Novel automobile exhaust pipe

A technology for automobile exhaust and exhaust pipes, applied in exhaust devices, mufflers, engine components, etc., can solve problems affecting engine exhaust conditions and power performance, pilot fuel pipes or fuel tank oil leakage, and exhaust pipe heat insulation problems such as poor effect, to achieve the effect of reducing temperature, reducing noise, and good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

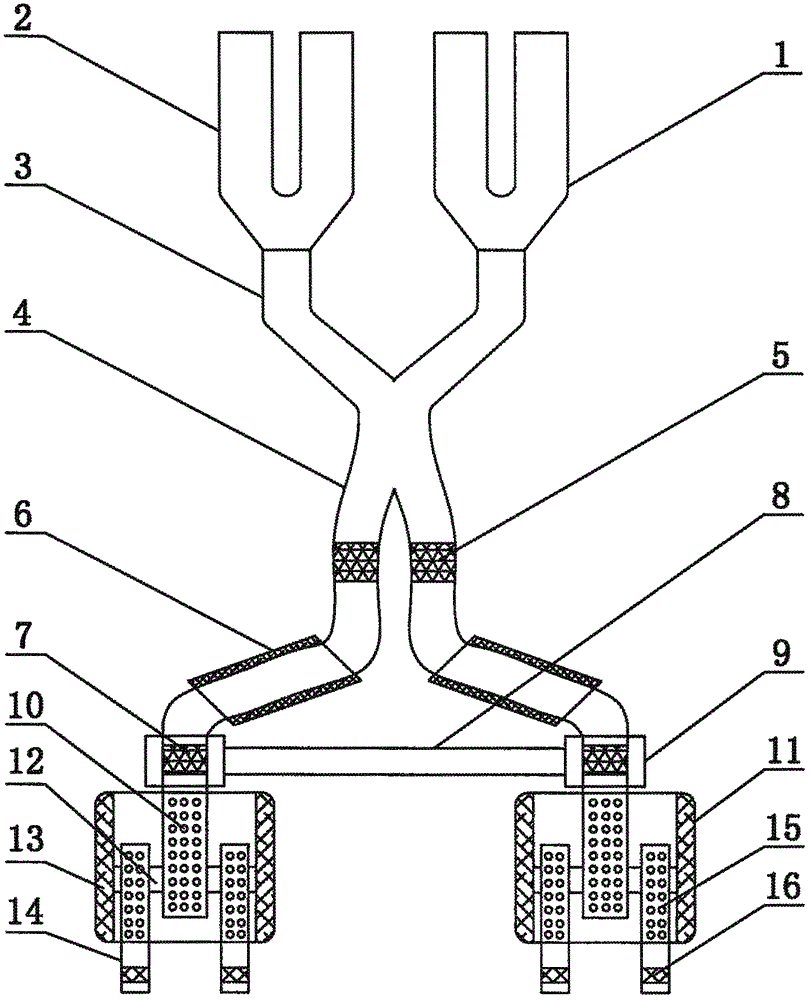

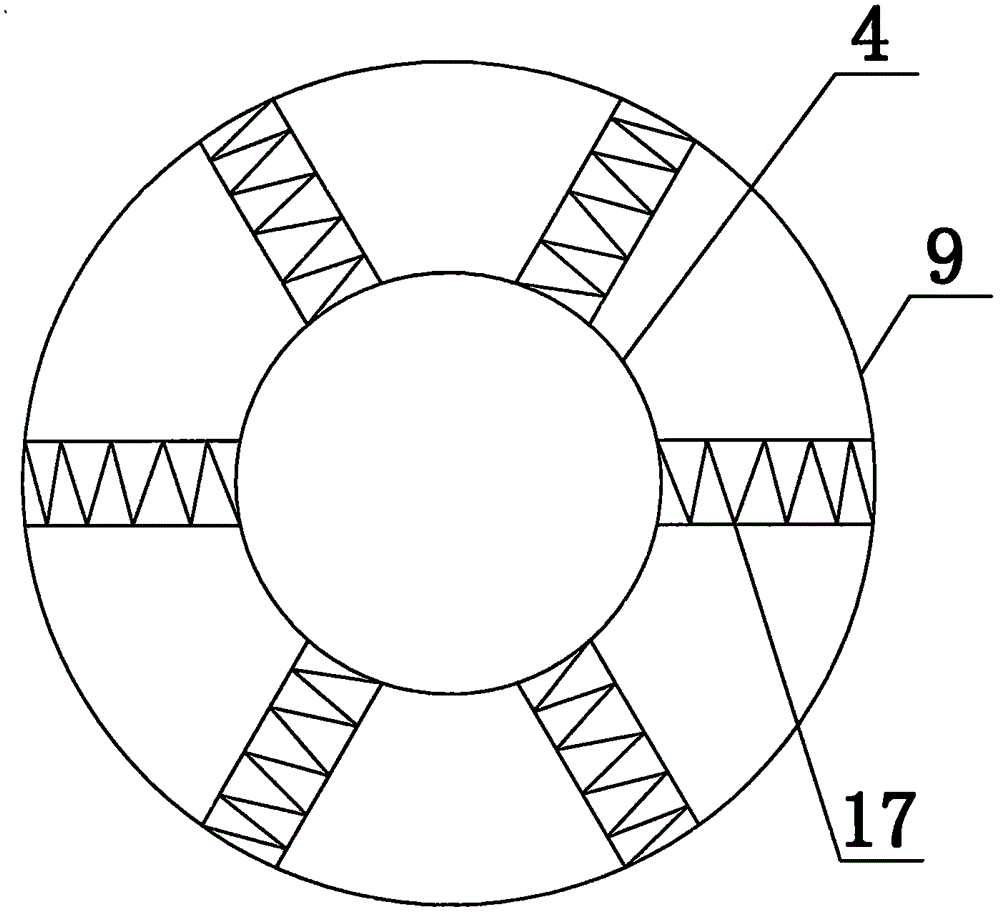

[0018] Such as figure 1 and figure 2 As shown, a novel automobile exhaust pipe includes an exhaust pipe body 1, and the exhaust pipe body 1 is equipped with a joint 2, and the joint 2 is connected with an air intake pipe 3, and the air intake pipe 3 is connected to There is an exhaust pipe 4, the first filter device 5 is installed on the exhaust pipe 4, the heat sink 6 is installed on the outside of the exhaust pipe 4, and the second filter device 7 is installed on the exhaust pipe 4 , the end of the exhaust pipe 4 is provided with an exhaust hole A10, the exhaust pipe 4 is equipped with a shock absorber 9, and the inside of the shock absorber 9 is equipped with a shock absorber spring 17, the described The shock absorbing device 9 is connected with a shock absorbing device fixing frame 8, and the end of the exhaust pipe 4 is connected with a sound absorbing device 11, and the sound absorbing device 11 is equipped with a sound absorbing panel 13, and the inside of the descri...

Embodiment 2

[0021] Such as figure 1 and figure 2 As shown, a novel automobile exhaust pipe includes an exhaust pipe body 1, and the exhaust pipe body 1 is equipped with a joint 2, and the joint 2 is connected with an air intake pipe 3, and the air intake pipe 3 is connected to There is an exhaust pipe 4, the first filter device 5 is installed on the exhaust pipe 4, the heat sink 6 is installed on the outside of the exhaust pipe 4, and the second filter device 7 is installed on the exhaust pipe 4 , the end of the exhaust pipe 4 is provided with an exhaust hole A10, the exhaust pipe 4 is equipped with a shock absorber 9, and the inside of the shock absorber 9 is equipped with a shock absorber spring 17, the described The shock absorbing device 9 is connected with a shock absorbing device fixing frame 8, and the end of the exhaust pipe 4 is connected with a sound absorbing device 11, and the sound absorbing device 11 is equipped with a sound absorbing panel 13, and the inside of the descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com