Patents

Literature

100results about How to "Solve bonding problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

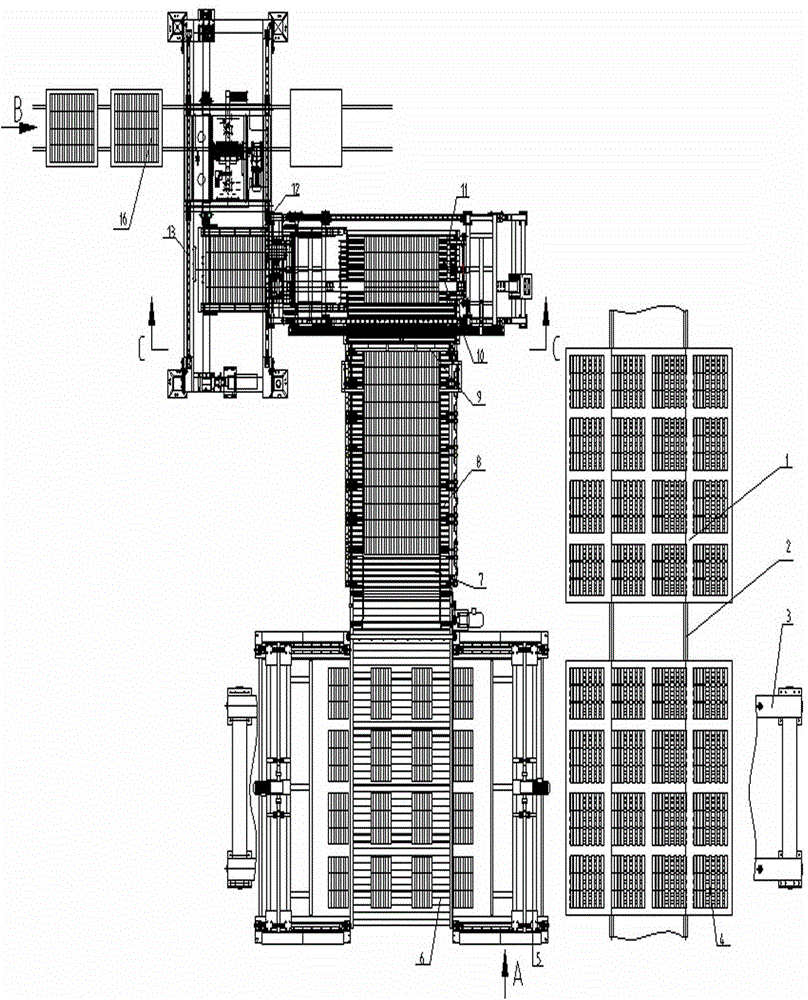

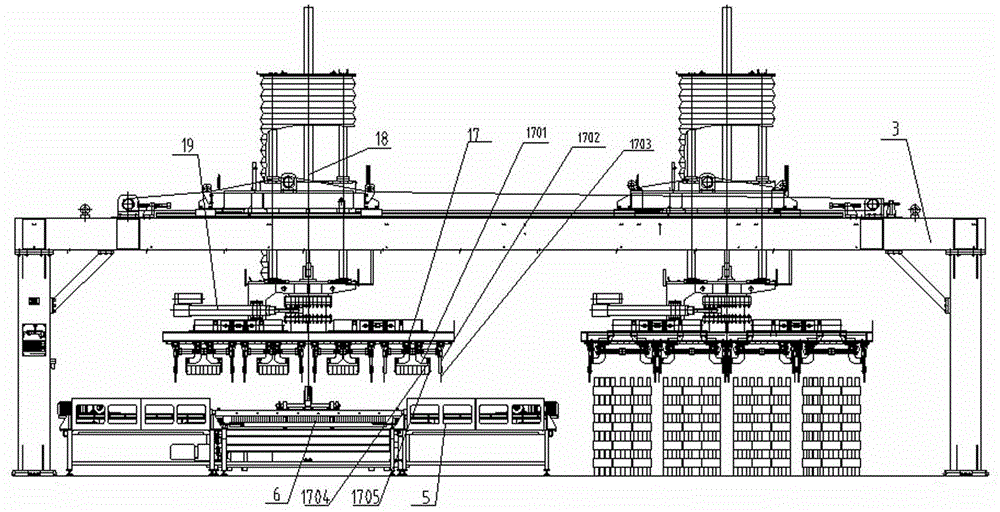

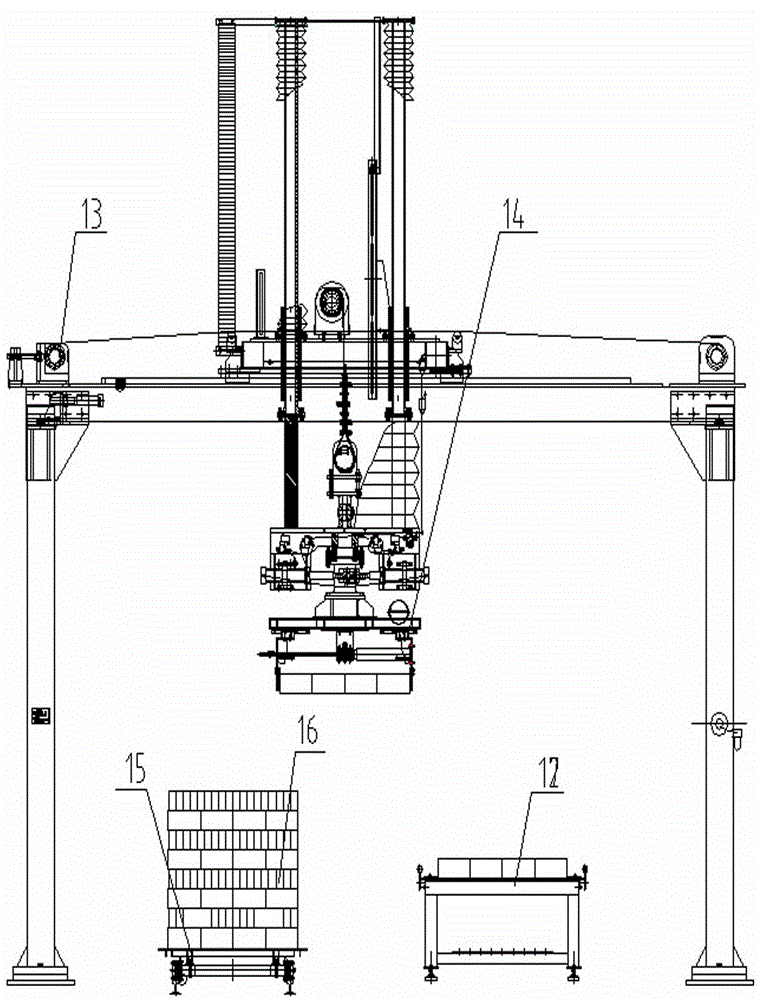

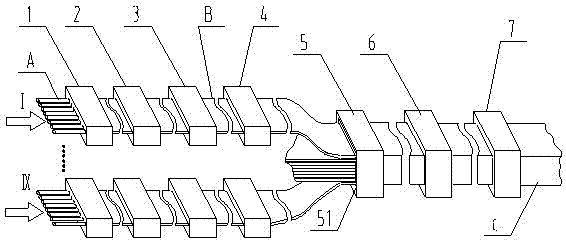

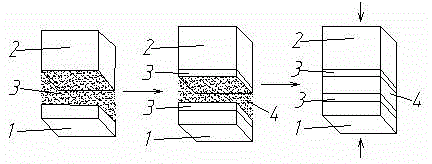

Brick unloading and stacking unit and brick unloading and stacking method for sintered bricks

ActiveCN103552832ASolve bonding problemsReduce labor intensityStacking articlesDe-stacking articlesBrickPalletizer

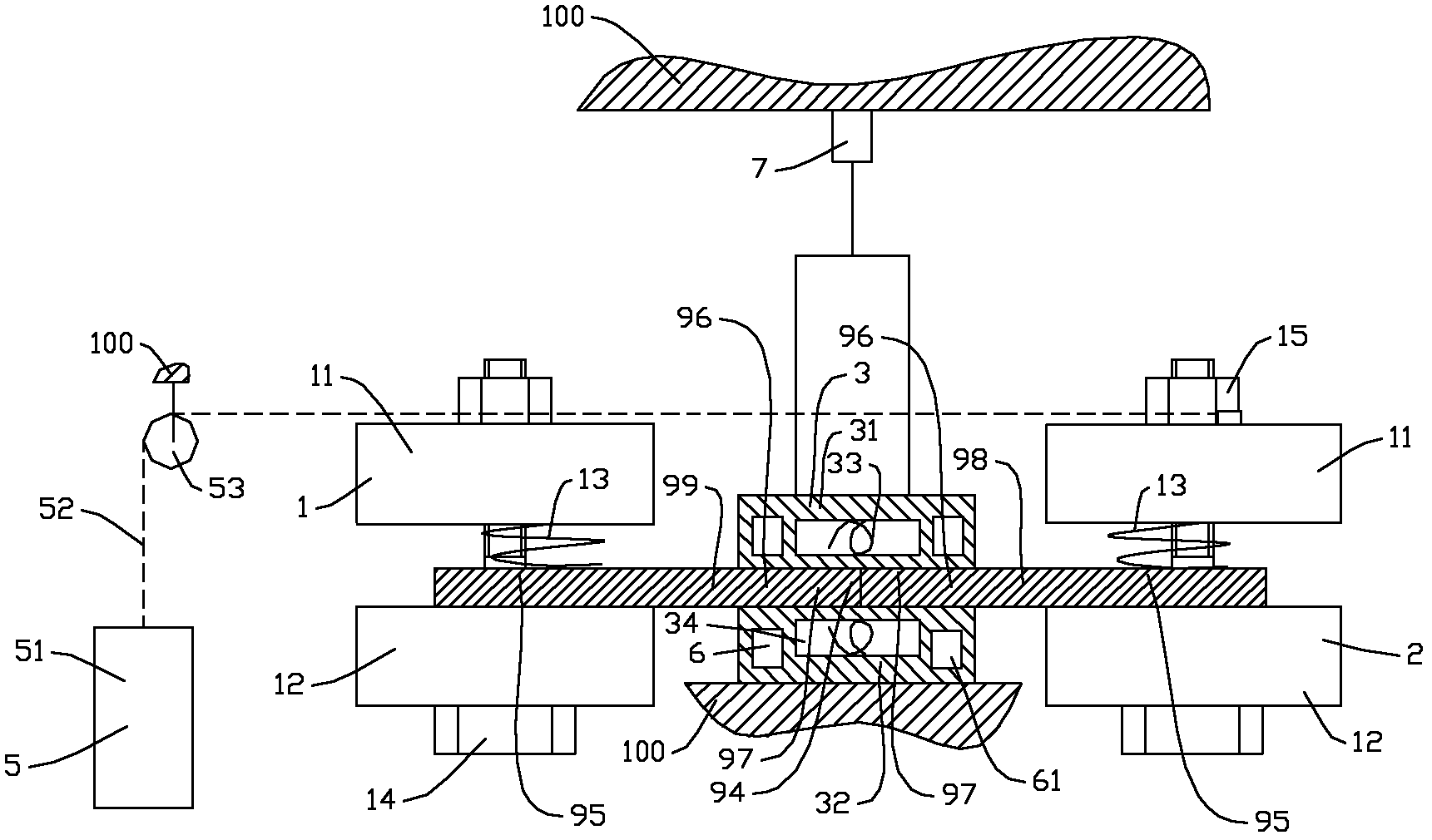

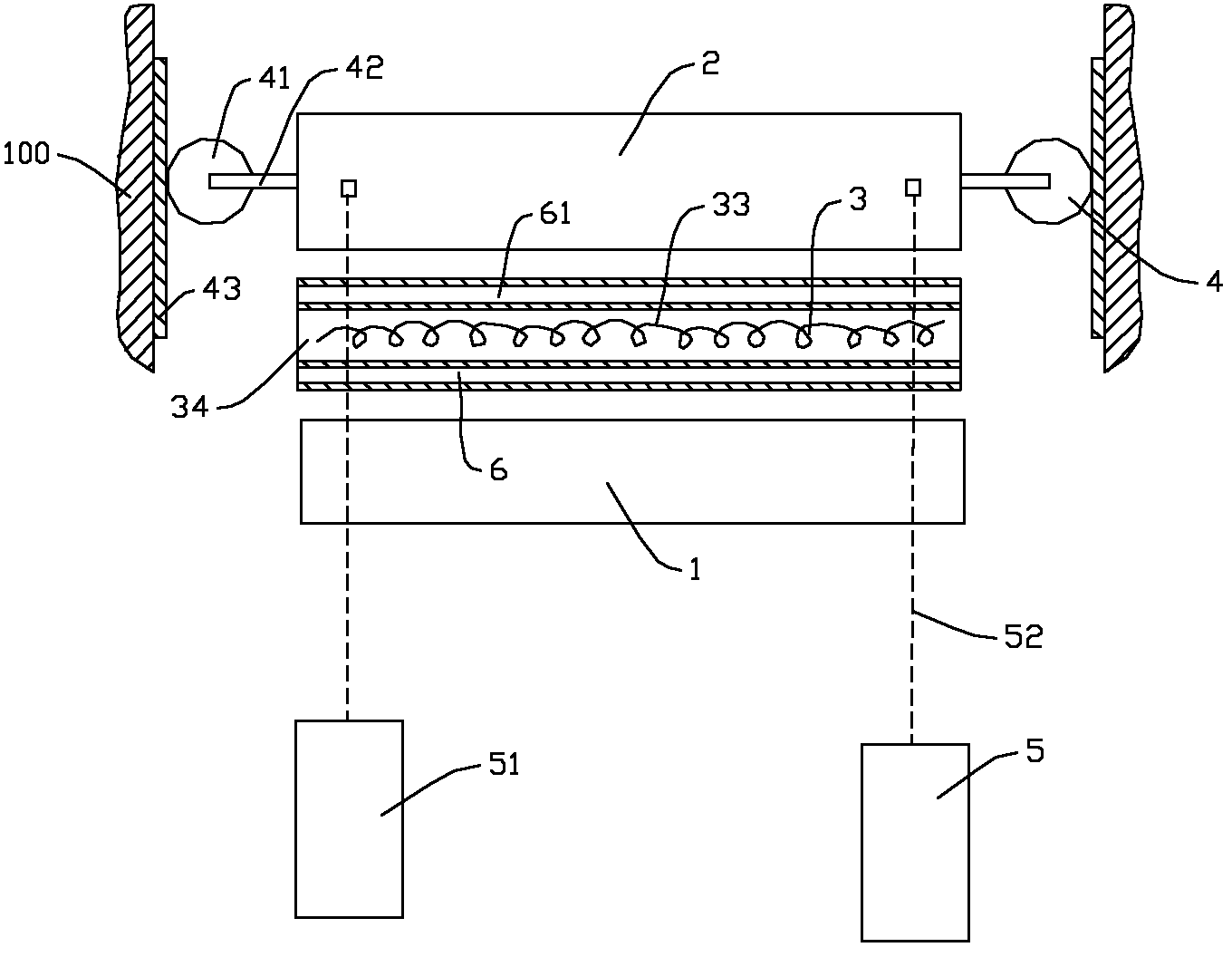

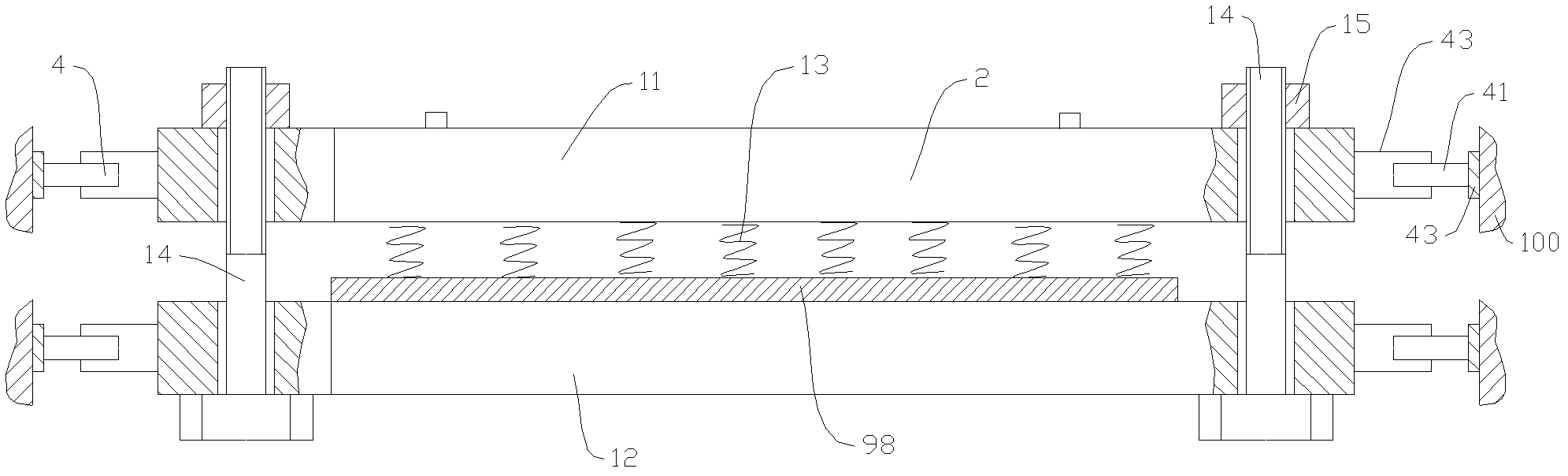

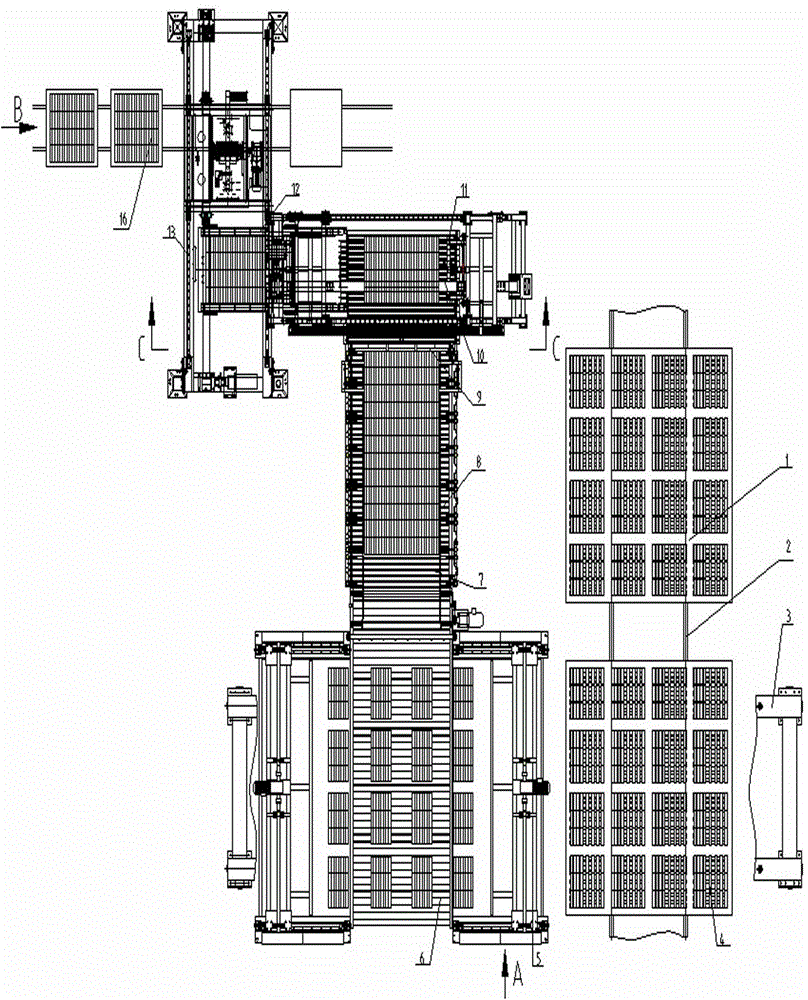

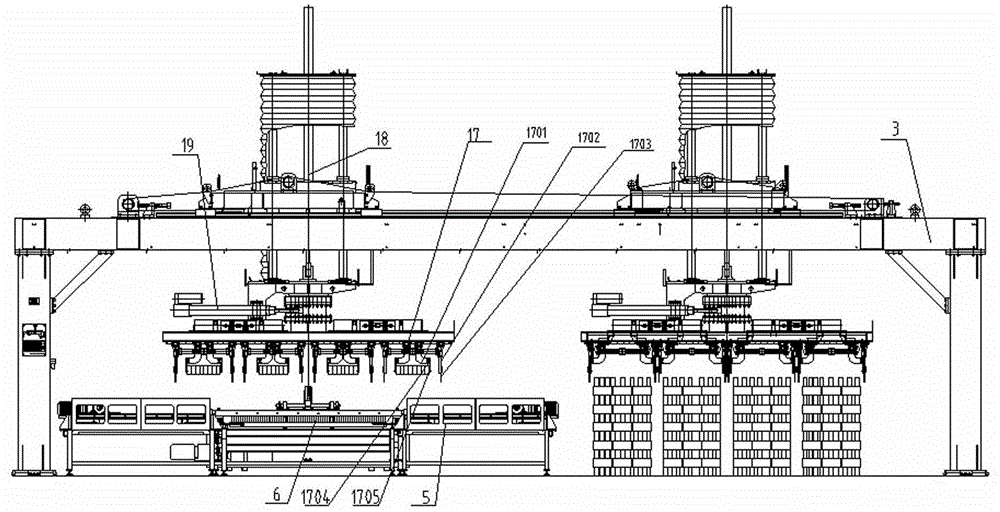

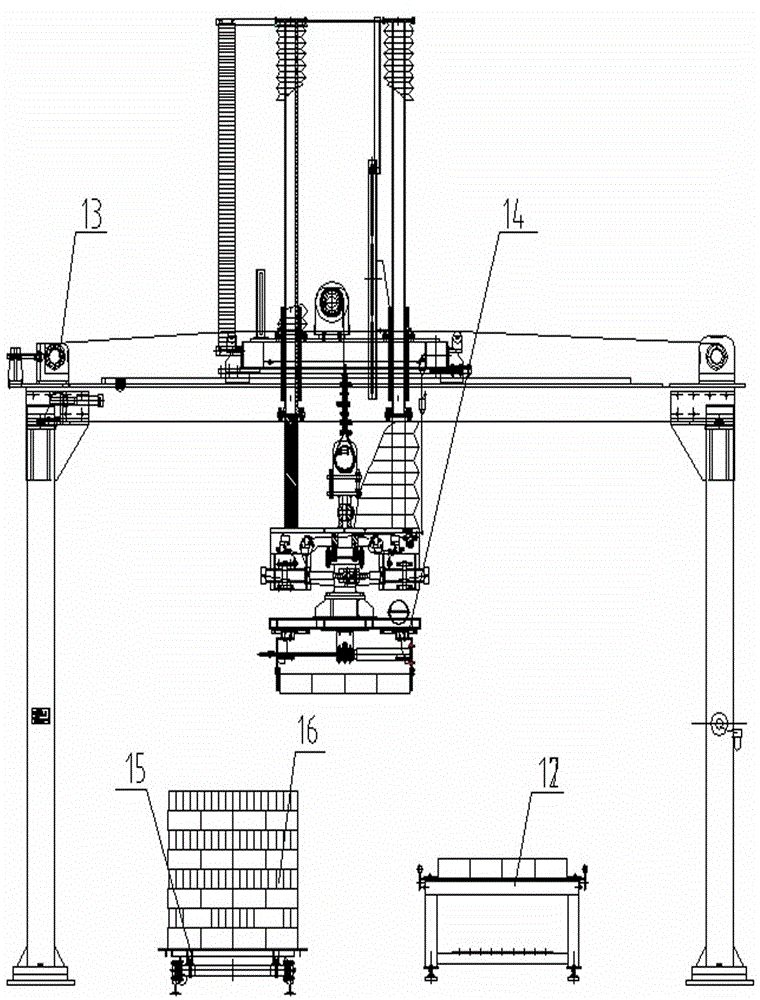

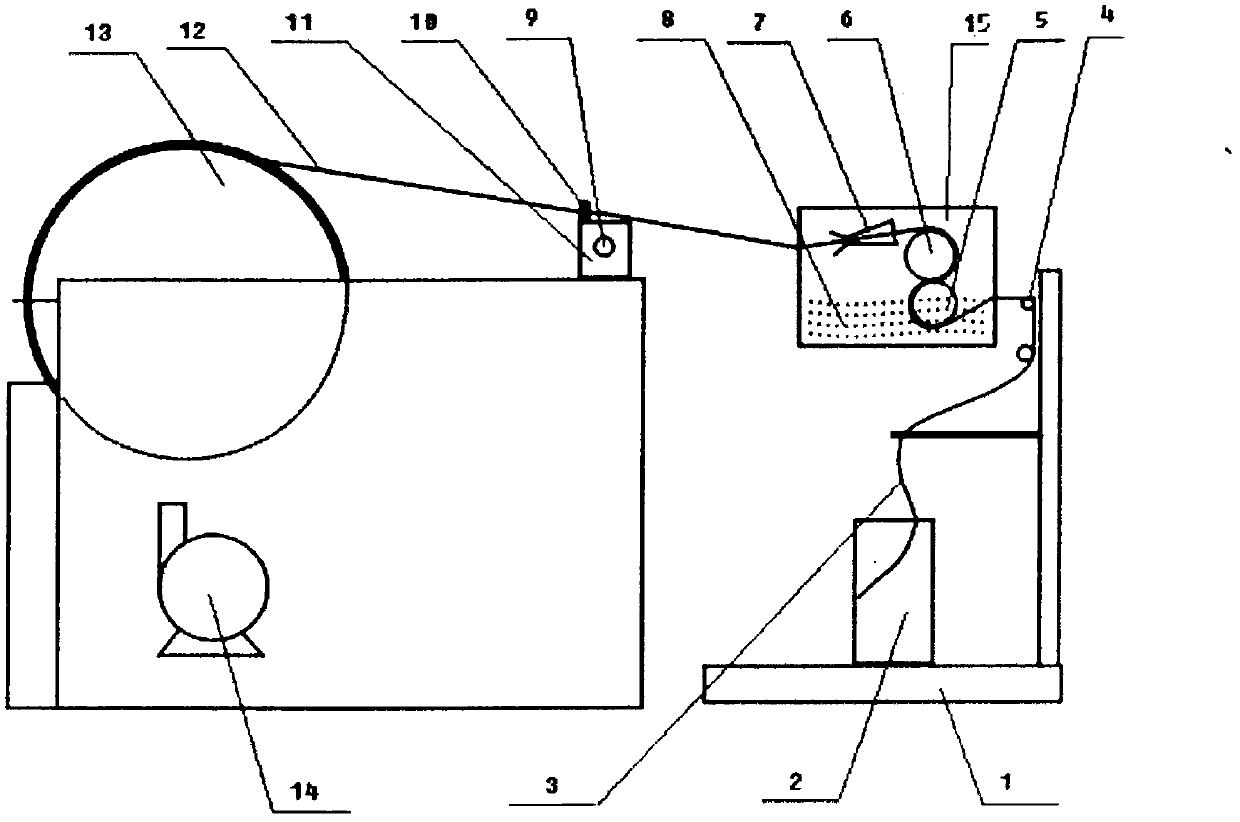

The invention discloses a brick unloading and stacking unit and a brick unloading and stacking method for sintered bricks. The brick unloading and stacking unit comprises a brick unloading machine for unloading the sintered bricks from a kiln car layer by layer and a pushing mechanism for gathering the bricks transversely; a first roller way conveying platform which is connected behind the brick unloading and stacking unit is provided with a brick collimating device capable of gathering the bricks longitudinally; the first roller way conveying platform is used for grouping the bricks and conveying the bricks onto a second roller way conveying platform which is connected with the first roller way conveying platform under the control of a controller; a conveying device for conveying the grouped bricks along a direction vertical to the conveying direction of the first roller way conveying platform forward is arranged above the second roller way conveying platform; a brick gathering platform is arranged at the tail end of the second roller way conveying platform; a stacking machine for stacking the bricks on the brick gathering platform by clamping in groups is arranged above the brick gathering platform. According to the brick unloading and stacking unit, a full mechanical process from unloading to stacking is realized, the problem of bonding caused by deformation of sintered bricks is solved effectively, the requirement of automatic production is met, and the labor force of workers and production cost are greatly reduced.

Owner:洛阳曜辰自动化科技有限公司

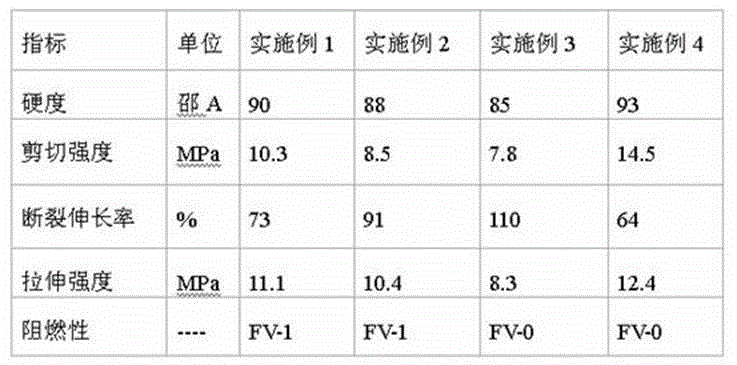

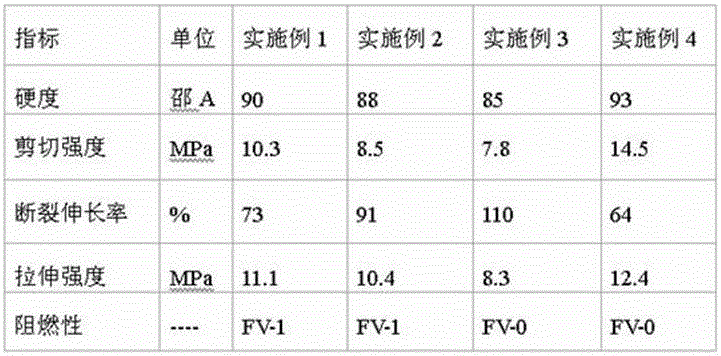

Halogen-free flame-retardant two-component polyurethane adhesive for railway vehicle and preparation method thereof

ActiveCN104694068AImprove rigidityHigh strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesRetardation effectChemistry

The invention provides a halogen-free flame-retardant two-component polyurethane adhesive for a railway vehicle and a preparation method thereof, belonging to the technical field of two-component polyurethane adhesives. The main objective of the invention is to overcome problems in bonding of the structures of the bodies of a high-speed railway carriage and a rail transit vehicle. The polyurethane adhesive mainly a component A and a component B, wherein the component A and the component B are in a weight ratio of 6: 1, the component A comprises, by weight, 10 to 35% of castor oil polyol, 10 to 40% of polyester polyol, 5 to 30% of bisphenol A polyether polyol, 5 to 25% of a flame-retardant plasticizer, 30 to 60% of a flame-retardant inorganic filling material, 0.5 to 3% of a coupling agent and 0.1 to 0.5% of a catalyst, and the component B is an isocyanate curing agent containing liquefied methyl diphenylene diisocyanate. The polyurethane adhesive has the characteristics of good flame retardation effect, environment friendliness, good bonding strength after curing and good toughness and is mainly applied to self-adhesion and mutual adhesion of materials like metals and timber of the bodies of railway vehicles.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +1

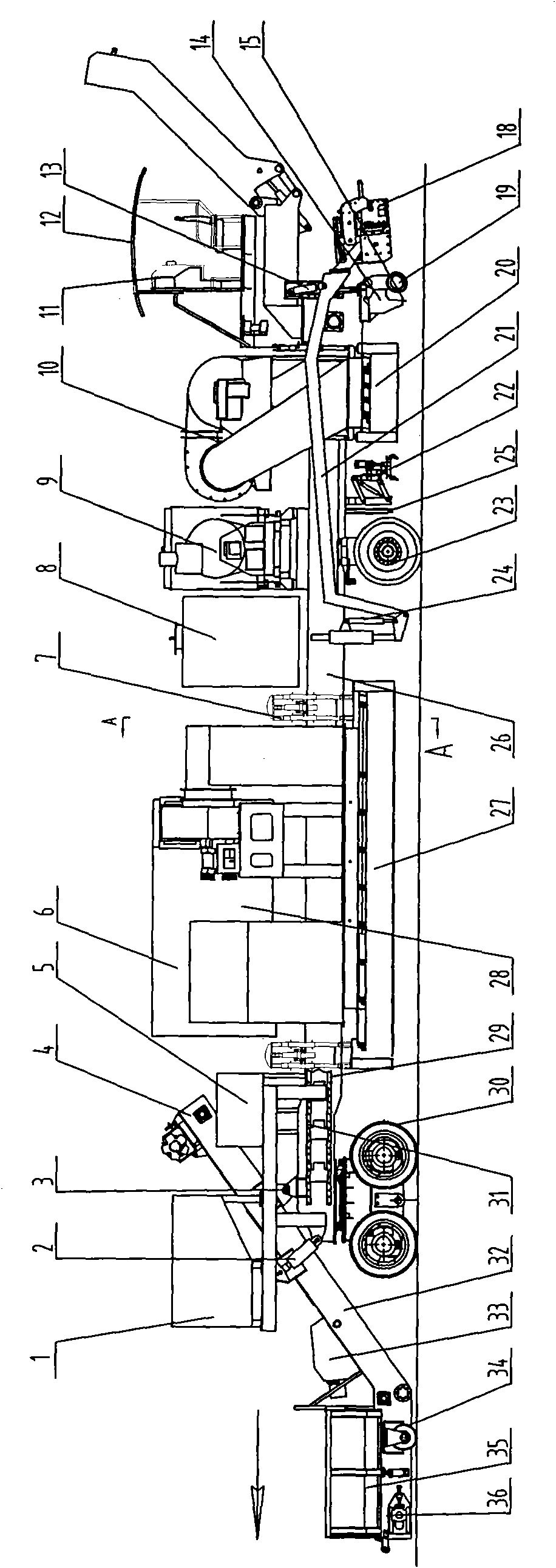

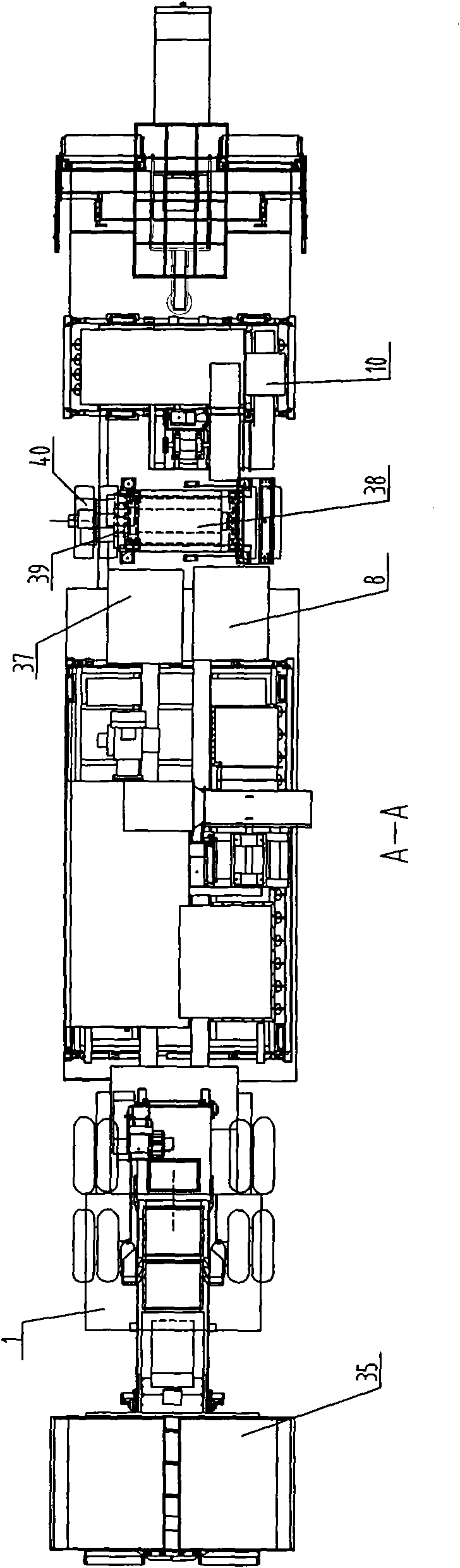

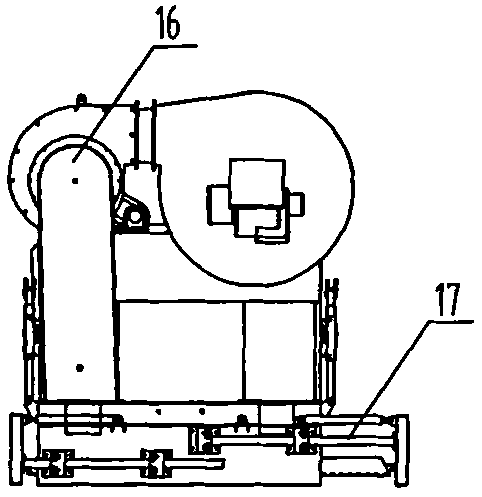

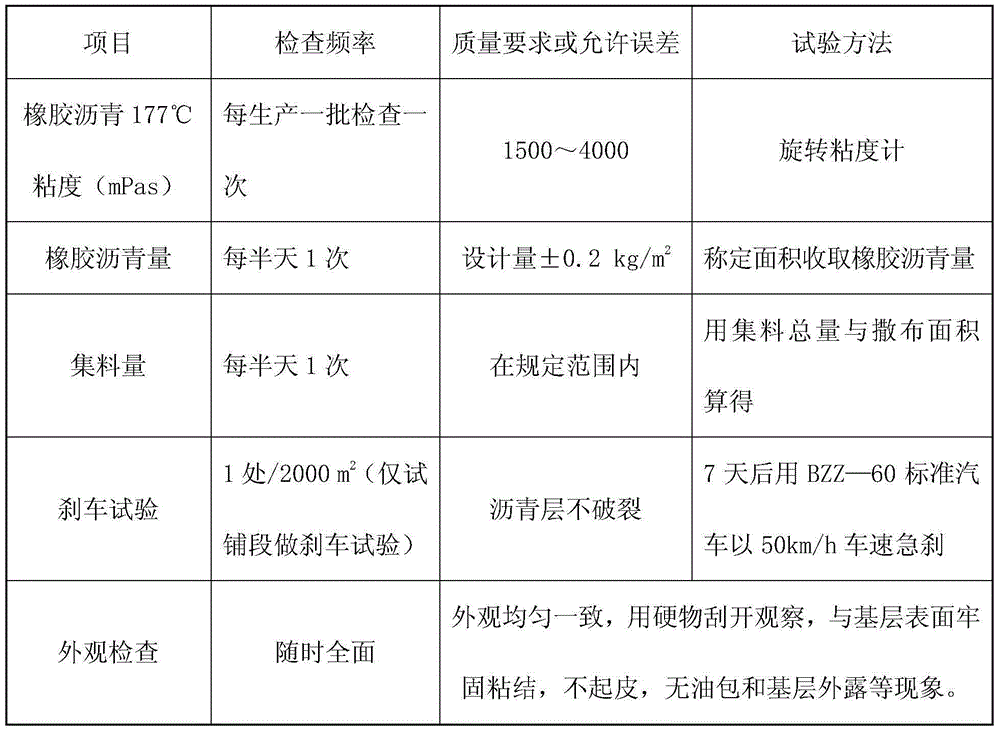

Hot in-place recycling ultrathin overlaying machine of bituminous pavement and construction method thereof

InactiveCN102011362ARestoration of slip resistanceGood lookingIn situ pavingsRoads maintainenceTraffic noiseScreed

The invention provides a hot in-place recycling ultrathin overlaying machine of a bituminous pavement and a construction method thereof. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement comprises an automobile chassis, an integral power device, an electric control system, a diesel tank, a receiving and transporting device, a material transfer hopper, a horizontal transporting device, a heating device, a hydraulic system, a recycling agent spraying system, a harrowing device, a distributing spiral device, a paving screed device, a cab, and an electric control operating floor, wherein the automobile chassis is a special automobile chassis. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement finishes the continuous overlay repair work of the pavement through a series of processes such as receiving the materials, feeding the materials quantitatively, transporting the materials horizontally, spraying the recycling agent, harrowing, heating, distributing and paving the materials, ironing, and grinding and the like, and has the advantage of carrying out one-time maintenance on the defects such as loose, shallow vertical and horizontal cracks, track, slight crack, bituminous aging, pavement seepage and the like of a functional layer of the pavement. By adopting the invention, the antiskid resistance of the pavement is restored, the profile of the pavement is corrected, the appearance and the evenness of the pavement are improved, the pavement strength of the pavement is increased, the traffic noise is reduced, and the service life of the pavement is prolonged.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

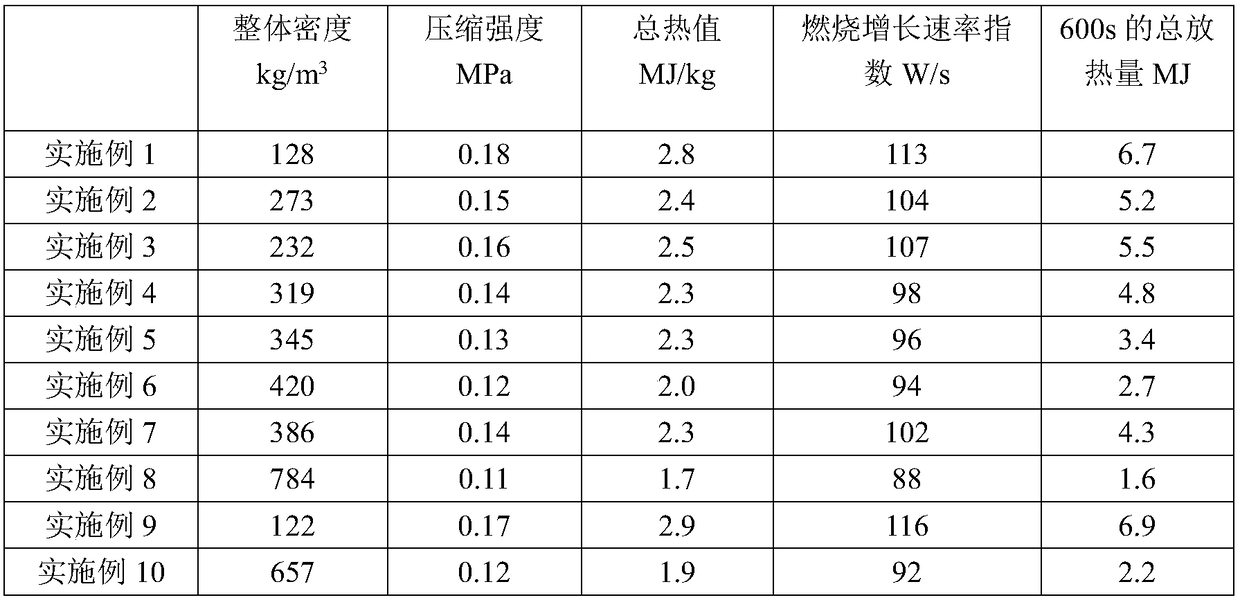

Homogeneous non-combustible polyurethane foam heat insulating material and preparation method thereof

ActiveCN108774306AHigh fire ratingImprove flame retardant performanceCombustionVolumetric Mass Density

The invention discloses a homogeneous non-combustible polyurethane foam heat insulating material and a preparation method thereof. The heat insulating material is prepared by reacting the following raw materials in parts by weight: 6~20 parts of polyurethane rigid foaming material, 4~20 parts of flame retardant and 60~90 parts of inorganic filler, wherein the loose packing density of the inorganicfiller is 1.0~2.0 g / cm<3>. The heat insulating material prepared by the invention has overall density between 120 and 800 kg / m<3>, compressive strength being greater than and equal to 0.10 MPa, highmechanical strength, good durability, total heat value being smaller than and equal to 3.0 MJ / kg, combustion growth rate index being smaller than and equal to 120 W / s and 600 s total heat release ratebeing smaller than and equal to 7.5 MJ, and belongs to A2 grade non-combustible material, and has high fire-proofing safety and simple preparation process, and can realize industrial production.

Owner:南京红宝丽新材料有限公司

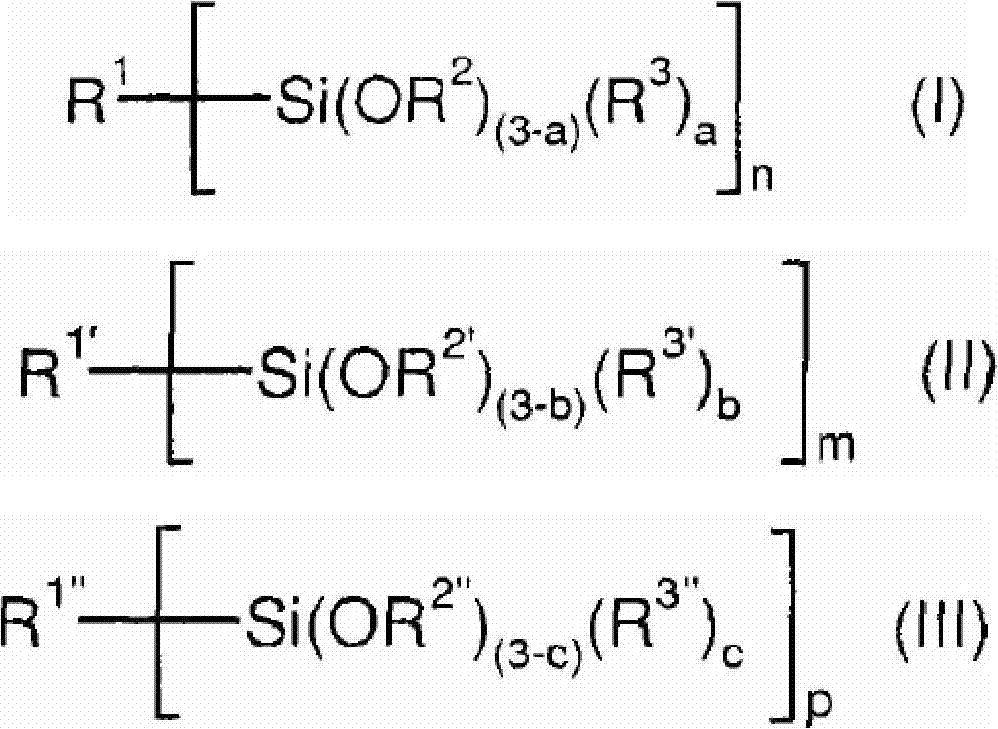

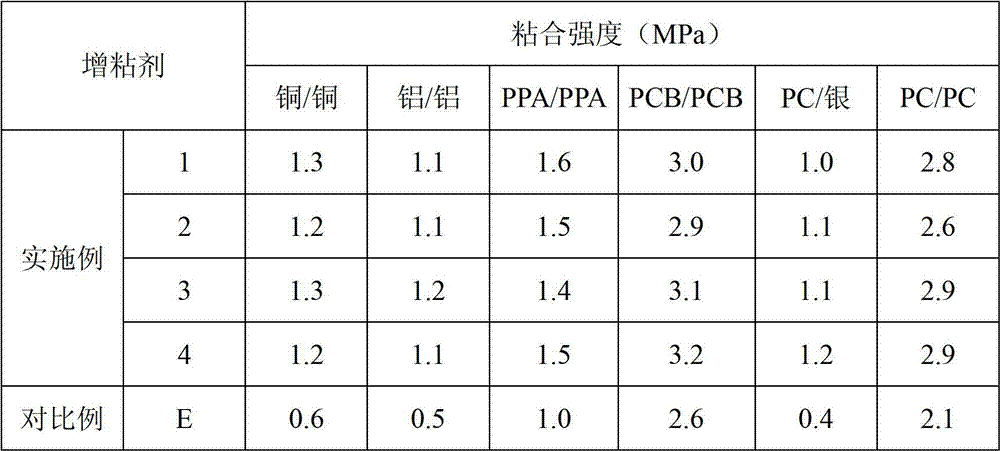

Tackifier and production method thereof

ActiveCN102775611ASolve bonding problemsGood miscibilityMacromolecular adhesive additivesChemistrySilicone resin

The invention relates to a tackifier which is prepared by the following steps of: adding 500-700 parts by weight of hydroxy silicone oil and 120-230 parts by weight of KH560 in a reactor; heating, slowly adding 0.2-1.0 parts by weight of organic tin at the temperature of 35 DEG C to 45 DEG C, slowly adding 50-70 parts by weight of KH570 under the temperature of 45 DEG C within 60min; reacting for more than 0.3h at the temperature of 40 DEG C to 60 DEG C; reacting for more than 0.5h under a vacuum condition, controlling the vacuum degree so that the material solution does not foam; and stopping vacuumizing, keeping on reacting for more than 0.3h, stopping heating, cooling, and discharging to the tackifier. The tackifier is colorless or faint yellow transparent liquid; when the tackifier is used in the two-component addition-type silicone resin, the inter-solubility is very good, and no chameleon phenomenon and peculiar smell appears; the bonding force is enhanced by 50% than that of the traditional tackifier; and the bonding force to PPA (polyphthalamide) reaches 100N, and meanwhile, the bonding problem of PC (poly carbonate) and metal sliver is solved.

Owner:兆舜科技(广东)有限公司

Conductive adhesive

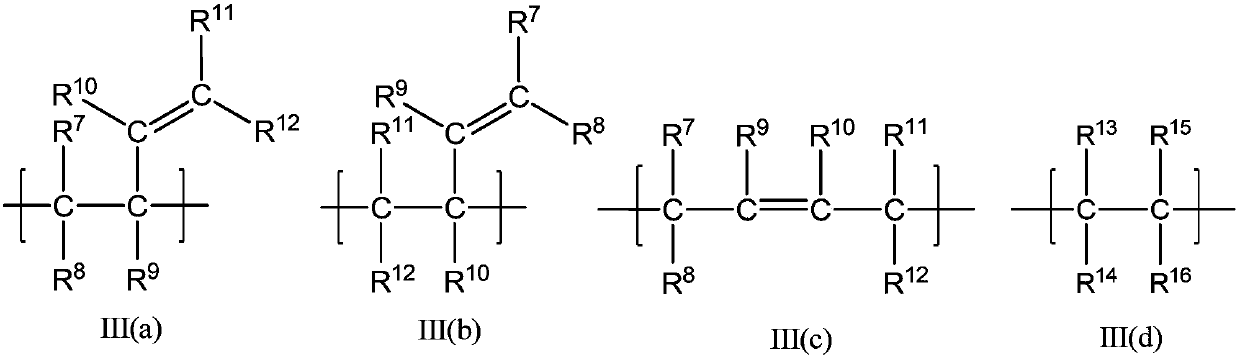

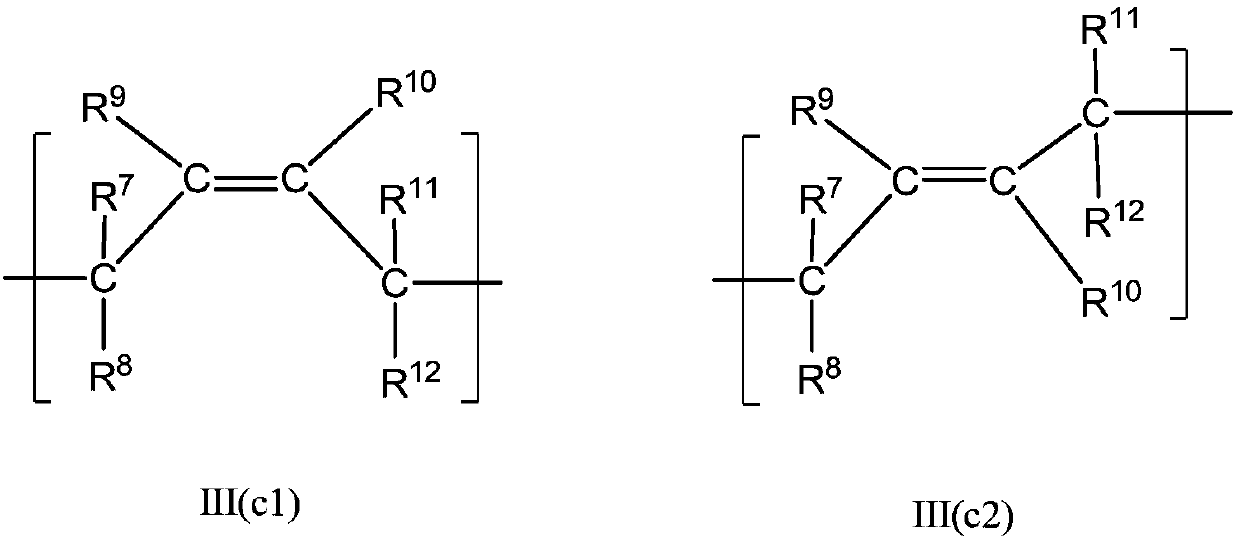

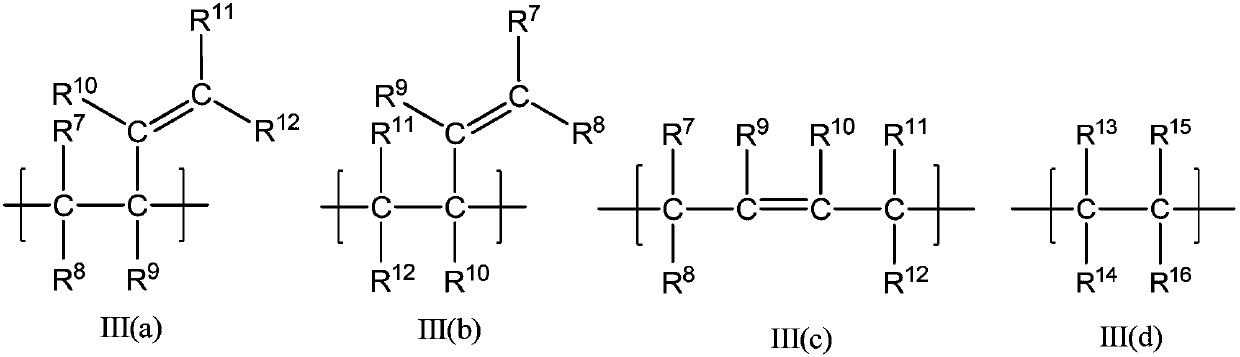

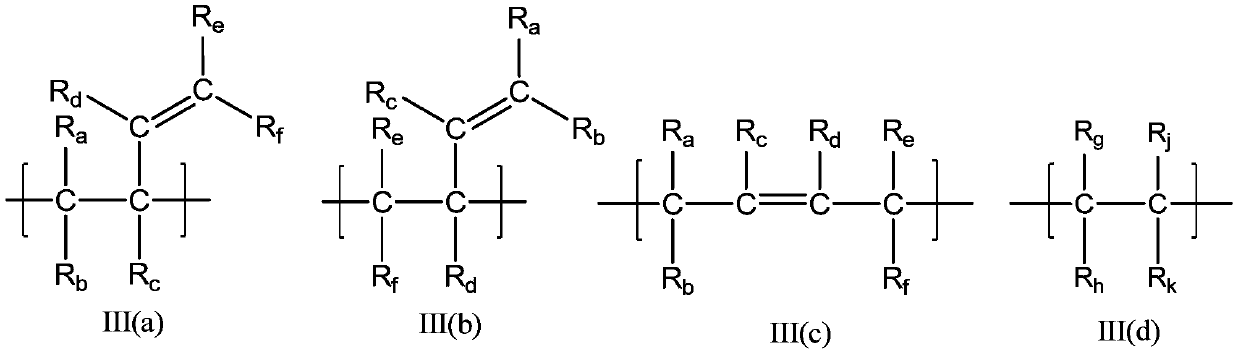

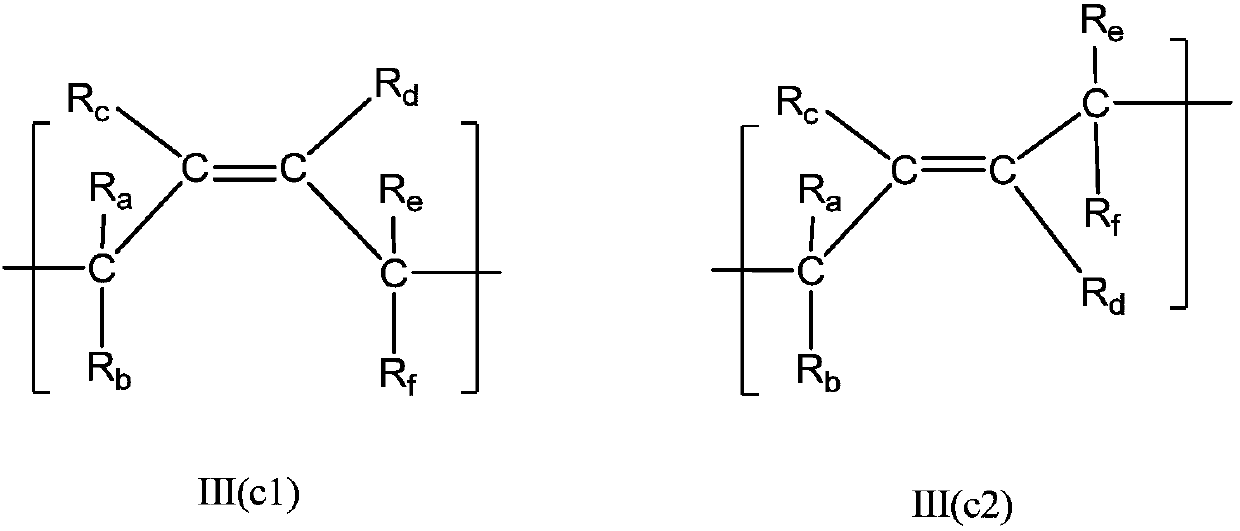

InactiveCN101081969AFlexibleModerate bond strengthNon-macromolecular adhesive additivesConjugated diene hydrocarbon adhesivesEnd-groupElectromagnetic shielding

The present invention relates to conductive adhesive, and is especially one kind of conductive adhesive for adhering electromagnetic shielding material. The conductive adhesive has polybutadiene liquid rubber containing active end group as the base material, silver coated powder as the conductive stuffing and other assistants. Having low resistivity, moderate adhesion strength, certain elasticity and cold resistance, and low cost, the conductive adhesive may be applied widely in adhering electromagnetic shielding material, especially of great adhered area.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

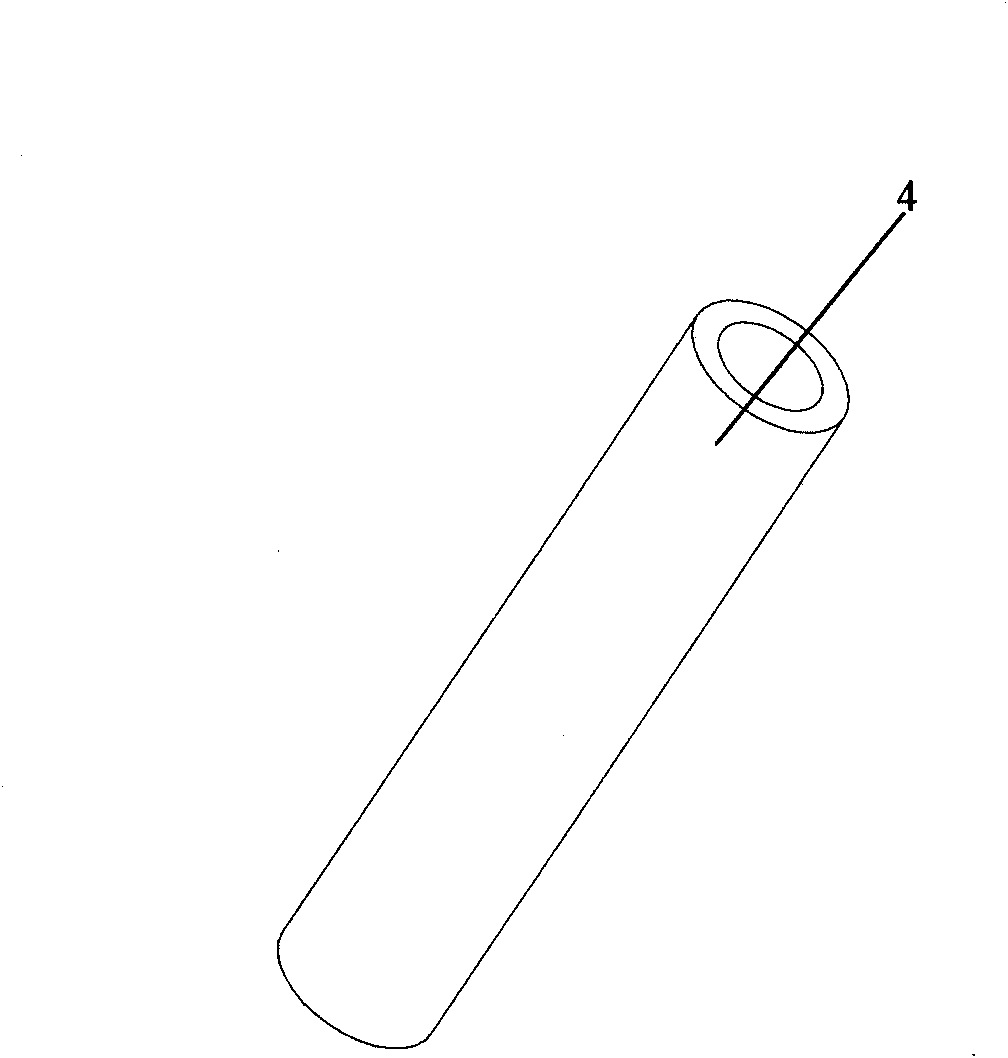

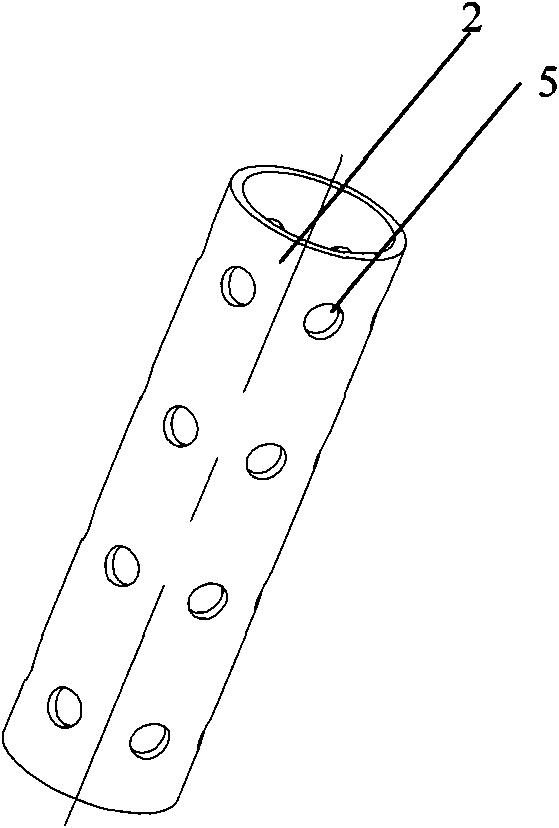

Oxygen supply sizing agent groove system and ceramic surface exposure 3D continuous printing method

ActiveCN105034138AUniform air pressureAvoid bondingAdditive manufacturing apparatusCeramic shaping apparatusBonding problemsSizing

The invention discloses an oxygen supply sizing agent groove system and a ceramic surface exposure 3D continuous printing method. The oxygen supply sizing agent groove system comprises an oxygen supply device, a base plate, a connecting pipe, an air-permeable thin film and a sizing agent groove which is of a cylindrical structure; an annular protrusion is horizontally arranged on the inner wall of the sizing agent groove, the upper surface of an annular groove is covered with the air-permeable thin film, the annular groove is formed in the lower surface of the annular protrusion, the base plate is fixed to the bottom of the sizing agent groove, an annular seal structure is defined by the annular groove and the base plate, and a seal chamber is defined by the base plate, the annular protrusion and the air-permeable thin film; multiple through holes are evenly formed in the side wall of the annular protrusion, the annular seal structure is communicated with the seal chamber through the through holes, one end of the connecting pipe is connected with the oxygen supply device, and the other end of the connecting pipe passes through the wall surface of the sizing agent groove and the side face of the annular groove and is inserted into the annual seal structure. By means of the oxygen supply sizing agent groove system, the bonding problem of ceramic biscuits and base plates can be effectively solved, and thereby the continuous ceramic printing is achieved.

Owner:陕西科陶增材智造科技有限公司

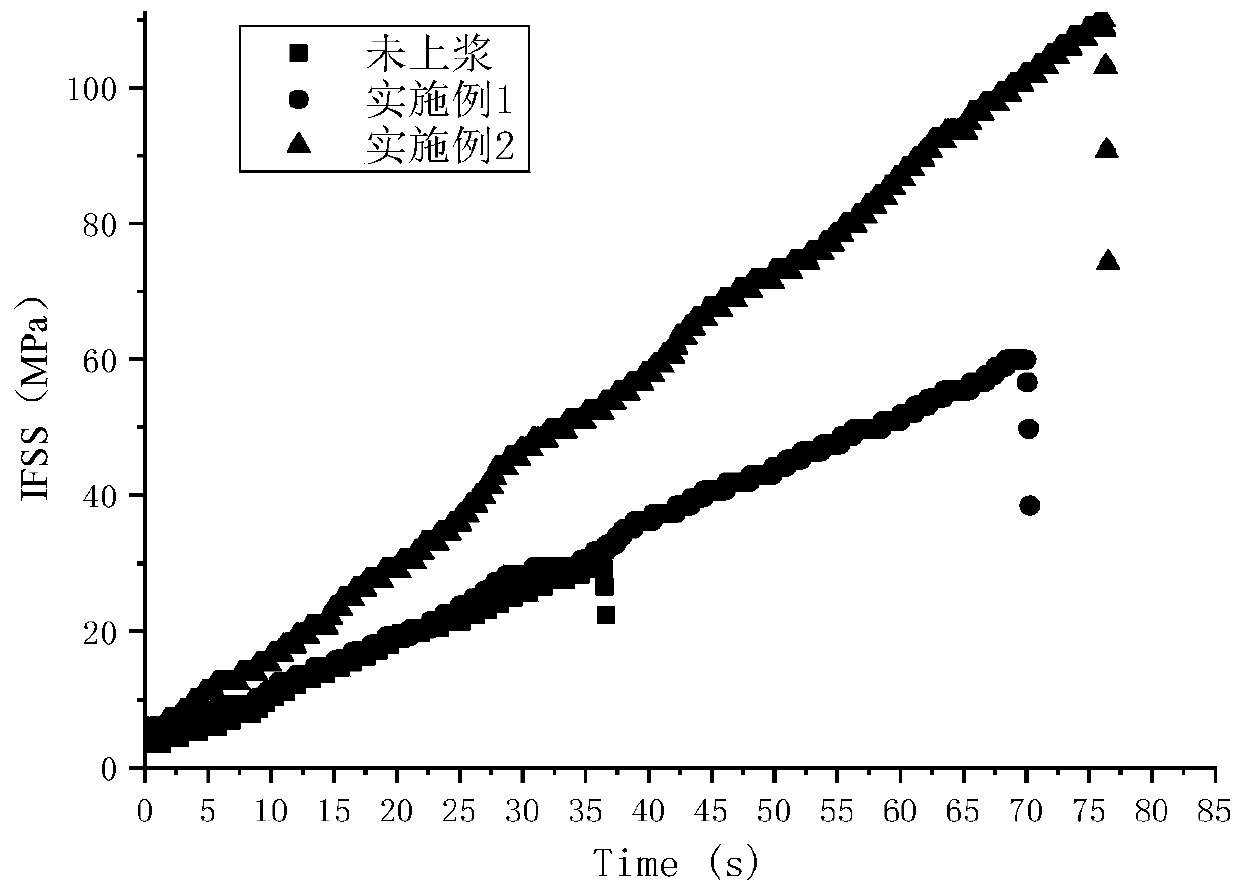

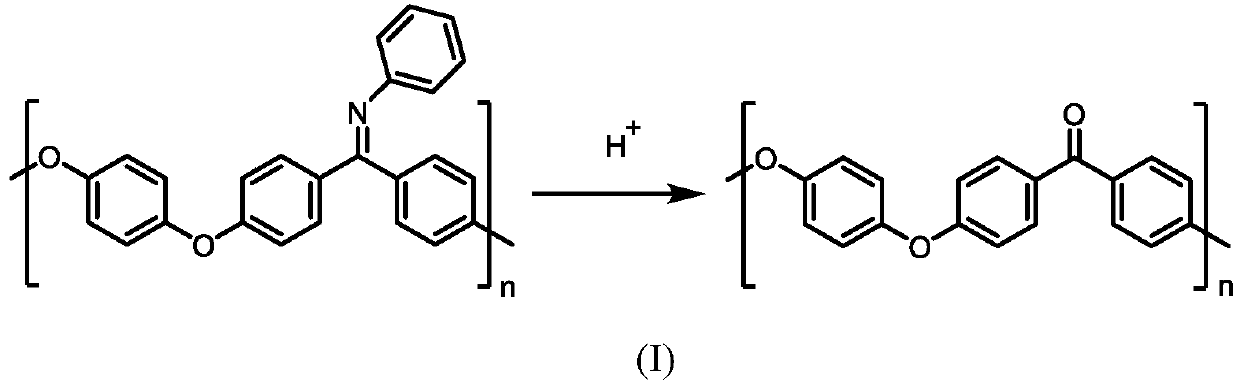

Method for performing surface modification on reinforcing fiber by using crystalline polyaryletherketone sizing agent

ActiveCN110924162AUniform sizingReduce energy consumptionCarbon fibresSurface modificationOrganosolv

The invention discloses a method for performing surface modification on a reinforcing fiber by using a crystalline polyaryletherketone sizing agent, and belongs to the technical field of reinforcing fiber surface treatment. A soluble polyaryletherketone precursor is configured as a solution, an interface reinforcing filler is added under the ultrasonic oscillation condition to prepare the solublepolyaryletherketone sizing agent, and the soluble polyaryletherketone sizing agent is placed in a sizing tank; after the sizing agent is used for sizing the reinforcing fiber, a solvent is dried by evaporation to enable the soluble polyarylether precursor to be uniformly adhered to the surface of the reinforcing fiber, and then the precursor on the surface of the reinforcing fiber generates a hydrolysis reaction under the acidic condition and is converted into polyaryletherketone with the crystallinity, the heat resistance and the insolubility in the organic solvent; and finally, water is evaporated to obtain the reinforcing fiber modified by the crystalline polyaryletherketone sizing agent. When the modified reinforcing fiber is used for reinforcing PEEK resin, the interfacial shear strength (IFSS) of a composite material is remarkably improved (267%) compared with an unsized carbon fiber, and the modified reinforcing fiber is solvent-resistant and can be used at the high temperature.

Owner:JILIN UNIV

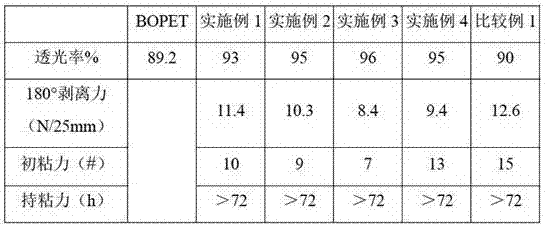

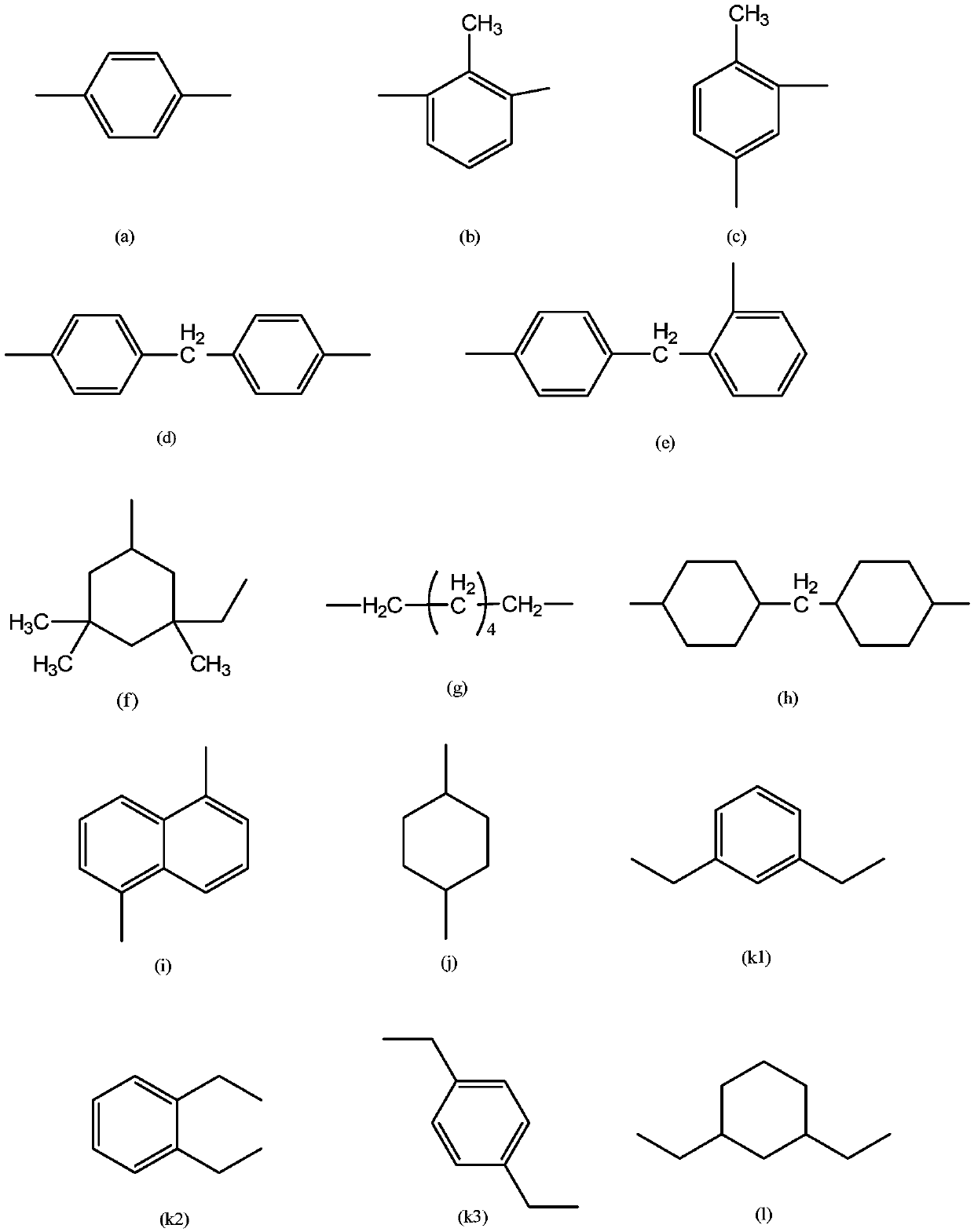

High-transparency acrylic acid pressure-sensitive adhesive and preparation method thereof

InactiveCN107057612AHigh refractive indexHigh light transmittanceEster polymer adhesivesFunctional monomerSolvent

The invention discloses a high-transparency acrylic acid pressure-sensitive adhesive. The acrylic acid pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 0-30 parts of cohesion monomers, 50-75 parts of adhesive monomers, 1-10 parts of functional monomers, 5-10 parts of o-phenylphenoxyethyl acrylate, 0.3-0.8 part of an initiator, 100-150 parts of a solvent and 0.1wt%-0.5wt% of a curing agent. The high-transparency acrylic acid pressure-sensitive adhesive provided by the invention has very high permeability (transparency being more than or equal to 93%), an adhesive remaining phenomenon does not occur in normal use and processing processes, the adhesive force is strong, the release force is high, and phenomena of adhesive failure and damaging of an adhesive layer and an interface do not occur in the use process, so that the adhesion problem in the fields of aerospace, electrons, electrical engineering and optical devices such as LCDs, PDPs and OLEDs is well solved.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

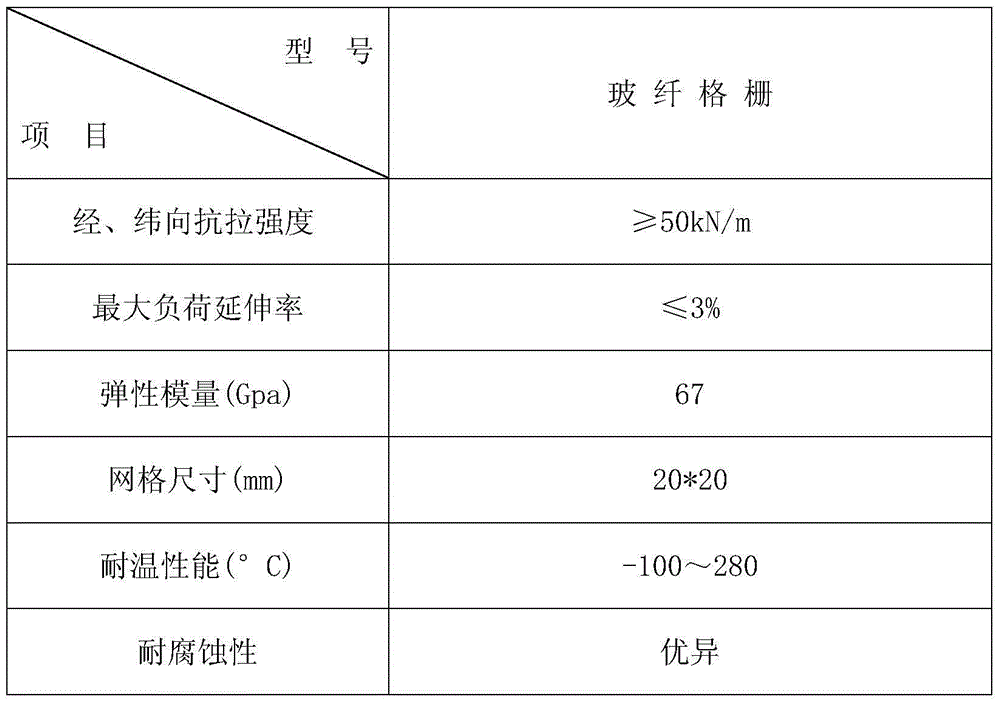

Construction method for reconstruction of old cement pavement into asphalt concrete pavement

InactiveCN104831598AExtended service lifeImprove the immunityIn situ pavingsPaving detailsSocial benefitsSurface layer

The invention discloses a construction method for reconstruction of an old cement pavement into an asphalt concrete pavement, the steps are as follows: 1, pouring seams of the to-be-reconstructed old cement pavement, 2, judging the damage degree of the to-be-reconstructed old cement pavement, and processing damages; 3, spraying hot rubber asphalt on the damage-processed pavement, spreading an aggregate on the hot rubber asphalt, and rolling to embed the spread aggregate into an asphalt film to form a stress absorption and seepage prevention rubber asphalt stress absorbing layer; 4, paving a grating net sheet on the rubber asphalt stress absorbing layer, and fixing; and, paving an asphalt concrete surface layer on the grating net sheet, wherein the asphalt concrete surface layer is paved in two times. The maintenance cost is greatly reduced, the highway overhaul time is greatly extended, the pavement service life is prolonged more than 1 time, and good economic and social benefits are received. In the rubber asphalt production process, tire waste is used, energy is saved, and the construction method is conducive to environmental protection.

Owner:成军

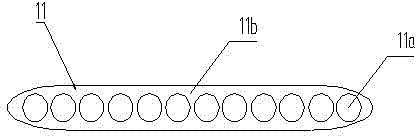

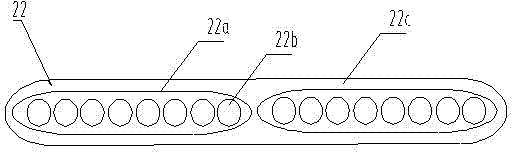

Optical fiber bundle and manufacturing method thereof

InactiveCN102393547ASolve bonding problemsFacilitate strippingBundled fibre light guideIsolation layerEngineering

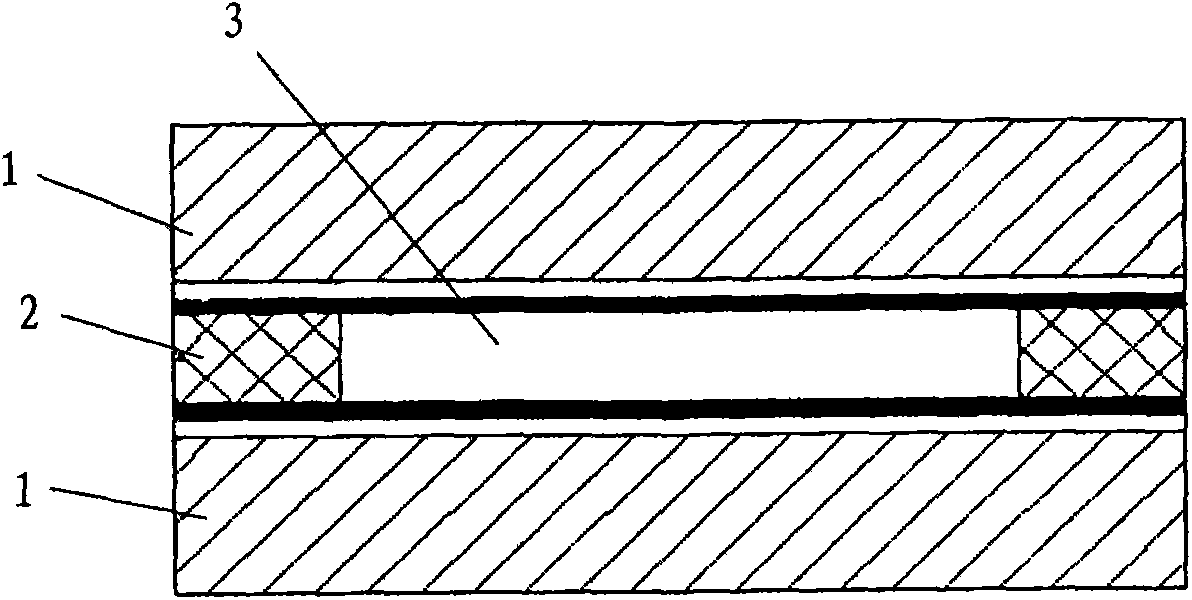

The invention relates to the technical filed of optical fiber, and particularly relates to an optical fiber bundle and a manufacturing method thereof. The UV (Ultraviolet) optical fiber bundle comprises a plurality of optical fiber ribbons, each optical fiber ribbon is provided with an isolation layer on the outer surface along the ribbon length, the plurality of optical fiber ribbons with isolation layers are stacked and consolidated by UV (Ultraviolet) resin integrally. 2 to 12 optical fiber ribbons are stacked into 2 to 12 layers. The optical fiber ribbons are wrapped. A plurality of stacked optical fiber ribbons are consolidated as optical fiber bundles with circular or rectangular cross sections by UV resin; the diameter of the optical fiber bundle with a circular cross section is 3000 to 3050mu m, the long side of the optical fiber bundle with a rectangular cross section is 2150 to 2200mu m long. The optical fiber bundle contains 2 to 8 optical fiber ribbons which are stacked in parallel, and each optical fiber ribbon contains 8 optical fibers tiled horizontally and in parallel. The optical fiber bundle is manufactured by stacking and placing the optical fiber ribbons in parallel, thus overcoming the technical prejudice in prior art that the optical fiber ribbons in the optical fiber bundle cannot be stacked and placed in parallel and meeting the requirement of people on optical cables with a large number of cores, the processing technology is simple and the processing quality is stable.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

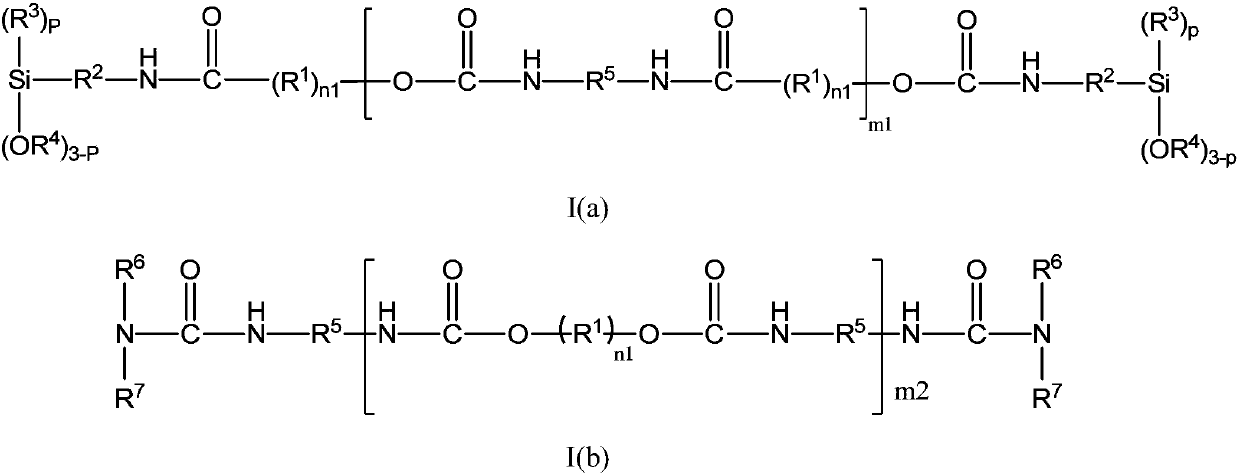

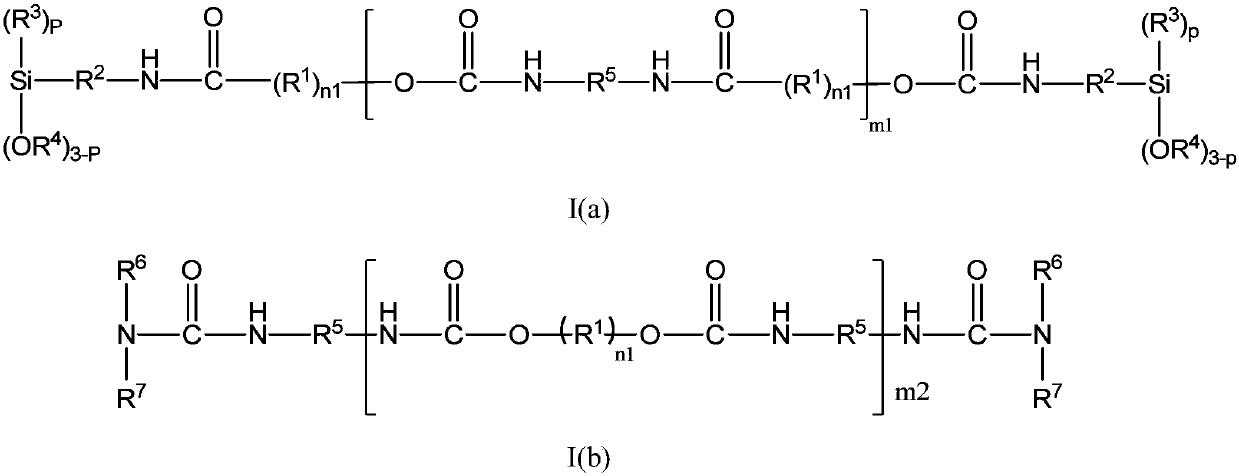

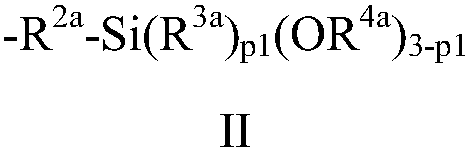

Primer for silane modified building sealant

ActiveCN111117376AExcellent adhesive compatibilityEffective blockingRubber derivative coatingsPolyether coatingsEndcappingPolymer science

The present invention relates to a primer composition. which comprises: 100 parts by mass of an alkoxy-modified polymer (A) having a P1-[(CR<1>2)a-Si(OR<2>)bR<3>(3-b)]c structure, 10 to 250 parts by mass of a cross-linking agent (B) containing more than three alkoxy silicon groups, 5 to 80 parts by mass of a silane coupling agent C comprising at least more than 1 part by mass of a nitrogen-containing organosilane coupling agent (C<1>) having a ZkSiR<23>1(OR<24>)mO(4-k-l-m) / 2 unit, 0 to 10 parts by mass of a catalyst (D), and a solvent (E) in an amount satisfying m(E) / m (primer) of 0.5 to 0.9.The primer composition can be used for pretreating a porous base material bonded by a silane-modified building sealant, is hydrolyzed and cross-linked in the presence of moisture after being applied,has excellent hydrolysis resistance and sealant precipitate erosion resistance after being cured, and can be suitable for most of silane modified sealants sold in the market, such as modified silicone(MS), silane terminated polyurethane (SPU), silane terminated polyether (STPE) and the like.

Owner:娄从江

Novel metal diffusion bonding technology

ActiveCN103337464AGuaranteed uniformityImprove bonding abilitySemiconductor/solid-state device manufacturingWorking temperatureHigh pressure

The invention discloses a novel metal diffusion bonding technology. Main steps comprises steps that: two parts on which a bonding metal layer is deposited are packaged in a vacuum sealing soft bag, the vacuum sealing soft bag is then put in a container filled with liquid, the container is connected with a pressure device, pressure generated by the pressure device is exerted on a part needing bonding through the liquid in the container and the vacuum sealing soft bag, temperature rising is further realized simultaneously, so metal diffusion bonding is realized under effects of the temperature and the pressure. The novel metal diffusion bonding technology can guarantee uniform bonding pressure in each direction and does not easily cause rupture damage to a crimping material even under high pressure intensity, so a bonding effect is improved. The exerted pressure is great, so reliable bonding can further be realized even under lower temperature, lowest work temperature can be 80 DEG C, moreover, the novel metal diffusion bonding technology can reduce requirements for technology clamps and physical dimensions of bonding materials.

Owner:CETC CHIPS TECH GRP CO LTD

Method and device for welding PTFE (Polytetrafluoroethylene) plates

ActiveCN102873860ASolve bonding problemsPhysical and mechanical properties are not lowButt jointEngineering

The invention provides a method and a device for welding PTFE plates. The weld strength and the elongation at break of the welded PTFE plates are not less than 80% of the physical mechanical property of an original plate. The method comprises the following steps: two PTFE plates are in butt joint with each other, and butt-joint areas are heated so as to be melted, then are cooled, and are pressed when being heated, and melts in heating areas can freely flow in the direction vertical to butt-joint seams and parallel to the PTFE plates under the condition of bearing pressure. The device comprises a fixing device used for fixing one PTFE plate, a heating device used for heating the butt-joint areas, a clamping device used for clamping the other PTFE plate, and a pressing device including ropes and pulleys; the ropes are used for hanging balance weights, and are connected with the clamping device through the pulleys; and the balance weights enable the clamped PTFE plate to tightly press the other fixed one in the direction vertical to the butt-joint seams and parallel to the PTFE plates.

Owner:NANJING COMPTECH COMPOSITES CORP

Preparation process of carbon/ceramic-graphite composite material and carbon/ceramic-graphite composite material prepared through preparation process

ActiveCN104139572AHigh thermal conductivityHigh strengthCeramic layered productsAdhesiveWear resistance

The invention discloses a preparation process of a carbon / ceramic-graphite composite material and the carbon / ceramic-graphite composite material prepared through the preparation process. The carbon / ceramic-graphite composite material is characterized in that a coupling layer and a carbon / ceramic material reinforced layer are sequentially bonded to a graphite base body through high-temperature adhesives, wherein the thickness of the carbon / ceramic material reinforced layer ranges from 1.5 mm to 2.5 mm. The carbon / ceramic-graphite composite material has high thermal conductivity (150 W / m.k) and excellent strength, wear resistance and corrosion resistance, and is especially applicable to manufacturing of continuous casting crystallizers.

Owner:YANTAI KAIBO COMPOSITE MATERIAL TECH

A brick unloading and palletizing unit for sintered bricks and a brick unloading and palletizing method

ActiveCN103552832BSolve bonding problemsReduce labor intensityStacking articlesDe-stacking articlesBrickPalletizer

A brick unloading and stacking unit and a brick unloading stacking method for sintered bricks, which are provided with a brick unloading machine for unloading the sintered bricks from the kiln car layer by layer and a pushing mechanism for horizontally gathering the bricks, followed by The connected first roller conveying platform is equipped with a device for aligning bricks longitudinally. A transfer device is provided above the roller conveying platform for conveying the grouped bricks forward in a direction perpendicular to the conveying direction of the first roller conveying platform, and a brick collecting platform is provided at the end of the second roller conveying platform. Above the brick platform, there is a palletizer for clamping and stacking the bricks on the brick collecting platform. The invention realizes the fully mechanized process from unloading to stacking, and effectively overcomes the bonding problem caused by deformation of bricks after sintering, thereby meeting the requirements of automatic production and greatly reducing labor intensity and production cost of workers.

Owner:洛阳曜辰自动化科技有限公司

Method for preparing TZ-PSBSR soldering rubber blended waterproof coiled material

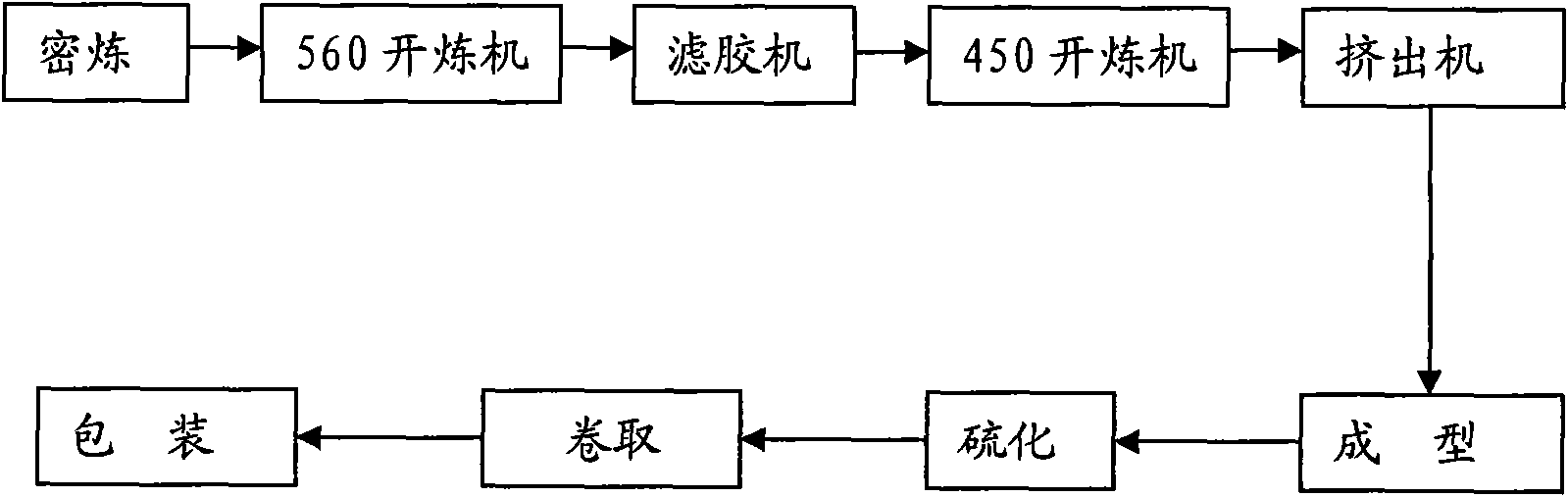

The invention discloses a method for preparing a TZ-PSBSR soldering rubber blended waterproof coiled material. The TZ-PSBSR soldering rubber blended waterproof coiled material consists of POE (7380), styrene-butadiene rubber (1502), SBS (1401), precipitated calcium carbonate, carbon black N330, DOP, sulfur, an age inhibiter RD, TMTD, and an age inhibiter 4010. The preparation method comprises the following steps: adding all raw materials in formula proportion into a banbury machine for banburying at a temperature of between 130 and 150 DEG C for 9min, evenly mixing the raw materials, and discharging; performing rubber reversing on a 560 mill mixer, reducing the temperature to less than or equal to 90 DEG C to discharge strips, filtering impurities by a rubber strainer, performing thinning and mixing on a 450 mill mixer, and discharging strips after even mixing; performing extrusion molding by an extruder, and vulcanizing the formed coiled material in a 20m continuous vulcanizing boiler at 160 DEG C and 0.3MPa; and finally rolling and packaging. The method solves the problem of adhesion of the rubber blended waterproof coiled material so as to make the rubber blended waterproof coiled material form an integral waterproof layer.

Owner:曹天志 +2

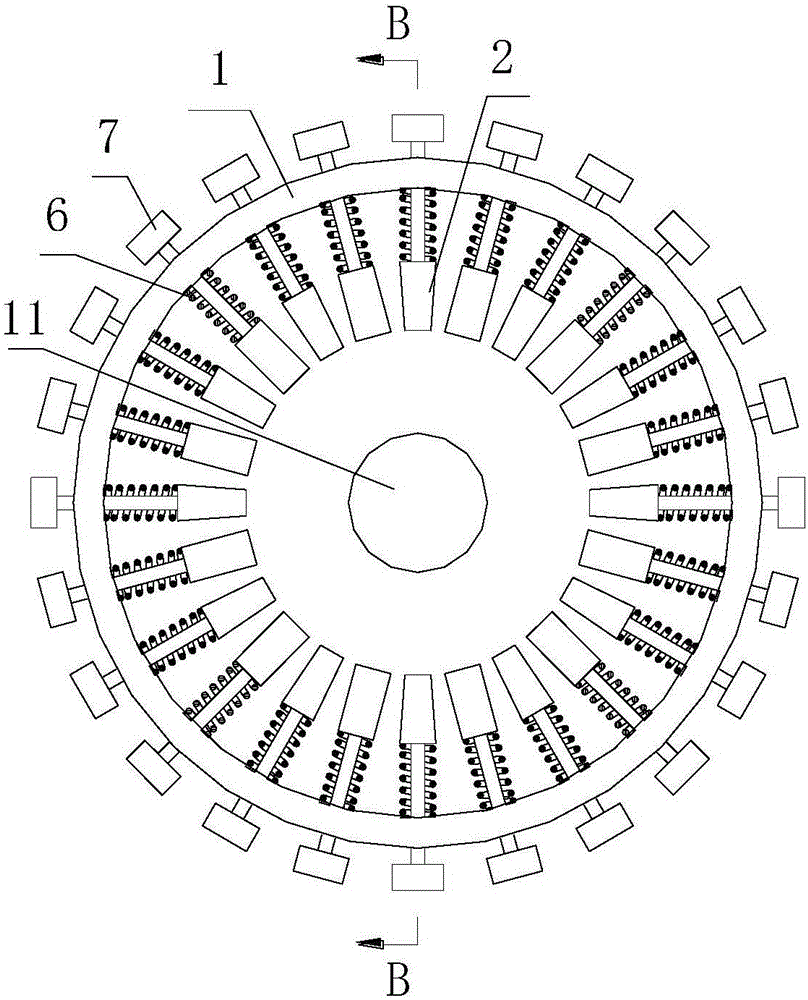

Rotor homopolarity magnetic steel bonding and positioning device

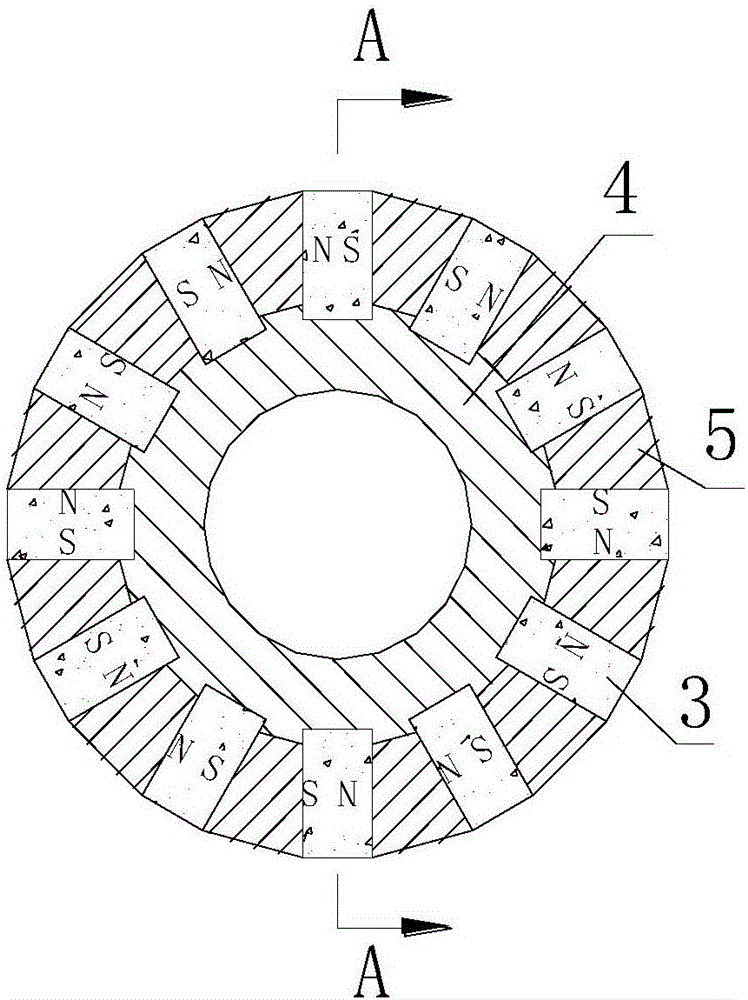

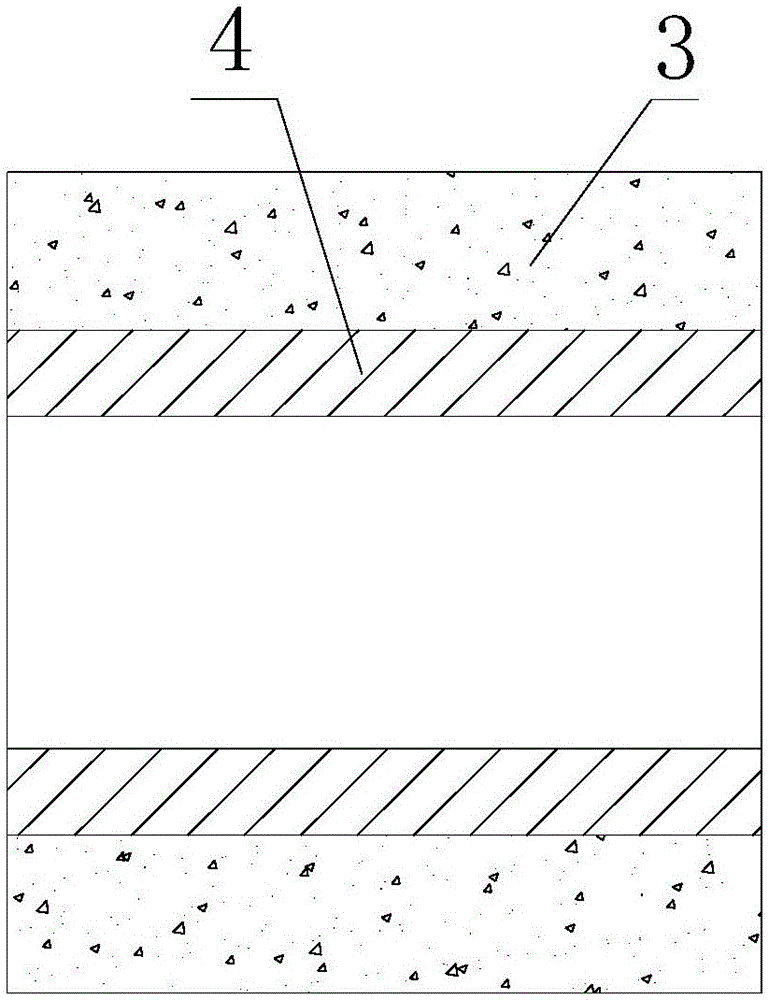

ActiveCN106130273ASolve bonding problemsQuick bondingManufacturing stator/rotor bodiesMechanical engineering

The invention discloses a rotor homopolarity magnetic steel bonding and positioning device. The device comprises a positioning sleeve and a plurality of elastic assemblies, wherein the plurality of elastic assemblies are uniformly arranged along a circumferential direction of the positioning sleeve, each elastic assembly comprises a screw, a tightening block and a spring, the tightening block is arranged at an inner side of the positioning sleeve and is connected with an end part of the screw, the spring sleeves the screw and is arranged between the tightening block and the positioning sleeve, a positioning boss is further arranged at the center of the positioning sleeve, the screw comprises a screw rod and a screw head, the screw rod and the screw head are connected by a square boss, a screw insertion hole is formed in the positioning sleeve and is used for installing the screw, and a square groove is formed above the screw insertion hole and is matched with the square boss. By the device, adjacent magnetic steels repellent to each other can be rapidly and reliably bonded, and the assembly speed and the assembly accuracy are obviously improved. The device is simple in structure, is easy to manufacture and rapid to operate, and can be widely promoted and applied in the technical field of rotor magnetic steel bonding.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

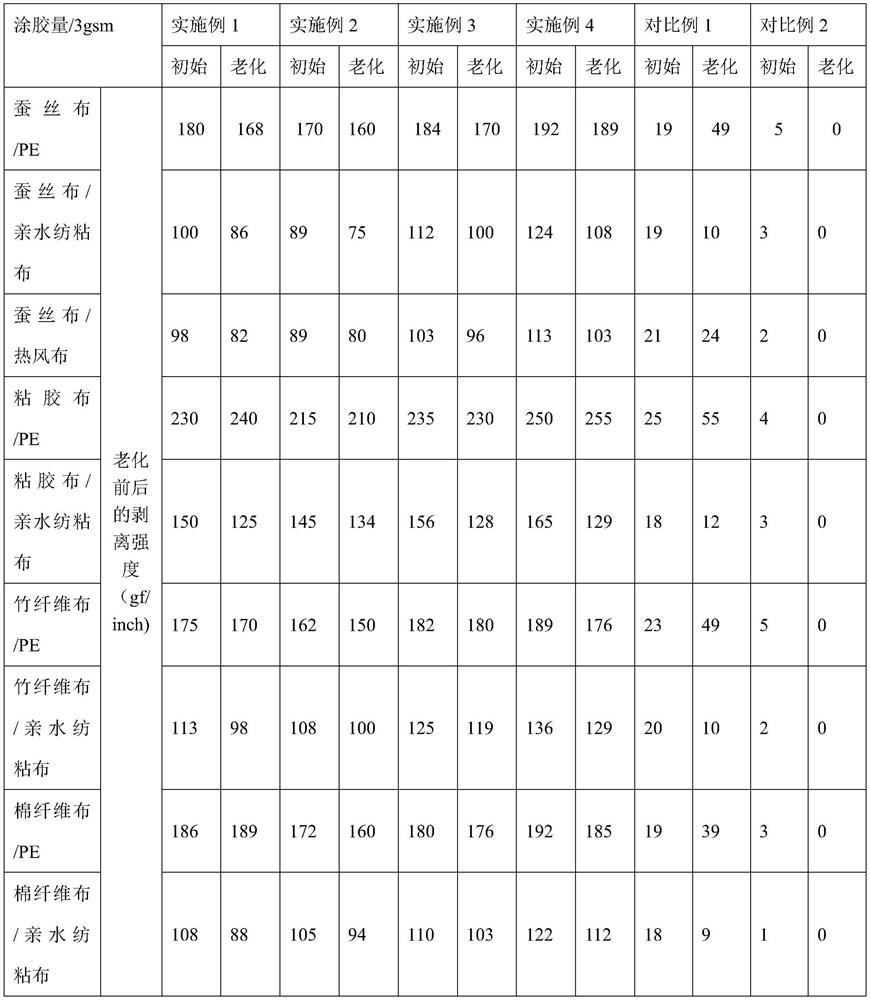

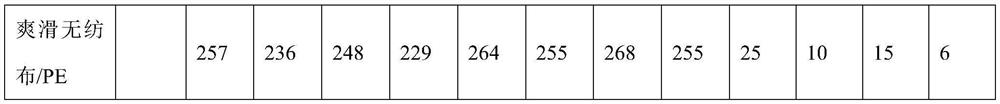

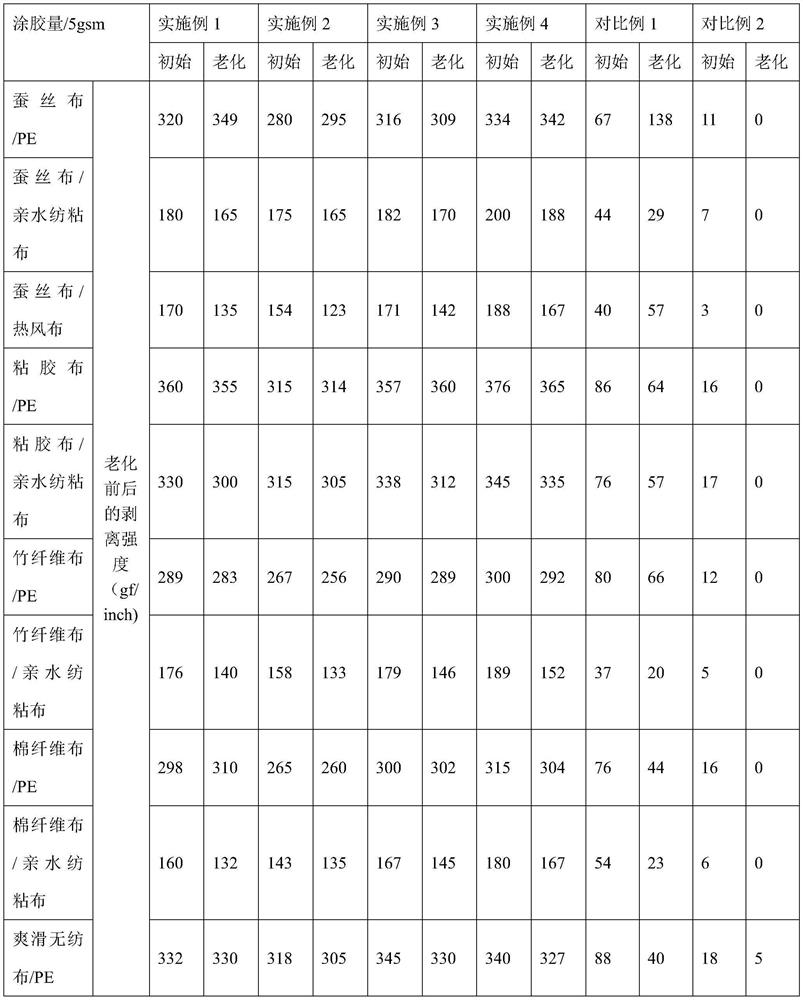

Hot melt adhesive for difficult-to-stick base material and preparation method thereof

ActiveCN111849397ASolve bonding problemsGood adhesionMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesElastomerPolymer science

The invention discloses a hot melt adhesive for a difficult-to-stick base material and a preparation method of the hot melt adhesive. The hot melt adhesive for the difficult-to-stick base material isprepared from the following components in parts by weight: 10 to 30 parts of naphthenic oil, 10 to 30 parts of styrene elastomer, 7 to 20 parts of solution polymerized styrene-butadiene rubber, 3 to 20 parts of polyolefin elastomer, 15 to 70 parts of tackifying resin, 0.35 to 3 parts of an antioxidant and 0.2 to 1 part of an ultraviolet light absorber. The hot melt adhesive disclosed by the invention can be used for well bonding difficult-to-adhere base materials so as to meet the adhesion requirements of different difficult-to-adhere fabrics, so manufacturers of sanitary material products such as paper diapers and sanitary towels can be provided with more options for high-quality fabrics, such as silk fabrics, hot through-air fabrics, smooth non-woven fabrics, cotton fiber fabrics, bamboofiber fabrics and viscose fabrics.

Owner:佛山南宝高盛高新材料有限公司

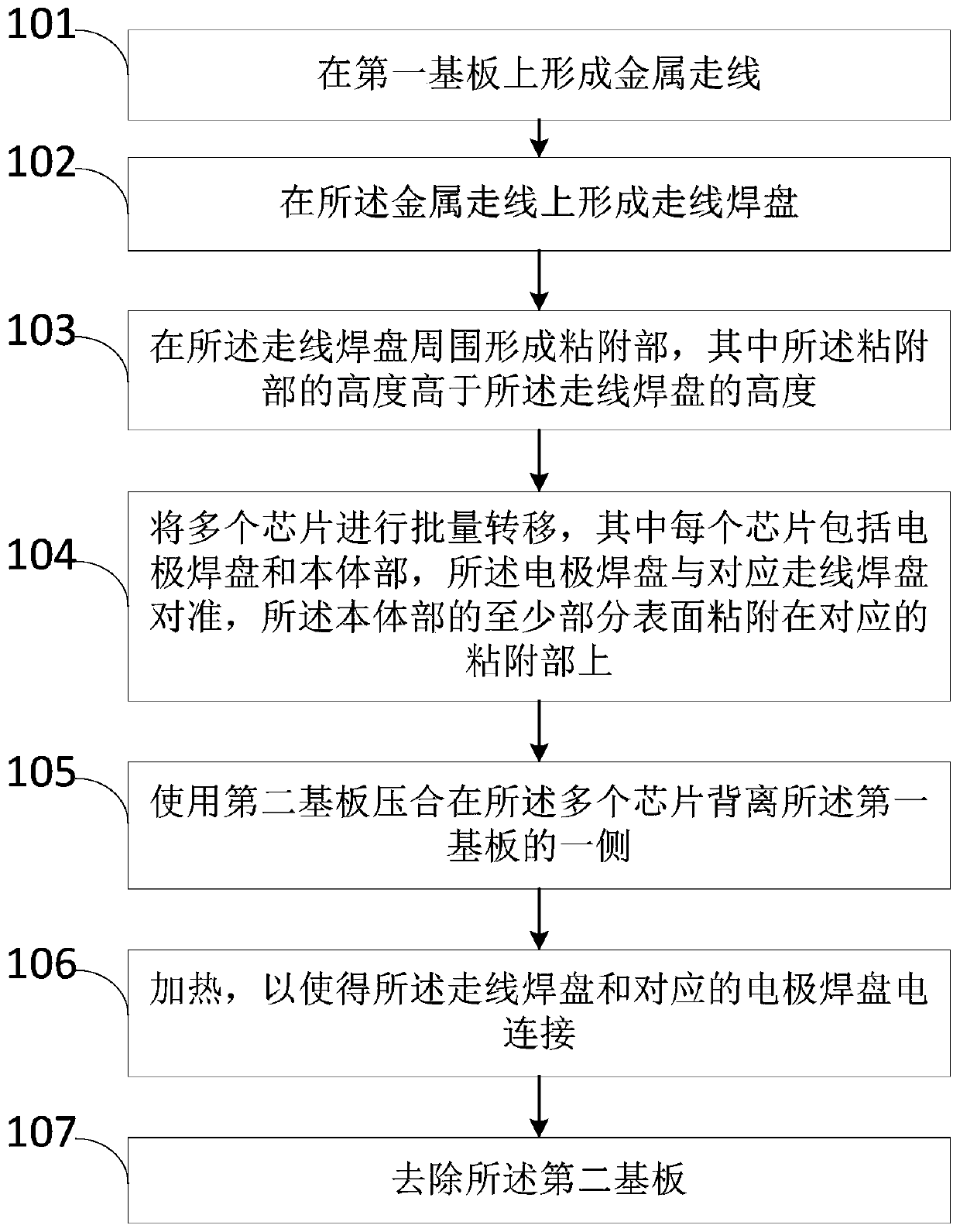

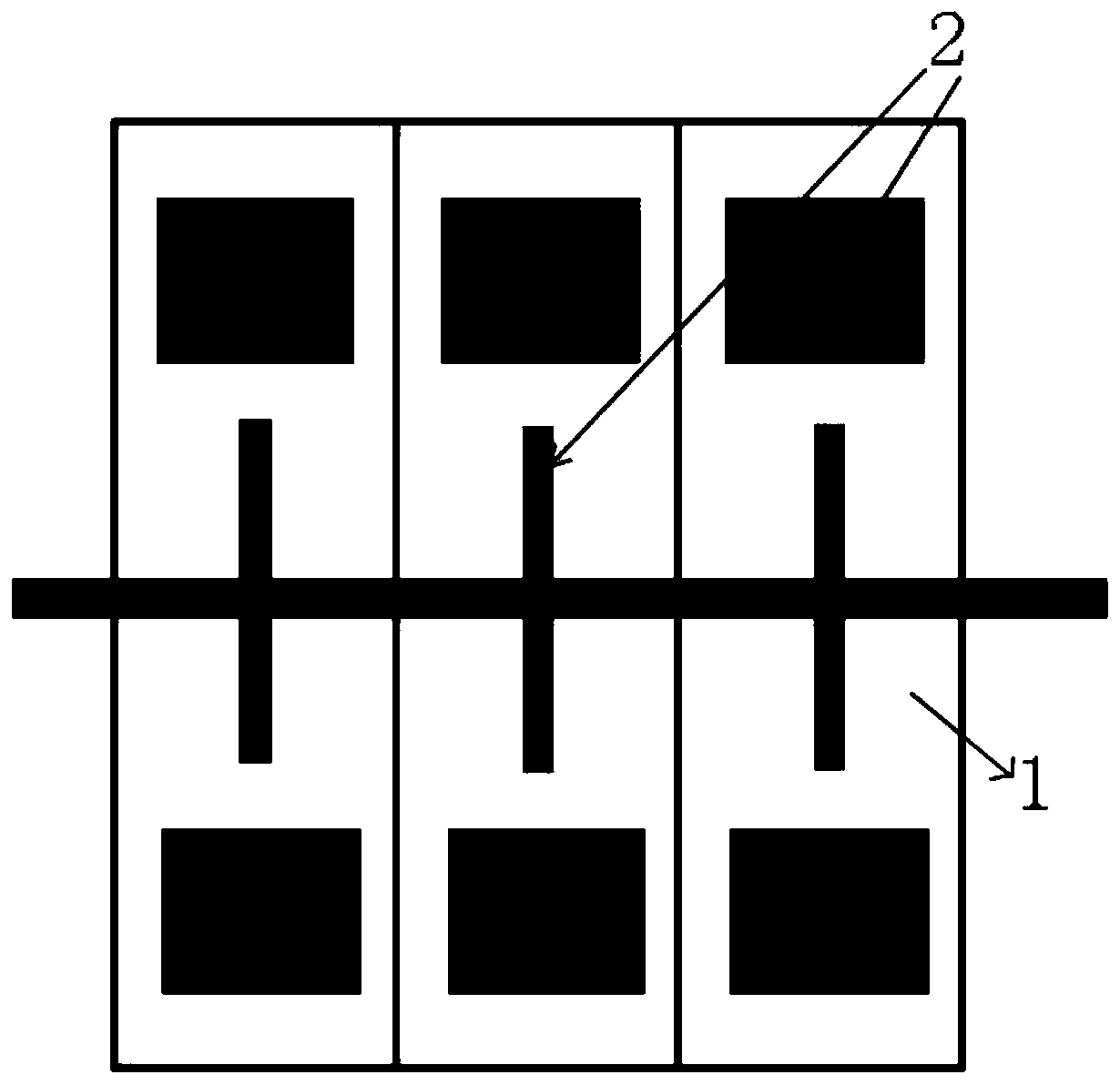

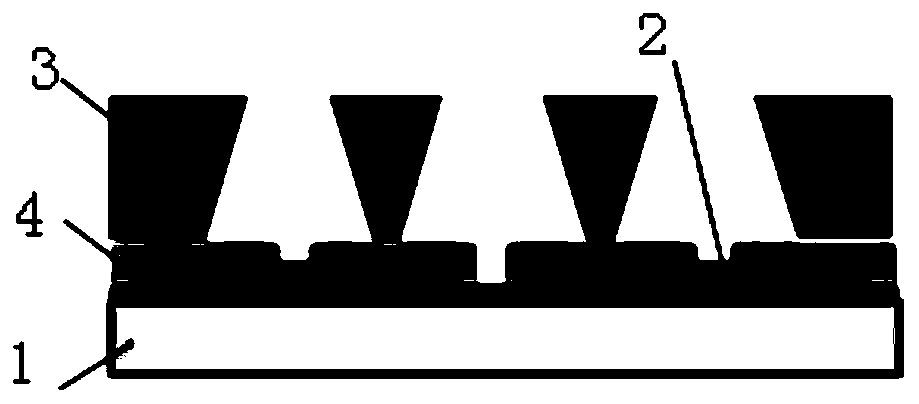

Chip transfer method and semiconductor device

ActiveCN110783254ALow costThe principle is clearSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialElectrical connection

The invention discloses a chip transfer method, which includes the following steps: forming a metal wire on a first substrate; forming a wire bonding pad on the metal wire; forming an adhesive portionaround the wire bonding pad, wherein the height of the adhesive portion is greater than the height of the wire bonding pad; transferring a plurality of chips in batches, wherein each chip includes anelectrode bonding pad and a body portion, the electrode bonding pad is aligned to the corresponding wire bonding pad, and at least a part of the surface of the body portion is attached to the corresponding adhesive portion; pressing a second substrate against the sides of the plurality of chips away from the first substrate; performing heating to electrically connect the wire bonding pad to the corresponding electrode bonding pad; and removing the second substrate. The method solves the bonding problem when the chips are transferred to the substrate, can not only reduce the technical threshold and cost of a transfer device, but also can improve the transfer yield without an increase in cost.

Owner:BOE TECH GRP CO LTD

Silane modified building sealant primer capable of quickly forming film and having high barrier property

ActiveCN111117489AExcellent adhesive compatibilityGood adhesionRubber derivative coatingsEndcappingPolymer science

The invention discloses a silane modified building sealant primer capable of quickly forming a film and having high barrier property. The silane modified building sealant primer comprises the following components in percentage by mass: 4-45% of a siloxane-based modified polymer (A), 3-30% of a primer cross-linking agent (B), 2-22% of a reactive film-forming resin (F), 0.5-10% of a silane couplingagent (C), 0.001-2% of a catalyst (D) and 10-90% of a solvent (E). The primer composition can be used for pretreating a porous base material bonded by a silane-modified building sealant, and is volatilized along with the solvent after application, the reactive film-forming resin (F) can quickly form a film on the surface of the base material, and the reactive group can be hydrolyzed and cross-linked with the alkoxy modified polymer (A) and the cross-linking agent (B) in the presence of a catalyst when meeting moisture, so that the silane modified building sealant primer has excellent barrier property and hole sealing property after being cured, and can be suitable for most of silane modified sealants sold in the market, such as modified silicone (MS), silane-terminated polyurethane (SPU),silane-terminated polyether (STPE) and the like.

Owner:娄从江

Conductive adhesive

InactiveCN109652005AGood adhesionImprove conductivityElectrically-conducting adhesivesOrganic solventAdhesive

The invention relates to a conductive adhesive. The conductive adhesive is prepared by: taking diethylene glycol and cyanate ester resin as the organic mixed solvent, incorporating silver powder A andB, then adding a dispersant and performing mixing. The silver powder A and B are obtained by: subjecting silver powder with purity of 99.95% to high-energy ball milling into micro-nanoscale silver powder, and then conducting sorting to obtain silver particles A with a diameter of 3-20microm and silver particles B with a diameter of less than or equal to 200nm. The conductive adhesive provided bythe invention has the advantages that: (1) diethylene glycol and cyanate ester resin are employed as the mixed solvent system to strengthen the bonding performance of thermoplastic resin, and endows small electronic components with sufficiently strong bonding force, thus expanding the application range; (2) the high content micro-nanoscale silver particles are cooperated with the similar three-dimensional chain-like path of the mixed solvent to enhance the high conductivity of the silver-based adhesive; (3) bonding as many electronic components as possible by one adhesive can be ensured in onepackaging chamber; and (4) the process is simple and is convenient for batch production. The conductive adhesive is suitable for bonding various integrated circuits.

Owner:GUIZHOU ZHENHUA FENGGUANG SEMICON

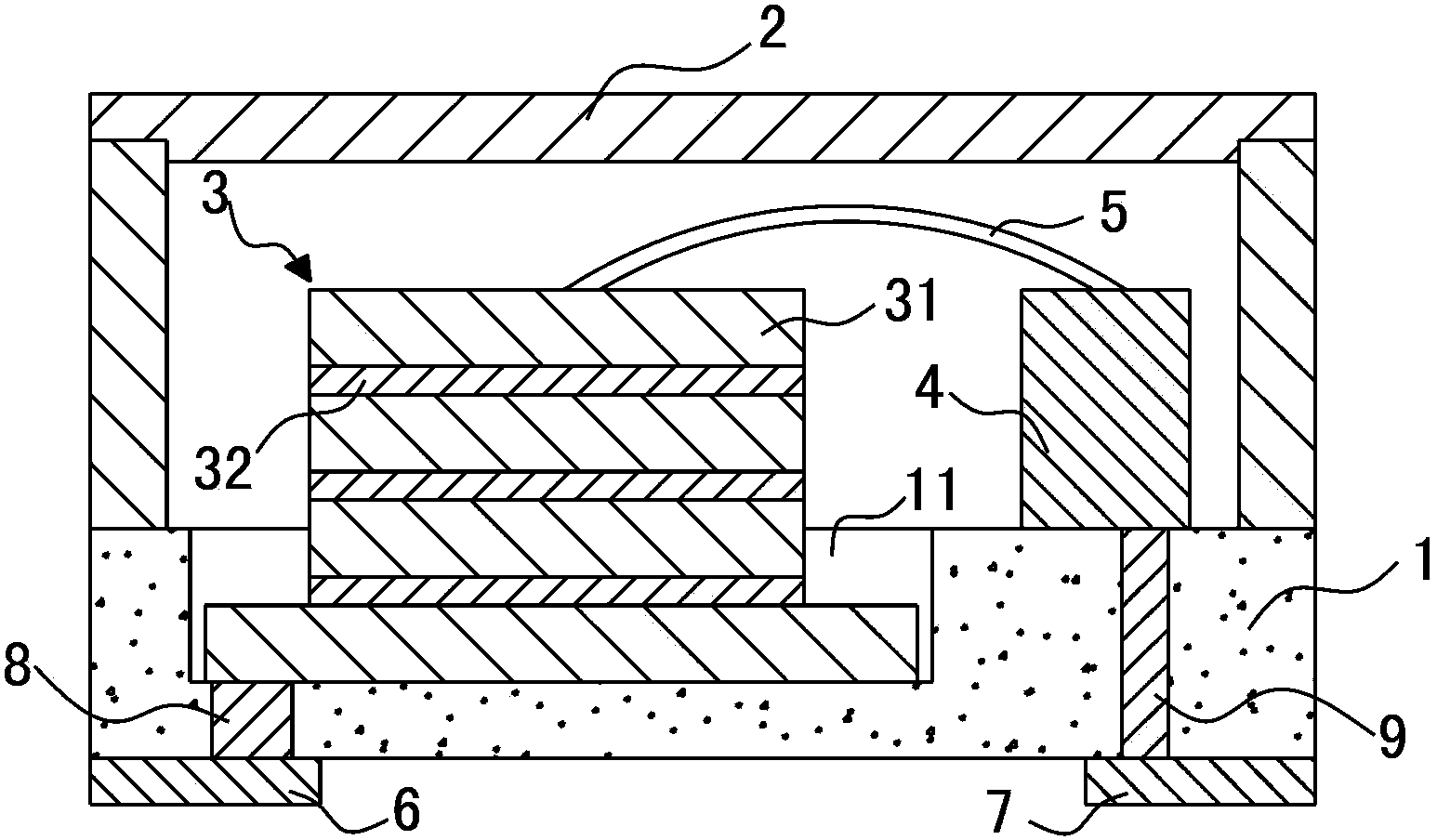

Diode packaging structure

ActiveCN104347556AFirmly connectedNot easy to shakeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

The invention relates to a semiconductor structure, and specifically relates to a diode packaging structure. The diode packaging structure comprises a substrate, a packaging body arranged at the upper end surface of the substrate, and a plurality of electrodes arranged at the lower end surface of the substrate. The upper end of the substrate is provided with a groove, the groove is internally provided with a tube core assembly, the upper end surface of the substrate is provided with a bonding block, the tube core assembly and the bonding block are connected through a lead wire, the packaging body and the substrate form a cavity, and the tube core assembly and the bonding block are arranged in the cavity. According to the invention, the problem of bonding between the tube core assembly and the electrodes is effectively solved, the connection between the tube core assembly and the bonding block is facilitated, the production process difficulty is lowered, the production efficiency is improved, the lead wire connecting the tube core assembly and the bonding block is not easily shaken and is not easily broken, and the quality of a manufactured product is enabled to be better. Besides, the diode packaging structure also has the advantages of good sealing performance, high heat dissipation performance and the like.

Owner:CHINA ZHENHUA GRP YONGGUANG ELECTRONICS CO LTD STATE OWNED NO 873 FACTORY

High-water-resistance primer for silane modified building sealant

ActiveCN111117410AExcellent adhesive compatibilityGood adhesionRubber derivative coatingsPriming paintsPolymer sciencePtru catalyst

The invention discloses a high-water-resistance primer for a silane modified building sealant, wherein the high-water-resistance primer comprises the following components in percentage by mass: 5-50%of an alkoxy modified polymer (A), 3-50% of a cross-linking agent (B), 0.5-10% of a silane coupling agent (C), 0-2% of a catalyst (D) and 10-90% of a solvent (E). According to the invention, the primer can be used for pretreating a porous base material bonded by a silane modified building sealant; and the primer is volatilized along with the solvent after being applied,, the primer is hydrolyzed and cross-linked by siloxane groups after curing in the presence of moisture, a film is formed on the bonding interface of the porous base material, the cured film-forming polymer contains a large number of non-polar main chain structures, the hydrolysis resistance is excellent, and the siloxane curing bonding point and the bonded sealant have excellent bonding compatibility, so that the bonding capability between the sealant and the base material can be improved, and the primer is suitable for most silane modified sealants sold in the market, such as modified silicone (MS), silane terminated polyurethane (SPU), silane terminated polyether (STPE) and the like.

Owner:娄从江

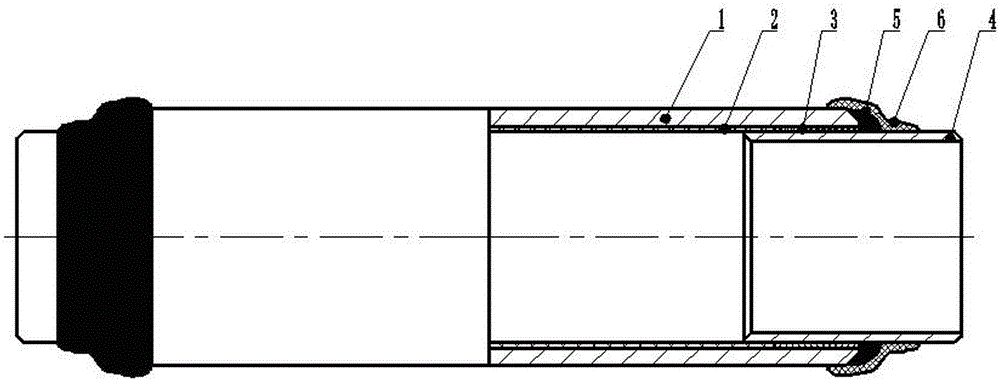

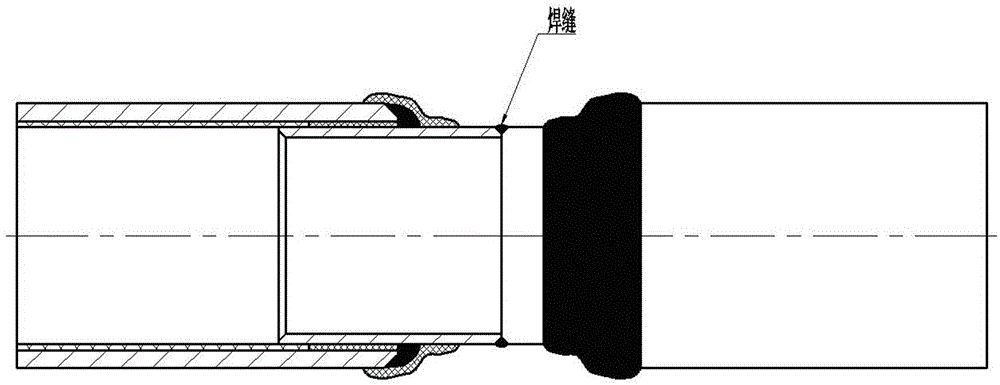

Method for manufacturing lining plastic pipe by using welded connection

ActiveCN105697896ASolve the problem of electrochemical corrosionSolve the defects of utility modelsCoatingsRigid pipesStructural ProblemEngineering

The present invention discloses a method for manufacturing lining plastic pipe by using welded connection. The method comprises the following steps: (1) stripping one section of the plastic anticorrosive coating of the lining plastic pipe port that has been subjected to lining plastic recombination, wherein the lining plastic pipe port being stripped the plastic anticorrosive coating is the connection end of the external steel pipe; (2) lining the inner wall of the connection end that is not lined with the plastic anticorrosive coating with a hot melt adhesive, wherein the hot melt adhesive is adhered to the inner wall of the connection end to form a hot melt adhesive layer; (3) inserting a stainless steel pipe into the external steel pipe from the connection end of the external steel pipe, wherein the outer wall of the stainless steel pipe is adhered with the hot melt adhesive layer; and (4) welding the outer wall of the stainless steel pipe and the port of the external steel pipe. The lining plastic pipe manufactured by this method can efficiently solve the problem of electrochemical corrosion after welding the dissimilar steel, solve the structural problem that the steel-plastic pipe cannot directly adopt welded connection, and expands the application of the stainless steel in steel-plastic pipe manufacture.

Owner:SICHUAN XIN YUAN TONG STEEL PLASTIC PIPE CO LTD

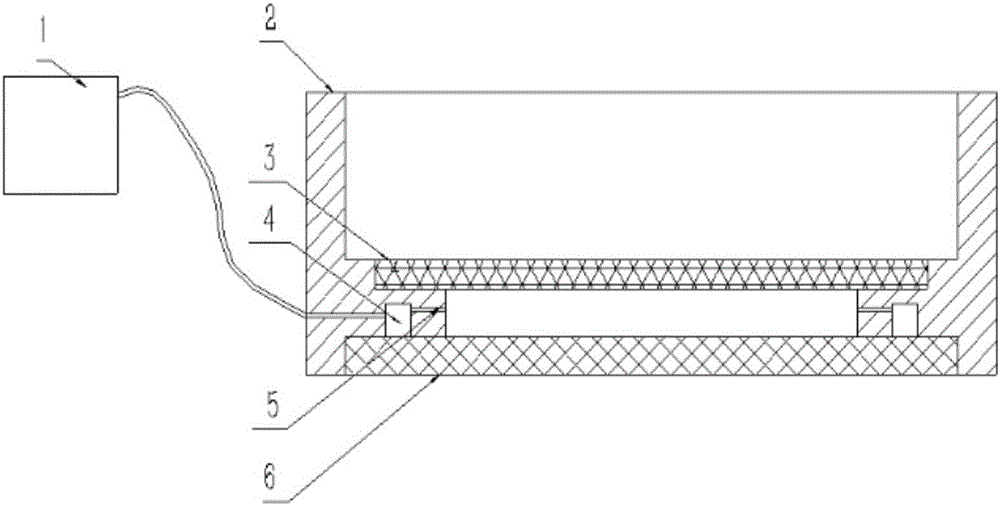

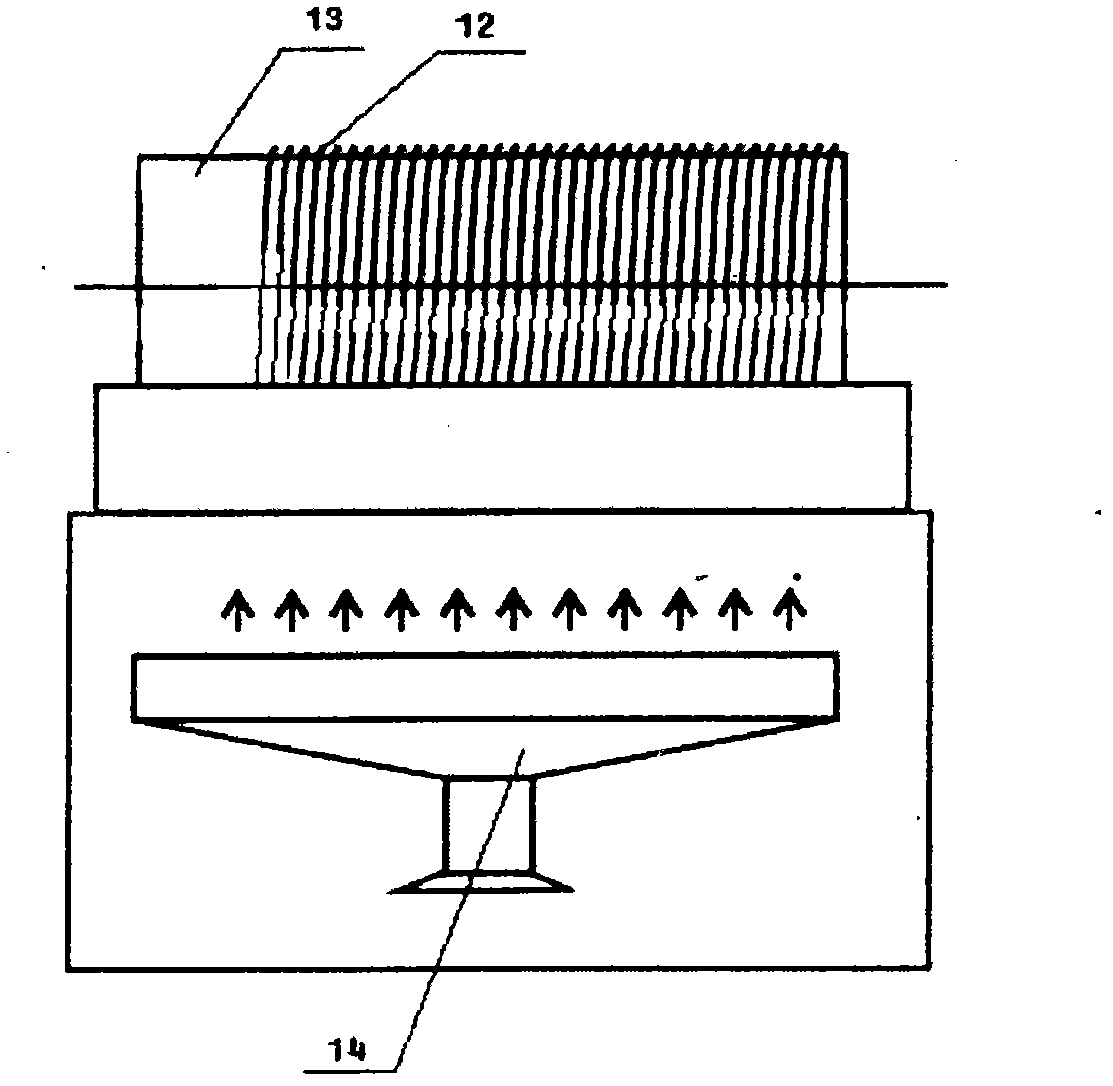

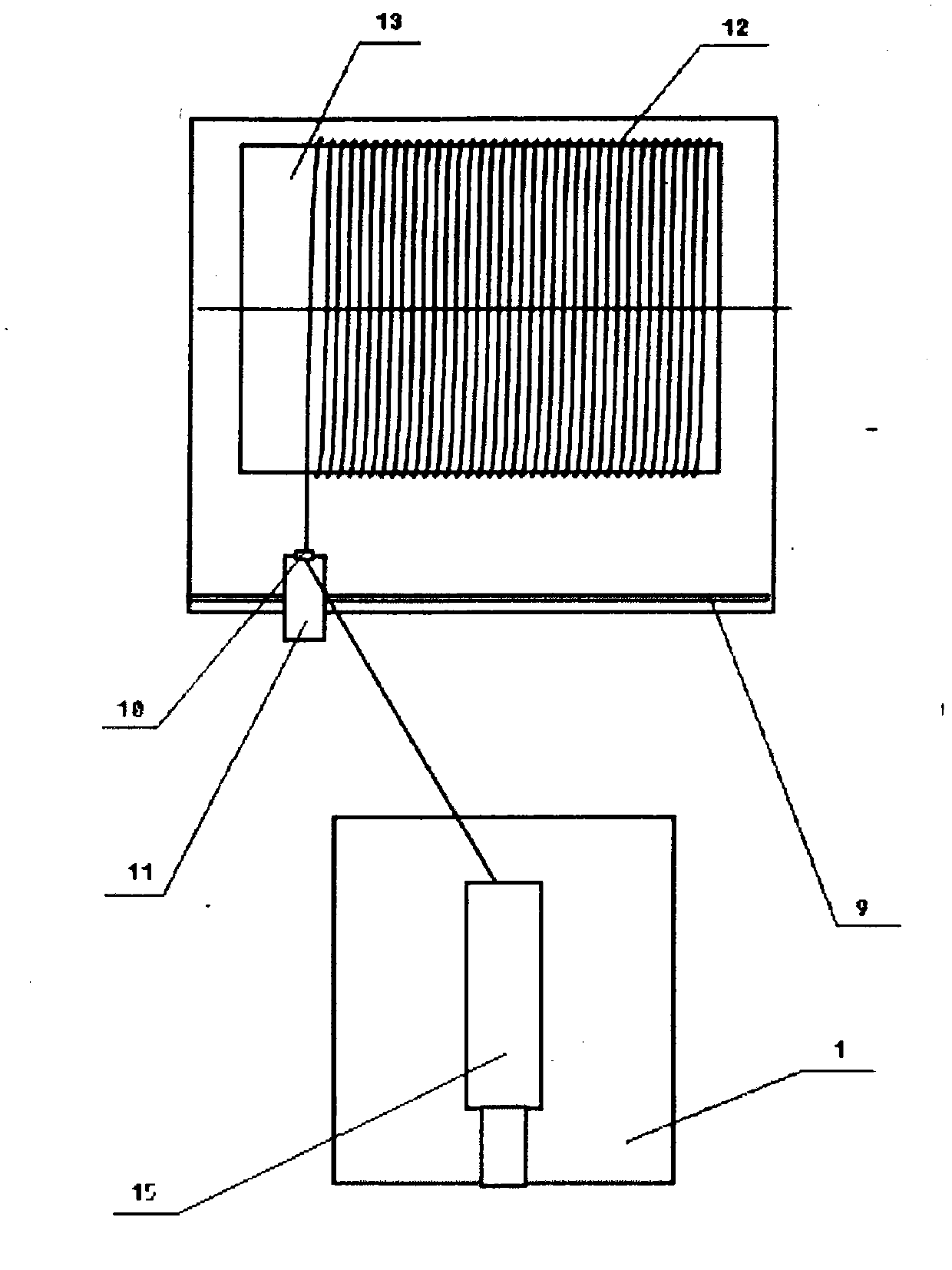

Small sample sizing machine

InactiveCN102605576ASolve bonding problemsLiquid/gas/vapor yarns/filaments treatmentYarnSmall sample

The invention discloses a small sample sizing machine and relates to the field of textile sizing production equipment, solving the problem that as a yarn is wound on a bobbin when not being fully dried after one yarn is sized by the small sample sizing machine, yarns among a plurality of layers are bonded after being wound on bobbins. A yarn guide device does reciprocating movement along a screw rod, so that the sized yarns are uniformly distributed and wound on round frames. Therefore, the small sample sizing machine is simple in structure and can enable the yarns among the plurality of layers after being sized to be not bonded.

Owner:FOSHAN NANHAI SOUTH TECH INNOVATION CENT

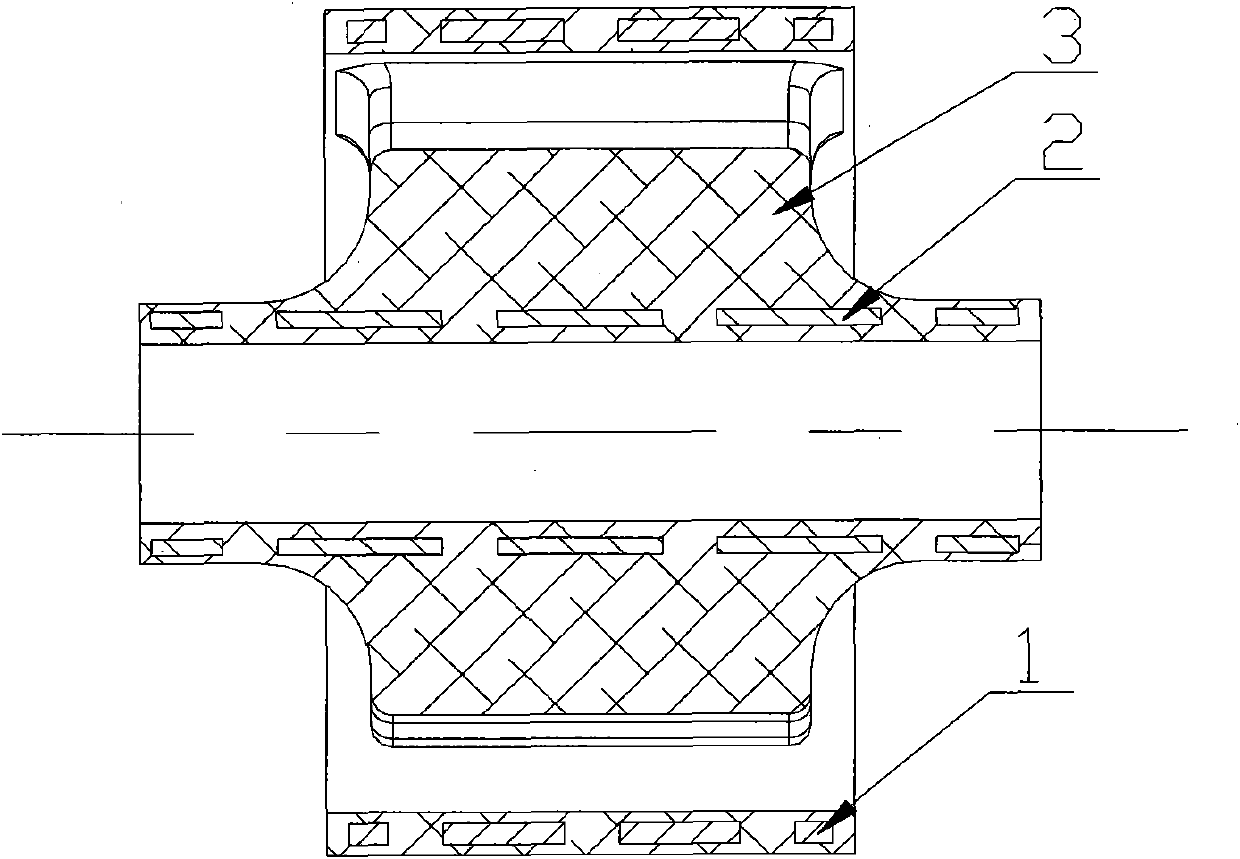

Injection molding suspension

InactiveCN101907146AOptimize the suspension structureSolve bonding problemsRubber-like material springsMetallurgyInjection moulding

The invention relates to an injection molding suspension, which is characterized in that: a thermoplastic elastomer, a metal outer liner tube and a metal inner liner tube are subjected to injection molding to form an injection molding body; and a metal inner tube is pressed into the metal inner liner tube to ensure interference fit between the metal inner tube and the metal inner liner tube, wherein the thermoplastic elastomer is positioned between the metal outer liner tube and the metal inner liner tube and is respectively connected with the metal outer liner tube and the metal inner liner tube; and through holes are uniformly distributed on the surfaces of the metal outer liner tube and the metal inner liner tube. By injection-molding the thermoplastic elastomer, the optimized suspension structure solves the problem of bonding TPV and metal pieces, the TPV replaces rubber, and the pollution of waste gas, waste water and dust to the environment in the suspension manufacturing process is reduced.

Owner:宁波添也汽车部件有限公司

A kind of halogen-free flame-retardant two-component polyurethane adhesive for rail passenger cars and its preparation method

ActiveCN104694068BImprove rigidityHigh strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +1

Two-component bonding nylon silica gel and preparation method thereof

InactiveCN108929650AGood adhesionStrong enoughNon-macromolecular adhesive additivesPlatinum complexHydrogen

The invention discloses a two-component bonding nylon silica gel, belonging to the technical field of silicone rubber materials. The two-component bonding nylon silica gel comprises, by weight, 100 parts of methyl vinyl rubber containing 0.25% by mol of vinyl groups, 30-80 parts of fumed silica, 3-6 parts of hydroxyl silicone oil, 3-6 parts of vinyl triethoxysilane, 2 to 4 parts of stearic acid 1801, 3 to 5 parts of a binder, 0.5 to 5 parts of hydrogen-containing silicone oil, 0.5 to 5 parts of an inhibitor and 0.5 to 5 parts of a platinum complex. The two-component a bonding nylon silica gelprepared in the invention has excellent bonding performance with nylon, sufficient strength and good processing properties, is not prone to deformation, and can fully meet the requirements of food tableware.

Owner:JIANGSU TIANCHEN NEW MATERIALS

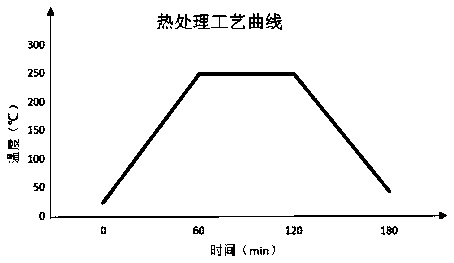

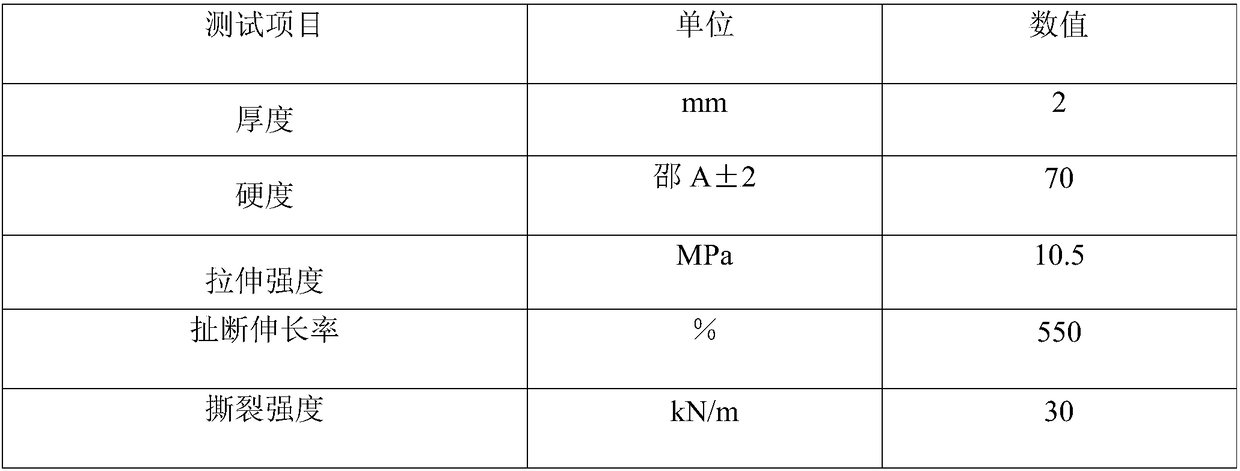

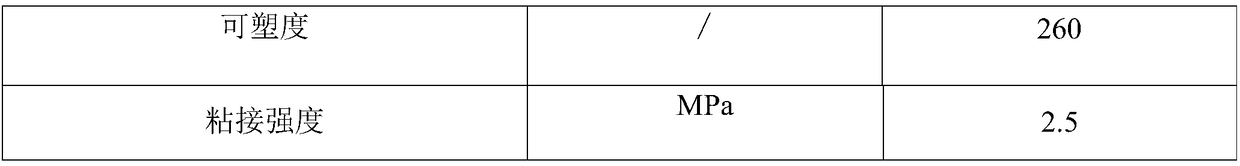

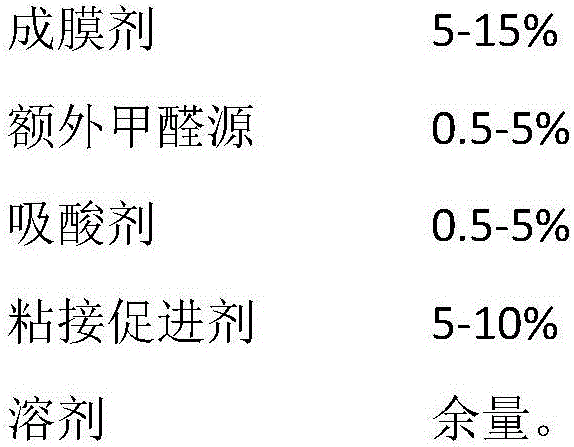

Heat-vulcanization adhesive for adhering ceramics with elastomer

ActiveCN106554736ASolve bonding problemsAdhesive adaptationNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesElastomerVulcanization

The invention discloses a heat-vulcanization adhesive for adhering ceramics with elastomer. The heat-vulcanization adhesive comprises the following components in percentage by weight: 5-15% of phenolic resin, 5-15% of a film-forming agent, 0.5-5% of an extra formaldehyde source, 0.5-5% of an acid acceptor, 5-10% of an adhesion promoter and the balance solvent. The heat-vulcanization adhesive is characterized in that a phenolic compound supported by a silicane-containing modified organic porous material is used as the adhesion promoter, so that the adhesive forms a high-strength high-activity active transition layer between the elastomer and hard ceramics, and therefore, adhesion of the high-strength hard ceramics by the adhesive is effectively realized.

Owner:SHANGHAI TONTEE NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com