Oxygen supply sizing agent groove system and ceramic surface exposure 3D continuous printing method

A slurry tank and ceramic surface technology, which is applied in the field of oxygen supply slurry tank system and ceramic surface exposure 3D continuous printing, can solve the problems of easy bonding between molded parts and the bottom, inability to achieve continuous printing of parts, and imperfect solutions. , to achieve good curing performance, stable properties, and the effect of solving bonding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

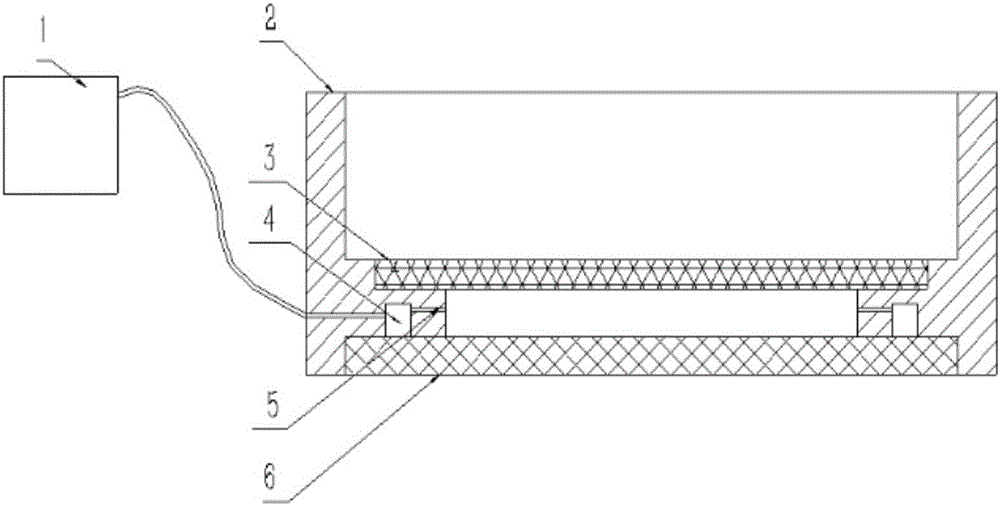

[0028] refer to figure 1 , the oxygen supply slurry tank system of the present invention comprises an oxygen supply device 1, a bottom plate 6, a connecting pipe, a breathable film 3 and a slurry tank 2 of a cylindrical structure; the inner wall of the slurry tank 2 is horizontally provided with The annular protrusion, the breathable film 3 covers the upper surface of the annular groove 4, the lower surface of the annular protrusion is provided with an annular groove 4, the bottom plate 6 is fixed on the bottom of the slurry tank 2, and the annular groove 4 and the bottom plate 6 form a A ring-shaped sealing structure is formed, and a sealed cavity is surrounded by the base plate 6, the annular protrusion and the breathable film 3; the side wall of the annular protrusion is evenly provided with a number of through holes 5, and the gap between the annular sealing struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com