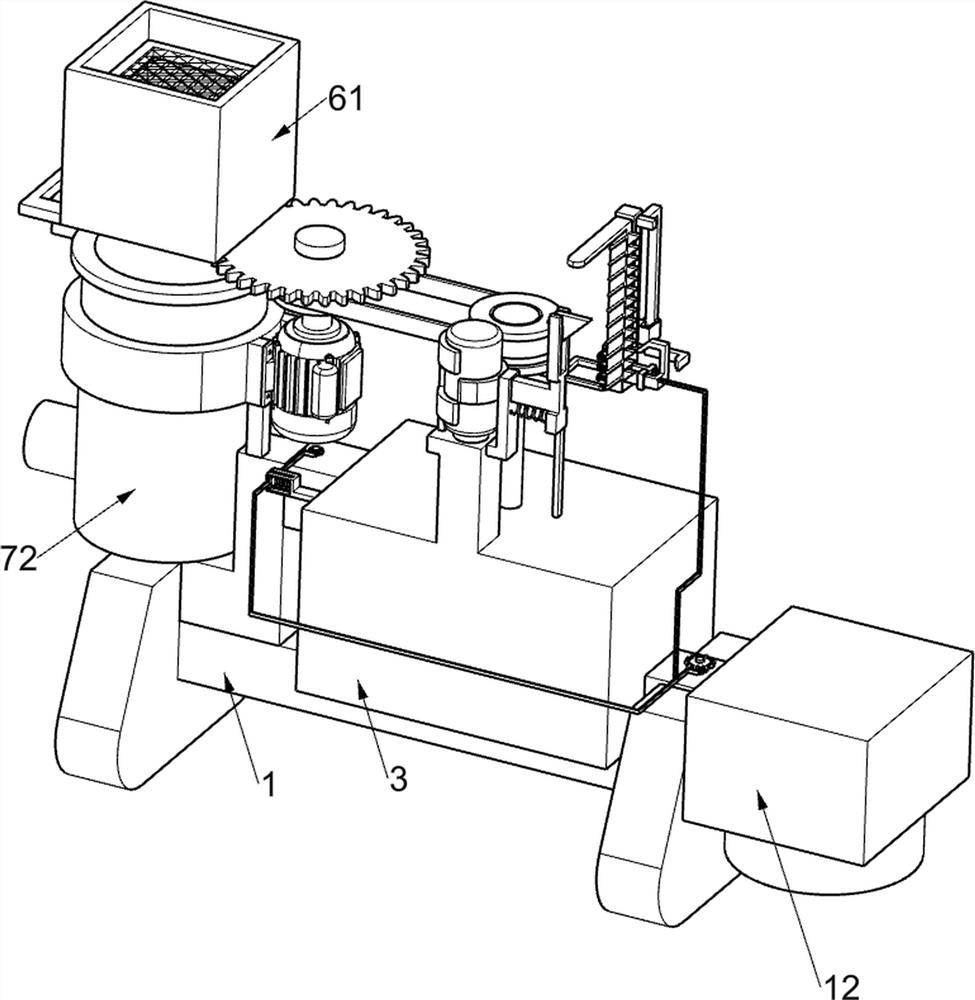

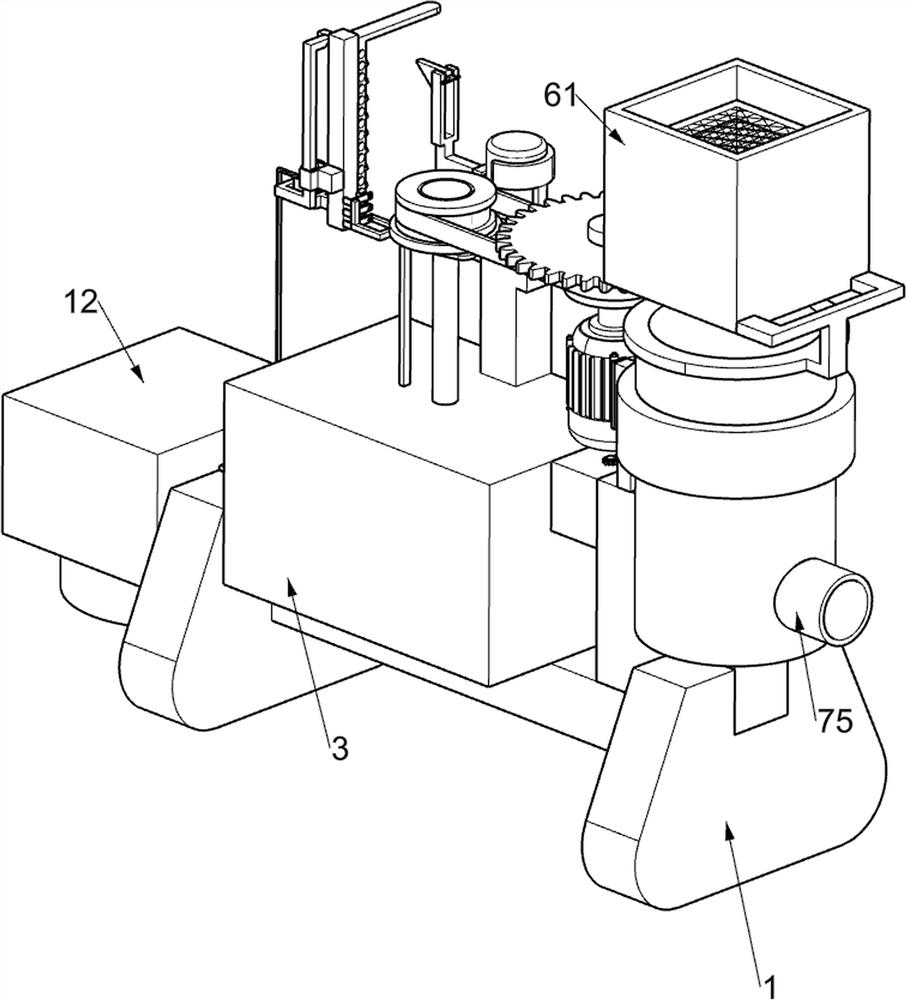

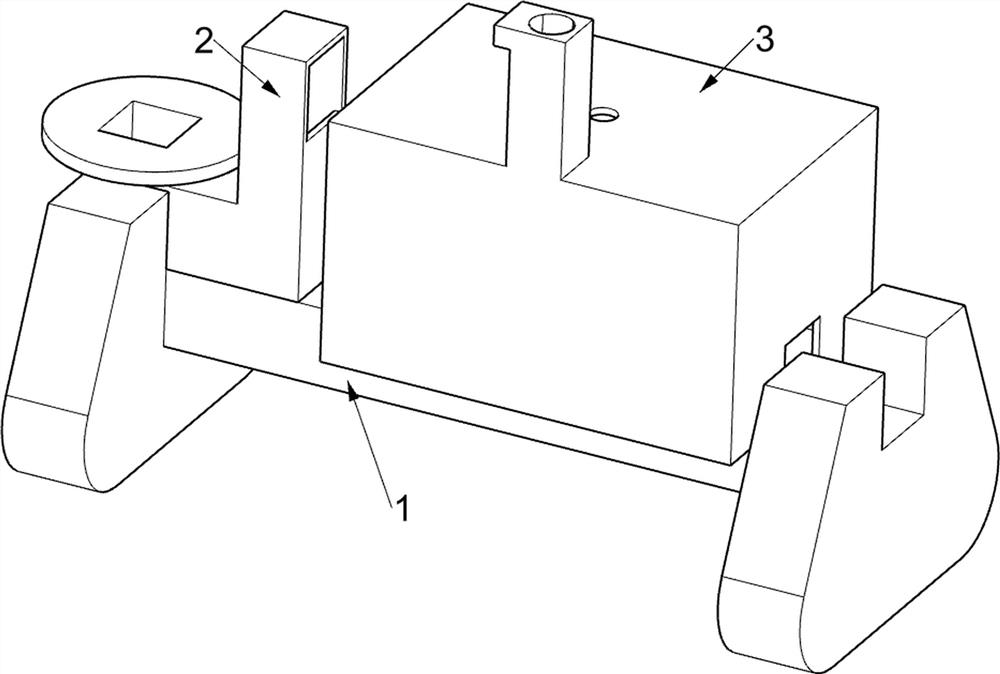

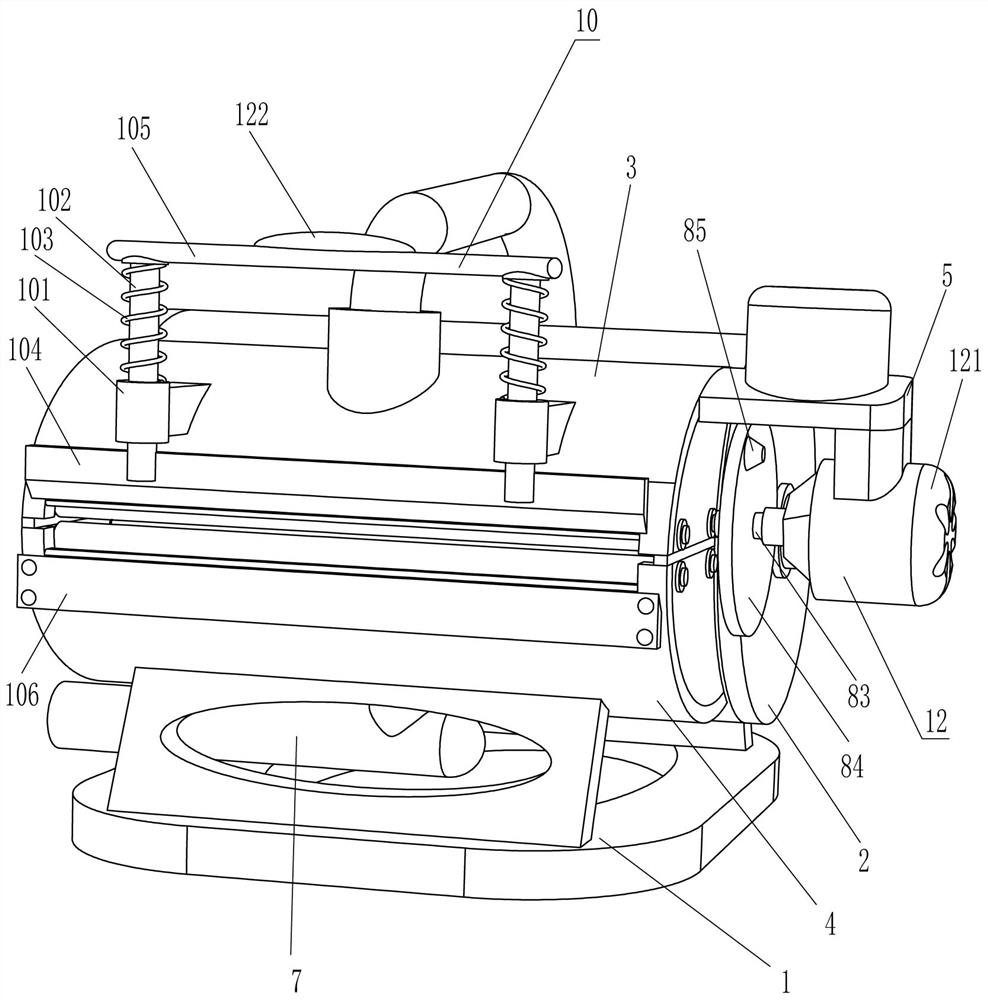

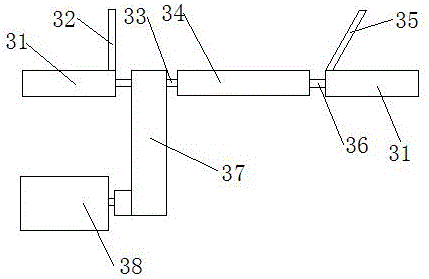

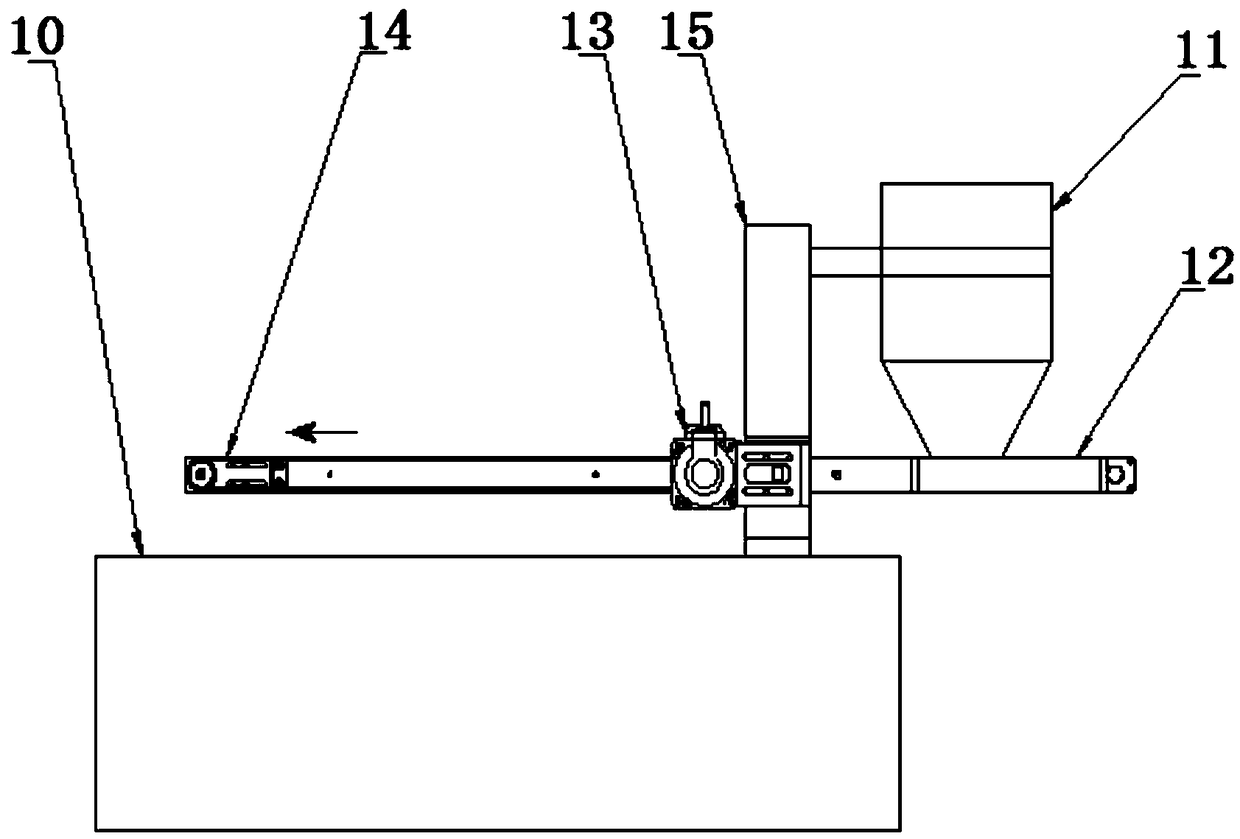

Automatic cutting liquid adding robot of machine tool

InactiveCN110091212AAutomatically addedControl the liquid levelManipulatorMaintainance and safety accessoriesEngineeringMachine tool

The invention relates to cutting liquid adding robots of machine tools, in particular to an automatic cutting liquid adding robot of the machine tool. The automatic cutting liquid adding robot of themachine tool can conveniently control the addition amount and achieve automatic stirring. The automatic cutting liquid adding robot of the machine tool comprises a base plate, wheels, an installationplate, a straight sliding rail, two straight sliding blocks, a rack, a first fixing plate, a rotating motor, a gear, a second fixing plate, a cylinder body, a piston and the like. The front side, theback side, the left side and the right side of the lower portion of the base plate are all connected with the wheels. The right portion of the upper side of the base plate is connected with the installation plate. The straight sliding rail is connected with the upper portion of the left side of the installation plate. The two straight sliding blocks are connected to the straight sliding rails in asliding manner. The automatic cutting liquid adding robot of the machine tool is provided with a first travel switch and a second travel switch and can achieve automatic adding of the cutting liquid;and a first liquid level sensor, a second liquid level sensor and a third liquid level sensor are arranged, so that the effect that the liquid level of the cutting liquid is grasped so as to accurately feed enough cutting liquid is achieved.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Chemical fiber production sewage comprehensive treatment device

InactiveCN113321350AEasy to handleStir wellWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesFiberSewage

The invention relates to the field of chemical sewage treatment, and in particular, relates to a chemical fiber production sewage comprehensive treatment device which comprises a fixed base, a special-shaped water injection pipe, a reaction tank, a gate opening mechanism and the like. The special-shaped water injection pipe is fixedly mounted on the upper left portion of the fixed base, a reaction tank is fixedly connected to the upper portion of the fixed base, the interior of the reaction tank is of a cavity structure, and the reaction tank is located on the right side of the special-shaped water injection pipe and provided with the gate opening mechanism. Through cooperation of a first filter plate, a second filter plate and a carbon filter screening layer, the first filter plate and the second filter plate can preliminarily filter chemical fiber production sewage so as to remove most of suspended solids, particulate matters and the like in the chemical fiber production sewage, and the carbon filter screening layer can adsorb organic matters, residual chlorine and the like in the chemical fiber production sewage. Therefore, the impurities in the chemical fiber production sewage can be further removed, and the effect of effectively removing the impurities in the chemical fiber production sewage is achieved.

Owner:JIANG SU TIANDI CHEM FIBER

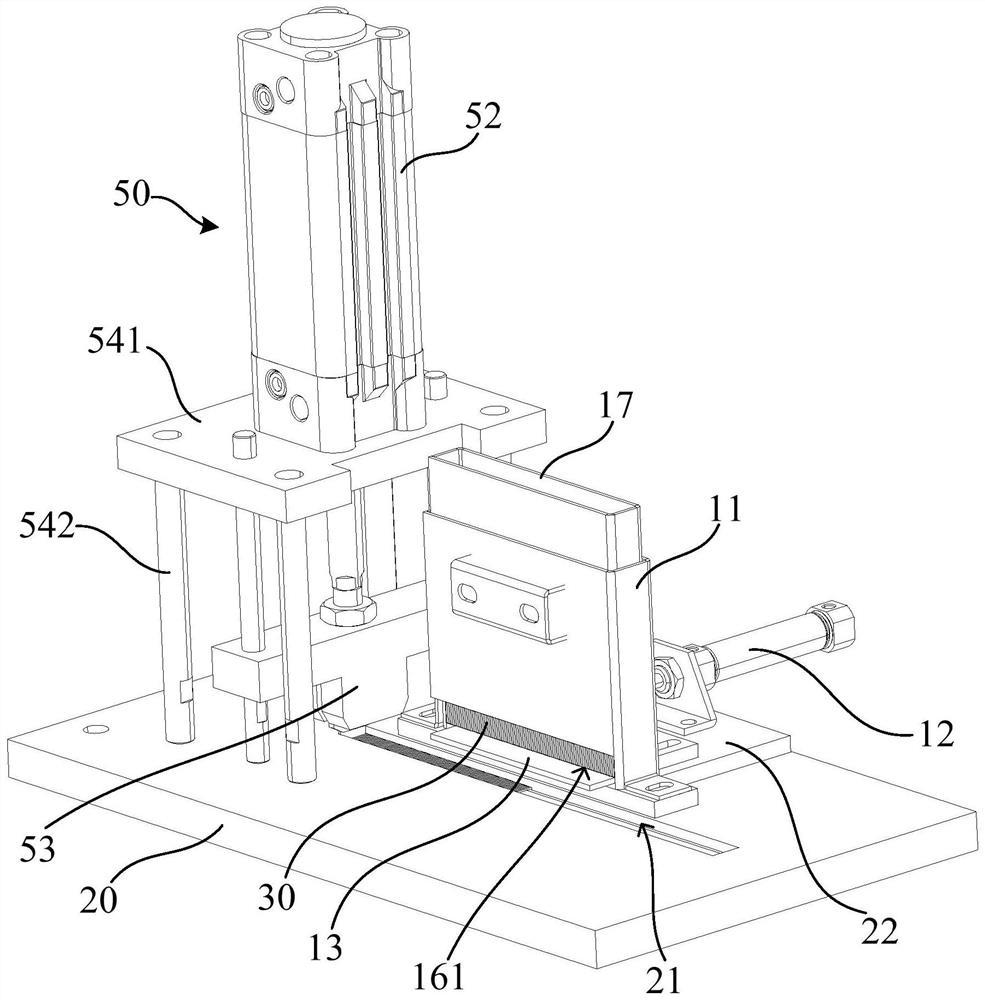

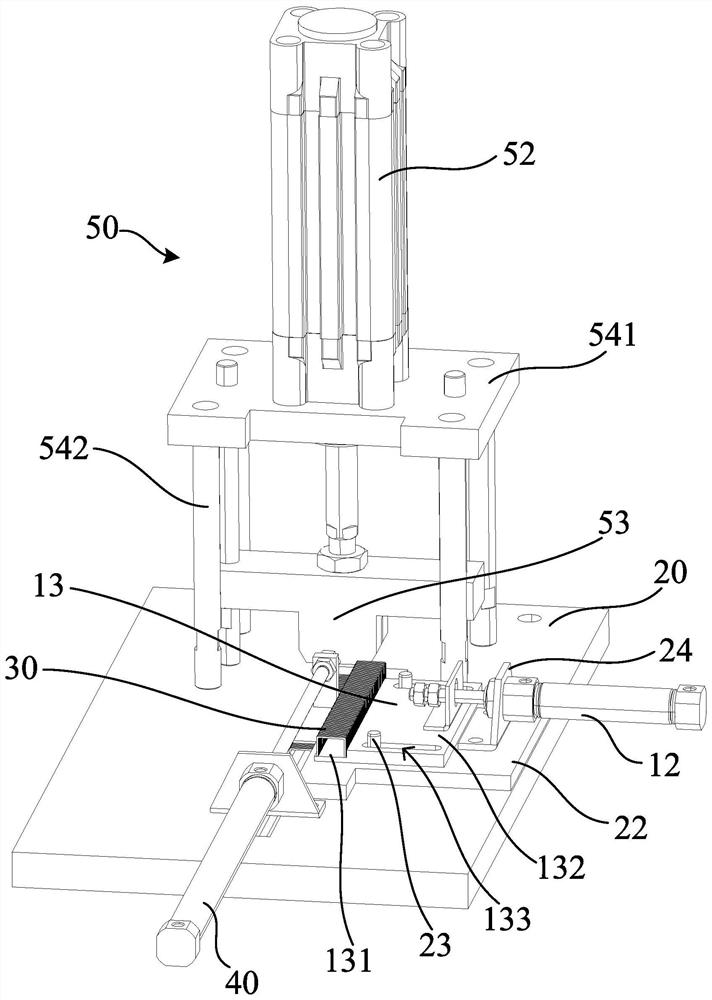

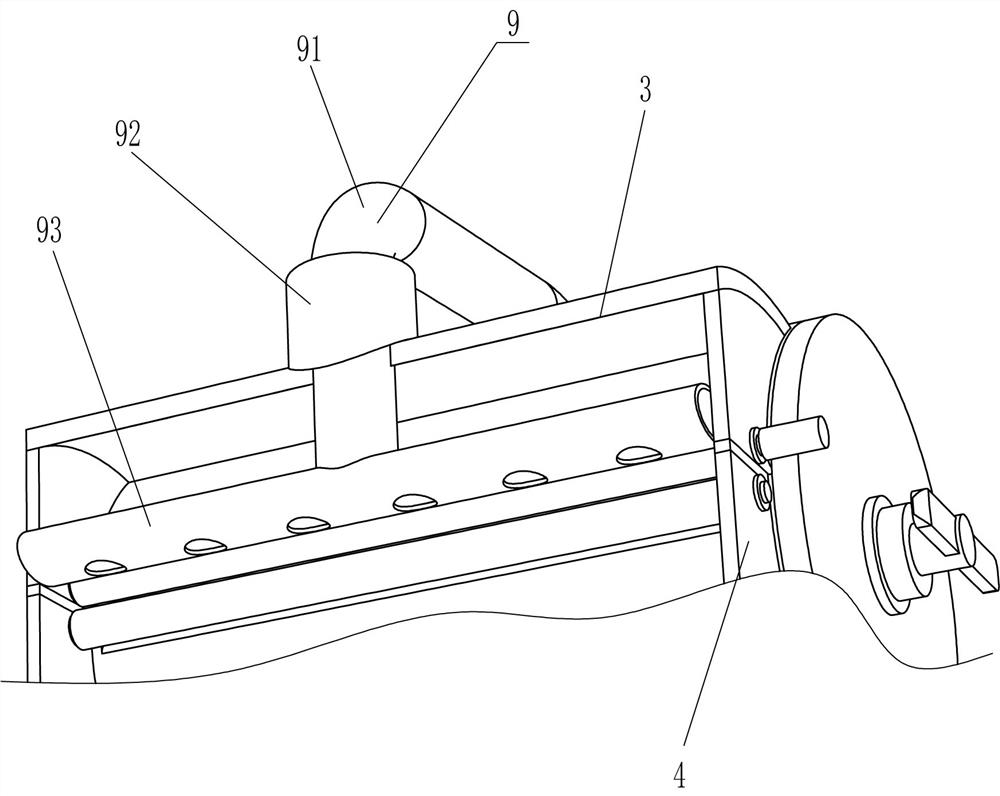

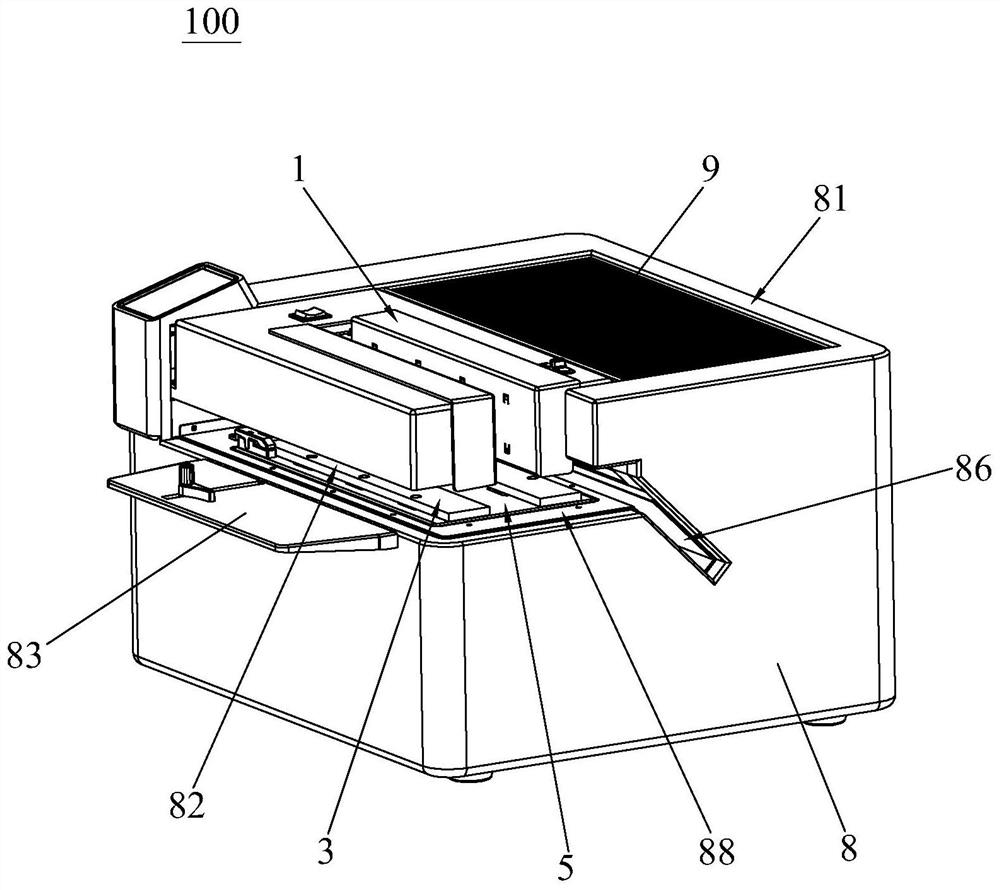

Staple adding assembly and staple driving device

ActiveCN112440352AAutomatically addedHigh degree of automationStapling toolsNailing toolsEngineeringStructural engineering

The invention relates to a staple adding assembly and a staple driving device. The staple adding assembly comprises a containing shell sleeve, a first push-pull mechanism, a first moving plate, a second push-pull mechanism and a positioning shell sleeve, wherein the bottom end of the containing shell sleeve is used for being installed on an installation base; a first gap allowing the staple row topenetrate out is formed between the bottom end of the first side wall of the containing shell sleeve and the installation base; the first moving plate is movably arranged at the bottom end of the containing shell sleeve and used for bearing the staple row. the first push-pull mechanism is used for pushing the first moving plate to move so as to drive the staple row at the bottommost portion of the containing shell sleeve to penetrate out of the first gap and move to the position above a conveying groove of the installation base. the positioning shell sleeve can be arranged in a sleeving modeand located outside the staple row; and the second push-pull mechanism is used for pushing the positioning shell sleeve to move to the position above the conveying groove and be arranged in a sleevingmode and located outside the staple row. Compared with the prior art, the staple adding assembly has the advantages that the staple row does not need to be manually added into the conveying groove, staples can be automatically added, the automation degree is relatively high, and the labor cost is saved.

Owner:GUANGZHOU HUAXINKE ENTERPRISE

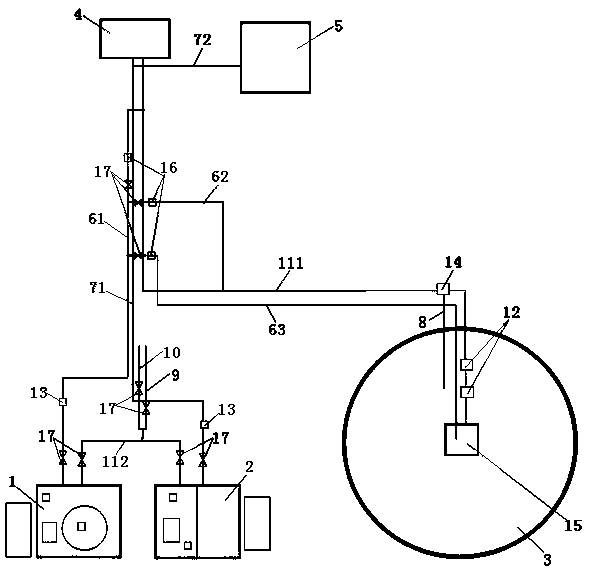

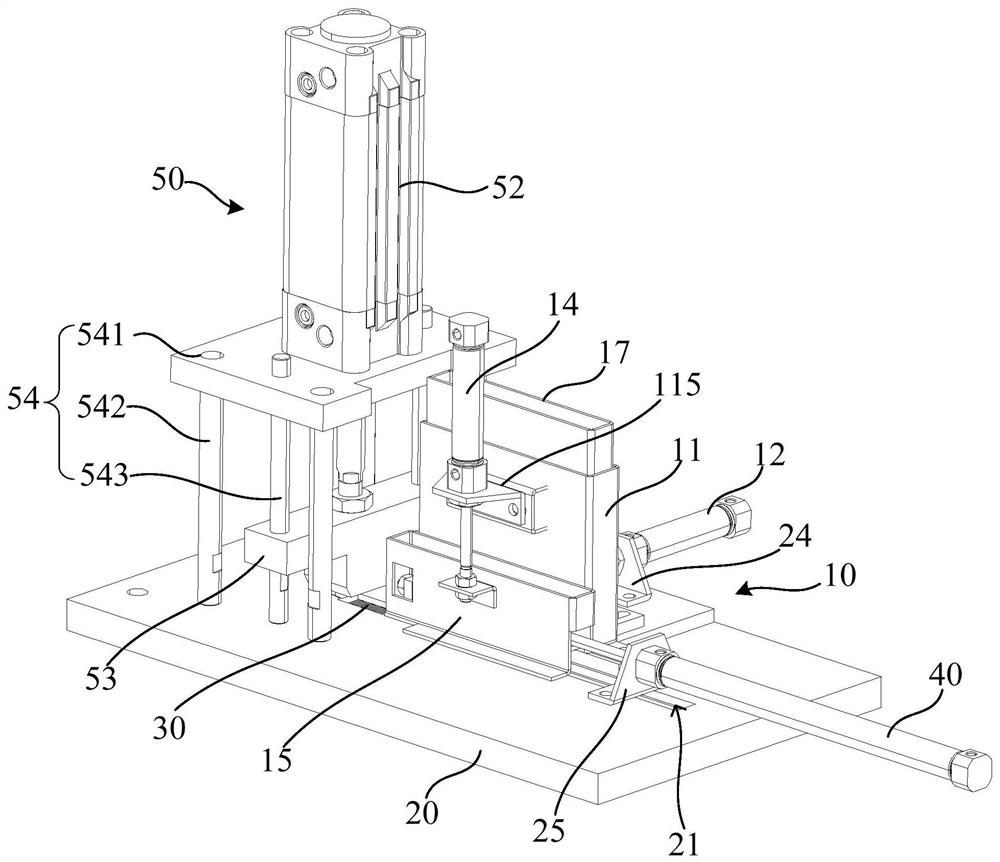

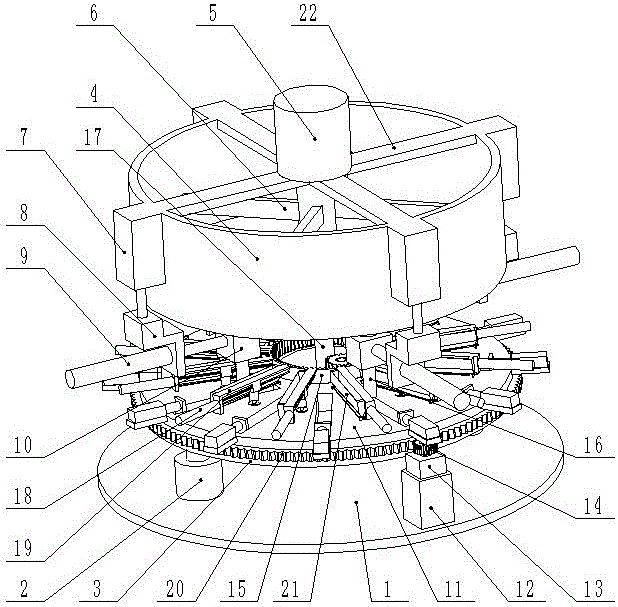

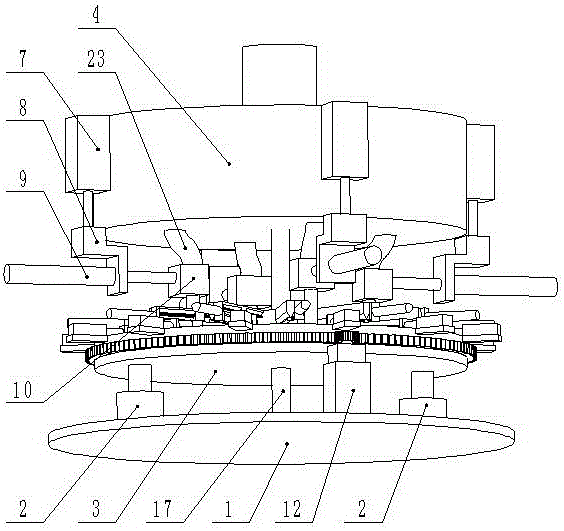

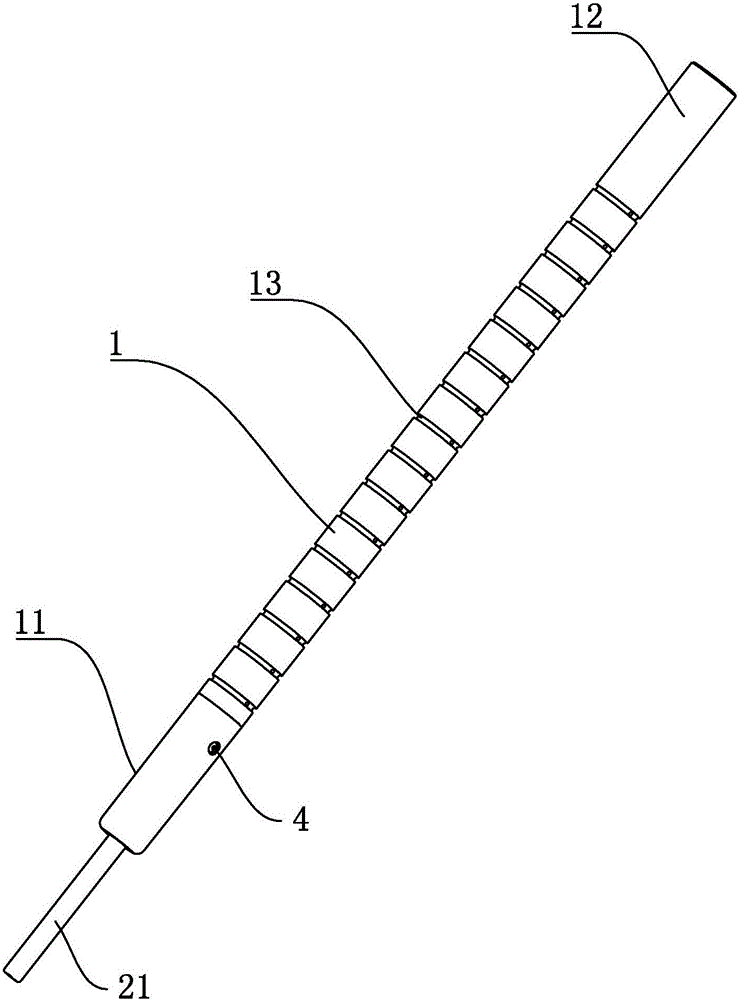

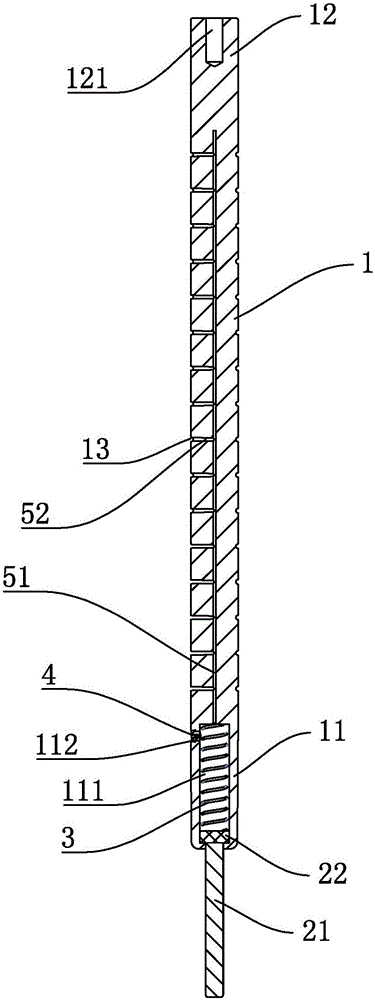

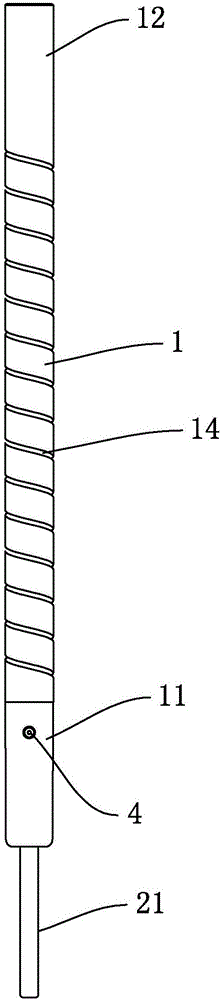

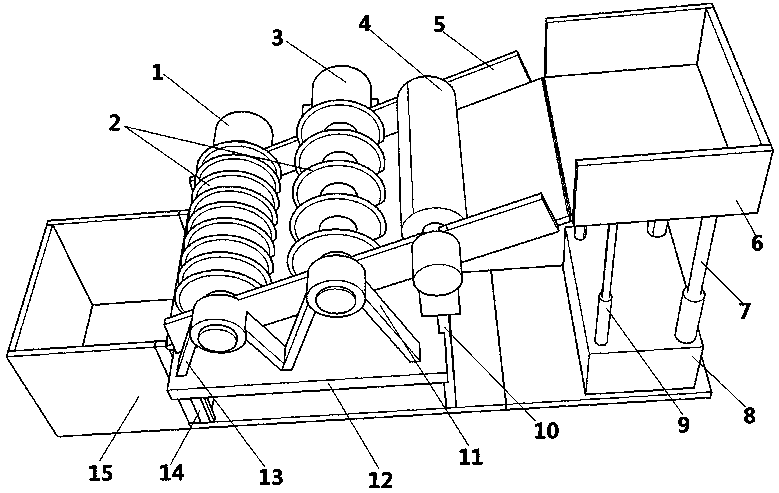

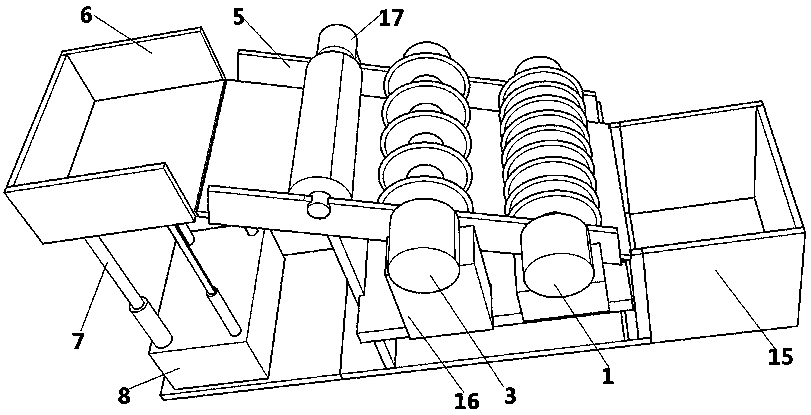

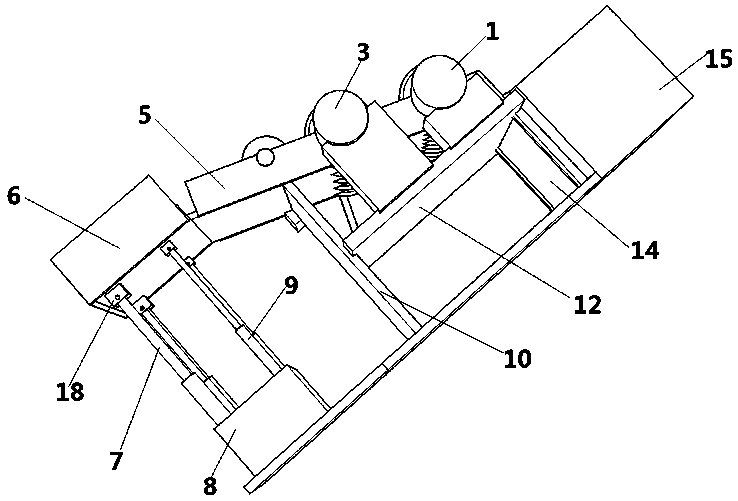

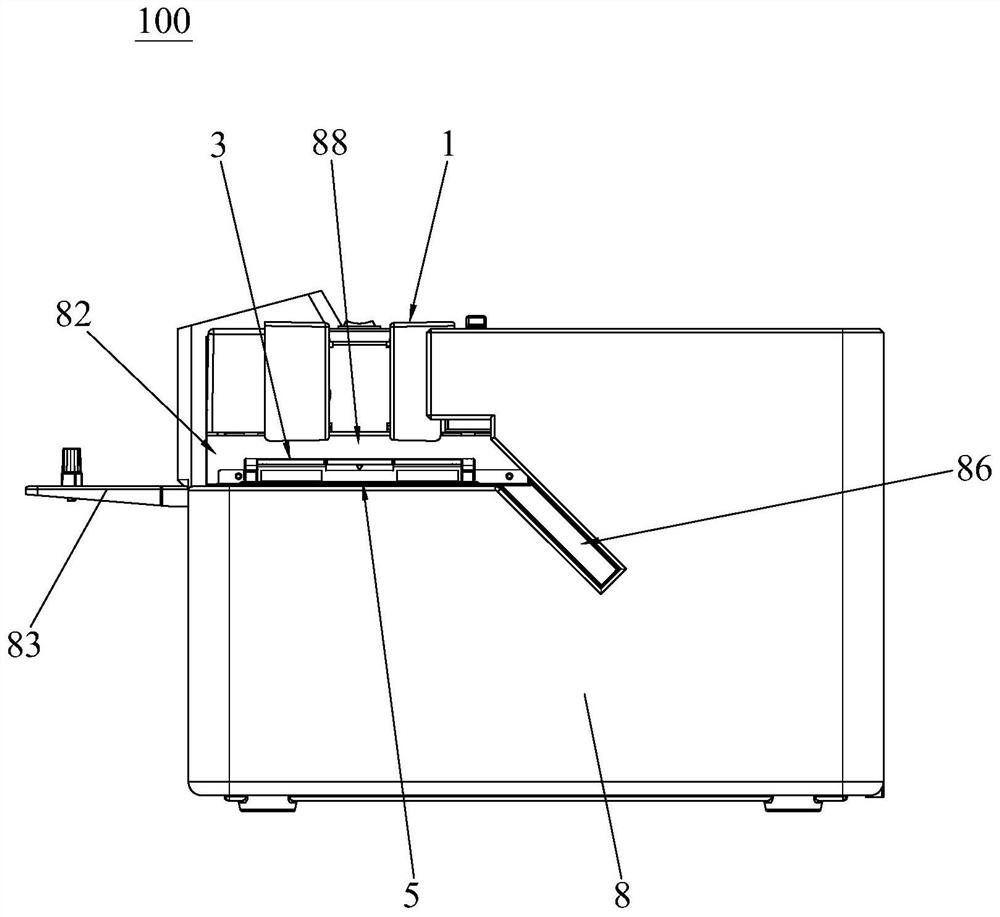

Vertical rod automatic pouring robot for grape ridge cultivation

ActiveCN106677538AImplement addAutomatically addedCultivating equipmentsBuilding material handlingHydraulic cylinderMotor drive

The invention discloses a vertical rod automatic pouring robot for grape ridge cultivation. The vertical rod automatic pouring robot comprises a base, a spindle, a supporting plate, two supporting plate adjusting hydraulic cylinders, a rotary disc, a rotation motor and the like. The spindle is vertically installed in the center of the base. The rotary disc is rotationally installed on the spindle. A large rotating gear is coaxially installed on the outer circumference of the rotary disc. A rotation motor mounting rack is arranged on one side of the base. The rotation motor is installed on the rotation motor mounting rack. A small rotating gear is coaxially installed on an output shaft of the rotation motor. The rotation motor drives the rotary disc to rotate around the spindle. According to the vertical rod automatic pouring robot for grape ridge cultivation, through the arrangement and cooperation of the rotary disc and the supporting plate, the purpose of automatically pouring a vertical rod is achieved; through the arrangement of length adjusting hydraulic cylinders and length plates, the purpose of automatically adjusting the length of the vertical rod can be achieved; through the arrangement of a steel bar storage box capable of being opened and closed automatically, the purpose of automatically adding steel bars is achieved; and the vertical rod automatic pouring robot is reasonable in structure and high in working efficiency, and the productivity is effectively liberated.

Owner:泉州昀康工业设计服务有限公司

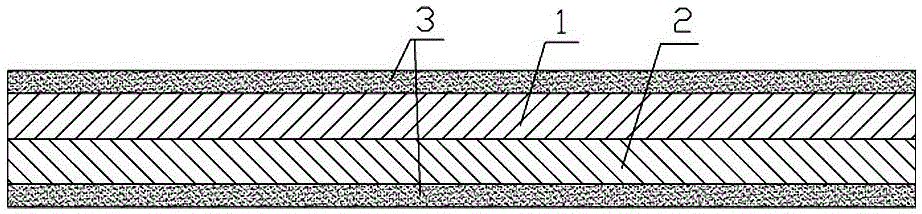

Wetting-piloted composite solder and preparation method thereof

InactiveCN106181124ABeautiful shapeHigh tin contentMolten spray coatingWelding/cutting media/materialsComposite solderMaterials science

The invention discloses wetting-piloted composite solder which comprises a tin layer and a solder alloy layer, which are compositely rolled, wherein soldering flux layers are sprayed and deposited on the outer surfaces of the tin layer and the solder alloy layer respectively to form a finished composite solder product with a four-layer structure; the thicknesses of the tin layer and the solder alloy layer can be adjusted within 0.01-20 mm according to the clearance filling property of the solder and the size of a clearance; and the thicknesses of the soldering flux layers are adjusted within 0.01-10 mm according to the level of difficulty in removing an oxide film of a workpiece. During preparation of the composite solder, a tin belt and a solder alloy belt are put into a precision rolling machine to be compositely rolled so that the uniform-thickness tin layer is formed on the surface of the solder alloy layer, and then the uniform thickness soldering flux layers are deposited on the outer surfaces of the tin layer and the solder alloy layer in a hot spraying way to form the finished composite solder product with the four-layer structure. A preparation method provided by the invention saves energy and protects the environment, the composite solder is high in tin content and uniform in thickness and beautiful in forming, and since the composite solder has soldering flux, automatic, accurate and quantified addition of the soldering flux is realized during soldering.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Automatic-drive-adding system installation method

The invention provides an automatic-drive-adding system installation method, which includes: installing a Linux system automatically and disposing a drive module on a server to be added automatically when configuring a pxe server to be loaded. Particularly, the automatic-drive-adding system installation method includes the following steps of firstly configuring the pxe server to be loaded, disposing the drive in a catalog of the pxe server, and naming the drive as mega.img if the drive is disposed at / home. A starting file of the system is initrd.img-2.6.32-21-server.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

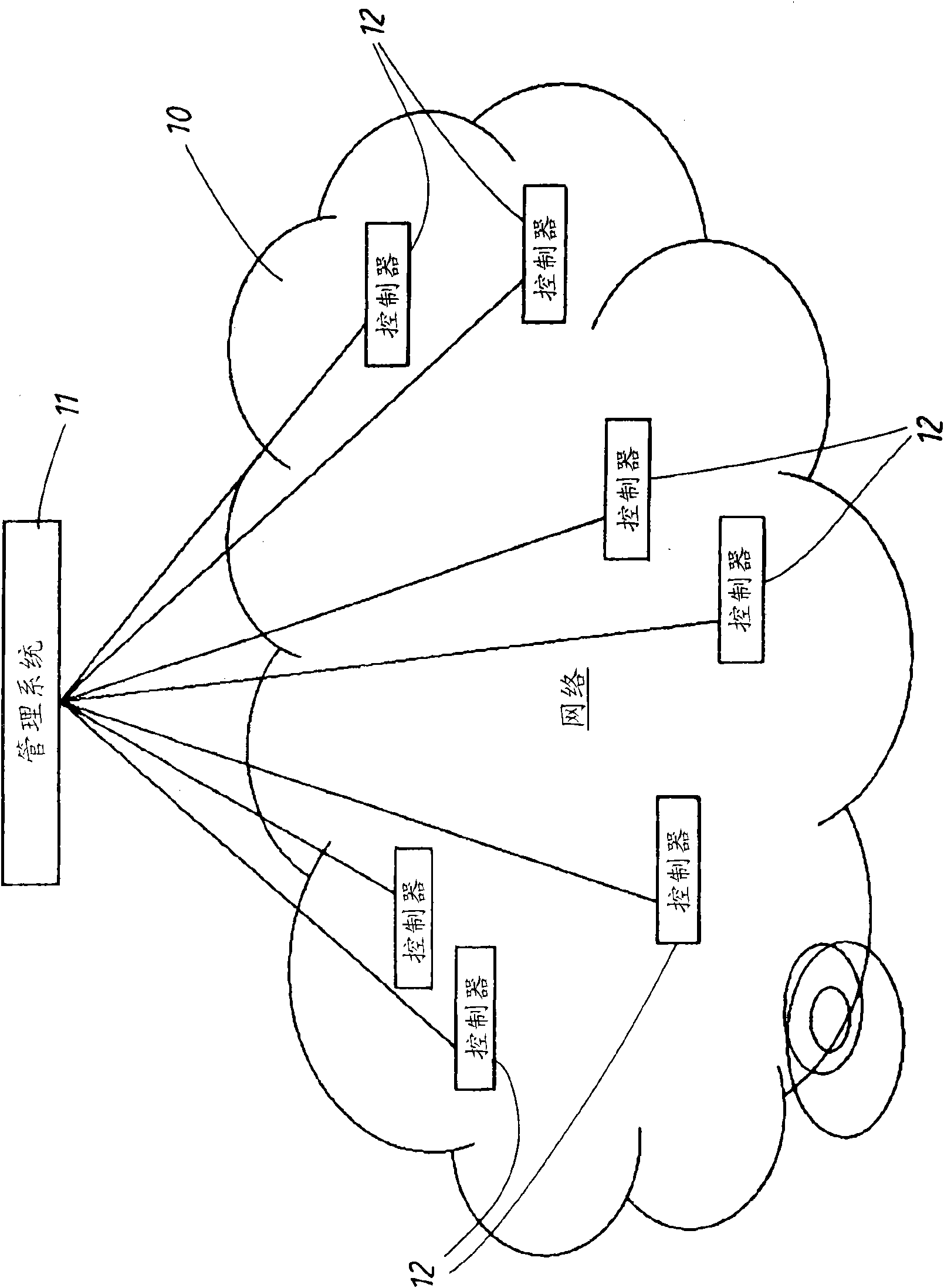

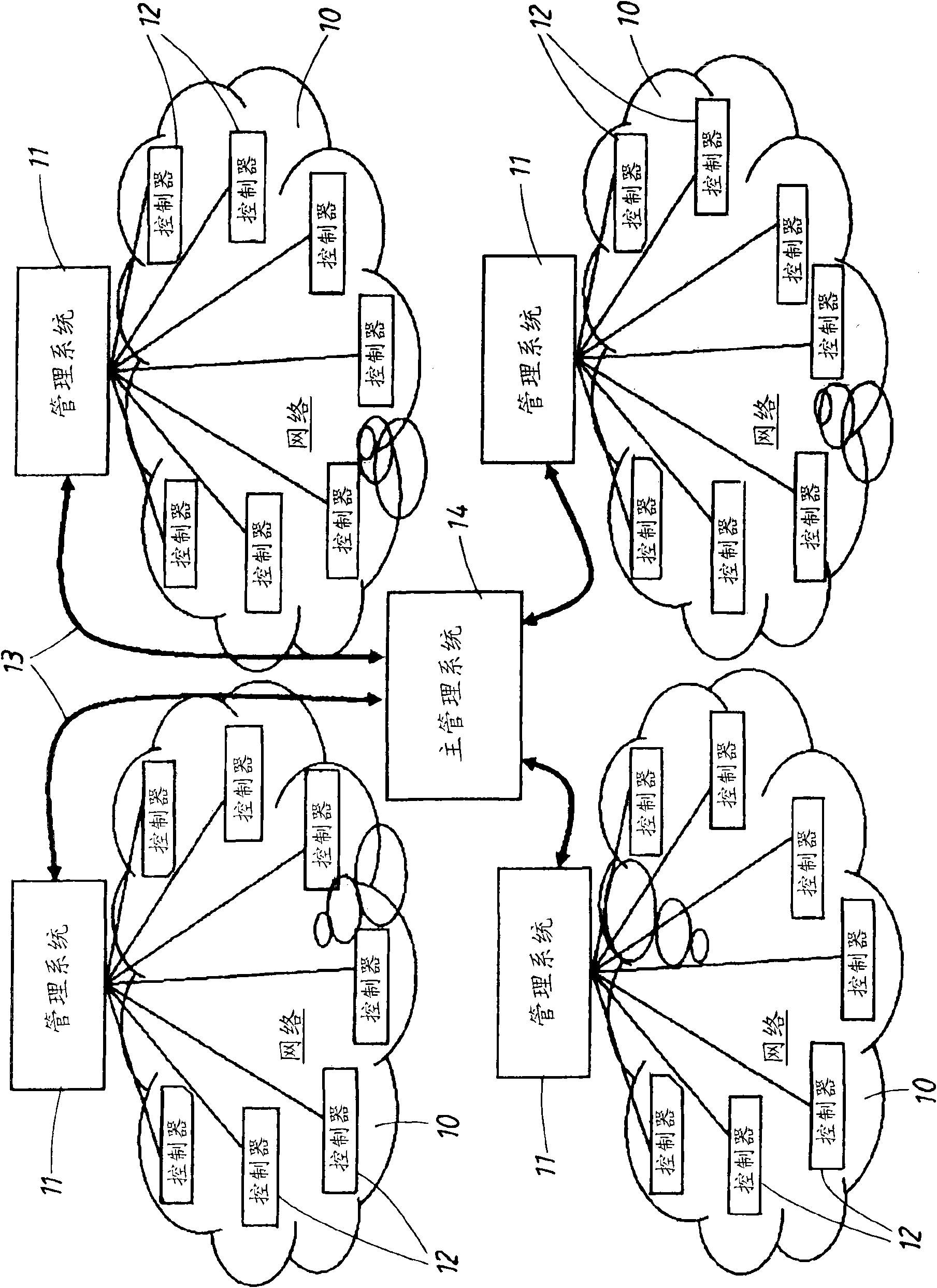

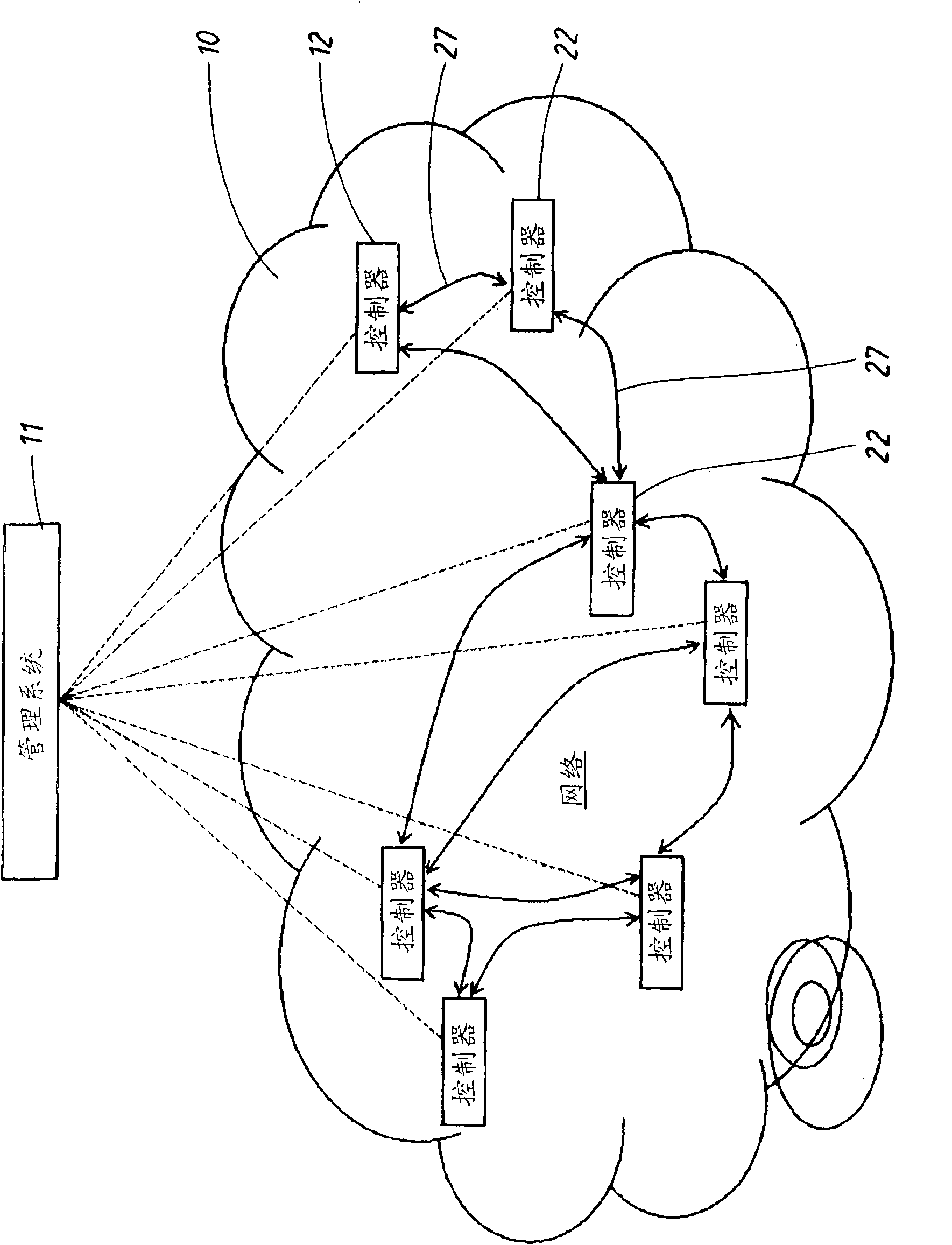

A method for exchanging cell information between networks

InactiveCN101690381AAutomatically addedChange configurationNetwork topologiesTransceiverRadio networks

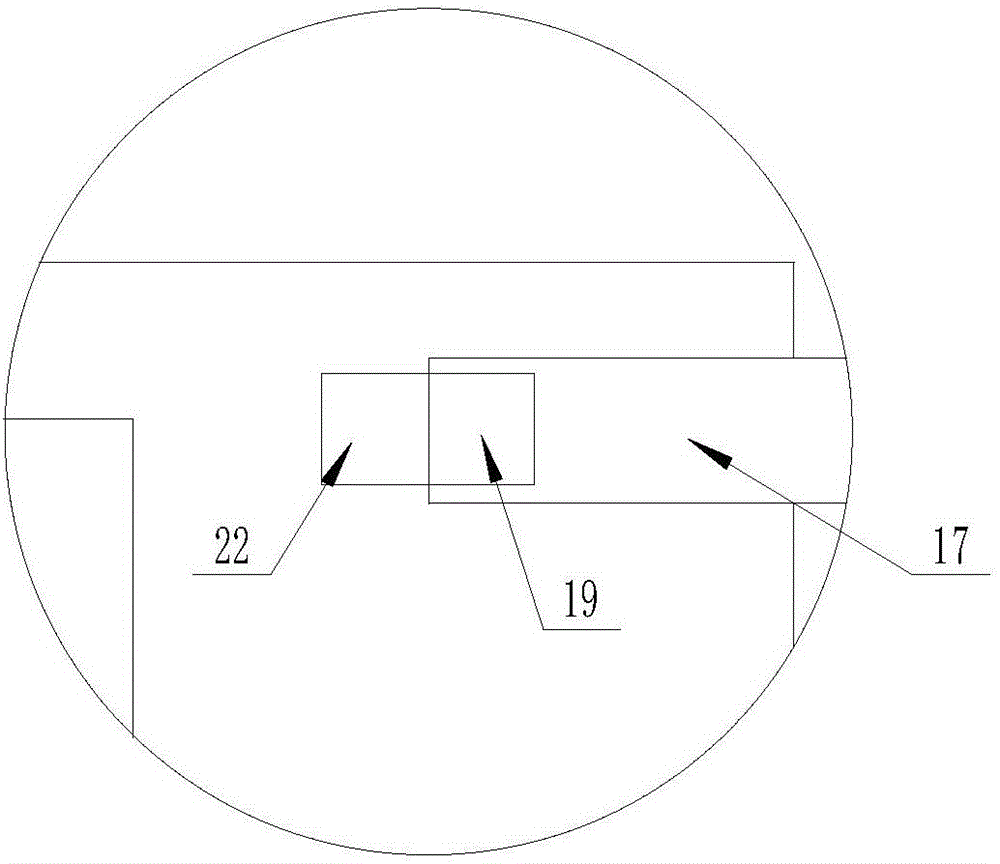

The present invention relates to a controller (12), such as a base station or radio network controller, for a local cellular network (10) or network segment comprising one or more local cells (16) being served by at least one transceiver, the controller (12) communicating with the local cell or cells (16) and comprising controlling means (18) for controlling said local cell or cells (16) and register means (19) for register and share information (20) about the local cell or cells (16) and their relationships and also register and share (14, 38, 39) information about one or more external cells(21) within at least one external cellular network (29) or network segment and their relationships with the local cell or cells (16). The controller (12) of the present invention in particular comprises communication means (26) for communicating (27) directly with one or more neighbouring controllers (22) for the external cellular network (29) or network segment, for sharing (34, 38, 39) of the registered information (20) about cells (16, 21) and their relationships. The present invention also relates to a method for said controller (12) and a cellular network (10) including said controller (12).

Owner:TELEFON AB LM ERICSSON (PUBL)

Medical plaster bandage box capable of automatically injecting water

InactiveCN111643275AEasy to operateShorten the timeSpraying apparatusStone-like material working toolsBandageBiomedical engineering

The invention relates to a plaster bandage box, in particular to a medical plaster bandage box capable of automatically injecting water. The technical problem to be solved by the invention is to provide a medical plaster bandage box capable of automatically injecting water, which is simple in operation and can save time. According to the technical implementation scheme, the medical plaster bandagebox capable of automatically injecting the water comprises a mounting frame and a flip cover, wherein the upper side of the mounting frame is fixedly connected with a placing box and a water collecting box; the placing box is fixedly connected with the water collecting box; and the flip cover is rotationally connected with the upper side of the placing box. The medical plaster bandage box can spray water on a plaster bandage to add water through a water spray mechanism, so that the water can be automatically added to the plaster bandage, and the operation is simple to save time; and the plaster bandage can be centered through a centering mechanism, so that the plaster bandage is prevented from being damaged by friction between the plaster bandage and an inner wall of the placing box.

Owner:黄云飞

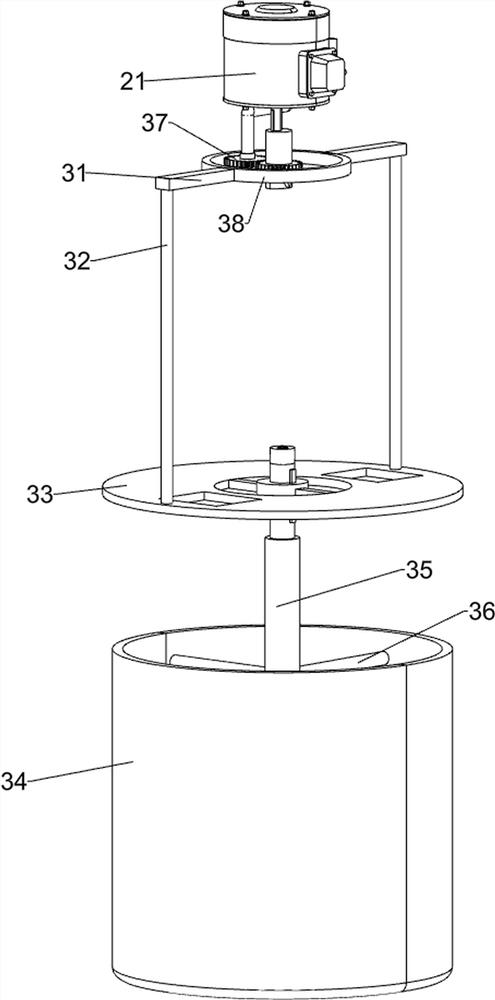

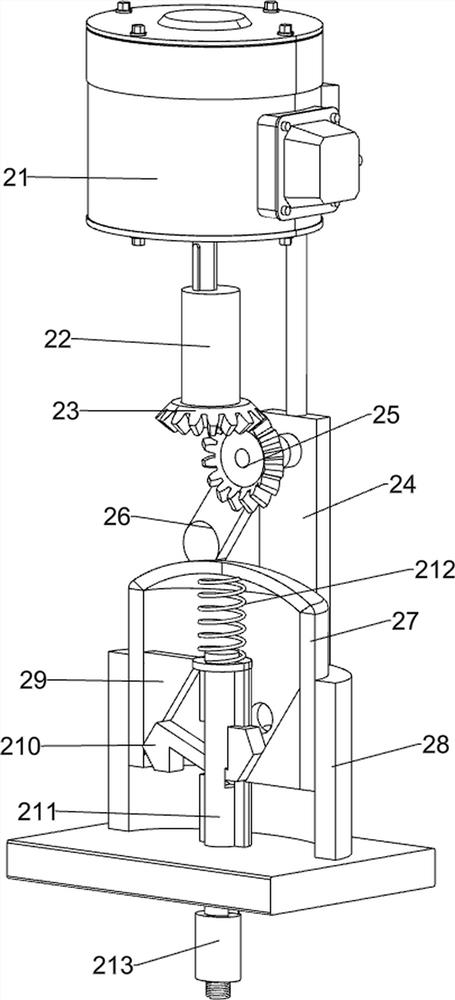

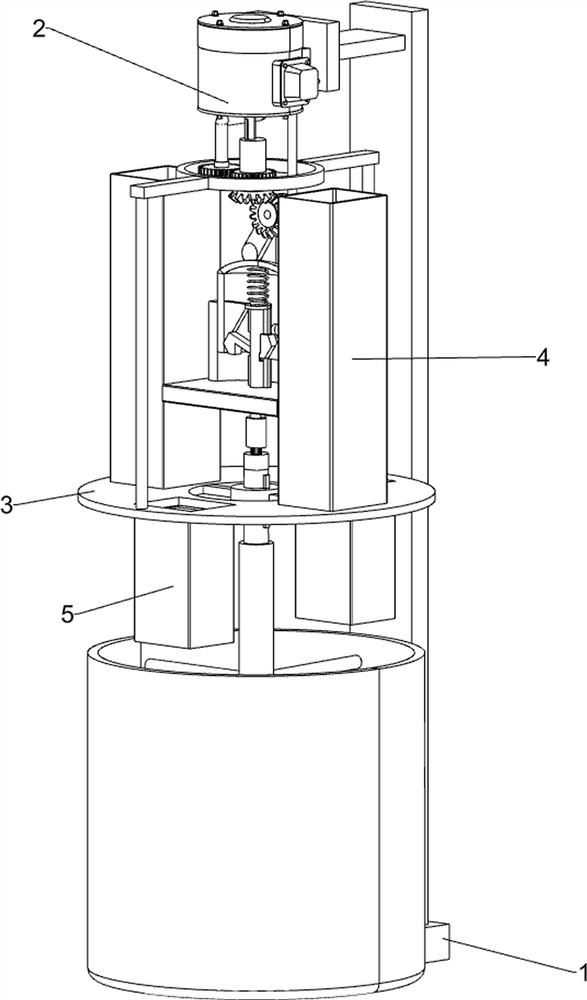

Automatic material mixing stirrer

InactiveCN112121674AWell mixedAutomatically addedRotary stirring mixersTransportation and packagingBLENDER/MIXEREngineering

The invention relates to a stirrer, in particular to an automatic material mixing stirrer. The technical problem to be solved is to provide an automatic material mixing stirrer which can automaticallyadd materials for mixing and increase the mixing speed. The automatic material mixing stirrer comprises a support; a lifting assembly which is installed on the support and ascends and descends in a rotating mode; and a stirring assembly which is installed on the lifting assembly and conducts stirring in a rotating mode. Through mixing of the lifting assembly and the stirring assembly, a stirringrod can rotate and move up and down at the same time, and material mixing is accelerated. Due to the fact that a rotating rod needs to move up and down along with a connecting rod, the connecting rodcan move up and down, and meanwhile due to a rotating connector, the rotating rod can also rotate. Through the cooperation of a material storage pipe and a discharging pipe, before materials are mixed, the materials can be placed in the material storage pipe, so that the materials can be automatically added, and the equipment is more convenient to use.

Owner:黄彬

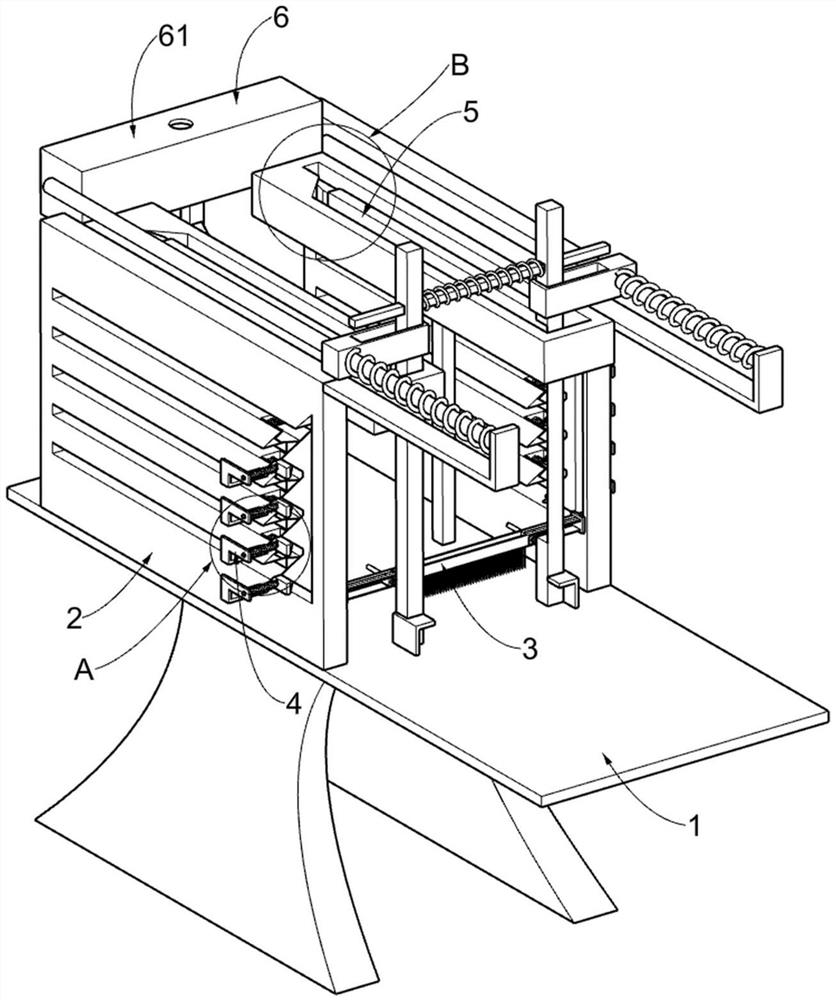

Easy-to-tidy material sticking machine for neodymium iron boron production

ActiveCN113140403ANeatly stackedFully coveredLiquid surface applicatorsCoatingsEngineeringScrub brushes

The invention relates to the field of neodymium iron boron, in particular to a convenient-to-tidy material sticking machine for neodymium iron boron production. The easy-to-tidy material sticking machine comprises a fixed supporting frame, a reset mechanism, a glue brushing mechanism, a lifting mechanism, a guide mechanism and the like. The reset mechanism is arranged on the fixed supporting frame, the glue brushing mechanism is arranged on the reset mechanism, the lifting mechanism is arranged on the reset mechanism, and the guide mechanism is arranged on the reset mechanism. Through cooperation of the glue brushing mechanism and the lifting mechanism, when a guide block is separated from neodymium iron boron on a fixed supporting frame, the guide block and a device on the guide block move in the direction away from a fixed frame, so that a brush brushes glue on the surface of the neodymium iron boron on the fixed supporting frame, and then the brush moves upwards along a sliding groove in a first fixed frame, the second wedge-shaped block can clamp the brush, and then the brush can glue the next neodymium iron boron, so that the effect of fully gluing the neodymium iron boron and neatly stacking the neodymium iron boron together is achieved.

Owner:江西粤磁稀土新材料科技有限公司

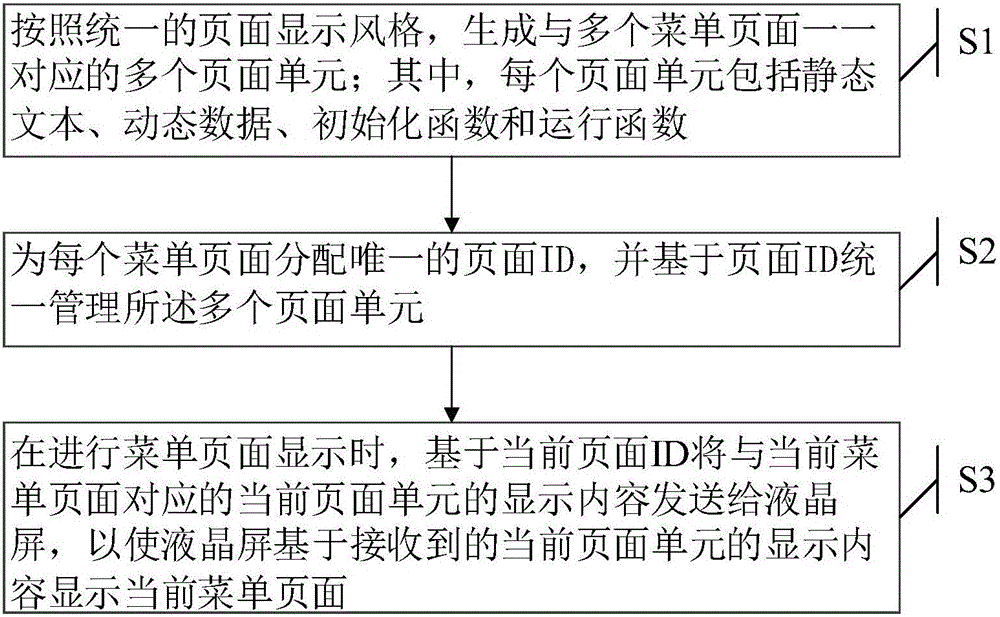

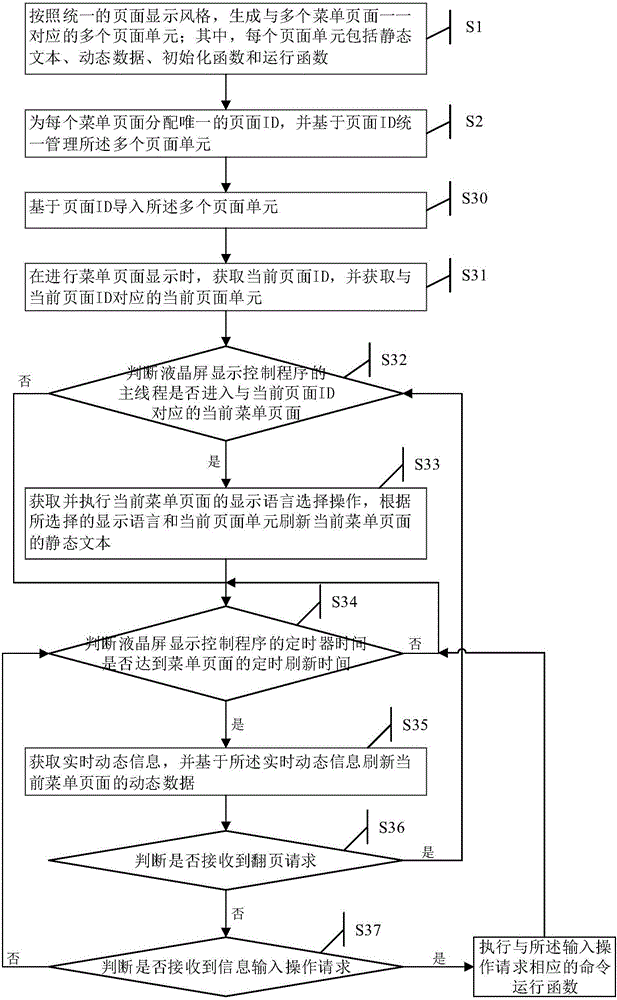

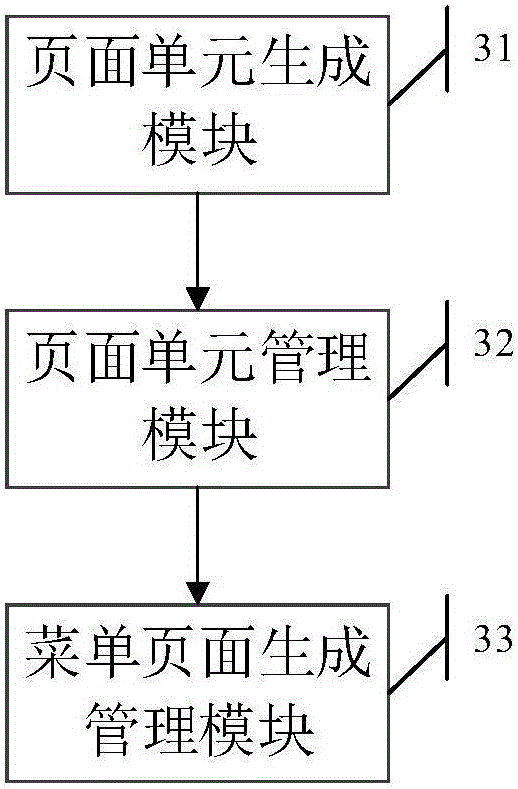

Liquid crystal display based menu generation method and device

ActiveCN105930041AQuick addRealize automatic dynamic refreshInput/output processes for data processingComputer hardwareLiquid-crystal display

The invention discloses a liquid crystal display based menu generation method and device, and belongs to the technical field of human-computer interaction. The menu generation method includes the steps: S1, generating a plurality of page units which are corresponding to a plurality of menu pages one-to-one, according to a unified page display style, wherein each page unit includes a static text, dynamic data, an initialization function, and an operation function; S2, distributing a unique page ID to each menu page, and uniformly managing the plurality of page units based on the page ID; S3, sending display content of a current page unit corresponding to a current menu page to the liquid crystal display based on a current page ID during displaying of the menu pages so as to allow the liquid crystal display to display the current menu page based on the received display content of the current page unit. A menu of a lattice liquid crystal display can be quickly established; menu service treatment and user interface design are separated; adding, deletion, and change of menu options are facilitated; and a software architecture is clear and is easy to maintain.

Owner:SHENZHEN SINEXCEL ELECTRIC

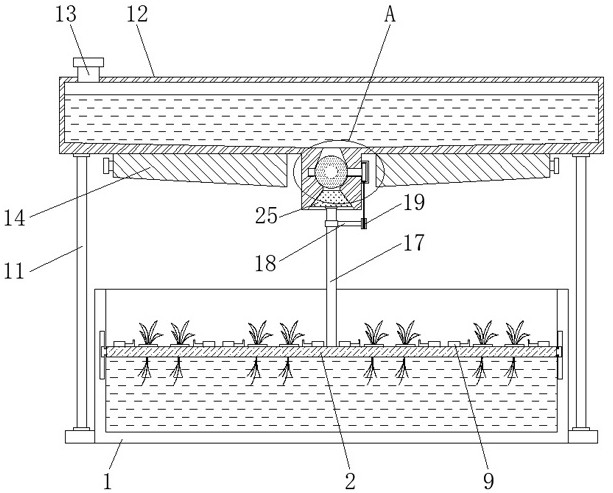

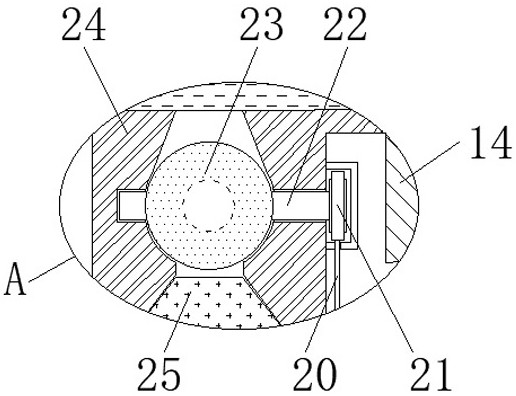

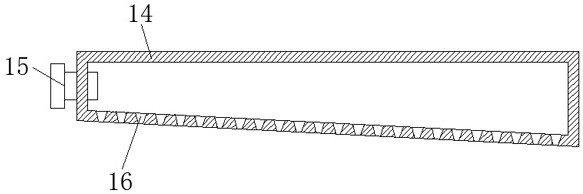

Semi-arid region high-saline-alkali water body aquatic plant culture device and culture method

ActiveCN112715343AAutomatically addedImprove protectionAgriculture gas emission reductionCultivating equipmentsAridAlkaline water

The invention discloses a semi-arid region high-saline-alkaline water body aquatic plant culture device and culture method. The semi-arid region high-saline-alkaline water body aquatic plant culture device comprises a culture box, a top box and supporting rods. A transverse plate is mounted in the culture box, a water culture plate is mounted on the transverse plate, a mounting block is arranged on the water culture plate, and a limiting plate is connected to the lower end of the mounting block; and a connecting block is fixedly connected to the lower surface of the edge of the mounting block, the connecting block is located in a limiting groove, the limiting groove is formed in a water planting plate, a control block is arranged above the water planting plate, the outer end of the control block is located in a fixing cylinder, and a liquid inlet is formed in the left side of the upper end of the top box. According to the semi-arid region high-saline-alkaline water body aquatic plant culture device and culture method, a nutrient solution can be automatically added, manpower is saved, it can be guaranteed that the nutrient solution is always sufficient, aquatic plant seedlings can be protected conveniently, damage to roots is avoided when the aquatic plant seedlings are taken and placed, and pesticide can be evenly sprayed.

Owner:湖北省长江水生态研究院有限责任公司

PVC guardrail automatic production equipment

The invention discloses PVC guardrail automatic production equipment which includes a feed stirring device, an injection molding cooling device, an extrusion device, a cutting device, a conveying device, a material collecting device, a slanting rod, a support, a baffle, a telescopic rod, a telescopic cylinder, a fixing plate, a rotating shaft, a left side material blocking plate, a right side material blocking plate, a conveying belt, a feeding belt and a drive motor. The PVC guardrail automatic production equipment has the advantages of being simple in structure, reduced in labor cost, high in automation degree, convenient and safe in use, high in working efficiency, and good in cooling effect.

Owner:山东东明石化集团有限公司

Rotary cleaning device for shelly seafood

The invention discloses a rotary cleaning device for shellfish, which comprises a bar-shaped base, a rotary cleaning mechanism is provided on the upper surface of the bar-shaped base, and a shaking mechanism is provided on two opposite side surfaces of the bar-shaped base. A lifting mechanism is provided on the side surface of the strip-shaped base, an additive bearing mechanism is provided at the edge of the upper surface of the strip-shaped base, and a controller is provided on the side surface of the strip-shaped base. The invention has the advantages of simple structure and strong practicability.

Owner:QINGDAO RUBBER VALLEY INTPROP CO LTD

Hot runner protection structure and guide column thereof

The invention discloses a guide column. The guide column comprises a column body. One end of the column body is an insertion end. A supporting foot with the diameter being smaller than that of the insertion end is arranged at the end socket of the insertion end in the axial direction of the column body, and the supporting foot extends out of the insertion end. When the guide column is used as a bearing part to support objects, the supporting foot arranged at the insertion end is supported on the ground, and the insertion end of the column body is prevented from making contact with the ground directly, so that the condition that the insertion end bears excessive weight and then is deformed, and consequently the normal guiding function of the guide column is influenced is avoided; and the diameter of the supporting foot is smaller than that of the insertion end, the support foot does not interfere a guide hole when the guide column is used, and thus the normal guide function of the guide column can be achieved.

Owner:台州市黄岩亿德塑模有限公司

Spinnable fiber production system for regeneration of waste clothes and method thereof

ActiveCN108085792ASimple and efficient operationIngenious designTextile disintegration and recoveryFibre disintegrationMotor shaftEngineering

The invention discloses a spinnable fiber production system for regeneration of waste clothes. The system comprises a first driving motor, cutting devices, a second driving motor, an inclined slidingplate groove, a material transporting groove, first telescopic rods and second telescopic rods. The system is characterized in that an ironing barrel, the first cutting device and the second cutting device are sequentially installed on the inclined sliding plate groove from top to bottom, the number of cutters on the first cutting device is different from that of cutters on the second cutting device, other parts are identical, a rotating shaft of the ironing barrel penetrates through the groove wall of the inclined sliding plate groove, one end of the rotating shaft of the ironing barrel is connected with a motor shaft of a third driving motor, a bearing plate is fixedly installed above the middle of the lower bottom surface of the inclined sliding plate groove, a supporting plate is fixedly installed on the lower edge of the lower bottom surface of the inclined sliding plate groove, a material storage box is fixedly installed on the left side of the supporting plate, and the materialtransporting groove is installed in the right side of the upper most side of the inclined sliding plate groove. Cutting speed is high, it will be avoided that the waste clothes are wound around the cutters, cutting is flat, and follow-up processing will not be affected.

Owner:杭州新天元织造有限公司

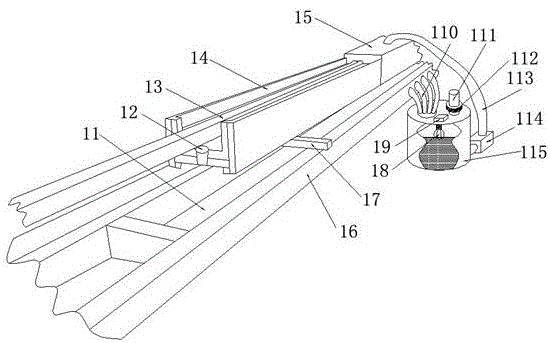

Diamond wire production process with quantitative sanding and online monitoring function

InactiveCN108645340AExtended missionSimple structureProgramme controlComputer controlFriction reductionSurface cleaning

The invention discloses a diamond wire production process with quantitative sanding and online monitoring function. The process comprises the following specific steps of: A, payoff, B, surface cleaning, C, surface pretreatment, D, diamond attachment, E, diamond consolidation, F, friction reduction clad layer coating and G, drying, wherein an on-line monitoring device is arranged between the step Eand the step F; the device applied in the step D is an automatic adding diamond device which is arranged on a corundum plating tank and includes a sand storage tank, a conveyor and a storage tank fixing support frame. The diamond wire production process with quantitative sanding and online monitoring function solves the problem that the content of the corundum in the plating solution caused by the manual addition greatly fluctuates, and the quality of the diamond wire quality is greatly improved, the labor cost of the enterprise is reduced, and the diamond wire production process can providedata support for the quality assessment and production process adjustment of the of the diamond wire.

Owner:江苏亿荣新材料科技有限公司

Gluing piece and gluing device of bookbinding machine

PendingCN112024264AAutomatically addedCompact layoutLiquid surface applicatorsCoatingsAdhesive glueMechanical engineering

The invention discloses a gluing device of a bookbinding machine. The gluing device comprises a gluing piece, a gluing driving mechanism and a glue tank used for loading glue, wherein the surface of the gluing piece is provided with a glue dipping face, the gluing piece is arranged in the glue tank, and the gluing driving mechanism drives the gluing piece to descend and enter the glue tank or drives the gluing piece to ascend and extend out of the glue tank. The gluing device has the advantages that vertical gluing is achieved, the layout of the bookbinding machine is more compact, and the size is smaller. In addition, the invention further discloses a gluing piece and the gluing device.

Owner:DONGGUAN ELITE ELECTRIC HARDWARE PRODUCT CO LTD +1

A message processing method and message processing device

ActiveCN104754066BSelf-directed learningAutomatically addedData switching networksDomain nameIp address

The application discloses a message processing method and message processing equipment, which are used to realize the autonomous learning of IP addresses by matching conditions, and are applicable to various scenarios where message features are static parameters and dynamic parameters. The method in the embodiment of the present invention includes: obtaining an IP message, and judging whether the obtained IP message is a domain name system DNS response message; if the IP message is a DNS response message, parsing the domain name requested by the user terminal from the IP message ; Judging whether the domain name requested by the user terminal exists in the matching condition of the control strategy, the matching condition includes the domain name that needs to be controlled according to the policy action of the control strategy; if the domain name requested by the user terminal exists in the matching condition, the IP packet If the IP address corresponding to the domain name requested by the user terminal is added to the matching condition, the matching condition also includes the added IP address.

Owner:XFUSION DIGITAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com