Patents

Literature

47results about How to "Improve caulking ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and preparation method thereof

InactiveCN102319963AReduce brittlenessImprove surface activityWelding/cutting media/materialsSoldering mediaSlagAlloy

The invention relates to an Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and a preparation method thereof. The components of the aluminum-based brazing filler metal are 7 to 13 percent by weight of Si, 5 to 11 percent by weight of Cu, 4 to 11 percent by weight of Zn, 1 to 6 percent by weight of Sn, 1 to 3 percent by weight of Ni, 0.02 to 0.3 percent by weight of Ce, 0.01 to 0.1 percent by weight of Sr, 0.01 to 0.2 percent by weight of Zr and the balance of Al. The process flow for preparing the aluminum-based brazing filler metal is that: pure aluminum is added into a graphite crucible and covered by flux for aluminum under the condition of 800 DEG C to 900 DEG C, and slag is removed after melting; the aluminum-based intermediate alloy of high-melting point elements and flux for aluminum are added at the same time, and melting, stirring and slag removal are carried out; the aluminum-based intermediate alloy of low-melting point elements is added under the protection of nitrogen, and melting and stirring are carried out; the mixture of argon and hexachloroethane is added to carry out refining, and standing and slag removal are carried out; the intermediate alloy of trace elements is added, and melting and stirring are carried out; secondary refining and slag removal are carried out; and under the protection of nitrogen, casting formation is carried out. The Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal has the advantages of low melting point, high strength, high toughness, high corrosion-resistant property and good wetting property and spreadability.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

Polybasic silver solder

ActiveCN103111770AReduce dosageImprove plasticityWelding/cutting media/materialsSoldering mediaRare-earth elementMetallurgy

The invention relates to polybasic silver solder characterized in that the polybasic silver solder comprises, by weight, 12-28% of Ag, 37-49% of Cu, 1.0-3.0% of In, 0.5-2.5% of Ni, 0.001-0.1% of rare earth elements and the balance Zn, wherein the polybasic silver solder contains little precious metal of silver, and the content of the silver is reduced by about 20% compared with high-silver solder such as Bag40CuZnSn. Therefore, production cost is greatly reduced, and use amount of the precious metal of the silver is saved.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

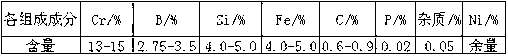

Wetting pilot strip-shaped brazing filler metal and preparation method thereof

InactiveCN106181106AHigh tin contentPrecise control of tin contentWelding/cutting media/materialsSoldering mediaAlloyFiller metal

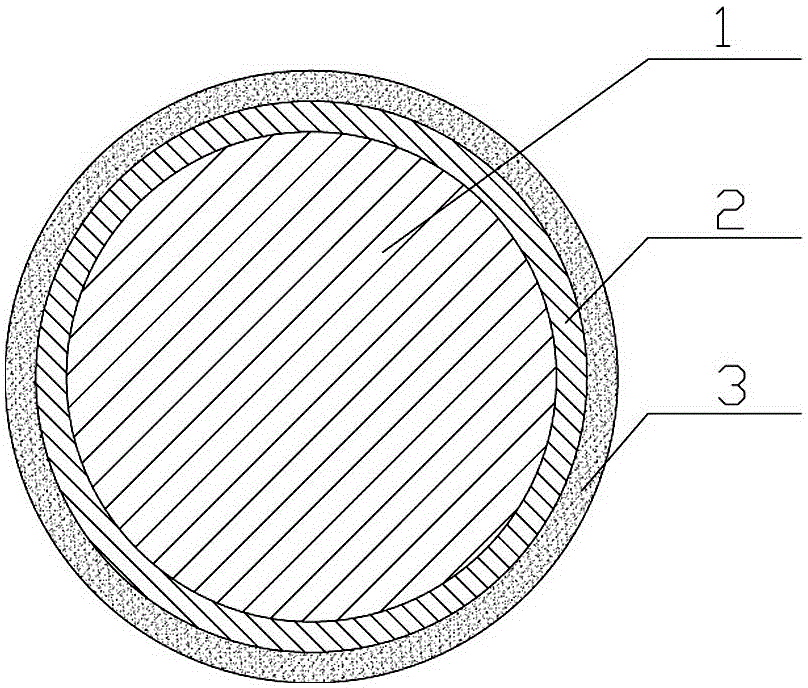

The invention discloses wetting pilot strip-shaped brazing filler metal. The wetting pilot strip-shaped brazing filler metal comprises a brazing filler metal alloy inner core. A tin layer and a coating brazing flux layer sequentially wrap the brazing filler metal alloy inner core. The cross section of the formed strip-shaped brazing filler metal is in a circular or polygonal shape. The diameter of the brazing filler metal alloy inner core is determined according to the size of a brazing filler metal filling seam, the thickness of the tin layer is determined according to the brazing filler metal seam filling ability, and the thickness of the coating brazing flux layer is determined according to the difficulty of removing an oxidation film from the surface of a workpiece. During preparation, firstly, a brazing filler metal alloy is machined to be in the shape of a wire with the diameter meeting the requirement; after deoiling and acid pickling are conducted, the wire-shaped brazing filler metal alloy is placed in a tinning machine to be subjected to hot-dipping wire plating and then prepared to be in a strip shape after being straightened and cut off; and then, the surface of the tin layer is coated with a brazing flux in a press smearing manner, and a finished product of the pilot strip-shaped brazing filler metal is formed. A preparation method is simple, the tin content can be accurately controlled, and compared with traditional brazing filler metal, the wetting and seam filling performance of the brazing filler metal is greatly improved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Palladium-containing high-temperature nickel-base multicomponent alloy brazing materials

InactiveCN1583353ALow melting pointHigh melting pointWelding/cutting media/materialsSoldering mediaPalladiumImpurity

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Novel non-corrosion fluoride solder and preparation method

InactiveCN101125398AWell formedUniform weld rootWelding/cutting media/materialsSoldering mediaChemical synthesisNitrogen gas

The present invention relates to a fluoride soldering flux without causticity of a soldering 6063 aluminum alloy and the method of preparation, which belongs to soldering material field of the aluminum and the aluminum alloy. The compounding ratio of the component by the weight percent is: the neutral QF soldering flux: 99.0 to 99.7 percent; ZnSiF6: 0.3 to 1.0 percent. The neutral QF soldering flux is prepared by adopting the chemical synthesis, and the ratio of K+ / A13+ is 1.9175, and the melting point of the soldering flux is 560 DEG C, and the soldering temperature is 580 to 620 DEG C. The soldering flux protects the soldering 6063 aluminum alloy in the stove by cooperating the AI-11.7Si eutectic soldering material nitrogen gas. The length of the clearance with the same clearance of the soldering material is more than 160 mm. The obverse and inverse surfaces of the soldering clearance are of good shaping with even welding root, and have no disadvantages of air holes on the surface and claming dregs. The cutting intensity for the soldering is more than 120 MPa. The soldering flux preparation art and the material of the present invention have low price, and do not absorb the damp. The present invention does not loose the efficiency when stored in the atmosphere for a long time, which is suitable for being widely applied.

Owner:JIANGSU UNIV OF SCI & TECH

Low-silver-copper-phosphorus brazing material containing trace indium

InactiveCN105149813AMobility is suitableSuitable brazing temperatureWelding/cutting media/materialsSoldering mediaIndiumSilver copper

The invention relates to a low-silver-copper-phosphorus brazing material containing trace indium. The low-silver-copper-phosphorus brazing material is characterized by comprising the following components in percentage by weight: 1.0-3.0% of silver, 6.7-8% of phosphorus, 0.05-0.2% of indium, 0.01-0.05% of mixed rare earth and the balance of copper, wherein the melting temperature range of the brazing material is 600-780 DEG C. The low-silver-copper-phosphorus brazing material has the advantages that the low-silver-copper-phosphorus brazing material can be used for replacing a BCu80AgP copper-based brazing material during brazing copper alloys, the content of the silver is reduced, the low-silver-copper-phosphorus brazing material has appropriate spreadability and liquidity, the low-silver-copper-phosphorus brazing material has appropriate liquidity during brazing copper and copper alloys, the brazing process is high in performance, stable in quality and smooth in surface, the technique performance index is equivalent to that of the Bag15CuP copper-based brazing material, and the brazing material can be prepared into various forms such as filaments, rings and strips by improving the molding technique.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

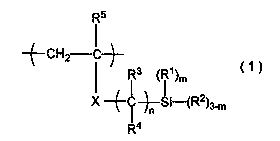

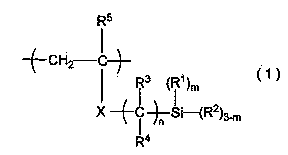

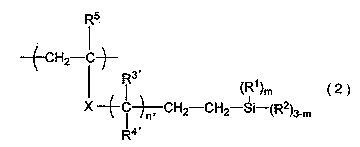

Vinyl alcohol polymer, and aqueous solution, coating agent, inkjet recording material, heat-sensitive recording material, and release paper base paper containing same

ActiveCN103732639AImprove water resistanceImprove adhesionCoatings with pigmentsWater-repelling agents additionPolymer sciencePaper based

The purpose of the present invention is to provide: a vinyl alcohol polymer which can form a coating film exhibiting superior water resistance and binder performance, and which has sufficient viscosity stability and water solubility, even in the neutral range; an aqueous solution, coating agent, inkjet recording material, heat-sensitive recording material, and release paper base paper containing such a vinyl alcohol polymer; and manufacturing methods for the same. A vinyl alcohol polymer that comprises monomer units represented by formula (1), and that satisfies formula (I). The PVA preferably also satisfies formula (II) and (III). (I) 370=PS=6,000 (II) 200=P=4,000 (III) 0.1=S=10 (in the formulae, P represents the viscosity-average polymerization degree, and S represents the content of the abovementioned monomer units (mol%)).

Owner:KURARAY CO LTD

Composite brazing material and preparation method thereof

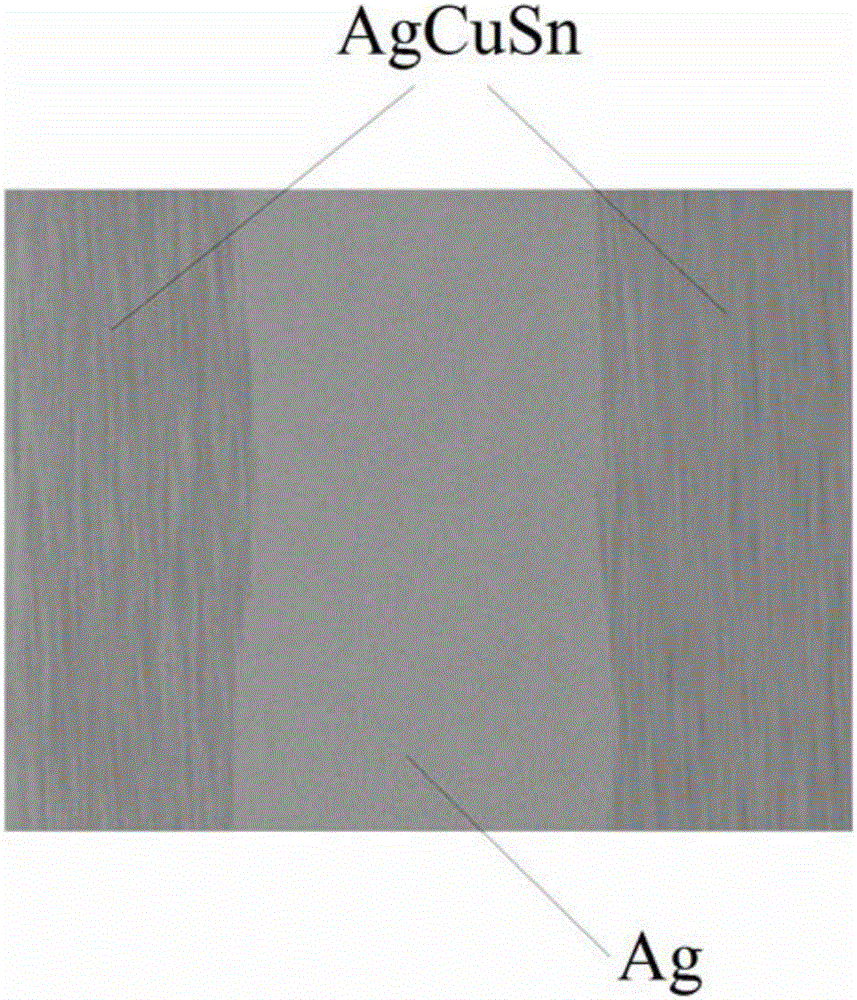

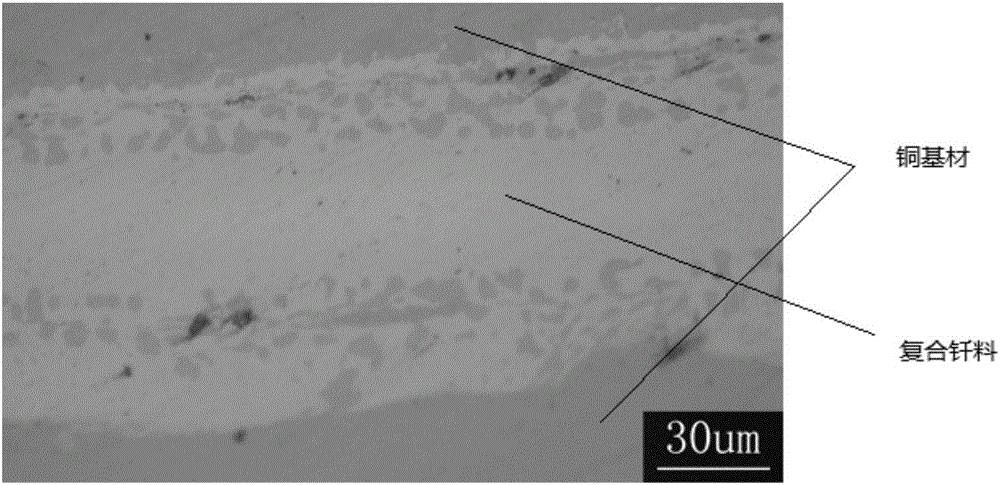

ActiveCN106271202AImprove caulking abilityImprove welding effectWelding/cutting media/materialsSoldering mediaCold airCopper

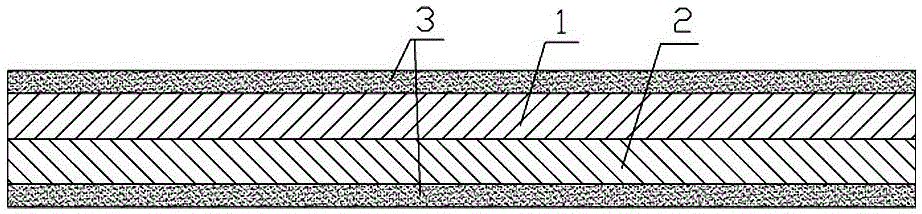

The invention discloses a composite brazing material and a preparation method thereof. A cross-section structure of the composite brazing material is a typical sandwich structure, alloys of two sides of the sandwich structure are silver, copper and tin, the weight percentage of the silver is 55-65%, the weight percentage of the copper is 27-35%, the weight percentage of the tin is 8-15%, and a middle layer of the sandwich structure is high-purity silver. The preparation method includes the steps: rolling to needed thickness by the aid of vacuum melting AgCuSn, linearly cutting into two plates with same sizes, grinding surfaces by abrasive paper, washing cleanness by ethyl alcohol, and drying in a blowing manner by cold air; compositing the two plates and Ag plates treated by the same modes together by a hot-pressing diffusion connection method, and preparing 0.02-0.5mm foil materials by a rolling method. The composite brazing material is excellent in brazing performance and can serve as electric vacuum solders to weld components and parts of same or different metals such as copper, nickel, steel and kovar alloys.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Ruthenium-vanadium binary alloy high-temperature brazing material

ActiveCN101412163ALow vapor pressureLow melting pointWelding/cutting media/materialsSoldering mediaMg elementImpurity

The invention discloses a high-reliability cathode component for a vacuum electron device, wherein the ruthenium-vanadium binary alloy high-temperature cored solder taking refractory metal tungsten and molybdenum as base materials consists of the following materials in weight percentage: 23 to 40 percent of vanadium, and the balance being ruthenium and inevitable micro impurities; and the contents of Zn, Pb, Bi and Mg elements in the micro impurities are no more than 0.001 percent respectively. The cored solder can be used to braze-solder refractory metal w, Mo and alloy of w or Mo in the H2 or Ar gas atmosphere or in a vacuum state, the cored solder does not absorb hydrogen, can spread over base metal, and has good wettability; the wet angle is less than 10 degrees; and when a soldering piece is soldered under the vacuum working condition with a temperature of between 1,000 and 1,200 DEG C, the vapor pressure of the cored solder is lower than 1x10<-5>Pa; moreover, the cored solder is low in price, and is the first choice of solder replacing the Pt and Pt-based solder for the braze solder of the cathode component for the vacuum electron device, and the melting temperature of the cored solder is between 1,750 and 1,850 DEG C.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

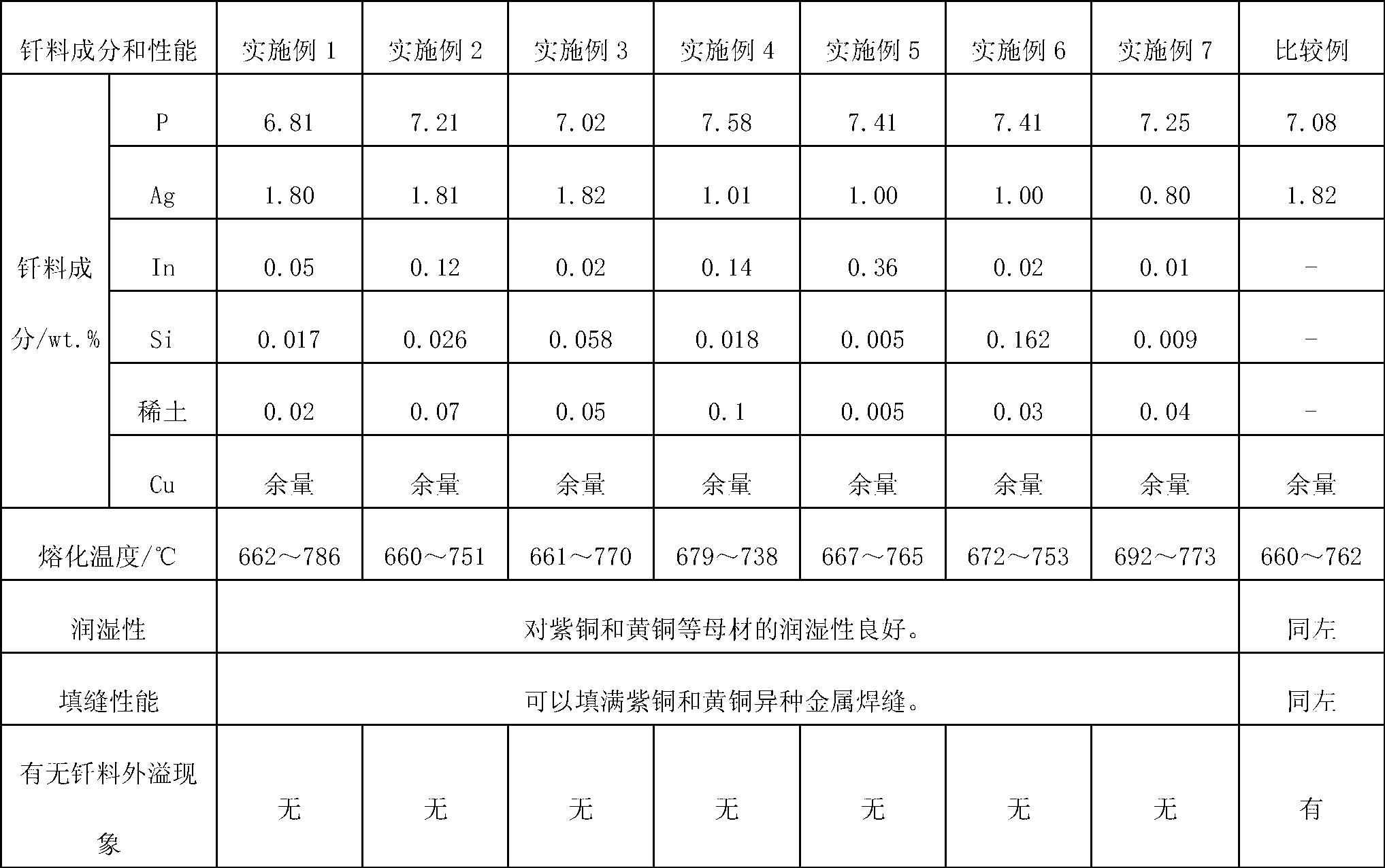

Low-silver copper-based solder free of spillover phenomenon during weld period

ActiveCN103008915ANo spillageRight melting pointWelding/cutting media/materialsSoldering mediaIndiumRare earth

The invention discloses a low-silver copper-based solder free of a spillover phenomenon during a weld period. Aiming at the defect that the spillover phenomenon of the solder often occurs when brazing is performed by using traditional low-silver copper-based solder, the invention aims to provide the low-silver copper-based solder which is controllable in flowability and is free of the spillover phenomenon of the traditional low-silver copper-based solder during a process of welding copper and copper alloy. The low-silver copper-based solder disclosed by the invention is realized through the following technical scheme: the low-silver copper-based solder free of the spillover phenomenon during the weld period comprises the following components in weight percent: 6.6-7.8 percent of phosphorus (P), 0.5-2.2 percent of silver (Ag), 0.01-0.4 percent of indium (In), 0.001-0.2 percent of silicon (Si), 0.001-0.1 percent of rare earth and the balance copper (Cu).

Owner:浙江信和科技股份有限公司

CVD (chemical vapor deposition) diamond brazing nickel-based alloy brazing sheet and preparation method thereof

InactiveCN103302419AOvercome costsOvercome the problems of high melting point and poor filling abilityWelding/cutting media/materialsSoldering mediaLanthanumChemical vapor deposition

The invention discloses a CVD (chemical vapor deposition) diamond brazing nickel-based alloy brazing sheet and a preparation method thereof. The CVD diamond brazing nickel-based alloy brazing sheet comprises the following components in weight percentage: 8.0-12% of Cr, 2.5-4.0% of Si, 1.5-2.0% of B, 7.8-11% of Sn, 0.4-1.0% of Ag, 0.1-1.0% of lanthanum neodymium, not more than 0.05% of impurities and the balance of Ni. The CVD diamond brazing nickel-based alloy brazing sheet overcomes the defects that the conventional Ag-based brazing material is high in cost and low in strength; the CVD diamond brazing nickel-based alloy brazing sheet contains Sn, so that the problems that the conventional Ni-Cr brazing material is high in melting point and poor in filling ability are solved; when the prepared nickel-based alloy brazing sheet is used for brazing a CVD diamond, the CVD diamond and the brazing sheet can form a chromium carbide compound, so that the bonding strength between the CVD diamond and the brazing sheet is high; the melting point of the brazing sheet is relatively low, so that heat damage to the CVD diamond is relatively small and the brazing sheet is easy to braze.

Owner:HENAN UNIV OF SCI & TECH

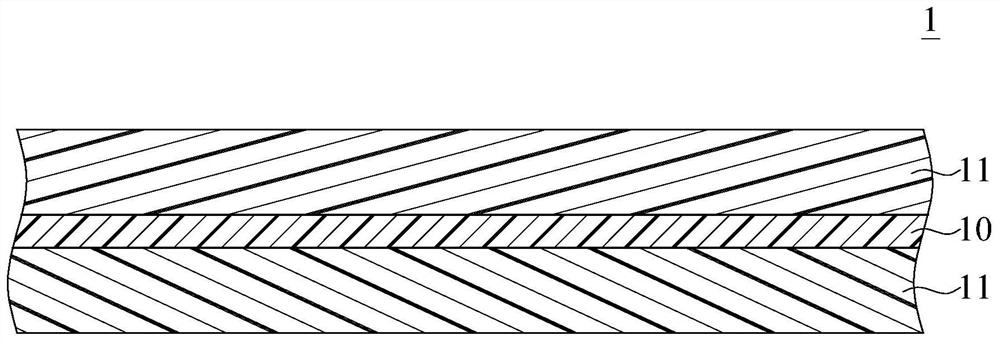

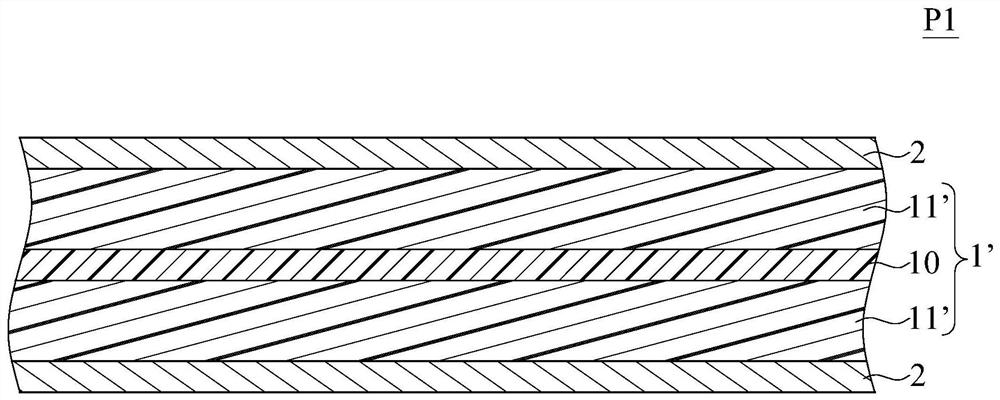

Multi-layer flux-cored silver solder and preparation method thereof

PendingCN113084390AImprove plasticityImprove liquidityWelding/cutting media/materialsSoldering mediaAlloySoldering process

The invention belongs to the technical field of soldering materials, and particularly relates to a multi-layer flux-cored silver solder and a preparation method thereof. The multi-layer flux-cored silver solder comprises an inner core layer, a middle layer attached to the surface of the inner core layer and an outermost layer wrapped on the middle layer. The inner core layer is an alloy wire, the middle layer is a silver soldering flux layer, and the outermost layer is a silver-based solder metal skin. And the melting point of the alloy wire is lower than that of the silver soldering flux layer. According to the multi-layer flux-cored silver solder, the melting temperature of the alloy wire of the core part is lower than that of soldering flux, in the soldering process, the alloy wire is firstly melted and then adheres to the soldering flux, the soldering flux is driven to flow out in advance and permeate into a soldering seam, and therefore the seam filling performance and flowing performance of the soldering flux are improved. The problems that conventional flux-cored silver solder is poor in fluidity and not prone to seam crossing during soldering, and the soldering flux is accumulated on the front face during soldering are solved, and therefore the soldering effect is improved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

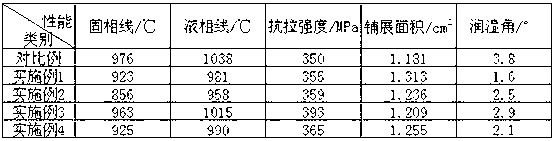

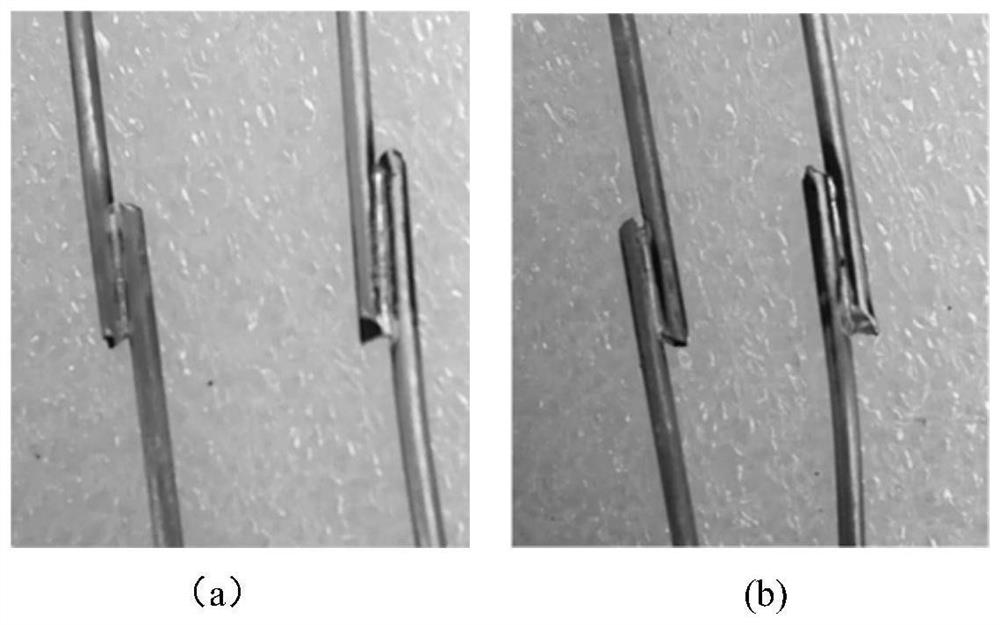

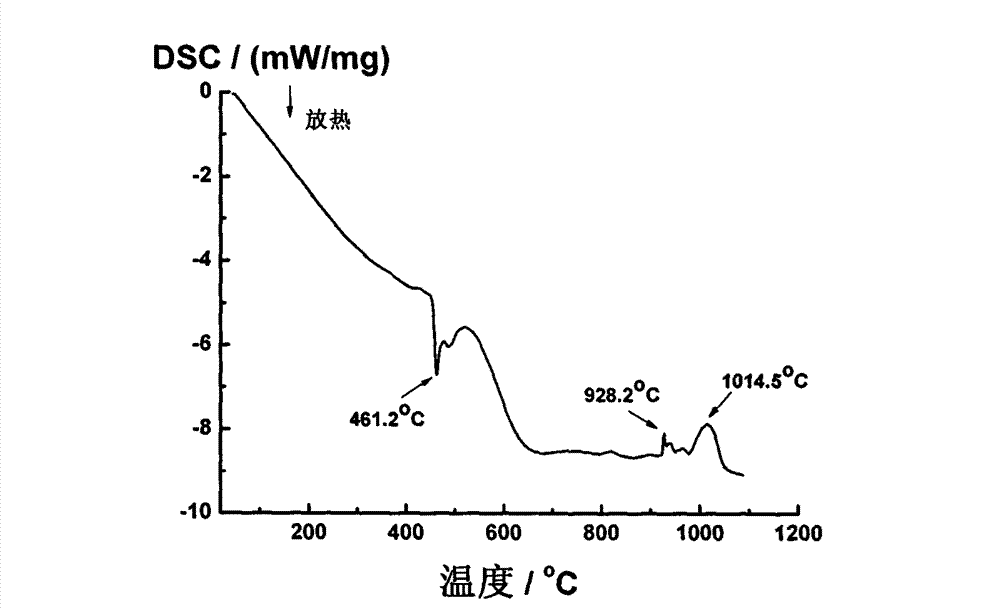

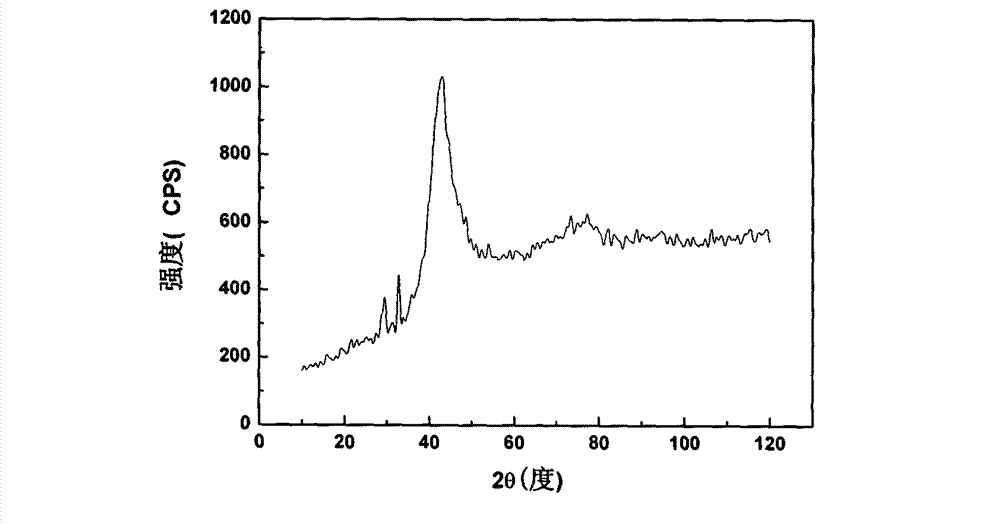

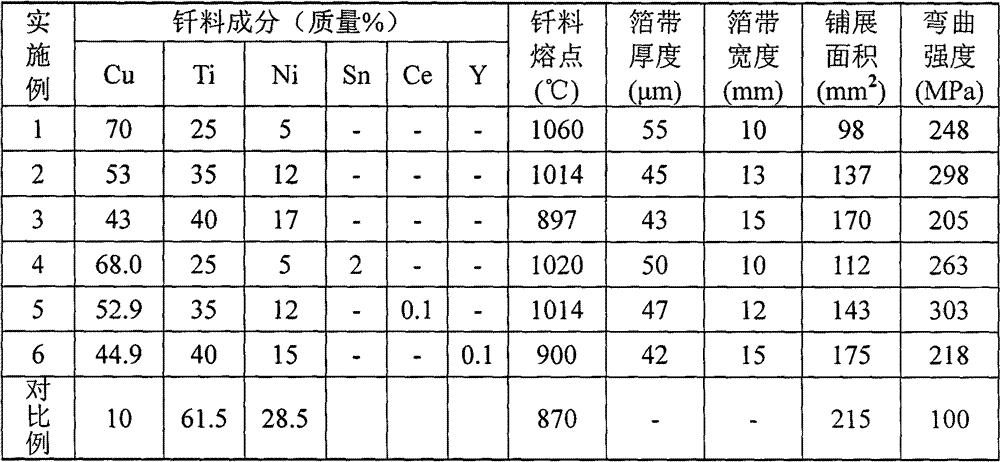

Amorphous foil brazing filler metal for ceramic braze welding

InactiveCN102814600AGood flexibilityEasy to assembleWelding/cutting media/materialsSoldering mediaFiller metalMetal

The invention relates to an amorphous foil brazing filler metal for ceramic braze welding. The amorphous foil brazing filler metal for ceramic braze welding is characterized by comprising following components according to mass percent: 43-70% of Cu, 25-40% of Ti and 5-17% of Ni, and further comprising 0.1-2% of Sn, Ce or Y. The brazing filler metal, provided by the invention, is the amorphous foil brazing filler metal which is easily assembled and welded and free of expensive Ag metal. The brazing filler metal has ductility, so that the fragility of crystalline brazing filler metal is avoided, and the brazing filler metal is easily assembled and shimmed when a complicated structure is subjected to braze welding. The melting range of the brazing filler metal is 895-1060 DEG C, the temperature of braze welding is 950-1100 DEG C, and the amorphous foil brazing filler metal is suitable for vacuum brazing of ceramic / ceramic or ceramic / metal.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

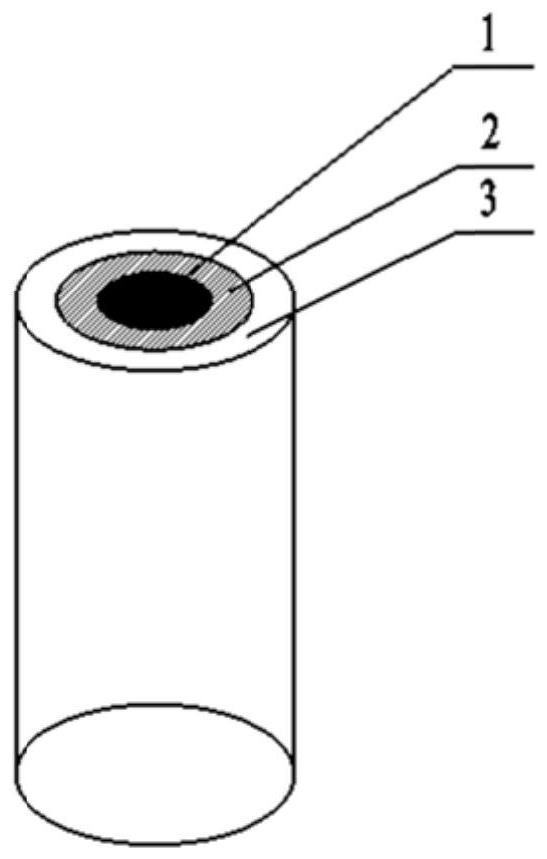

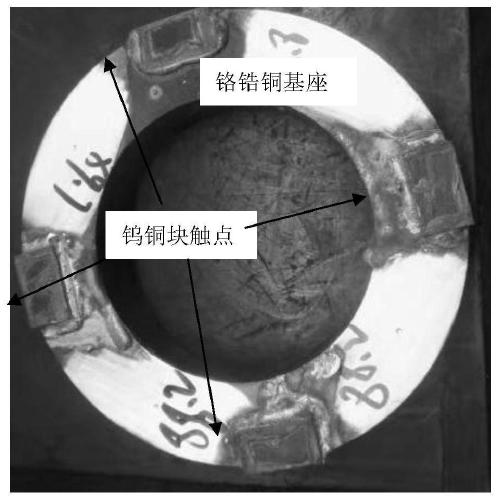

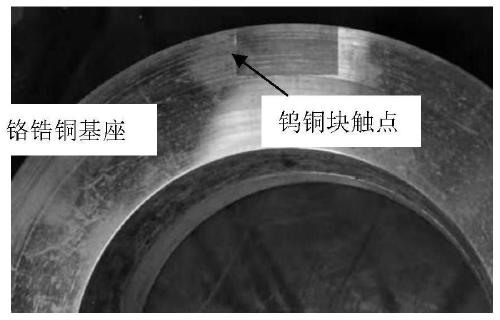

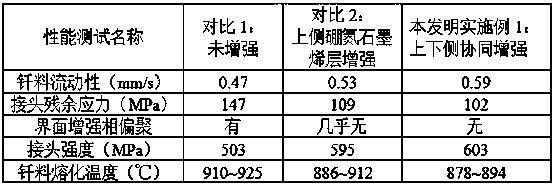

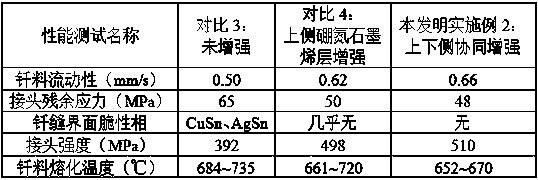

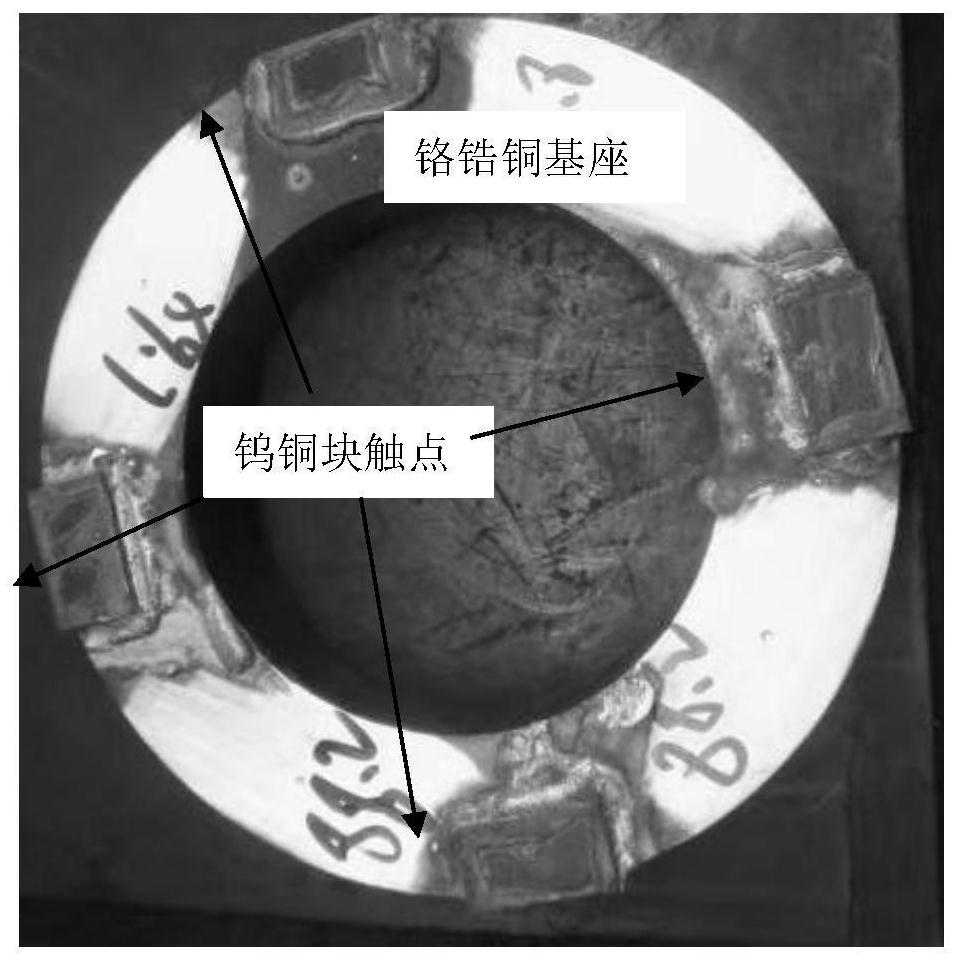

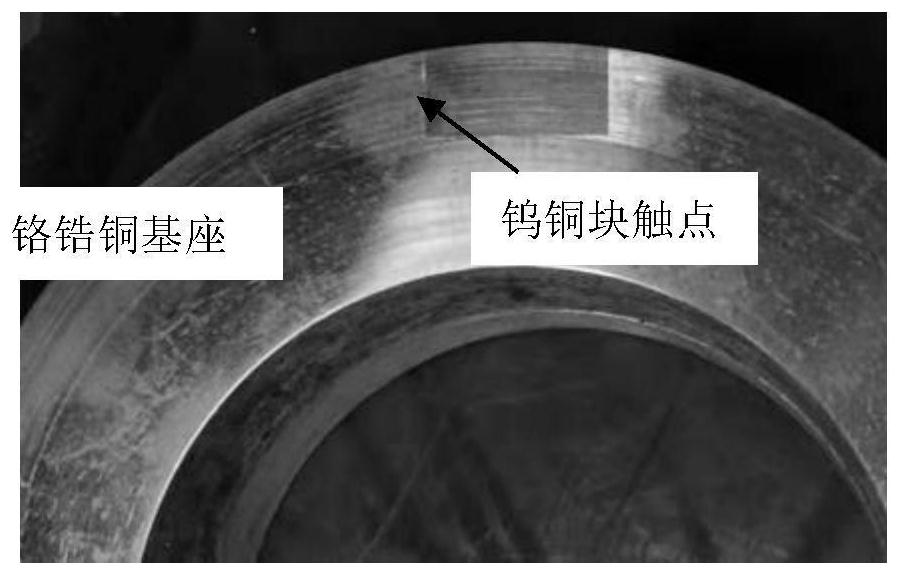

Brazing method of tungsten-copper alloy and chromium-zirconium-copper alloy

ActiveCN111360352AReduce hardnessLow soldering temperatureSoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedCavitation

The invention discloses a brazing method of a tungsten-copper alloy and a chromium-zirconium-copper alloy, and relates to the field of welding. The method aims to shorten the brazing time for the tungsten-copper alloy and the chromium-zirconium-copper alloy, avoid the use of a solder resist, reduce the brazing cost and improve the brazing efficiency. According to the method, the tungsten-copper alloy and the chromium-zirconium-copper alloy are connected by adopting an ultrasonic wave-assisted brazing method, ultrasonic waves are used in the brazing process through a titanium alloy intermediatelayer, and the spreading and wetting of melted brazing filler metal on a brazing surface are promoted by utilizing the acoustic cavitation effect; when the tungsten-copper alloy and the chromium-zirconium-copper alloy are combined and brazed, one of a base metals is moved to promote the discharge of bubbles, and then the ultrasonic wave-assisted brazing process is completed in a short period of time under the low brazing pressure; and in addition, the method can perform brazing in an atmospheric environment, the technical requirements for brazing operators are low, and the brazing efficiencyis high. The invention is applied to the field of brazing.

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

Low-melting-point and high-strength aluminum-based brazing filler metal and preparation method thereof

InactiveCN102000924BReduce brittlenessReduce surface tensionWelding/cutting media/materialsSoldering mediaHigh intensityNitrogen gas

The invention discloses a low-melting-point and high-strength aluminum-based brazing filler metal and a preparation method thereof. The brazing filler metal consists of the following components in percentage by mass: 6 to 13 percent of Si, 6 to 13 percent of Cu, 1 to 3 percent of Ni, 0.01 to 0.1 percent of Sr, 0.01 to 0.2 percent of Ti, 0.01 to 0.2 percent of Y and the balance of Al. The preparation method comprises the following steps of: weighing each component; adding the components into a graphite crucible melting furnace according to a certain sequence; melting and then refining twice, wherein argon gas and hexachloroethane are used as refining agents during the refining; introducing the hexachloroethane from bottom of solution by the argon gas, wherein the introduction pressure of the argon gas is 5 to 7KPa; and continuously casting solution which is subjected to the second refining process under the protection of nitrogen gas as required or performing gas atomization to form the aluminum-based brazing filler metal in different forms. The aluminum-based brazing filler metal prepared by the method has the superior characteristics of low melting point, high strength, toughness, wettability and spreadability and the like.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

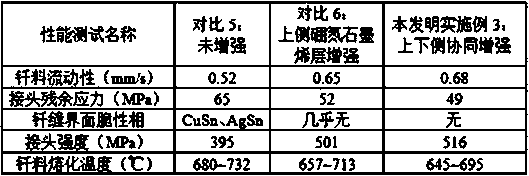

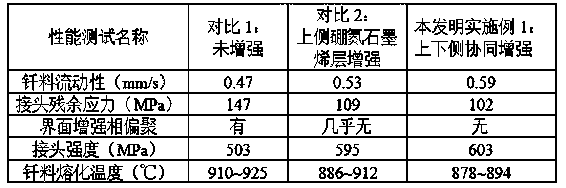

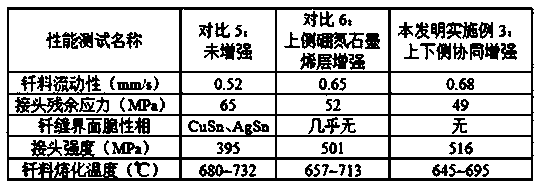

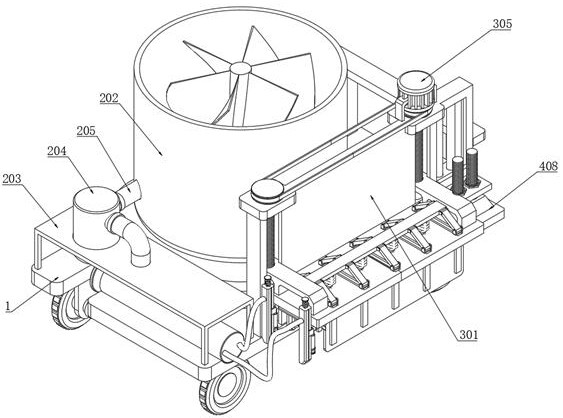

Variable-scale boron-nitrogen graphene modified layer brazing filler metal as well as preparation method and application thereof

ActiveCN110497116AImprove organizationLow melting pointWelding/cutting media/materialsSoldering mediaGas phaseWeld strength

The invention discloses a variable-scale boron-nitrogen graphene modified layer brazing filler metal. The brazing filler metal comprises a variable-scale modified layer composed of a boron-nitrogen graphene reinforced alloy layer which is formed in an upper surface layer, a brazing filler metal layer which is formed in a middle layer and a boron-nitrogen graphene coated foam metal layer which is formed in the lower surface layer, and the preparation method comprises the following steps that a silver brazing material sheet or a gold brazing filler metal sheet is selected, firstly, a boron-nitrogen graphene reinforced nickel-based alloy is sputtered on the upper surface of the brazing filler metal sheet, wherein the nickel-based alloy is a binary or ternary nickel-based alloy consisting of nickel, palladium, gold and copper, then a boron-nitrogen graphene coated foam metal layer is subjected to vapor deposition on the lower surface of the brazing filler sheet, wherein the foam metal is binary nickel-based alloy consisting of nickel-chromium, nickel-gold, nickel-silver or nickel-copper; and the prepared modified layer brazing filler metal can be used for connection of high-nitrogen steel and high-strength steel, the tensile strength of the high-nitrogen steel and the high-strength steel subjected to braze connection is not lower than 500 MPa. The brazing filler metal prepared through the method has a variable-scale layer and can generate a nano-scale effect, so that the mechanical property of the brazing filler metal can be synergistically enhanced, and the welding strength ofthe high-strength steel and the high-nitrogen steel can be improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and preparation method thereof

InactiveCN102319963BReduce brittlenessImprove surface activityWelding/cutting media/materialsSoldering mediaSlagAlloy

The invention relates to an Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal and a preparation method thereof. The components of the aluminum-based brazing filler metal are 7 to 13 percent by weight of Si, 5 to 11 percent by weight of Cu, 4 to 11 percent by weight of Zn, 1 to 6 percent by weight of Sn, 1 to 3 percent by weight of Ni, 0.02 to 0.3 percent by weight of Ce, 0.01 to 0.1 percent by weight of Sr, 0.01 to 0.2 percent by weight of Zr and the balance of Al. The process flow for preparing the aluminum-based brazing filler metal is that: pure aluminum is added into a graphite crucible and covered by flux for aluminum under the condition of 800 DEG C to 900 DEG C, and slag is removed after melting; the aluminum-based intermediate alloy of high-melting point elements and flux for aluminum are added at the same time, and melting, stirring and slag removal are carried out; the aluminum-based intermediate alloy of low-melting point elements is added under the protection of nitrogen, and melting and stirring are carried out; the mixture of argon and hexachloroethane is added to carry out refining, and standing and slag removal are carried out; the intermediate alloy of trace elements is added, and melting and stirring are carried out; secondary refining and slag removal are carried out; and under the protection of nitrogen, casting formation is carried out. The Al-Si-Cu-Zn-Sn-Ni aluminum-based brazing filler metal has the advantages of low melting point, high strength, high toughness, high corrosion-resistant property and good wetting property and spreadability.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

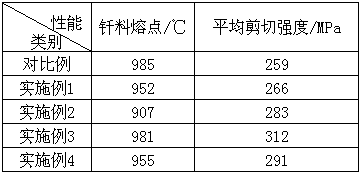

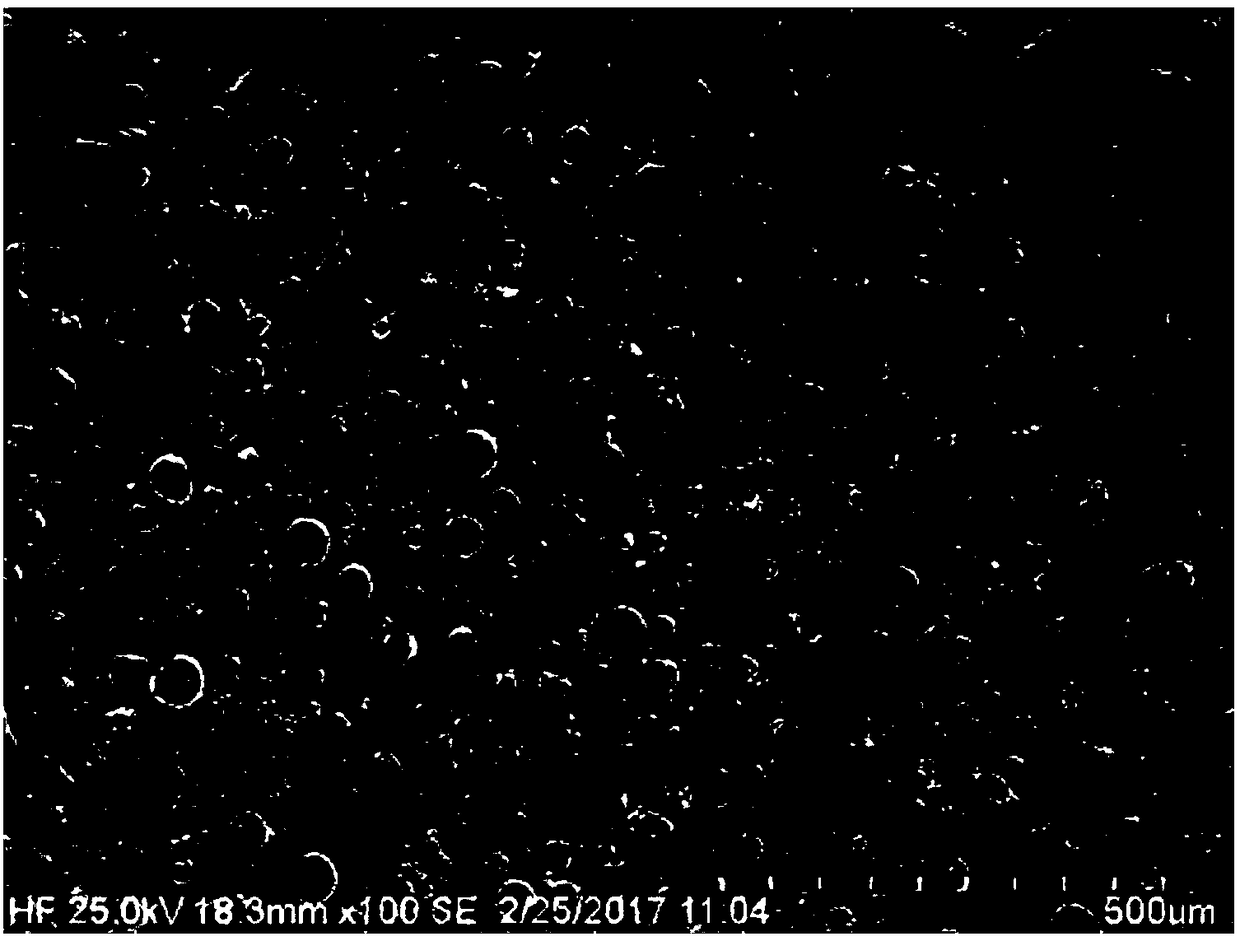

Rare earths-containing iron-based solder for stainless steel braze welding and method for braze welding by using same

InactiveCN103817457AImprove mechanical propertiesHigh melting pointWelding/cutting media/materialsSoldering mediaLanthanideRare earth

The invention discloses a rare earths-containing iron-based solder for stainless steel braze welding and a method for braze welding by using the solder, and relates to a rare earths-containing iron-based solder and a method for braze welding by using the solder. The invention aims to solve the problems of the existing iron-based solder that the melting temperature is high, phosphorus brittle phase is caused when the existing iron-based solder is used for welding, and the shearing strength of a joint is greatly lowered. The rare earths-containing iron-based solder for stainless steel braze welding is prepared from Cr, Ni, Si, P, Cu, rare earths of the lanthanide series and Fe according to the mass fraction. Powder of the Fe, Cr, Ni, Cu, P, Si and rare earths of the lanthanide series is heated so as to reach a liquid alloy state, an atomization method is adopted for obtaining alloy powder, the powder and a binder are uniformly mixed, and are coated on a to-be-welded surface of stainless steel, a workpiece to be welded is obtained, the workpiece is put into a vacuum braze welding furnace, and then vacuum braze welding treatment is carried out. The solder and the method have the advantages that the shearing strength of a welding joint can reach 180-200Mpa, and excellent mechanical property can be realized.

Owner:HARBIN INST OF TECH

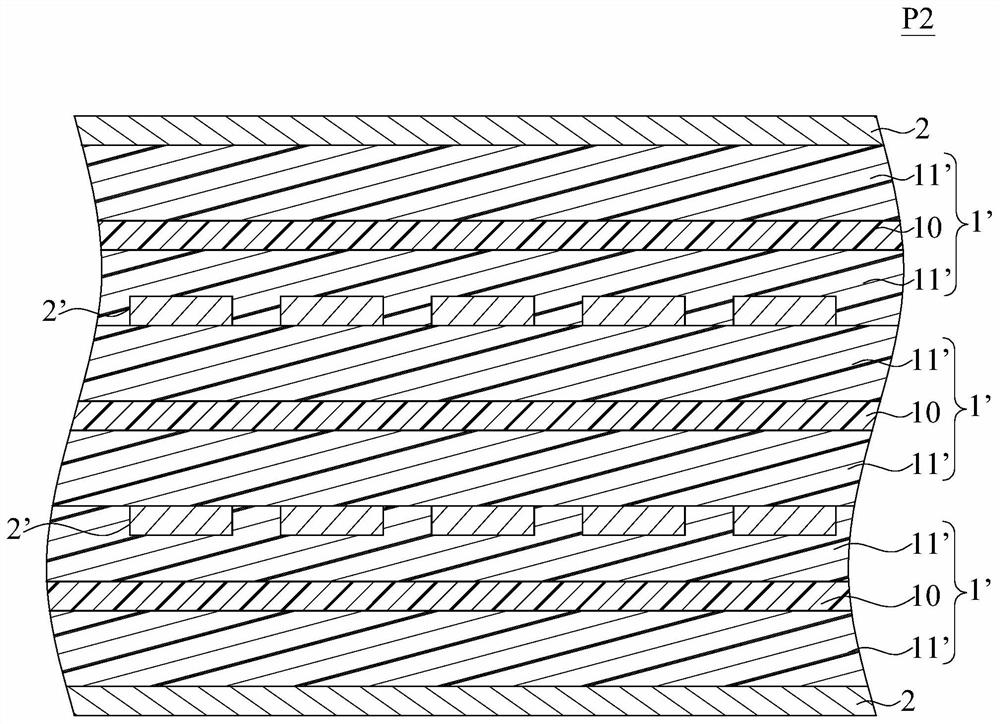

Wetting-piloted composite solder and preparation method thereof

InactiveCN106181124ABeautiful shapeHigh tin contentMolten spray coatingWelding/cutting media/materialsComposite solderMaterials science

The invention discloses wetting-piloted composite solder which comprises a tin layer and a solder alloy layer, which are compositely rolled, wherein soldering flux layers are sprayed and deposited on the outer surfaces of the tin layer and the solder alloy layer respectively to form a finished composite solder product with a four-layer structure; the thicknesses of the tin layer and the solder alloy layer can be adjusted within 0.01-20 mm according to the clearance filling property of the solder and the size of a clearance; and the thicknesses of the soldering flux layers are adjusted within 0.01-10 mm according to the level of difficulty in removing an oxide film of a workpiece. During preparation of the composite solder, a tin belt and a solder alloy belt are put into a precision rolling machine to be compositely rolled so that the uniform-thickness tin layer is formed on the surface of the solder alloy layer, and then the uniform thickness soldering flux layers are deposited on the outer surfaces of the tin layer and the solder alloy layer in a hot spraying way to form the finished composite solder product with the four-layer structure. A preparation method provided by the invention saves energy and protects the environment, the composite solder is high in tin content and uniform in thickness and beautiful in forming, and since the composite solder has soldering flux, automatic, accurate and quantified addition of the soldering flux is realized during soldering.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

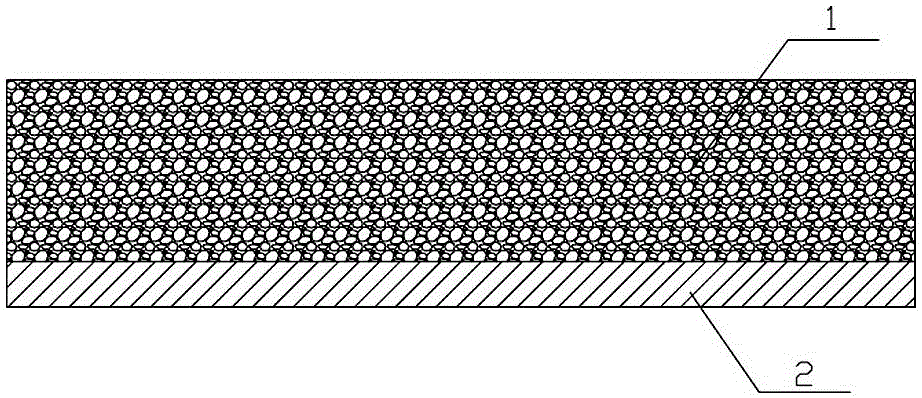

Brazing filler metal-carried hard alloy block and preparation method thereof

InactiveCN106112315AImprove assembly accuracyEasy assembly precisionWelding/cutting media/materialsSoldering mediaCemented carbideThermal spraying

The invention discloses a brazing filler metal-carried hard alloy block. The brazing filler metal-carried hard alloy block has a double-layer structure; and a brazing filler metal alloy layer is compounded on the lower surface of the hard alloy block. The thickness of the brazing filler metal alloy layer can be adjusted within 0.01-20 mm according to the size of a brazing filler metal filling gap. The brazing filler metal alloy layer is one of pure copper, copper base, silver base, manganese base, palladium base and titanium base brazing filler metal. During preparing, the brazing filler metal alloy is prepared as a coiled wire for future use by smelting, extruding and drawing procedures; the oil removal and the sand blasting are performed for the surface of the hard alloy block to guarantee no oil, no impurity and no oxidation on the surface to be welded; and then, the coiled wire-shaped brazing filler metal alloy is sprayed on the surface to the welded of the hard alloy block by thermal spraying equipment to form the brazing filler metal alloy layer with a certain thickness. The brazing filler metal-carried hard alloy block has the advantages of high assembly precision and convenience; as the thickness of the brazing filler metal layer compounded on the hard alloy block is controllable, the quantitative and precise adding of brazing filler metal is realized; and the hard alloy and the brazing filler metal interface form metallurgic bonding, so that the gap filling performance of the brazing filler metal to the hard alloy in the brazing process is improved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

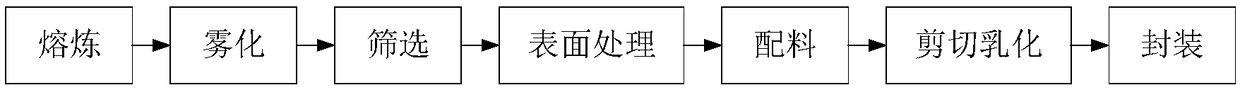

Composite silver brazing welding paste and preparing method thereof

ActiveCN108296671AShape controllableSolve liquidity problemsWelding/cutting media/materialsSoldering mediaEmulsionColloid

The invention provides composite silver brazing welding paste. The composite silver brazing welding paste comprises components including 30-60 wt% of alloy welding powder, 10-30 wt% of brazing flux and 20-40 wt% of colloid. The alloy welding powder is composed of AgCu alloy powder and CuP alloy powder, wherein the mass ratio of the AgCu alloy powder to the CuP alloy powder meets the formula: AgCu:CuP=0.5-2. The invention further relates to a preparing method of the above welding paste. Starting from the brazing character of brazing filler metal, AgCu high-conductivity, high-heat-conduction andhigh-strength brazing filler metal and CuP high-wetability and high-joint-filling-capability brazing filler metal are guided, the component and grain size distribution combination design is adopted for the AgCu high-conductivity, high-heat-conduction and high-strength brazing filler metal and the CuP high-wetability and high-joint-filling-capability brazing filler metal, then, the colloid and thebrazing flux are added, and the composite silver brazing welding paste material is prepared through shearing emulsion machining. The composite silver brazing welding paste has the beneficial effectsthat the operation technology is simple, and feasibility is high; and the prepared welding paste material has good fluidity and high joint filling capability, and the characters of high conductivity,high heat conduction and high strength are kept after welding.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

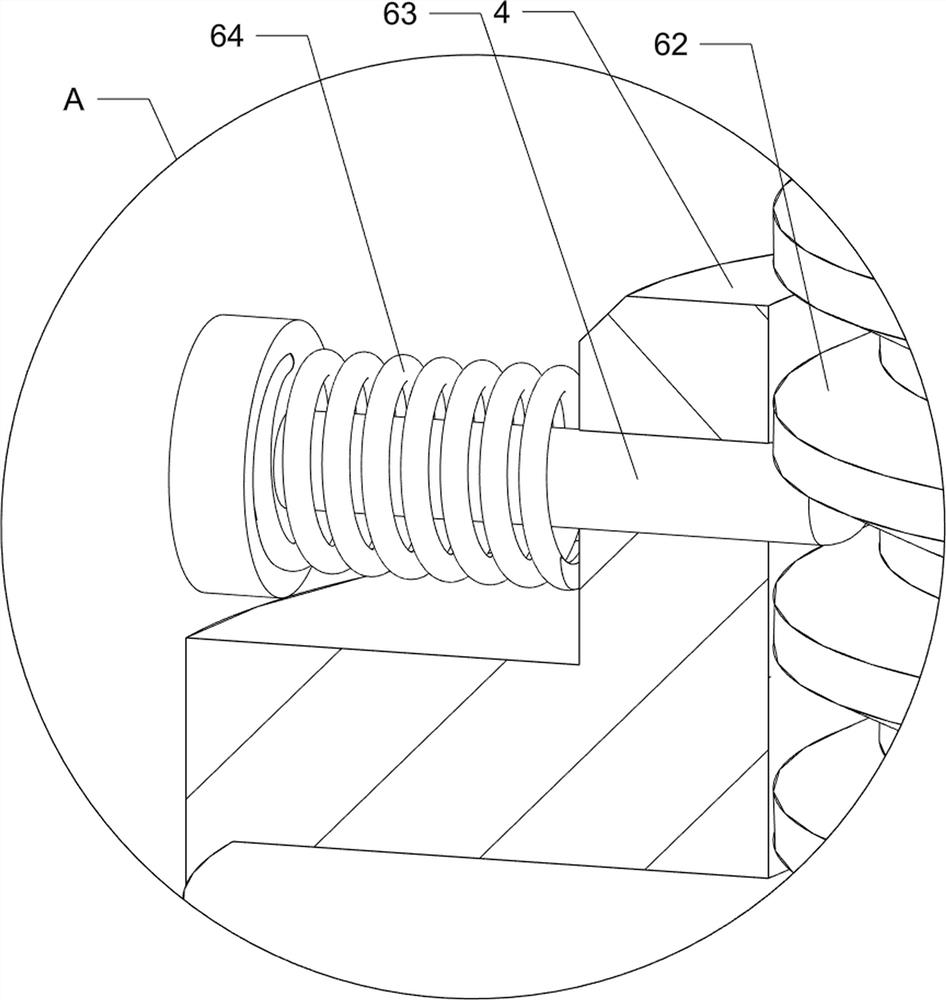

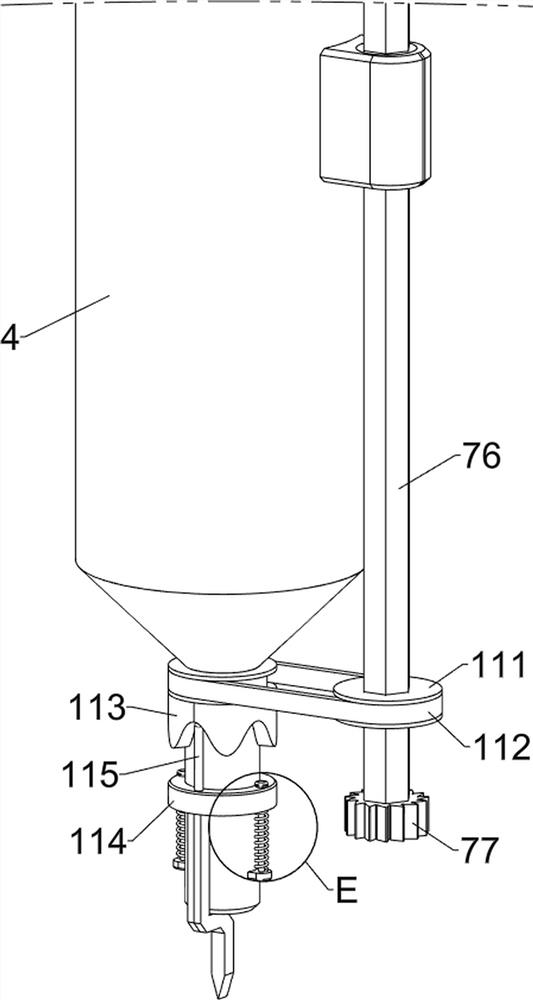

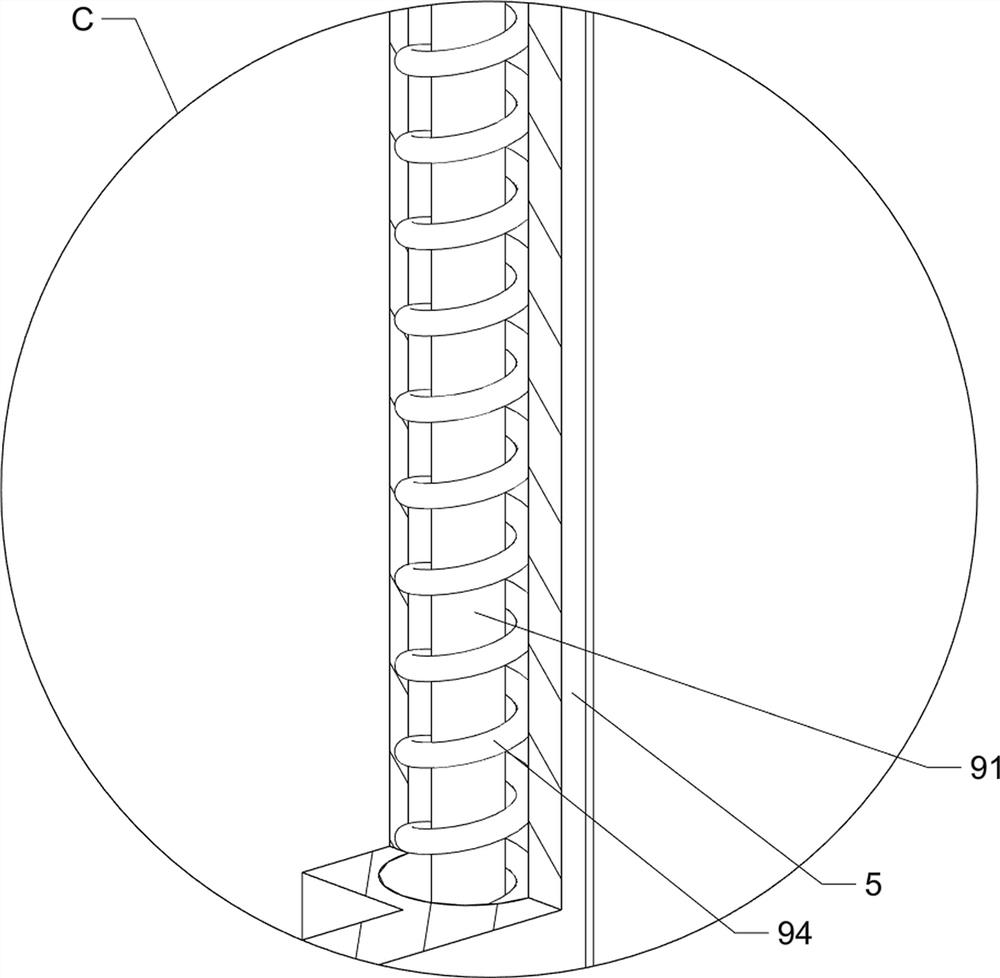

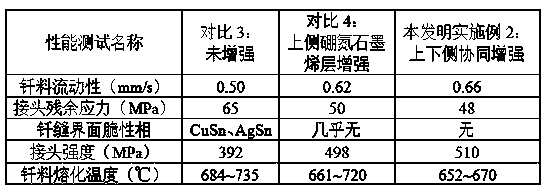

Ceramic tile joint filling device for building decoration

PendingCN114197833AHigh precisionEnhance the effect of caulkingBuilding constructionsElectric machineryCeramic tiles

The invention relates to a ceramic tile joint filling device, in particular to a ceramic tile joint filling device for building decoration. The ceramic tile joint filling device for building decoration saves time and labor and is high in precision. The ceramic tile joint filling device for building decoration comprises a sliding rail, two first supporting rods, a shell, a storage tank and the like, the two first supporting rods are arranged in the middle of the inner side of the sliding rail in a sliding mode, and the shell is arranged between the tops of the first supporting rods; a material storage tank used for conveying the joint mixture into gaps between the ceramic tiles is arranged between the upper portions of the inner sides of the first supporting rods. The first motor is used as driving force to drive the rolling wheels to rotate so as to drive the storage tank to move left and right, meanwhile, the lead screw can be driven to rotate, the lead screw can drive the push block to move downwards so as to extrude a joint mixture in the storage tank downwards, the joint mixture falls into gaps between tiles, time and labor are saved, and the precision is high.

Owner:淦家旺

Nickel-based brazing material and preparation method thereof

ActiveCN114378481AHigh strengthLarge grainWelding/cutting media/materialsSoldering mediaRare-earth elementManganese

The invention belongs to the technical field of brazing materials, and discloses a nickel-based brazing material and a preparation method thereof. The nickel-based brazing material comprises the following chemical components in percentage by weight: 8-17% of Mn, 2-6% of Mo, 10-20% of Cr, 0.5-3% of Si, 2-10% of R and the balance of Ni and inevitable impurities. Wherein R is a rare earth element. Manganese and silicon in the brazing filler metal reduce the melting point of the brazing filler metal, meanwhile, silicon is added to improve oxidation resistance and fluidity, molybdenum is added to improve the wettability of the brazing filler metal to a weldment, rare earth is combined to further improve the joint filling capacity of the brazing filler metal, the toughness and strength of a brazed joint are improved, and the service life of the brazing filler metal is prolonged. And the problem of high brittleness of a brazed joint caused by the existence of silicon is solved. In addition, chromium can form an anti-oxidation layer, and the corrosion resistance of the brazed joint is improved.

Owner:JIANGSU PROVINCE XUZHOU TECHNICIAN INST

A kind of brazing method of tungsten-copper alloy and chromium-zirconium-copper alloy

ActiveCN111360352BReduce hardnessLow soldering temperatureSoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedTitanium alloy

A brazing method for tungsten-copper alloy and chromium-zirconium-copper alloy, which relates to the field of welding. The purpose of the invention is to shorten the welding time of tungsten-copper alloy and chromium-zirconium-copper alloy, avoid the use of solder resist, reduce welding cost, and improve welding efficiency . The invention adopts the method of ultrasonic-assisted brazing to connect tungsten-copper and chromium-zirconium-copper alloy, and uses the ultrasonic wave in the welding process through the titanium alloy intermediate layer to promote the spreading and wetting of the melted solder on the welding surface by using the acoustic cavitation effect . When tungsten-copper alloy and chromium-zirconium-copper alloy are welded together, one of the base metals is moved to promote the discharge of air bubbles, and then the ultrasonic-assisted brazing process is completed in a short period of time under a lower welding pressure. In addition, the present invention can Welding in the atmospheric environment has low technical requirements for welding operators and high welding efficiency. The invention is applied in the field of welding.

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

Ruthenium-vanadium binary alloy high-temperature brazing material

ActiveCN101412163BLow vapor pressureLow melting pointWelding/cutting media/materialsSoldering mediaMg elementImpurity

The invention discloses a high-reliability cathode component for a vacuum electron device, wherein the ruthenium-vanadium binary alloy high-temperature cored solder taking refractory metal tungsten and molybdenum as base materials consists of the following materials in weight percentage: 23 to 40 percent of vanadium, and the balance being ruthenium and inevitable micro impurities; and the contents of Zn, Pb, Bi and Mg elements in the micro impurities are no more than 0.001 percent respectively. The cored solder can be used to braze-solder refractory metal w, Mo and alloy of w or Mo in the H2 or Ar gas atmosphere or in a vacuum state, the cored solder does not absorb hydrogen, can spread over base metal, and has good wettability; the wet angle is less than 10 degrees; and when a soldering piece is soldered under the vacuum working condition with a temperature of between 1,000 and 1,200 DEG C, the vapor pressure of the cored solder is lower than 1x10<-5>Pa; moreover, the cored solder islow in price, and is the first choice of solder replacing the Pt and Pt-based solder for the braze solder of the cathode component for the vacuum electron device, and the melting temperature of the cored solder is between 1,750 and 1,850 DEG C.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Fluorine-containing resin prepreg and circuit board using same

PendingCN114479322AReduce the temperatureImprove caulking abilityDielectric materialsSynthetic resin layered productsVinyl etherTetrafluoroethylene

The invention discloses a fluorine-containing resin prepreg and a circuit substrate using the same. The fluorine-containing resin prepreg comprises the following components in parts by weight: 100 parts of fluorine-containing resin and 20 to 110 parts of inorganic filler, the fluorine-containing resin includes polytetrafluoroethylene (PTFE) at a weight percentage concentration of 10% to 80%, a perfluoroethylene propylene copolymer (FEP) at a weight percentage concentration of 10% to 50%, and a tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer (PFA) at a weight percentage concentration of 0.1% to 40%. The circuit substrate comprises a fluorine-containing resin substrate and a circuit layer formed on the fluorine-containing resin substrate. The fluororesin prepreg and the circuit substrate using the same disclosed by the invention can improve the gummosis property and the caulking property of the fluororesin prepreg during pressing, so that the fluororesin prepreg is suitable for manufacturing a high-frequency circuit substrate.

Owner:NANYA PLASTICS CORP

Copper-base alloy tin solder and its use method

InactiveCN100588493CGrain refinementImprove wettabilityWelding/cutting media/materialsSoldering mediaAlloyCopper

The invention discloses a copper-based alloy solder comprising copper, phosphorus, tin and palladium. The mass percentage and the proportion of each composition are as follows: phosphorus, 0.1 percentto 0.3 percent; tin, 4 percent to 12 percent; palladium, 0.05 percent to 0.2 percent; the remaining is copper and inevitable impurities. The operation method of the copper-based alloy solder is thatthe copper-based alloy solder is used for welding the suction pipes of air conditioners and refrigerators and the exhaust pipes of air conditioners and refrigerators; the welding adopts gas-protectingwelding. The tin and palladium are added to the copper-based alloy solder, on one hand the wetting property, the spreading and sealing properties of alloy materials are improved, and on the other hand alloy grains is refined, thereby leading to compact welding seams, high strength of mechanical property, good welding quality and low cost. The copper-based alloy solder of the invention adopts themethod of welding the suction pipes and the exhaust pipes of the compressors of air conditioners and refrigerators in a gas-protecting state to get non-pickling welding seams, thus saving environmentgovernance cost.

Owner:ZHEJIANG HUAYANG SOLDER

A kind of variable-scale boron nitrogen graphene modified layer solder, preparation method and application

ActiveCN110497116BImprove organizationLow melting pointWelding/cutting media/materialsSoldering mediaNichromeAlloy

The invention discloses a variable-scale boron-nitrogen graphene modified layer brazing filler metal. The brazing filler metal comprises a variable-scale modified layer composed of a boron-nitrogen graphene reinforced alloy layer which is formed in an upper surface layer, a brazing filler metal layer which is formed in a middle layer and a boron-nitrogen graphene coated foam metal layer which is formed in the lower surface layer, and the preparation method comprises the following steps that a silver brazing material sheet or a gold brazing filler metal sheet is selected, firstly, a boron-nitrogen graphene reinforced nickel-based alloy is sputtered on the upper surface of the brazing filler metal sheet, wherein the nickel-based alloy is a binary or ternary nickel-based alloy consisting of nickel, palladium, gold and copper, then a boron-nitrogen graphene coated foam metal layer is subjected to vapor deposition on the lower surface of the brazing filler sheet, wherein the foam metal is binary nickel-based alloy consisting of nickel-chromium, nickel-gold, nickel-silver or nickel-copper; and the prepared modified layer brazing filler metal can be used for connection of high-nitrogen steel and high-strength steel, the tensile strength of the high-nitrogen steel and the high-strength steel subjected to braze connection is not lower than 500 MPa. The brazing filler metal prepared through the method has a variable-scale layer and can generate a nano-scale effect, so that the mechanical property of the brazing filler metal can be synergistically enhanced, and the welding strength ofthe high-strength steel and the high-nitrogen steel can be improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Shoulder stone treatment equipment for road construction

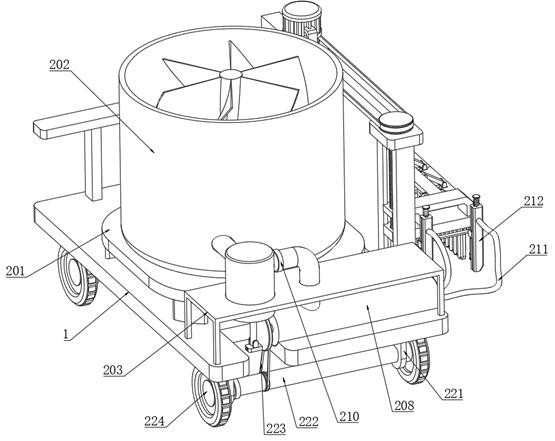

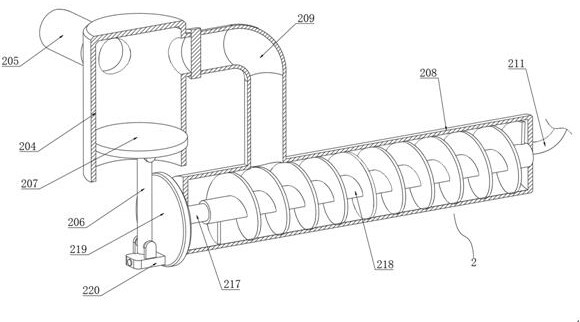

ActiveCN114737454AScientific and reasonable structureEasy to useRoads maintainenceVehicle frameTransmission belt

The shoulder stone treatment equipment for road construction comprises a movable vehicle frame, a movable discharging mechanism is arranged at the top end of the movable vehicle frame, a supporting roller and a connecting shaft rotate to drive a transmission belt, a conveying rotating rod and a rotating disc to rotate, and a push plate is pushed to move back and forth in a piston drawing cylinder through cooperation of a connecting supporting plate and a rocking rod; the concrete temporary storage device is scientific and reasonable in structure and safe and convenient to use, through cooperation of a transmission belt, a connecting shaft can conveniently drive a conveying rotating rod and a rotating disc to rotate, through cooperation of a connecting supporting plate and a rocker, an assembly is formed, and the concrete temporary storage device is convenient to use and high in practicability. And the push plate is pushed to move back and forth in the piston extraction cylinder, so that concrete in the temporary storage cylinder is pumped into the piston extraction cylinder through the slurry extraction pipe and then is fed into the slurry conveying cylinder through the slurry discharge pipe.

Owner:GUANGDONG PROVINCIAL ARCHITECTURAL ENG MACHINERY CONSTR

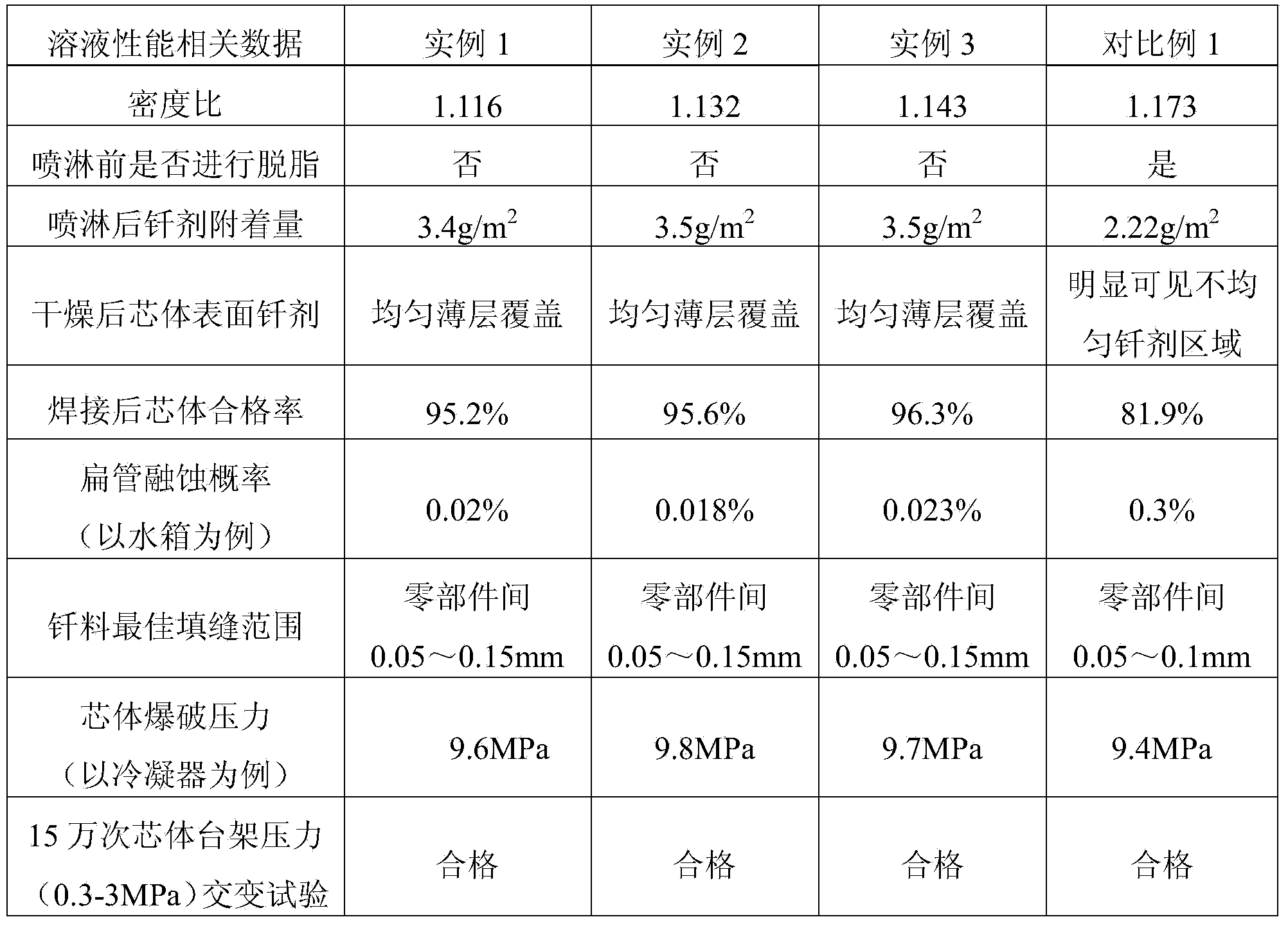

Brazing flux solution and application thereof

ActiveCN103506773AImprove caulking abilityWelding/cutting media/materialsSoldering mediaMetallurgyFiller metal

The invention discloses a brazing flux solution and application of the brazing flux solution. The brazing flux solution comprises, by weight, 16.0-20.0 parts of brazing flux, 9.5-10.5 parts of brazing flux additives, 1.6-2.0 parts of functional additives, and 68.0-72.4 parts of water. The brazing flux solution can remove volatile oil on the surface of base metal and enhances the brazing filler metal joint filling capacity.

Owner:GREAT WALL MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com