Metal hydride reactor

A hydride and reactor technology, applied in indirect heat exchangers, heat exchanger types, reducing greenhouse gases, etc., can solve the problems of small heat exchange area of heat exchange medium, low reaction efficiency, poor heat exchange capacity, etc., to achieve The effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

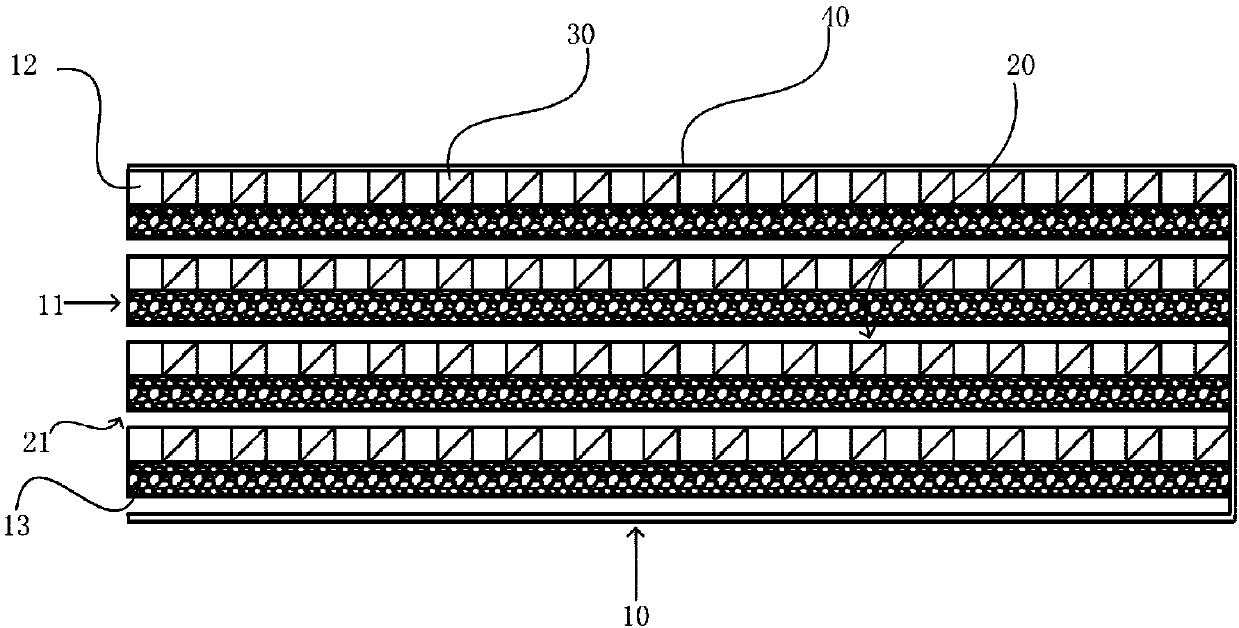

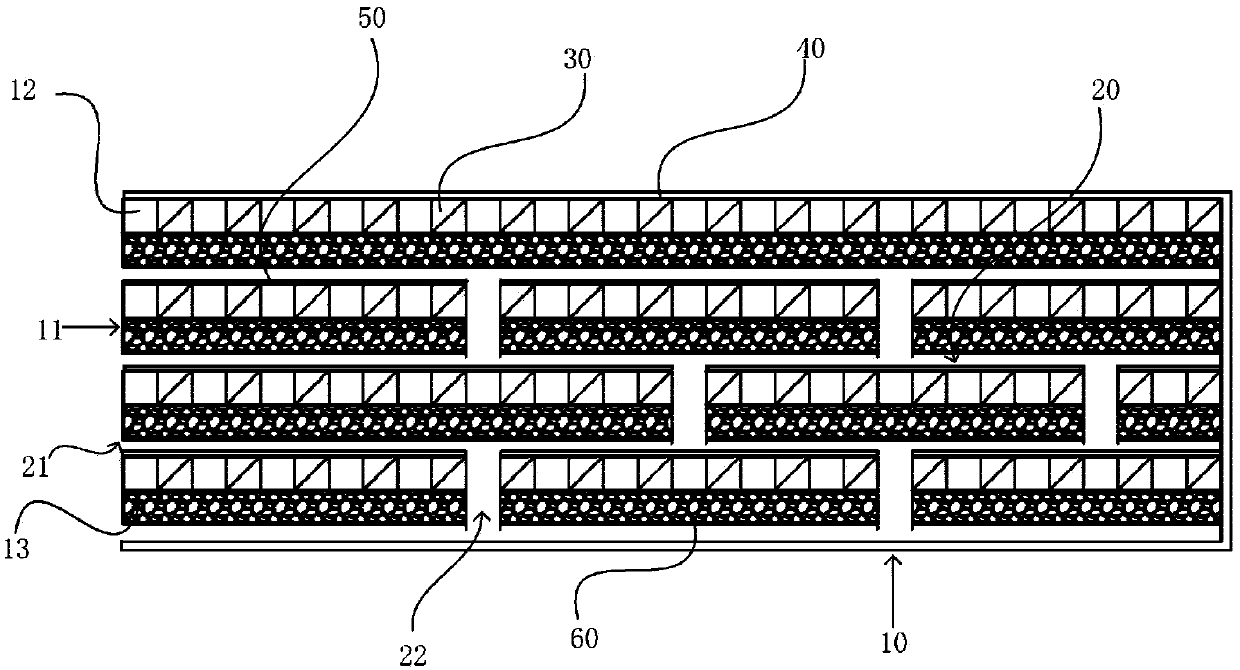

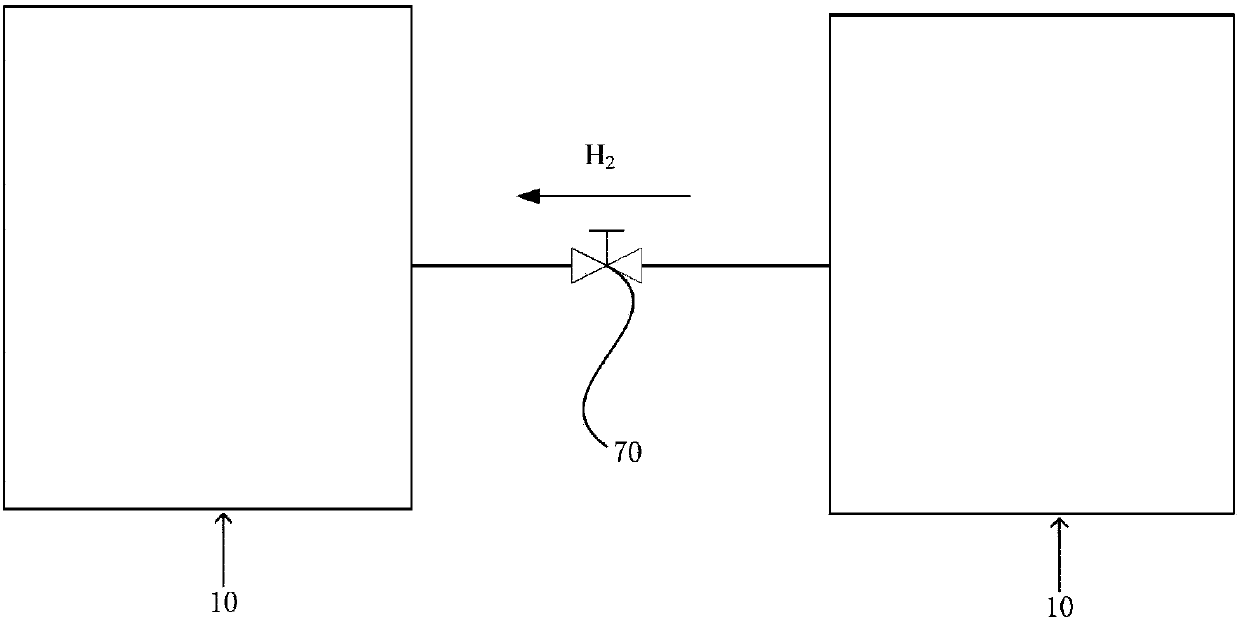

[0026] This embodiment provides a metal hydride reactor 10, which is used for the reaction of hydrogen storage alloy and hydrogen gas to generate metal hydride and release heat at the same time, or for the reaction of metal hydride to absorb heat to generate hydrogen storage alloy and hydrogen gas. figure 1 is a schematic diagram of a metal hydride reactor 10 according to an embodiment of the present invention, and the metal hydride reactor 10 includes: a multi-layer reaction bed 11 .

[0027] In this embodiment, the multi-layer reaction beds 11 are stacked in the vertical direction, and each layer of reaction beds 11 has a structure of upper and lower layers in the stacking direction of the multi-layer reaction beds 11 .

[0028] The lower layer is the composite material layer 13. The composite material layer 13 contains hydrogen storage alloys and / or metal hydrides. When the hydrogen pressure and hydrogen concentration inside the metal hydride reactor 10 are high, the hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com