Patents

Literature

334results about How to "Improve bonding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technical wood and manufacture method thereof

ActiveCN103171014AImprove the utilization rate of solid woodHigh densityWood compressionWood impregnation detailsHot pressHot pressing

The invention relates to technical wood and a manufacture method thereof. The manufacture method comprises the steps of dying and drying eucalyptus and poplar veneers, conducting gum dipping and thickening on the wood veneers by using an ultrasonic vibration method, assembling gum dipping boards, conducting semi-solidification hot-pressing maintaining by using a curve die high-frequency press, conducting square slicing on the technical wood or cutting the technical wood into wood veneers, assembling the wood veneers in the same direction according to needed thickness, and conducting hot pressing and thickening. The thickness of the technical wood veneers or wood square produced by using the manufacture method is as high as 0.8-1.8kg / cm<3>, the thickness of the technical wood is more than 1.5 times of that of common technical wood, a plurality of items of physical and mechanical properties are improved by more than 1.5 times, the technical wood is not easy to crack, product durability improves to more than one time, service life of products is prolonged, and using fields of the products are extended.

Owner:SINO MAPLE JIANGSU CO LTD

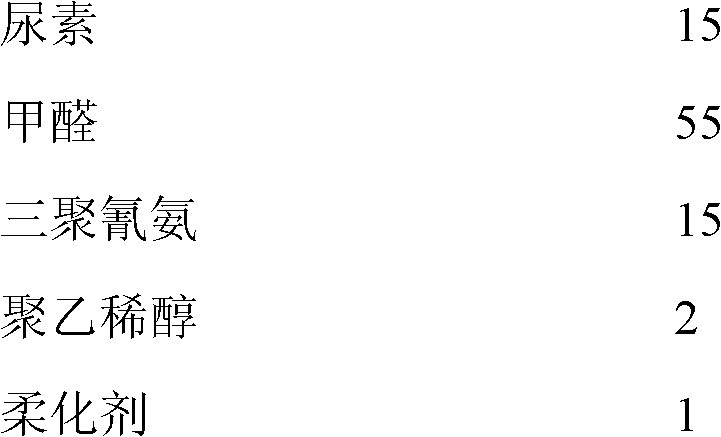

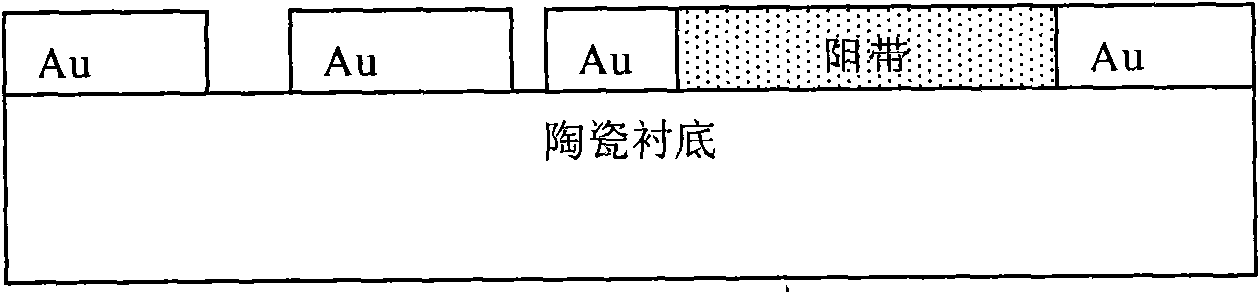

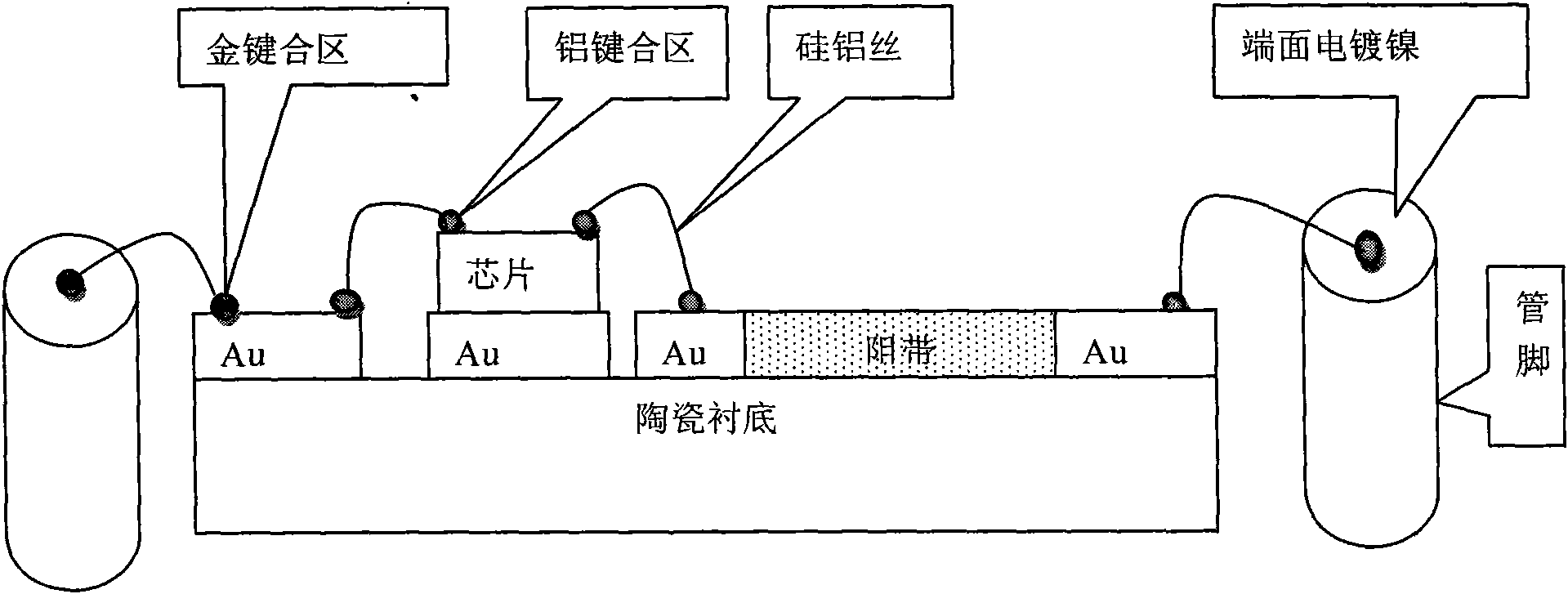

Bonding system of high-reliability thick-film mixed integrated circuit and manufacturing method thereof

InactiveCN101673693AImprove reliabilityImprove bonding performanceSolid-state devicesSemiconductor/solid-state device manufacturingAviationSpaceflight

The invention discloses a bonding system of a high-reliability thick-film mixed integrated circuit and a manufacturing method thereof. The system and the method are characterized in that the bonding system is an indirectly bonded bonding system, namely, a layer of blocking layer metal film is added on the surface of the metal bonding area and a layer of metal film capable of carrying out high-reliability bonding with the silicon-aluminium wire is then added on the surface of the metal bonding area so as to form a multilayer transitional film; and subsequently the bonding system of the silicon-aluminium wire is carried out on the surface of the metal bonding area. The system and the method have the advantages of: (1) improving the bonding performance of the bonding area of the thick-film gold conducting belt and the silicon-aluminium wire; (2) forming local nickel bonding area or an aluminium bonding area on the bonding area of the same gold conducting belt, and being compatible with the gold wire bonding and silicon-aluminium wire bonding; and (3) adopting a metal mask location register and high-vacuum deposition film-formation technology and having no damaging effects on the substrate of the thick-film. When being applied to all thick-film mixed integrated circuit taking gold conducting belts or silver conducting belts as substrates, the reliability of the mixed integrated circuit can be improved and the mixed integrated circuit has wide application prospect in the fields such as aviation, spaceflight, navigation, communication, industrial control and the like.

Owner:GUIZHOU ZHENHUA FENGGUANG SEMICON

Ultrafine grain wolfram carbide/ cobalt hard alloy and preparation method thereof

The invention discloses an ultrafine grain wolfram carbide (WC) / cobalt hard alloy containing rare-earth hexaboride and a preparation method thereof and belongs to the field of high-performance powder metallurgy materials. The hard alloy comprises the following components in percentage by weight: 0.1 to 2 percent of the rare-earth hexaboride, 0.1 to 0.6 percent of chromium carbide, 0.1 to 0.4 percent of vanadium carbide, 5 to 15 percent of cobalt powder, and the balance of wolfram carbide powder. The preparation method comprises the following steps of: weighing the wolfram carbide powder, the cobalt powder, the rare-earth hexaboride powder, the chromium carbide powder and the vanadium carbide powder with certain granularity in percentage by weight; uniformly mixing the powder by ball milling; pressing the mixture by a mold pressing process to form a green ware body in a certain shape; degreasing the green ware body and sintering the degreased green ware body in a high-temperature low-pressure sintering furnace; and cooling the obtained product along with the furnace to obtain the ultrafine grain wolfram carbide / cobalt hard alloy. The hard alloy has the advantages of rational proportion of the components, simple production process, effective reduction in the grain size of the WC in the hard alloy and improvement on the hardness and fracture toughness of the hard alloy by adulterating the rare-earth hexaboride to inhibit the growth of the wolfram carbide grains in the sintered hard alloy, achievement of high hardness and fracture toughness and application in industrial production.

Owner:昆山长鹰硬质材料科技股份有限公司

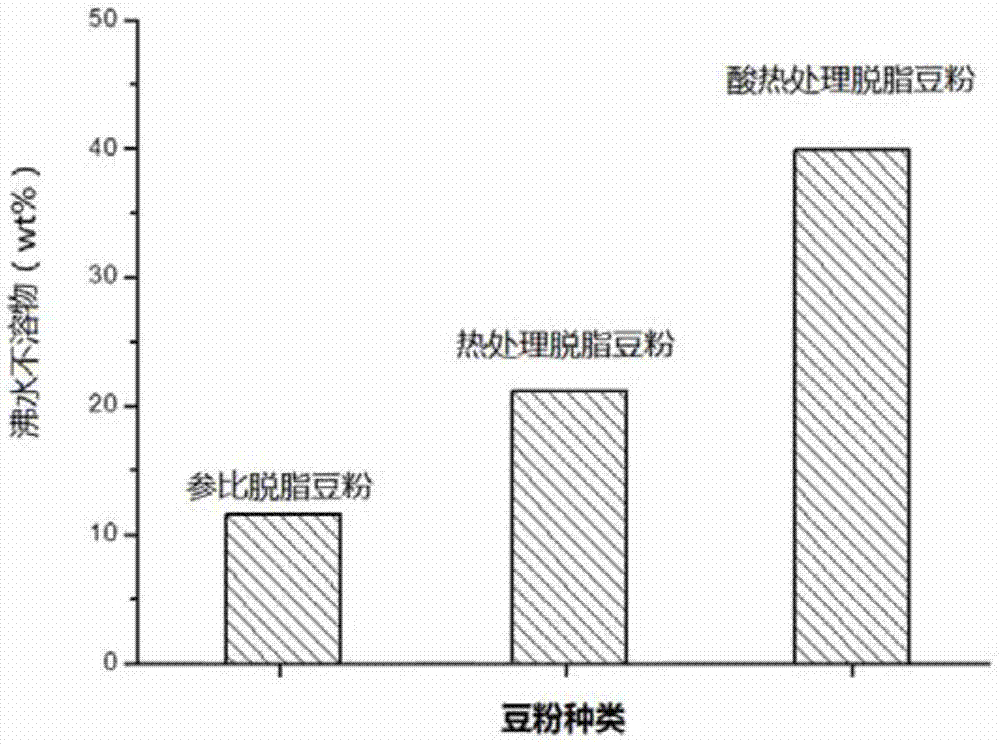

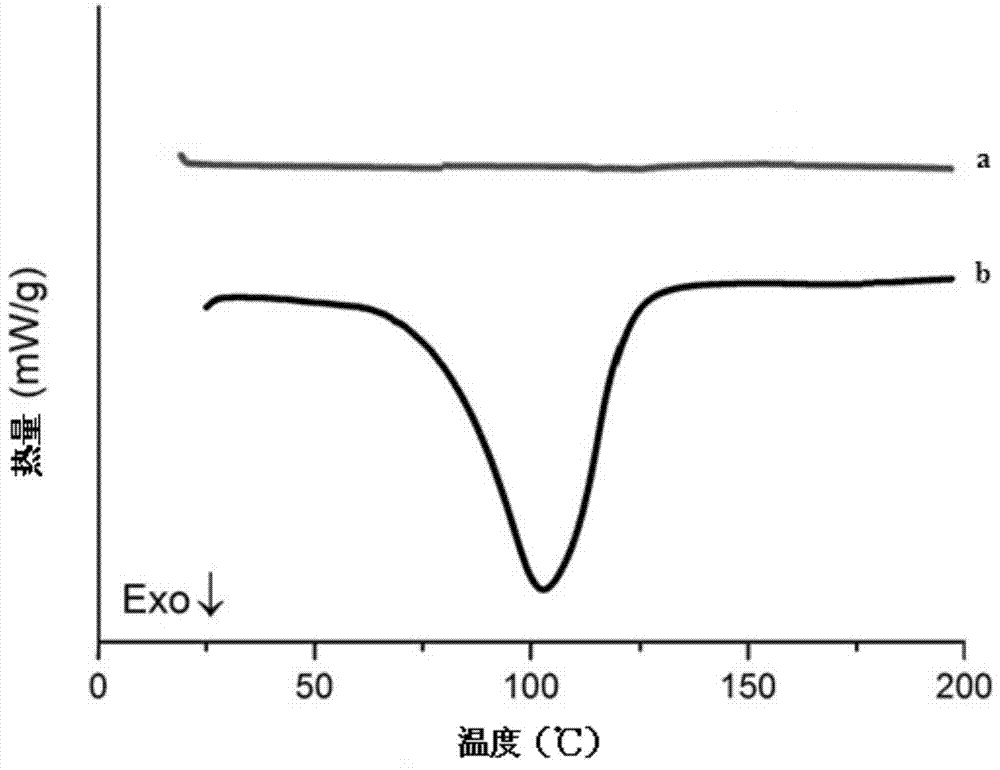

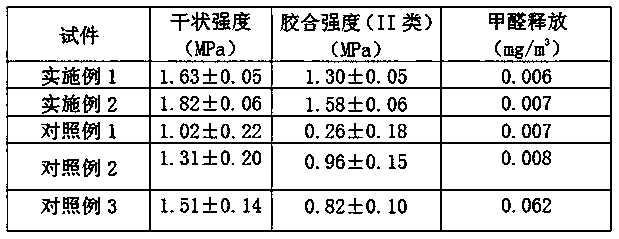

Waterproof-level soy protein adhesive and preparation method thereof

ActiveCN104497965AFacilitate cross-linkingImprove water resistanceProtein adhesivesGlue/gelatin preparationAdhesiveWorking life

The invention provides a waterproof-level soy protein adhesive and a preparation method thereof and relates to an adhesive and a preparation method thereof, in particular to a modified soyabean protein adhesive for waterproof-level plywood. The waterproof-level soy protein adhesive aims at solving the technical problem that an existing adhesive for plywood is not waterproof. The preparation method comprises the steps of beam flour acid heat treatment, beam flour liquidation, polyamide solution synthesis and adhesive modulation. Degreased beam flour or soya bean meal left after soybean oil expelling is used as a main raw material, the water resisting property of the beam flour and the solid content of the soy protein adhesive are improved through acid heat treatment, the cross-linking efficiency, cementing effect and process usability of the soy protein adhesive are improved through liquidation, the water resisting property of the soy protein adhesive is improved through cross-linking of polyamide polyamine resin, and finally the soy protein adhesive high in beam flour content, low in viscosity, long in working life and good in water resisting property and used for the waterproof-level plywood is prepared. The waterproof-level soy protein adhesive and the preparation method belong to the field of adhesive preparation.

Owner:浙江蓝歌新材料科技有限公司

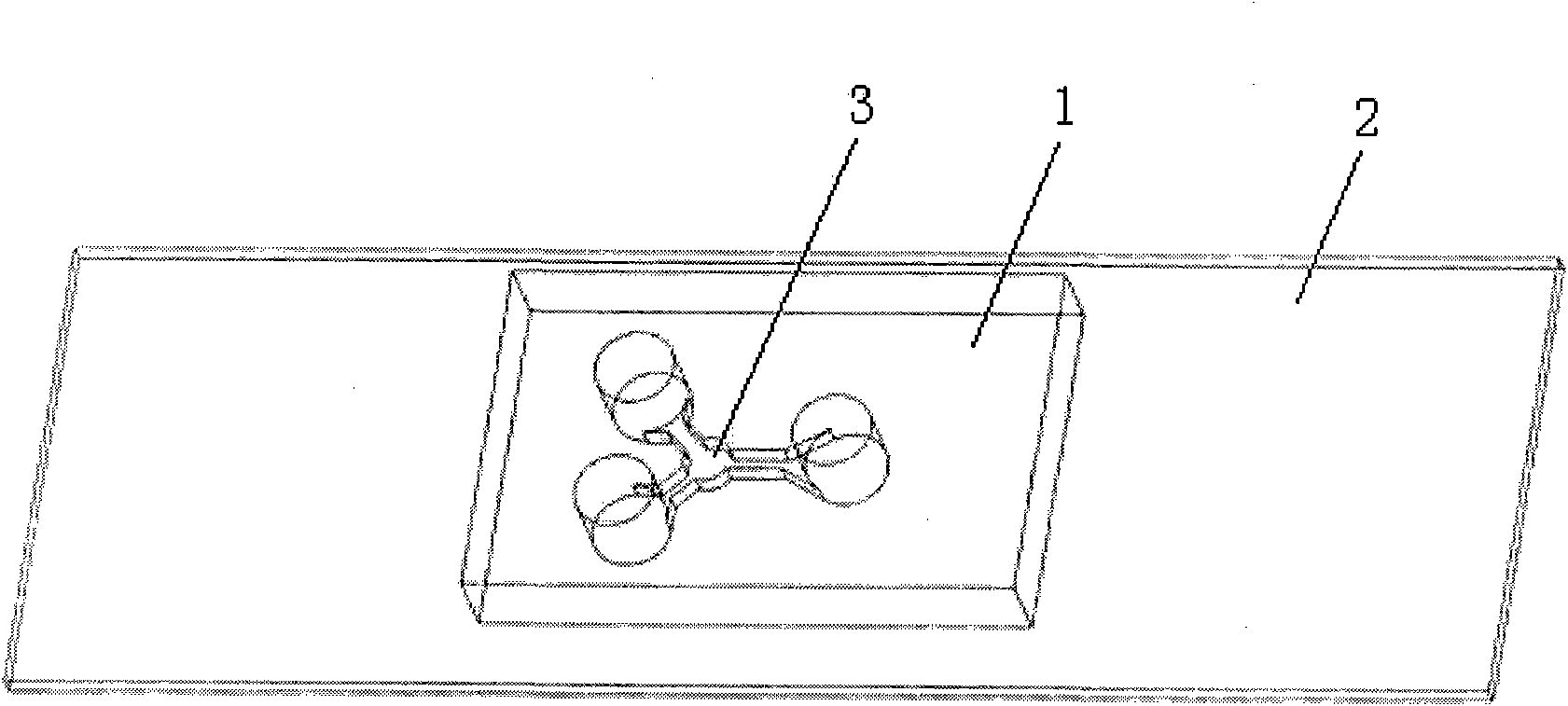

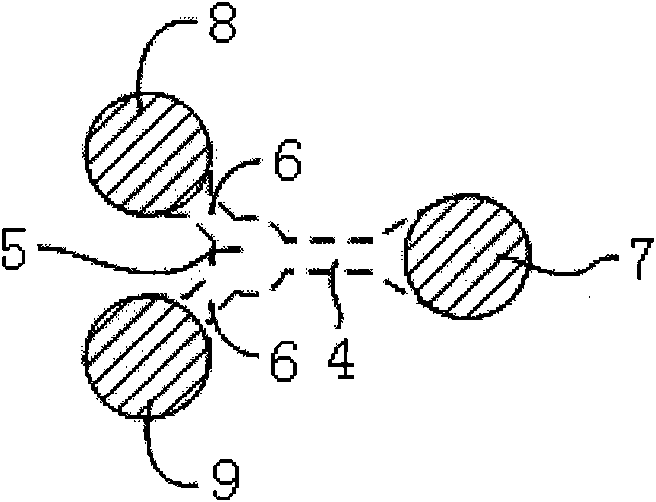

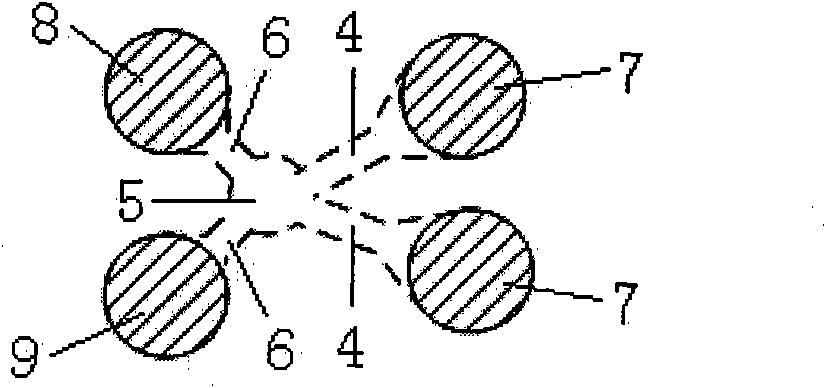

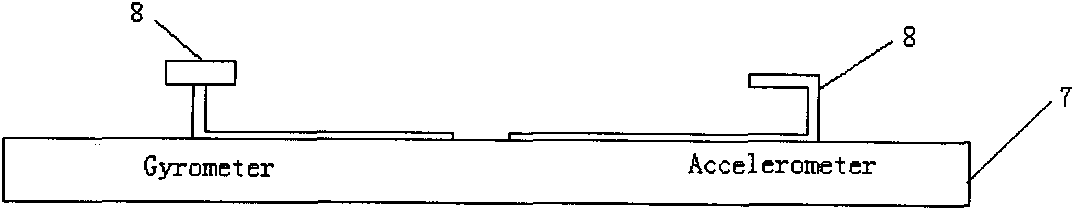

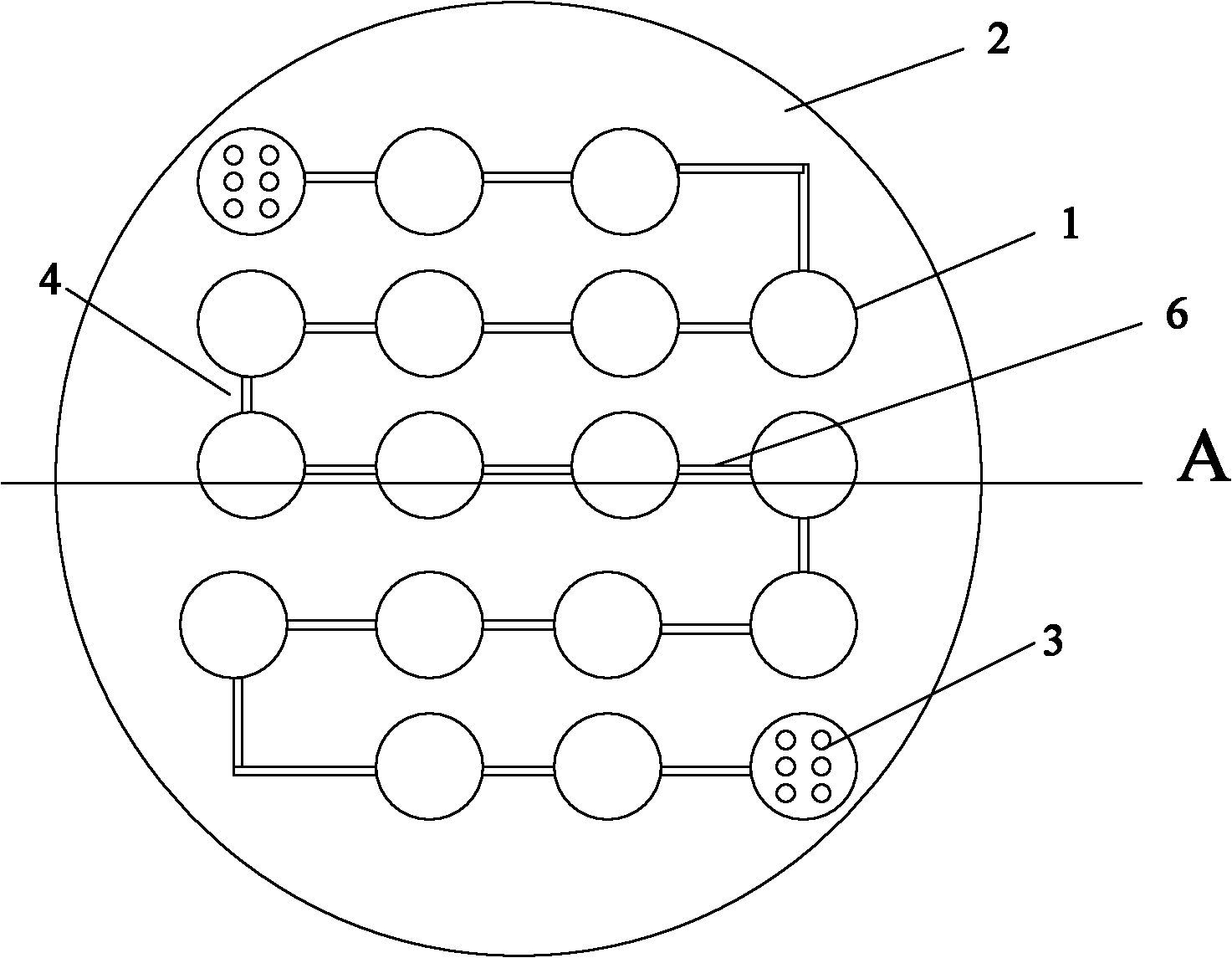

Microtube device and using method thereof

ActiveCN101914435AReduce consumptionImprove breathabilityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringTop cap

The invention relates to a microtube device and a using method thereof. The microtube device is characterized by comprising an upper layer of top cap layer and a lower layer of substrate layer, wherein the top cap layer is tightly connected with the surface of the substrate layer; the top cap layer and / or the substrate layer are / is provided with a branch microtube; the branch microtube consists of at least one activity screening tube, a buffer cavity and at least two branch tubes which are symmetrically distributed to the center of the buffer cavity; the buffer cavity is connected with the activity screening tube and the branch tube; meanwhile, the top cap layers corresponding to all the end positions of the branch microtube are provided with a hole respectively to form a sample inlet pool and a sample outlet pool; the sample inlet pools are communicated with the corresponding activity screening tube respectively; and the sample outlet pools are communicated with the corresponding branch tubes respectively. Cells can be cultured in situ in the sample outlet pool and can continuously generate a chemotactic matter by selectively adding cells capable of releasing the chemotactic matter into one or more sample outlet pools, so that uniform and stable chemical gradient fields are generated in the buffer cavity and the branch tubes. The microtube device has the advantages of simple manufacturing steps, low cost, quick and effective screening process, and easy popularization and use in ordinary laboratories.

Owner:CAPITALBIO CORP +1

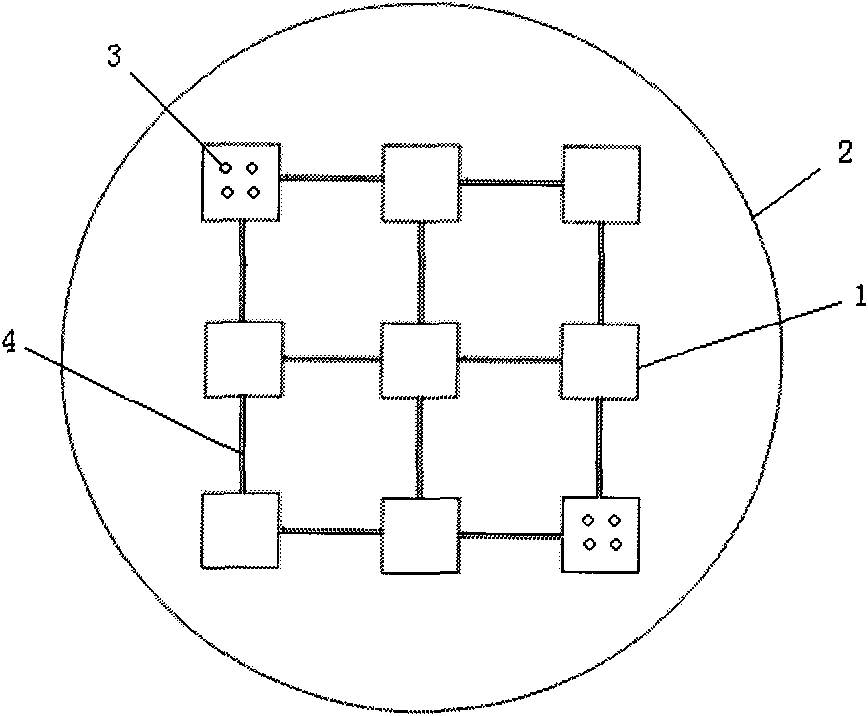

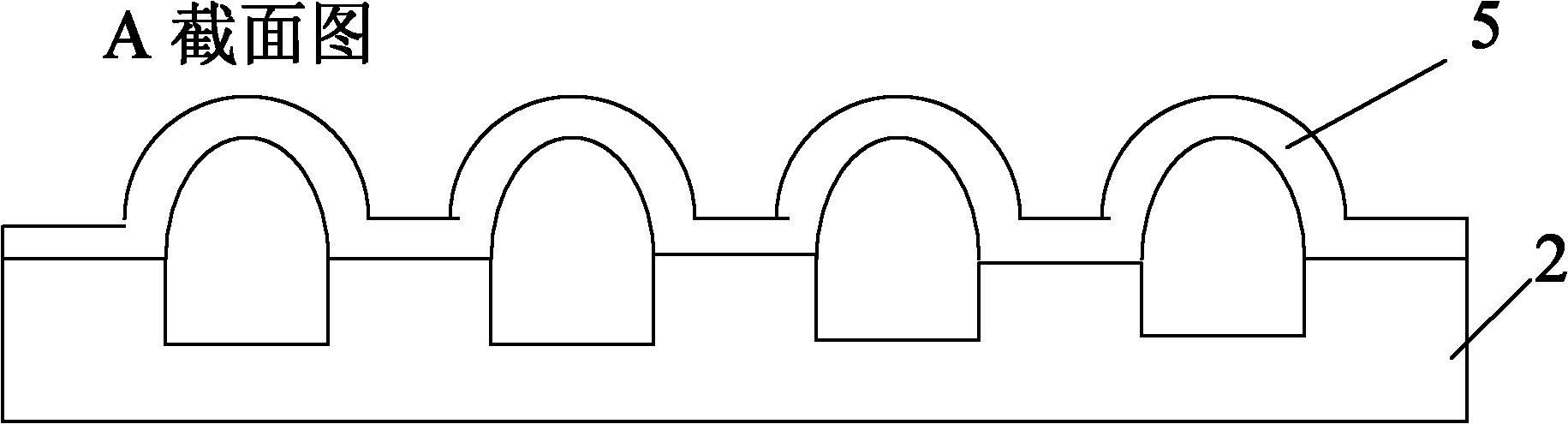

Wafer-level integrated encapsulation method of MEMS (Micro Electric Mechanical System) devices requiring different atmosphere pressures

ActiveCN101898746AHigh quality factorSmall coefficient of thermal expansionPrecision positioning equipmentDecorative surface effectsThermoformingEngineering

The invention discloses a wafer-level integrated encapsulation method of MEMS (Micro Electric Mechanical System) devices requiring different atmosphere pressures. The method comprises the following steps of: 1. preparing at least two MEMS devices requiring different quality factors on a silicon wafer; 2. preparing a glass micro-cavity for sealing an MEMS chip corresponding to the positions of the MEMS devices on a glass wafer with a thermoforming method, and depositing a getter in the glass micro-cavity in which the MEMS chip is encapsulated to obtain a functionalized glass wafer; 3. carrying out anodic bonding on the functionalized glass wafer and the silicon wafer with the MEMS devices so as to hermetically encapsulating the MEMS devices; and 4. selectively heating the getter in the glass micro-cavity in which the MEMS chip is encapsulated by laser to absorb air so that the quality factor in the cavity is changed. In the method, the getter is arranged in each cavity, and the quality factor in the encapsulation cavity is changed selectively by heating and activating.

Owner:SOUTHEAST UNIV

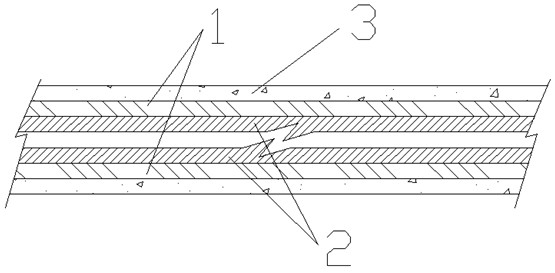

Method for producing multi-layer board using poplar board, enzyme treated lumber and stalk fibre

InactiveCN101439525AExpand sourceImprove bonding performanceCane mechanical workingWood veneer joiningFiberHigh density

The invention relates to a method for manufacturing a multilayer board by a poplar veneer, enzyme treated wood and straw fiber. The method is characterized by comprising the following steps: (1) manufacturing wood fiber; (2) manufacturing the straw fiber; (3) processing the wood and the straw fiber by enzyme; (4) manufacturing a high-density fiber board; and (5) assembling and compregnating the poplar veneer and the fiber board into the multilayer board. The method has the advantages of improving the bonding performance by the enzyme treated wood and straw fiber, manufacturing the high-density fiber board by the enzyme treated wood and straw fiber, being capable of enlarging material sources of the multilayer board by manufacturing the multilayer board by replacing part of the veneers, and using the wood felling and processing remainders and crop straw materials. The enzyme treated wood and straw fiber improve the wetting property of the multilayer board (a surface contact angle is reduced by 10-20%), improve the bonding performance and reduces the application amount of urea formaldehyde resin adhesive by 6-8%. Generally, the application amount of urea formaldehyde resin adhesive is 10-14%.

Owner:NANJING FORESTRY UNIV

Room-temperature vulcanized one-component dealcoholized silicone rubber sealant and preparation method thereof

ActiveCN103642451AImprove bonding performanceGood yellowing resistanceNon-macromolecular adhesive additivesOther chemical processesPtru catalystSilicone oil

The invention discloses a room-temperature vulcanized one-component dealcoholized silicone rubber sealant and a preparation method thereof. The sealant comprises the following components in parts by weight: 100 parts of (A) alpha, omega-dihydroxyl polydimethylsiloxane, 10-30 parts of (B) simethicone, 5-10 parts of (C) a cross-linking agent, 1-5 parts of (D) a silane coupling agent, 50-150 parts of (E) reinforcing filler, 0.5-3 parts of (F) a catalyst and 0.5-2 parts of (G) storage stabilizer. Due to addition of the silane coupling agent containing various active functional groups, the defect that common dealcoholized silicone rubber sealant cannot have good adhesion performance and good storage performance at the same time is overcome, and storage performance is not affected when the adhering performance is improved. In addition, as the sealant uses the titanate catalyst with low yellowing property, the sealant has excellent yellowing resistance, the defect that common dealcoholized silicone rubber sealant is easy to yellow is overcome, and the sealant provided by the invention can be widely applied to adhering and sealing in the industries such as electronics, automobiles and home appliances.

Owner:SUZHOU TIANSHAN NEW MATERIAL TECH

New method for treating surface of dental zirconia-based ceramic and improving bonding performance of ceramic

InactiveCN103431918AImprove bonding performanceGood surface roughness and spatial structureDental prostheticsBonding strengthZirconia ceramic

The invention discloses a new method for treating the surface of dental zirconia-based ceramic and improving the bonding performance of the ceramic. The new method comprises the following steps: without sand-blasting treatment, immersing the dental zirconia-based ceramic into an acid-mixed solution serving as etching agent for 20-30 minutes at the temperature of 100 DEG C, and etching to realize surface roughening. The new method has the advantages that the surface roughness of the dental zirconia-based ceramic is effectively improved, the bonding strength of the dental zirconia-based ceramic with resin and veneering ceramic is improved, the microcrack is not generated in the ceramic, and the influence on long-term mechanical strength is avoided; according to the surface roughening method, high temperature or stress is not involved, so that a low-temperature attenuation effect of the dental zirconia-based ceramic is reduced, the long-term mechanical performance of a dental all-ceramic restoration body is not influenced, and the clinical service life is guaranteed. Therefore, the obtained roughened surface of the dental zirconia ceramic has clinical application value.

Owner:SOUTHEAST UNIV +1

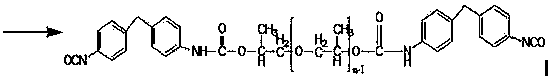

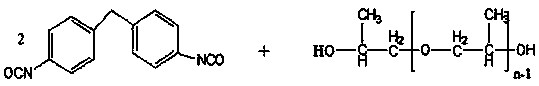

A preparation method of a polyurethane/epoxy resin composite material

ActiveCN103524703AImprove rigidity and comprehensive mechanical propertiesImprove bonding performancePolyureas/polyurethane adhesivesIsocyanateChemistry

A preparation method of a polyurethane / epoxy resin composite material comprises a step of adding a polyether polyol into a reactor to be treated, adding a diisocyanate and heating, controlling the mass content of free -NCO, and obtaining an A component after vacuum deaeration; a step of heating a binary aromatic amine, adding dropwise the liquid epoxy resin and heating again, and reacting to obtain a B component; and a step of stirring and mixing uniformly the A component and the B component stoichiometrically, and reacting and curing to obtain the polyurethane / epoxy resin composite material. When being used as an adhesive, the composite material has good bonding strength, high-temperature resistance, low-temperature resistance, impact resistance and flexibility. The composite material has a wide application scope, and can be prepared into a high-hardness polyurethane elastomer composite material to be applied.

Owner:太原英可奥笔墨科技有限公司

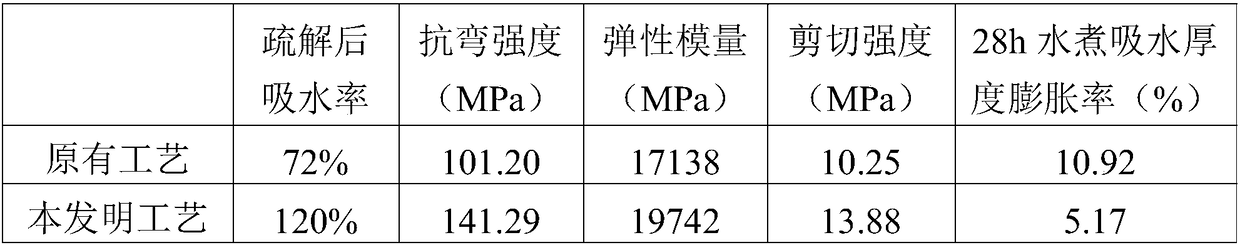

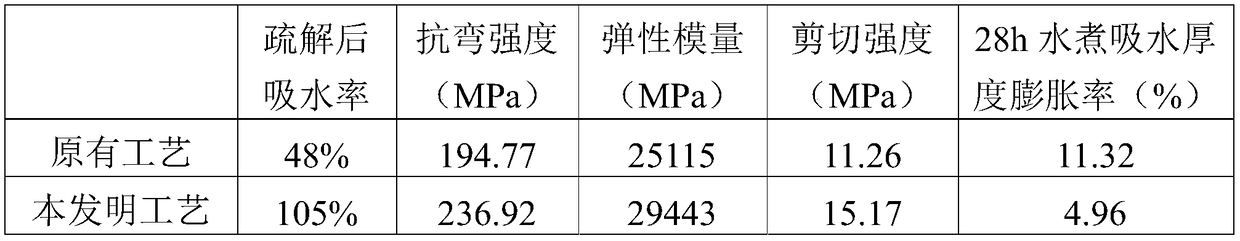

Method for using thin-wall bamboo materials to prepare bamboo scrimbers

PendingCN108127753AEnhance the ability to defuseEffective chemical attackWood compressionReed/straw treatmentWaxLiquid waste

The invention discloses a method for using thin-wall bamboo materials to prepare bamboo scrimbers. The method includes the steps that alkali is adopted for stewing thin-wall bamboo sheets, and then defibering, gum dipping, laying and hot pressing are carried out in sequence; NaOH is used for stewing the bamboo sheets, and the bamboo sheets are processed by lipase and then subjected to defibering,wherein by means of the procedures above, the defibering effect of bamboo bundles is obviously improved by 35% or above, bamboo green and tabasheer on the surfaces of the bamboo materials are effectively subjected to chemical erosion, the purpose of breaking wax layers and silicon layers is achieved, and the effect of improving gluing is achieved. A waste liquid generated after stewing is used fordiluting a glum liquid, and the problem of discharging the waste liquid is solved; by adopting a vacuum pressurizing dipping mode, even permeation of an adhesive in the bamboo materials is achieved,consumption of the adhesive is reduced, the production cost is reduced, efficient utilization of the thin-wall bamboo materials is achieved, and the environment is protected. The physical and chemicalstrength of the scrimbers are obviously improved, the horizontal shearing strength is improved by 25% or above, the thickness swelling rate of water absorption is reduced by 100% or above, the bending strength is improved by 20% or above, and the elasticity modulus is increased by 15% or above.

Owner:GUANGDONG ACAD OF FORESTRY

Self-adhesive flame retardant butyl rubber damping material and preparation method thereof

The invention discloses a self-adhesive flame retardant butyl rubber damping material and a preparation method thereof. The rubber material is prepared from the following components in parts by weight: 100 parts of butyl rubber, 50 to 400 parts of damping and adhesion aids, 50 to 400 parts of tackifying resin, 100 to 800 parts of compound flame retardant and 0 to 1000 parts of filler. The self-adhesive and flame retardant butyl rubber damping material obtained by the invention has the characteristics of wide-temperature-range damping, high damping peak, and excellent self-adhesive property and flame retardant property. According to the self-adhesive flame retardant butyl rubber damping material and the preparation method thereof, the self-adhesive flame retardant butyl rubber damping material is prepared by using a simple blending method through the proper formula adjustment; the method has the advantages of simple and convenient method, low cost, simple industrialization, high production efficiency and good industrial application prospect.

Owner:SICHUAN UNIV

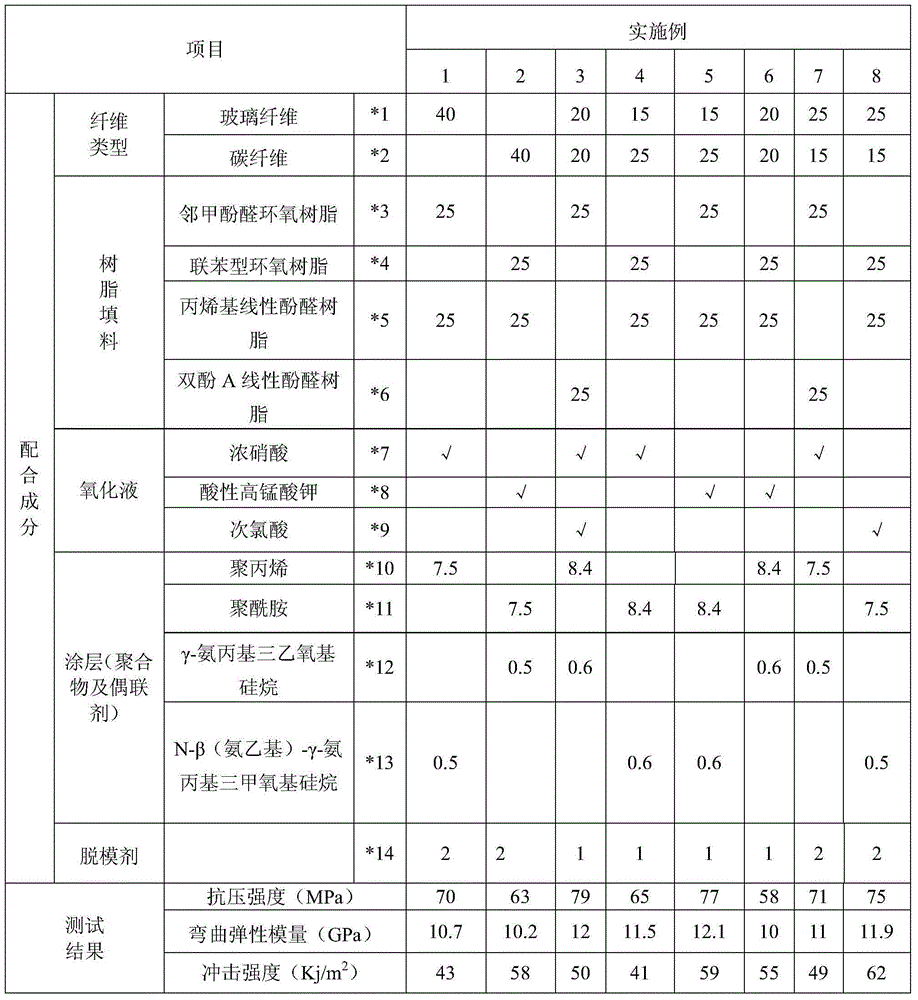

Fiber reinforced resin composite material, preparation method and applications thereof

ActiveCN105315475AImprove the interface binding forceImprove bonding performanceElectric vehicleResin composite

The invention discloses a preparation method of a fiber reinforced resin composite material. The preparation method comprises the following steps: subjecting the fibers, which have been subjected to a surface oxidization treatment, to a coating treatment; subjecting the fibers, which have been subjected to the coating treatment, to three-dimensional knitting according to a required shape; placing the knitted three-dimensional textile into a mould, pouring thermosetting resin into the mould, and carrying out low-temperature injection moulding. According to the preparation method, a three-dimensional textile is taken as the skeleton, and thermosetting resin is taken as the filling material. The preparation method is characterized in that the processing temperature is low (not higher than 160 DEG C), the obtained three-dimensional composite material has a high mechanical strength in the vertical direction and in the horizontal direction; and moreover, due to the existence of the three-dimensional textile framework, the impact-resistant and anti-knock performances of the composite material are greatly improved. A fiber reinforced resin composite material prepared by the provided preparation method is also disclosed. The composite material can be used to produce the battery tank of electric vehicle.

Owner:江苏南创化学与生命健康研究院有限公司

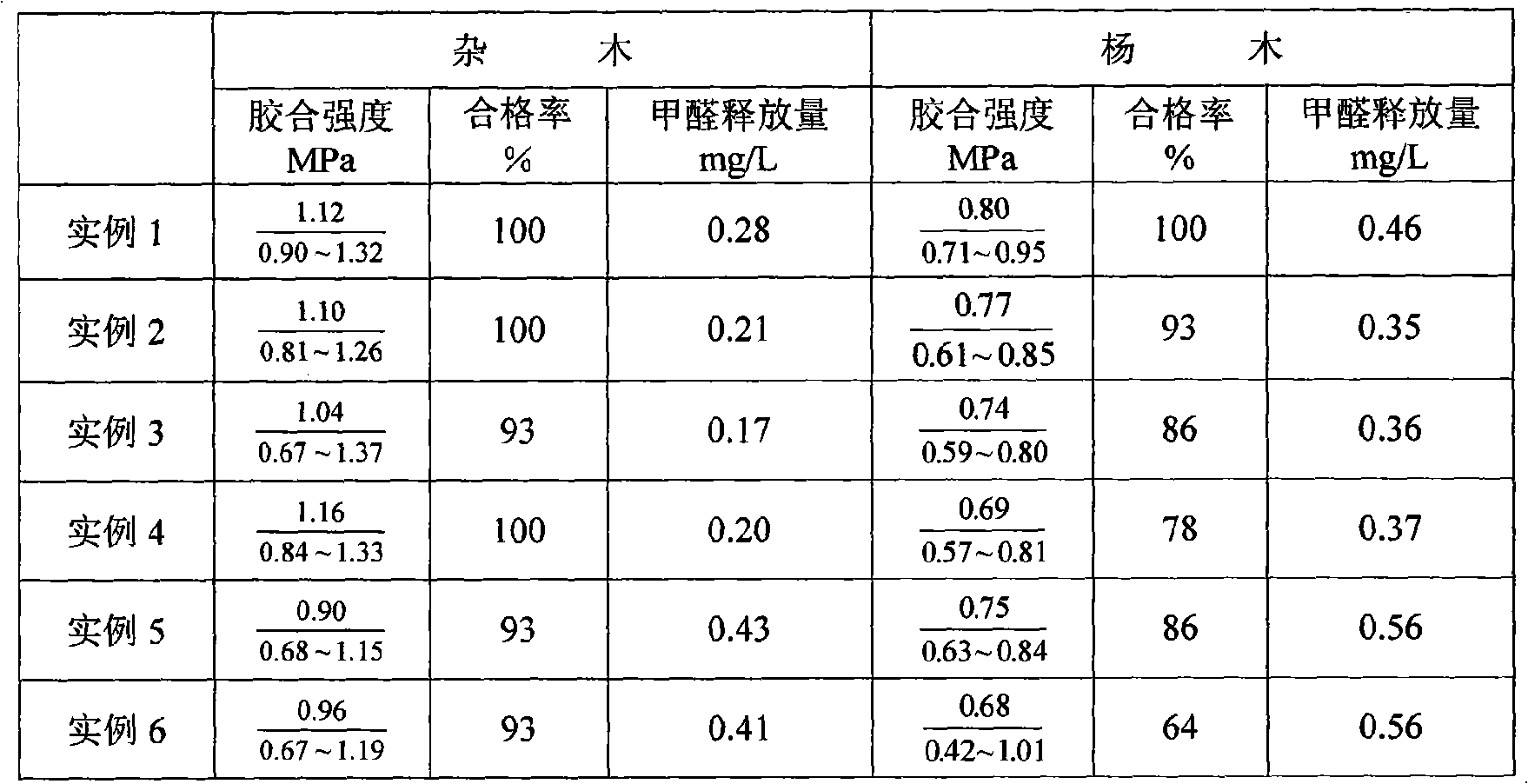

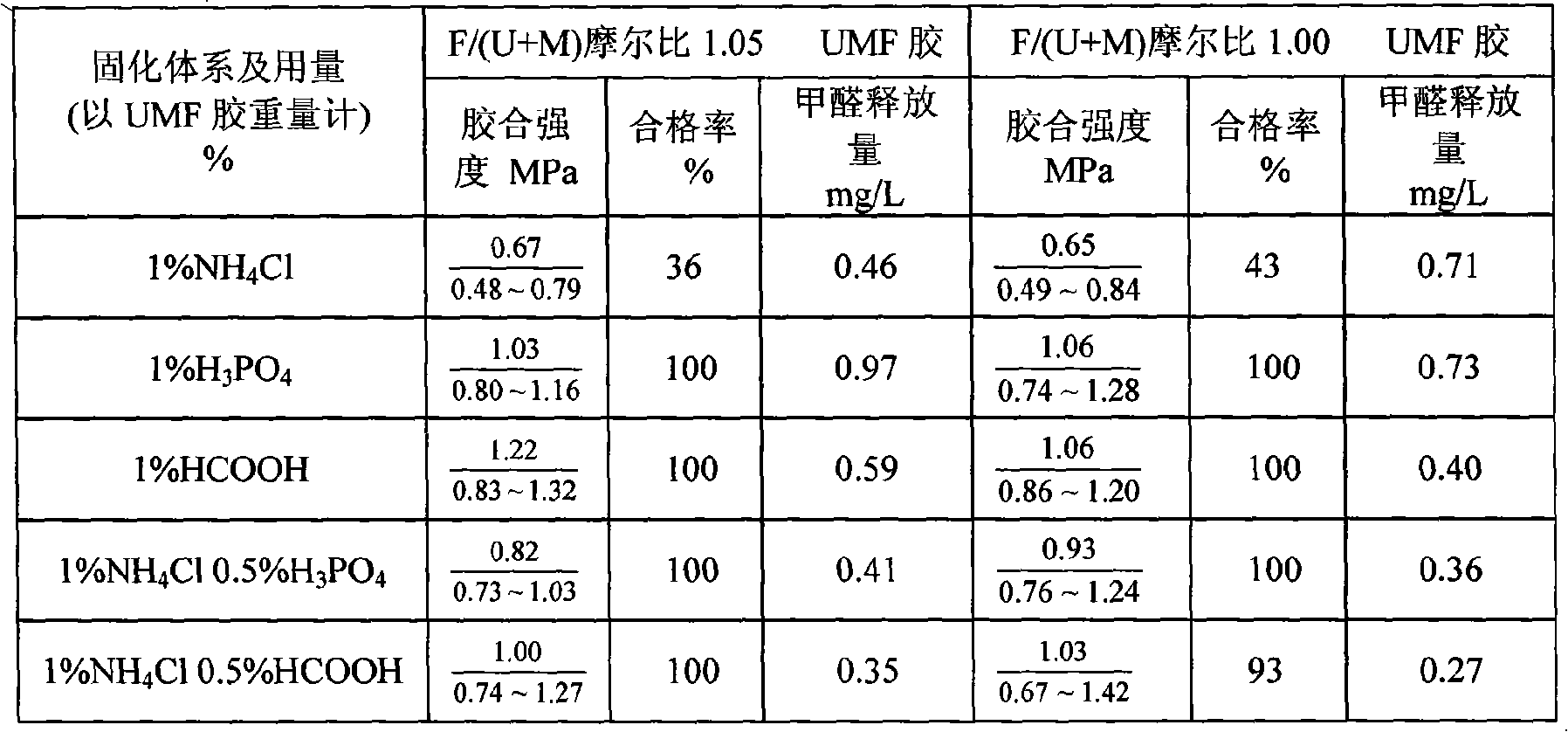

Preparation method of low-cost UMF resin adhesive used for E0-level plywood

InactiveCN101550323AReduce releaseIncrease the degree of cross-linkingAldehyde/ketone condensation polymer adhesivesEtherStrong acids

The invention discloses a preparation method of low-cost UMF resin adhesive used for an E0-level plywood. The preparation method of the adhesive is simple and has good reproducibility, lower cost and long storage period. For serayah plywood and poplar plywood pressed by the adhesive, the bonding strength and the formaldehyde emission thereof conform to the requirements of the E0-level plywood. The preparation method adopts the technique of a strong acid method, urea is selected for adding by four batches; melamine is added by three batches; the urea is added by batches, which can play the role of regulating the molecular weight of resin, especially the third adding of the urea not only can degrade macromolecule parts in rearranged molecules, but also can reduce the content of ether linkage therein, thus reducing the formaldehyde emission.

Owner:NANJING TECH UNIV

Modified phenolic resin for bamboo structure material and preparation method thereof

ActiveCN101864053AMeet strength requirementsImprove bonding performanceAldehyde/ketone condensation polymer adhesivesAqueous solutionAdhesive

The invention discloses modified phenolic resin for a bamboo structure material, which comprises 35 to 85 percent of phenolic aldehyde stock solution, 0 to 40 percent of aqueous solution of formaldehyde, 7 to 20 percent of alkali aqueous solution and 0.5 to 5 percent of resorcinol. The phenolic aldehyde stock solution is mixed solution prepared from 2 to 85 weight percent of phenol and 15 to 98 weight percent of formaldehyde. A preparation method for the modified phenolic resin comprises the following steps of: adding the phenolic aldehyde stock solution into a reaction kettle, adding the aqueous solution of formaldehyde into the reactor for the first time, adding partial alkali aqueous solution into the reactor, heating the solution to between 30 and 70 DEG C, and reacting the solution for 30 to 90 minutes; adding the aqueous solution of formaldehyde into the reactor for the second time within an additional proportion range, uniformly heating the solution to between 70 and 98 DEG C, and reacting the solution for 20 to 90 minutes with heat preservation; adding the alkali aqueous solution into the reactor within an additional proportion range, and reacting the solution; adding a resorcinol modifying agent into the reactor till the viscosity of the tested glue solution is 15 to 700mPa.s; and cooling the reaction product to below 40 DEG C, and discharging the product. The gluing performance of the resin on the bamboo material is remarkably improved by adding the resorcinol modifying agent to modify the phenolic resin, and the adhesive has low free formaldehyde content and has the characteristics of energy conservation and environmental protection.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

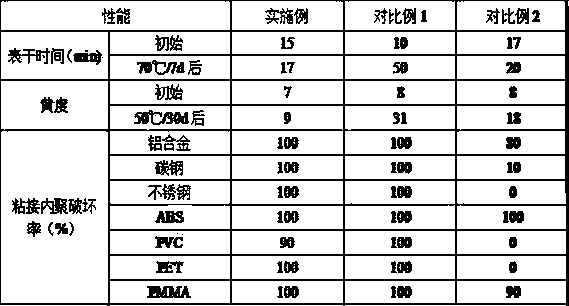

One-component deoximation type room-temperature vulcanized silicone rubber sealant and preparation method thereof

InactiveCN104610907AImprove bonding performanceGood water resistanceNon-macromolecular adhesive additivesMethyl siliconeAluminium alloy

The invention discloses a one-component deoximation type room-temperature vulcanized silicone rubber sealant and a preparation method thereof. The sealant is prepared through the following steps: mixing alpha,omega-dyhydroxylpolydimethylsiloxane and a silane coupling agent at a high temperature, terminating alpha,omega-dyhydroxylpolydimethylsiloxane with the silane coupling agent, and then adding dimethyl silicone oil, a de-ketoxime type cross-linking agent, a filling material and a catalyst. Compared with a traditional deoximation type sealant, the sealant has excellent adhesive properties for stainless steel, aluminium alloy, magnesium alloy, PPO, PC, PVC, PMMA, ABS, PET and the like, and can be used for adhesion and sealing in the industries of electronics, automobiles, household appliances, photovoltaic modules and the like. Besides, the sealant has excellent water resistance and especially has a high strength retention rate under high-temperature and high-humidity conditions.

Owner:TONSAN ADHESIVES INC

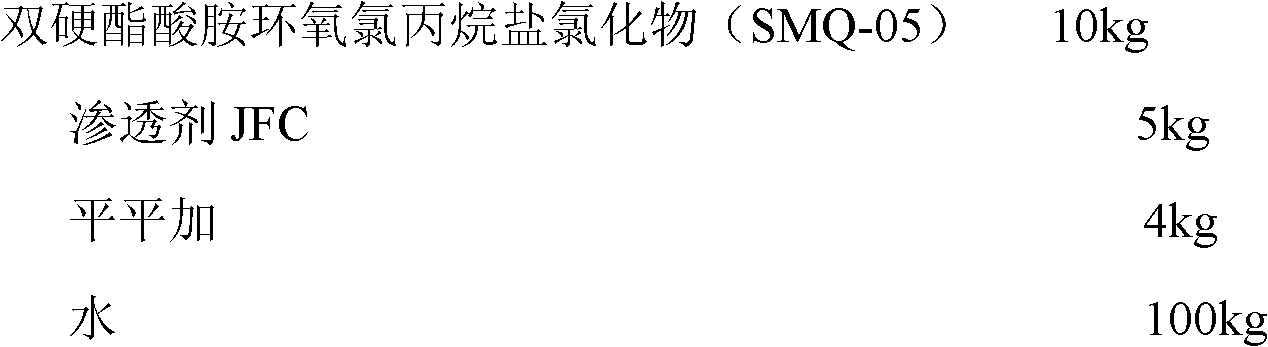

Method of utilizing compound enzyme improved straw particle and urea acetal resin glue performance

InactiveCN101204823AImprove bonding performanceFlat articlesDomestic articlesWood shavingsBuffer solution

The invention relates to a method for using compound enzyme to improve gluing property between straw shavings and urea-formaldehyde resin, of which technique steps are as follows: (1) straws are processed into shaving units of straw units with a length of 20-25mm though a straw cutter before being put into an enzyme processing reactor; (2) 20kg citric acid-sodium dihydrogen phosphate buffer solution with pH5.0 is added into 1kg straws, in which enzyme solution of the compound enzyme is then added, (3) processing time in the enzyme processing reactor is 4 to 8 hours and processing temperature is 40 to 50 DEG C; (4) the straw shavings after being processed is dried and the temperature of 80-100 DEG C causes the moisture content of the straw shavings to reach 3-5 percent; (5) 12-14 percent (percentage between absolute resin and absolute dry straw shavings) of urea-formaldehyde resin adhesive is added into the straw shavings obtained in the step (4); (6) the straw shavings are formed, precompressed, thermocompressed through a mechanical forming machine and conducted post treatment processing steps. The invention has the advantages that the compound enzyme improves the gluing property between the straw shavings and the urea-formaldehyde resin, thus producing qualified products.

Owner:NANJING FORESTRY UNIV

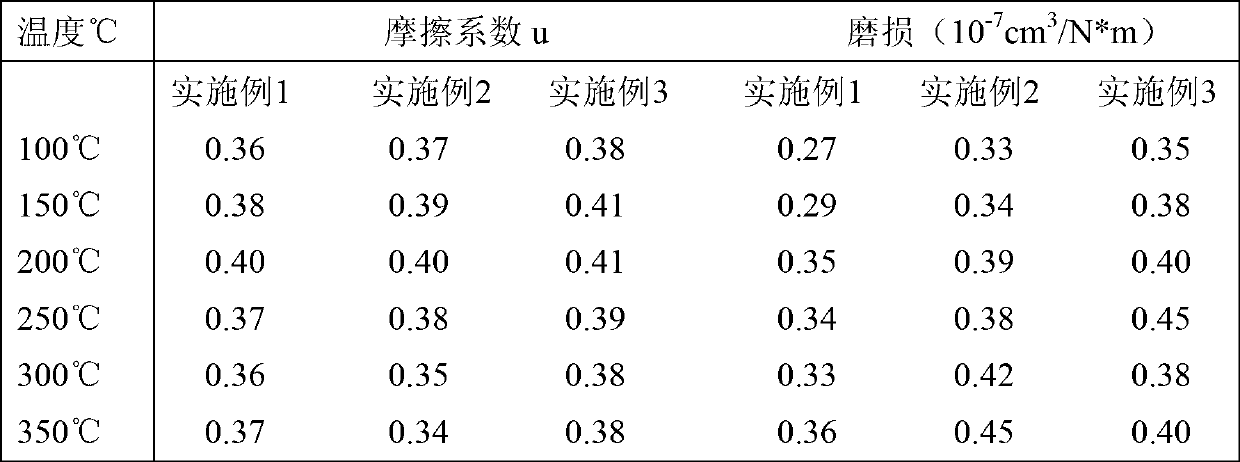

Method for preparing clutch facing through taking water soluble phenol-formaldehyde resin as adhesion agent

The invention discloses a method for preparing a clutch facing through taking water soluble phenol-formaldehyde resin as an adhesion agent. The method adopts the water soluble phenol-formaldehyde resin which is multiply modified by polyvinyl alcohol, nanoscale attapulgite and micron-order copper powder as the adhesion agent, the water soluble phenol-formaldehyde resin, a friction performance conditioning agent and water are mixed to produce slurry, fibers are soaked in the slurry, are dried and are wound to form a parison, the parison is then subjected to hot-press forming to form the facing, grinding and drilling are carried out after the thermal treatment, the clutch facing is obtained. The modified adhesion agent has high solubility, cohesiveness, toughness, heat resistance, thermal fading resistance and abrasion resistance; and the clutch facing which is produced through the adhesion agent is low in cost, green and environment-friendly, can bear impact force during the processing and using processes, cannot crack and has high thermal stability, high and stable friction coefficient and low abrasion resistance.

Owner:浙江科马摩擦材料股份有限公司

Artificial tooth base resin-nano zirconium oxide composite material and preparation thereof

InactiveCN101214196AImprove wear resistanceImprove the finishImpression capsDentistry preparationsPink colorFlexural strength

The present invention provides false tooth base resin applied to the oral cavity repair, which is nanometer zirconia composite material. Firstly, silane coupling agent Z-6030 is used to decorate the surface of the nanometer zirconia. The raw material components are 0.5 percent to 5.0 percent of silane coupling agent Z-6030 and 95 percent to 99.5 percent of the nanometer zirconia. The nanometer zirconia decorated by the coupling agent is obtained. Then the nanometer zirconia decorated by the coupling agent is synthesized with polymethyl methacrylate. The material components are 1 percent to 5 percent of the nanometer zirconia decorated by the coupling agent and 95 percent to 99 percent of the polymethyl methacrylate. The nanometer zirconia composite material is obtained, the flexural strength of which can be 95.61MPa. The nanometer zirconia composite material manufactured by the present invention has high flexural strength, easy polishing, good finish degree, pink color, easy adjustment and good biological compatibility and is the novel resin with good biological and mechanical performance, which can be widely applied to the dentistry.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +1

Respirable high-flame-retardance outer-wall facing material

The invention discloses a respirable high-flame-retardance outer-wall facing material, which comprises redispersible latex powder, an organic-silicon water repellent, methylcellulose ether, a defoaming agent, an air-entraining agent, lignocellulose, a thixotropic lubricant, silicate cement, heavy calcium powder, fly ash, calcium hydroxide, starch ether, calcium formate and colored quartz sand. The respirable high-flame-retardance outer-wall facing material has the advantages of reasonable proportion, energy saving and environmental protection, and not only are the quality and the service lifeof an outer-wall heat-preserving system ensured, and heat-preserving heat-absorbing heat-storing performances are enhanced, but also the service life of a building wall body is greatly prolonged.

Owner:SHANDONG FENGYU ENERGY SAVING MATERIAL MFG

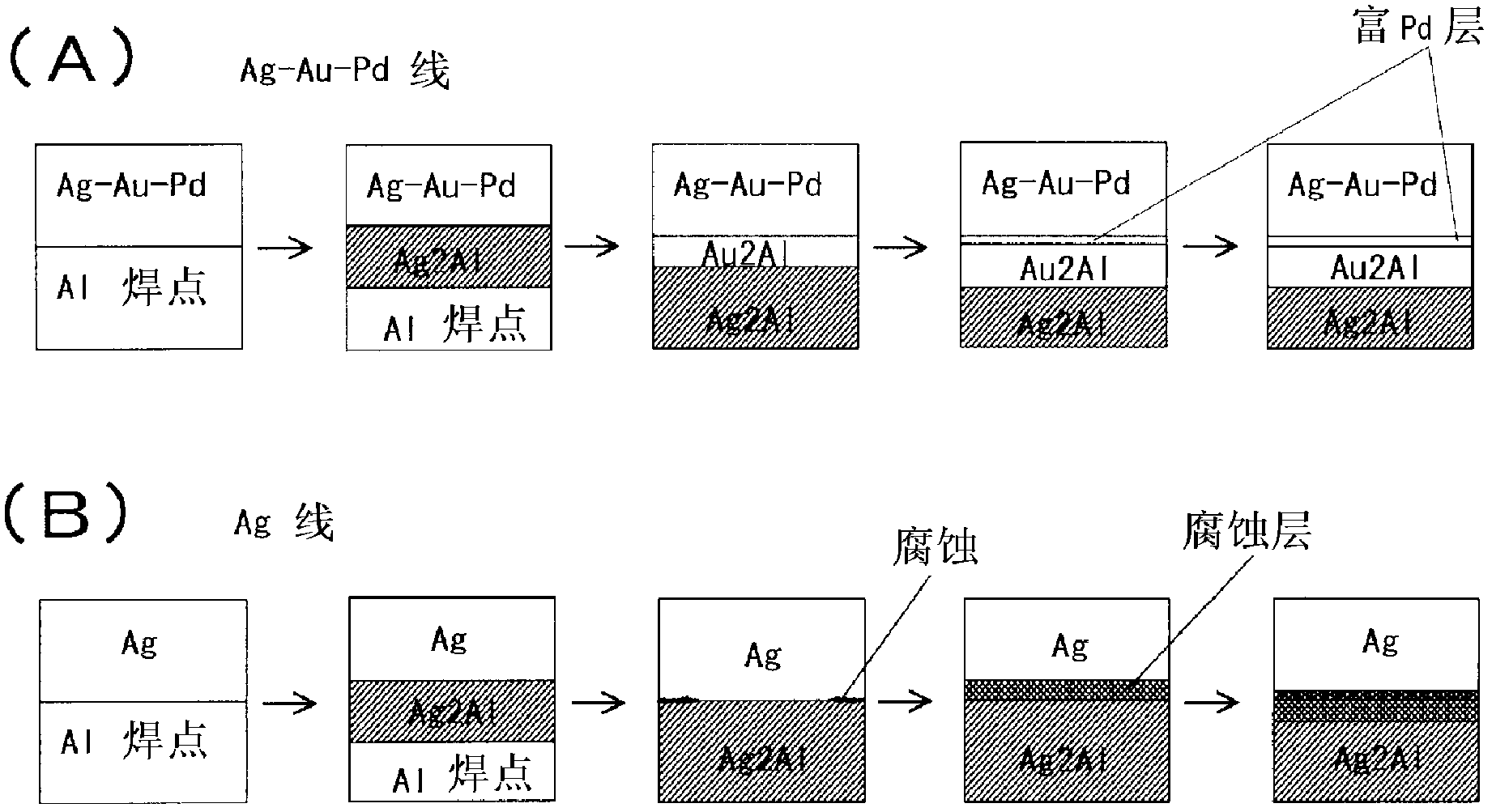

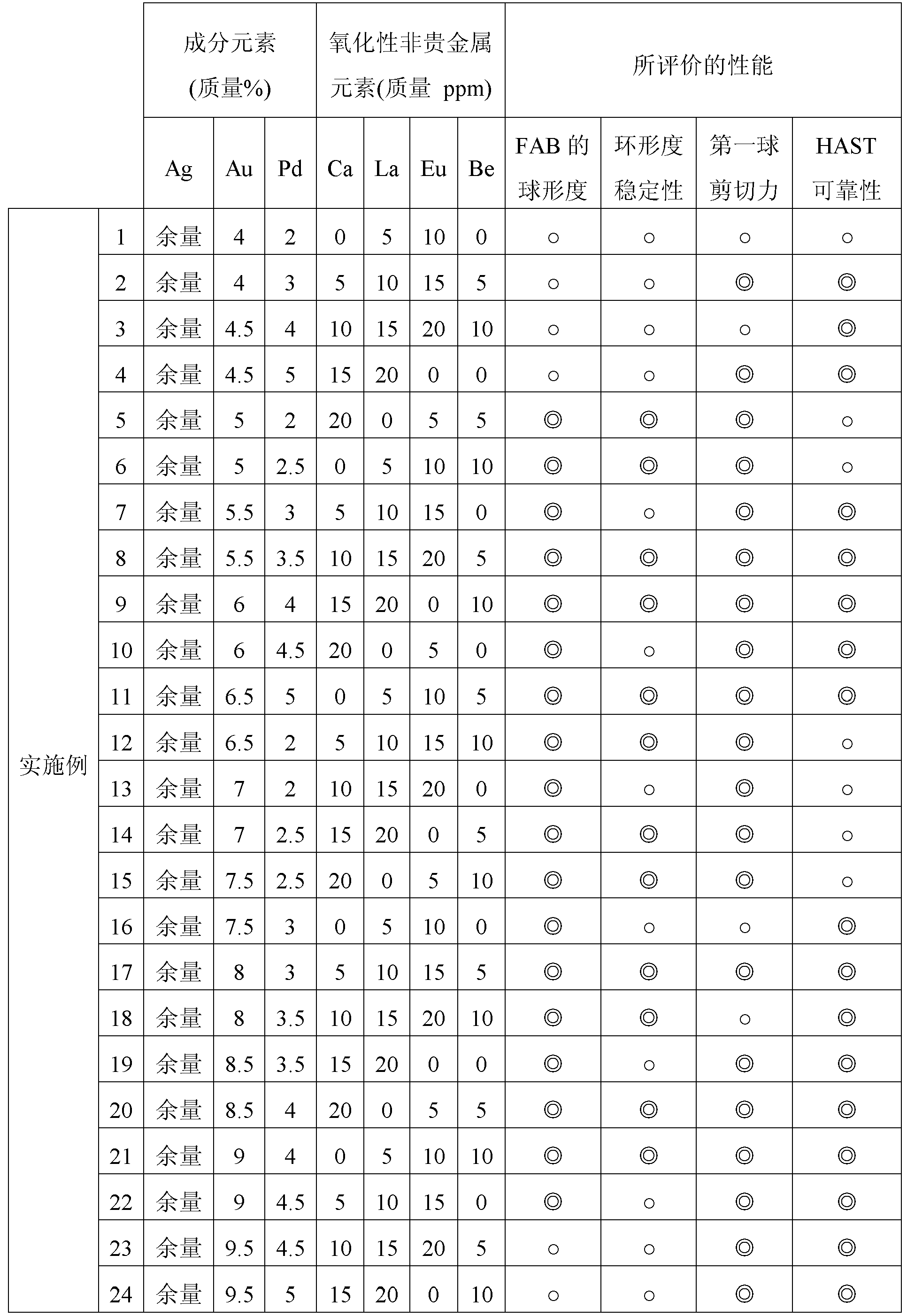

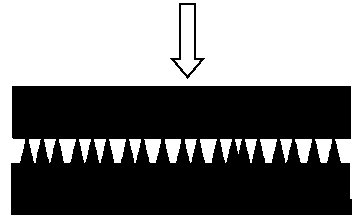

Ag-au-pd ternary alloy-based bonding wire

ActiveCN103155130AImprove bonding performanceImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingHigh humidityNitrogen atmosphere

The purpose of the invention is to improve the reliability at which a bonding wire for semiconductors that is used in high-temperature and high-humidity environments is bonded to an aluminum pad. The solution is that a ternary-alloy-based wire comprising 4-10 mass% of gold having a purity equal to or greater than 99.999 mass%, and 2-5 mass% of palladium having a purity equal to or greater than 99.99 mass%, the remainder being constituted by silver having a purity equal to or greater than 99.999 mass%. The bonding wire for semiconductors contains 15-70 wt ppm of an oxidizing non-noble metal j element, and is subjected to an annealing heat treatment before being continuously drawn using a die, to a refining heat treatment after being continuously drawn using a die, and to ball-bonding in a nitrogen atmosphere. Corrosion between an Ag2Al intermetallic compound layer and the Ag-Au-Pd ternary alloy wire at the bonding interface between an aluminum pad and the wire is inhibited by Au2Al and a Pd-rich layer.

Owner:TANAKA DENSHI KOGYO KK

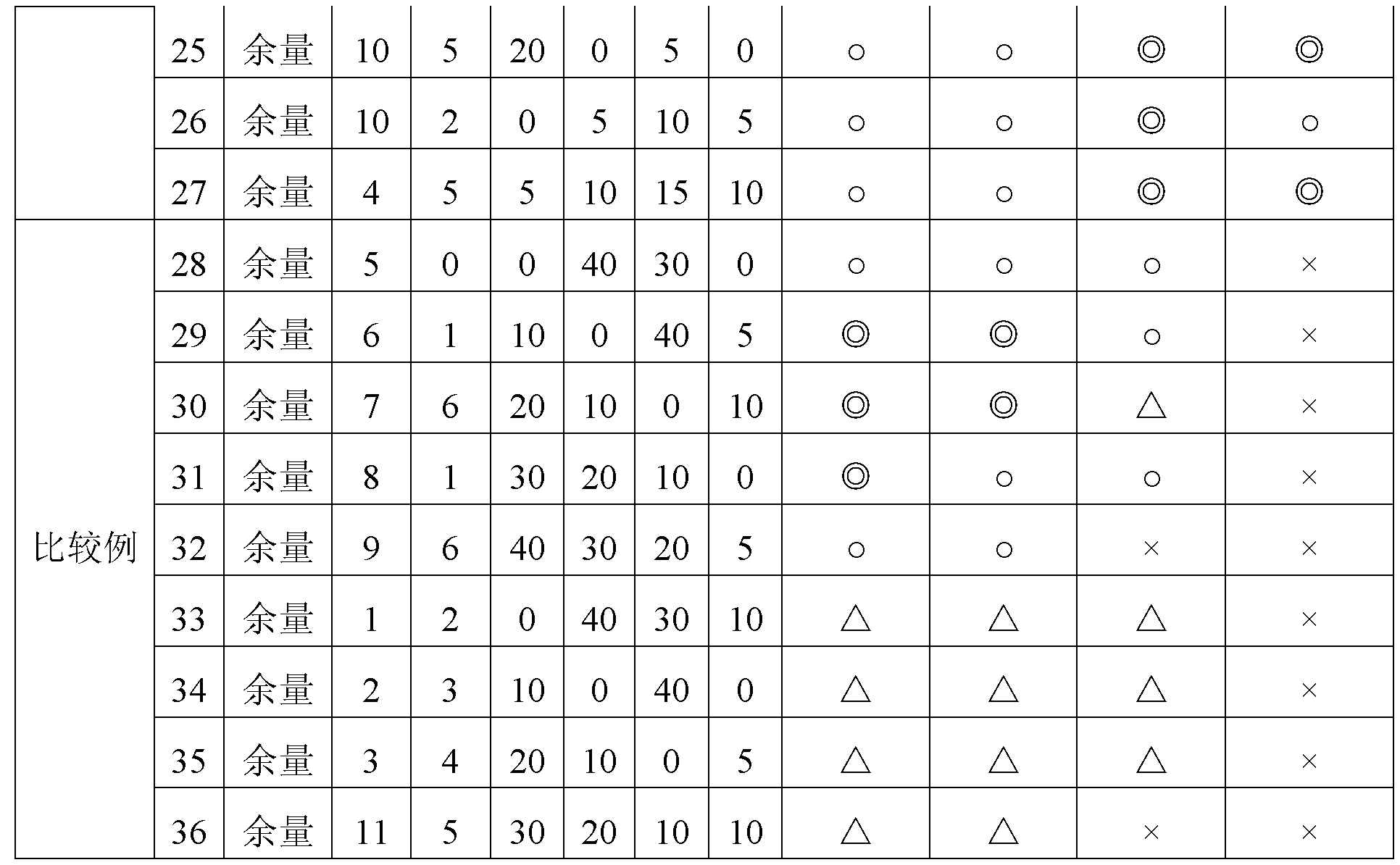

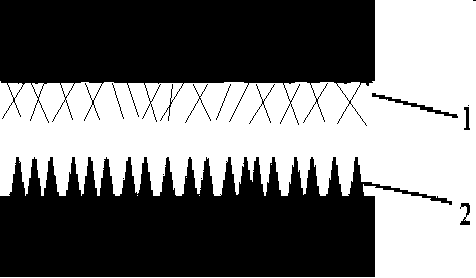

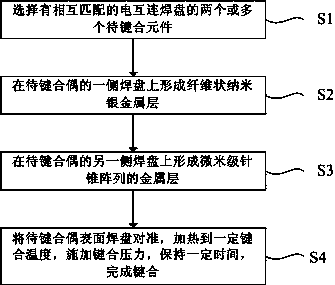

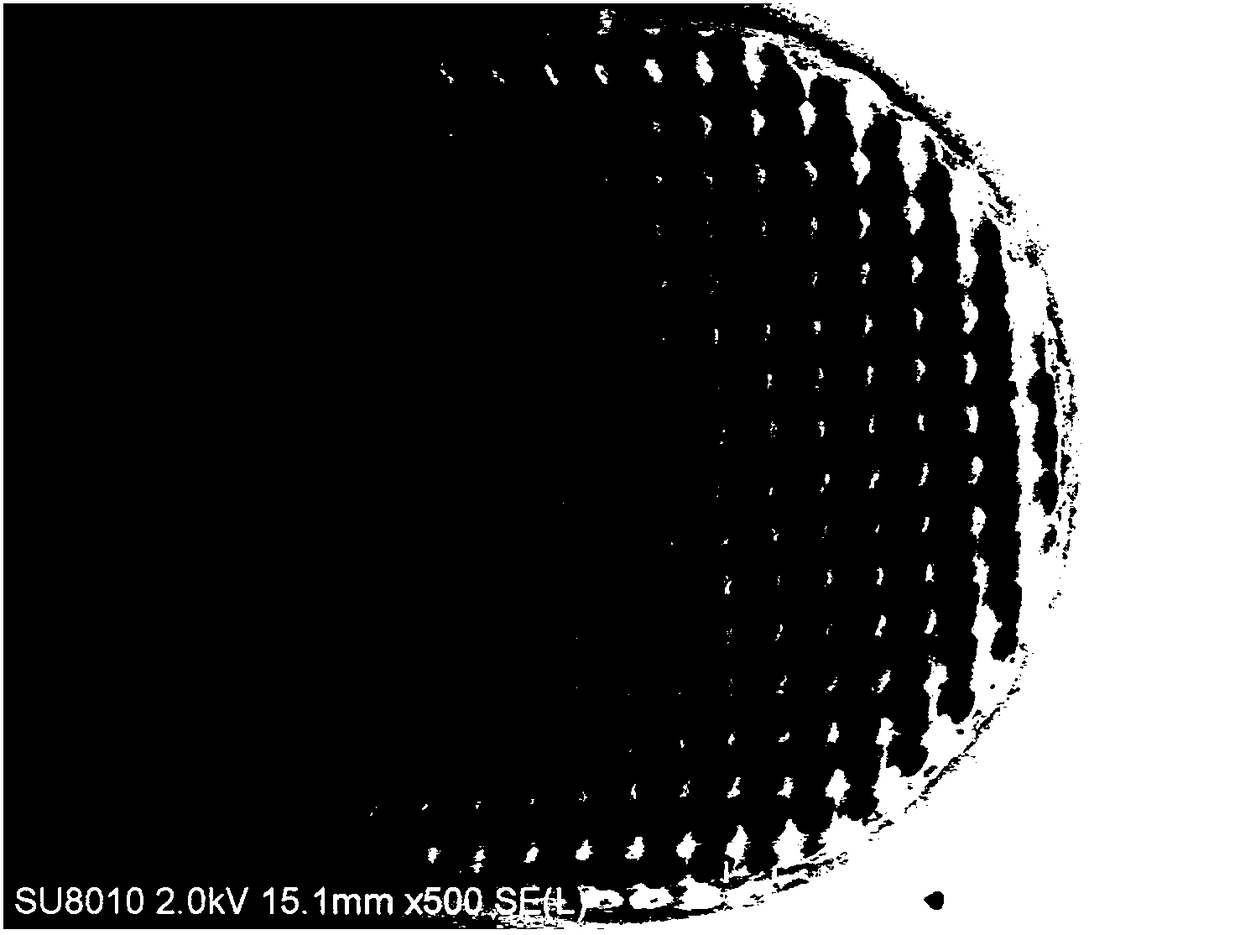

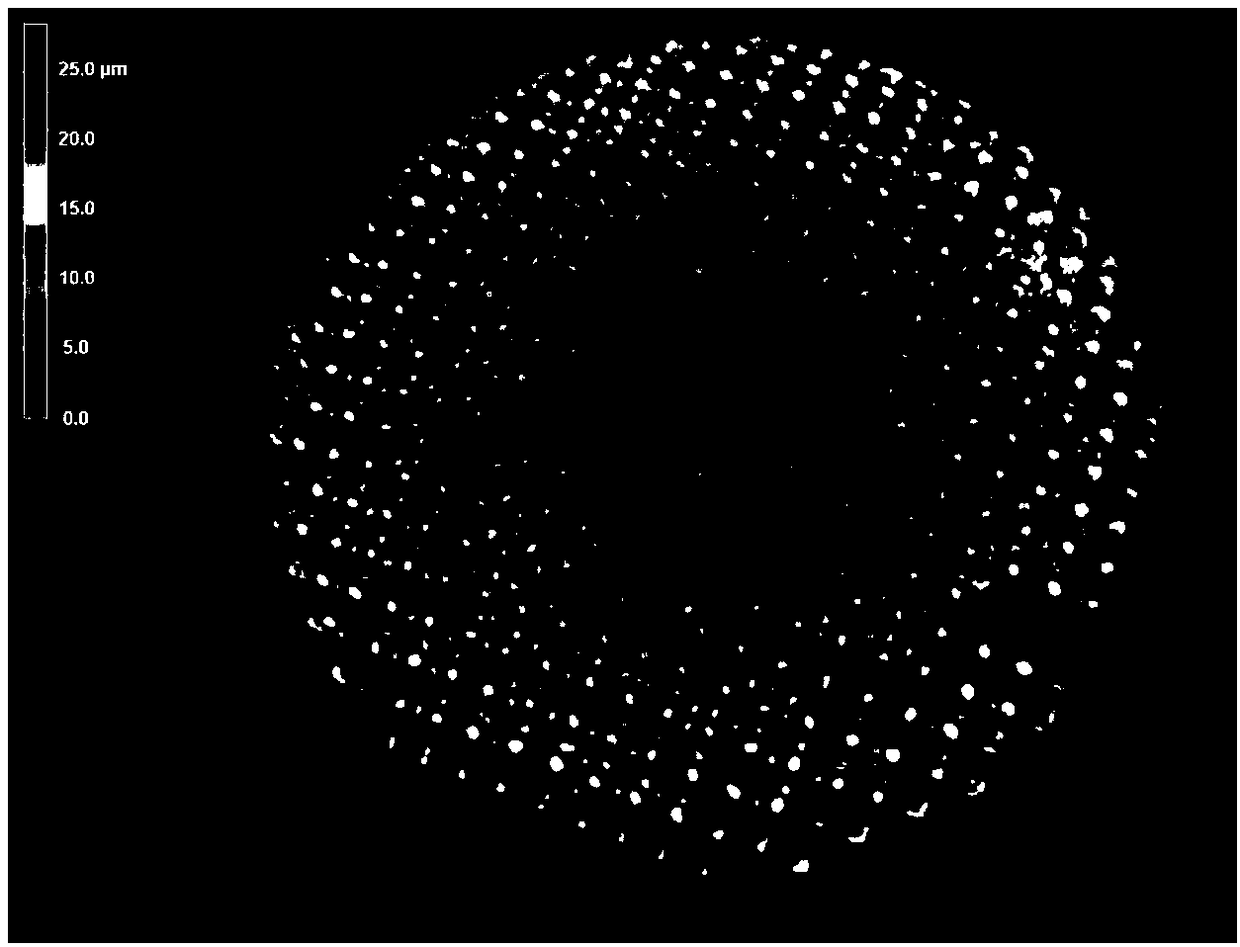

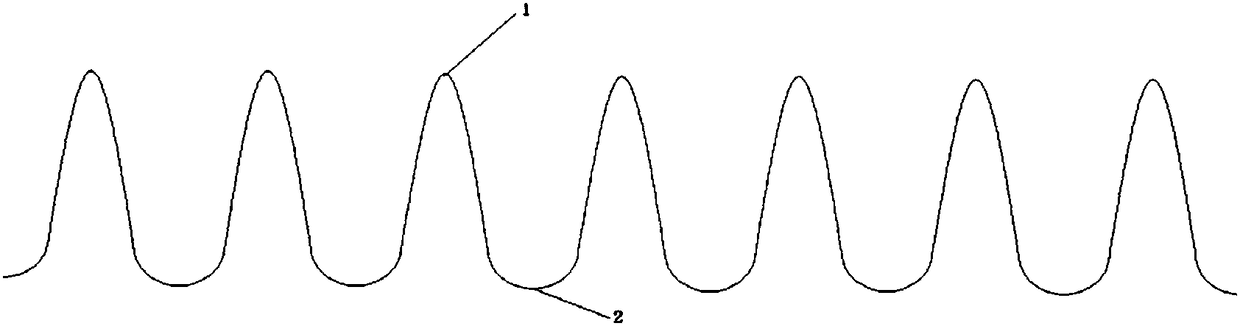

Low temperature solid state bonding method through surface micro-nano structure

InactiveCN104201123AImprove plastic deformation abilityImprove bindingSolid-state devicesSemiconductor/solid-state device manufacturingFiberElectricity

The invention discloses a low temperature solid state bonding method through a surface micro-nano structure. The low temperature solid state bonding method through the surface micro-nano structure comprises choosing two or more elements to be bonded with matching electrical interconnecting pads, wherein every two elements forms a to-be-boned couple; forming fiber-shaped nano silver metal layers on pads on one side of the to-be-boned couples; forming a metal layer of a micron size cone array structure on the pads of the other sides of the to-be-boned couples; aligning pads on the surfaces of the to-be-boned couples, and heating contact areas to a certain temperature lower than a metal melting point and meanwhile applying pressure to one or two sides of the to-be-boned couples and maintaining the state for a certain period to enable the fiber-shaped nano silver metal layers to be in solid state bonding with the metal layers of the micron size cone array structure. According to the low temperature solid state bonding method through the surface micro-nano structure, the conductivity and the electrical conductivity are higher, temperature of thermocompression bonding can be greatly reduced and bonding strength is improved.

Owner:SHANGHAI JIAO TONG UNIV

Chopper for improving bonding strength of lead

ActiveCN108389806AIncreased wearable areaExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingWear resistantBonding strength

The invention discloses a chopper for improving bonding strength of a lead. The chopper is a welding ceramic chopper and comprises a body, a welding nozzle and a hole, wherein the welding nozzle is arranged at one end of the body, the hole extends along a longitudinal axis of the body and the welding nozzle, and a tip surface of the welding nozzle comprises convex parts and concave parts which arealternatively distributed. By the design of a chopper surface structure, the wear-resistant region of the surface can be expanded, the hardness of the tip surface is improved, the roughness of the surface is improved, and the service lifetime is prolonged; compared with a traditional polishing and thermal processing chopper, the chopper has the advantages of better bonding effect and higher stability; on one hand, the gold reservation degree of a tip is effectively reduced by the design; and on the other hand, the wear-resistant degree of a porcelain nozzle is improved, and thus, the servicelifetime of the porcelain nozzle is prolonged.

Owner:CHAOZHOU THREE CIRCLE GRP

Tough aldehyde-free soybean meal-based wood adhesive and preparation method thereof

ActiveCN110272716AIncrease crosslink densityImprove water resistance bonding performanceProtein waste adhesivesMacromolecular adhesive additivesDispersed mediaAdhesive

The invention discloses a tough aldehyde-free soybean meal-based wood adhesive and a preparation method thereof. The adhesive comprises, by weight, 30-33 parts of a main agent, 70 parts of dispersed medium water, 3-6 parts of a reinforcing agent, 0.1-0.2 part of a viscosity regulator, 2-4 parts of a crosslinking agent and 0.3-0.6 part of a catalyst. The preparation method comprises the following steps of weighing each component according to the corresponding weight ratio first, adding the crosslinking agent into the dispersed medium water, adding the main agent and the reinforcing agent, and homogenizing and emulsifying the mixture for 20 minutes under the action of an emulsifying force of 0.5 MPa at the pressure of 30 MPa through a high-pressure homogenizer; then, adding the catalyst into the obtained mixture, triggering a reaction at 80 DEG C for 30 minutes, cooling a finished product to 30 DEG C, and then discharging the finished product. The adhesive is likely to form a crosslinking structure, high in crosslinking density and low in reaction temperature; the prepared adhesive is stable in performance, the weak interface layer is obviously reduced, the cost is lowered, the dry / wet strength is high, and the product quality is stably improved.

Owner:山东千森木业集团有限公司

Solar cell back panel material and preparation method and product thereof

InactiveCN102690477AGood mechanical propertiesImprove bonding performanceFinal product manufacturePhotovoltaic energy generationPolyvinylidene fluorideWeather resistance

The invention discloses a type of solar cell back panel material and a preparation method and a product thereof. The solar cell back panel material contains modified PVDF (Polyvinylidene Fluoride)and modified PET (polyethylene terephthalate); the modified PVDF comprises 70-80 parts of PVDF, 5-20 parts of modifying polymer resin |, 0.5-5 parts of inorganic filling | and 0.1-0.2 part of modifier in parts by weight; and the modified PET comprises 70-80 parts of PET, 5-15 parts of modifying polymer resin II, 0.5-10 parts of inorganic filling II and 0.1-0.2 part of modifier in parts by weight. In the preparation method disclosed by the invention, modifying resins, organic fillings and modifiers are used to respectively modify the PET and the PVDF so that the structure formed by coextrusion of the PET and the PVDF can have better mechanical property; the bonding performance between layers is improved; and the material is weather-resistant and can resist moisture and oxygen. The service life of the solar cell back panel made of the material is guaranteed to be more than 25years.

Owner:贵州省复合改性聚合物材料工程技术研究中心

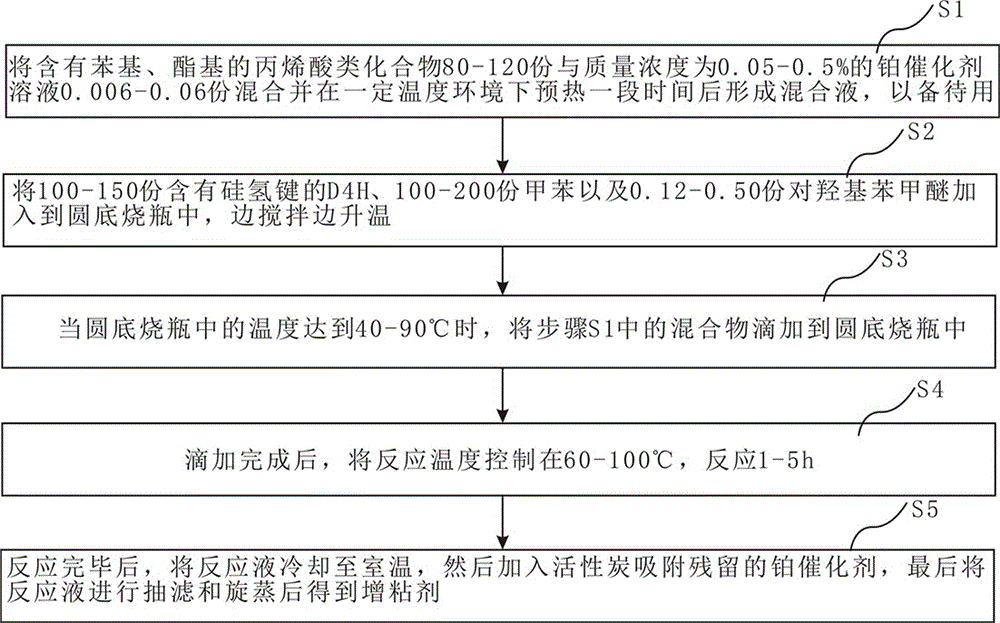

Addition type liquid silicone rubber tackifier, as well as preparation method and application thereof

InactiveCN106279700AImprove bonding performanceGood mold releaseNon-macromolecular adhesive additivesMacromolecular adhesive additivesActivated carbonHydroxybenzoate Ethers

The invention discloses an addition type liquid silicone rubber tackifier, as well as a preparation method and application thereof. The preparation method comprises the following steps of step 1, mixing 80-120 parts of an acrylic compound containing phenyl groups and ester groups with 0.006-0.06 part of a platinum catalyst solution of which the mass concentration is 0.05-0.5% to obtain a mixture, and preheating the mixture at certain temperature environment for some time so as to obtain mixed liquor for standby application; step 2, adding 100-150 parts of D4H containing silicon-hydrogen bonds, 100-200 parts of toluene and 0.12-0.50 part of p-hydroxyanisole to a round-bottomed flask, and raising temperature while stirring; step 3, when the temperature in the round-bottomed flask reaches to 40-90 DEG C, dropwise adding the mixture in the step 1 to the round-bottomed flask; step 4, after the mixture is dropwise added, controlling the reaction temperature to 60-100 DEG C, and performing a reaction for 1-5h; and step 5, after the reaction is completed, cooling reaction fluid to room temperature, then adding activated carbon for adsorbing residual platinum catalysts, and finally performing sucking filtration and rotary evaporation on the reaction fluid so as to obtain the tackifier. According to the addition type liquid silicone rubber tackifier, as well as the preparation method and application thereof disclosed by the invention, a small quantity of the tackifiers are added to shaping liquid silicone rubber, so that the bonding failure between the shaping liquid silicone rubber and PC plastic cement reaches to 100% cohesive failure.

Owner:岳胜武

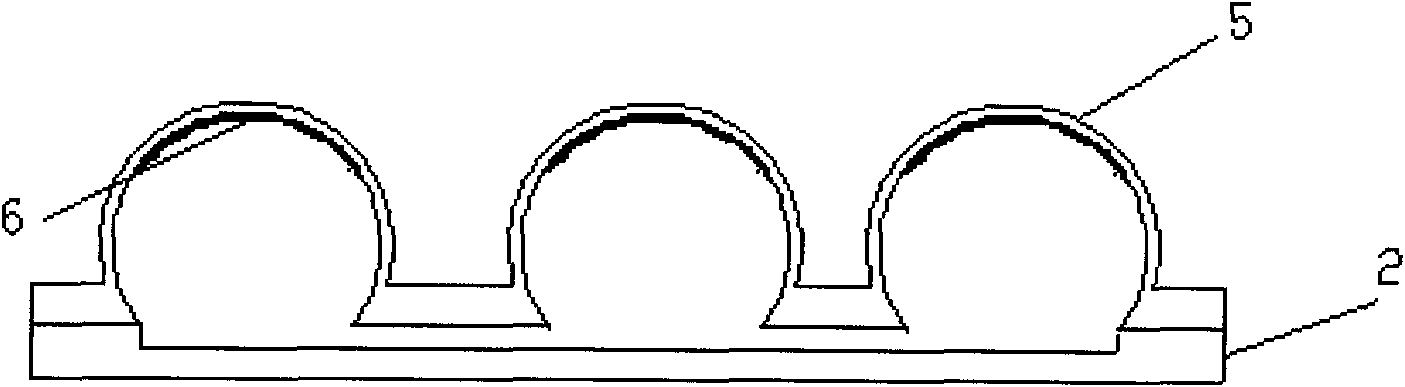

Method for packaging wafer level glass micro-cavity of light-emitting diode (LED)

ActiveCN102110750AReduce optical interfaceGood optical performanceSolid-state devicesSemiconductor devicesLed arrayLight beam

The invention discloses a method for packaging a wafer level glass micro-cavity of a light-emitting diode (LED), and the method comprises the following steps: (1) etching a micro-slot array corresponding to the pattern of a packaged LED array on a silicon wafer, wherein the micro-slots are communicated through a micro-channel, and a proper amount of heat gas releasing agent is arranged inside the micro-slots; (2) forming a closed cavity; (3) heating the bonded wafer in the air to form a spherical glass micro-cavity and a cylindrical glass micro-channel connected with the spherical glass micro-cavity, cooling to room temperature, annealing, and removing silicon to obtain a wafer level glass micro-cavity; (4) sputtering a metal layer on the silicon wafer, and preparing a metal lead through photolithography, so as to obtain a lead substrate, wherein the position of the metal lead corresponds to the position of the micro-channel of the glass micro-cavity; (5) mounting an LED chip on the lead substrate, and leading; (6) bonding the wafer level glass micro-cavity with the substrate to form a bonded wafer; and (7) filling the gap between the LED chip and the wafer level glass micro-cavity with silicone through the glass micro-channel. According to the invention, the light emitting efficiency is high, and a packaged glass lens realizes beam collimation.

Owner:SOUTHEAST UNIV

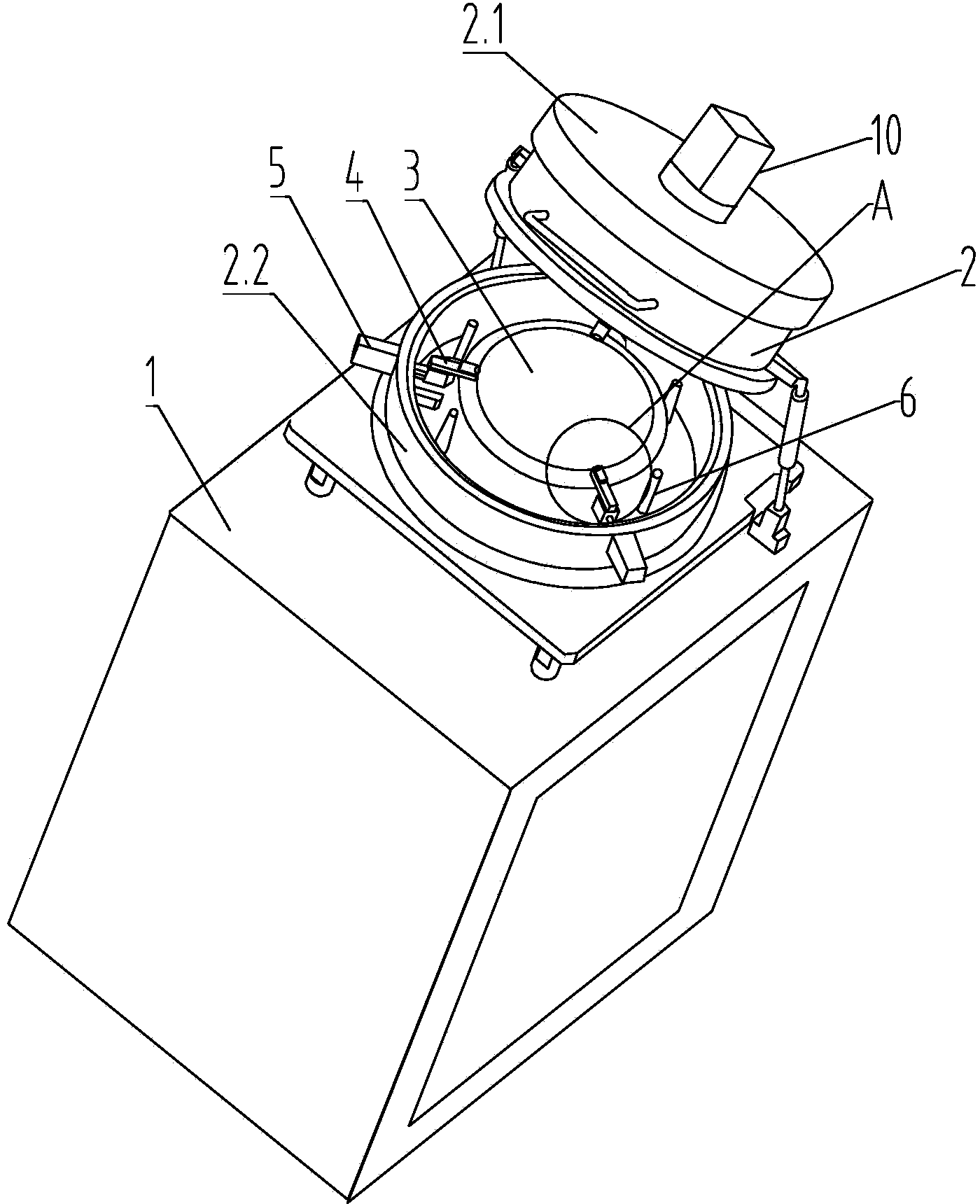

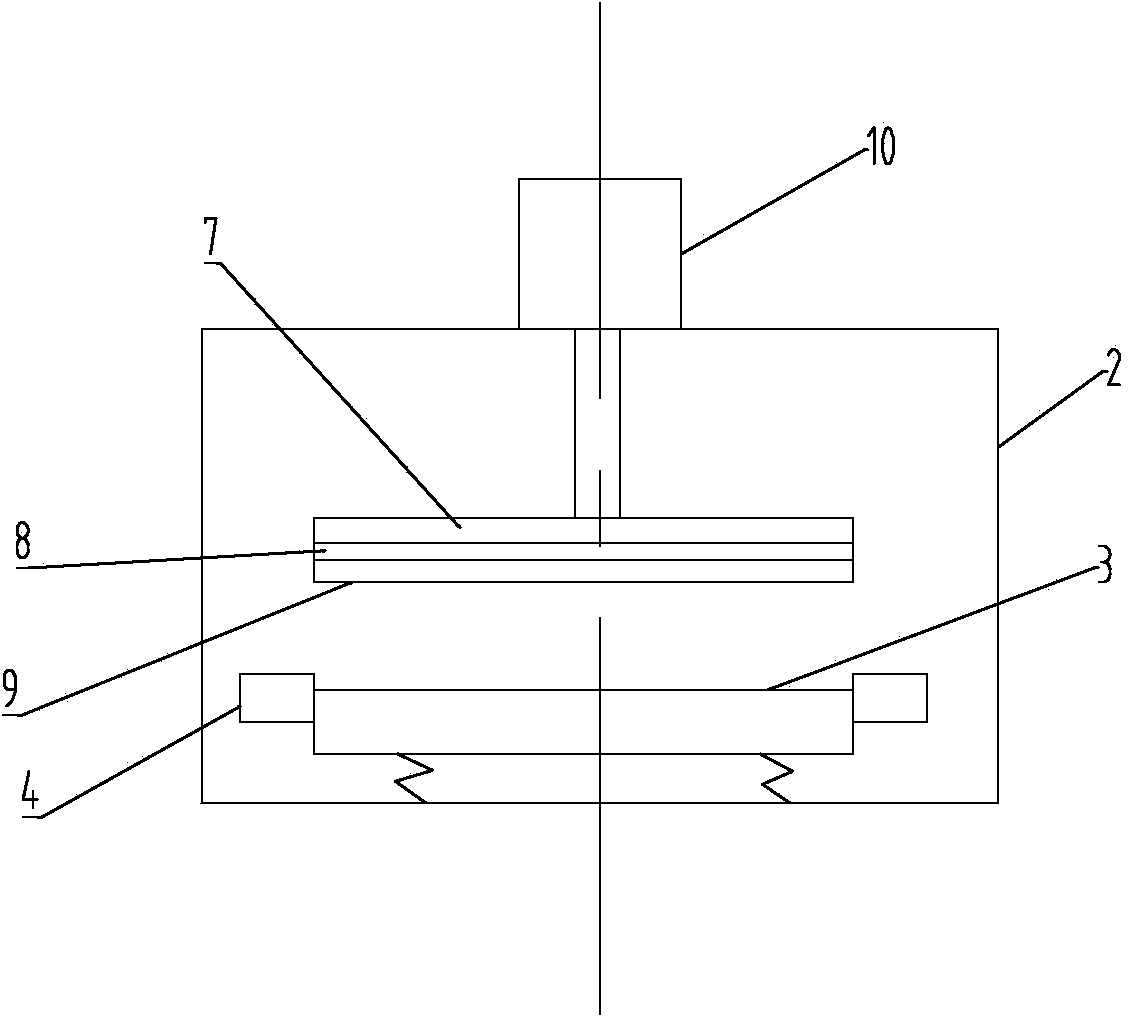

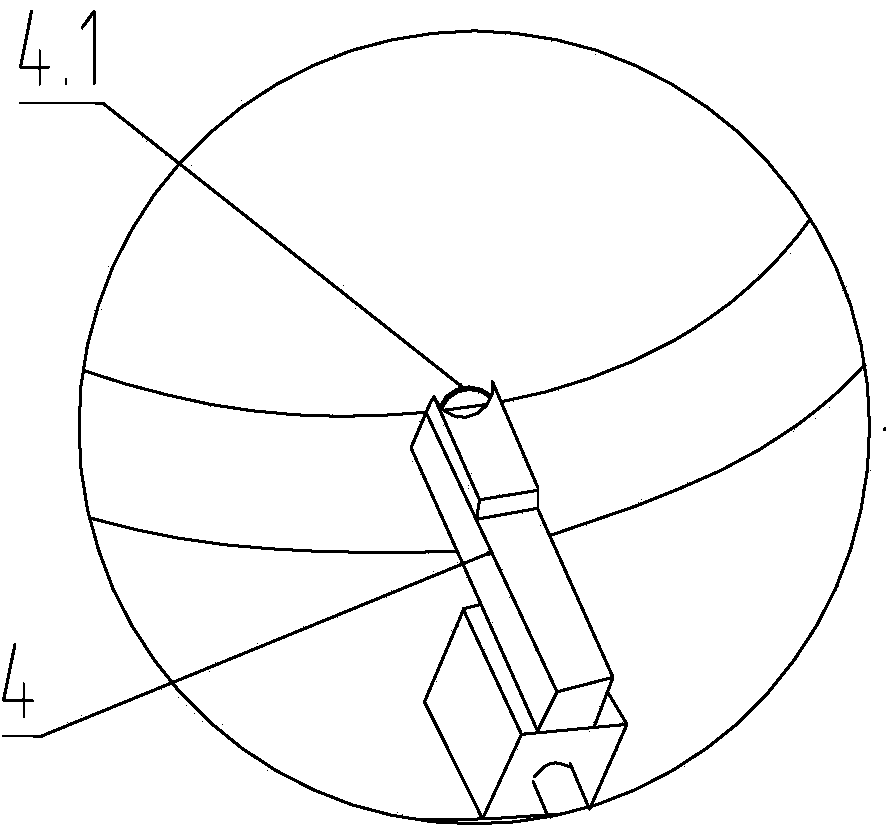

Wafer vacuum bonding machine and bonding method

ActiveCN104362107ASimple stepsImprove bonding performanceSolid-state devicesSemiconductor/solid-state device manufacturingVacuum pumpingElectrical and Electronics engineering

The invention discloses a wafer vacuum bonding machine and a wafer vacuum bonding method. The wafer vacuum bonding method includes: limiting the position of a first wafer after a positioning block moves forwards for the first time, and then placing a second wafer, performing vacuum pumping, enabling the second wafer to fall onto the first wafer under vacuum status when the positioning block is retreated, and afterwards, simultaneously limiting the position of the second wafer and the first wafer by moving the positioning block forwards, pressing the first wafer and the second wafer together, and finally retreating the positioning block after pressing the first wafer and the second wafer together. Accordingly, the wafer vacuum bonding machine and the wafer vacuum bonding method can guarantee that the positions of the two wafers are perfectly corresponding when the two wafers are pressed together. The wafer vacuum bonding machine is simple in structure, convenient to operate, low in cost, and capable of achieving perfect bonding for the wafers.

Owner:ZHEJIANG MICROTECH MATERIAL CO LTD

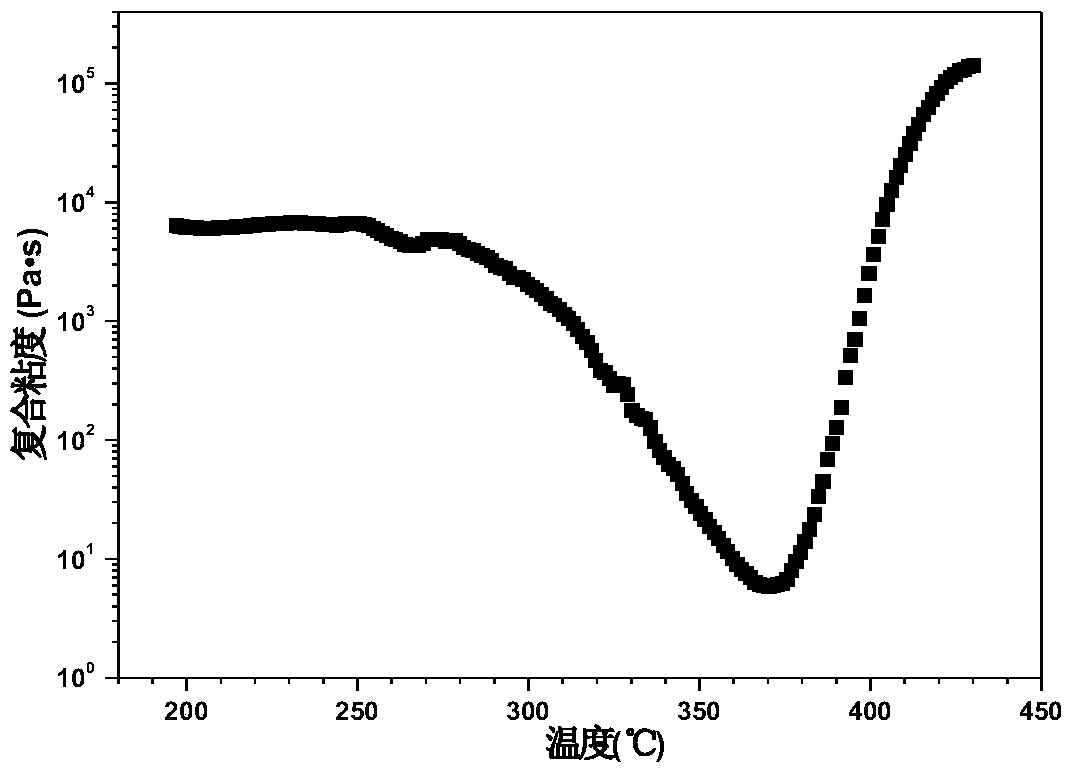

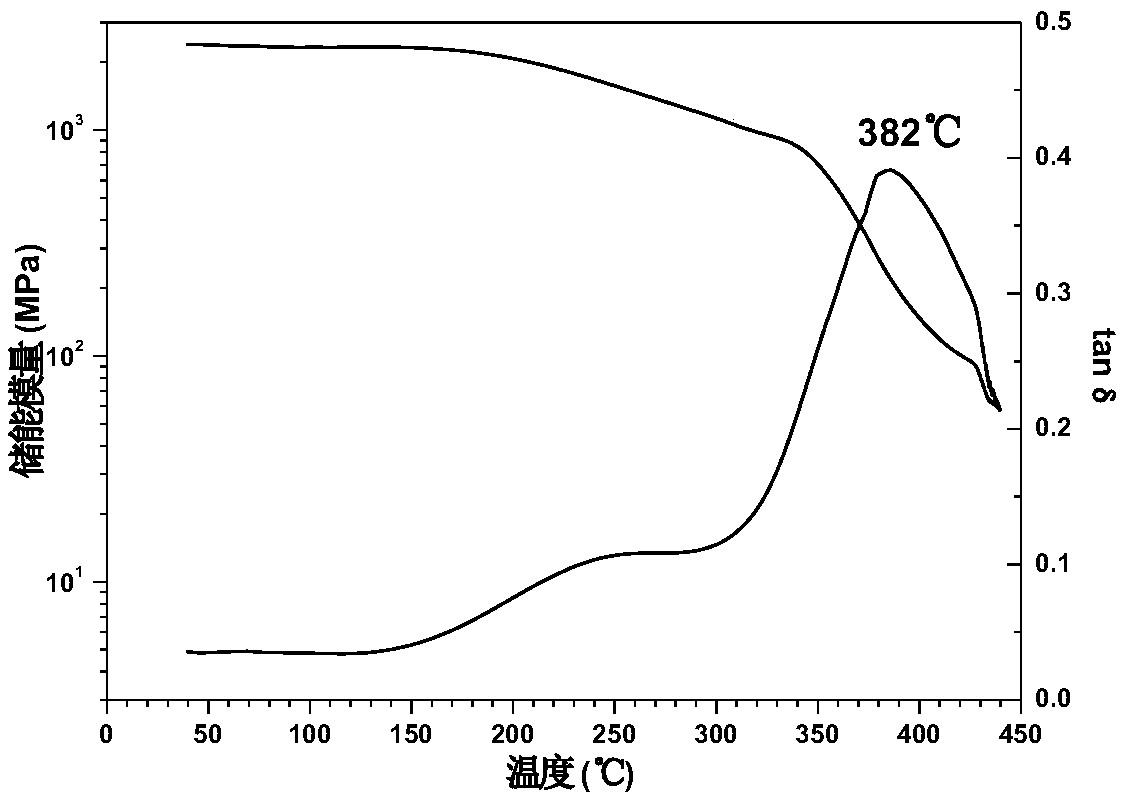

Polyimide adhesive and preparation method thereof

The invention relates to a polyimide adhesive and a preparation method thereof and belongs to the technical field of adhesives. The polyimide adhesive solves the problem that the polyimide adhesive ata temperature of greater than 350 DEG C has poor thermal instability and low adhesive properties. The polyimide adhesive is prepared from a polyimide adhesive prepolymer through curing. The preparation raw materials of the polyimide adhesive prepolymer comprise aromatic diamine containing a biphenyl structure, aromatic diamine containing a siloxane structure, aromatic dianhydride and a blocking agent. The preparation method comprises dissolving the polyimide adhesive prepolymer in an organic solvent to obtain a homogeneous solution, coating the surface of the adherend with the homogeneous solution, removing the organic solvent, carrying out curing to obtain the polyimide adhesive and bonding the adherend The polyimide adhesive can be used for the bonding of high temperature resistant parts in the fields of aviation, aerospace, precision machinery and petrochemical industry.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Bonding silver alloy wire for semiconductor, and manufacturing method thereof

ActiveCN104073676AObvious advantagesObvious effectSolid-state devicesSemiconductor devicesHydrogenVulcanization

The invention provides a bonding silver alloy wire for a semiconductor, and a manufacturing method thereof. The performance of the silver alloy wire material is improved through injection of certain amount of hydrogen into palladium-contained silver wire and combination of an alloy technology and a wire stretching technology, the vulcanization and oxidization resistant ability of the wire is improved, and the bonded area and the bonding strength under N2 atmosphere in ball bonding are improved, so that the electric conducting ability and the reliability of the wire are improved.

Owner:NICHE TECH KAISER SHANTOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com