Composite silver brazing welding paste and preparing method thereof

A composite silver brazing technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of high price and increased manufacturing cost, and achieve low manufacturing cost, improved welding and brazing rate, and strong implementability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

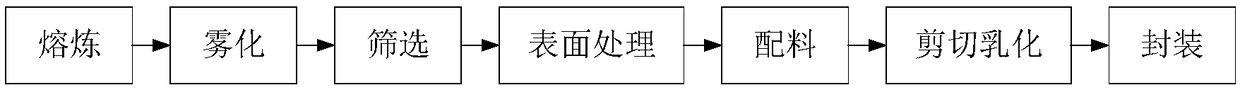

[0042] The present embodiment provides a kind of preparation method of composite silver solder paste, its implementation steps are as follows figure 1 Shown:

[0043] The first step: mix the AgCu alloy powder and the CuP alloy powder; weigh 6kg of the mixed powder and put it into the ball mill barrel, the mass ratio of the ball to material is 2:1, and weigh the stainless steel ball, and the speed is set to 30 rpm, Carry out homogeneous ball milling; obtain alloy solder powder; wherein: the mass ratio of AgCu alloy powder to CuP alloy powder is AgCu:CuP=0.5.

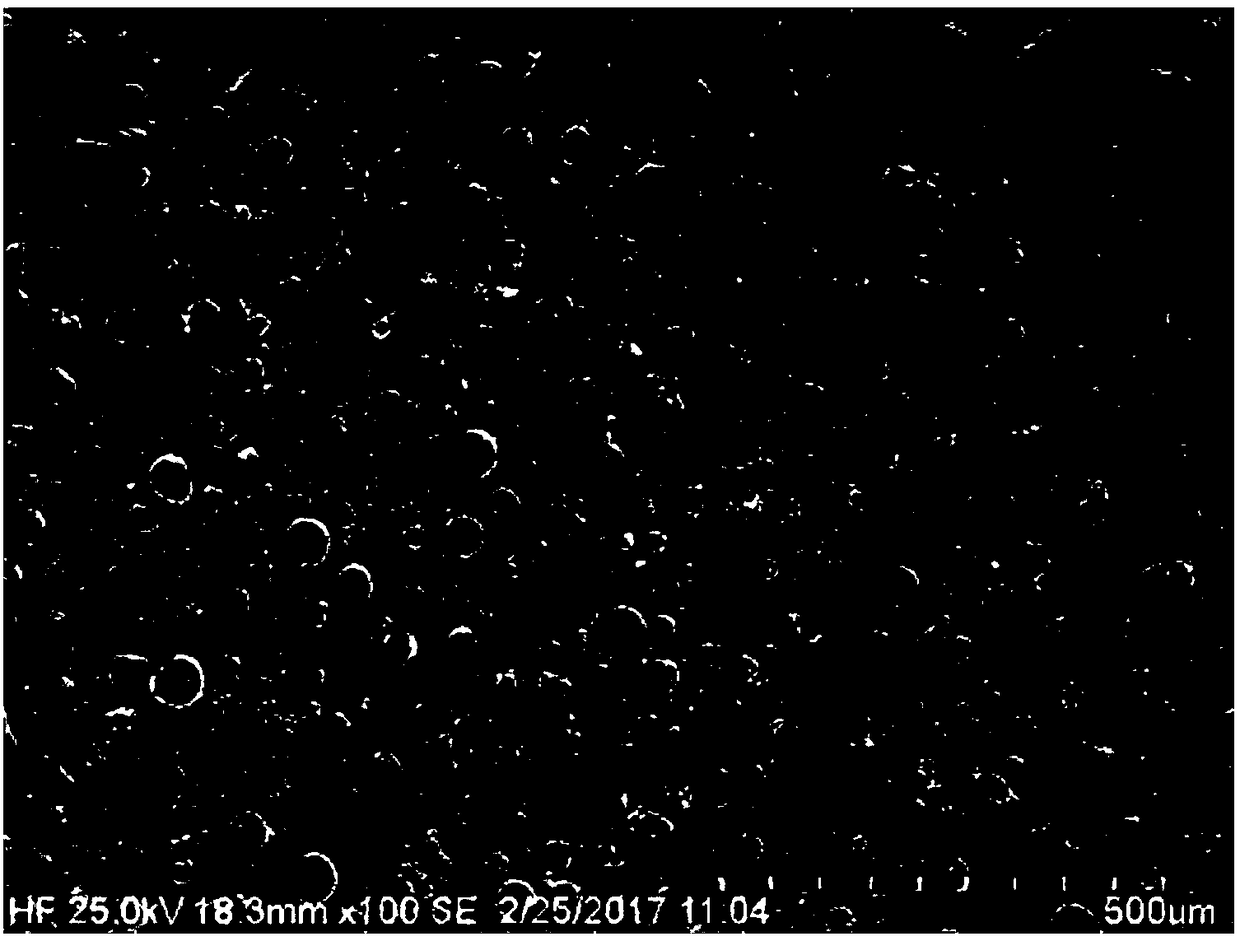

[0044] In this step, the AgCu alloy powder is produced by an atomization process, and of course, other methods can also be used in other embodiments.

[0045] In this step, the composition mass ratio of the AgCu alloy powder is selected as Ag:Cu=0.8;

[0046] In this step, the particle size of the AgCu alloy powder is selected as 200 mesh powder;

[0047] In this step, the grade of the CuP alloy powder is selected as C...

Embodiment 2

[0056] The present embodiment provides a kind of preparation method of composite silver solder paste, its implementation steps are as follows figure 1 Shown:

[0057] The first step: mix the AgCu alloy powder and the CuP alloy powder; weigh 6kg of the mixed powder and put it into the ball mill bucket, the ball-to-material ratio is 5:1, weigh the stainless steel ball, set the speed to 50 rpm, and carry out Homogenized ball milling to obtain alloy solder powder; wherein: the proportion of AgCu alloy powder and CuP alloy powder is AgCu:CuP=2.

[0058] In this step, the composition of the AgCu alloy powder is selected as Ag:Cu=4;

[0059] In this step, the particle size of the AgCu alloy powder is selected as 400 mesh powder;

[0060] In this step, the grade of the CuP alloy powder is selected as CuP-2;

[0061] In this step, the particle size of the CuP alloy powder is selected as 300 mesh powder.

[0062] The second step: the alloy solder powder processed in the first step is ...

Embodiment 3

[0069] The present embodiment provides a kind of preparation method of composite silver solder paste, its implementation steps are as follows figure 1 Shown:

[0070] The first step: mix the AgCu alloy powder and the CuP alloy powder; weigh 6kg of the mixed powder and put it into the ball mill bucket, the ball-to-material ratio is 3:1, weigh the stainless steel ball, set the speed to 40 rpm, and carry out Homogenized ball milling process to obtain alloy solder powder; wherein: the proportion of AgCu alloy powder and CuP alloy powder is AgCu:CuP=1.5.

[0071] In this step, the composition of the AgCu alloy powder is selected as Ag:Cu=3;

[0072] In this step, the particle size of the AgCu alloy powder is selected as 300 mesh powder;

[0073] In this step, the grade of the CuP alloy powder is selected as CuP-3;

[0074] In this step, the particle size of the CuP alloy powder is selected as 200 mesh powder.

[0075] The second step: the alloy solder powder processed in the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com