Wetting-piloted composite solder and preparation method thereof

A composite brazing filler metal and composite rolling technology, which is applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of reduced plasticity, difficult forming of brazing filler metals, low Sn content, etc., and achieves high tin content, beautiful molding, The effect of high adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the wetting leading composite solder of the present invention is as follows:

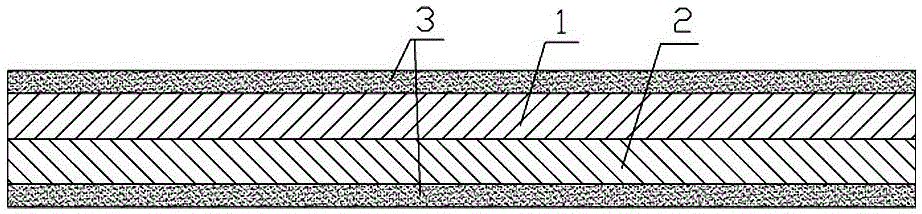

[0018] The tin strip and the solder alloy strip are put into a precision rolling mill for compound rolling, so that a tin layer 1 with uniform thickness is formed on the surface of the solder alloy layer 2, and then on the outer surface of the tin layer 1 and the solder alloy layer 2, A layer of flux layer 3 with uniform thickness is deposited by thermal spraying to form a four-layer structure with excellent wettability, gap filling and formability, and a finished composite solder with flux.

[0019] The solder alloy is one of silver-based solder and copper-based solder, and the solder is a general-purpose solder. During the preparation process, the solder alloy strip must go through a strict degreasing and pickling process to ensure that the side combined with the tin strip is free of oil, impurities and oxidation.

Embodiment 1

[0022] The solder alloy is BAg25CuZn alloy strip with a thickness of 0.2mm, and the thickness of the tin strip is 0.1mm. After multi-pass rolling by a precision rolling mill, a BAgCuZnSn solder alloy strip with a tin layer thickness of 0.02mm and a solder alloy layer thickness of 0.18mm is formed. In the form of thermal spraying, FB102 flux is deposited on both surfaces of the solder alloy strip, and the thickness of the flux layer is 0.1 mm. According to chemical analysis, the tin content is 8.68%. The BAgCuZnSn solder with this tin content is difficult to process through conventional smelting, casting, extrusion, rolling and other processes. According to DSC analysis, compared with the matrix BAg25CuZn solder, the melting point of the solder prepared by this method is lowered by nearly 60°C. According to the national standard GB / T 11364-2008 "Test Method for Wettability of Solder", a comparison test of wettability was carried out between the base solder and the solder prepar...

Embodiment 2

[0024] The solder alloy is BAg30CuZn alloy strip with a thickness of 0.2mm, and the thickness of the tin strip is 0.1mm. After multi-pass rolling by a precision rolling mill, a BAgCuZnSn solder alloy strip with a tin layer thickness of 0.01mm and a solder alloy layer thickness of 0.18mm is formed. Then FB102 flux is deposited on both surfaces of the solder alloy strip by thermal spraying, and the thickness of the flux layer is 0.1 mm. According to chemical analysis, the tin content is 8.12%. The BAgCuZnSn solder with this tin content is difficult to process through conventional smelting, casting, extrusion, rolling and other processes. According to DSC analysis, compared with the matrix BAg30CuZn solder, the melting point of the solder prepared by the method of the present invention is lowered by nearly 55°C. According to the national standard GB / T 11364-2008 "Test Method for Wettability of Solder", a comparison test of wettability was carried out between the base solder and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com