Method for adhering and combining zirconia prosthesis and natural tooth

A technology of zirconia and restorations, which is applied in the field of bonding and bonding of zirconia restorations and natural teeth to achieve the effect of improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] 2. Preparation of molding and coating raw materials:

[0074] 2.1 Suspension slurry of zirconia

[0075] Add zirconium hydroxide suspension with a concentration of 0.5-1mol / L into the reactor, then add yttrium oxide into the reactor in 3-5 times, heat the reactor to 40-60°C, and keep it warm for 2-3 Hours, after the added yttrium oxide is completely dissolved, add 0.5-1% dispersant polyethylene glycol accounting for the weight of zirconium hydroxide, then heat to 200-250°C, keep warm for 55-65 hours to carry out hydrothermal-hydrolysis reaction, during Keep the internal pressure of the reactor at 2-3MPa to gradually hydrolyze the precipitate; use a centrifuge to quickly separate the precipitate, vacuum filter the precipitate, wash with distilled water and ethanol, and dry to obtain a partially stable oxidized yttrium with a yttrium content of 2-6mol%. Zirconium precursor; mix the yttrium partially stabilized zirconia precursor with the dispersant polyethylene glycol ac...

Embodiment 1

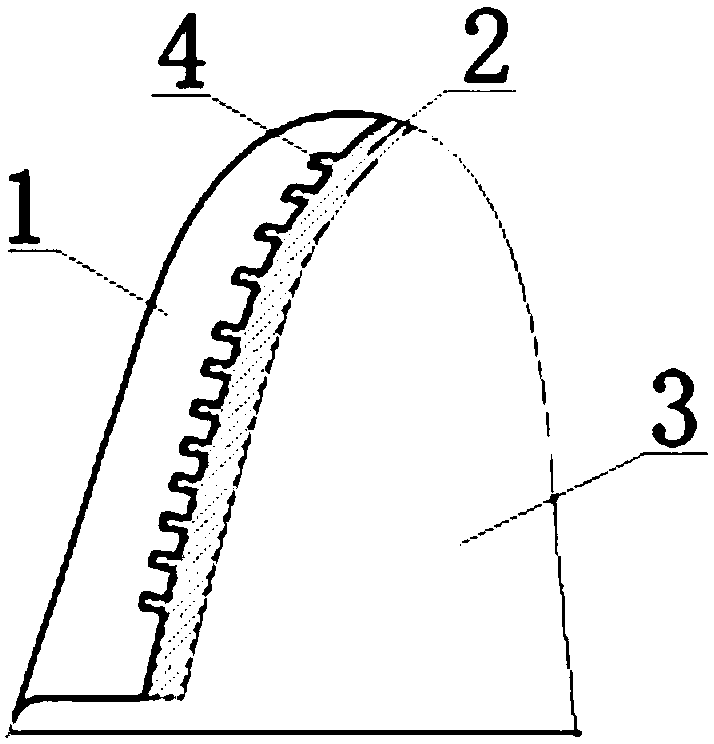

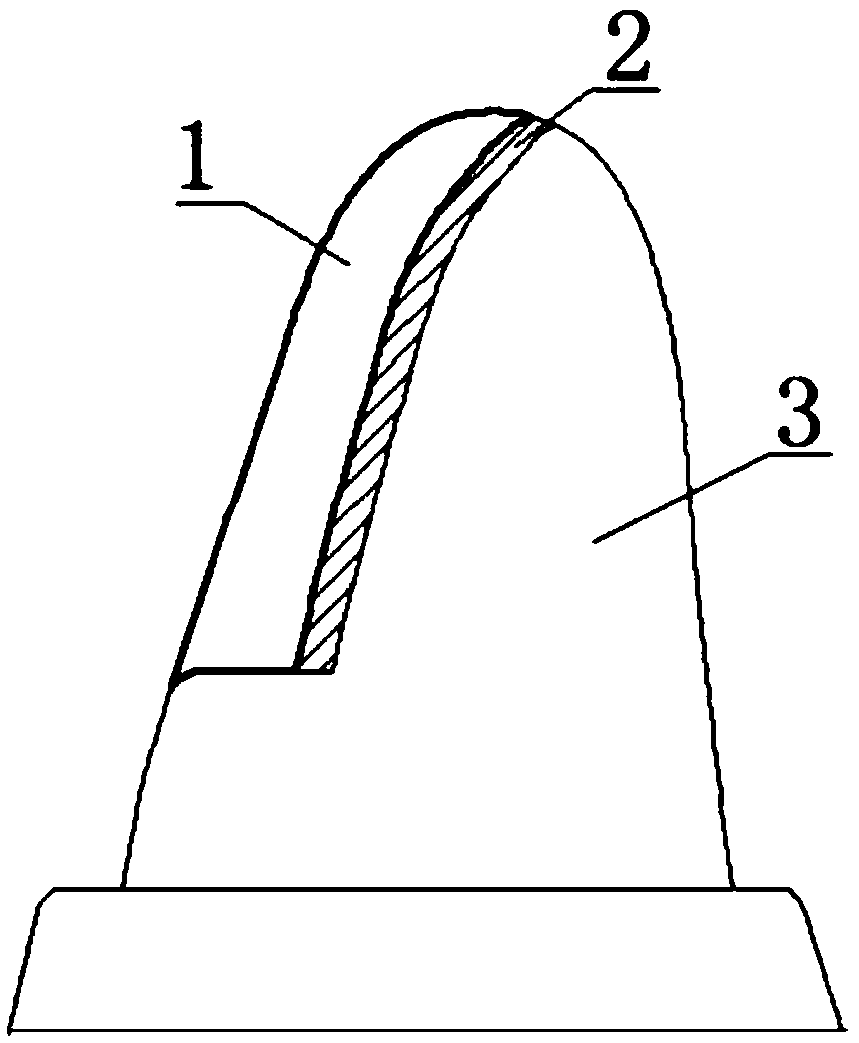

[0088] Restoration type is veneer restoration 1 (eg figure 2 ), the area is larger, the whole is thicker, and the edges are also thicker. It is required that the bonding surface is completely covered with mesh, and the mesh depth is deepened.

[0089] Step 1. All mesh processing requires high edge strength. Partially sintered zirconia ceramic green bodies can reduce the risk of edge cracking. Prepare partially sintered zirconia ceramic green bodies with a diameter of 20 mm and a height of 20 mm.

[0090] Step 2. Use NX10.0 for processing programming, set the grid tool path as a horizontal line, the grid depth is 0.05mm, the grid spacing is 0.98mm, and the grid range covers the entire bonding surface, such as image 3 , 4 . The tool is a 1mm hard alloy coated ball end milling cutter, the spindle speed is 12000rpm, the milling feed is 600mmpm, and the processing program is generated. The micro-decoration shape that the present invention can process in addition can also be as...

Embodiment 2

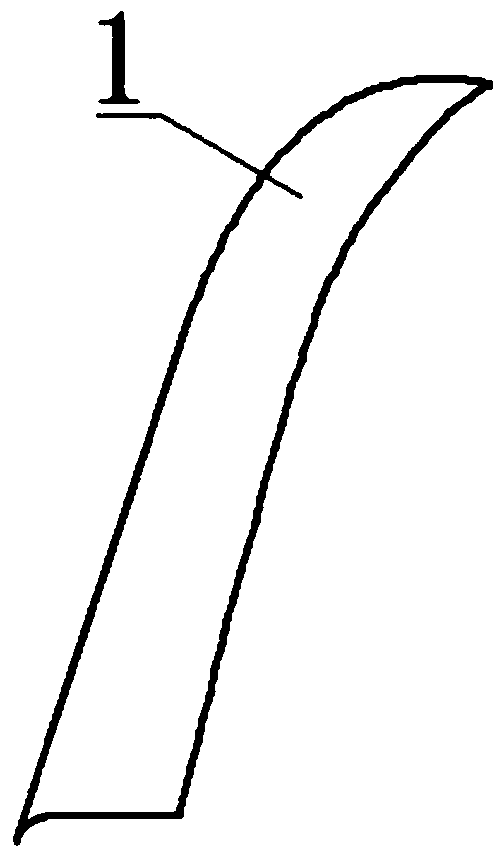

[0100] The type of restoration is a veneer restoration, which has a larger area, thinner overall, and thinner edges. It is required that only part of the mesh should be made on the bonding surface to protect the edges, and the mesh depth should not be too deep.

[0101] Step 1. Prepare an unsintered zirconia ceramic green body, the length, width and height are respectively 40×17×20 mm;

[0102] Step 2. Use SUM3D for processing programming, set the grid tool path to be vertically staggered, the grid depth is 0.03mm, the grid spacing is 0.3mm, and the grid range is 2mm from the edge, such as Figure 5 . The tool is a 0.6mm carbide ball end milling cutter, the spindle speed is 15000rpm, the milling feed is 1000mmpm, and the processing program is generated.

[0103] Step 3. Import the processing program into the three-axis numerical control machine tool to process the zirconia ceramic green body. During the processing, the zirconium powder peeled off was continuously blown away ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com