Patents

Literature

196results about How to "Shape controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

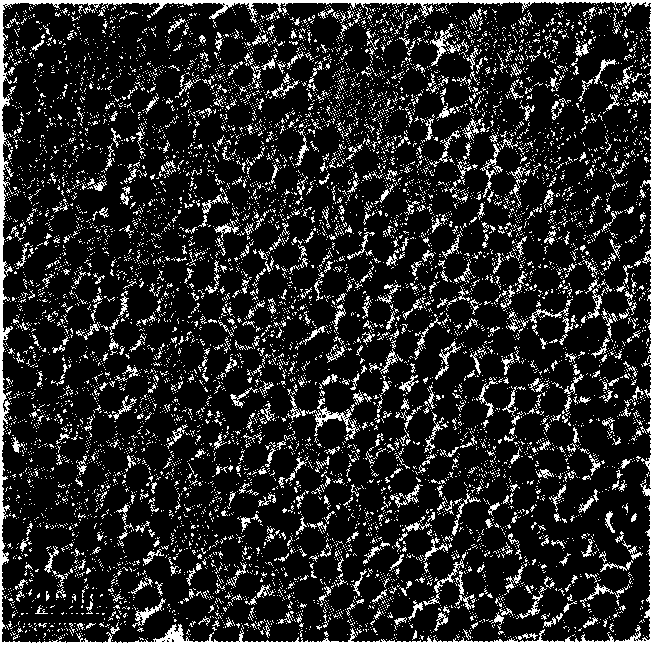

Nuclear shell nanometer catalyst packaged with noble metal nanometer grains and method thereof

InactiveCN101623634AShape controllableControllable shapeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystHeterojunction

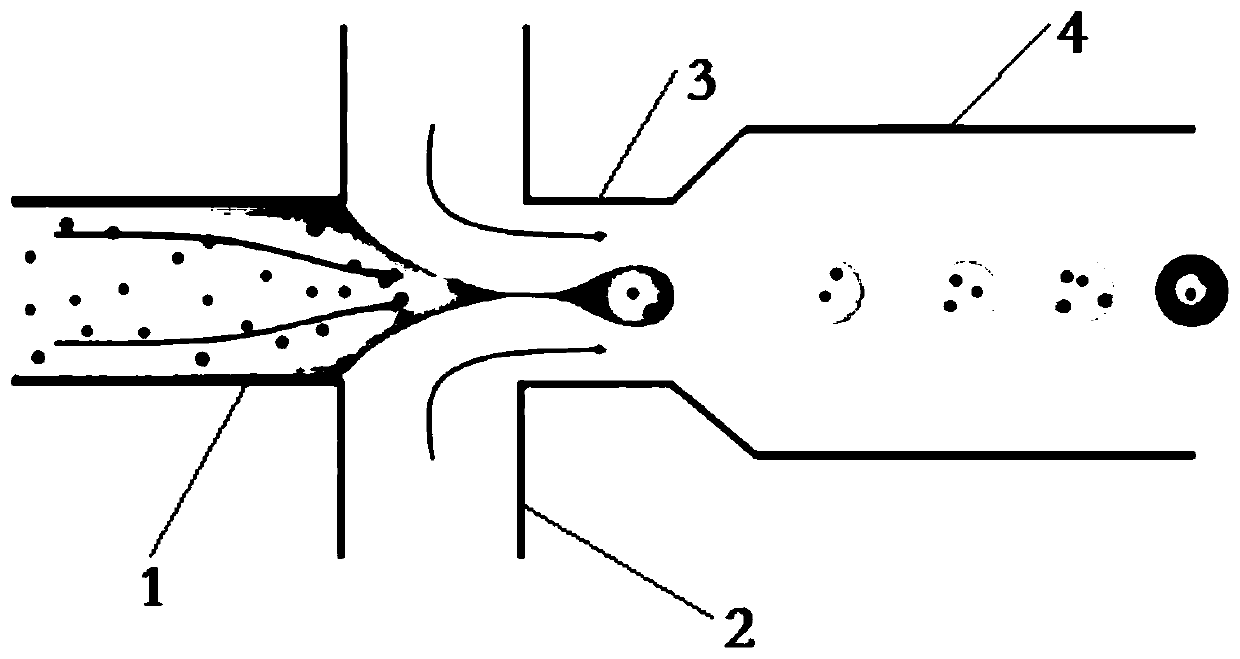

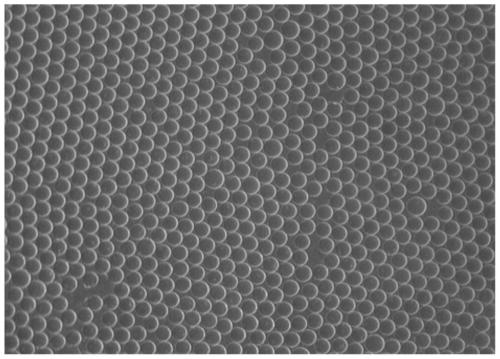

The invention relates to a nuclear shell nanometer catalyst packaged with noble metal nanometer grains and a method thereof, which relate to a nanometer catalyzing material. The invention provides a nuclear shell nanometer catalyst packaged with noble metal nanometer grains, which has a size of the noble metal grains less than 10nm, and higher contact level among noble metal grains and stability of the catalyst, can be reused and is adaptive to different using conditions by multi-level derivation, and also provides a preparation method thereof. The catalyst has a formula of NMP@X, NMP is nanometer grains such as Pd, AgPd or Au, and the like, and X is spherical SiO2, hollow SnO2 ball or hollow C ball. The method comprises the following steps: synthesizing noble metal nanometer grains and adorning the surface to obtain noble metal-iron oxide nanometer heterojunction; coating a silicon dioxide to obtain noble metal iron heterojunction oxide @ silicon dioxide nuclear shell nanometer material, growing porous pores on the surface, removing the silicon dioxide, and removing iron oxide on the noble metal nanometer grains so that the noble metal nanometer grains are located in a nanometer capsule of the hollow porous pores to obtain the product.

Owner:XIAMEN UNIV

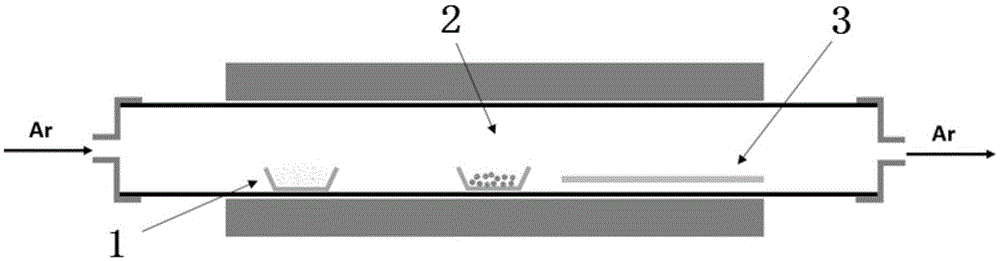

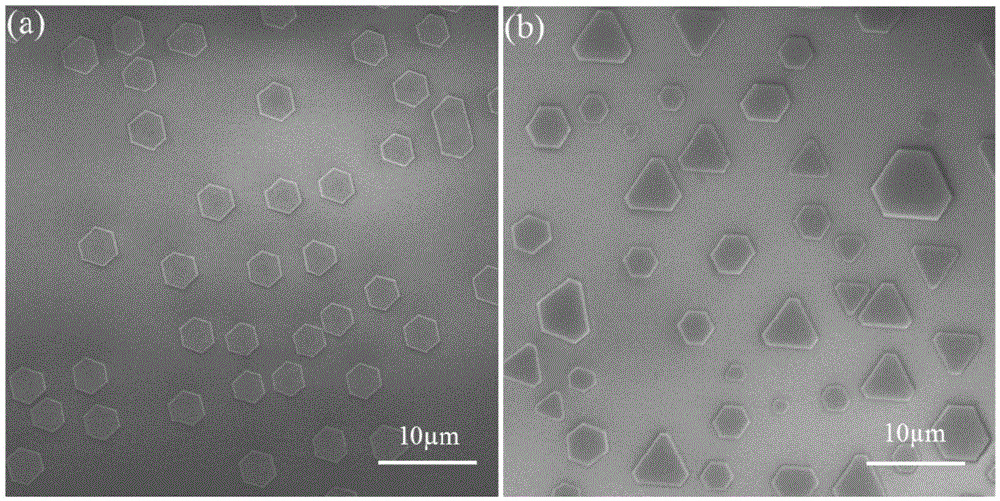

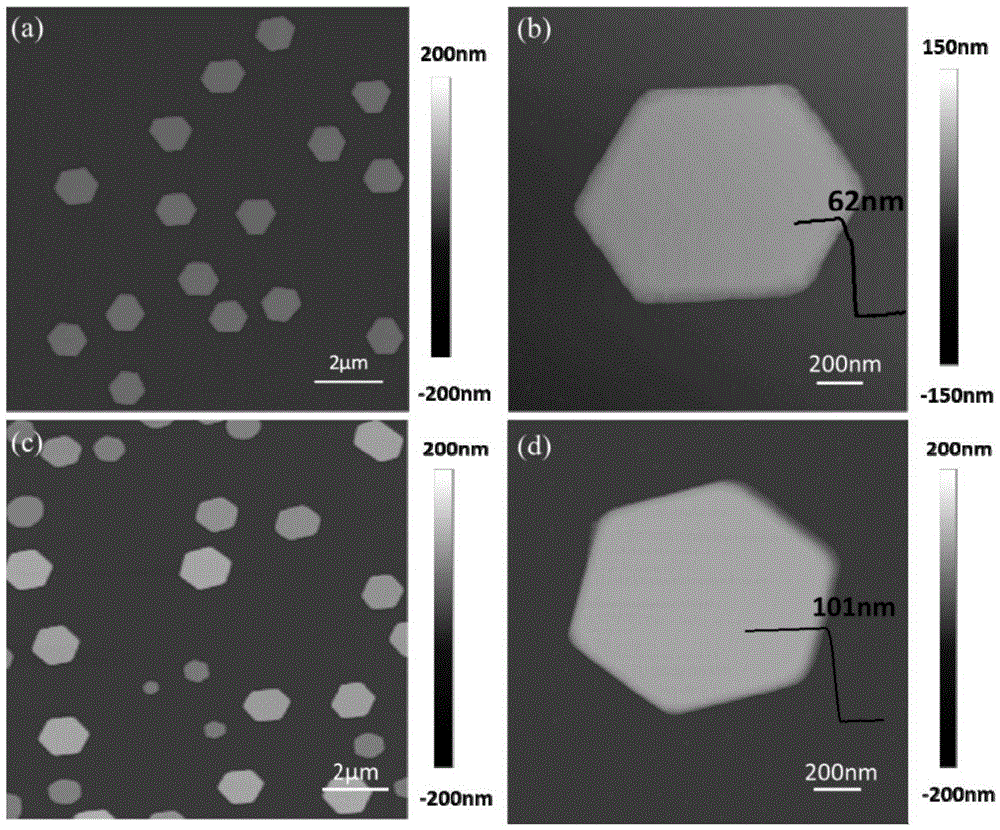

Preparation method of cadmium selenide or cadmium sulfide two-dimensional monocrystal nanosheet

ActiveCN105463580AIncrease the areaHigh crystallinityPolycrystalline material growthFrom chemically reactive gasesSource materialSingle crystal

The invention discloses a preparation method of a cadmium selenide or cadmium sulfide two-dimensional monocrystal nanosheet. The method comprises the steps that the CdSe or CdS two-dimensional monocrystal nanosheet is prepared through a van der Waals epitaxial growth technology, the method is characterized in that a mica sheet which is smooth in surface and free of chemical dangling bond is adopted to serve as a substrate, CdCl2 powder or Se powder or S powder serves as a source material, argon serves as carrier gas, CdCl2 stream is reacted with Se or S steam to form CdSe or CdS steam at high temperature, and the steam is deposited on the mica sheet for nucleation and epitaxially grows into the CdSe or CdS two-dimensional monocrystal nanosheet. The preparation method of the cadmium selenide or cadmium sulfide two-dimensional monocrystal nanosheet is easy to operate, low in cost and strong in controllability, the obtained CdSe or CdS has the advantages of being good in size uniformity, high in degree of crystallinity and the like, and important research value and wide application prospect in the fields of solar cells, field effect transistors, photoelectric detectors, photocatalyses and the like are achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

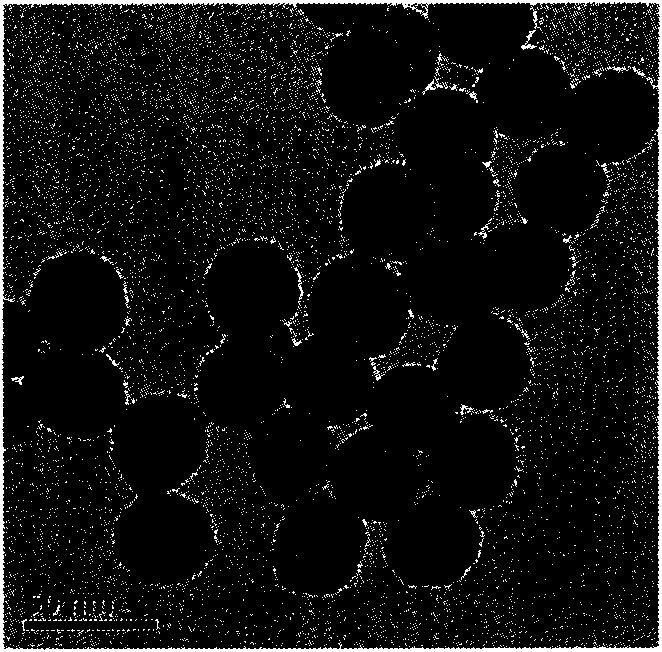

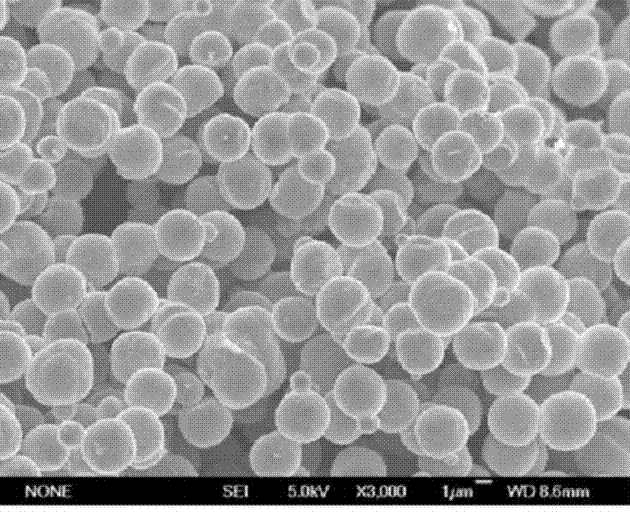

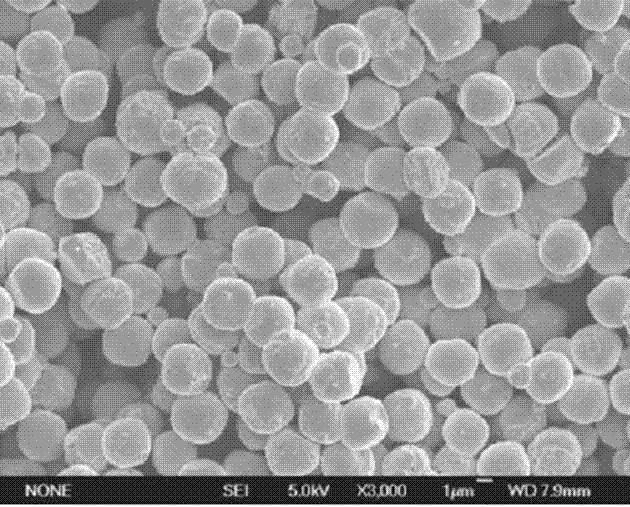

Preparation method of coal tar-based mesocarbon microbead

InactiveCN102653397AHigh content of phase carbon microspheresControl granularityCarbon preparation/purificationMicrosphereQuinoline

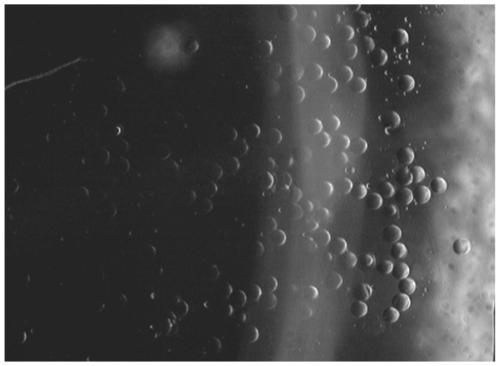

The invention discloses a preparation method of a coal tar-based mesocarbon microbead, comprising a process flow of pretreatment of raw materials, pyrocondensation polymerization reaction, separation and drying. The preparation method specifically comprises the following steps of: extracting, separating and removing primary quinoline insolubles of coal tar, as the raw materials, by using a mixed solvent to obtain coal tar refined soft pitch; then polymerizing the coal tar refined soft pitch for 1-8 hours at 350-450 DEG C under the rotating speed of 100-500 r / min and under the protection of inert gases by using anthracene oil or silicone oil as a reaction system viscosity regulator to obtain carbon microbead-containing mesophase pitches; and extracting by using a solvent, and drying to obtain the mesocarbon microbead. The particle diameter of the coal tar-based mesocarbon microbead prepared by using the method is 1-150 mu m, and the mass percent can reach 20-50%. The preparation method of the coal tar-based mesocarbon microbead has the characteristics of high product yield, controllable particle diameter, good sphericity, simple and convenient process, rich raw material sources, low cost and the like.

Owner:UNIV OF SCI & TECH LIAONING

Fiber-reinforced heat-insulating silicone aerogel composite material and preparation method thereof

The invention relates to a fiber-reinforced heat-insulating silicone aerogel composite material and a preparation method thereof. The fiber-reinforced heat-insulating silicone aerogel composite material is prepared by the following steps of taking siloxane polymers with porous structure as a base, as well as flexible fiber felt as a reinforcement; blending a silicone solution; immersing the fiberfelt with the silicone solution; carrying out sol-gel processing; and carrying out washing and drying and so on. Compared with the prior art, the fiber-reinforced heat-insulating silicone aerogel composite material prepared by the preparation method is excellent in heat-insulating property, very high in mechanical durability and hydrophobicity, simple in preparation processes, and low in cost; moreover, the fiber-reinforced heat-insulating silicone aerogel composite material has certain flexibility, so that the fiber-reinforced heat-insulating silicone aerogel composite material is high in designability and convenient for future size-cutting. Generally, the fiber-reinforced heat-insulating silicone aerogel composite material meets basic insulation requirements; and thus, the fiber-reinforced heat-insulating silicone aerogel composite material is applicable to a variety of areas, including buildings, walls, pipes and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

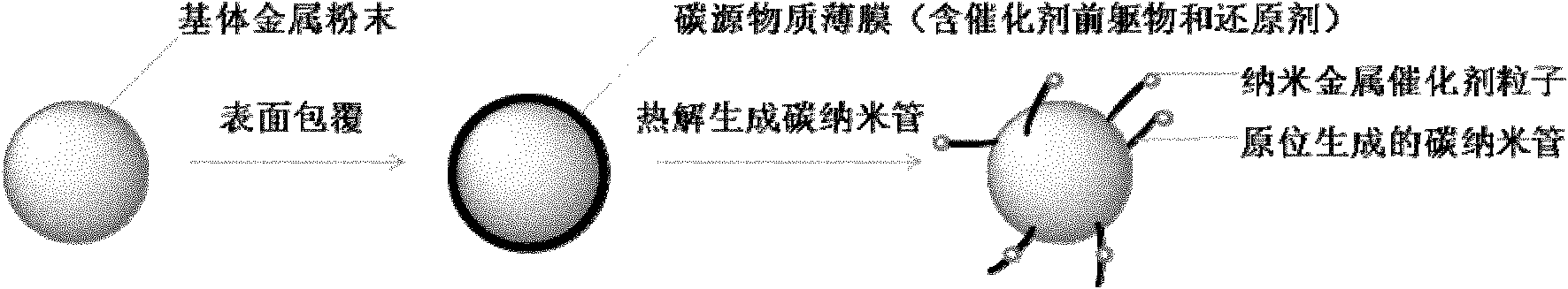

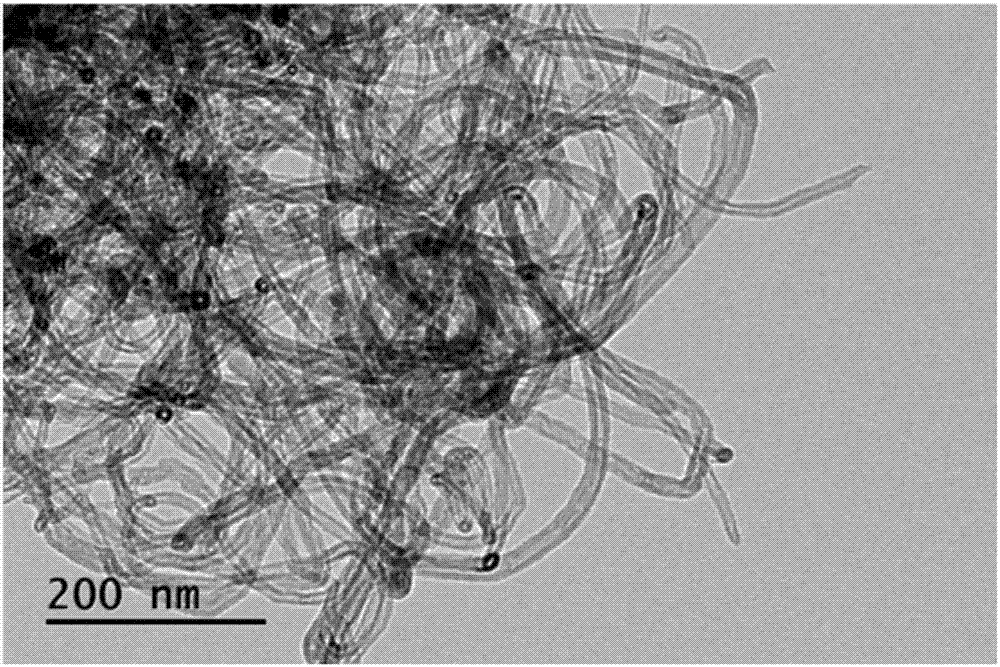

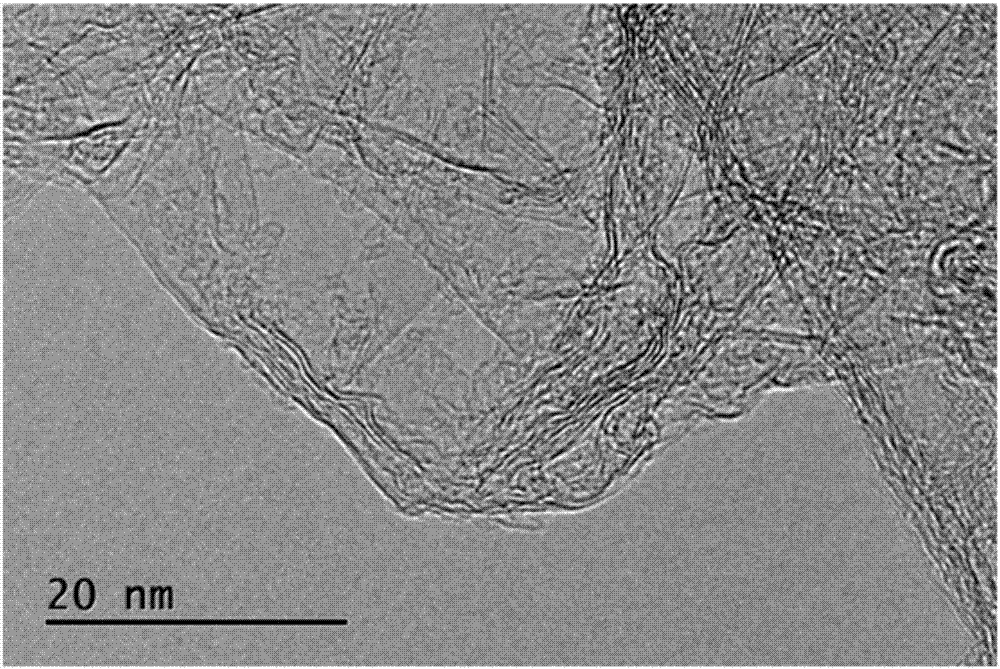

Carbon nano tube reinforced metal matrix composite material and in-situ preparation method thereof

The invention discloses a carbon nano tube reinforced metal matrix composite material and an in-situ preparation method thereof in the technical field of composite materials. The in-situ preparation method comprises the following steps of: firstly, coating a carbon source substance and a catalyst precursor on the surface of metal powder; secondly, generating carbon nano tubes in situ on the surface of the metal powder on the basis of a catalytic pyrolytic reaction to obtain composite powder of the carbon nano tubes and a metal; and finally, performing densification by adopting a powder metallurgy technique to obtain the carbon nano tube reinforced metal matrix composite material. In the preparation method, tiny and dispersed catalyst particles are generated in situ by bringing the steric effect of the carbon source substances such as an organic substance or a polymer and the like, and then uniformly dispersed carbon nano tubes are generated in situ on the surface of the metal powder through the catalytic pyrolytic reaction of the organic substance or the polymer.

Owner:SHANGHAI JIAO TONG UNIV

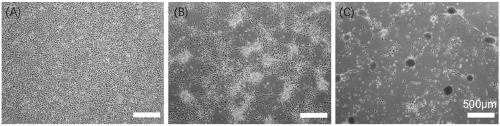

Preparation method of composite gel micro-spheres as well as composite gel micro-spheres and application thereof

PendingCN110078947AHigh strengthShort time required for stress relaxationMacromolecular non-active ingredientsProsthesisPolymer scienceMicrosphere

The invention discloses a preparation method of composite gel micro-spheres. The preparation method comprises the following steps: performing modification treatment on silk fibroins to obtain a methacrylate anhydride silk fibroin solution; adding a methacrylate anhydride bio-polymerized molecular solution and a photo-initiator to obtain a pre-polymer solution; preparing composite micro-droplets bythe pre-polymer solution, performing radiation treatment with blue light to obtain the silk fibroin protein and the bio-polymerized molecule composite gel microspheres. The composite gel microsphereswith high mechanical property and good biocompatibility can be prepared by the method. The invention further discloses a cell coating method based on the preparation method; composite gel microsphere-coated cells are small in damage and low in toxicity and can be obtained with good survival and proliferation. The invention also discloses the composite gel micro-spheres prepared by the method andapplication thereof to cell 3D culture, 3D printing and use as biomedical materials; the composite gel micro-spheres have a wide application to the biomedical field through good biocompatibility and mechanical property.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

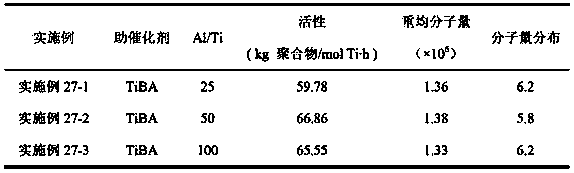

Supported olefin polymerization catalyst, preparation method and application thereof

The invention discloses a supported olefin polymerization catalyst, a preparation method thereof, and an application of the supported olefin polymerization catalyst in production of olefin homopolymer and olefin copolymer. The supported olefin polymerization catalyst mainly comprises a multihole carrier A, a magniferous carrier B, and a supported transition-metallic-titanium-contained active component and is a compound supported efficient Ziegler-Natta titanium catalyst formed by a magnesium compound and a silicon compound. The raw material for the carrier of the magnesium compound is any soluble magnesium salt. The compound carrier supported olefin polymerization catalyst can be used for preparing the olefin homopolymer or olefin copolymer. The catalyst is simple in preparation method, low in cost, easy to control the form, and excellent in polymerization performance. By changing the type and dosage of an organic metal promoter, molecular weight modifier and other factors, the molecular weight and molecular weight distribution of the olefin homopolymer or olefin copolymer, and content and distribution of a comonomer can be conveniently and easily adjusted, therefore, a polymer product with required performance is acquired.

Owner:EAST CHINA UNIV OF SCI & TECH

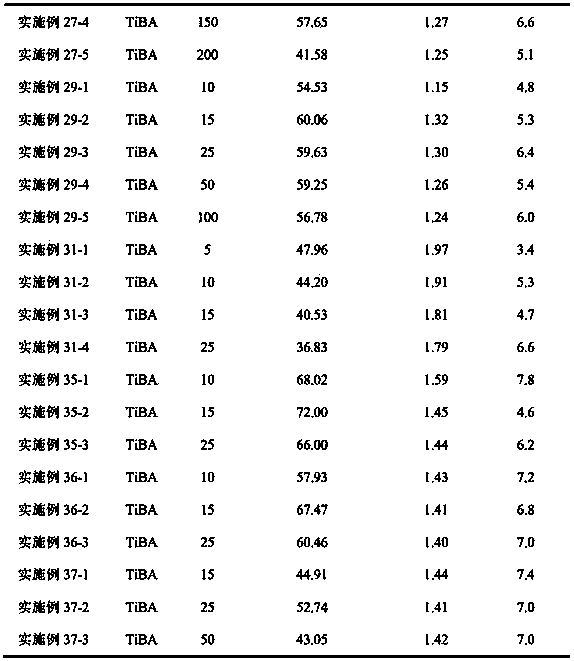

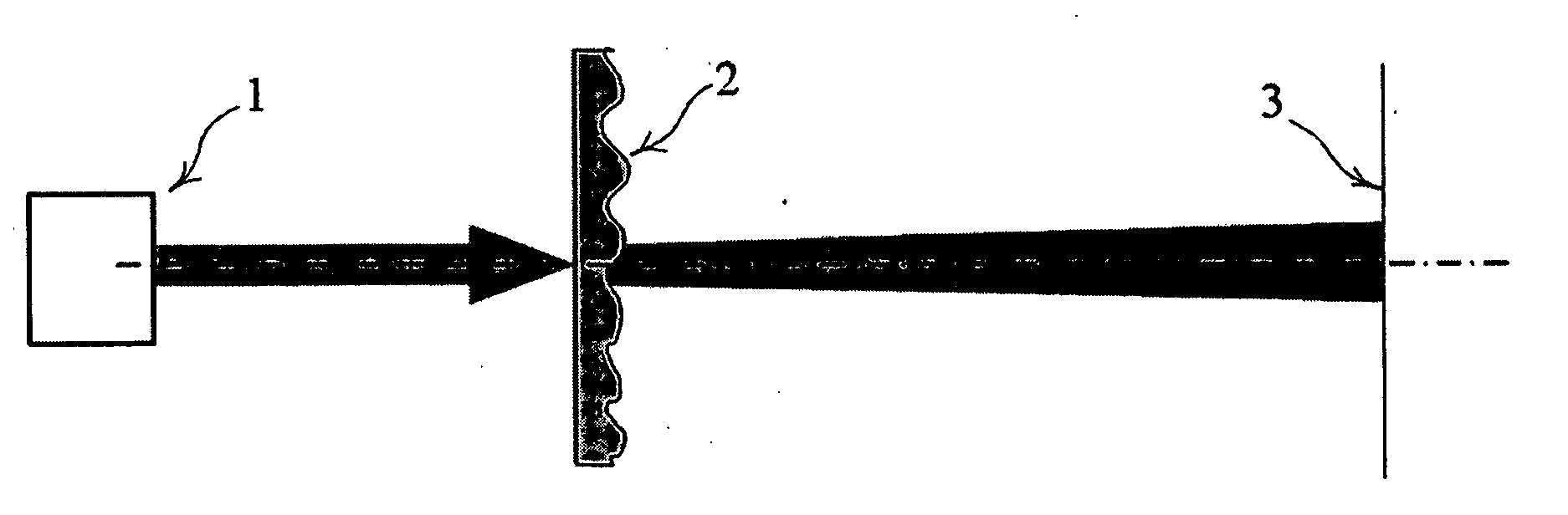

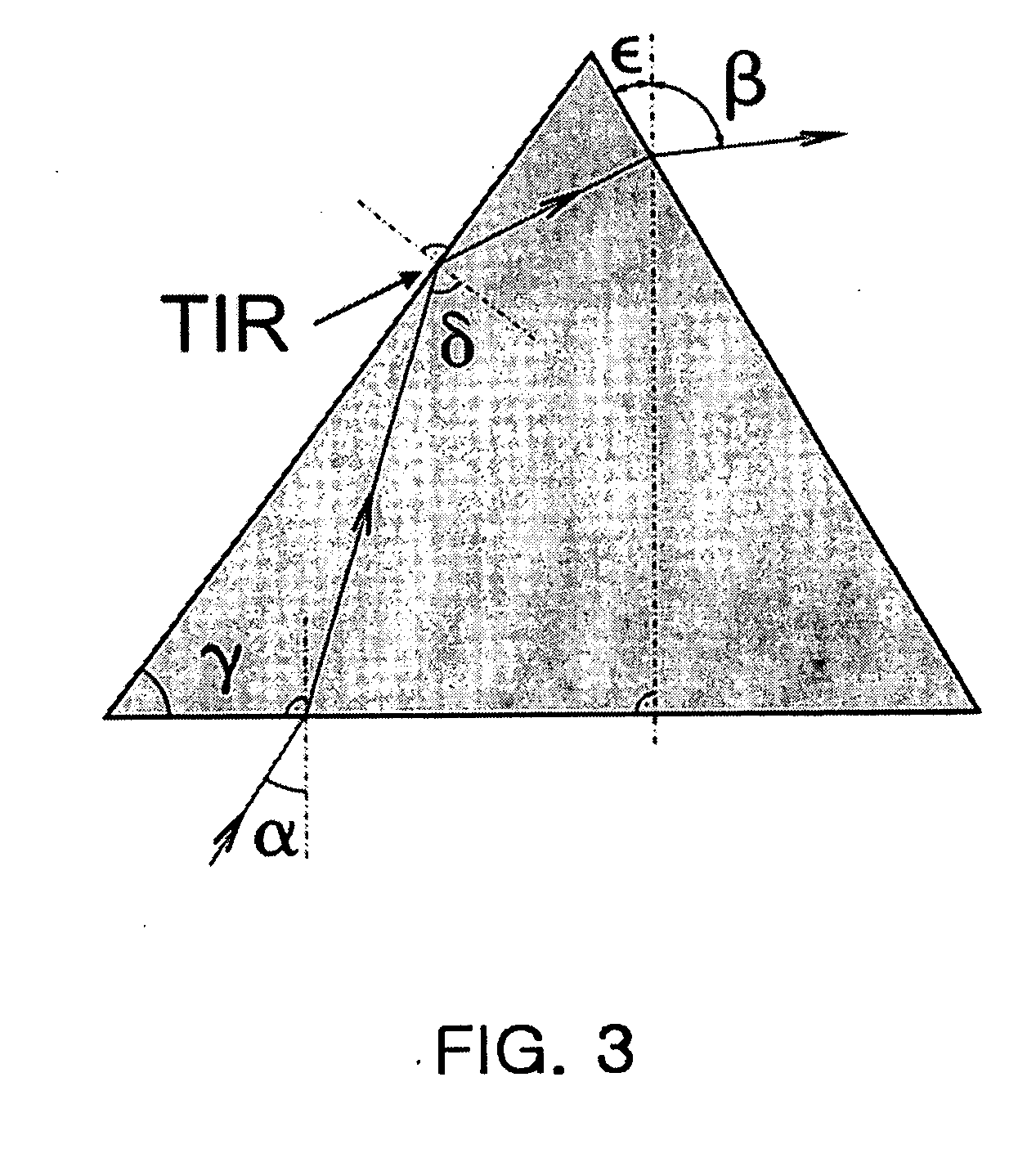

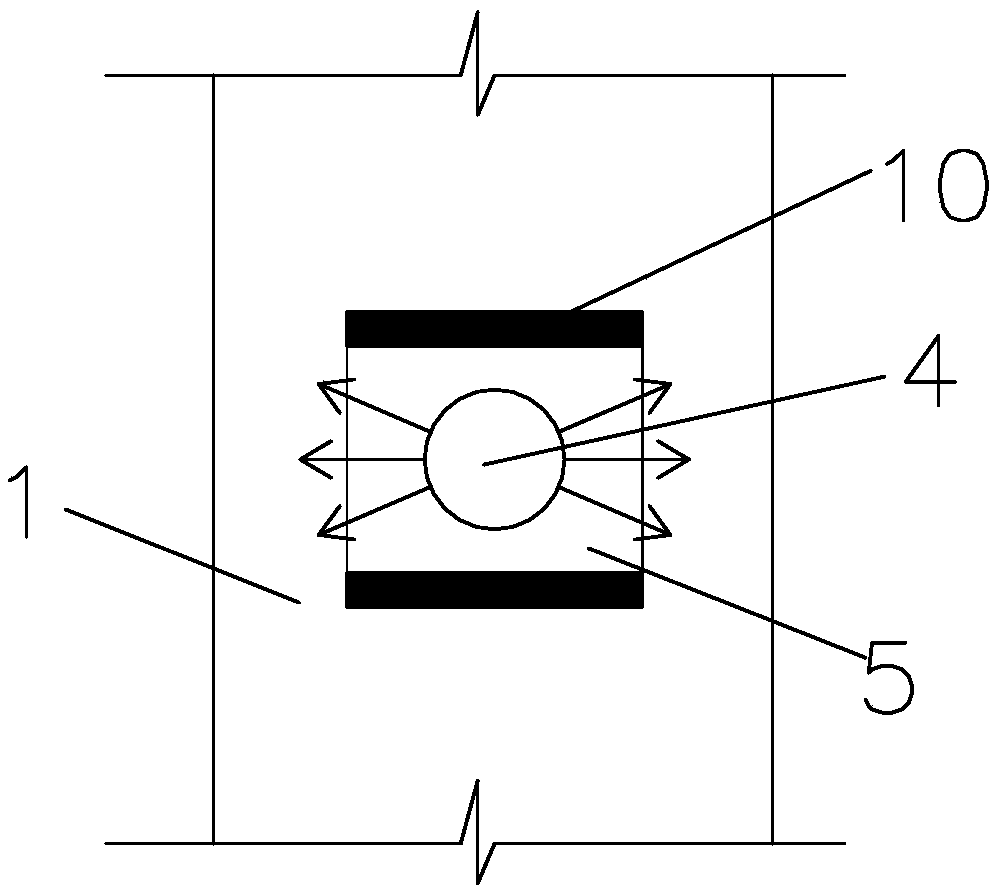

Total internal reflection micro lens array

InactiveUS20070091444A1Improve divergence angleShape controllableLensRefractorsFresnel lensTotal internal reflection

The invention relates to a total internal reflection micro lens array for a wide-angle lighting system. The micro lens array includes a plurality of Fresnel lens structures formed on a same optical incidence surface. Each of the Fresnel lens structure comprises a plurality of grooves, each having a reflecting surface and a refractive surface. Incoming radiation incident through the incidence surface of the lens structure is internally totally reflected by the reflecting surface, refracted by the refractive surface and exits the lens structure.

Owner:SAMSUNG ELECTRONICS CO LTD

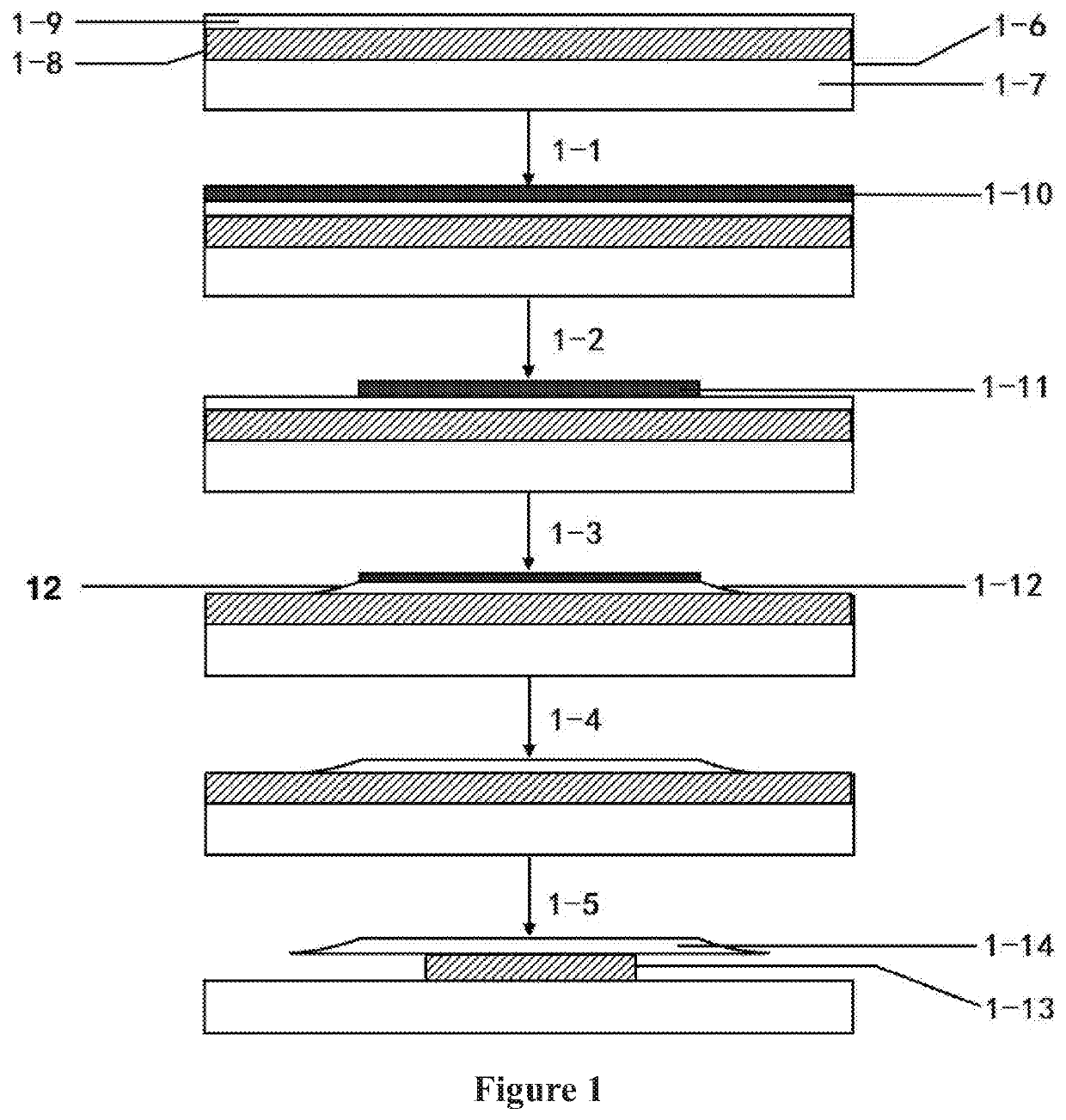

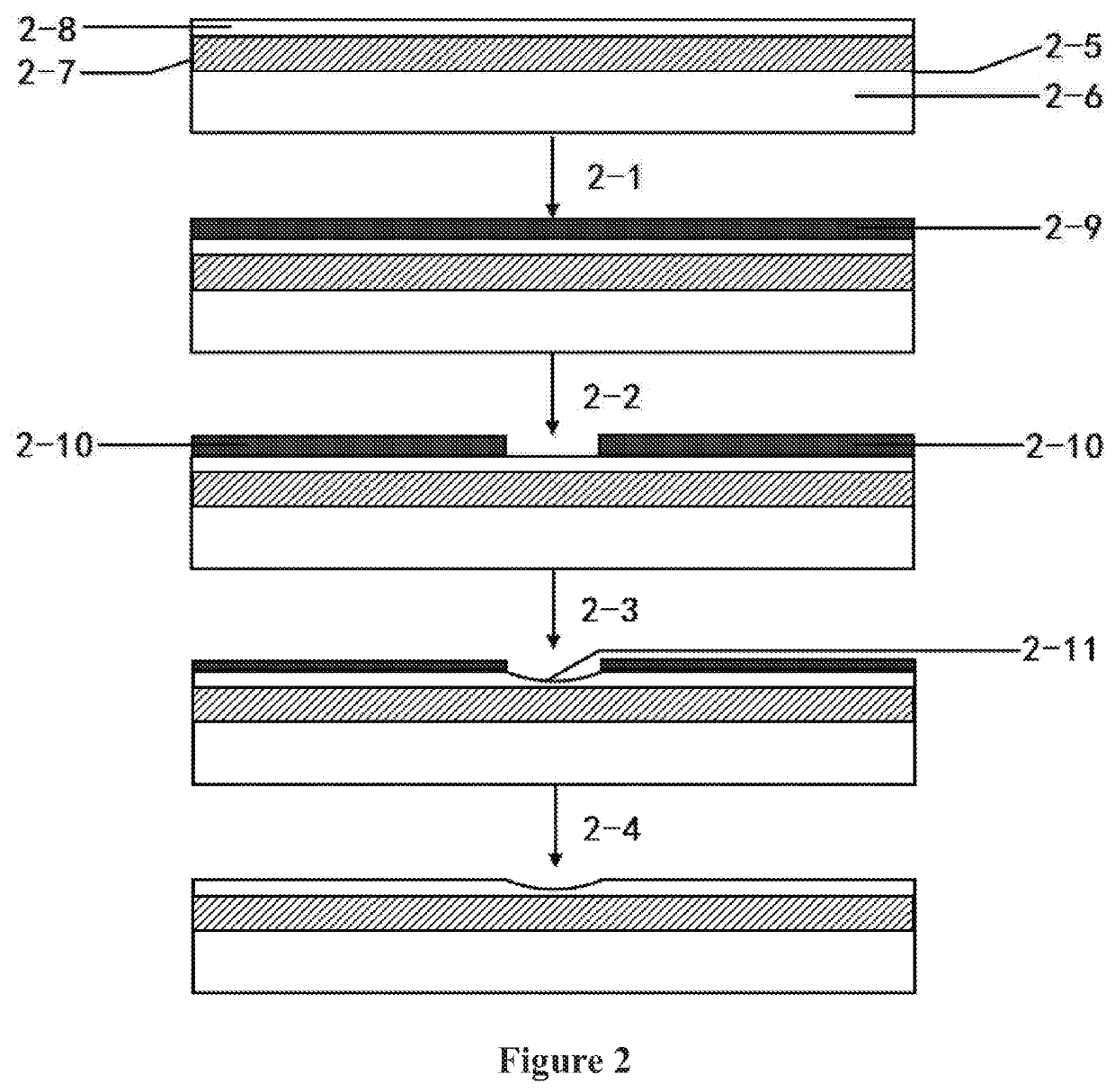

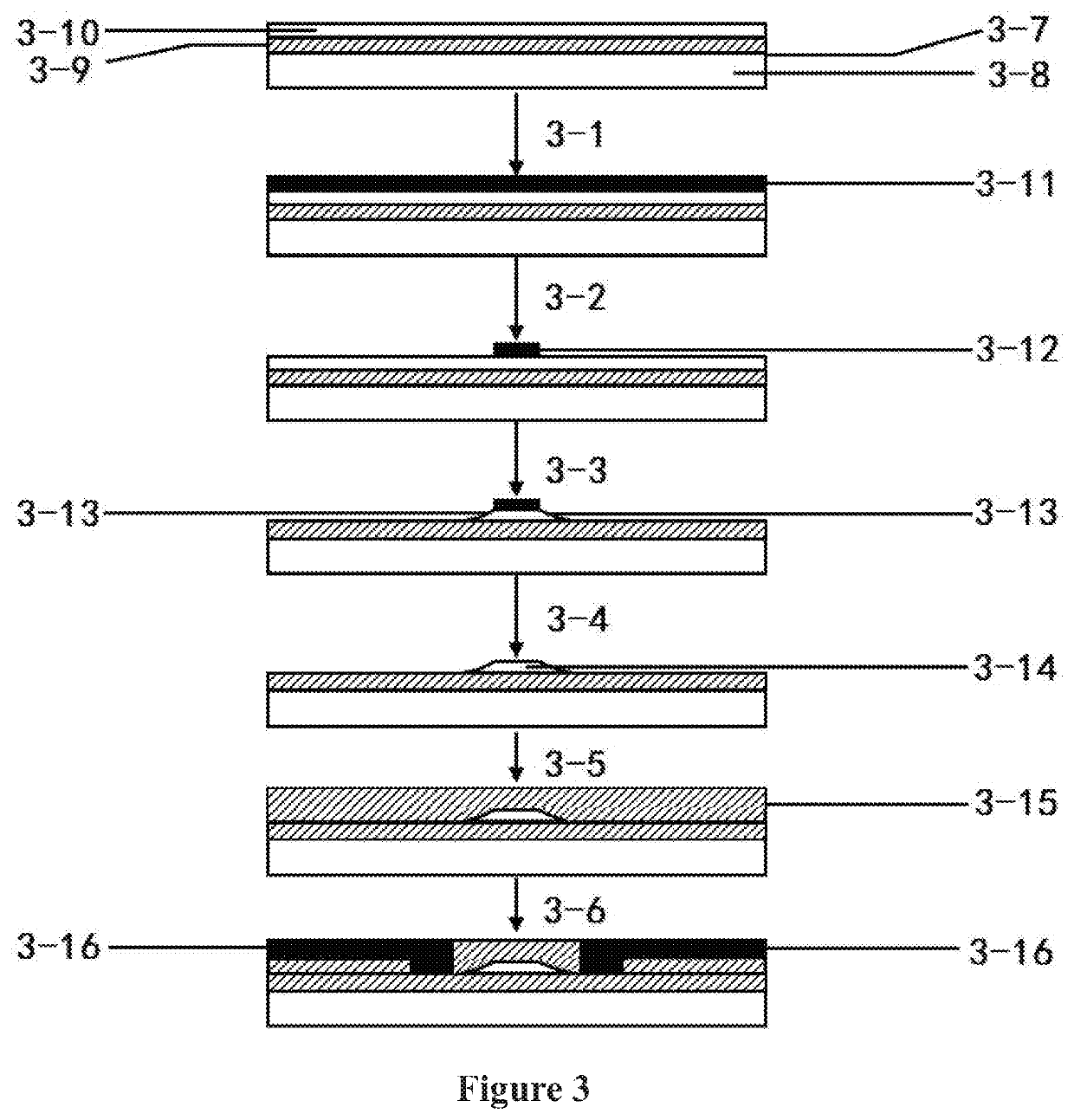

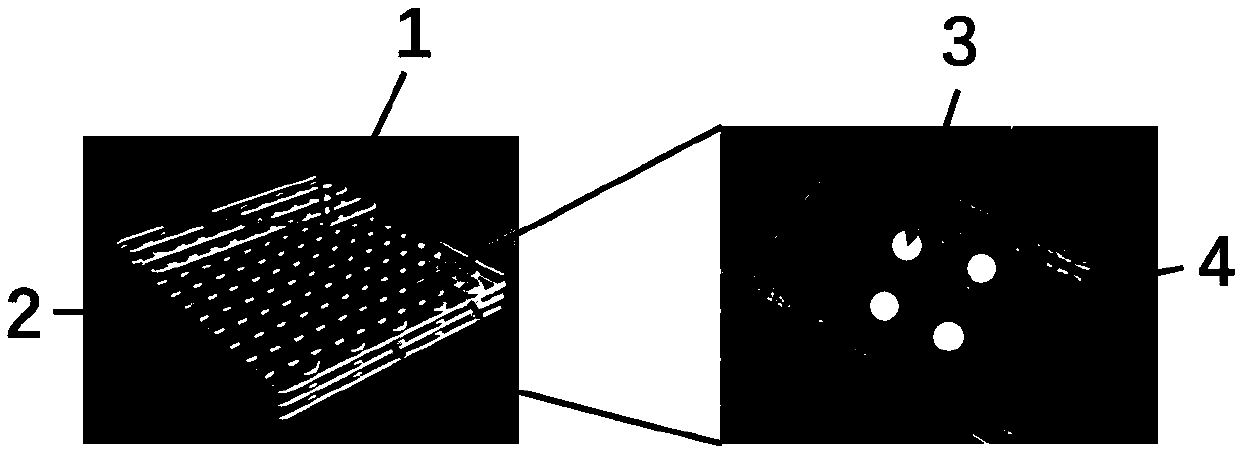

Method for preparing film micro-optical structure based on photolithography and chemomechanical polishing

ActiveUS20190346625A1Shape controllableReduce lossPhotomechanical apparatusOptical light guidesFilm baseSingle crystal

Method for preparing micro-optical structure on a film based on chemical mechanical polishing etching, combining photolithography technology with chemical mechanical polishing technology to make preparation and large-scale integration of large-size high-quality micro optical devices on-chip possible. The method comprises coating metal on film surface, selectively removing the metal film by photolithography (such as femtosecond laser selective ablation, ultraviolet photolithography, electron beam etching, ion beam etching, and reactive ion etching), chemical mechanical polishing, chemical corrosion or over polishing and other steps. Micro-optical devices on-chip prepared by the method have extremely high surface finish and extremely low optical loss. The method is applicable to preparing high-quality micro-optical structures (including but not limited to microdisc cavities, microring cavities, optical waveguides and coupled devices thereof) on various films on-chip (including but not limited to lithium niobate single crystal films, quartz films, silicon films, silicon dioxide films, diamond thin films, etc.).

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

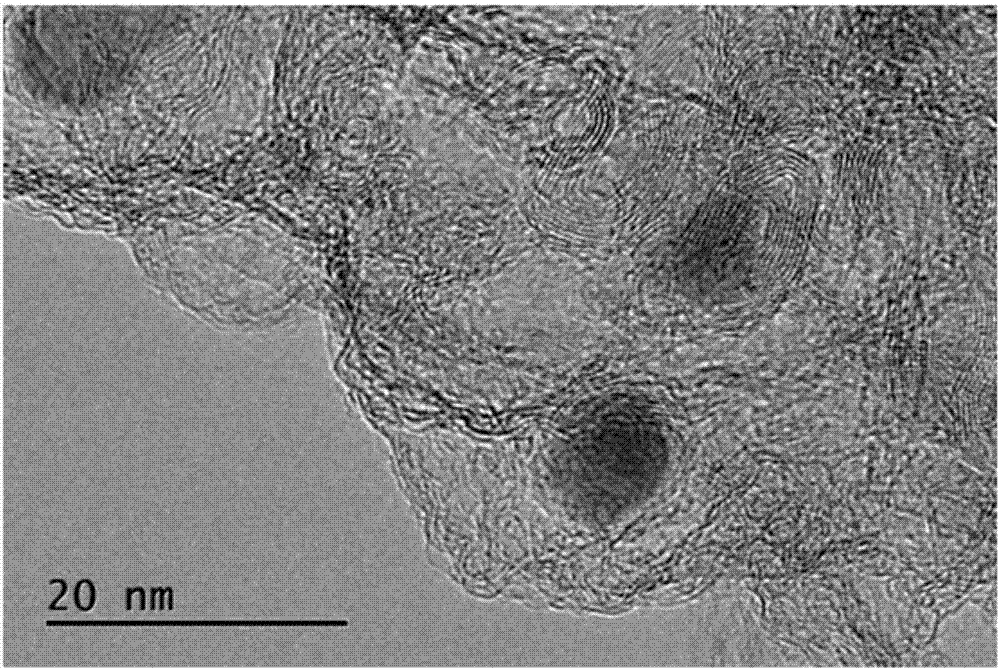

Process for preparing Al2O3 aerogel carried catalyst and its application in preparing nano carbon tubes by catalytic cracking of methane

InactiveCN1363425ASmall diameterShape controllableCatalyst carriersCatalyst activation/preparationSupercritical dryingDeposition precipitation

A process for preparing Al2O3 aerogel carried catalyst includes such steps as preparing Al(OH)3 gel, depositing active component to Al(OH)3 gel by deposition-precipitation method, supercritical drying in high-pressure reactor and calcining. A process for preparing nano carbon tubes by catalytic cracking of methane with said catalyst is also disclosed. The resulant nano carbon tube features small diameter, easily controllable form and simple preparing process.

Owner:TIANJIN UNIV

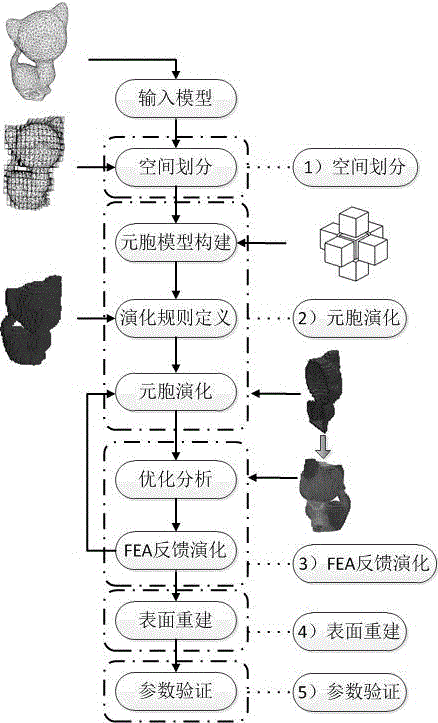

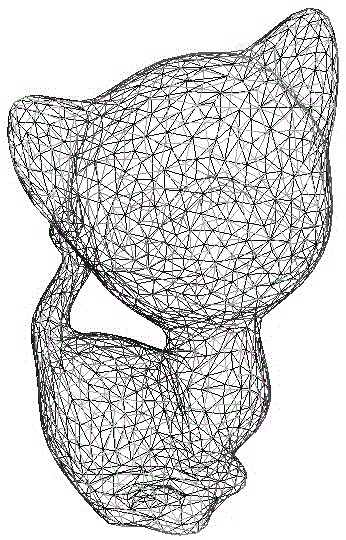

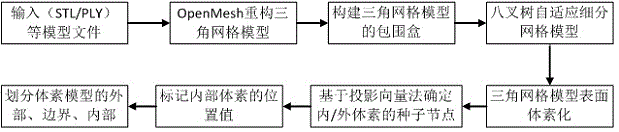

Three-dimensional cellular automaton based lightweight model and optimizing method

InactiveCN105528494AWith lightweight performanceReduce consumptionDesign optimisation/simulationMulti-objective optimisationCellular automationElement analysis

The invention relates to a three-dimensional cellular automaton based lightweight model and optimizing method, comprising operation steps: firstly, performing space dividing on an input network model with an octree, then according to design demands, establishing neighborhood information based cellular evolution, then, defining the relation that a neighborhood information based cellular automaton combines with FEA feedback information based finite element analysis, establishing FEA analysis feedback evolution, and generating a lightweight structure based on two evolution rules. A feedback based optimizing strategy is established, simulated information can be fed back to a design flow, and a drive structure is optimized to change macro attributes of a design target. Finally, the generated lightweight model is subjected to surface recreating and related parameters verifying, and an experiment proves that the invention is very suitable for establishing a 3D (three-dimensional) printing lightweight model.

Owner:SHANGHAI UNIV

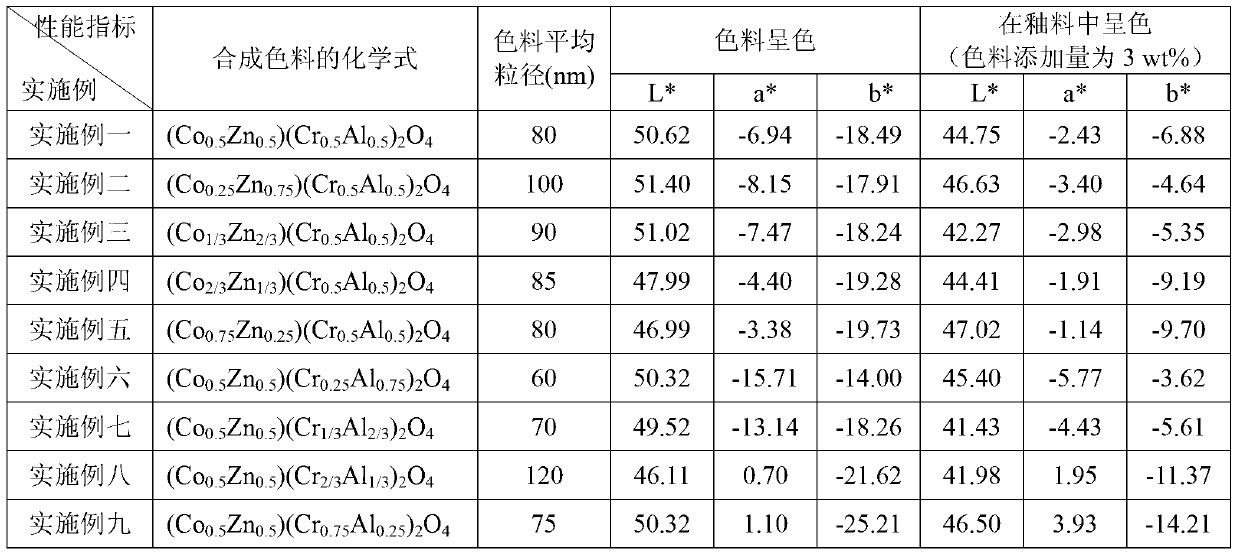

Co-Zn-Cr-Al composite spinel type blue ceramic pigment and preparation method thereof

The invention discloses a Co-Zn-Cr-Al composite spinel type blue ceramic pigment which is expressed by a general formula (CoxZn1-x)(CryAl1-y)2O4, wherein x and y represents mole fractions; x is 0-1; y is 0-1; and when x and y are different in value, the products are different in color. Besides, the invention also discloses a preparation method of the Co-Zn-Cr-Al composite spinel type blue ceramic pigment. The ceramic pigment disclosed by the invention is small in particle size and uniform in distribution, has high coloration capability in glaze, and is high in coloration stability. Besides, the ceramic pigment is simple in preparation process and controllable in color and shape, and can meet different application requirements; and the whole process is easy to control and realize, and the product quality is stable, thereby being beneficial to large-scale popularization and application.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Preparation method for carbide catalyst for organic carbon vapor phase growth and application thereof

InactiveCN107252682AReduce manufacturing costShape controllableHeterogenous catalyst chemical elementsGrapheneRare-earth elementSolvent

The invention discloses a preparation method for a carbide catalyst for organic carbon vapor phase growth and an application thereof. The method comprises the following steps: adding a precipitator or a complexing agent or a dispersing agent, or a precipitator and a dispersing agent, or a complexing agent and a dispersing agent into a compound or complex containing a catalytic element, wherein the compound or complex containing the catalytic element is the compound containing one or more of rare earth elements, iron, cobalt, nickel, molybdenum, zirconium, copper, zinc, magnesium, aluminium and silicon or the complex thereof; through one or more of a precipitation method, a complexing method, a hydrothermal method, a high-pressure hydrothermal method and a sol-gel method, synthesizing to prepare mixed solution containing the catalytic elements, spray-drying the mixed solution by a spray drying machine, rapidly removing a solvent to form a catalyst precursor with catalytic element nano-state distribution, and calcinating the catalyst precursor in the high temperature, to obtain the carbide catalyst for the organic carbon vapor phase growth.

Owner:陈永

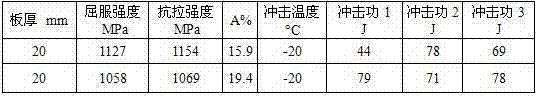

Cold-rolled non-oriented electrical steel 35WD1900 and production method thereof

ActiveCN109825775AEasy to controlStable productionRoll force/gap control deviceTemperature control deviceElectrical steelSheet steel

The invention discloses a cold-rolled non-oriented electrical steel 35WD1900 and a production method thereof. The cold-rolled non-oriented electrical steel 35WD1900 comprises the following chemical components by weight: <= 0.005% of C, 2.0-2.5% of Si, 0.2-0.4% of Mn, 0.08-0.12% of P, <= 0.008% of S, 0.3-0.5% of Al, 0.004-0.006% of B and the balance of Fe and unavoidable impurities. The productionmethod includes the following steps: (1) a steel plate is subjected to continuous casting to form a continuously-cast billet, which is heated in a heating furnace after being cooled, and then subjected to hot rolling; (2) the hot-rolled billet is subjected to acid pickling, first cold rolling, decarburizing annealing and second cold rolling; and (3) after being subjected to the second cold rolling, the electrical steel is subjected to secondary annealing and coating to obtain the product. The performance of the cold-rolled non-oriented electrical steel 35WD1900 of the invention can meet the requirements of the high-strength non-oriented electrical steel used in the drive motors of new energy automobiles; and the welding performance and the stamping performance are good.

Owner:GUANGDONG ZHONGSHENG ELECTROMAGNETIC TECH CO LTD

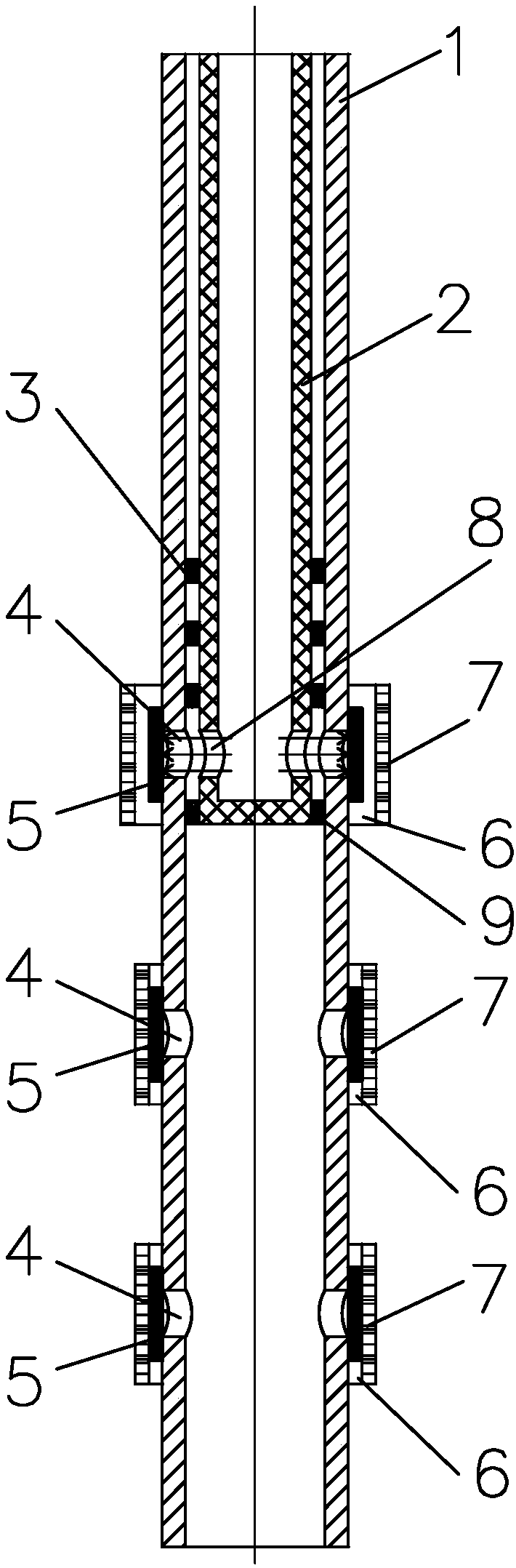

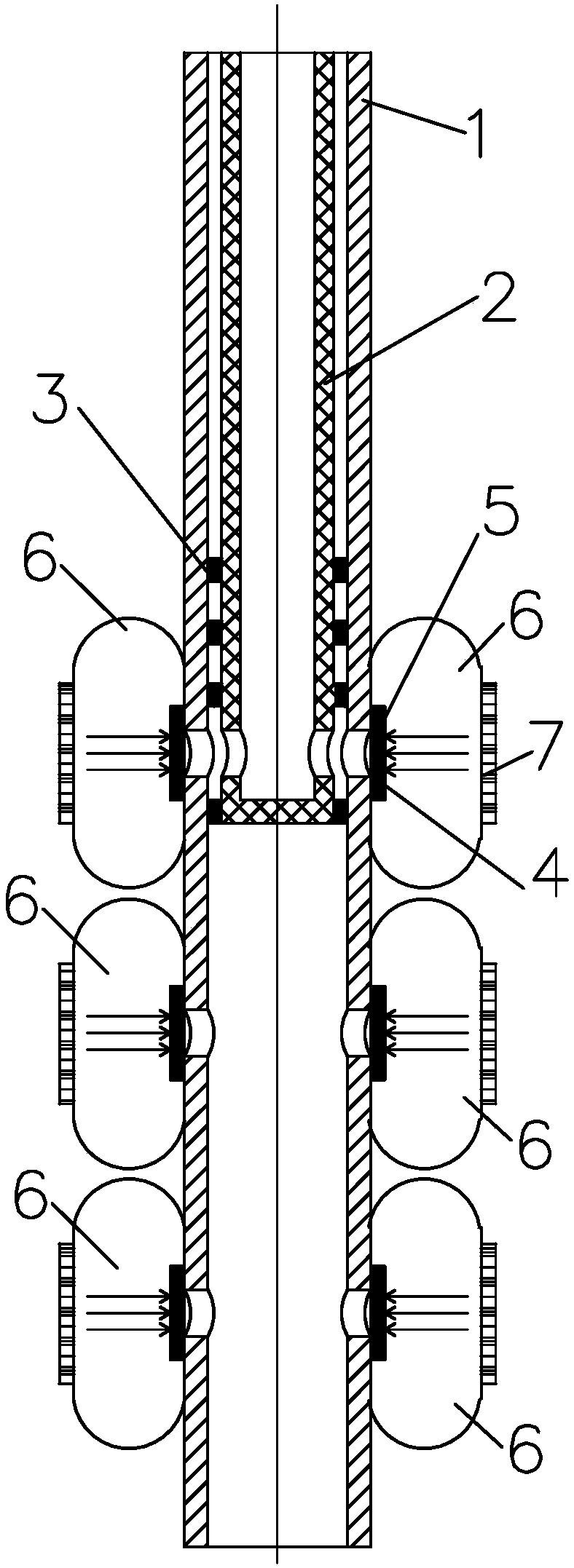

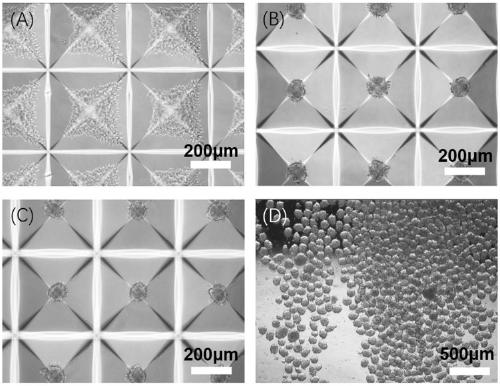

Multi-point bag type grouting device for controlling soil deformation and method thereof

PendingCN108411920AEasy to controlPrevent upward phenomenonUnderground chambersFoundation engineeringRubber ringLiquid state

The invention discloses a multi-point bag type grouting device for controlling soil deformation. The grouting device comprises a sleeve valve pipe, wherein the sleeve valve pipe comprises an outer sleeve pipe and a grouting pipe, a plurality of first rubber rings are arranged between the outer wall of the lower portion of the grouting pipe and the outer sleeve pipe, a plurality of first overflow holes are formed in the pipe body of the outer sleeve pipe, and the outer sides of the first overflow holes are provided with one-way rubber films; and annular grouting bags are tightly and firmly connected with the peripheries of the one-way rubber films of the first overflow hole on the outer pipe sleeve and in the same height of outer pipe sleeve, and protective bag sleeves with cutting marks are arranged on the outer peripheral surfaces of the grouting bags. According to the grouting device, in the grouting process, grout is directly pressurized and injected into the high-elasticity high-strength grouting bags, the size, the position and the shape of the grouting body can be accurately controlled, so that the grout is prevented from being in contact with underground water and a soil body in a liquid state, the influence on the adjacent environment is prevented, and meanwhile, the one-way rubber films are adopted to prevent the grout from flowing back so that fine control and directional deviation rectification of soil body deformation can be realized.

Owner:TIANJIN UNIV

Pancreatic-like structural body and construction method and application thereof

ActiveCN111197024AHigh activityFunction increasePancreatic cellsArtificial cell constructsVascularizesPancreatic A Cells

The invention provides a pancreatic-like structure and a construction method thereof. The construction method comprises the following steps: A, inducing stem cells and / or progenitor cells in vitro todifferentiate into pancreatic-like cell clusters; B, mixing the vascularized cells, the pancreatic-like cell clusters and a hydrogel material, and performing biological printing to obtain a pre-gel three-dimensional structure body; and C, culturing the pre-gel three-dimensional structure body by adopting a multi-cell culture solution and / or a bioreactor to obtain the pancreas-like structure body.The pancreatic-like structure provided by the invention is composed of vascularized cells and pancreatic-like tissue cells, and has the form, phenotypic characteristics and physiological functions ofnatural tissues. The method can be applied to the aspects of organoid construction, tissue / organ / human body chips, tissue engineering, regenerative medicine, in-vitro physiological model / pathologicalmodel / pharmacological model construction, cytobiology or drug research and the like.

Owner:REGENOVO BIOTECH +1

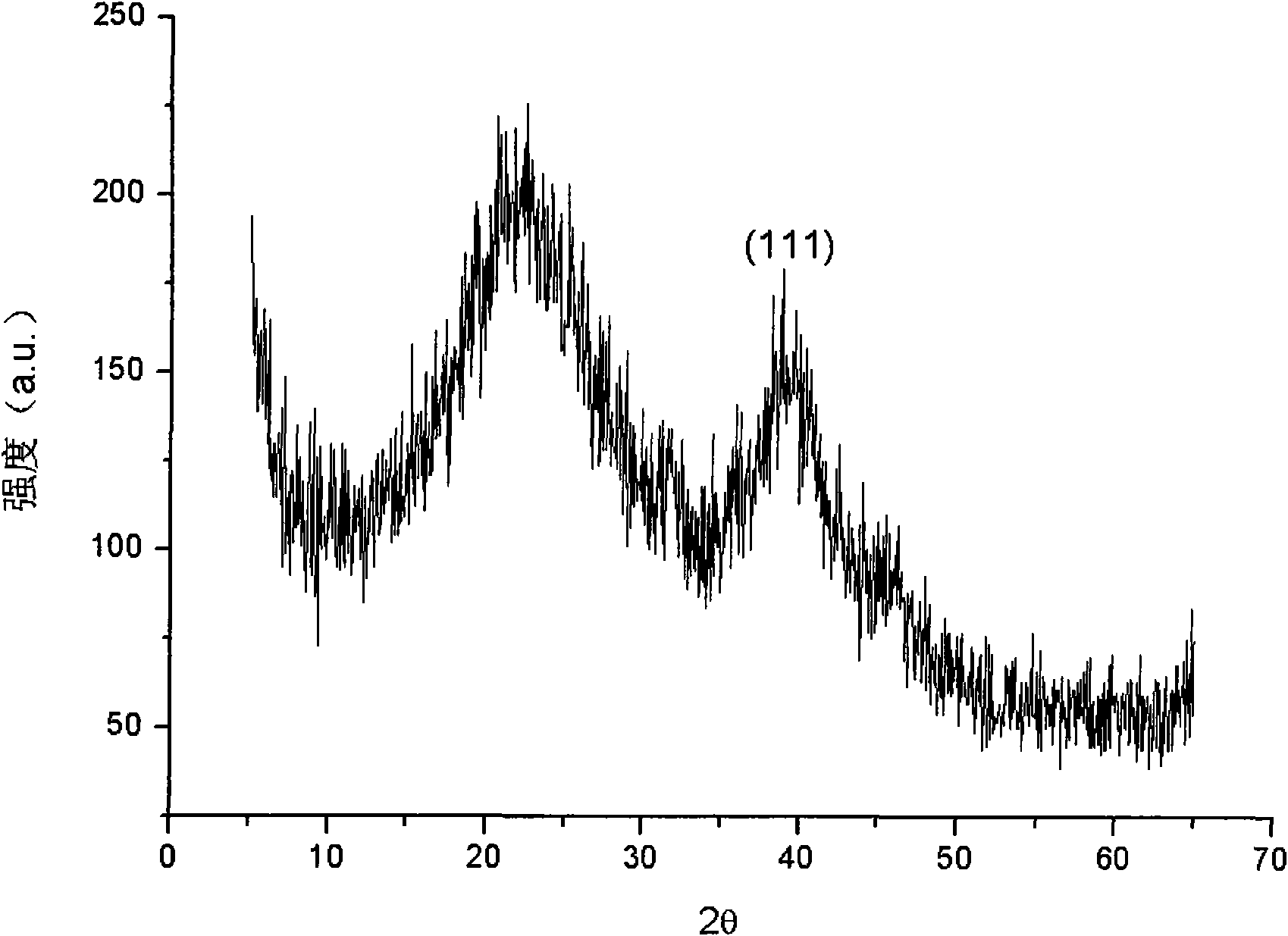

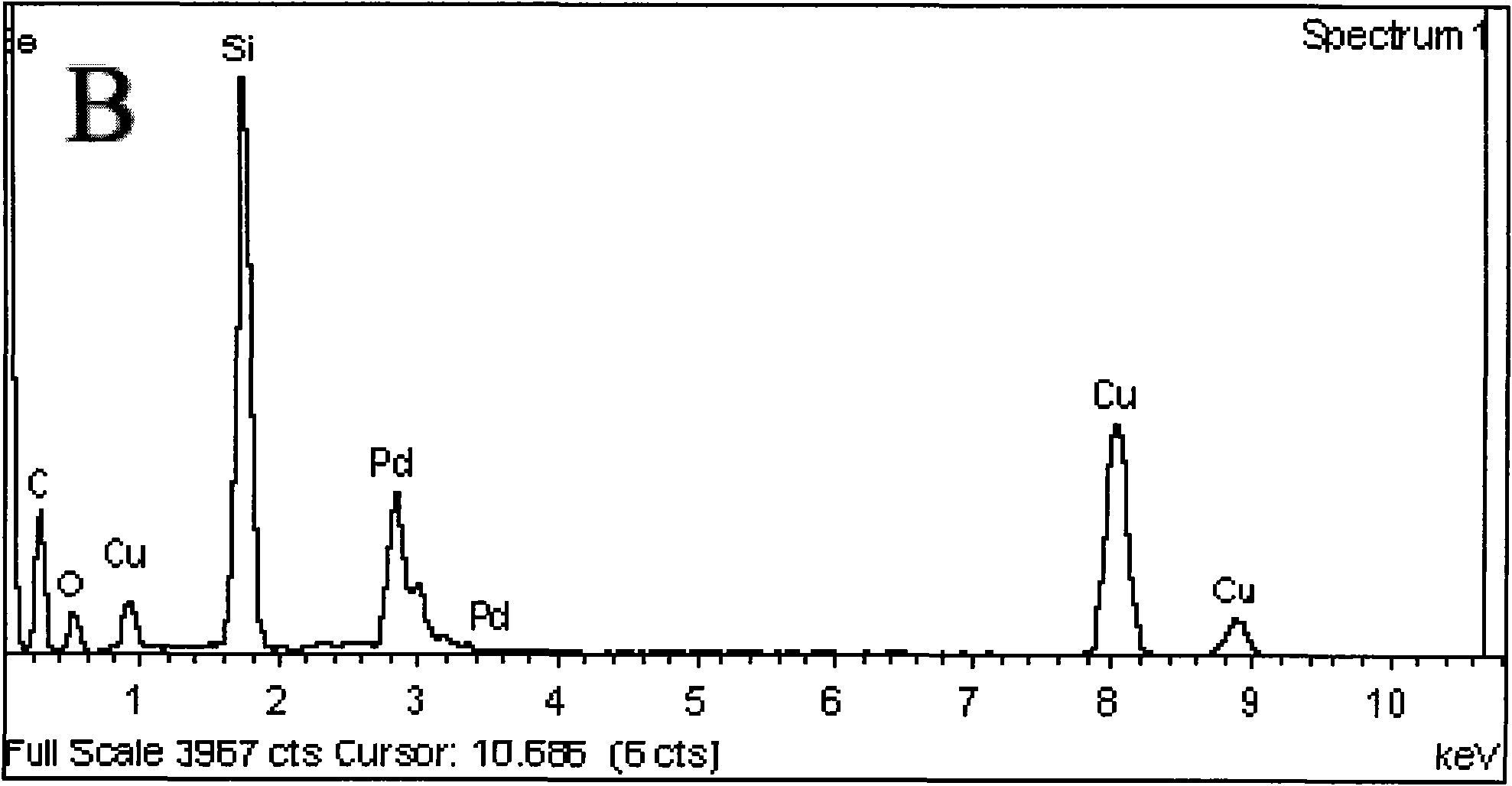

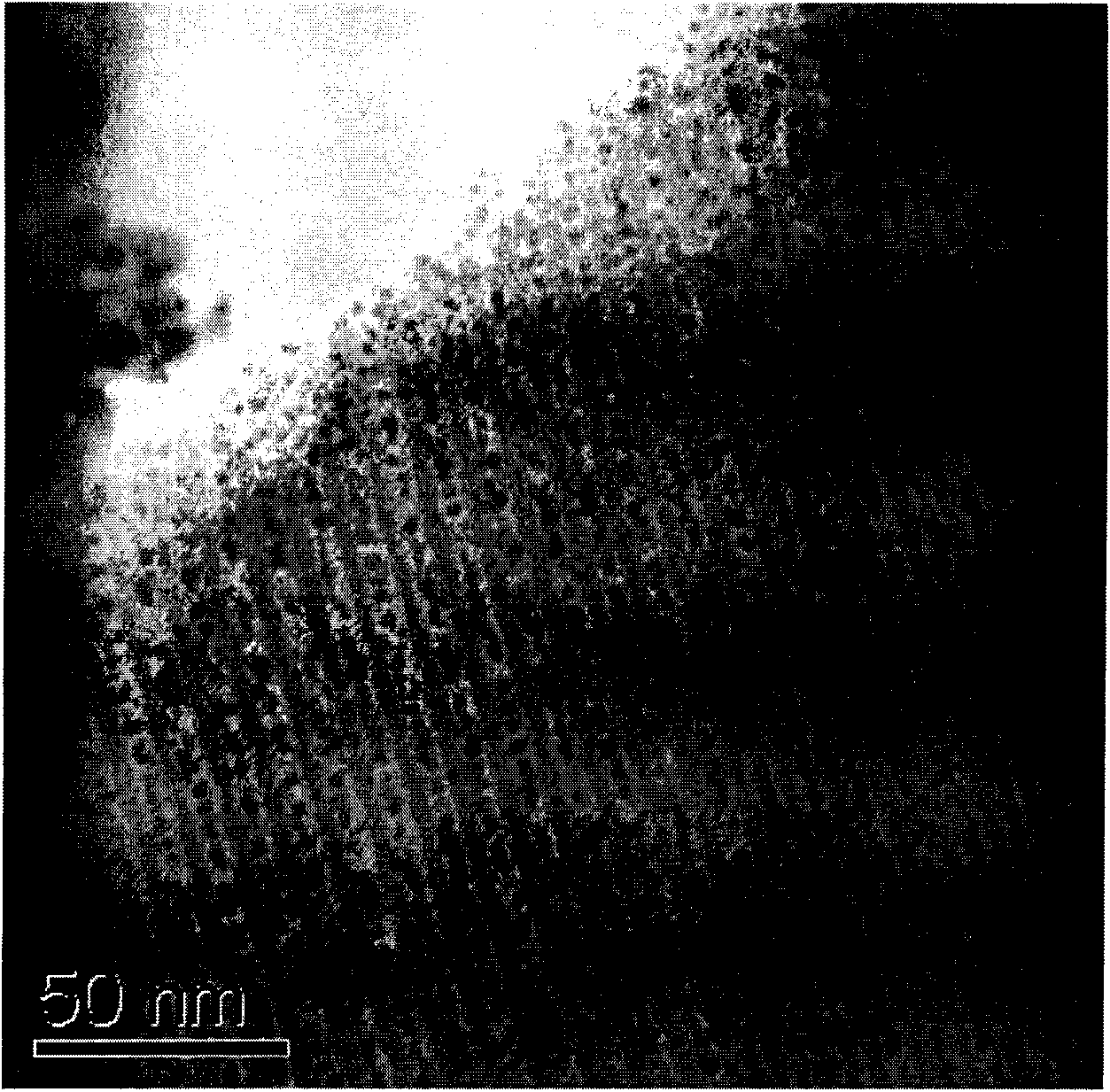

Palladium nanoparticle catalyst and preparation method as well as application thereof

InactiveCN101875010AAdvantages of preparation methodAdjust the size appropriatelyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSuzuki reactionNanoparticle

The invention relates to a palladium nanoparticle catalyst and a preparation method as well as an application thereof. The preparation method comprises the following steps: controlling the pH of the reaction environment to be equal to 2; combining metal ions of different concentrations with inner N of branches; and finally, reducing the metal ions by utilizing NaBH4 to generate a metal Pd nanoparticle catalyst with different diameters (1-3nm) of particles. The catalyst has good catalytic effect on the Suzuki reaction aided by microwaves. The method has the characteristics of simple process, convenient operation, controllable shape, good application effect and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Production method of non-oriented electrical steel 50W800 by traditional hot continuous rolling process

The invention discloses a production method of non-oriented electrical steel 50W800 by a traditional hot continuous rolling process. The production method comprises the steps of: 1) pretreatment of molten iron; 2) converter smelting; 3) argon blowing; 4) RH refining; 5) casting; 6) acid washing and cold rolling; 7) degreasing and cleaning, decarbonization and annealing; and 8) coating. The half-process cold-rolled non-oriented electrical steel with a mark of 50W800 and a thickness of 0.50 mm has the product electromagnetic performance of P15 / 50 not more than 5.2 W / kg and the magnetic induction strength of B50 not less than 1.74 T; and compared with the national standard of traditional half-process non-oriented electrical steel, the iron loss is lower by 2.8 W / kg, the magnetic induction strength is higher by 0.04 T, the interlayer resistance is not less than 2100 omega.mm 2 / p to satisfy the national standard and the customer requirements, the Vickers hardness is 80-100 HV10, the repeated bending times are not smaller than 12 times, and the welding performance is excellent.

Owner:SOUTH CHINA UNIV OF TECH

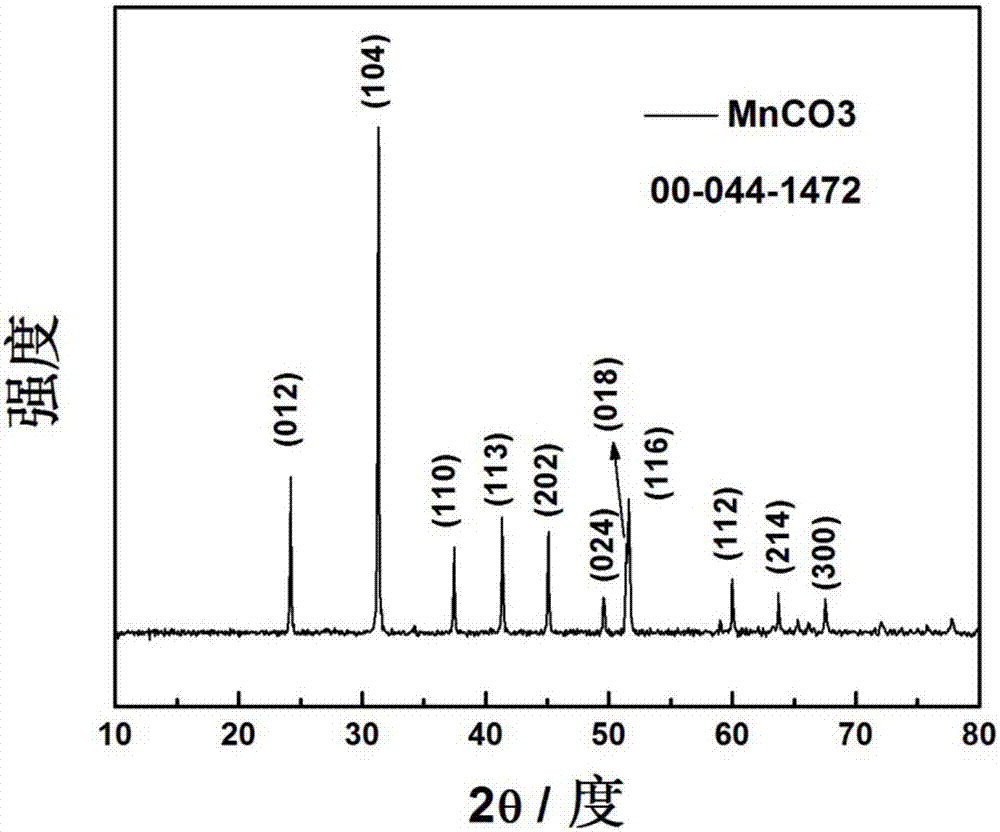

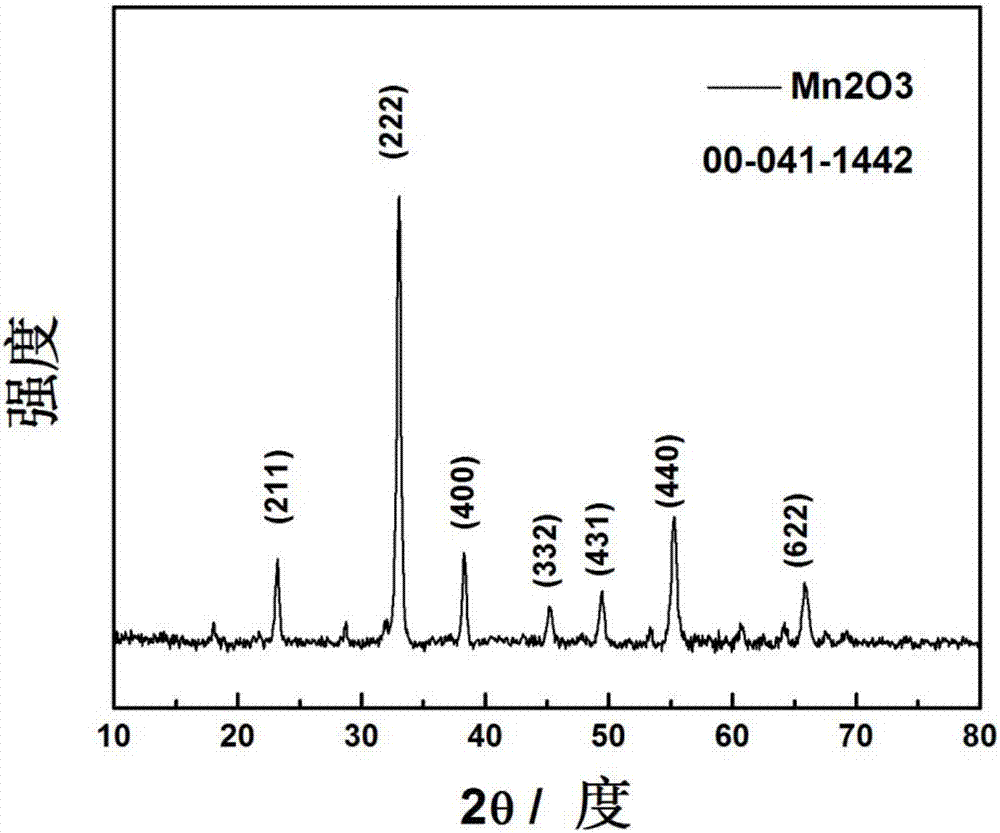

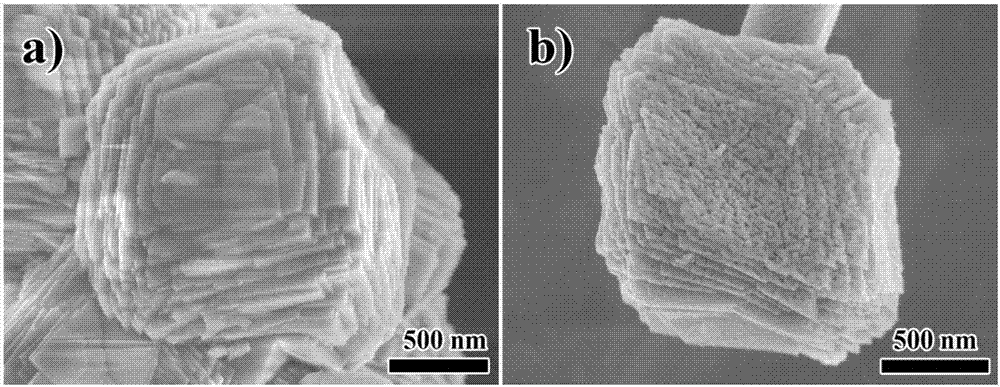

Method for preparing Mn2O3 porous micro-nano structure material having controllable morphology

InactiveCN106853996AThe experimental equipment is simpleShape controllableCell electrodesSecondary cellsIonSolvent

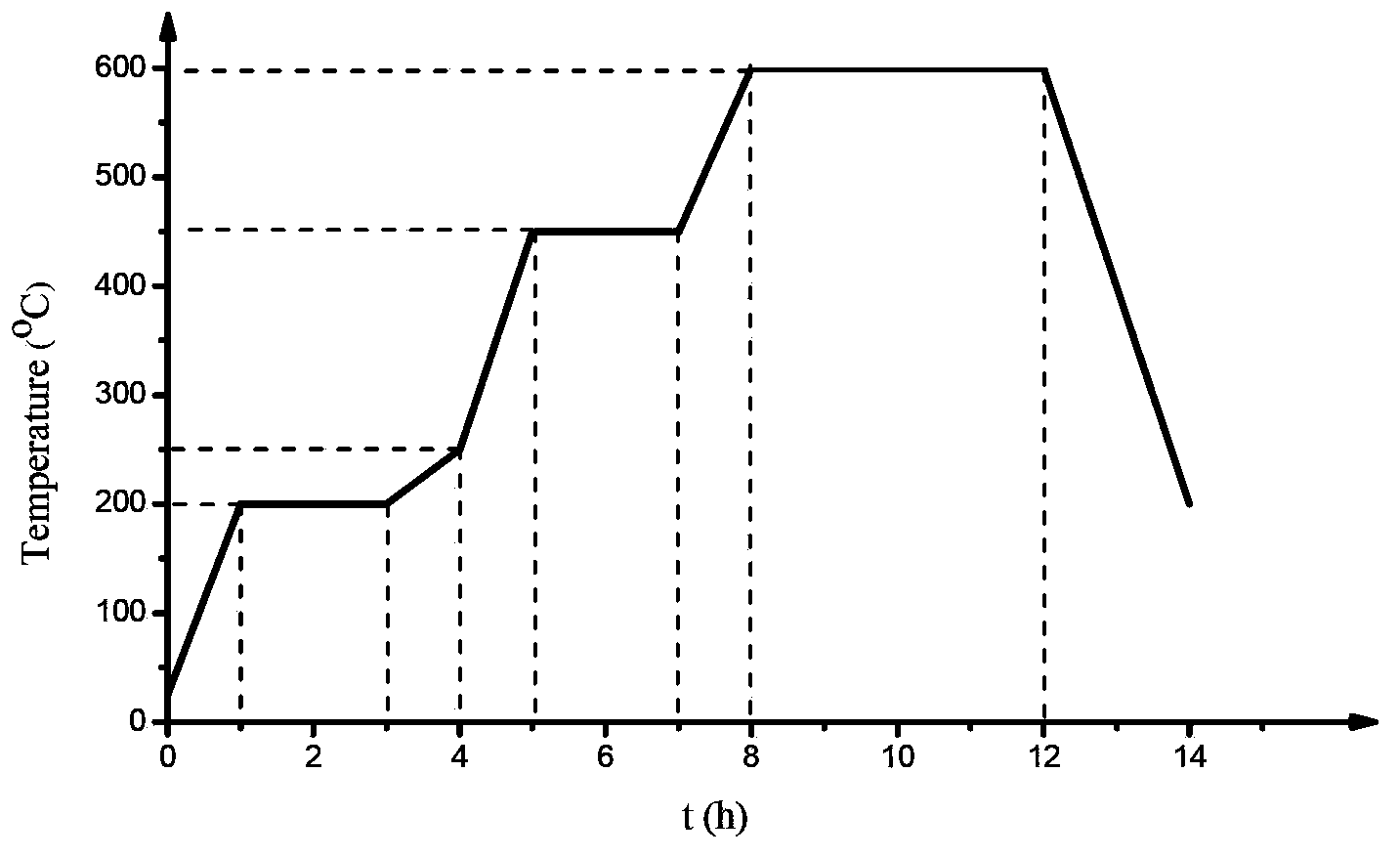

The invention discloses a method for preparing a Mn2O3 porous micro-nano structure material having controllable morphology. The method comprises that ammonium bicarbonate and manganese acetate as raw materials in water as a solvent undergo a reaction under control of concentrations of the two raw materials, a mixing rate and reaction time to produce manganese carbonate precursors having different main body morphologies, and the manganese carbonate precursors are sintered at a high temperature to form a Mn2O3 porous negative electrode material having a controllable main body structure. The Mn2O3 material microstructure can be controlled and changed from a porous ball to a porous cube and has the sizes of 1-1.5 microns and mesoporous sizes of 10-30nm. The method has the advantages of common and nontoxic raw materials, simple and easy reaction, high conversion rate, large yield, industrial production feasibility and excellent performances in the field of sodium ion batteries.

Owner:WUHAN UNIV OF TECH

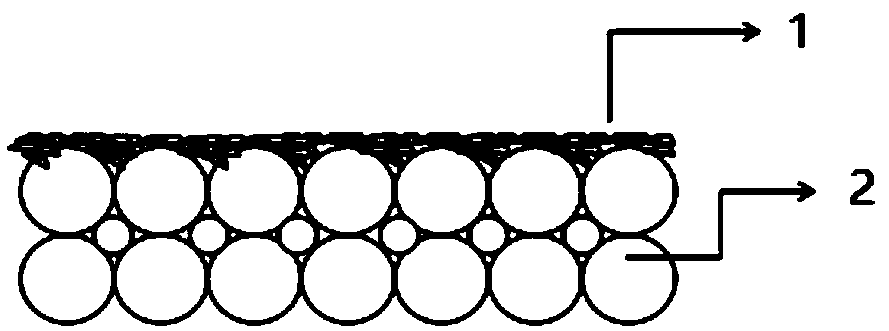

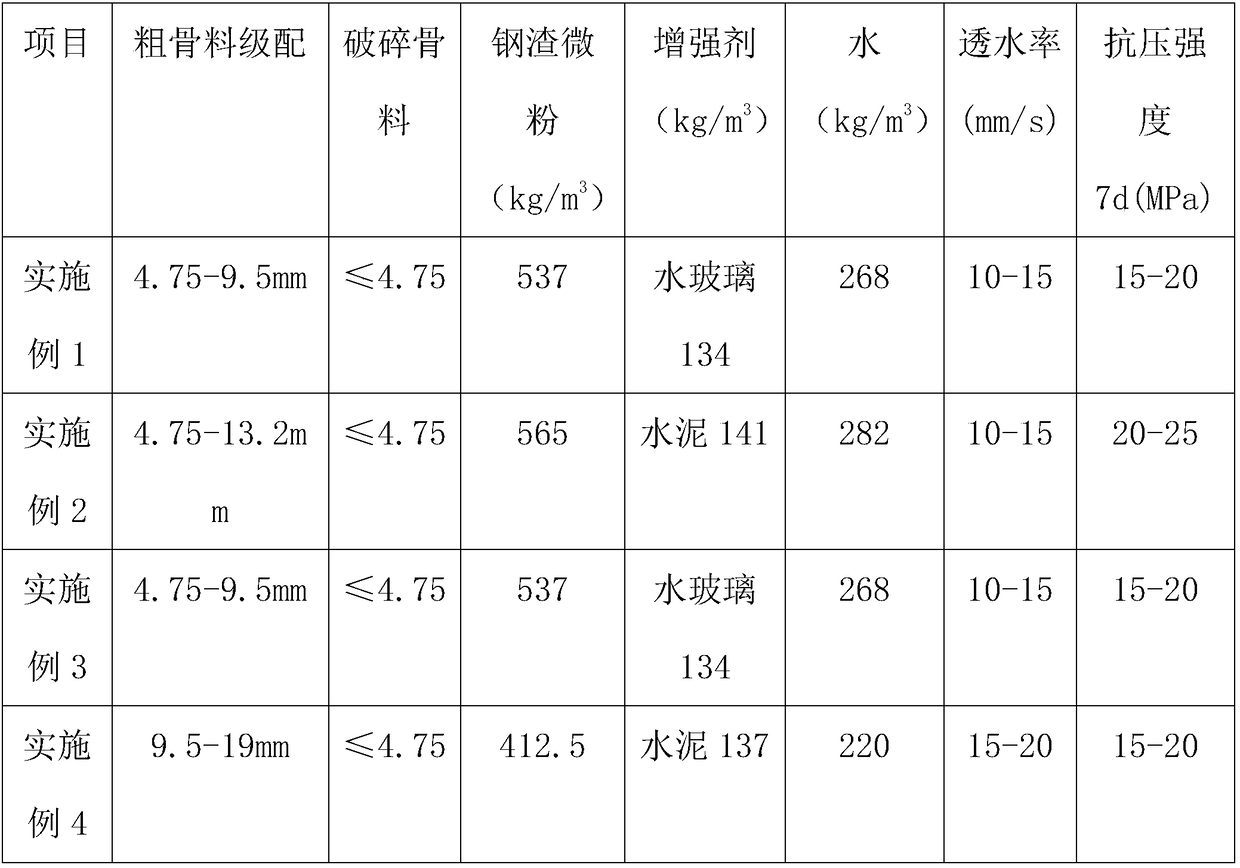

Water-permeable brick with artificial carbonized steel slag pellets as aggregates and preparation method thereof

ActiveCN108774041AUniform compositionShape controllableSolid waste managementPaving gutters/kerbsBrickSlag

The invention provides a water-permeable brick with artificial carbonized steel slag pellets as aggregates and a preparation method thereof, belonging to the technical field of green building materials. The water-permeable brick comprises a base layer and a surface layer, wherein the surface layer is located on the base layer; the base layer is made of continuously graded artificial carbonized steel slag pellet aggregates; and the surface layer is made of fine aggregates obtained by crushing and sieving carbonized steel slag bricks and formed after filling and leveling of the fine aggregates.The water-permeable brick comprises the following components by weight: 60 to 70% of artificial carbonized steel slag pellet aggregates, 5 to 10% of the fine aggregates obtained by crushing and sieving carbonized and cured steel slag bricks and having a particle size of no more than 4.75 mm, 15 to 20% of steel slag micropowder, 4 to 5% of a reinforcing agent and 4 to 5% of tap water. According tothe invention, through large addition amount of steel slag, industrial waste residues are greatly consumed; meanwhile, industrial waste gas CO2 is used as a raw material in the process of carbonization and curing, and the reaction of the CO2 with steel slag products in a carbonization kettle is an exothermic reaction, so no external heat source is need; and the advantages of waste utilization, carbon sequestration, energy conservation, emission reduction, simple preparation process, low equipment requirements, short production cycle and low cost are obtained.

Owner:DALIAN UNIV OF TECH

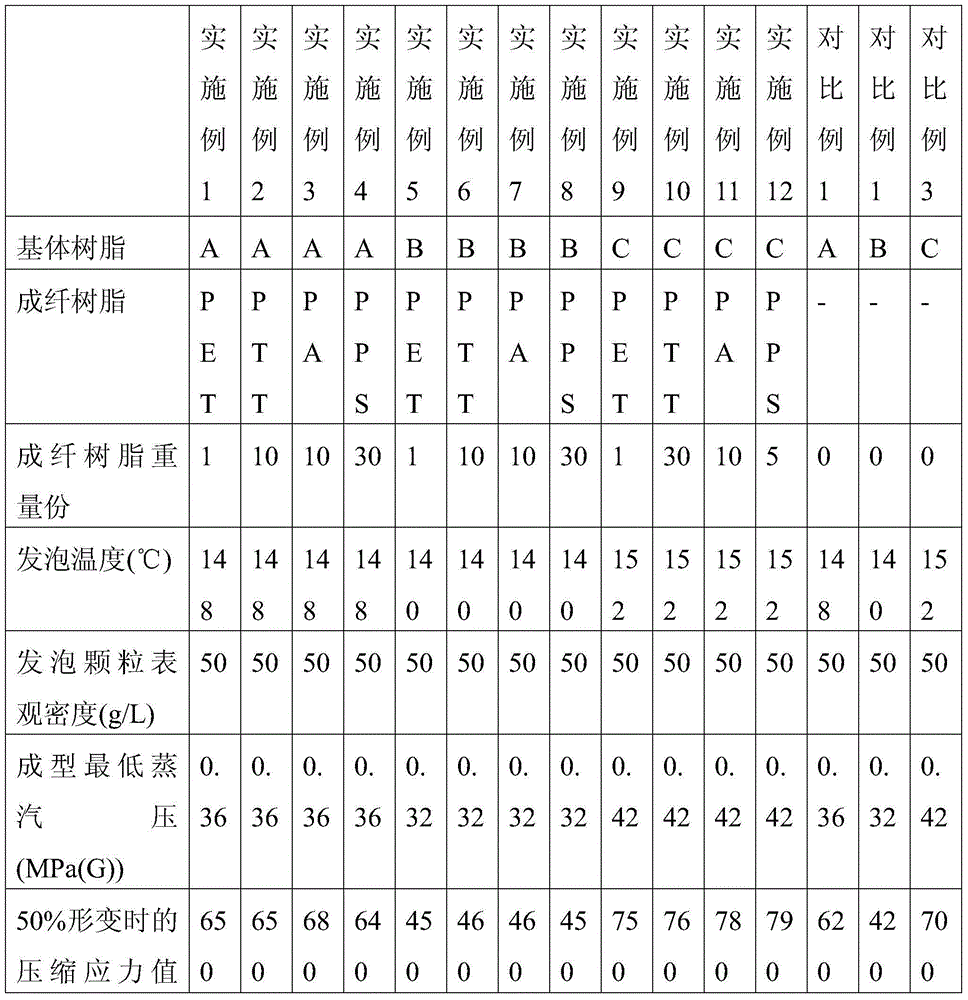

In-situ microfibrillar polypropylene series resin composite foamed particles and application thereof

The invention discloses in-situ microfibrillar polypropylene series resin composite foamed particles and application thereof, and belongs to the technical field of foaming materials. By adopting the in-situ microfibrillar polypropylene series resin composite foamed particles, the technical problem of high in-mold forming pressure of polypropylene series resin foamed particles caused by improving the rigidity of the polypropylene series resin foamed particles in the prior art can be solved. The composite foamed particles are prepared from in-situ microfibrillar polypropylene mixed resin particles by using a dispersion medium release process, wherein the in-situ microfibrillar polypropylene mixed resin particles comprise matrix resin and fiber-forming resin, the diameters of the in-situ microfibrillar polypropylene mixed resin particles are 0.5-2mm, the heights are 1-2 times that of the diameters, the matrix resin is polypropylene series resin, the melting temperature of the fiber-forming resin is more than that of the matrix resin, the fiber-forming resin is not completely compatible with the matrix resin, and the mass percentage of the fiber-forming resin is 1-30%. According to the composite foamed particles disclosed by the invention, the in-mold forming pressure cannot be increased, the composite foamed particles can be formed by using a general forming machine, the preparation cost cannot be increased, and an obtained foam forming body has relatively high rigidity and is smooth in surface.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

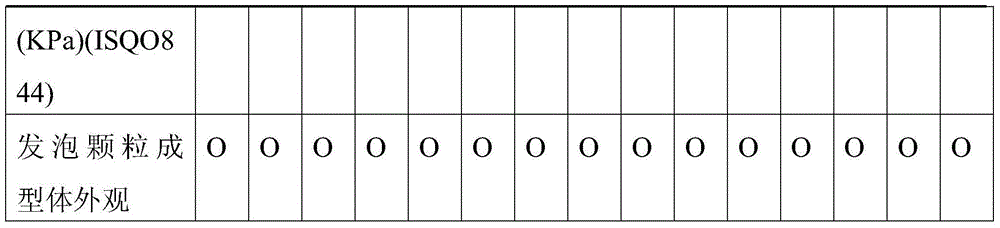

Lead-containing raw material wet recovery treatment method

ActiveCN107641714AAddressing Excessive Lead ContentShape controllableProcess efficiency improvementMother liquorRadiochemistry

The invention discloses a lead-containing raw material wet recovery treatment method, which comprises: 1) carrying out a reaction on a reaction mother liquor and a lead-containing raw material to obtain a lead-containing reaction liquid, wherein the reaction mother liquor contains a sulfate, a catalyst, a reducing agent and a complexing agent and has a pH value of 6.0-13.0; 2) carrying out a reaction on the lead-containing reaction liquid obtained in the step 1) and a precipitating agent or a solution containing a precipitating agent, and controlling the pH value at 4.5-11.0 to obtain a sulfur-containing reaction liquid and a solid precipitate A; and 3) carrying out a reaction on the all or part of the sulfur-containing reaction liquid and a desulfurization agent or a solution containing adesulfurization agent to obtain a regenerated reaction liquid and a solid precipitate B, wherein the solid precipitate A is one or a plurality of materials selected from lead carbonate, basic lead carbonate, NaPb2(CO3)2OH, lead sulfite and lead sulfate, and the solid precipitate B is one or a plurality of materials selected from calcium sulfate, calcium sulfate dihydrate and barium sulfate.

Owner:北京中金瑞丰环保科技有限公司

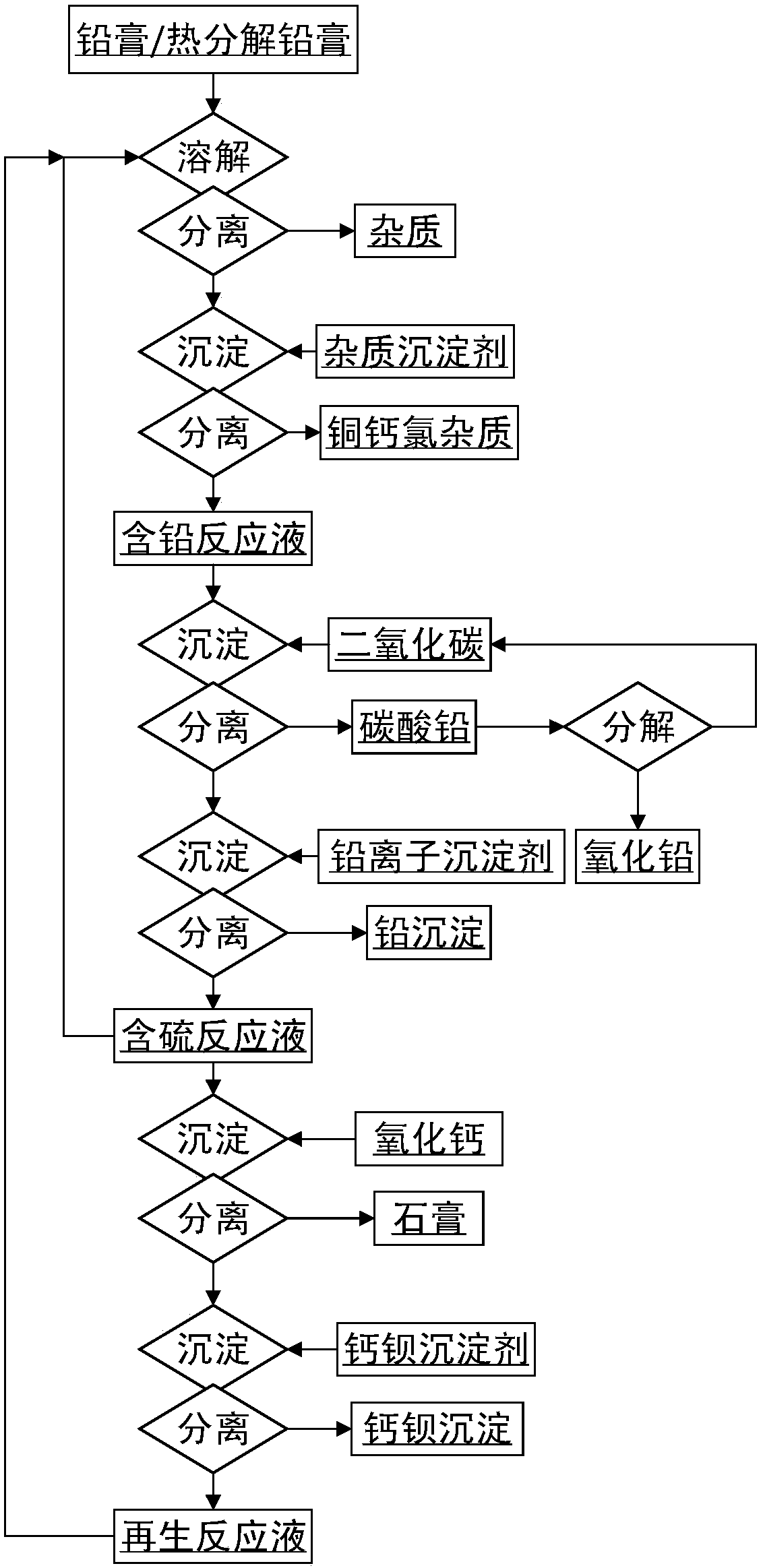

Method for adhering and combining zirconia prosthesis and natural tooth

ActiveCN108658628AImprove bonding performanceUniform structureImpression capsCeramic shaping apparatusProsthesisSurface finishing

The invention discloses a method for adhering and combining a zirconia prosthesis and a natural tooth. The method has the advantages that an existing sand blast process for processing is not used, thesurface of dental-department zirconia ceramic is milled, material mechanical damage is avoided, micro-ornamentation is formed on the surface of the dental-department zirconia ceramic to perform surface roughening under the condition that the later mechanical strength of the ceramic is unaffected so as to increase the specific surface area of the zirconia ceramic, and the zirconia prosthesis and the natural tooth are adhered and combined by using resin as the adhesive through methods such as surface processing, coating and novel sand blast.

Owner:HANGZHOU ERRAN TECH

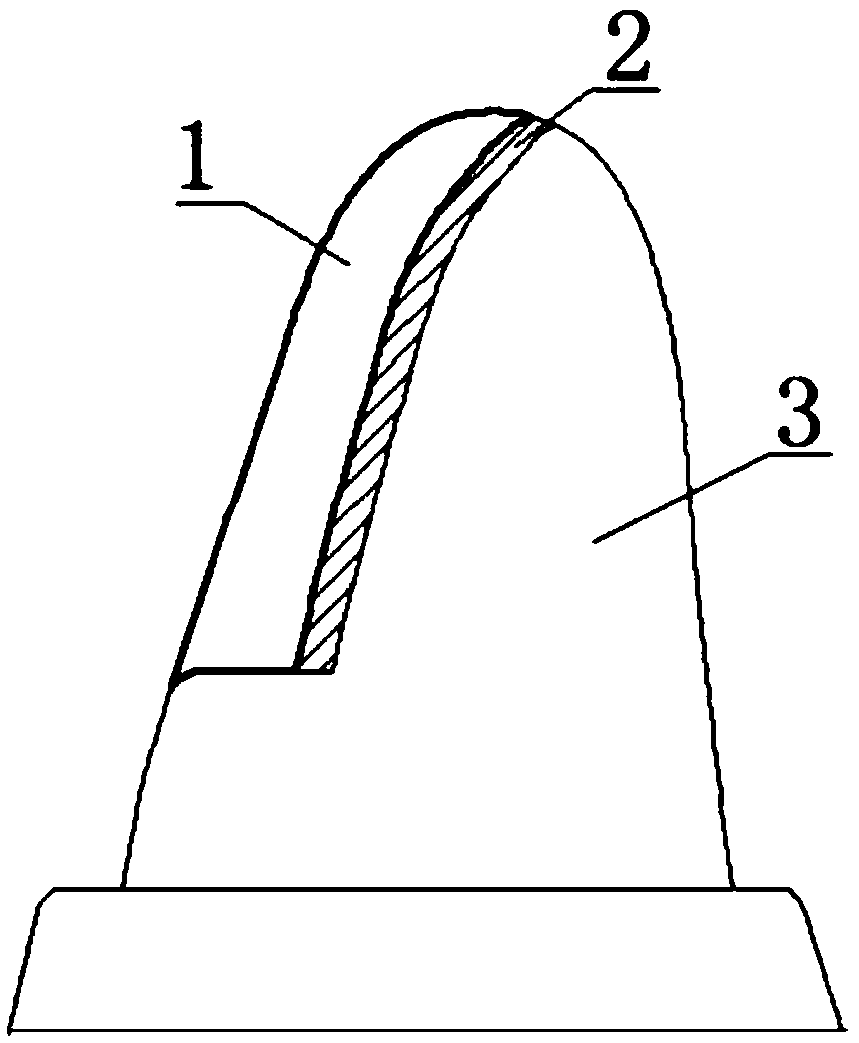

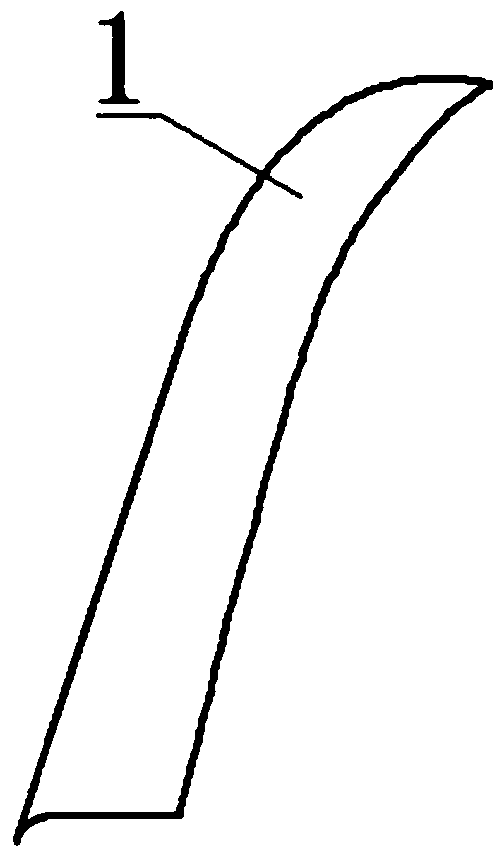

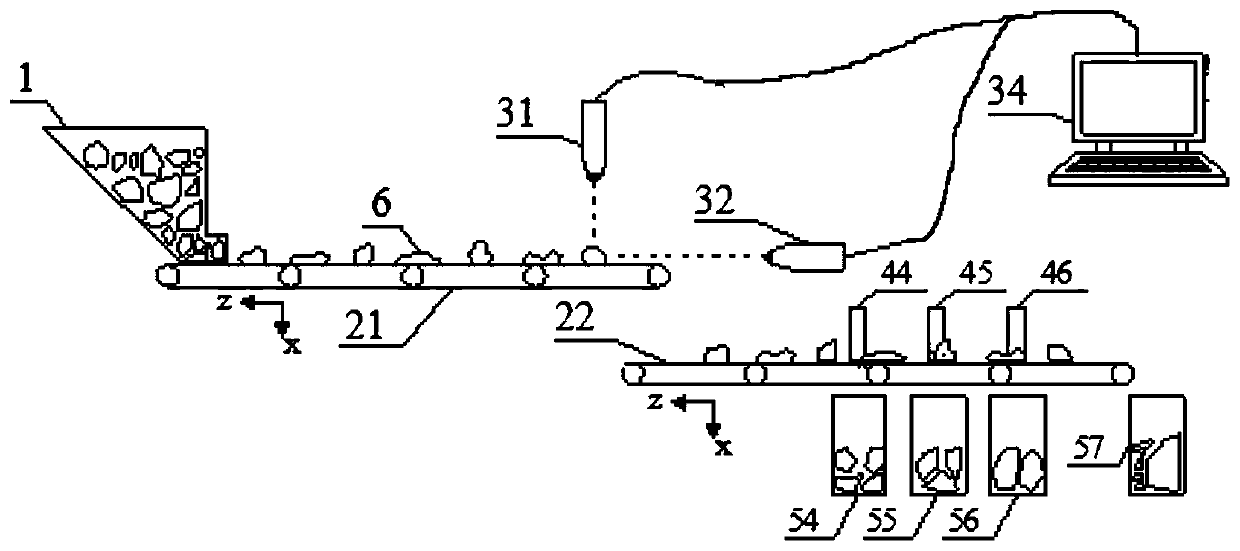

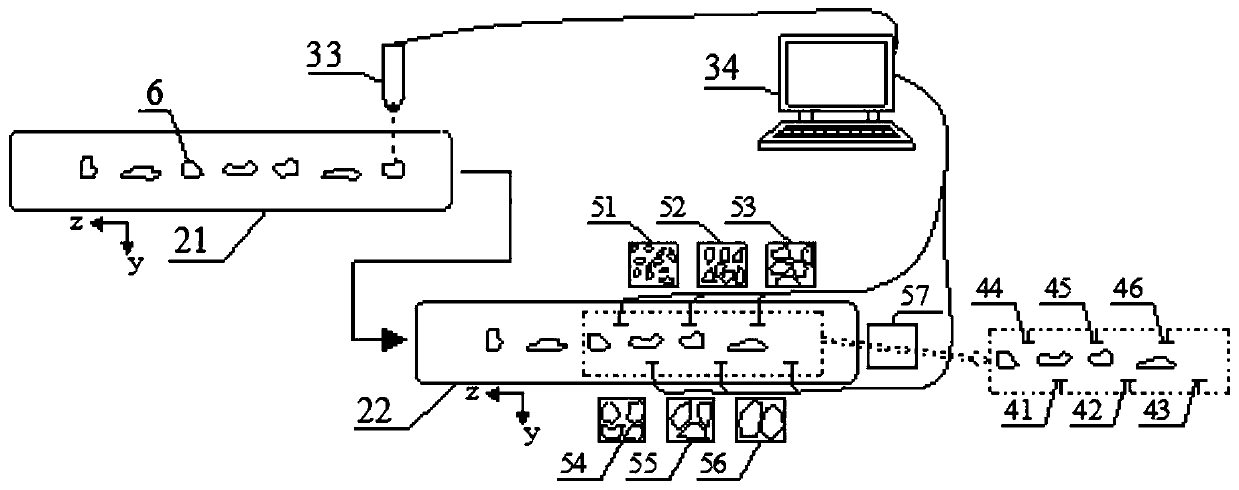

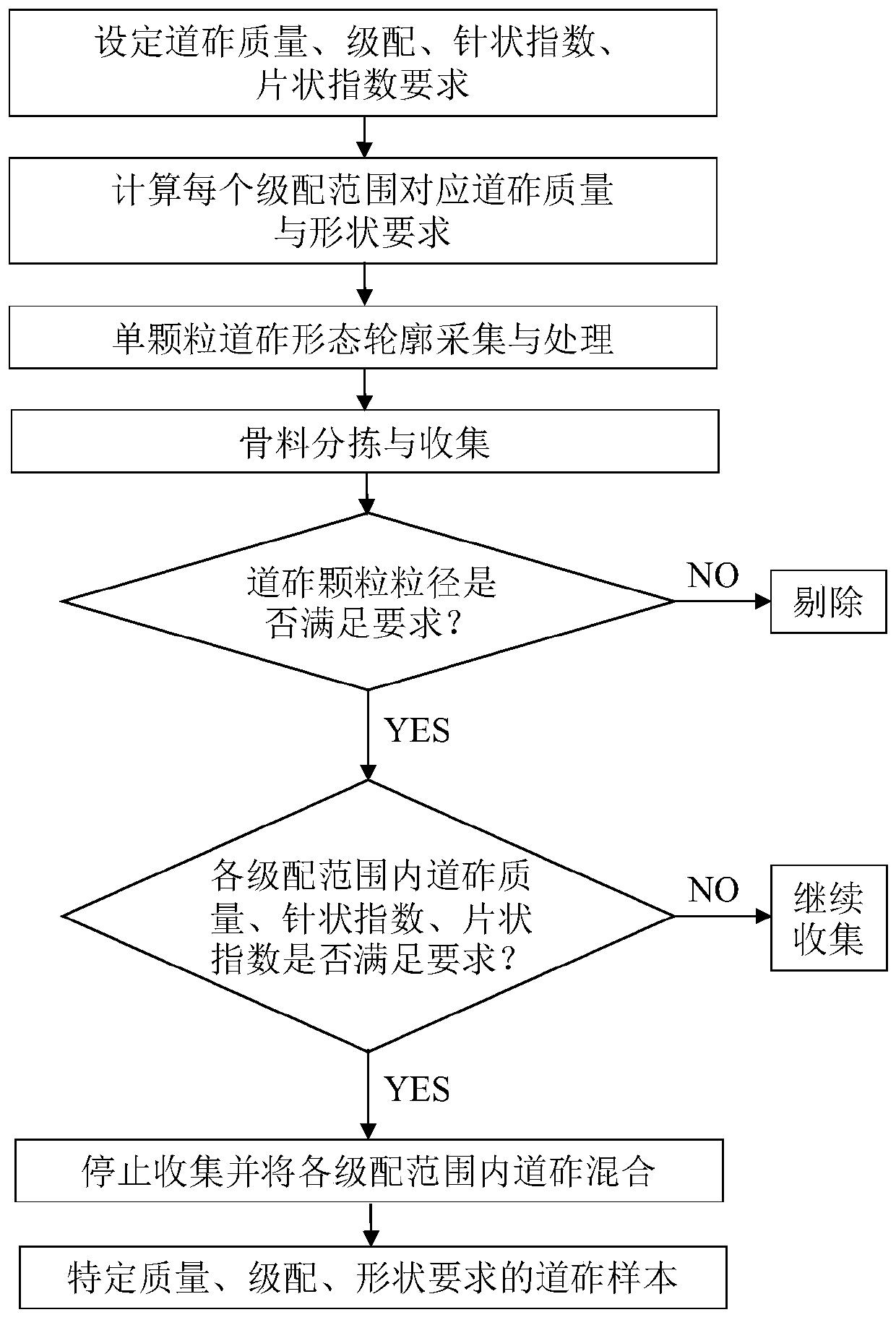

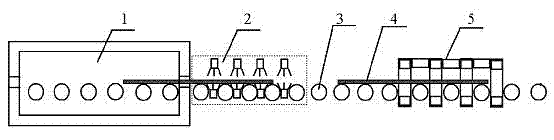

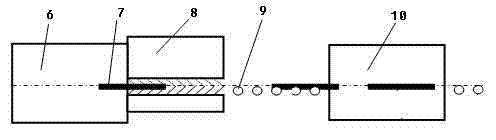

Ballast intelligent screening device based on particle morphology identification

InactiveCN111515138AShape controllableHigh degree of automationSortingProcess engineeringImage acquisition

The invention discloses a ballast intelligent screening device based on particle morphology identification. The ballast intelligent screening device comprises an aggregate bin, a conveying mechanism,an image acquisition and processing system, an aggregate sorting mechanism and an aggregate collecting mechanism, ballast particle form characteristic parameters are obtained through the image acquisition and processing system, the aggregate sorting mechanism is used for sorting particles meeting the requirements into the aggregate collecting mechanism corresponding to the particle size range, anda ballast sample with specific quality, grading and shape requirements is obtained after mixing. According to the screening device, the shape size of the ballast particles is automatically detected through an instrument, and the ballast particles meeting specific requirements can be selected according to the morphological parameters; and the screening device is applied to ballast screening in a laboratory or a railway site, automatic screening of ballast samples with specific quality and grading requirements can be achieved, the ballast morphology is controllable, and the degree of automationand the screening efficiency are higher.

Owner:TONGJI UNIV

Heat treatment system used for producing ultrahigh strength steel

InactiveCN102363829AFully return redEasy to shapeFurnace typesHeat treatment process controlSheet steelHearth

The invention discloses a heat treatment system used for producing ultrahigh strength steel. The technological layout of the system is that: (1) a quenching machine is arranged behind a roller-hearth quenching furnace; a long transporting roll table with a length of 30 to 35m is arranged behind the quenching machine; and an open-fire low-temperature roller-hearth tempering furnace is arranged behind the transporting roll table; (2) a steel plate is heated in the roller-hearth quenching furnace, and the temperature is maintained; (3) the quenching machine is configured as in a quenching mode; and the technological speed of the quenching machine is controlled at 5 to 6m / min according to the thickness of the steel plate, wherein the thickness of the steel plate is 8 to 60mm. (4) the steel plate is heated; the temperature is maintained; the steel is fetched and quenched; the quenched steel plate is places on the transporting roll table for self-tempering, wherein the self-tempering temperature is Ms to Mf (the specific temperature is determined according to the steel type); (5) when self-tempering is finished, the steel plate is delivered to the tempering furnace in time with high speed for carrying out carbon distribution, wherein the temperature is maintained; the steel plate is delivered forward according to a preset technological speed; (6) when a carbon distribution time is satisfied, the steel plate is fetched from the furnace in time to be air-cooled; (7) when the steel plate is processed through a Q+P process, the steel plate can be transported to another tempering furnace for tempering when necessary.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

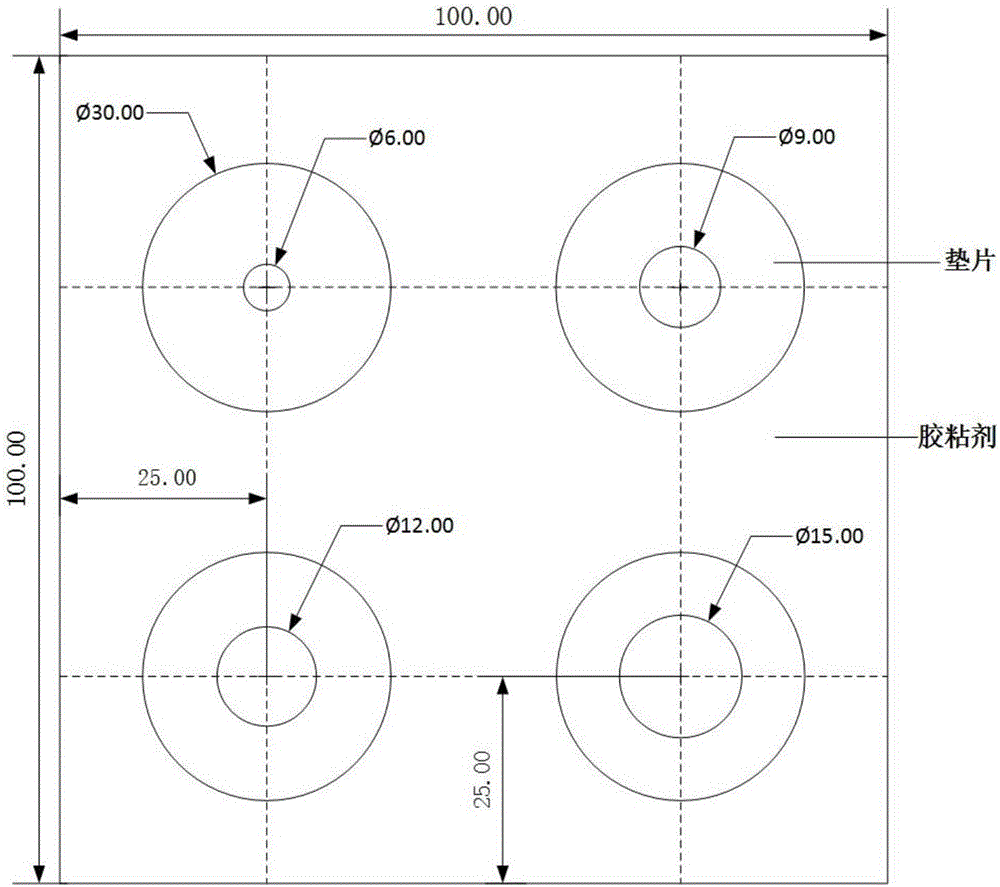

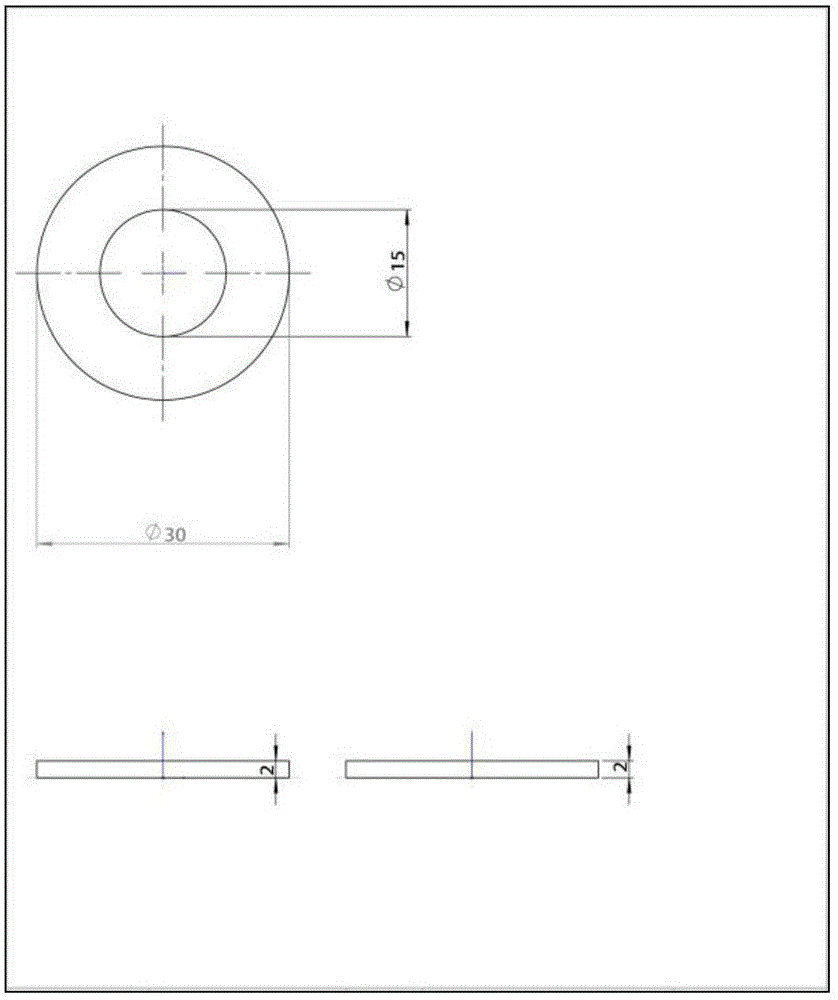

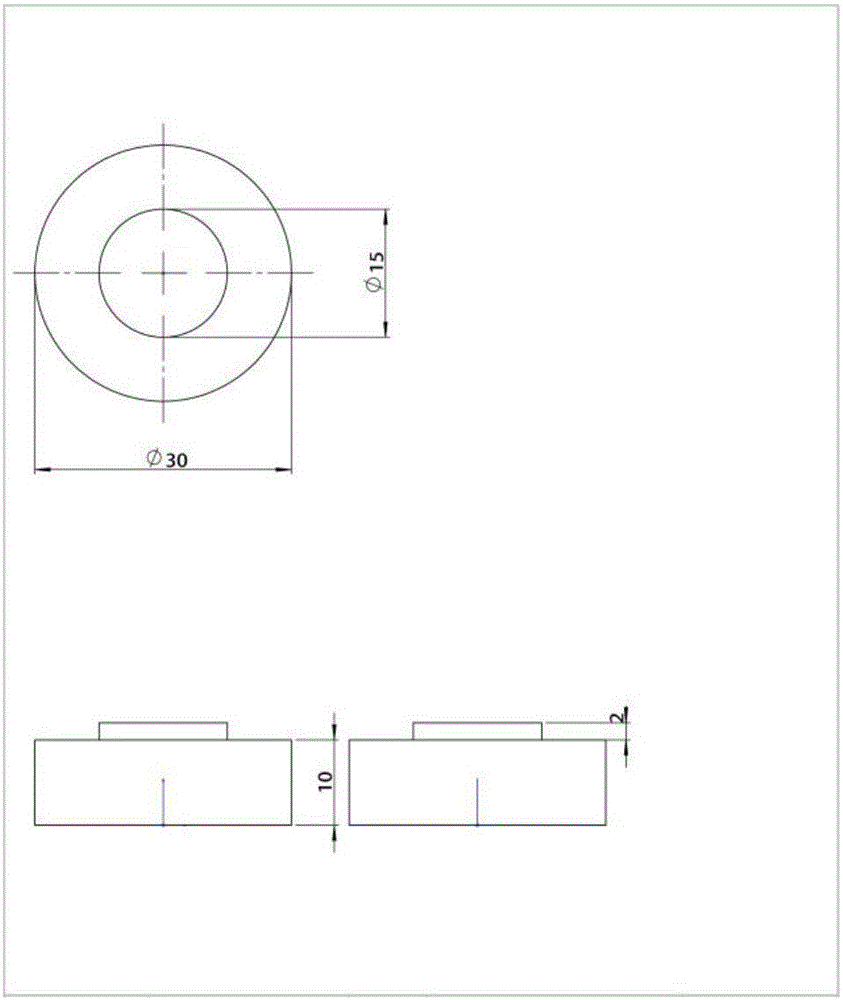

Manufacture method for composite-material cementing structural test piece with defect of air holes in glue layer

ActiveCN106093211AConducive to accurate quantificationClear identificationMaterial analysis using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationNon destructiveNondestructive testing

The invention provides a manufacture method for a composite-material cementing structural test piece with a defect of air holes in a glue layer, and belongs to non-destructive detection field. The method realizes simulation of the air hole defect in the glue layer of the composite-material multi-layer cementing structure by employing 3D printing technology for preparing a glue-layer pad, and solves the technical problems that the size, shape, thickness and the like of an air hole defect in the glue layer cannot be quantitatively designed by employing the prior art. The method possesses the advantages of real and reliable simulation, high quantization precision, good expandability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

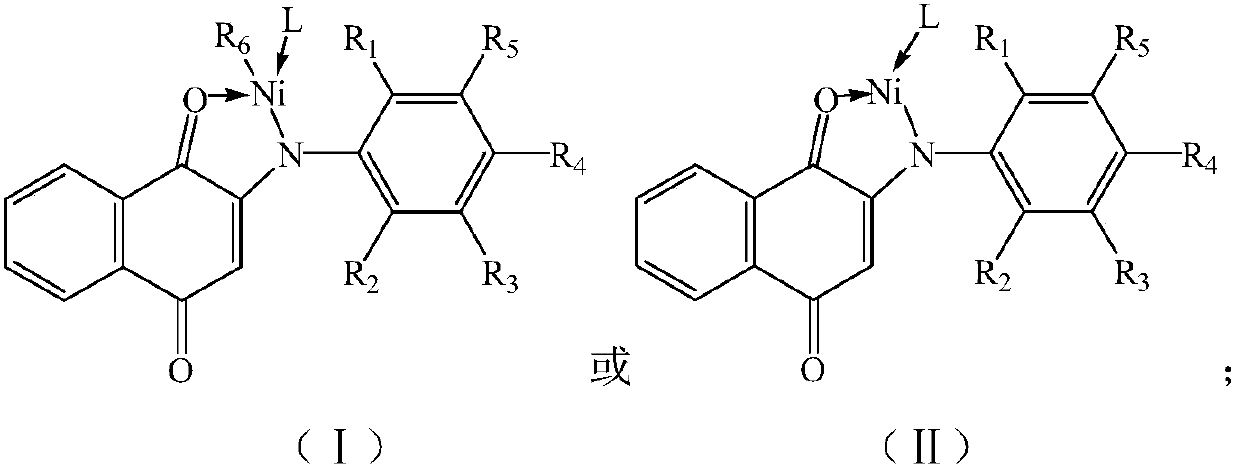

Heterogeneous polymerization reaction catalyst and application of heterogeneous polymerization reaction catalyst to preparing homopolymer and copolymer

The invention relates to a heterogeneous polymerization reaction catalyst and application of the heterogeneous polymerization reaction catalyst to preparing a homopolymer and a copolymer. The heterogeneous polymerization reaction catalyst mainly comprises a supported catalyst promoter A and a catalyst B, the structure of the catalyst B is shown in the formula (I) or the formula (II), R1-R5 are respectively independently chosen from hydrogen, alkyl group, substituendum of the alkyl group, alkoxy group, alkyl sulphanyl, halogen, nitryl, aryl group or substituendum of the aryl group in the formula, the adjacent groups in the R1-R5 form a ring and the number of the formed ring structures is less than 4, R6 is the alkyl group or the aryl group, and L is alkyl group substituted phosphine or allyl. The heterogeneous polymerization reaction catalyst can be used to prepare the homopolymer and the copolymer, the activity is relatively high, the tolerance of the polar functional group is relatively good, the molecular weight of the prepared polymer is relatively large, the distribution of the molecular weight is relatively narrow, the morphology is controllable, no subsequent processing is needed, and the phenomenon of adhesion on a kettle is effectively improved.

Owner:DONGHUA UNIV

Preparation method of spherical nickel diselenide powder

InactiveCN103043630AEasy to operateShape controllableMaterial nanotechnologyBinary selenium/tellurium compoundsSolventActive agent

The invention belongs to the technical field of preparation of nano materials, and relates to a preparation method of spherical nickel diselenide powder. The method comprises the following steps: 1) mixing Ni<2+>-containing water soluble salt and simple substance selenium powder in a solvent, ultrasonic oscillation for 20-40 minutes, and uniformly stirring to obtain a reaction solution, wherein the solvent is prepared by mixing ethylenediamine and 60-80 wt% hydrazine hydrate in a volume ratio of 1:(3-6); 2) reacting the reaction solution at 100-180 DEG C in a sealed environment for 12-20 hours; and cooling, washing with ethanol and distilled water 2-3 times, and drying at 60-80 DEG C to obtain the spherical nickel diselenide powder of which the average diameter is 2.8-3.2 mu m. The method provided by the invention does not need to previously prepare any template or use any surfactant, and has the advantages of mild reaction, one-step synthesis and simple technique; and the prepared nickel diselenide has the advantages of regular shape and uniform structure, and is beneficial to subsequent application.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

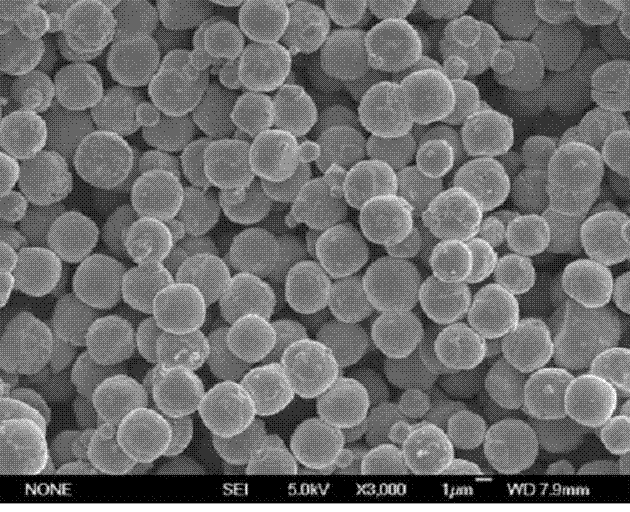

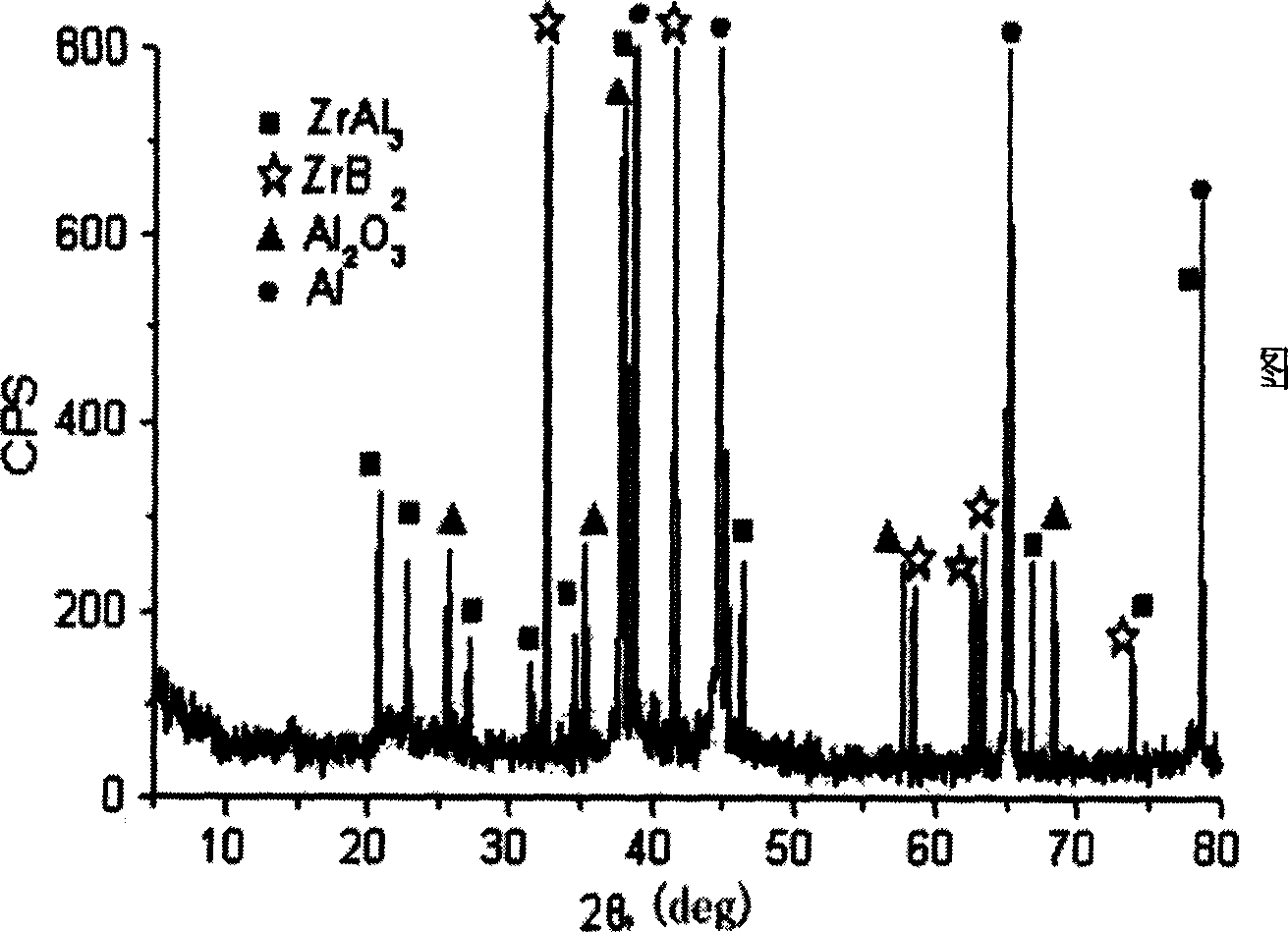

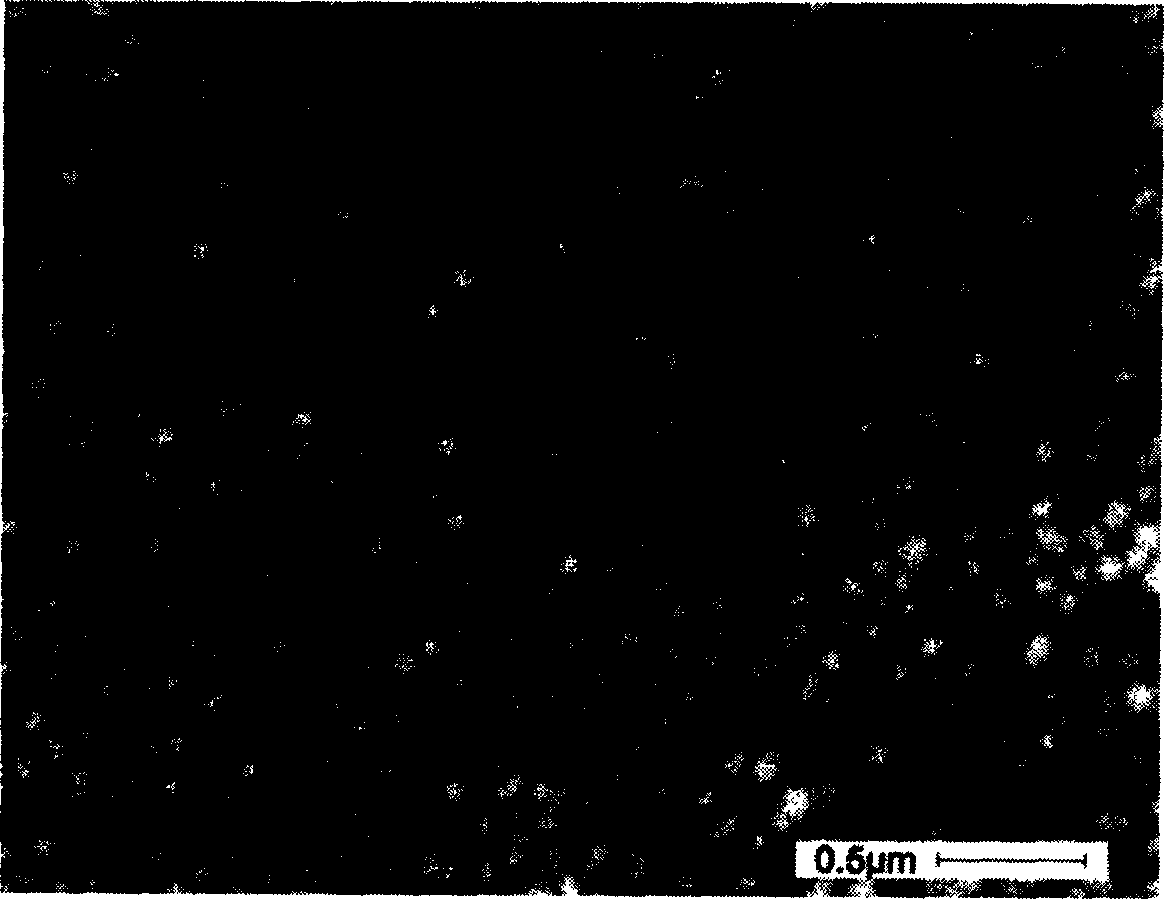

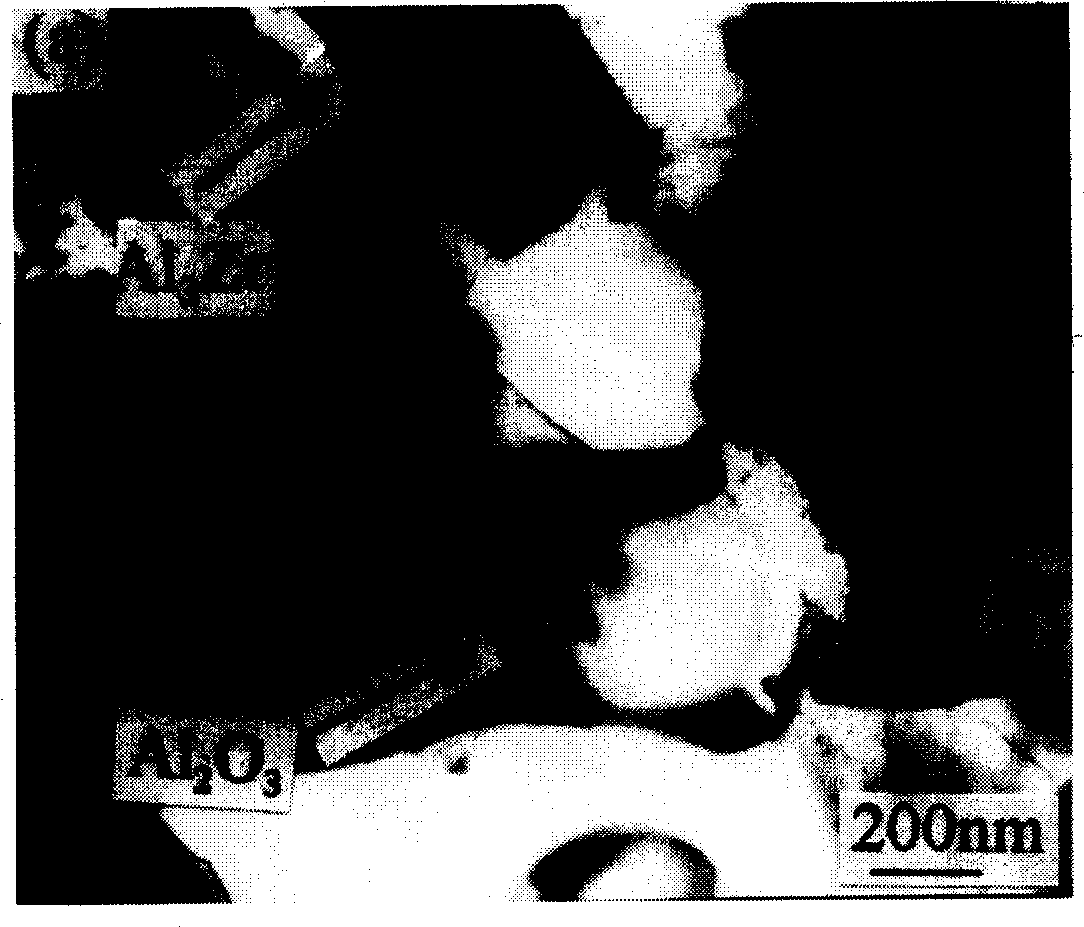

AI-Zr-B-O reacting system for synthesizing high-performance aluminium-base copmosite material in-situ and synthetic material thereof

ActiveCN1644722AModerate initial reaction temperatureSmooth responseWear resistantSynthetic materials

The invention has provided a Al-Zr-B-O reaction system which can synthesis the high performance aluminium base in situ composite. In the 800-900 deg.C Al or Al-alloy fusant, we can addinto the mixture of Zr and B oxidation or salt which is 5-25% Al or al-alloy fusant. The Al-Zr-B-O reaction system solidify to the high performance aluminium base composite which insist of Al3Zr, ZrB2, Al2O3-15%, and Al or Al-ally. The initial temperature for the reaction for the reaction of Al-Zr-B-O system is obviously lower than the Al-Ti-O system. The new (Al3Zr+Al2O2+ZrB2) / Al and the (Al3Zr+Al2O3+ZrB2) / A356 have the good performance of mechanics, physics and wear resistant.

Owner:JIANGSU UNIV

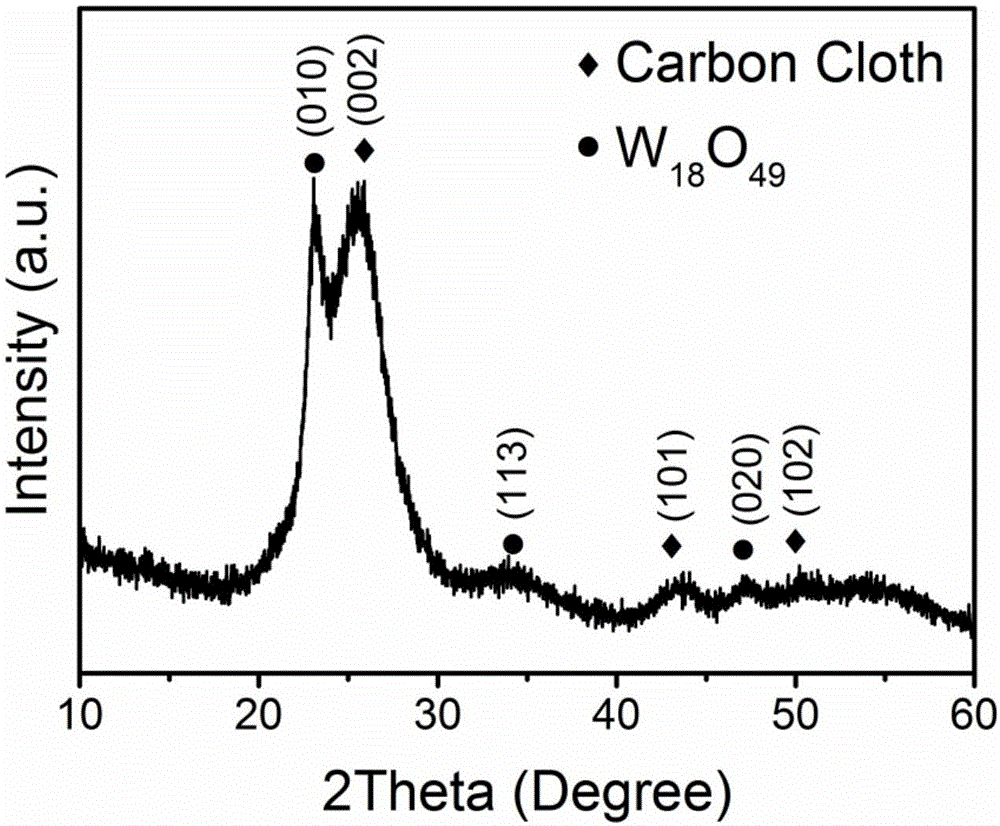

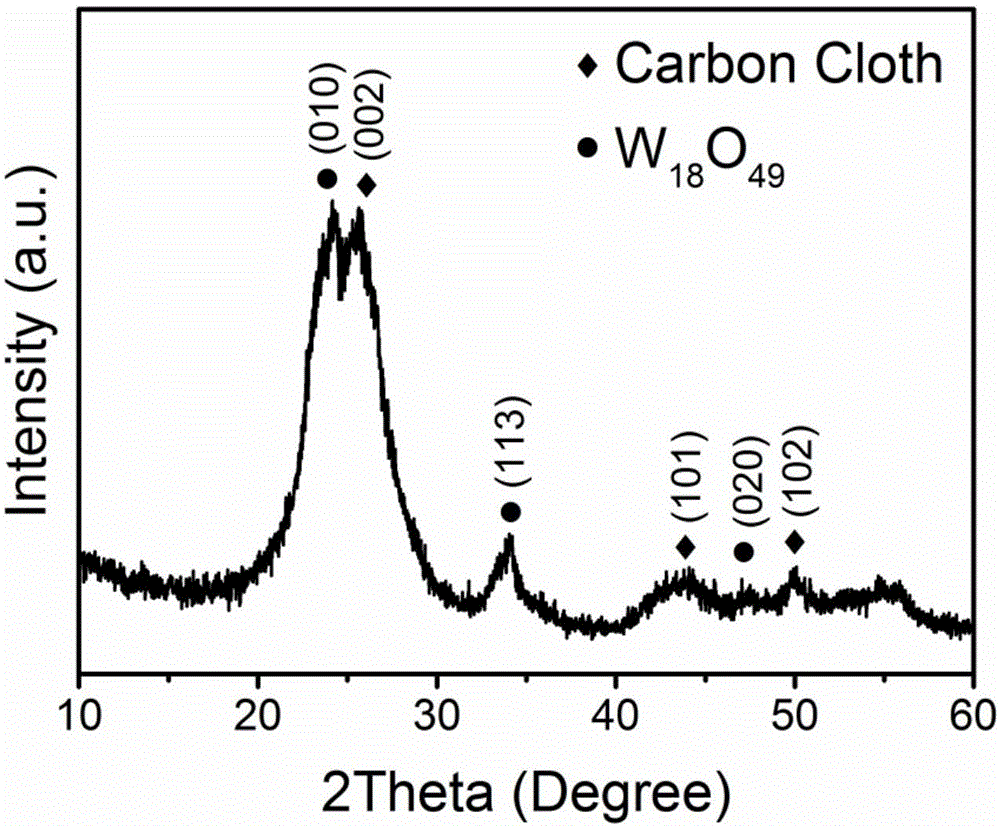

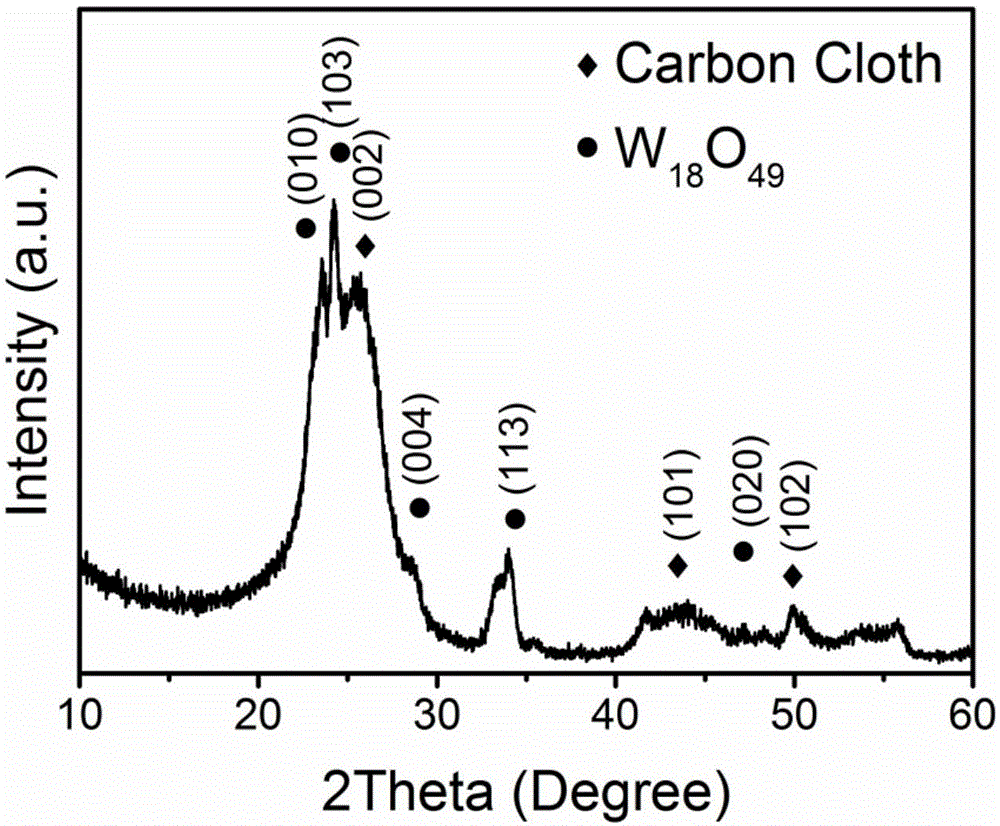

W18O49 coated carbon fiber composite material and preparation method thereof

The invention discloses a W18O49 coated carbon fiber composite material and a preparation method thereof. The W18O49 coated carbon fiber composite material takes carbon fibers as a reaction source and the W18O49 coated carbon fiber composite material is produced by adopting a solvothermal method; a monoclinic W18O49 nano-material grows on the carbon fibers through the solvothermal method in a coating manner; in a solvothermal preparation process, any template and any catalyst are not needed; the technology is simple, the yield is high and the cost is low, so that the W18O49 coated carbon fiber composite material is suitable for batch production; the W18O49 nano-material directly grows on carbon cloth and the prepared nano composite material has a uniform shape and coating tightness and can be used as photocatalysis, electrocatalysis, solar cell, flexible sensor, field emission and lithium-ion battery negative electrode materials.

Owner:NORTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com