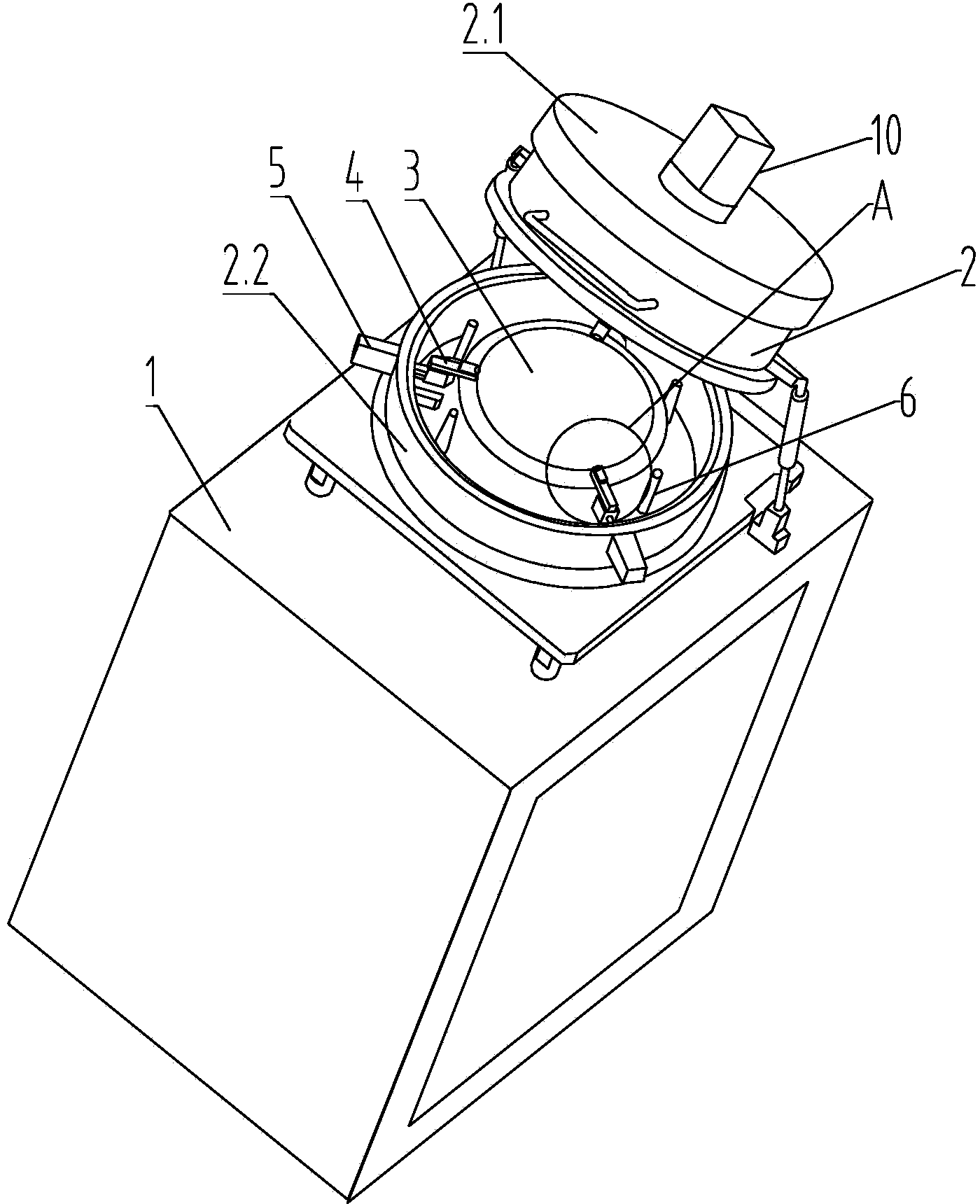

Wafer vacuum bonding machine and bonding method

A vacuum bonding machine and wafer technology, applied in the field of microelectronics, can solve the problems of complex structure and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

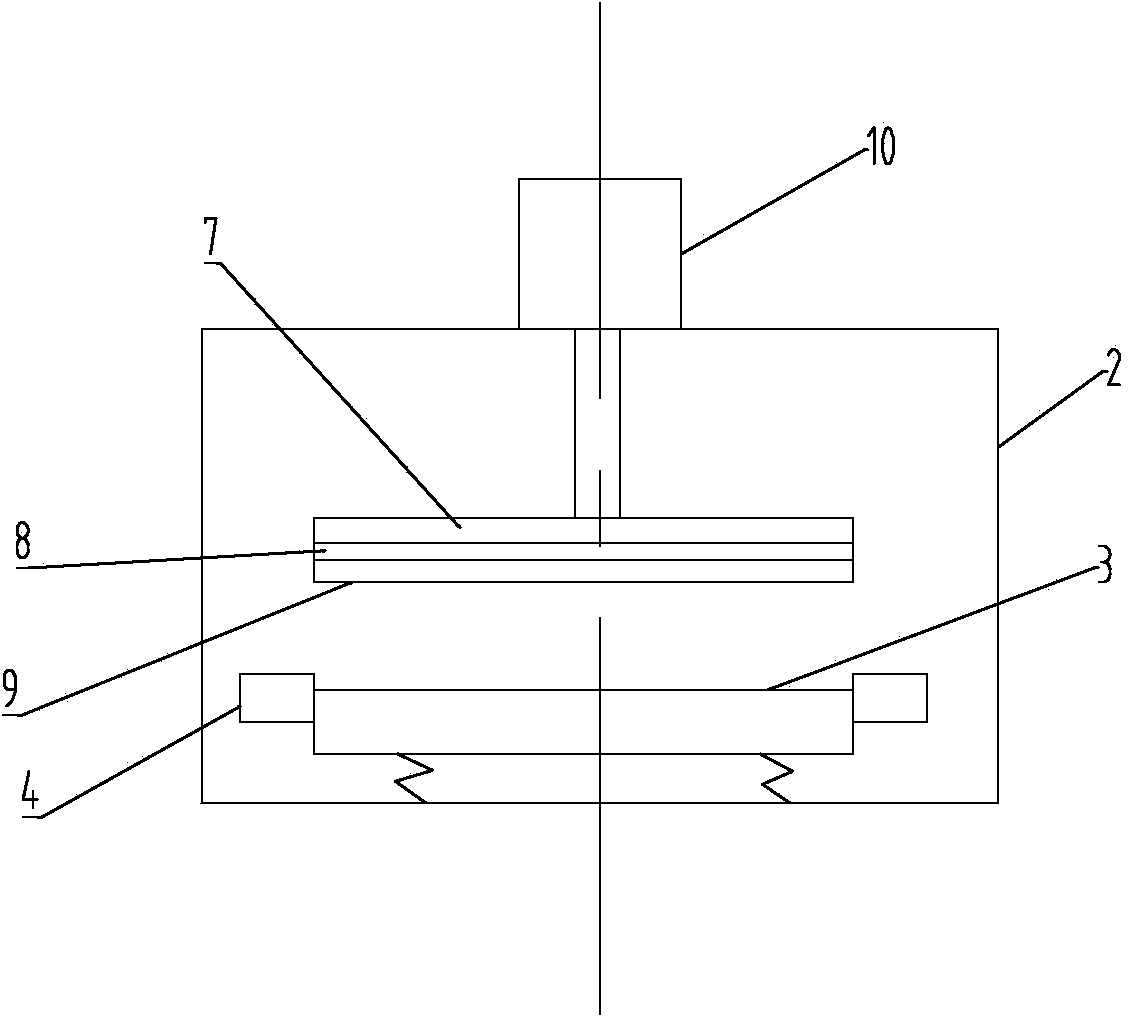

Method used

Image

Examples

Embodiment

[0048] Embodiment: In this embodiment, two wafers with a thickness of more than 0.3 mm and a diameter of 200 mm are used, and the bonding steps are as follows:

[0049] S1. Put the first wafer coated with bonding glue on the tray;

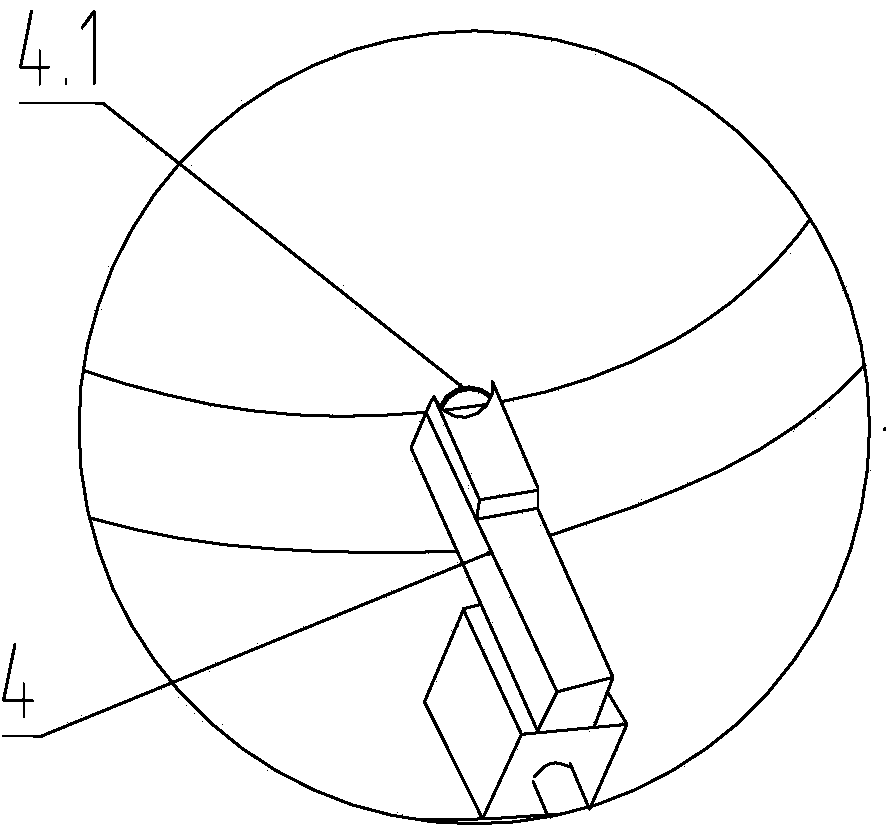

[0050] S2. Control multiple positioning blocks to advance toward the pallet through the cylinder, and position the first wafer at the center;

[0051] S3. Place the second wafer on the positioning block support, then close the cover to close the press, and evacuate;

[0052] S4, when the vacuum degree reaches 10 Pa, control multiple positioning blocks to retreat, and the second wafer falls from the positioning block support to the first wafer;

[0053] S5, the multiple positioning blocks are controlled by the cylinder to advance toward the tray again, and the two wafers are positioned to completely overlap the edges of the two wafers;

[0054] S6. The pressing plate is controlled downward by the press, so that the first wafer and the second wafer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com