W18O49 coated carbon fiber composite material and preparation method thereof

A fiber composite material and carbon-coated technology, which is applied in the fields of carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of cumbersome preparation process, limited material properties and applications, and lack of directional growth, and achieves simple process and increased Effect of lifetime and carrier concentration, excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the present invention can grow W on the surface of all carbon fibers 18 o 49 Nanomaterials, for the convenience of the preparation process, the diameter of the carbon fiber is uniform, the present invention uses carbon cloth as the presentation form of the carbon fiber in the research and development process, the used carbon cloth (Carbon Fiber Cloth), the abbreviation of the carbon fiber cloth, the fabric of the carbon fiber, is made of pre-oxidized Polyacrylonitrile fiber fabric is made by carbonization or carbon fiber weaving, also known as carbon fiber cloth, carbon fiber cloth, carbon cloth, carbon fiber fabric, carbon fiber tape or carbon fiber sheet (prepreg cloth), etc. In principle all carbon cloths can realize the scheme of the present invention, the carbon cloth used in the embodiment of the present invention is directly purchased at Ce Tech Co., Ltd company, and the model is WOS1002, and the single carbon fiber diameter that forms c...

Embodiment 1

[0034] The WOS1002 carbon cloth purchased at Ce Tech Co., Ltd. was punched and cut into a circular substrate with a diameter of 12mm, placed in a concentrated nitric acid solution at 100°C for 1 hour, washed with deionized water for several times, and dried , Put into the reaction kettle of polytetrafluoroethylene lining (the reaction kettle volume is 50ml) for subsequent use. 0.1g (4g / L) of WCl 6 Add to 25ml absolute ethanol, stir well, when WCl 6After completely dissolving, a yellow transparent precursor solution is formed. Move the precursor solution into a reaction kettle containing carbon cloth, place it in an oven, and react at 160°C for 3 hours. After the reaction is completed, take out the carbon cloth and dry it with deionized water After cleaning several times, the carbon arrangement was dried at 60°C to obtain W 18 o 49 Wrapped with carbon cloth composite material.

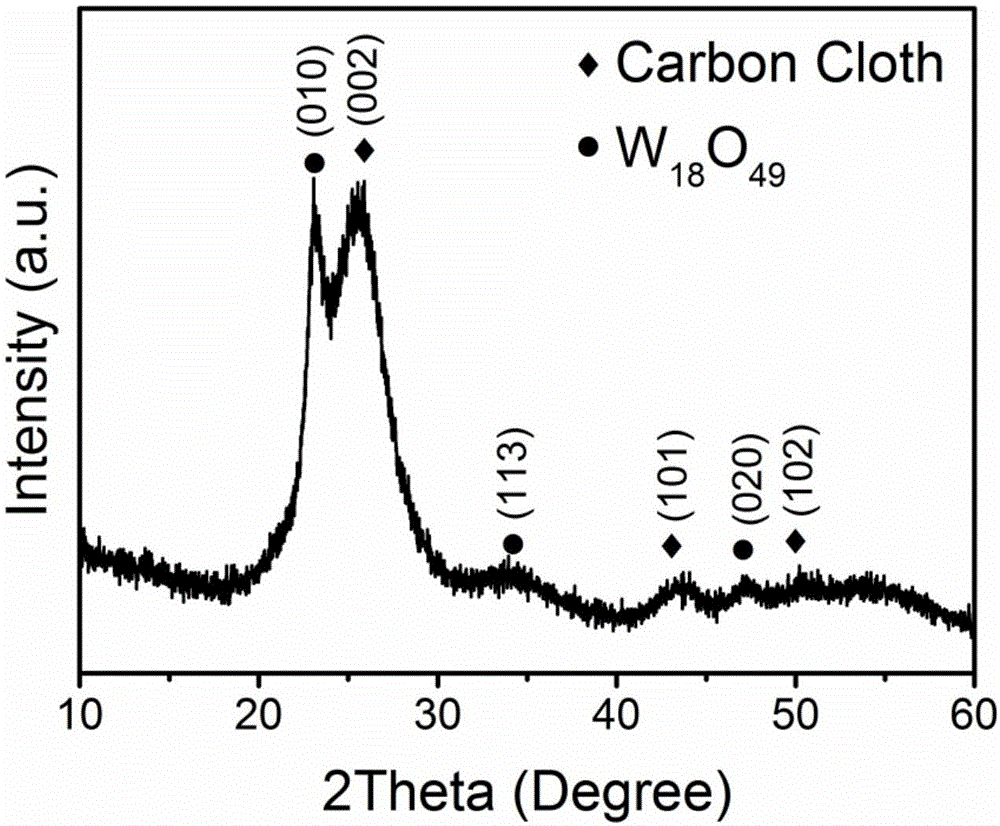

[0035] figure 1 Illustrate the product W of embodiment one 18 o 49 / Carbon fiber composite ma...

Embodiment 2

[0037] The WOS1002 carbon cloth purchased at Ce Tech Co., Ltd. was punched and cut into a circular substrate with a diameter of 12mm, put into a concentrated nitric acid solution at 100°C for 1 hour, washed with deionized water for several times, and dried , Put into the reaction kettle of polytetrafluoroethylene lining (the reaction kettle volume is 50ml) for subsequent use. 0.2g (8g / L) of WCl 6 Add to 25ml absolute ethanol, stir well, when WCl 6 After completely dissolving, a yellow transparent precursor solution is formed. Move the precursor solution into a reaction kettle containing carbon cloth, place it in an oven, and react at 180°C for 10 hours. After cleaning several times, the carbon arrangement was dried at 60°C to obtain W 18 o 49 Wrapped in carbon fiber composite.

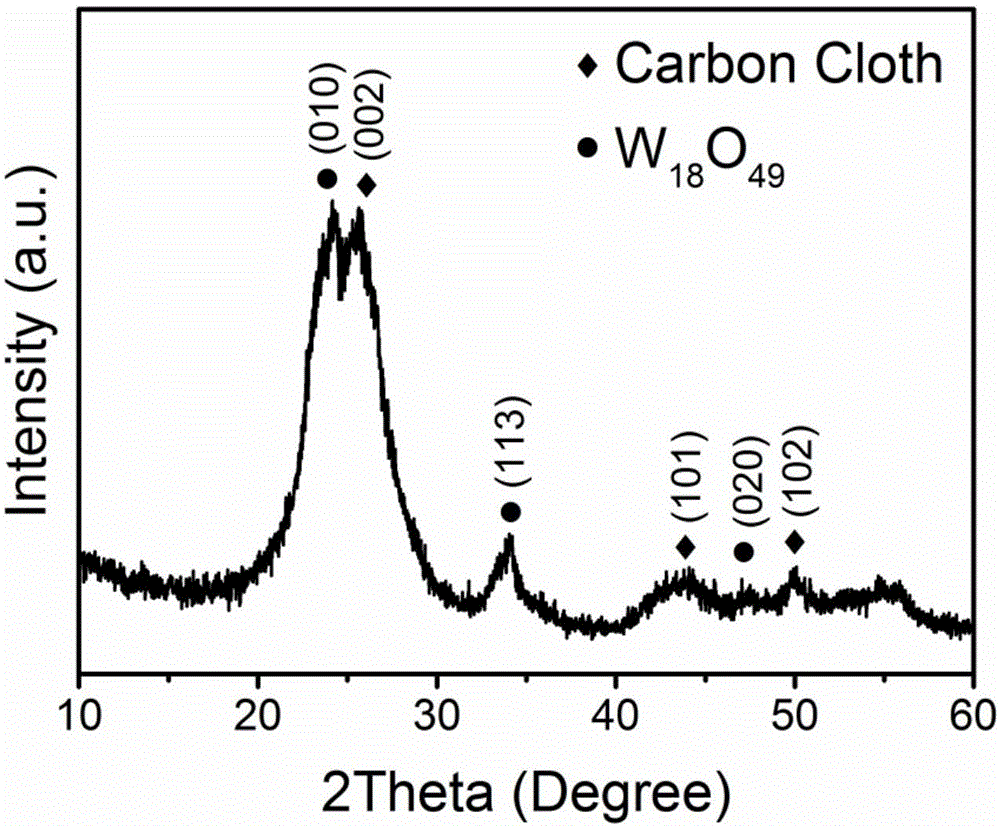

[0038] figure 2 Illustrate the product W of embodiment two 18 o 49 / Carbon fiber composite material, Figure 6 Illustrate the product W of embodiment two 18 o 49 Nanomaterials are very unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com