Polyimide adhesive and preparation method thereof

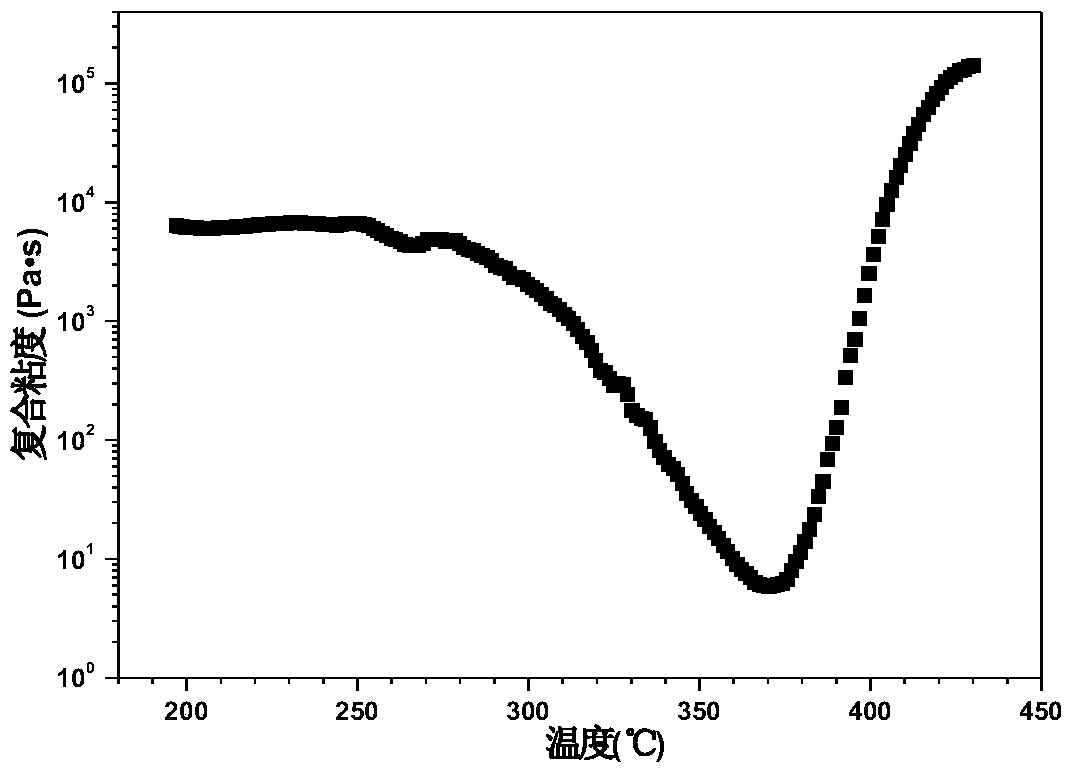

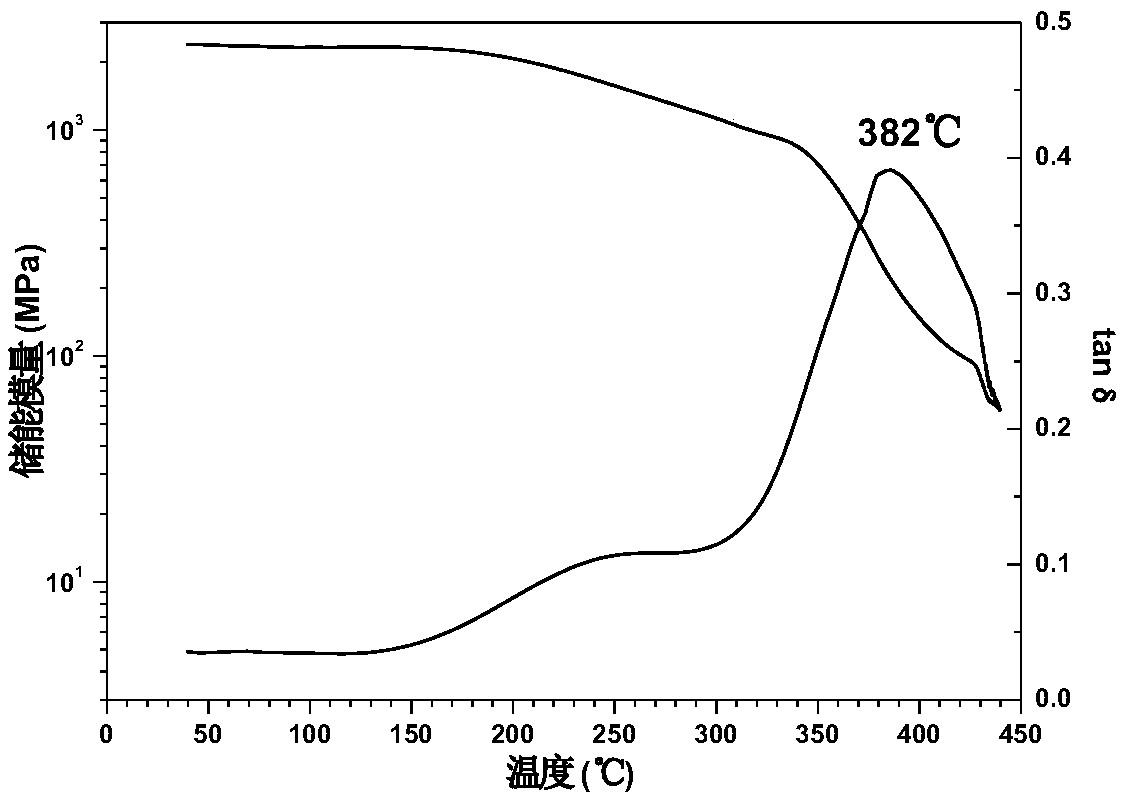

A technology of polyimide adhesives and adhesives, which is applied in the direction of adhesives, etc., can solve the problems of decreased adhesive performance, heat-resistant instability of polyimide adhesives, etc., to achieve glass transition temperature increase, lower melting The effect of improving the bulk viscosity and improving the adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) In a three-necked flask equipped with a mechanical stirrer, water separator, nitrogen inlet and outlet, and a thermometer, add 28.82 grams (0.09 moles) of 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl, 3.49 g (0.01 mol) of bis(4-aminophenoxy)tetramethyldisiloxane and 110 g of N-methylpyrrolidone were stirred under nitrogen protection until completely dissolved. After that, 16.11 g (0.05 mol) of 3,3',4,4'-benzophenone tetraacid dianhydride and 24.82 g (0.10 mol) of 4-phenylethynylphthalic anhydride were added, and stirred under a nitrogen atmosphere until completely dissolved. Stir at room temperature for 12 hours to obtain a homogeneous solution with a solid content of 40 wt.%.

[0060] (2) Add 16 grams of toluene to the above homogeneous solution, raise the temperature of the reaction system to 175° C., react for 12 hours under nitrogen protection, then raise the temperature to 200° C. to evaporate the toluene and stop heating.

[0061] (3) Cool the reaction soluti...

Embodiment 2

[0066] (1) In a three-necked flask equipped with a mechanical stirrer, water separator, nitrogen inlet and outlet, and a thermometer, add 25.62 grams (0.08 moles) of 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl, 6.97 g (0.02 mol) of bis(4-aminophenoxy)tetramethyldisiloxane and 215 g of N,N-dimethylacetamide were stirred under nitrogen protection until completely dissolved. After that, 19.33 g (0.06 mol) of 3,3',4,4'-benzophenone tetraacid dianhydride and 19.86 g (0.08 mol) of 4-phenylethynylphthalic anhydride were added, and stirred under a nitrogen atmosphere until completely dissolved. Stir at room temperature for 12 hours to obtain a homogeneous solution with a solid content of 25 wt.%.

[0067] (2) 11 grams of xylene was added to the above homogeneous solution, the temperature of the reaction system was raised to 150° C., and the reaction was carried out under nitrogen protection for 12 hours, and then the temperature was raised to 166° C. to evaporate the xylene and stop ...

Embodiment 3

[0073] (1) In a three-neck flask equipped with a mechanical stirrer, a water separator, a nitrogen inlet and outlet, and a thermometer, add 22.42 grams (0.07 moles) of 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl, 10.46 g (0.03 mol) of bis(4-aminophenoxy)tetramethyldisiloxane and 165 g of N,N-dimethylformamide were stirred under nitrogen protection until completely dissolved. After that, 21.49 g (0.067 mol) of 3,3',4,4'-benzophenone tetraacid dianhydride and 16.56 g (0.067 mol) of 4-phenylethynylphthalic anhydride were added, and stirred under a nitrogen atmosphere until completely dissolved. Stir at room temperature for 8 hours to obtain a homogeneous solution with a solid content of 30 wt.%.

[0074] (2) 8 grams of toluene was added to the above homogeneous solution, the temperature of the reaction system was raised to 140° C., and the reaction was carried out under nitrogen protection for 12 hours, and then the temperature was raised to 153° C. to evaporate the toluene and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com