Suction filtering tank and suction filtering method

A filter tank and filter plate technology, applied in the field of chemical production suction filtration treatment, can solve problems such as material waste, and achieve the effects of improving recovery rate, preventing falling off, and uniform air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

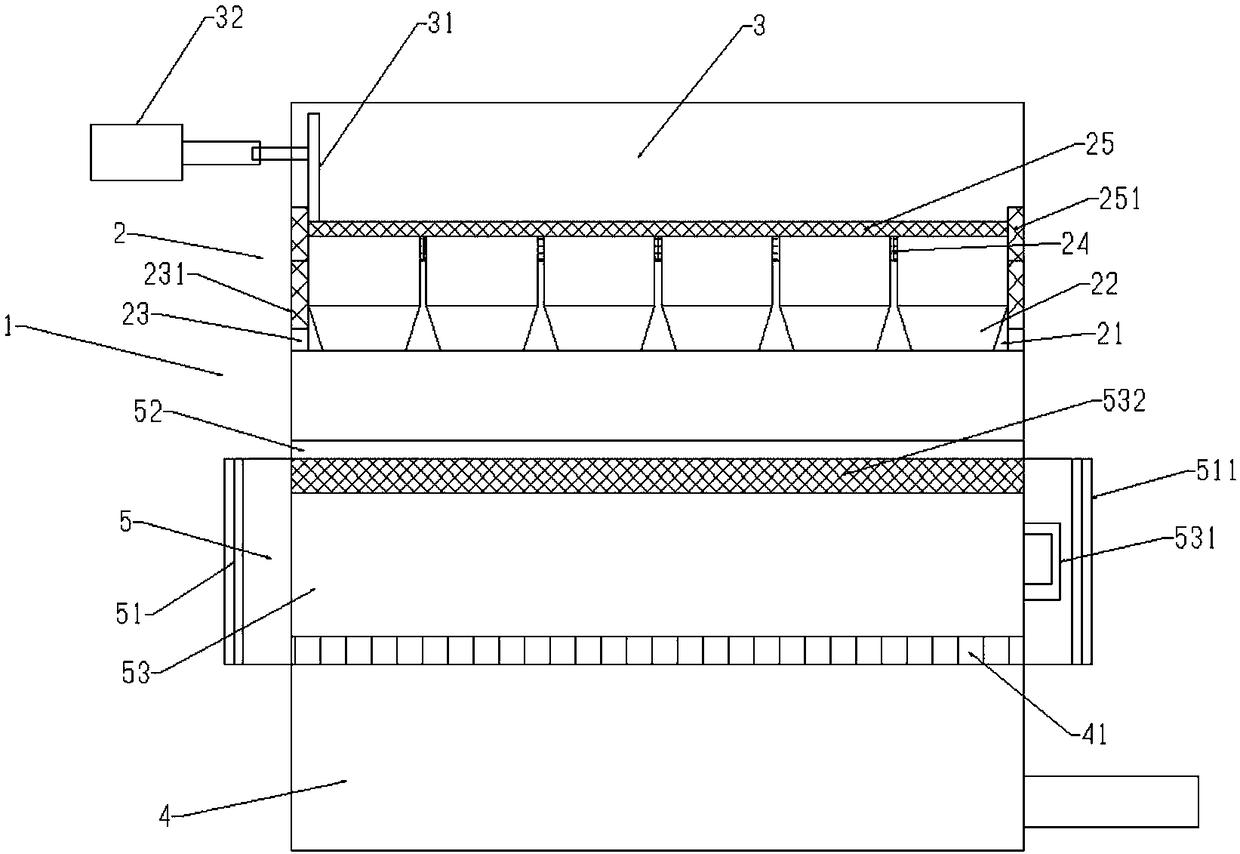

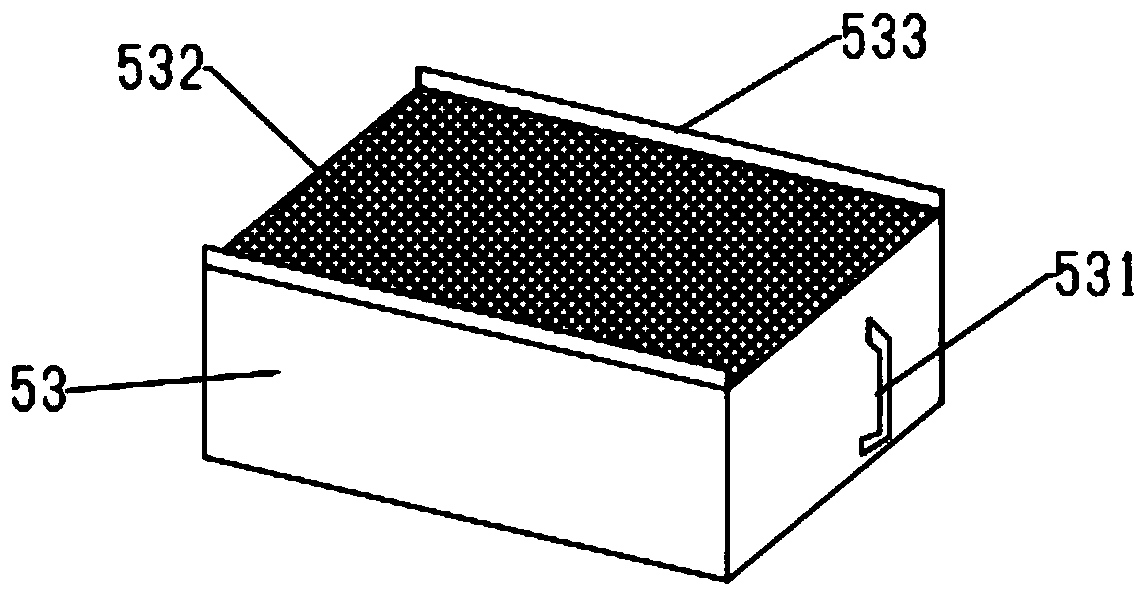

[0028] Such as Figure 1-Figure 2 As shown, a suction filter tank includes a rectangular tank body 1 with an upward opening, a filter layer 2 is arranged in the rectangular tank body 1, a material tank 3 is arranged above the filter layer 2, and a suction filter chamber is arranged below the filter layer 2 4. The filter layer 2 includes a filter plate frame 21 whose edge is fixedly connected to the side wall of the rectangular tank body 1. The filter plate frame 21 is provided with a number of filter plate holes 22 for placing filter plates. The filter plate holes 22 are arranged from top to bottom It is divided into a straight section for placing the filter plate and a tapered section whose inner diameter decreases from top to bottom. The upper end of the straight section of the filter plate hole 22 is provided with a filling rubber strip 24, and the connection between the rectangular tank body 1 and the filter plate holder 21 is along the circumference. There is a slot 231 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com