Shoulder stone treatment equipment for road construction

A technology for road construction and processing equipment, which is applied in the direction of roads, buildings, roads, etc., which can solve the problems of staggered heights of shoulder stones, staggered front and back, waste of shoulder stone joints, and inability to level shoulder stones, etc., so as to achieve safe and convenient use, Improve convenience and prevent spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

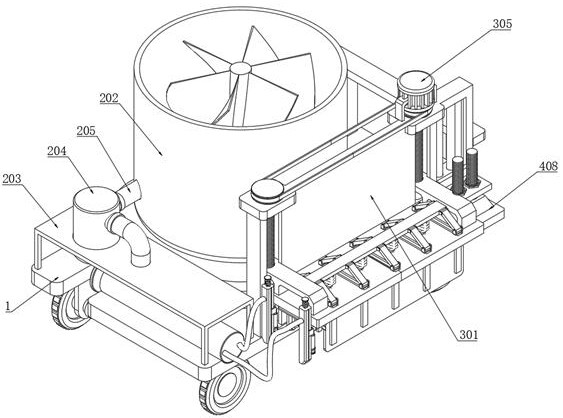

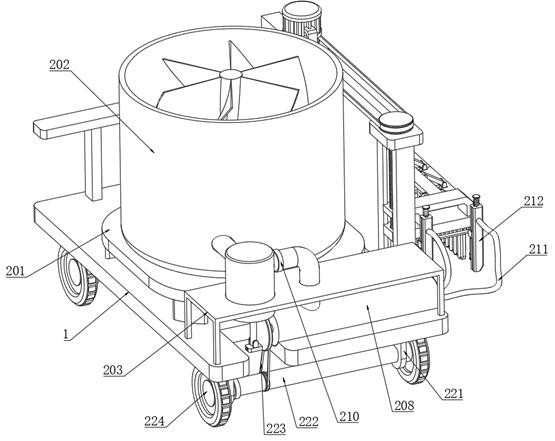

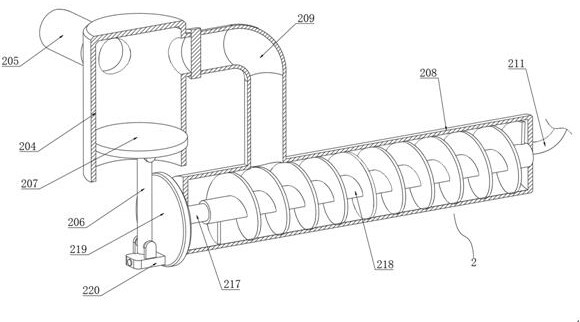

[0033] Example: as Figure 1-9 As shown, the present invention provides a technical solution, a shoulder stone treatment equipment for highway construction, including a mobile frame 1, a mobile discharge mechanism 2 is provided at the top of the mobile frame 1, the supporting roller 224 and the connecting shaft 222 rotate to drive The transmission belt 223, the conveying rod 217 and the rotating disc 219 rotate, and through the cooperation of the connecting support plate 220 and the rocker 206, push the push plate 207 to move back and forth inside the piston cylinder 204, so that the concrete inside the temporary storage cylinder 202 is drawn out through the slurry The cooperation of the pipe 205, the piston pumping cylinder 204 and the slurry discharge pipe 209 enters the interior of the slurry conveying cylinder 208, and then uses the conveying auger 218 to convey again;

[0034] A shoulder stone leveling and anti-deviation mechanism 3 is arranged at the top side of the mobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com