Room-temperature vulcanized one-component dealcoholized silicone rubber sealant and preparation method thereof

A technology of room temperature vulcanization and silicone rubber, which is applied in the direction of chemical instruments and methods, adhesives, adhesive additives, etc., can solve the problems of decreased curing performance, difficult bonding performance, poor storage performance and bonding performance, and achieve improved bonding Good performance, good yellowing resistance, and the effect of solving yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

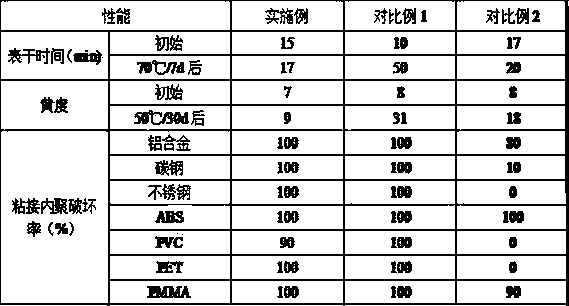

Examples

Embodiment

[0042] Choose α, ω-dihydroxypolydimethylsiloxane with a viscosity of 20000mpa.s and simethicone oil with a viscosity of 500mpa.s. The component ratios are as follows:

[0043] A. α, ω-Dihydroxypolydimethylsiloxane 100 parts

[0044] B. 20 parts of simethicone oil

[0045] C. 8 parts of methyltrimethoxysilane

[0046] D. The above silane coupling agents 2 copies

[0047] E. 80 parts of calcium carbonate, 10 parts of fumed silica

[0048] F. Tetra-tert-amyl titanate 2 parts

[0049] G. Hexamethyldisilazane 1 part

[0050] Add the hydroxyl-terminated polydimethylsiloxane, simethicone oil and fillers with the above-mentioned viscosity and parts into the stirring tank, and stir for 2-4 hours at 110°C~130°C and -0.09~-0.1MPa vacuum condition. Hours later, the temperature was lowered to below 40°C, and the above-mentioned parts of methyltrimethoxysilane, silane coupling agent, tetra-tert-amyl titanate, and hexamethyldisilazane were added in sequence and stirred evenly.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com