Addition type liquid silicone rubber tackifier, as well as preparation method and application thereof

A liquid silicone rubber and tackifier technology, which is applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of complex synthesis process, high cost, production danger, etc., achieve simple synthesis process, solve sticky The effect of solving adhesion problems and improving adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

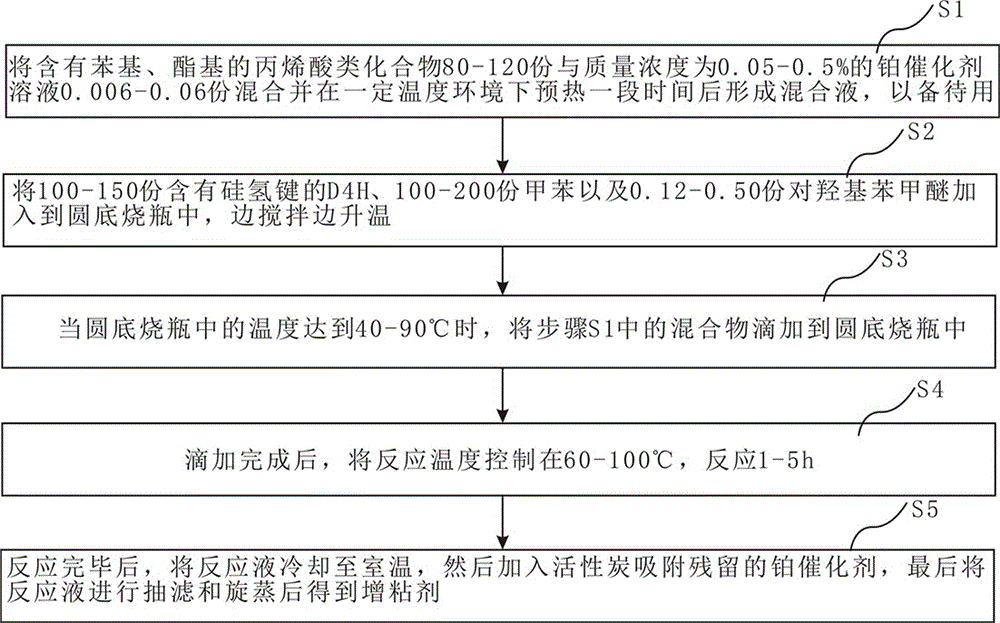

[0031] see further figure 1 , the present invention also provides a kind of preparation method of addition type liquid silicone rubber tackifier, comprises the following steps:

[0032] Step S1, mixing 80-120 parts of acrylic compounds containing phenyl and ester groups with 0.006-0.06 parts of a platinum catalyst solution with a mass concentration of 0.05-0.5%, and preheating for a period of time under a certain temperature environment to form a mixed solution, It is ready for use; wherein the temperature environment in this step is 40-80°C, and the preheating time is 30-60 min; and the platinum catalyst in the step accounts for 0.5-10ppm of the mass of the acrylic compound containing phenyl and ester groups; Acrylic compounds with phenyl / ester groups are acrylic compounds containing phenyl / ester groups, diallyl phthalate, allyl acetoacetate, 1,4-butanediol diacrylate, methacrylate shrink One or more of glycerides; the platinum catalyst is Speier catalyst or Karstedt catalys...

Embodiment 1

[0045] 1. Synthesis of tackifier

[0046] Mix 62g of terephthalic acid diacrylate and 0.10g of 4000ppm platinum-divinyltetramethyldisiloxane complex in a round-bottomed flask, preheat at 50°C for 50min, and set aside.

[0047] Add 120g of tetramethylcyclotetrasiloxane, 200g of toluene, and 0.25g of p-hydroxyanisole into a four-necked flask with a thermometer and a condensing reflux tube, stir and heat up to 60°C under nitrogen protection, and place the preheated The mixture of terephthalic acid diacrylate and platinum-divinyltetramethyldisiloxane complex was slowly added dropwise into a four-neck flask, and the dropping time was 2 hours. After the dropwise addition, the reaction temperature was controlled at 65° C. for 2 h. Then add 20g of coconut shell activated carbon particles to the four-necked flask and the adsorption time is 2h. Finally, the reaction solution was subjected to suction filtration and rotary evaporation to obtain the final product, which was designated as...

Embodiment 2

[0053] 1. Synthesis of tackifier

[0054] Mix 71g of glycidyl methacrylate and 0.10g of 4000ppm platinum-divinyltetramethyldisiloxane complex in a round-bottomed flask, preheat at 50°C for 50min, and set aside.

[0055] Add 120g of tetramethylcyclotetrasiloxane, 200g of toluene, and 0.15g of p-hydroxyanisole into a four-necked flask with a thermometer and a condensing reflux tube, stir and heat up to 60°C under nitrogen protection, and place the preheated The mixture of glycidyl methacrylate and platinum-divinyltetramethyldisiloxane complex was slowly added dropwise into a four-neck flask for 1 h. After the dropwise addition, the reaction temperature was controlled at 80° C. for 4 h. Then add 20g of coconut shell activated carbon particles to the four-necked flask and the adsorption time is 2h. Finally, the reaction solution was subjected to suction filtration and rotary evaporation to obtain the final product, which was designated as viscosifier 2.

[0056] 2. Application ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com